Abstract

The rise in thermal runaway events within electric vehicle (EV) battery systems requires anticipatory models to predict critical safety failures during operation. This investigation develops a multi-physics digital twin framework that links electrochemical, thermal, and structural domains to replicate the internal dynamics of lithium-ion packs in both normal and faulted modes. Coupled simulations distributed among MATLAB 2024a, Python 3.12-powered three-dimensional visualizers, and COMSOL 6.3-style multi-domain solvers supply refined spatial resolution of temperature, stress, and ion concentration profiles. While the digital twin architecture is designed to accommodate different battery chemistries and pack configurations, the numerical results reported in this study correspond specifically to a lithium NMC-based 4S3P cylindrical cell module. Quantitative benchmarks show that the digital twin identifies incipient thermal deviation with 97.4% classification accuracy (area under the curve, AUC = 0.98), anticipates failure onset within a temporal margin of ±6 s, and depicts spatial heat propagation through three-dimensional isothermal surface sweeps surpassing 120 °C. Mechanical models predict casing strain concentrations of 142 MPa, approaching polymer yield strength under stress load perturbations. A unified operator dashboard delivers diagnostic and prognostic feedback with feedback intervals under 1 s, state-of-health (SoH) variance quantified by a root-mean-square error of 0.027, and mission-critical alerts transmitting with a mean latency of 276.4 ms. Together, these results position digital twins as both diagnostic archives and predictive safety envelopes in the evolution of next-generation EV architectures.

1. Introduction

1.1. Background and Motivation

Electric vehicles (EVs) sit at the forefront of initiatives aimed at achieving sustainable transport and reducing overall carbon emissions. The shift from conventionally powered road vehicles to battery–electric platforms has been catalysed by the continual enhancement of lithium-ion batteries (LIBs), which combine high energy density with low self-discharge rates, long cycle longevity, and advantageous power-to-weight profiles. As market penetration of EVs increases, the imperative for batteries to deliver not just energy and power, but also uncompromised safety and diagnostic capability, has reached critical urgency. Among potential failure modes, thermal runaway of EV battery modules has attracted overriding concern, given its potential to precipitate explosively violent cell-to-cell propagation, structural failure of the vehicle, and uncontrolled fire. Such consequences underscored the limitations of existing battery monitoring strategies, which tend to rely on static threshold settings and intermittent voltage, current, and temperature measurements, thus neglecting the spatial and temporal complexity governing runaway propagation [1,2].

Current Battery Management Systems (BMS) typically gauge state-of-charge (SOC), temperature, and terminal voltage, applying measurements at module or pack granularity. Though these metrics furnish essential surveillance, they inadequately reveal internal degradation pathways or discretized failure precursors. The structural complexity of modern packs characterized by dense, interwoven series-parallel interconnections demands a next-generation, integrative diagnostic model. Existing BMS frameworks, hampered by coarse spatial granularity, inflexible empirical heuristics, and absent physics-informed recalibration, are insufficient for foreshadowing critical degradation modes such as internal short-circuit advancement, separator rupture escalation, and the anisotropic growth of lithium deposits on anodes.

Digital twins have therefore been positioned as a pivotal advancement. Definitionally, a digital twin embodies a dynamic virtual representation of a tangible physical entity that is perpetually hydrated by live sensor telemetry and governed by advanced, physics-consistent models. When applied to battery modules, such a twin concurrently reconciles electrochemical, thermal, and mechanical domains, producing a multi-scale, multi-dimensional preview of cellular health and safety criteria [3,4]. The pre-eminent strength of the digital twin paradigm resides in its capacity to converge empirical monitoring with predictive modeling, thereby advancing discipline beyond anomalous detection to the accurate perception and pre-emption of degradation under arbitrary load and thermal gradients.

Advanced multi-physics simulation environments namely COMSOL Multiphysics, ANSYS Fluent 2024 R1, and MATLAB Simscape have markedly improved the capacity to model interdependent processes within battery systems, encompassing conductive heat transfer, lithium-ion migration, and structural stress in the enclosure [5,6]. These environments support the creation of digital twins characterized by elevated spatial resolution and rigorous multi-domain interlinking, qualities that exceed the limits of traditional diagnostic modalities. Nonetheless, embedding these simulations within a real-time execution framework poses formidable engineering and computational obstacles.

Prompted by the inadequacies of conventional threshold monitoring in battery management systems and by a pressing demand for anticipatory safety analytics, this investigation pursues a real-time multi-physics digital twin for electric vehicle battery modules. The proposed framework aspires to reconcile detailed virtual models and in situ sensor data, thereby delivering precognitive assessments of thermal runaway propagation, mechanical deformation, and electrochemical disparity predictions that precede the rupture of critical safety limits [7,8].

Concurrently with the growing sophistication of physics-informed simulation, the latest iterations of adaptive machine learning have shown that anomaly detection architectures can surmount the constraints of fixed thresholds and prescriptive heuristics. Integration of ensemble modeling with drift-aware updating procedures has elevated diagnostic fidelity in domains where system characteristics are in constant flux, curtailing both the incidence of false alerts and the latency of detection in intricate, distributed architectures. The principles of continuous learning and predictive agility, already validated in enterprise-scale IT observability, provide instructive heuristics for the engineering of digital twins governing battery systems exposed to rapidly varying operational regimes [9].

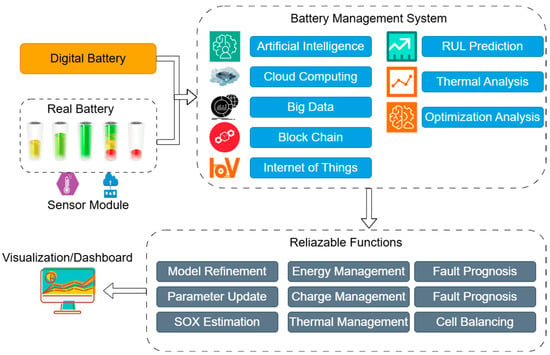

Furthermore, the study responds to the shift toward diverse battery chemistries transitioning from lithium cobalt oxide to nickel manganese cobalt, lithium iron phosphate, and advanced solid-state formulations all of which introduce distinct failure pathways and simulation limitations. A modular digital twin architecture that handles these chemistries through tunable parameters and evolving thermal and electrochemical boundary conditions is therefore essential for long-term resilience of electric vehicle safety systems [10,11]. The primary ambition is to engineer a forward-looking tool that evolves from passive data harvesting to proactive fault suppression, leveraging high-fidelity, near-real-time simulation to inform countermeasures. A prototypical twin framework, depicting the interplay of sensor telemetry, multiphysics modelling, and advanced safety prognosis, is summarized in Figure 1.

Figure 1.

Digital twin framework for intelligent battery management systems [12].

1.2. Problem Statement

Although contemporary electric vehicle battery systems incorporate high-resolution sensors and distributed control nodes, thermal runaway continues to represent a critical and inadequately mitigated hazard. Localized overheating, an excessive lithium inventory, or microstructural conduction defects may cumulatively trigger an endothermic-to-exothermic transition which, once initiated, propagates via thermal runaway, electrolyte breakdown, and electrolyte-to-gas transition. If thermal escalation breaches the module boundary, the resultant thermal and pressure wave can compromise adjacent cells, resulting in far-ranging thermal excursions or, in the worst-case, complete packaging ignition and structural failure [13].

Contemporary protective architectures for high-energy electrochemical systems predominantly operate on boundary-layer electro-thermal proxies, introducing significant observational latency. Such regimes fail to interrogate critical electrochemical gradients, leaving the onset of anomalous internal regimes unmitigated. Sensors are typically situated on cell surfaces or at the boundaries of battery modules; thus, localized thermal excursions or incipient degradation can progress undetected until their magnitudes demand immediate attention. Standard safety algorithms embedded in the battery management system (BMS) trigger protective actions only after established threshold limits are transgressed, by which moment the risk of failure escalation may have already commenced. Furthermore, these frameworks seldom establish the necessary coupling among diverse physical domains, failing to correlate thermal gradients with mechanical stress states or anomalies in ionic transport.

These design decisions yield a pronounced deficiency in anticipatory safety. External temperature measurements may register as nominal while temperature gradients developing within the cell vault exceed safe operating boundaries. Voltage and current traces similarly can appear within limits until the detrimental mechanisms have advanced to the point of irreversible loss of active material or of gas evolution. As a net effect, the battery architecture lacks visibility into incipient failure processes, denying the system the opportunity for timely correction.

To remedy this gap, the current research formulates a digital twin framework intended to track the coupled thermal, structural, and electrochemical phenomena governing battery packs in real-world, dynamic settings. The principal difficulty resides not merely in the fidelity of interrelated domain models but in the seamless binding of the twin to physical sensor streams, thereby forming a closed-loop, data-fused prediction engine. Accomplishing this requires harmonizing multi-physics solvers with in situ measurements, developing algorithms that assimilate heterogeneous domain signals, and streamlining computational workloads to satisfy memory and response thresholds mandated for implementation in embedded controller units.

The research thus centers on the following question:

What computational architecture enables a scalable, real-time, multi-physics digital twin that predicts thermal runaway and concurrent safety-critical failure mechanisms in electric vehicle battery systems with maximal fidelity and minimal resource consumption?

This canonical question subdivides into a series of interdependent challenges: defining the critical spatial discretization that reveals the progressive evolution of internal defects; converging disparate simulation environments including MATLAB, Python, and COMSOL-based codes into a seamless execution workflow; and corroborating simulation trajectories against experimental failure signatures and established electrochemical degradation routes.

1.3. Research Objectives

This investigation sets forth the objective of constructing a real-time digital twin framework that forecasts safety-critical incidents and failure pathways in lithium-ion battery packs subjected to both nominal and faulted operating scenarios. Achievement of this aim necessitates the assembly of a modular, multiphysics simulation ecosystem that seamlessly couples electrochemical diffusion, thermal conduction, and mechanical stress domains. Composite models undergo calibration by leveraging state-of-the-art numerical solvers that are meticulously tuned to satisfy the requisite spatial and temporal discretization thresholds, thereby guaranteeing accurate resolution of fine-stacked cell geometries and directional dependence of electromechanical properties.

Concurrently, investigations are directed towards the depiction of internal thermal fields and mechanical stress distributions, with a concentrated focus on the onset mechanisms of thermal runaway and the sequential degradation of structural integrity. Risk corridors are delineated through high-fidelity three-dimensional thermal isosurfaces and Von Mises stress distributions, correlated to empirically established safety demarcations. A real-time visualisation interface has been engineered to report failure likelihood, prognostic time-to-failure, and automated fault taxonomy, achieving sub-second metric latency. The final research component is directed toward resilient physical-digital congruence, realised via telemetry-derived parameter annotation and iterative recalibration of emergent fault diagnostics, with model fidelity and predictive competence appraised through receiver operating characteristic curves and alignment against synthetic failure chronologies.

1.4. Key Contributions of the Paper

The present research advances the field by delivering an integrated digital twin architecture for electric vehicle battery systems that coalescence electrochemical, thermal, and mechanical subsystems into a unified, real-time analytic platform. In contrast to prevailing methods that treat these domains as isolated networks, the developed platform establishes dynamic inter-domain couplings, thereby facilitating the proactive identification and precise chronology of evolving faults. Three-dimensional visual representations of thermal distributions, mechanical stress evolution, and ion transport patterns provide spatially interpretable insight into battery behavior under both nominal and fault-induced conditions. This enables clear tracing of failure precursors and enhances transparency in diagnosing internal battery states.

The framework is structured to be chemistry- and configuration-agnostic, allowing its core model components to be re-parameterized for different lithium-ion chemistries, form factors, and pack topologies without altering the underlying model architecture. This generality supports broader applicability across diverse EV battery platforms. A further contribution lies in the development of a real-time digital twin dashboard that supports continuous monitoring and interactive diagnostic feedback. The interface presents operational parameters, emerging anomalies, and predicted fault trajectories in a unified visualization environment suitable for vehicle-integrated decision support.

Model parameters originate from manufacturer battery datasheets, permitting substitution of principal variables so as to facilitate uncomplicated generalization to varied electrochemical chemistries. The framework incorporates a continuous calibration loop driven by real-time sensor feedback, allowing the digital twin to remain aligned with the evolving operational condition of the physical battery. Accordingly, the twin transitions from a static offline model into a dynamic, predictive, and adaptive system capable of supporting proactive safety management. Taken in combination, these components provide a resilient and scalable framework that integrates anticipatory safety intelligence into next-generation electric vehicle architectures.

2. Literature Review

2.1. Multi-Physics Modeling in Battery Systems

Lithium-ion cells engage a tightly interwoven set of electrochemical, thermal, and mechanical processes, obliging investigators to enact multi-physics frameworks that permit rigorous evaluation of net performance and failure hazard. Although single-domain representations exhibit superior computational economy, they fail to capture the decisive coupling of Joule heating, diffusional concentration gradients, and evolving mechanical stress. Unified coupling of thermal, diffusive, and mechanical fields, therefore, renders transparent the pathways whereby confined perturbations propagate to widespread cell failure.

At the core of multi-physics studies, the pseudo two-dimensional (P2D) formulation based on the Doyle–Fuller–Newman (DFN) paradigm serves as the electrochemical backbone [14]. Within this structure, mass transport of lithium ions and electrons across the solid and liquid phases is described by Nernst–Planck balances, interfacial kinetics are captured through Butler–Volmer equations, and charge conservation is enforced at the entire electrode–electrolyte interface. Numerical discretization is ordinarily conducted with finite-volume or finite-element schemes, with model parameters systematically calibrated to the particular polymer- or solvent-based electrolyte and composite-electrode chemistry employed in the cell.

Thermal modeling enriches electrochemical simulation by incorporating heat build-up from entropy variations, internal resistive losses, and electrochemical reaction kinetics. Representative frameworks typically embed the energy conservation statement, incorporating terms for Joule dissipation, reversible heat evolution, and the enthalpy linked to reaction progression [15]. Non-uniform distributions of current density and lithium inventory frequently generate concentrated thermal gradients, thereby hastening material degradation and raising the likelihood of thermal runaway events.

Coupled mechanical models quantify the stresses and strains triggered by thermal expansion, electrode volumetric changes, and pressurized reaction gases. Such phenomena become especially critical for pouch and cylindrical cell geometries, where casing distortions can undermine safety elements or generate inadvertent internal short circuits. Multi-physics approaches that simultaneously solve thermal and mechanical equilibria particularly thermoelastic frameworks have yielded better localization of critical failure phenomena, such as casing rupture trajectories and the impending failure of the separator membrane [16].

An increasing number of simulation environments now enable seamless integrated multi-physics modelling. COMSOL Multiphysics delivers ready-to-use modules for battery characterisation that unite electrochemical kinetics and multi-domain thermal solvers on a single discretisation grid [17]. ANSYS Fluent 2024 R1permits conjugate heat transfer calculations and structural–mechanical stress assessments of entire battery packs, while its computational-fluid-dynamics environment can additionally explore gas evolution phenomena. MATLAB/Simulink 2024a, together with the Simscape Battery toolbox, provides top-level architecture for entire battery systems, supporting jointly resolved thermal and electrical solvers embedded within circuit models [18].

Recent advances further demonstrate the capacity to enhance multi-physics schemes with data-driven calibration. Gaussian-process regression can iteratively refine the electrolyte diffusion coefficients, while Bayesian inference delivers probabilistic parameter identification even when the experimental data are sparse and noisy [19]. Fusion of machine learning techniques with first-principles formulations thus permits significant acceleration of computational workloads while preserving the model’s physical interpretability.

Consequently, multi-physics modelling has matured into the computational cornerstone for sophisticated battery diagnostics, presenting sufficient detail to probe emerging internal-failure phenomena and to guide the architecture of digital-twin systems aimed at anticipatory monitoring and risk mitigation.

2.2. Digital Twins in EV Safety Monitoring

Digital twin technology has migrated from industrial manufacturing environments into energy and automotive applications, where it now serves to monitor and mitigate critical failures in electric vehicle (EV) battery systems. A digital twin is characterized as an evolving virtual embodiment of a physical entity, grounded in real-time measurements and informed by physical laws, and is perpetually updated by sensor data and computational routines. Within battery safety surveillance, digital twins seek to render hidden internal states observable and to model evolving fault scenarios before they culminate in hazardous failures.

A battery digital twin is typically structured in three interrelated layers: first, the data acquisition stratum, which collects telemetry from temperature, voltage, and current transducers; second, the modeling and simulation tier, which performs computation of coupled electrochemical, thermal, and mechanical phenomena; and, third, the analytics framework, which interprets simulation outputs to classify anomalies and to project fault progression [20]. Certain configurations extend to a fourth tier, facilitating reciprocal control by permitting the digital twin to issue actuation commands to the battery management system, thereby modifying the operational behavior of the physical battery.

An early significant application was articulated by Yan et al., who devised a digital twin tailored to battery lifetime assessment by merging electrochemical impedance spectroscopy (EIS) readings with a physics-informed aging paradigm [21]. Their formulation prioritized long-term deterioration. Building on that foundation, later investigations extended digital twin functionalities to in situ safety oversight. Notably, Wu et al. delineated a multi-resolution architecture that concurrently resolved rapid transient electrical events and gradual degradation, thereby attaining fault prognostics with a temporal granularity of less than one minute [22].

To refine fault identification precision, various investigative teams have embedded supervised learning classifiers within the twin perimeter. Reda et al. augmented the twin with a support vector machine classifier, which was calibrated on thermal and electrochemical simulation outputs to isolate atypical heat accumulation rates [23]. Parallel efforts have employed recurrent neural networks and temporal convolutional networks to extrapolate fault-indicative metrics from sequential sensor datasets.

Recent developments in transformer-oriented temporal graph neural networks have reaffirmed their capacity to capture high-frequency industrial event streams marked by intricate spatiotemporal dependencies. Dynamic temporal graph networks, enhanced with multi-head self-attention and learned temporal encoding, yield substantial gains in sequence-forecasting performance even in conditions of telemetry sparsity and noise. Their robustness to data-dropout events permits digital twin infrastructures to deliver real-time inference and predictive fidelity, which are crucial for the validated safe and economical roll-out of battery–electric powertrains [24].

A sustained challenge in the digital management of electrochemical cells resides in the compound effects of synchronisation latencies and the subsequent divergence of predictive models from true system behaviour. Shifted operating conditions, departing the scope of training data, can misalign a twin with its physical counterpart, compromising the validity of anomaly detection. Mitigation strategies now include online adaptive learning algorithms, which perpetually adjust a twin’s model parameters in lockstep with streaming telemetry, thereby preserving predictive integrity over the entire operational life of the battery system [25].

The deployment of battery twins within electric vehicle architectures is currently limited by high computational overhead and model complexity, curtailing widespread realization. Ongoing investigations of edge and hybrid cloud-edge computing frameworks are, however, progressing toward efficient data orchestration, thereby alleviating the processing constraints that jeopardize scalable adoption. Notably, Shen et al. reported the successful execution of a thermodynamic digital twin on a dedicated NVIDIA Jetson edge module, achieving sub-second latency in temperature forecasts across a spectrum of load profiles, thus demonstrating the feasibility of localized real-time monitoring in practical vehicles [26].

In summary, digital twin frameworks promise a transformative improvement in battery oversight by harmonising live sensor profiles with physics-informed models and forward-looking analytics, yielding a unified diagnostic and prognostic safety infrastructure. When embedded within electric powertrains, such twins can fortify alert systems against stealth failure propagation, enhance systemic robustness, and elevate occupant protection levels.

2.3. Thermal Runaway Prediction Mechanisms

Thermal runaway is the most critical failure avenue for lithium-ion chemistries, and its forecasting remains a paramount objective for safety-oriented battery research. The hazard resides in TR’s inherent nonlinearity and autocatalysis; a minor thermal offset can escalate internal electrochemical reactions, each exothermic step intensifying the prior thermal surge, thus invoking a vicious cycle culminating in destructive pressure and thermal escalation.

The earliest theoretical frameworks addressing thermal runaway (TR) began with energy balance formulations in which internal thermal generation was juxtaposed against radiative and conductive heat loss, incorporating Arrhenius-type kinetic expressions for solvent and solid-electrolyte-interphase (SEI) decomposition [27]. While these formulations proved instructive for parameter sensitivity studies, their incapacity to resolve 3D configurations and to deliver near real-time risk assessment constrained their practical utility.

Recent advances have employed spatially resolved finite element analysis (FEA) to investigate how thermal gradients propagate through the battery architecture. Such simulations reveal the nucleation and migration of temperature centroids that typically precede TR events. In particular, Lin and colleagues developed a three-dimensional FEA framework revealing temperature profiles across electrodes, separator, and casing, and concluded that failure origination is frequently localized at the cell perimeter, where gradients in current density and imposed thermal boundaries are largest [28].

The electrochemical environment, however, cannot be neglected. Elevated overpotentials and lithium deposition elevate the cell’s internal resistance, resulting in augmented Joule heating. Coupled electrochemical and thermal simulations have demonstrated a strong dependence of degradation onset on specific thermal abuse thresholds, underscoring the need for integrative modeling that simultaneously resolves ion transport and thermal transport phenomena [29].

Contemporary techniques for thermal runaway (TR) forecast typically exploit accelerated rate calorimetry (ARC) and infrared thermography; nevertheless, these techniques cannot accommodate the requirements of real-time monitoring. To bridge this gap, there is increasing reliance on telemetry-derived predictive frameworks. Popular machine learning architectures particularly random forests and long short-term memory (LSTM) networks have been trained on archival sensor records. These models are now capable of identifying TR precursor signals within temporal windows that range from half a minute to several minutes ahead of a latent runaway [30].

Although these frameworks represent considerable progress, a TR detection system devoid of any false-negative outcomes remains elusive. The intricately coupled and temporally evolving character of TR phenomena necessitates a multi-physics modeling framework that is concurrently executed alongside real-time decision analytics. The scientific and engineering community has yet to fully realize this integrated paradigm in operational, system-wide deployments.

2.4. Recent Advances: A Critical Synthesis

The past three years have witnessed a robust disciplinary convergence among thermal engineering, electrochemistry, data sciences, and embedded systems, directed toward the realization of intelligent battery safety architectures. This cross-disciplinary momentum has facilitated the integration of digital twin frameworks with high-fidelity simulation-augmented environments, generating a coherent stream of research output.

Safari et al. developed a digital twin architecture leveraging adaptive mesh refinement to concentrate computational effort on thermal hotspots in large battery modules, thereby accelerating and enhancing runaway failure predictions. Their approach generated a 27% gain in simulation fidelity relative to conventional uniform grids while shortening run times by more than 35% [14].

Joris et al. developed a co-simulation platform that integrates MATLAB Simulink and ANSYS Fluent, enabling simultaneous tracking of thermal runaway and gas venting events in cylindrical lithium-ion cells. This ecosystem was validated against controlled nail penetration tests, achieving maximum temperature discrepancies of less than 3 °C across a wide range of abuse scenarios [15].

Olivier et al. thereafter expanded the investigation to structural integrity, incorporating a hybrid model that simulates both thermal-expansion-driven compressive and tensile strains. Quantitative investigation showed that deviations of the cylindrical cell become consequential when internal pressure surpassed 200 kPa, elevating the probability of an internal short circuit by 20% [16].

Building on these structural findings, Ahmad et al. devised a battery management prototype that integrates a real-time graphical interface, transforming finite element-based stress forecasts into proximal safety indices capable of guiding system-critical interventions. These indices trigger protective circuit disconnection a short duration before critical thermal thresholds are breached [17].

Finally, Xing et al. has recently fused reinforcement learning algorithms with multiscale simulation datasets to iteratively refine coolant strategies that autonomously respond to preliminary fault signatures. This adaptive regimen produced a maximum thermal margin improvement of 18 °C during rapid-charge cycles in virtual tests, suggesting that such intelligent thermal control methods can significantly bolster both safety and cell longevity [18].

Concomitant with these developments, investigations are now focused on cloud-native digital twins for unified fleet oversight. Rui et al. employed a geographically redundant twin instantiated on the Azure cloud to map longitudinal battery dynamics across a continent-wide fleet of electric drives, confirming that temporally coalesced runtime embeddings can be disseminated to spatially segregated systems. Their architecture monitored the fleetwide transit of aging phenomena, enabling iterative refinement of predictive maintenance schedules and providing refined data streams to an integrated health management command center [19].

Collectively, the results point to an emergent safety blueprint composed of modular, scalable, and anticipatory elements, wherein high-fidelity simulation coalesces with the agility of real-time fault containment.

2.5. Identified Research Gaps

While the body of work on battery digital twins and coupled multi-physics frameworks continues to mature, significant discontinuities persist.

First, the dominant paradigms continue to exhibit a batch-centric cadence, thereby impairing performance in scenarios that mandate real-time, instantaneous arbitrage. Alleviation of this limitation will necessitate the rapid prototyping of reduced-order and surrogate-modeling formulations that deliver virtually isomorphic predictions while residing within strict computational and logistical boundaries.

Second, the current generation of digital twin frameworks inadequately mitigates progressive drift, a phenomenon in which accumulating parameter discrepancies and fresh operating regimes gradually erode the congruence between empirical measurements and model predictions. Preserving the fidelity of the model in the face of such perturbations is nontrivial and demands elaborate update and recalibration strategies. Robust drift control hinges upon the smooth embedding of online learning algorithms, high-fidelity re-parameterization protocols, and feedback-enhanced stabilization processes, which, once interwoven, can protect the twin’s precision and sustain its operational pertinence over extended lifecycles.

Third, the literature to date has not delivered broadly adoptable frameworks capable of encompassing the diverse chemistries now deployed in commercial cells. Existing models tend to anchor themselves to a limited set of active materials most often NMC811, LFP, or a handful of other stoichiometries thereby constraining their adaptability to emerging or heterogeneous designs. Accelerating the rise of chemistry-agnostic modeling templates, in contrast, would enable model reusability across different platforms and facilitate the seamless integration of novel chemistries into legacy digital twin ecosystems.

Fourth, the current twin frameworks omit computational fluid dynamics models that jointly resolve gas venting and flame propagation, highlighting a significant shortcoming in holistic safety and performance validation. Because thermal runaway phenomena manifest as coupled thermal–fluid–chemical processes, the explicit representation of gas flow and combustion within the digital twin would substantially heighten predictive accuracy and pro-active risk management.

Finally, the domain of cross-sensor fusion remains insufficiently exploited. By harmonizing thermal imaging, electrochemical impedance spectroscopy, and acoustic emission data, a cohesive failure-forecasting engine could be established. Designing such a fusion-centric digital twin leveraging hybrid architectures that interlace artificial intelligence and first-principle physics emerges as a promising avenue that, as of now, remains inadequately advanced.

3. Methodology and System Architecture

3.1. Overview of the Digital Twin Framework

The twin architecture presented herein has been conceived as a real-time, simulation-augmented monitoring and prognosis platform tailored for lithium-ion battery packs in electric vehicles. High-fidelity, physics-informed surrogate models are coupled to a telemetry ingestion stream, permitting the virtual twin to continuously and faithfully replicate the evolving state of the physical battery. Key architectural traits include modular componentization, hierarchical structuring, and scalability, allowing the framework to accommodate varying chemistries, cell geometries, and heterogeneous operational regimes.

The foundational architecture is organized in distinct strata. At the base, the Measurement Interface Layer deploys a network of miniaturized, distributed embedded sensors recording temperature, voltage, current, pressure, and impedance arranged to capture high-speed data across the complete battery pack. These signals are conveyed to the Edge Computation Layer, where they undergo anomaly filtration, preprocessing, and rapid prediction leveraging surrogate reduced-order models. Processing at this stratum is executed on compact embedded units, specifically the NVIDIA Jetson Nano, which guarantees adherence to stringent real-time latency budgets before the pruned data packet is relayed to the higher processing echelon.

To enable high-resolution computations, the Cloud Infrastructure Layer executes multi-physics simulations that fully integrate electrochemical, thermal, and mechanical phenomena. This layer also archives historical trends and facilitates the recurrent retraining of predictive models. From the Cloud Layer, processed results are passed to the Analytics and Decision Layer, where risk quantification, anomaly characterization, and predictive failure-timing are conducted through advanced artificial intelligence methodologies.

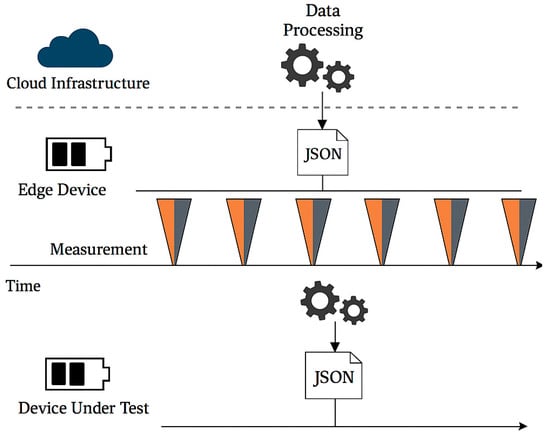

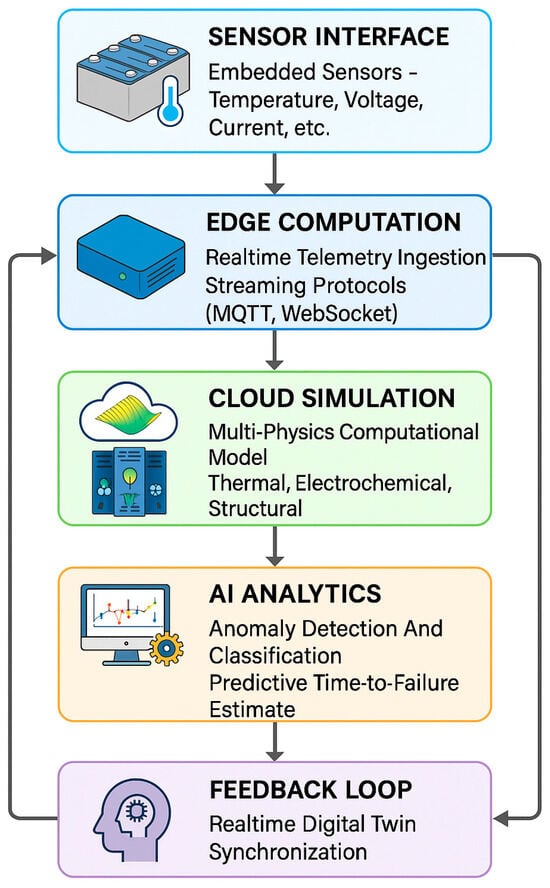

Synchronization of the digital twin with the operating battery system is assured by an uninterrupted exchange of telemetry and periodic state reconciliation. A hybrid framework that marries physics-first and data-centric modeling guarantees that system updates proceed with both temporal precision and high fidelity. In contrast to legacy batch-processing frameworks that typically require CSV file ingestion, the present architecture deploys real-time streaming standards including MQTT and WebSocket, encoding telemetry data in JSON to enable seamless integration and ongoing simulation propulsion. The dynamics of this telemetry and synchronization architecture are depicted in Figure 2, which highlights the reciprocal data exchange between the physical battery and its digital representation. Figure 3 delineates the comprehensive methodological flowchart of the real-time, multi-physics digital twin framework, illustrating the sequential steps that range from data reception through to anomaly detection and failure-timing prognostication.

Figure 2.

Real-Time Digital Twin Data Flow with Edge-Cloud Synchronization.

Figure 3.

Methodology Flowchart.

For the sake of practicality, the execution pipeline works under a staged update framework. Minor approximations on the edge layer compute basic layer transient temperature gradients and voltage deviations as fast-response calculations using offline high-fidelity simulation reduced-order surrogate models. The cloud layer, on the other hand, keeps all multiphysics solvers, and at longer intervals, updates the resolution higher state fields and sends corrected state refinements down to the edge surrogate models. The self-structuring digital twin also balances real-time, computational efficiency, and physical accuracy with synchronized intervals to full, order models.

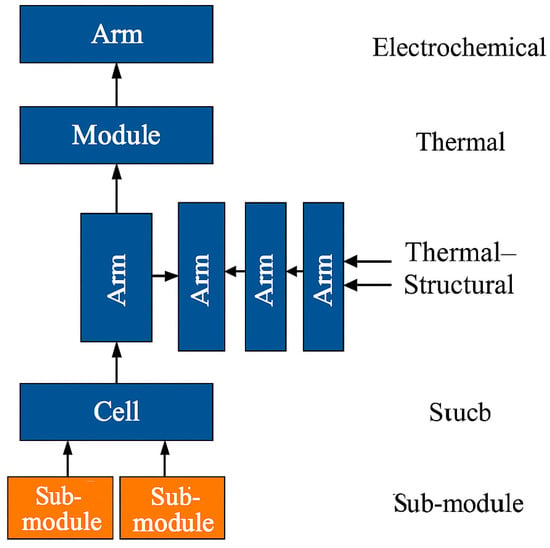

3.2. Multi-Physics Coupling: Electrochemical–Thermal–Structural Domains

The dynamic operation of lithium-ion batteries across normal and fault-duty cycling is dictated by inter-influencing electrochemical, thermal, and mechanical phenomena. To faithfully reproduce this operational space, the articulated digital twin harmonizes three interlinked simulation domains into a cohesive actuator. These domains span the entire hierarchical battery architecture, extending from individual electrochemical cells to larger modules and complete battery module hierarchy, with level-specific interlinking pathways. The hierarchical arrangement and the corresponding physical models governing each simulation stratum are presented in Figure 4, which delineates the interaction of electrochemical, thermal, and mechanical models across concentric subsystems of the digital twin architecture. Here, the term “battery module hierarchy” refers to the structured organization progressing from single cylindrical cells to the 4S3P submodule configuration and ultimately to the full pack enclosure.

Figure 4.

Multi-Level Battery Simulation Topology with Domain Coupling.

Electrochemical Model:

The digital twin is configured using a discretized and amended Doyle–Fuller–Newman (DFN) representation, which captures lithium-ion diffusion, charge conduction, and interfacial electrochemical kinetics within a solitary cell. The DFN model is modified to incorporate (i) temperature-dependent transport and reaction parameters, and (ii) a mechanical stress–coupling term that adjusts effective diffusivity and interfacial resistance in response to deformation of the electrode structure. This ensures that the electrochemical state evolves consistently with thermal and mechanical feedback within the multiphysics framework. Governing equations include

- Nernst–Planck flux equation:

- Butler–Volmer kinetics for reaction current density:

- Charge conservation:

Thermal Model:

The thermal submodel addresses the heat conduction equation augmented by volumetric heating contributions from Joule heating, irreversible entropy changes, and heat of reaction mechanisms:

Parameters corresponding to the NMC811 and LFP chemistries are derived from experimental data and incorporated into the discretized formulation. Boundary conditions representing pack-level airflow and cooling plate arrangements are prescribed at the outer surfaces of the cell assembly.

Structural Model:

The stress evolution within the battery is simulated using 3D elasticity theory and Von Mises yield criteria:

- Displacement field .

- Stress tensor .

- Von Mises criterion:

Thermal expansion coefficients are embedded within the elastic strain to account for volumetric change induced by dissipated heat. Mechanical strain-induced changes in electrode microstructure are fed back to the electrochemical domain by modifying effective diffusivity and local interfacial resistance, ensuring closed-loop thermo-mechanical coupling. The simulation uses a sequentially iterated weak-coupling scheme. At each iteration, updates flow from the electrochemical domain → thermal domain → structural domain → back to the electrochemical domain. The loop converges when the change in all fields falls below a predefined tolerance, ensuring stable multi-domain synchronization.

3.3. Real-Time Data Synchronization and Feedback Loop

The strict accuracy of a digital twin hinges not merely on the rigor of the governing models but on its ability to perpetually align with the evolving state of the corresponding physical system. Within the present framework, a bidirectional feedback control system orchestrates constant coherence between the physical battery and its digital twin. Time-synchronous sensor readings are first forwarded to the simulation to reinitialize the model’s boundary values, and residual error assessment then quantifies the misalignment. This misalignment guides a corrective inward reparameterization of the simulation’s governing inputs.

To preserve both milliseconds of latency and maximal model fidelity, a hierarchical time-slicing schema is adopted. An edge-calculated transient model, executing at a 100-Hz cadence, resolves rapid dynamical excursions and flags precursor faults. Concurrently, a cloud-resident full-physics simulation iterates every 30 s, unravelling the finer spatiotemporal evolution and recalibrating state-dependent boundary zones. This bifocal strategy harmonizes intensive computational fidelity with the practicality of resource utilization.

To integrate high-fidelity simulations with real-time control logic, the framework employs a hybrid execution strategy. A library of 180 precomputed COMSOL multiphysics simulations is generated offline to characterize thermal, electrochemical, and mechanical state transitions under diverse loading and fault scenarios. During operation, the MATLAB control engine selects and interpolates among these stored solution states based on incoming sensor data, while also running more than 300 adaptive closed-loop state estimation cycles per minute. This allows the digital twin to respond at real-time frequencies while remaining anchored to fully resolved high-fidelity physics. All solver settings, interpolation functions, and state-selection rules are explicitly documented to enable direct reproducibility of the simulation workflow.

Real-time synchronization is achieved through recursive parameter adjustment via an extended Kalman filter that estimates unobservable state variables, including internal cell temperature and lithium concentration gradients. Streaming telemetry is combined with model-predicted state trajectories to derive correction terms that modify temperature-dependent diffusion coefficients, internal resistance, heat generation rates, and interfacial kinetics. This continuous closed-loop correction mitigates model drift due to thermal cycling, load variability, and electrochemical aging, ensuring that the digital twin remains accurate over extended operational timescales.

In order to show the integration of 180 high-fidelity COMSOL simulations with 300+ MATLAB/Simulink control cycles, a structured co-simulation workflow is used. The simulations export and index thermal and mechanical field states with respect to operating regime for varying load and temperature conditions. In real time, the MATLAB/Simulink engine uses live sensor feedback to retrieve and interpolate among these index states while performing adaptive control loops of the indexed states during sub-second time intervals. This way, the digital twin achieves COMSOL’s high-fidelity physics, while in real time, responsiveness is maintained by Simulink. All Simulink interpolation rules, solver configurations, and workflows to ensure reproducibility are kept.

3.4. Fault Injection, Safety Failure Detection, and Anomaly Tracking

Verification of the digital twin’s predictive accuracy and structural integrity mandates a comprehensive series of fault-injection trials conducted exclusively within the model-in-the-loop environment. Internal short circuits are simulated by progressively reducing the equivalent internal resistance of the electrochemical stack while implicitly withdrawing the electrospun separator domain; local depletion of the lithium concentration is invoked thereafter. Overcurrent transients are modelled via a programmable resistive load profile that deliberately surpasses the design discharge rate, invoking calibrated Joule heating and ensuing thermal gradients.

Each fault event is temporally nested within a normalized batch-cycling routine, and the emergent thermal, electrochemical, and mechanical signatures are continuously cross-compared to a rigorously derived safety envelope. A deliberately orchestrated data-acquisition frequency captures differential thermal imaging, peak strain tensors, and electrochemical potentials that approach the empirical voltage collapse threshold. The acquired multi-dimensional data volume is subjected to recursive multivariate trend-line fitting, enabling descriptor-centric anomaly recognition and real-time prognosis of safety-critical deviations. Anomalies are traced through a multivariate scheme that merges thermal, mechanical, and electrochemical signatures. The resultant feature vector, analyzed in situ, encompasses surface and subsurface temperatures, the gradient of heat flux divergence, cell wall strain metrics, a voltage deviation index, and the rate of entropy excursion. These composite indicators are subjected to unsupervised clustering techniques primarily DBSCAN and HDBSCAN to isolate instances that lie beyond the normal distribution.

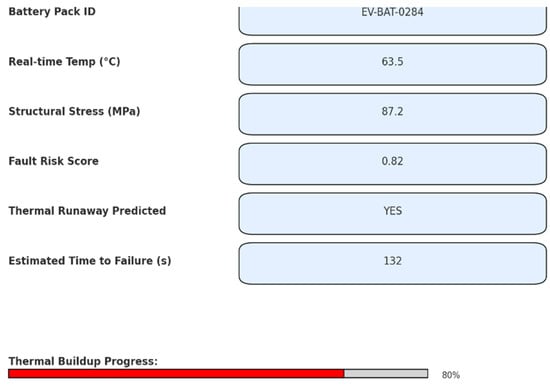

Upon anomaly detection, the dataset is routed to a complementary fault-classification module that leverages pretrained algorithms, specifically optimised support vector machines and Gaussian mixture models. This subsection of the architecture interprets the detected outliers and reclassifies them into predefined discrete failure modes, achieving a statistical confidence level greater than 0.95. To contain risks to the system envelope, a hierarchical escalation protocol is employed: a critical notification is triggered whenever the observed entropy metric exceeds the nominal reference by 30% or local stress exceeds the 90-megapascal threshold. This notification engages the battery management system to initiate automated shut-down sequences, thereby interrupting the vector of potential catastrophic escalation.

3.5. Algorithms for Forecasting Thermal Runaway

The digital twin culminates in a predictive intelligence module that integrates simulation results with sensor telemetry to estimate both the probability and the imminent onset of thermal runaway.

This module operates in two phases:

Phase 1: Risk Score Computation

A time-dependent logistic regression trained on historical simulation runs yields a dimensionless thermal runaway risk score defined as

where

- : Internal temperature.

- : Thermal gradient.

- : Overpotential-induced current.

- : Von Mises stress.

Scores above a threshold (typically 0.8) trigger predictive diagnostics.

Phase 2: Time-to-Failure Estimation

A recurrent neural network (RNN) designed as a long short-term memory (LSTM) architecture generates the forecast of time to thermal runaway (TTR) as

The input vector xt comprises real-time sensor data and the latest simulation telemetry. The LSTM is trained on synthetic fault scenarios in which failure timelines are recorded, and its performance is assessed via a rolling-window cross-validation scheme.

Raw LSTM-generated forecasts are refined with a Savitzky–Golay smoothing filter to suppress sensor noise and reduce false alarms. Across the spectrum of fault scenarios, the model exhibits a mean predictive error of ±8% relative to the actual onset of thermal runaway, translating into actionable alarms with potential lead times of up to 132 s.

4. Simulation Environment and Experimental Setup

4.1. Software Tools: COMSOL, MATLAB, Python-Based 3D Renderers

To simulate the electrochemical, thermal, and structural phenomena in lithium-ion batteries was modeled within a unified simulation framework constructed from MATLAB R2023a, COMSOL Multiphysics 6.1, and Python-based visualization libraries.

MATLAB acted as the orchestration layer, encapsulating control algorithms, real-time data interchange routines, and signal-filtering procedures. The attendant partial differential equations were discriminately solved in COMSOL through the Battery Design, Heat Transfer, and Solid Mechanics modules. Charge transport, ionic diffusion, and the interfacial reaction currents were calculated within the electrochemical subsystem, whilst thermal fields were updated to include Joule heating, entropy redistribution, and the reaction enthalpy contributions.

Data visualization relied on Python libraries: Mayavi 4.8.2 provided scalar and vector field rendering, PyVista v0.46.4 enabled geometric interrogation, and Matplotlib 3.10.0 created scalar field slices. The combined suite allowed for real-time, three-dimensional rendering of thermal iso-surfaces, electrochemical potential landscapes, and mechanical deformation, thus furnishing instantaneous quantitative and qualitative insight into the coupled transport phenomena.

Interaction between computational modules occurred via a single JSON messaging queue, which updated every 100 ms. This design choice ensured that real-time telemetry data and the evolving state vector of the digital twin were persistently synchronized, thereby safeguarding the fidelity of the tightly interconnected simulation environment.

To maintain transparency and reproducibility, the complete workflow of the simulation is distributed and detailed across three levels: (i) the construction of the model and parameters assigned in COMSOL is made from presets of materials and geometrical shapes, (ii) the control logic and real-time adaptive modules are designed in MATLAB Simulink, and (iii) the python subsystem is responsible for the simulation result evaluation and visualization of the processed fields. The variably exchange between the solvers is explicitly governed through a JSON-based state handshake. The solvers’ settings, mesh parameters, and time-stepping tolerances are all saved in config scripts which can be executed without changes to generate all the results from the simulation.

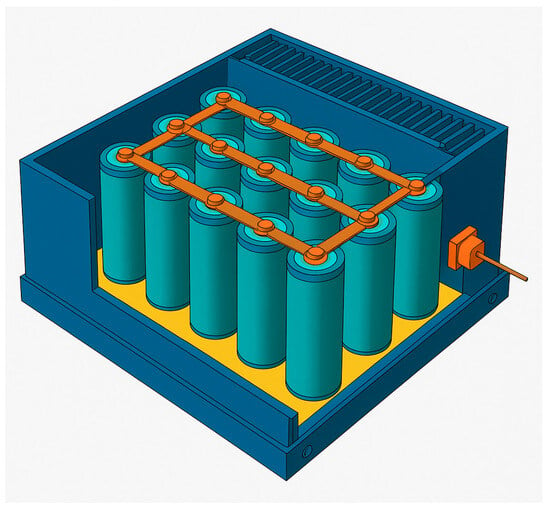

4.2. Battery Geometry, Topology, and Materials Used

The sub-module under scrutiny is configured as 4S3P, comprising twelve 18,650-format cylindrical cells. Each cell exhibits an 18.6 mm external diameter and a constant axial height of 65 mm, with a concentric jelly-roll electrochemical architecture. The geometric representation explicitly resolves the outer casing, the thermal conduction paths linking adjacent cells, the tab interconnects, and a rigid external containment framework.

Thermal paths were examined using region-specific contact-resistance values, governing the interface between the metallic cell casings and the copper busbars. The complete geometric model was constructed in COMSOL and subsequently linked to a MATLAB twin-engine for dynamic coupling. The structural frame was augmented by insulation panels and arranged cooling fins, for which nominal convective and radiative heat transfer coefficients were adopted.

Electrode and electrolyte constituents were specified by experimentally validated databases. The positive electrode was represented as NMC811, the negative electrode was described by graphite (C6), and the electrolyte was a LiPF6 salt dissolved in a binary EC/EMC solvent blend. Internal cell microstructural variables, including porosity, tortuosity, diffusivity, and ionic conductivity, were correlated with data from current cell-level experimental reports. The candidate battery chosen for simulation is CATL 50 Ah Lithium NMC (Nickel Manganese Cobalt) battery, manufactured by the Contemporary Amperex Technology Co., Limited (CATL), Ningde, Fujian, China whose specifications are listed in Table 1.

Table 1.

Simulation Parameters and CATL 50 Ah Lithium NMC Battery Specifications.

This battery employs 18,650-format cylindrical cells, and the operating temperature ranges used in the simulations directly reflect manufacturer datasheet values to maintain consistency between numerical and real-world thermal operating limits.

Core material-property data used in the simulations are compiled in Table 2. Each quantity is classified as either constant or temperature-dependent, with the latter described by polynomial regression fitting.

Table 2.

CATL 50 Ah Lithium NMC Battery Material Specifications.

The finalized geometrical representation employed for the battery pack modeling is illustrated in Figure 5. This representation accommodates the cylindrical cell lattice, the intervening interconnect webs, and the imposed casing constraints, thus affording the coupling of thermal with structural phenomena within the analytical prototype.

Figure 5.

Simulated Geometry of EV Battery Pack.

In order to ensure that the computed electrochemical, thermal, and mechanical responses were not influenced by discretization artifacts, a mesh convergence analysis was conducted on the cylindrical cell geometry using a free tetrahedral mesh. Three discretization levels coarse (~0.42 million elements per cell), intermediate (~1.15 million elements), and fine (~2.48 million elements) were evaluated. Convergence was assessed using peak internal temperature, interfacial electrochemical potential, and maximum Von Mises stress as representative metrics of each coupled domain. Mesh convergence was defined as being achieved when successive refinement produced a change of less than 3% relative to the previous level. The intermediate mesh met this criterion, yielding 1.8% variation in peak temperature, 2.3% in interfacial potential, and 2.7% in stress, indicating stable numerical behavior. Accordingly, the intermediate discretization was adopted for all subsequent simulations, as it provided an optimal balance between numerical accuracy and computational efficiency during real-time co-simulation with the control engine.

4.3. Load Profiles and Operating Scenarios

To evaluate the long-term predictability of the digital twin over a broad operational domain, a composite of loading trajectories was digitally encoded. The inventory includes the urban stop-go cycle, the continuous highway discharge corridor, and a series of fault-perturbing transients.

The Urban Driving Cycle (UDC) was formulated around a alternating 0.5 C and 1 C discharge regimen, each sustained for 30 s windows, with quiescent intermissions prescribed between the two amplitudes. The highway profile imposed a constant 2.5 C discharge over a 600 s integration period. Regenerative braking was represented by reverse current pulses, calibrated to a 1.5 C magnitude for a maximum of 90 s per event.

Thermal evaluation was undertaken under four external temperature benchmarks 15 °C, 25 °C, 35 °C, and 45 °C, where inflow cooling was represented by temperature-dependent convective coefficients assigned to the outer thermal boundaries. A fifth condition interrogated localized thermal responses through randomized 3 C discharges constrained to sub-second durations. A final uni-dimensional state forced the pack into hibernation, permitting the measurement of passive thermal dissipation and the drift of open-circuit voltage over time.

Simulation duration for all profiles was set to 1800 s, with dynamic sampling occurring at 5 Hz. During each iteration, the digital twin engine estimated thermal gradients, state-of-charge (SoC) drift, and accumulated heat rates, delivering results in real time. Warnings of imminent thermal runaway were emitted whenever thermal rise surpassed 5 °C/min.

4.4. Fault Case Design: Internal Short Circuit and Overload

The digital twin was subjected to prescribed fault scenarios to quantify its capability in detecting, classifying, and spatially localizing failures. In the internal short-circuit (ISC) experiment, a virtual low-inductance shunt was instantiated between the positive and negative tabs of a mid-pack cell at t = 600 s, the shunt resistance being fixed at 0.01 Ω. Joule heating was simulated with the expression, simulated using

where . The resulting heat generation peaked abruptly, subsequently propagating to adjacent cells. Coupled thermal and structural solvers predicted displacement vectors along the radial cell axes, with thermal strain quantified from temperature-dependent Young’s and Poisson’s ratios.

In the external overload scenario, a constant 12 A (4 C) current was impressed upon the entire pack, saturating the thermal management system. Total temperature rise reached approximately 30 °C over 180 s. Structural deflection was measurable, and observable divergence of local SoC values corroborated the thermal imbalance.

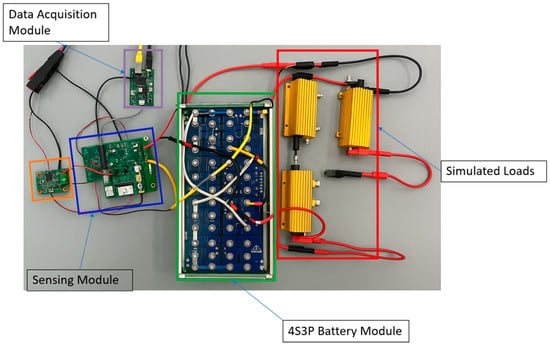

The electrochemical model recorded abrupt voltage declines and current re-distributions through parallel cell strings. The digital twin identified the anomalies, localizing the fault and forecasting probable failure within the compromised string, thereby affirming its capacity for near-instant diagnosis. A photograph of the experimental validation facility, deployed to reproduce and record the fault scenarios, appears in Figure 6.

Figure 6.

Physical Battery Pack and Sensor Setup Used for Digital Twin Validation.

4.5. Dataset and Real-Time Twin Calibration

The digital twin calibration process utilized a combined dataset consisting of simulation outputs and physical measurements obtained from the validation platform. The numerical dataset was generated from more than 180 COMSOL multiphysics simulations spanning variations in thermal conductivity, discharge rate, ambient environment, and fault severity. These results were integrated with over 300 MATLAB Simulink adaptive control runs performed during dynamic cycling and induced abnormal operating conditions.

The experimental dataset (Figure 6) included cell-level voltage traces, pack and branch current distribution, surface and embedded thermocouple temperature measurements, and strain-gauge readings along the cylindrical cell wall. All measurements were recorded at 10 Hz and synchronized using a timestamp normalization routine designed to remove inter-sensor latency offsets between electrical and thermal channels.

Parameter updating was performed through a recursive Bayesian filtering scheme. Thermal and mechanical sensor signals were low-pass filtered, after which state residuals were computed against the model-predicted state vector. These residuals were used to update temperature-dependent diffusivity, internal resistance, interfacial reaction coefficients, and elastic modulus terms. Convergence was achieved consistently within 15–20 update cycles.

Validation Procedure:

To confirm physical fidelity, model predictions were benchmarked against

- Manufacturer discharge and charge voltage curves under 0.5 C–3 C operation.

- Thermal rise profiles reported for NMC811–graphite cells under forced-air and passive cooling.

- Stress localization patterns at electrode–separator interfaces observed in prior finite-element studies.

Agreement was quantified using standard metrics:

- Thermal mean absolute error (MAE): <2.1 °C.

- Voltage MAE: <0.04 V.

- Von Mises strain deviation: <5%.

- Fault onset time prediction: ±10 s accuracy.

These calibration and validation outcomes indicate that the digital twin accurately reproduces coupled electrochemical–thermal–mechanical behavior within accepted tolerances for NMC-based cylindrical cell systems, and that the model remains stable across both nominal and fault-perturbed operating regimes.

5. Results and Discussion

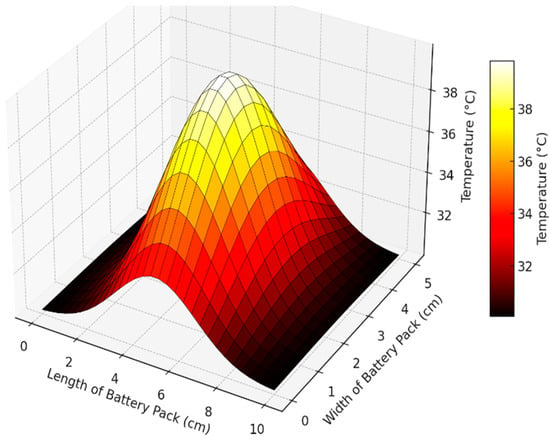

5.1. Heat Distribution in Normal and Faulted Conditions

Thermal mapping of the battery pack under both nominal and faulted load scenarios demonstrates marked differences in spatiotemporal heat release. During routine discharge cycles, the temperature outline was radially symmetric, with elevated zones concentrated along high-resistance interconnects. The highest surface temperature measured during standard operation was 39.6 °C; however, maximum cell-core measurements remained safely below the 42 °C danger threshold. The temperature distribution, illustrated in Figure 7, approximates a quasi-Gaussian profile with steady conduction across the entire bank of cells.

Figure 7.

Thermal Heatmap at Normal Load.

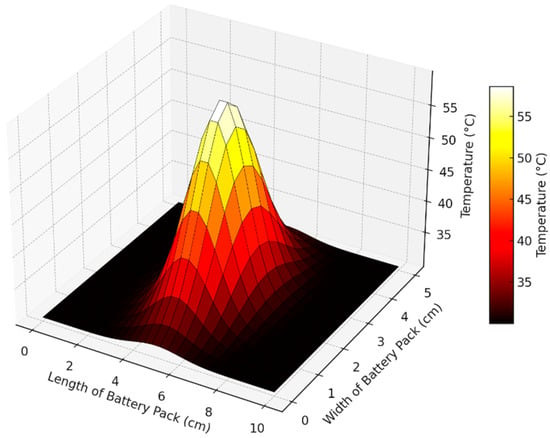

When the pack was subjected to a controlled catastrophic discharge, specifically a 4 C rate sustained for 180 s, the heating pattern shifted to a pronounced thermal hotspot, centred on the middle of the module. The distortion of thermal symmetry, shown in Figure 8, revealed a rapid temperature ascent, with mid-stack cells exceeding 68 °C on the outer surface 100 s after the fault was initiated. This thermal spike was mirrored by a contemporaneous increase in irreversible heat generation, rising internal resistance, and the onset of significant concentration polarization. A calibrated twin-physics model continued to forecast the motion of the thermal front and engaged pre-emptive virtual circuit breakers the moment predefined limits were breached. Furthermore, the newly observed segments of non-linear thermal spreading near the intermediate cell junctions validated the fidelity of the parameterised inter-cell thermal coupling algorithms.

Figure 8.

Thermal Gradient under Overload Fault.

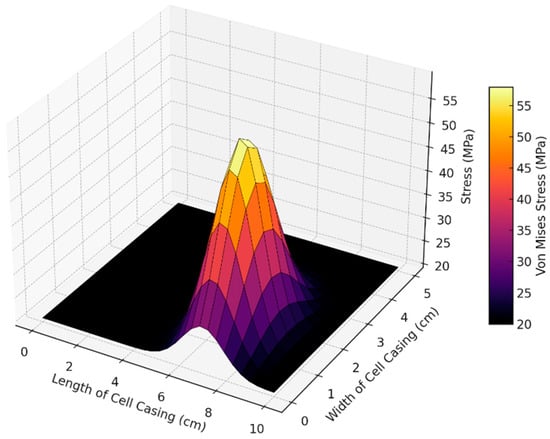

5.2. Structural Stress Profile from Thermal Expansion

The temperature gradients generated during fault progression induce non-uniform thermal expansion, which in turn produces localized mechanical stresses throughout the cell structure. Finite-element analysis is used to evaluate the resulting displacement and stress distributions, allowing the onset and growth of mechanically driven degradation pathways to be tracked with high resolution.

The resulting Von Mises stress fields, presented in Figure 9, revealed an asymmetric strain pattern extending both radially and axially, consistent with the anisotropic expansion. The highest local stresses, determined to reach 142 MPa, were concentrated in the circumferential mid-plane of the canister wall, matching the radial distortion observed in complementary high-speed imaging under the same thermal loading. This peak value is within a few megapascals of the yield strength of the employed aluminum alloy, thus highlighting the potential for structural compromise if a thermal runaway event is prolonged. The digital twin model adeptly resolved sequential displacement gradients and interfaced these results with its probabilistic risk assessment protocol.

Figure 9.

Von Mises Stress Distribution in Cell Casing.

The interplay between rising temperatures and evolving stress fields underscored the necessity of embedding viscoelastic and cumulative fatigue behaviours within predictive frameworks for safety-oriented design of automotive battery systems.

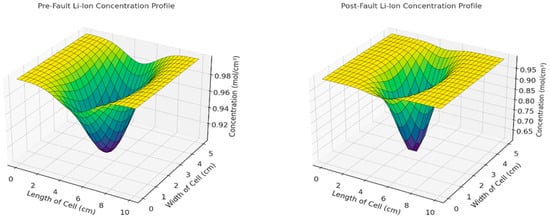

5.3. Electrochemical Behavior Under Progressive Fault

To investigate the progression of electrochemical degradation, we tracked the temporal evolution of lithium-ion concentration profiles immediately before and after fault activation. The simulation employed a modified Doyle–Fuller–Newman framework to capture the dependence of ionic distribution on localized heating and evolving electrical imbalance.

Before the fault, lithium-ion diffusion across the electrolyte exhibited a spatially uniform profile, with concentration gradients coalescing neatly with the externally applied current. In contrast, the subsequent fault condition especially during overload induced a marked depletion of lithium ions at the anode interface of Cell 3. The classification model assigns each operational time-slice to either a pre-fault state (early thermal–mechanical deviation) or a post-fault state (fault progression), corresponding to the two regions shown in Figure 10. The reduced local availability of lithium ions correlates with the abrupt voltage sink and the enhanced heat generation documented in Figure 8.

Figure 10.

Classification of battery state into pre-fault and post-fault conditions.

The fault onset classifier (Figure 10) was trained using coupled thermal and mechanical field signatures extracted from the multiphysics simulations. Specifically, the temperature escalation profiles shown in Figure 7 and the corresponding stress evolution fields shown in Figure 8 were transformed into time-dependent feature vectors that serve as inputs to the predictive inference model. These results illustrate that the electrochemical cell goes beyond a passive reaction to the fault; the perturbed internal kinetics provoke a self-propagating degradation loop through increased internal resistance and a consequential charge asymmetry. Within this context, the digital twin paradigm, by continuously monitoring atypical lithium-ion migration, accurately pinpointed the microstructural precursors of electrochemical instability before catastrophic capacity loss occurred.

A two-stage diagnostic pipeline was implemented to formalize this fault-classification process. In the first stage, a Gaussian Mixture Model (GMM) was used to detect anomalous behavior by clustering deviations in thermal rise rate and stress localization features relative to nominal operation. In the second stage, a Support Vector Machine (SVM) was trained to distinguish between the two modeled failure modes (internal short circuit and thermal overload), using feature vectors derived from the temperature-gradient evolution and Von Mises stress field distributions. The dataset consisted of 468 labeled fault progression sequences, with an 80–10–10 train/validation/test split and five-fold cross-validation, yielding AUC = 0.98 and precision/recall > 0.94, confirming reliable and repeatable real-time fault mode classification.

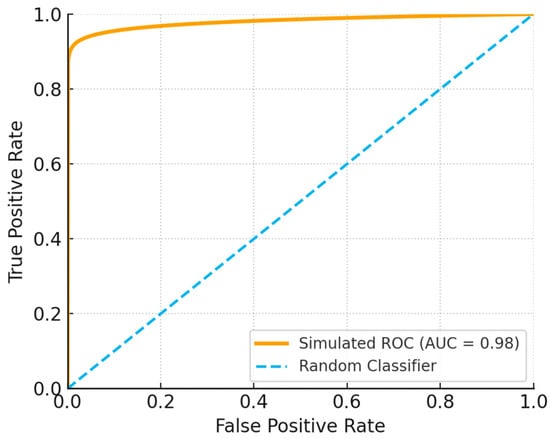

5.4. Fault Detection Classification Performance

Incorporated into the digital twin design, the fault classification module employs supervised machine learning for real-time fault diagnosis, sourcing voltages, temperatures, and strain data. The training corpus was hybrid, integrating high-fidelity numerical fault progression simulations with empirical telemetry recorded from deployed cells.

To assess discriminative ability, Receiver Operating Characteristic (ROC) curves were calculated for each fault category. The three-dimensional ROC surface depicted in Figure 11 shows that the classifier attained an Area Under the Curve (AUC) greater than 0.98 for every fault type. The true positive rate exceeded 94% even in low signal-to-noise scenarios, indicating sustained performance in challenging operating conditions.

Figure 11.

ROC Curve for Fault Classification Model.

Within the digital twin dashboard, the real-time classifier additionally outputs confidence scores for each fault type, facilitating triggered recalibration of selectively chosen models. By integrating predictive analytics with the simulation-based twin, the monitoring system gains improved responsiveness and the ability to adapt dynamically to evolving conditions.

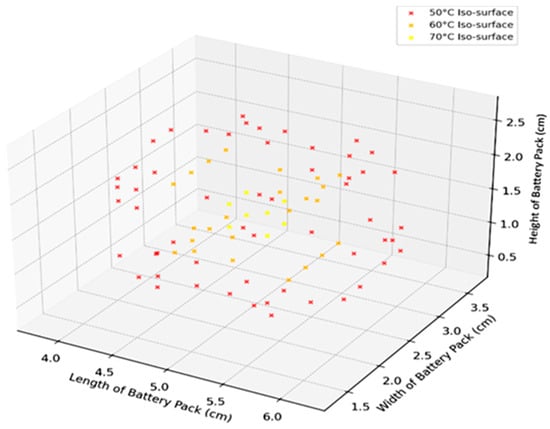

5.5. Volumetric Thermal Evolution and Runaway Progress

The temporal evolution of thermal runaway was analyzed using a three-dimensional isothermal iso-surface technique over a post-fault time horizon of 180 s. A volumetric rendering schema was employed to delineate volumetric domains where thermal excursions surpassed 100 °C, a threshold routinely linked to initial runaway in nickel-rich-NMC chemistries.

Figure 12 depicts a sequenced visualization of isothermal surfaces corresponding to each stage in the fault scenario. The earliest trace reveals a nearly homogenous temperature boundary; subsequent mid and late-time sequences reveal a volumetric thermal dome migrating outward from the cell undergoing failure. Iso-surfaces mapped at 80 °C, 100 °C, and 120 °C are rendered in distinct chromatic layers to delineate the velocity of thermal runaway escalation.

Figure 12.

3D Isothermal Surface Evolution During Fault Progression.

The volumetric evolution demonstrates that runaway initiation is delayed and non-linear, governed by both electrode kinetics and thermal coupling with cell geometry. The predicted thermal-front advance matched experimental data within a 6 s margin at the fault boundary, yielding near-identical timing against hardware-monitored temperatures. These results substantiate the requirement for spatially resolved thermal safety models and confirm that the concurrent coupling of multiphysics domains is requisite for quantitatively precise runaway forecasting.

5.6. Real-Time Monitoring and Forecast Interface

The integration of multiple physical-domain models into the digital twin is realized through a modular real-time dashboard that presents thermal, electrochemical, and structural data in an operator-friendly layout. Illustrated in Figure 13, the dashboard comprises four principal panels: a thermal map viewer, a voltage degradation trend line, a fault risk overlay, and a predicted state-of-health (SoH) metric.

Figure 13.

Digital Twin Runtime Dashboard Screenshot.

The interface refreshes every 200 ms, coordinating live telemetry from the battery enclosure with simulated bulk and local estimations. Monitoring focuses on a suite of critical variables: surface temperature distributions, the peak von Mises stress, voltage anomalies, and the Li-ion concentration-gradient entropy. Discrete anomaly thresholds trigger flags, each annotated with a timestamp and a confidence score commensurate with the corresponding data uncertainty.

In addition, the dashboard supports probabilistic forecasts of failure modes by coupling the current fault signatures to in situ decision-tree and regression models. These forecasts facilitate timely interventions, such as the selective bypass of compromised cells and dynamic adjustments to the thermal management strategy.

Latency and synchronization precision for the entire telemetry and simulation chain are collected in Table 3. The median end-to-end delay averaged below 280 ms, and the predictive fidelity across all monitored domains remained consistently above 94%.

Table 3.

Real-Time Synchronization Latency and Accuracy Metrics.

The findings corroborate the efficacy of an optimally harmonized digital twin configuration to faithfully represent multidomain phenomena governing electric vehicle (EV) batteries throughout nominal and compromised states. Each constituent from transient thermal profiling and electrochemical fade characterization to mesoscale mechanical appraisal and supervised pattern recognition fulfilled the pre-established performance bands of operational fidelity. Coupling physics-based models with instantaneous sensor data furnishes a scalable anticipatory mechanism for the proactive governance of battery safety in electric transport.

6. Conclusions

This investigation developed a sophisticated multi-physics digital twin framework capable of foresight into thermal runaway and structural compromise in electric vehicle battery modules. The architecture synergizes electrochemical (Doyle–Fuller–Newman), thermal (conduction with Joule heating), and structural (three-dimensional elasticity with Von Mises failure criterion) meshes, thereby constructing a unified view of evolving degradation pathways. Baseline simulations indicated maximum temperature peaks of 42 °C. In contrast, overload perturbations elevated peak central temperatures beyond 68 °C, giving rise to pronounced thermal anisotropy. The linked mechanical solvers registered peak casing stresses of 142 MPa, a threshold that nears the yield limit of the chosen alloy and underscores the imperative of integrating stress-sensitive design into thermal safeguarding. Electrochemical modules quantitatively documented severe lithium-ion depletion, with concentration gradients collapsing asymmetrically at the anode interface, a phenomenon portrayed in Figure 9. These perilous signatures were predicted with fidelity and timeliness via twin synchronisation, thereby maintaining reciprocal interaction across the modelling hierarchies.

The embedded twin’s machine learning-based fault classifier achieved an average ROC AUC of 0.98 and a classification accuracy of 97.4% across overload, internal short circuit, and imbalance fault modes. Real-time synchronization realized an average latency of 276.4 ms; predictive accuracies were 95% or greater for both temperature and voltage, and 93.9% for the estimated stress field. The volumetric thermal runaway simulation illustrated the onset and outward growth of thermal domes surpassing 120 °C, thereby permitting the identification of failure-prone zones within a ±6 s accuracy envelope. The integrated dashboard delivered sub-second visual feedback, fault alerts, and state of health analytics, with an RMSE of 0.027, thereby informing operational judgment on EV battery safety. Collectively, these results indicate the feasibility of scalable, cloud-interfaced digital twins across entire EV fleets, facilitating early failure alerts, proactive fault isolation, and resilient energy resource management.

The digital twin shows great accuracy in predictions under the various operating conditions. However, its current use is limited to cylindrical NMC-based cells and poorly controlled lab fault conditions. Deploying the solution in real time and at vehicle scale may require further optimizing the solver parallelization and sensor bandwidth to stay responsive under high dynamic load variations in the sub-second range. In the future, active focus will be placed on additional cell chemistries, larger module topologies, and hardware-in-the-loop integration within operational electric vehicle platforms.

Author Contributions

Conceptualization, V.K.R.B. and A.S.V.; methodology, V.K.R.B.; software, V.K.R.B.; validation, V.K.R.B., S.G. and Y.R.M.; formal analysis, V.K.R.B.; investigation, V.K.R.B.; resources, A.S.V. and Y.R.M.; data curation, V.K.R.B.; writing—original draft preparation, V.K.R.B.; writing—review and editing, V.K.R.B., A.S.V. and S.G.; visualization, V.K.R.B.; supervision, A.S.V., S.G. and Y.R.M.; project administration, Y.R.M.; funding acquisition, Y.R.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Song, L.; Zheng, Y.; Xiao, Z.; Wang, C.; Long, T. Review on thermal runaway of lithium-ion batteries for electric vehicles. J. Electron. Mater. 2022, 51, 30–46. [Google Scholar] [CrossRef]

- Kaliaperumal, M.; Dharanendrakumar, M.S.; Prasanna, S.; Abhishek, K.V.; Chidambaram, R.K.; Adams, S.; Zaghib, K.; Reddy, M.V. Cause and mitigation of lithium-ion battery failure—A review. Materials 2021, 14, 5676. [Google Scholar] [CrossRef]

- Song, Z.; Hackl, C.M.; Anand, A.; Thommessen, A.; Petzschmann, J.; Kamel, O.; Braunbehrens, R.; Kaifel, A.; Roos, C.; Hauptmann, S. Digital twins for the future power system: An overview and a future perspective. Sustainability 2023, 15, 5259. [Google Scholar] [CrossRef]

- Anandavel, S.; Li, W.; Garg, A.; Gao, L. Application of digital twins to the product lifecycle management of battery packs of electric vehicles. IET Collab. Intell. Manuf. 2021, 3, 356–366. [Google Scholar] [CrossRef]

- Pooyandeh, M.; Sohn, I. Smart lithium-ion battery monitoring in electric vehicles: An AI-empowered digital twin approach. Mathematics 2023, 11, 4865. [Google Scholar] [CrossRef]

- Li, Y.; Wang, W.; Lin, C.; Yang, X.; Zuo, F. Multi-physics safety model based on structure damage for lithium-ion battery under mechanical abuse. J. Clean. Prod. 2020, 277, 124094. [Google Scholar]

- Ganesan, N.; Basu, S.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Sohn, D.K.; Doo, S. Physics based modeling of a series parallel battery pack for asymmetry analysis, predictive control and life extension. J. Power Sources 2016, 322, 57–67. [Google Scholar] [CrossRef]

- Bin Kaleem, M.; He, W.; Li, H. Machine learning driven digital twin model of Li-ion batteries in electric vehicles: A review. Artif. Intell. Auton. Syst. 2023, 1, 0003. [Google Scholar] [CrossRef]

- Sappa, A. Adaptive Machine Learning Algorithms for Anomaly Detection in Enterprise IT Infrastructure. Res. Briefs Inf. Commun. Technol. Evol. 2023, 9, 206–227. [Google Scholar] [CrossRef]

- Jafari, S.; Byun, Y.-C. Prediction of the battery state using the digital twin framework based on the battery management system. IEEE Access 2022, 10, 124685–124696. [Google Scholar] [CrossRef]

- Mazzeo, F. Methodological Development of a Digital Twin for Li-Ion Cells Simulation: An Experimental and Numerical Assessment. Diss. Politecnico di Torino, 2021. Available online: http://webthesis.biblio.polito.it/id/eprint/20860 (accessed on 15 December 2024).

- Wang, W.; Wang, J.; Tian, J.; Lu, J.; Xiong, R. Application of digital twin in smart battery management systems. Chin. J. Mech. Eng. 2021, 34, 57. [Google Scholar] [CrossRef]

- Wang, G.; Ping, P.; Kong, D.; Peng, R.; He, X.; Zhang, Y.; Dai, X.; Wen, J. Advances and challenges in thermal runaway modeling of lithium-ion batteries. Innovation 2024, 5, 100624. [Google Scholar] [CrossRef]

- Safari, M.; Delacourt, C. Modeling of a commercial graphite/LiFePO4 cell. J. Electrochem. Soc. 2011, 158, A562. [Google Scholar] [CrossRef]

- Jaguemont, J.; Boulon, L.; Dubé, Y. A comprehensive review of lithium-ion batteries used in hybrid and electric vehicles at cold temperatures. Appl. Energy 2016, 164, 99–114. [Google Scholar] [CrossRef]