Methods for Enhancing Energy and Resource Efficiency in Sunflower Oil Production: A Case Study from Bulgaria

Abstract

1. Introduction

1.1. Context and Importance of Sunflower Oil Production

1.2. Environmental and Energy Efficiency Challenges

1.3. Objectives and Structure of the Study

2. Materials and Methods

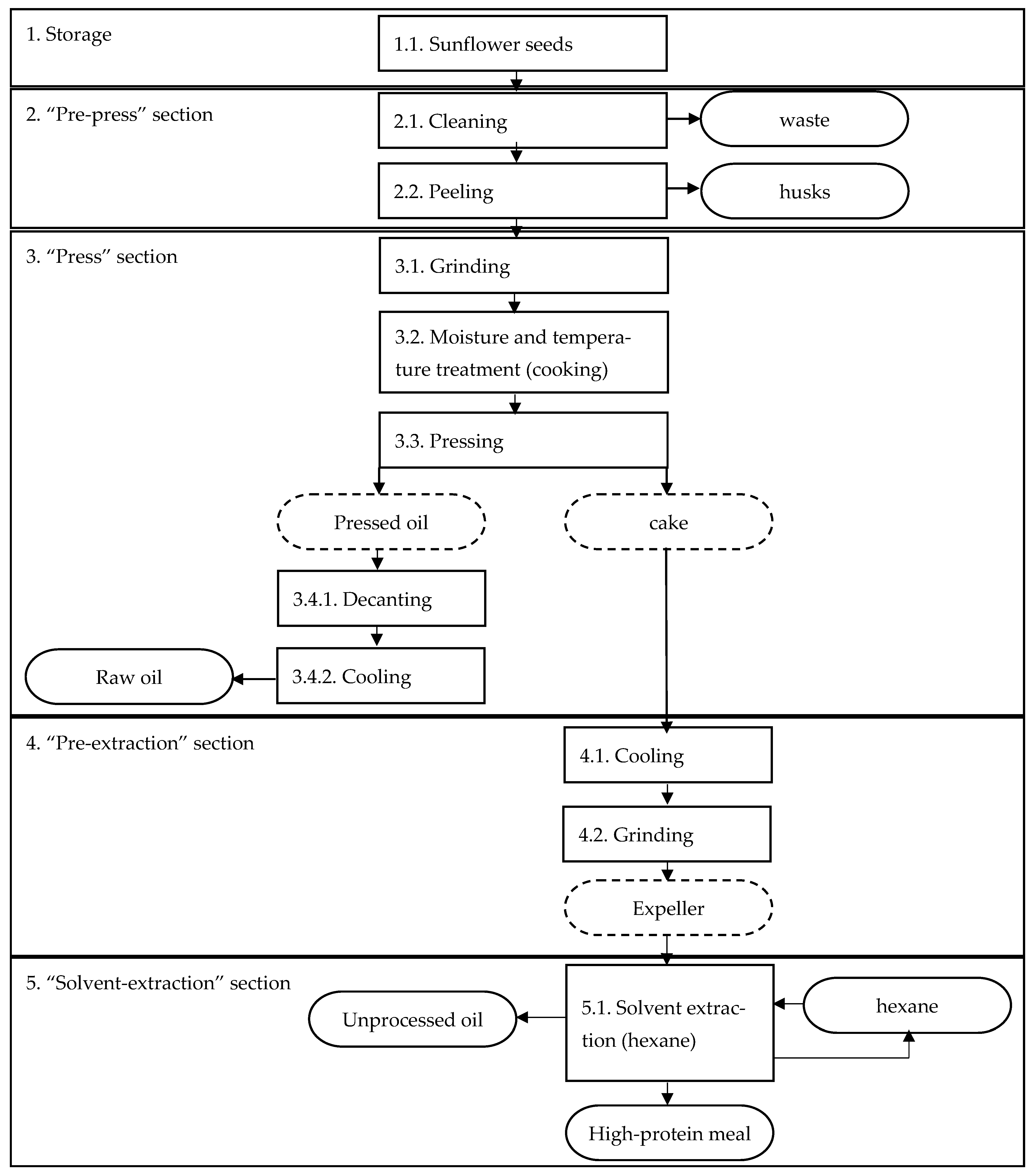

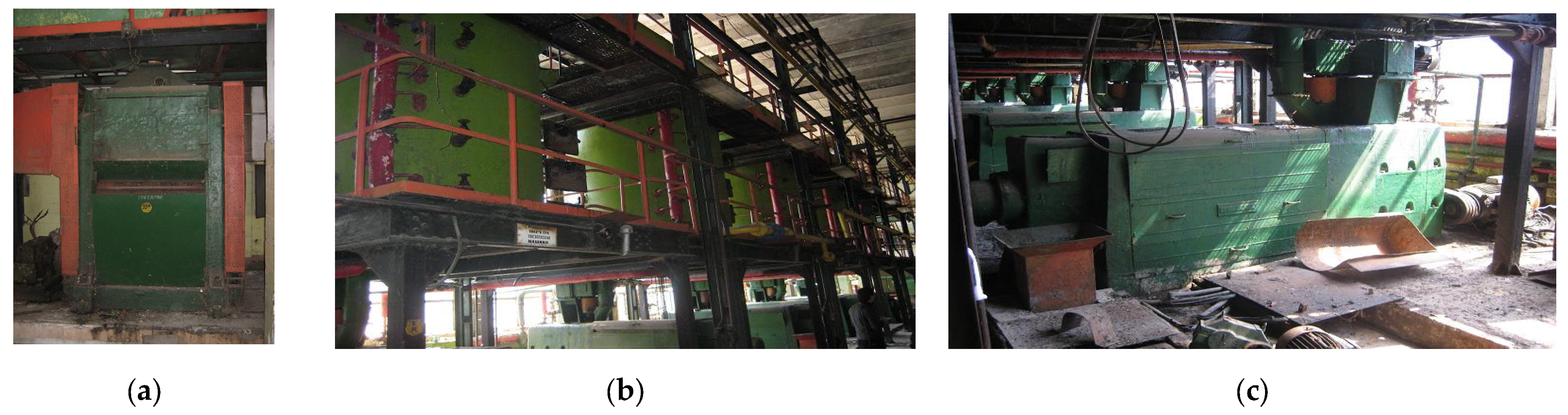

2.1. Base Information for the Existing Technological Equipment

2.2. Description of Technological Processes and Equipment in Workshops: “Pre-Press”, “Press”, and “Pre-Extraction”

2.2.1. “Pre-Press” Section

- De-hulled seeds are transported by two 50-ton grain transporters and taken up by a transversal screw and supply elevator, with a capacity of 100 tons;

- Poorly husked seeds, referred to as “repeats”, are transported by 2 grain transporters, with 50 tons capacity each. The repeats are returned for repeated de-hulling;

- Seed oil dust, transported for separation by 2 screws, with 25 tons capacity;

- Sunflower husk, transported with 4 screws (50 tons capacity each), and moved to the storage using pneumatic transport.

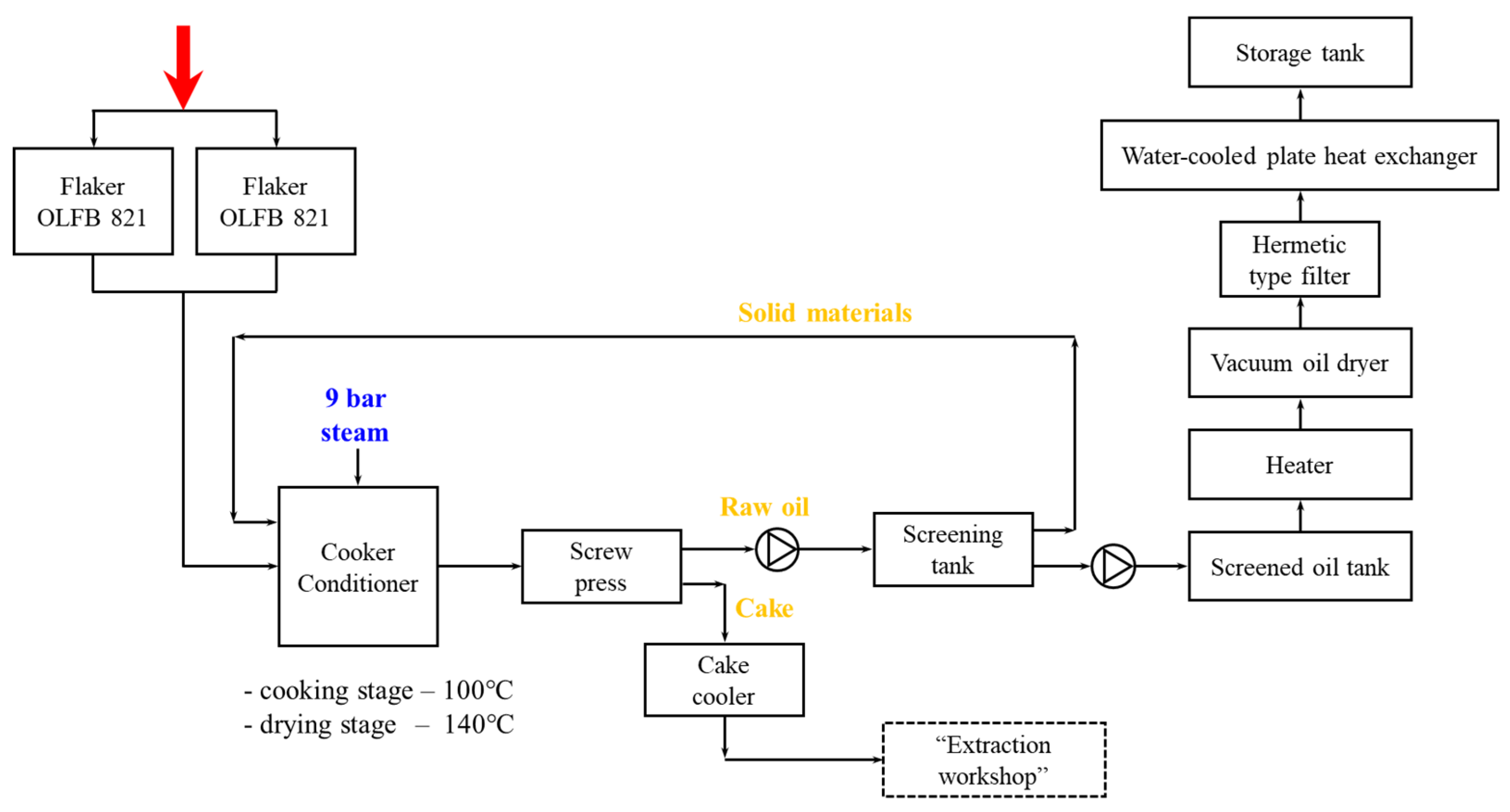

2.2.2. “Press” Section

- Screw for raw pressed oil—up to 50 tons is transported to the chain separator and filter;

- Screw for expeller—up to 100 tons is transported by an elevator, with a capacity of 100 tons, to the breher and corrugated rolls for grinding.

2.2.3. “Pre-Extraction” Section

2.2.4. Basic Technical Data and Annual Energy Consumption of Equipment in Sections “Pre-Press”, “Press”, and “Pre-Extraction”

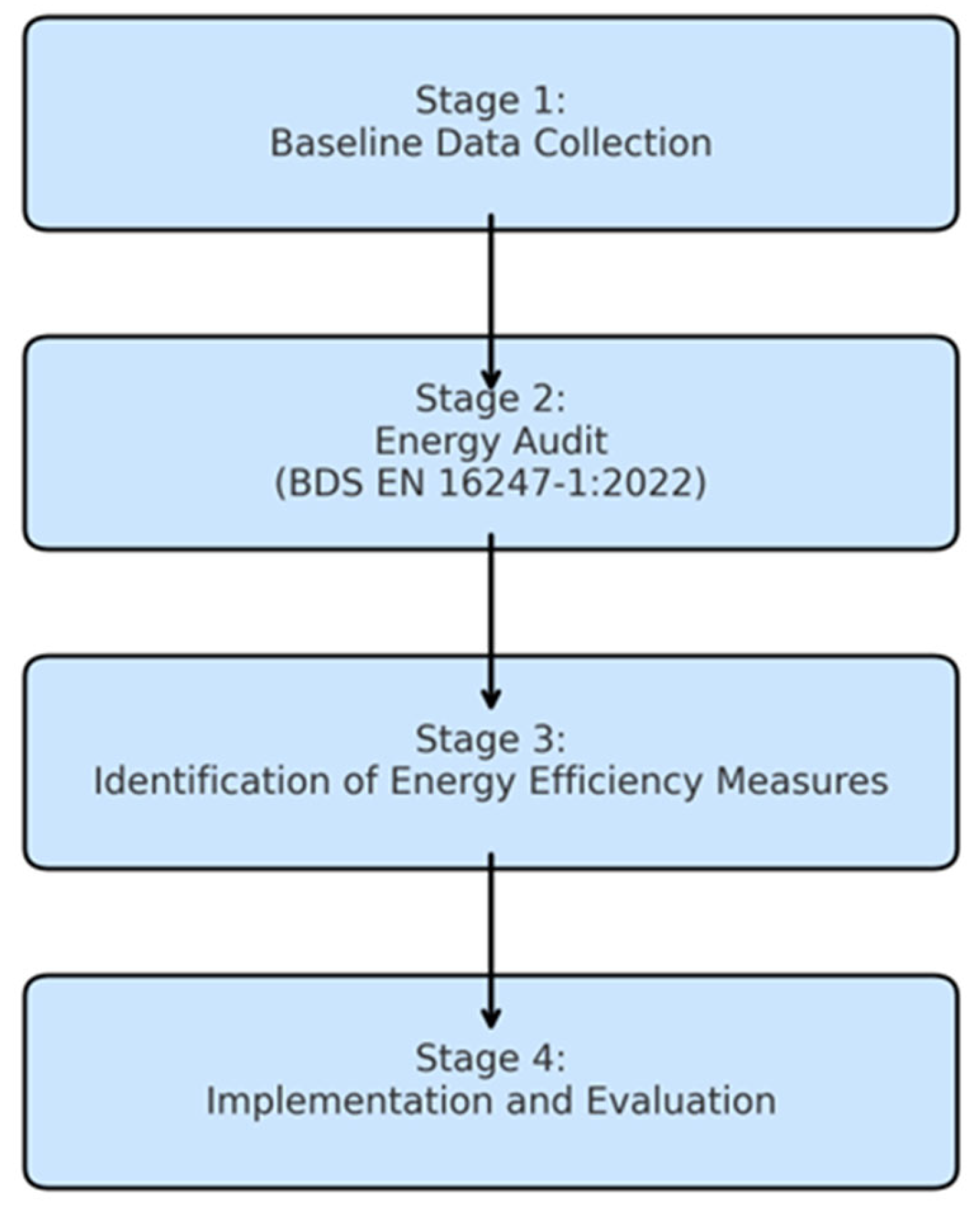

2.3. Methodology of the Energy Audit

3. Results

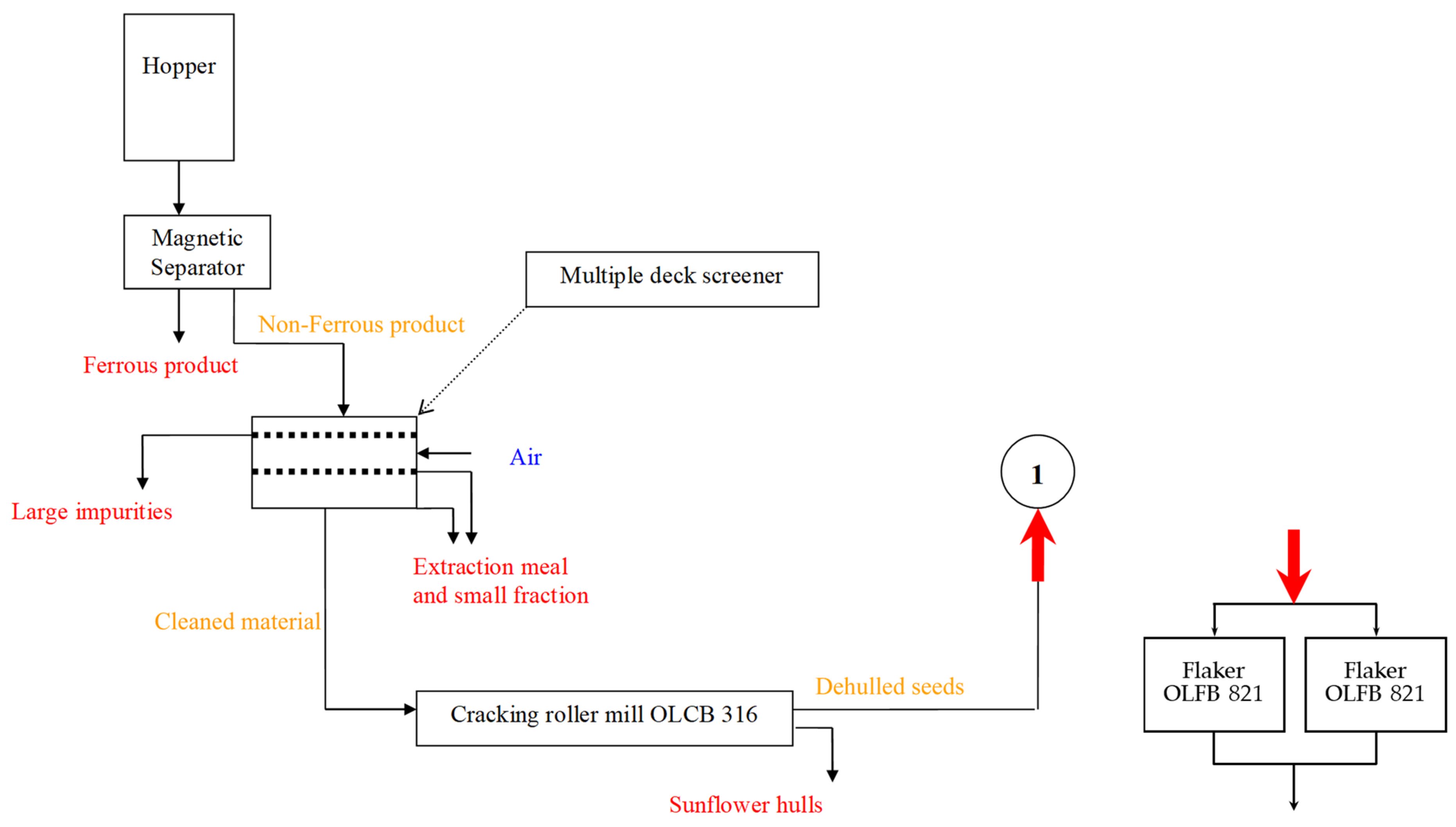

3.1. Introduction of New Energy Efficient Equipment in the Pre-Press Workshop

- The coarse fraction, which is retained by the upper screen. Large impurities (pods) consist of leaves and sticks. They are sent to a trash bin and discarded;

- The clean fraction, which is the intermediate fraction. It passes through the first screen and stays on top of the bottom one. This fraction is also subject to aspiration using a flow of air. The aspiration is used to remove light particles;

- The small fraction, which passes through the bottom screen, is collected and added to the extraction meal.

3.2. Introduction of New Energy Efficient Equipment in the Press Section

- Cooking stage

- Drying stage

3.3. Effect of Implementing Energy Efficiency Measures

3.4. Operational Cost Impact

4. Discussion

4.1. Comparison with Other Studies

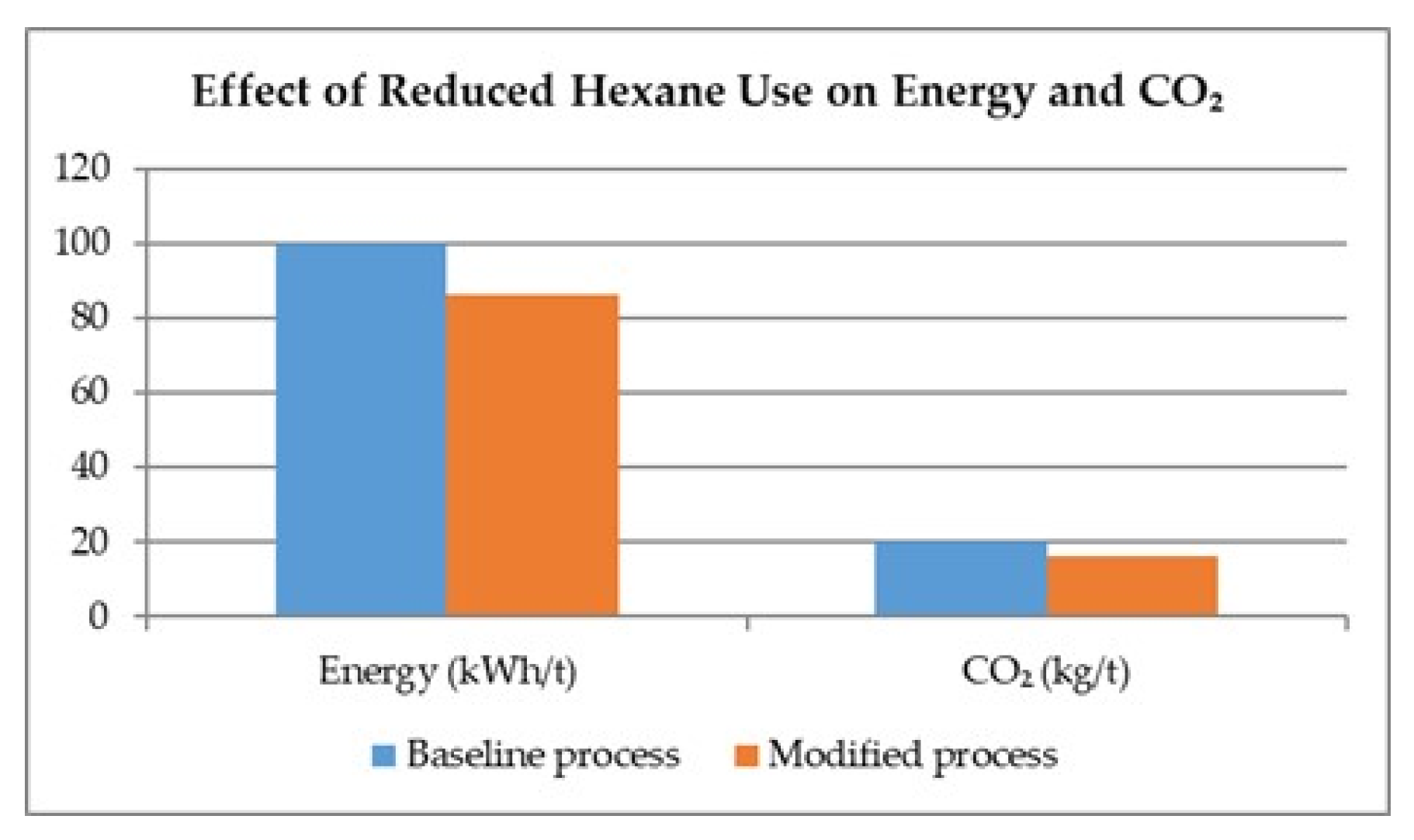

4.2. Impact of Solvent Reduction

4.3. Technological and Socio-Economic Aspects of Implementation

5. Conclusions

- Technological modernization and optimization of process parameters led to an improvement in overall energy efficiency of approximately 34% and a reduction in hexane consumption by 0.3 kg/t, resulting in additional energy savings of 12–15 kWh/t and CO2 emission reductions of 3–4 kg/t of processed seeds.

- The reduction in solvent circulation not only improved workplace safety by lowering volatile organic compound emissions but also decreased auxiliary energy requirements for pumping and heat recovery.

- The implementation of three-stage regeneration columns for hexane recovery demonstrated the importance of targeted technological measures for improving both resource efficiency and environmental performance.

- Socio-economic factors, such as workforce retraining and investment capacity, influence the successful adoption of new technologies and should be considered when transferring solutions to other production facilities.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghobakhloo, M.; Fathi, M. Industry 4.0 and opportunities for energy sustainability. J. Clean. Prod. 2021, 295, 126427. [Google Scholar] [CrossRef]

- Rosário, A.T.; Lopes, P.; Rosário, F.S. Sustainability and the Circular Economy Business Development. Sustainability 2024, 16, 6092. [Google Scholar] [CrossRef]

- Sadjadi, E.N.; Fernández, R. Relational Marketing Promotes Sustainable Consumption Behavior in Renewable Energy Production. Sustainability 2023, 15, 5714. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R. Sustainability in the Circular Economy: Insights and Dynamics of Designing Circular Business Models. Appl. Sci. 2022, 12, 1521. [Google Scholar] [CrossRef]

- Viles, E.; Kalemkerian, F.; Garza-Reyes, J.A.; Antony, J.; Santos, J. Theorizing the Principles of Sustainable Production in the context of Circular Economy and Industry 4.0. Sustain. Prod. Consum. 2022, 33, 1043–1058. [Google Scholar] [CrossRef]

- Cisneros-Yupanqui, M.; Chalova, V.I.; Kalaydzhiev, H.R.; Mihaylova, D.; Krastanov, A.I.; Lante, A. Preliminary Characterisation of Wastes Generated from the Rapeseed and Sunflower Protein Isolation Process and Their Valorisation in Delaying Oil Oxidation. Food Bioprocess Technol. 2021, 14, 1962–1971. [Google Scholar] [CrossRef]

- Konuskan, D.B.; Arslan, M.; Oksuz, A. Physicochemical properties of cold pressed sunflower, peanut, rapeseed, mustard and olive oils grown in the Eastern Mediterranean region. Saudi J. Biol. Sci. 2019, 26, 340–344. [Google Scholar] [CrossRef]

- Tekyalcin, A.B.; Bogrekci, I.; Demircioglu, P. Sustainable Process Design for Special Welded Profiles via Roll Forming Compression. Eng 2025, 6, 40. [Google Scholar] [CrossRef]

- Grahovac, N.; Lužaić, T.; Živančev, D.; Stojanović, Z.; Đurović, A.; Romanić, R.; Kravić, S.; Miklič, V. Assessing Nutritional Characteristics and Bioactive Compound Distribution in Seeds, Oil, and Cake from Confectionary Sunflowers Cultivated in Serbia. Foods 2024, 13, 1882. [Google Scholar] [CrossRef]

- Romani, A.; Pinelli, P.; Moschini, V.; Heimler, D. Seeds and oil polyphenol content of sunflower (Helianthus annuus L.) grown with different agricultural management. Adv. Hortic. Sci. 2017, 31, 85. [Google Scholar]

- Górski, K.; Smigins, R.; Matijošius, J.; Rimkus, A.; Longwic, R. Physicochemical Properties of Diethyl Ether—Sunflower Oil Blends and Their Impact on Diesel Engine Emissions. Energies 2022, 15, 4133. [Google Scholar] [CrossRef]

- Ollinger, N.; Blank-Landeshammer, B.; Schütz-Kapl, L.; Rochard, A.; Pfeifenberger, I.; Carstensen, J.M.; Müller, M.; Weghuber, J. High-Oleic Sunflower Oil as a Potential Substitute for Palm Oil in Sugar Coatings—A Comparative Quality Determination Using Multispectral Imaging and an Electronic Nose. Foods 2024, 13, 1693. [Google Scholar] [CrossRef] [PubMed]

- Rankovic, S.; Popovic, T.; Nenadovic, A.; Stankovic, A.; Debeljak Martacic, J.; Ilic, A.; Trbovich, A. Effects of Long-Term Sunflower Oil vs. Linseed Oil Diets on Fatty Acids Phospholipids and Desaturases in Hepatocytes. Proceedings 2023, 91, 172. [Google Scholar]

- Oliveira de Sousa, L.; Dias Paes Ferreira, M.; Mergenthaler, M. Agri-Food Chain Establishment as a Means to Increase Sustainability in Food Systems: Lessons from Sunflower in Brazil. Sustainability 2018, 10, 2215. [Google Scholar] [CrossRef]

- National Statistical Institute of the Republic of Bulgaria. Available online: https://www.nsi.bg/en/statistical-data/371/1061 (accessed on 21 May 2025).

- Mitrea, L.; Teleky, B.-E.; Leopold, L.-F.; Nemes, S.-A.; Plamada, D.; Dulf, F.V.; Pop, I.-D.; Vodnar, D.C. The physicochemical properties of five vegetable oils exposed at high temperature for a short-time-interval. J. Food Compost. Anal. 2022, 106, 104305. [Google Scholar] [CrossRef]

- Kabutey, A.; Herák, D.; Mizera, Č. Determination of Maximum Oil Yield, Quality Indicators and Absorbance Spectra of Hulled Sunflower Seeds Oil Extraction under Axial Loading. Foods 2022, 11, 2866. [Google Scholar] [CrossRef]

- Nid Ahmed, M.; Gagour, J.; Asbbane, A.; Hallouch, O.; Atrach, L.; Giuffrè, A.M.; Majourhat, K.; Gharby, S. Advances in the Use of Four Synthetic Antioxidants as Food Additives for Enhancing the Oxidative Stability of Refined Sunflower Oil (Helianthus annuus L.). Analytica 2024, 5, 273–294. [Google Scholar] [CrossRef]

- Jocković, M.; Jocić, S.; Cvejić, S.; Marjanović-Jeromela, A.; Jocković, J.; Radanović, A.; Miladinović, D. Genetic Improvement in Sunflower Breeding—Integrated Omics Approach. Plants 2021, 10, 1150. [Google Scholar] [CrossRef]

- Liu, R.; Lu, M.; Zhang, Z.; Chang, M.; Wang, X. Evaluation of the antioxidant properties of micronutrients in different vegetable oils. Eur. J. Lipid Sci. Technol. 2020, 122, 1900079. [Google Scholar] [CrossRef]

- Grompone, M.A. Sunflower Oil. In Vegetable Oils in Food Technology: Composition, Properties and Uses, 2nd ed.; Gunstone, F.D., Ed.; Blackwell Publishing Ltd.: Oxford, UK, 2011; pp. 137–167. [Google Scholar]

- Nakonechna, K.; Ilko, V.; Berčíková, M.; Vietoris, V.; Panovská, Z.; Doležal, M. Nutritional, Utility, and Sensory Quality and Safety of Sunflower Oil on the Central European Market. Agriculture 2024, 14, 536. [Google Scholar] [CrossRef]

- Moghadas, H.C.; Chauhan, R.; Smith, J.S. Application of Plant Oils as Functional Additives in Edible Films and Coatings for Food Packaging: A Review. Foods 2024, 13, 997. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.-K.; Zhong, L.; Santiago, J.L. Anti-Inflammatory and Skin Barrier Repair Effects of Topical Application of Some Plant Oils. Int. J. Mol. Sci. 2018, 19, 70. [Google Scholar] [CrossRef] [PubMed]

- Prathviraj, M.P.; Samuel, A.; Prabhu, K.N. Reprocessed waste sunflower cooking oil as quenchant for heat treatment. J. Clean. Prod. 2020, 269, 122276. [Google Scholar] [CrossRef]

- Malik, K.; Capareda, S.C.; Kamboj, B.R.; Malik, S.; Singh, K.; Arya, S.; Bishnoi, D.K. Biofuels Production: A Review on Sustainable Alternatives to Traditional Fuels and Energy Sources. Fuels 2024, 5, 157–175. [Google Scholar] [CrossRef]

- Vital-López, L.; Mercader-Trejo, F.; Rodríguez-Reséndiz, J.; Zamora-Antuñano, M.A.; Rodríguez-López, A.; Esquerre-Verastegui, J.E.; Farrera Vázquez, N.; García-García, R. Electrochemical Characterization of Biodiesel from Sunflower Oil Produced by Homogeneous Catalysis and Ultrasound. Processes 2023, 11, 94. [Google Scholar] [CrossRef]

- Khan, E.; Ozaltin, K.; Spagnuolo, D.; Bernal-Ballen, A.; Piskunov, M.V.; Di Martino, A. Biodiesel from Rapeseed and Sunflower Oil: Effect of the Transesterification Conditions and Oxidation Stability. Energies 2023, 16, 657. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V.; Aigbodion, V.S. Trends in the development and utilization of agricultural wastes as heterogeneous catalyst for biodiesel production. J. Energy Inst. 2021, 98, 244–258. [Google Scholar] [CrossRef]

- Havrysh, V.; Kalinichenko, A.; Pysarenko, P.; Samojlik, M. Sunflower Residues-Based Biorefinery: Circular Economy Indicators. Processes 2023, 11, 630. [Google Scholar] [CrossRef]

- Liu, H.; Han, P. Renewable energy development and carbon emissions: The role of electricity exchange. J. Clean. Prod. 2024, 439, 140807. [Google Scholar] [CrossRef]

- Havrysh, V.; Kalinichenko, A.; Mentel, G.; Mentel, U.; Vasbieva, D.G. Husk Energy Supply Systems for Sunflower Oil Mills. Energies 2020, 13, 361. [Google Scholar] [CrossRef]

- Nezhad, H.L.; Sharabiani, V.R.; Tarighi, J.; Tahmasebi, M.; Taghinezhad, E.; Szumny, A. Energy Flow Analysis in Oilseed Sunflower Farms and Modeling with Artificial Neural Networks as Compared to Adaptive Neuro-Fuzzy Inference Systems (Case Study: Khoy County). Energies 2024, 17, 2795. [Google Scholar] [CrossRef]

- Sayın, B.; Bozkurt, A.G.; Kaban, G. Assessing Waste Sunflower Oil as a Substrate for Citric Acid Production: The Inhibitory Effect of Triton X-100. Fermentation 2024, 10, 374. [Google Scholar] [CrossRef]

- Kesharvani, S.; Dwivedi, G.; Verma, T.N.; Chhabra, M. Optimization, production, and environmental sustainability of clean energy fuel utilizing reused cooking oil employing CaO catalysts. Sustain. Energy Technol. Assess. 2024, 63, 103655. [Google Scholar] [CrossRef]

- Foppa Pedretti, E.; Del Gatto, A.; Pieri, S.; Mangoni, L.; Ilari, A.; Mancini, M.; Feliciangeli, G.; Leoni, E.; Toscano, G.; Duca, D. Experimental Study to Support Local Sunflower Oil Chains: Production of Cold Pressed Oil in Central Italy. Agriculture 2019, 9, 231. [Google Scholar] [CrossRef]

- García-González, A.; Velasco, J.; Velasco, L.; Ruiz-Méndez, M.V. Attempts of Physical Refining of Sterol-Rich Sunflower Press Oil to Obtain Minimally Processed Edible Oil. Foods 2021, 10, 1901. [Google Scholar] [CrossRef]

- Ramos, P.R.; Sponchiado, J.; Echenique, J.V.F.; Dacanal, G.C.; Oliveira, A.L.d. Kinetics of Vegetable Oils (Rice Bran, Sunflower Seed, and Soybean) Extracted by Pressurized Liquid Extraction in Intermittent Process. Processes 2024, 12, 1107. [Google Scholar] [CrossRef]

- Beyer, R.; Rademacher, T. Species Richness and Carbon Footprints of Vegetable Oils: Can High Yields Outweigh Palm Oil’s Environmental Impact? Sustainability 2021, 13, 1813. [Google Scholar] [CrossRef]

- Romanić, R.; Lužaić, T.; Grgić, K. Examining the Possibility of Improving the Properties of Sunflower Oil in Order to Obtain a Better Medium for the Process of Frying Food. Proceedings 2021, 70, 104. [Google Scholar]

- Metzner Ungureanu, C.-R.; Poiana, M.-A.; Cocan, I.; Lupitu, A.I.; Alexa, E.; Moigradean, D. Strategies to Improve the Thermo-Oxidative Stability of Sunflower Oil by Exploiting the Antioxidant Potential of Blueberries Processing Byproducts. Molecules 2020, 25, 5688. [Google Scholar] [CrossRef]

- Kakimov, M.; Mursalykova, M.; Gajdzik, B.; Wolniak, R.; Kokayeva, G.; Bembenek, M. Optimal Ways of Safflower Oil Production with Improvement of Press Equipment. Foods 2024, 13, 1909. [Google Scholar] [CrossRef]

- Abdilova, G.; Sergibayeva, Z.; Orynbekov, D.; Shamenov, M.; Zhumadilova, G.; Bakiyeva, A.; Mukashev, N.; Bayadilova, A.; Dukenbayev, D. Influence of Grinding Degree and Screw Rotation Speed on Sunflower Oil Pressing Process. Appl. Sci. 2023, 13, 9958. [Google Scholar] [CrossRef]

- BDS EN 16247-1:2022; Energy audits—Part 1: General requirements. European Committee for Standardization: Bruxelles, Belgium, 2025. Available online: https://bds-bg.org/en/project/show/bds:proj:109839 (accessed on 15 May 2025).

- Martínez, J.; Cortés, J.F.; Miranda, R. Green Chemistry Metrics, A Review. Processes 2022, 10, 1274. [Google Scholar] [CrossRef]

- Cucciniello, R.; Cespi, D. Recycling within the Chemical Industry: The Circular Economy Era. Recycling 2018, 3, 22. [Google Scholar] [CrossRef]

- Branca, T.A.; Fornai, B.; Colla, V.; Pistelli, M.I.; Faraci, E.L.; Cirilli, F.; Schröder, A.J. Industrial Symbiosis and Energy Efficiency in European Process Industries: A Review. Sustainability 2021, 13, 9159. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Yang, L.; Zhang, Y. Research on Mechanical–Structural and Oil Yield Properties during Xanthoceras sorbifolium Seed Oil Extraction. Processes 2022, 10, 564. [Google Scholar] [CrossRef]

- Zheng, F.; Cho, H.M. Study on Biodiesel Production: Feedstock Evolution, Catalyst Selection, and Influencing Factors Analysis. Energies 2025, 18, 2533. [Google Scholar] [CrossRef]

- Almohasin, J.A.; Balag, J.; Miral, V.G.; Moreno, R.V.; Tongco, L.J.; Lopez, E.C.R. Green Solvents for Liquid–Liquid Extraction: Recent Advances and Future Trends. Eng. Proc. 2023, 56, 174. [Google Scholar]

- Yara-Varón, E.; Li, Y.; Balcells, M.; Canela-Garayoa, R.; Fabiano-Tixier, A.-S.; Chemat, F. Vegetable Oils as Alternative Solvents for Green Oleo-Extraction, Purification and Formulation of Food and Natural Products. Molecules 2017, 22, 1474. [Google Scholar] [CrossRef]

- Ncube, A.; Mtetwa, S.; Bukhari, M.; Fiorentino, G.; Passaro, R. Circular Economy and Green Chemistry: The Need for Radical Innovative Approaches in the Design for New Products. Energies 2023, 16, 1752. [Google Scholar] [CrossRef]

- Xiao, X.; Yan, B.; Fu, J.; Xiao, X. Absorption and recovery of n-hexane in aqueous solutions of fluorocarbon surfactants. J. Environ. Sci. 2015, 37, 163–171. [Google Scholar] [CrossRef]

- Thollander, P.; Paramonova, S.; Cornelis, E.; Kimura, O.; Trianni, A.; Karlsson, M.; Cagno, E.; Morales, I.; Jiménez Navarro, J.P. International study on energy end-use data among industrial SMEs (small and medium-sized enterprises) and energy end-use efficiency improvement opportunities. J. Clean. Prod. 2015, 104, 282–296. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Evaluating the barriers to specific industrial energy efficiency measures: An exploratory study in small and medium-sized enterprises. J. Clean. Prod. 2014, 82, 70–83. [Google Scholar] [CrossRef]

- Neves, F.d.O.; Ewbank, H.; Roveda, J.A.F.; Trianni, A.; Marafão, F.P.; Roveda, S.R.M.M. Economic and Production-Related Implications for Industrial Energy Efficiency: A Logistic Regression Analysis on Cross-Cutting Technologies. Energies 2022, 15, 1382. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Marchesani, F.; Spallina, G. Classification of drivers for industrial energy efficiency and their effect on the barriers affecting the investment decision-making process. Energy Effic. 2017, 10, 199–215. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farné, S. Barriers, drivers and decision-making process for industrial energy efficiency: A broad study among manufacturing small and medium-sized enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Trianni, A. A review of energy management assessment models for industrial energy efficiency. Energies 2020, 13, 5713. [Google Scholar] [CrossRef]

| Section | Equipment Name | Installed Electrical Power, kW | Quantity |

|---|---|---|---|

| Pre-press | Grain transporters | 4.0 | 2 |

| Elevators | 7.5 | 1 | |

| Grain transporters | 5.0 | 1 | |

| Grain transporters | 5.0 | 1 | |

| Screw | 2.2 | 1 | |

| Elevators | 3.0 | 2 | |

| Screw | 2.2 | 6 | |

| Screw | 2.2 | 6 | |

| De-huller | 16.0 | 5 | |

| Grain transporters | 4.0 | 1 | |

| Grain transporters | 5.0 | 1 | |

| Screw | 2.2 | 1 | |

| Elevators | 5.5 | 1 | |

| Grain transporters | 1.1 | 6 | |

| Press | Rolling mills | 30.0 | 6 |

| Screw | 7.5 | 2 | |

| Screw | 5.5 | 1 | |

| Screw before elevator | 10.0 | 1 | |

| Screw over elevator | 5.5 | 3 | |

| Screw repeats | 4.0 | 1 | |

| Stack cookers | 30.0 | 6 | |

| Screw Press | 55.0 | 5 | |

| Pre-extraction | Screw | 5.5 | 2 |

| Elevator | 10.0 | 1 | |

| Brecher | 7.5 | 1 | |

| Feeder rolls | 1.1 | 3 | |

| Screw | 4.0 | 1 | |

| Grain transporter to 37 | 4.0 | 1 | |

| Elevator to extraction | 4.0 | 1 |

| RAW MATERIALS | ||

| Suitably matured, commercial quality sunflower seeds with | ||

| Oil content | 41% | Average |

| 45% | Maximum | |

| Hulls content | 30% | |

| Moisture | 8% | minimum |

| Impurities content | 2% | maximum—but free of stone sand silica |

| Temperature | 2–3 °C | minimum, to be pre-heated Buyer’s supply to 20 °C before entering the flakers |

| Suitably matured, commercial quality rapeseed seeds with | ||

| Oil content | 41% | Average |

| 45% | Maximum | |

| Moisture | 8% | minimum |

| Impurities content | 2% | maximum—but free of stone sand silica |

| Temperature | 2–3 °C | minimum, to be pre-heated Buyer’s supply to 60 °C before entering the flakers |

| PROCESS STEPS | ||

| Unhulled sunflower seeds, before cracking, are to be prepared for pressing as follows | ||

| Clean to leave | 0.5% | impurities maximum |

| Pre = heat to | 20 °C | when necessary |

| Break to give | 2–3 mm | pieces |

| Cook to | 100 °C | |

| 4% | moisture | |

| Dehulled sunflower seeds, before flaking, are to be prepared for pressing as follows | ||

| Clean to leave | 0.5% | impurities maximum |

| Pre-heat to | 30 °C | when necessary |

| Dehull to leave | 12/13% | hulls, maximum (By Buyer), minimum 10% hulls left after dehulling |

| Flake to give | 0.4 mm | flake thickness |

| Cook to | 100 °C | |

| 4% | moisture | |

| Rapeseed seeds, before flaking, are to be prepared for pressing as follows | ||

| Clean to leave | 0.5% | impurities maximum |

| Pre Heat to | 60 °C | when necessary |

| Break to give | 0.3 mm | pieces |

| Cook to | 100 °C | |

| 4% | moisture | |

| QUALITY OF FINISHED PRODUCTS | ||

| Sunflower seeds or rapeseed press cake with: | ||

| Oil content | 18–22% | maximum |

| Temperature | 50–60 °C | |

| Crude, screened, and filtered/clarified sunflower or rapeseed oil | ||

| Electricity Consumption | HFO Consumption | Sunflower Husks Consumption | Energy Total | Carbon Emission | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MWh/y | tCO2/y 1 | t/y | MWh/y | tCO2/y 1 | t/y | MWh/y | tCO2/yr 1 | MWh/y | tCO2/y 1 | |

| Baseline | 7369 | 3581 | 350 | 3896 | 1130 | 1879 | 7152 | 286 | 18,417 | 4997 |

| After | 3350 | 1628 | 0 | 0 | 0 | 2668 | 10,154 | 406 | 13,503 | 2034 |

| Savings | 4019 | 1953 | 350 | 3896 | 1130 | −789 | −3002 | −120 | 4914 | 2963 |

| Indicator | Baseline Value | After Measures | Change (%) |

|---|---|---|---|

| Specific electricity consumption (kWh/t) | 1290.0 | 946.0 | −26.7 |

| Thermal energy consumption (kWh/t) | 2100.0 | 1750.0 | −16.7 |

| Hexane consumption (kg/t) | 10.5 | 10.3 | −2.0 |

| CO2 emissions (kg/t) | 25.0 | 21.5 | −14.0 |

| Technology Type | Specific Technology | Advantages | Disadvantages |

|---|---|---|---|

| Conventional (old) | Single-stage hexane recovery | Simple operation, low initial cost | Higher solvent losses, higher energy use |

| Conventional (old) | Standard pressing equipment | Well-proven, easy maintenance | Lower pressing efficiency, higher energy consumption |

| Energy-efficient (new) | Three-stage hexane regeneration columns | Reduced solvent losses (2–3%), lower VOC emissions, energy savings of 12–15 kWh/t | Higher initial investment; requires skilled operators |

| Energy-efficient (new) | Optimized pressing and extraction parameters (temperature, pressure, grinding degree) | Improved oil yield, reduced auxiliary energy consumption, lower CO2 emissions | Requires operator training and monitoring |

| Energy-efficient (new) | Alternative solvents (e.g., ethanol) | Lower toxicity, reduced environmental impact | Higher solvent cost, adaptation of process equipment |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zlateva, P.; Terziev, A.; Kolev, N.; Ivanov, M.; Murzova, M.; Vasilev, M. Methods for Enhancing Energy and Resource Efficiency in Sunflower Oil Production: A Case Study from Bulgaria. Eng 2025, 6, 195. https://doi.org/10.3390/eng6080195

Zlateva P, Terziev A, Kolev N, Ivanov M, Murzova M, Vasilev M. Methods for Enhancing Energy and Resource Efficiency in Sunflower Oil Production: A Case Study from Bulgaria. Eng. 2025; 6(8):195. https://doi.org/10.3390/eng6080195

Chicago/Turabian StyleZlateva, Penka, Angel Terziev, Nikolay Kolev, Martin Ivanov, Mariana Murzova, and Momchil Vasilev. 2025. "Methods for Enhancing Energy and Resource Efficiency in Sunflower Oil Production: A Case Study from Bulgaria" Eng 6, no. 8: 195. https://doi.org/10.3390/eng6080195

APA StyleZlateva, P., Terziev, A., Kolev, N., Ivanov, M., Murzova, M., & Vasilev, M. (2025). Methods for Enhancing Energy and Resource Efficiency in Sunflower Oil Production: A Case Study from Bulgaria. Eng, 6(8), 195. https://doi.org/10.3390/eng6080195