Fluid–Structure Interaction of Symmetrical and Cambered Spring-Mounted Wings Using Various Spring Preloads and Pivot Point Locations

Abstract

1. Introduction

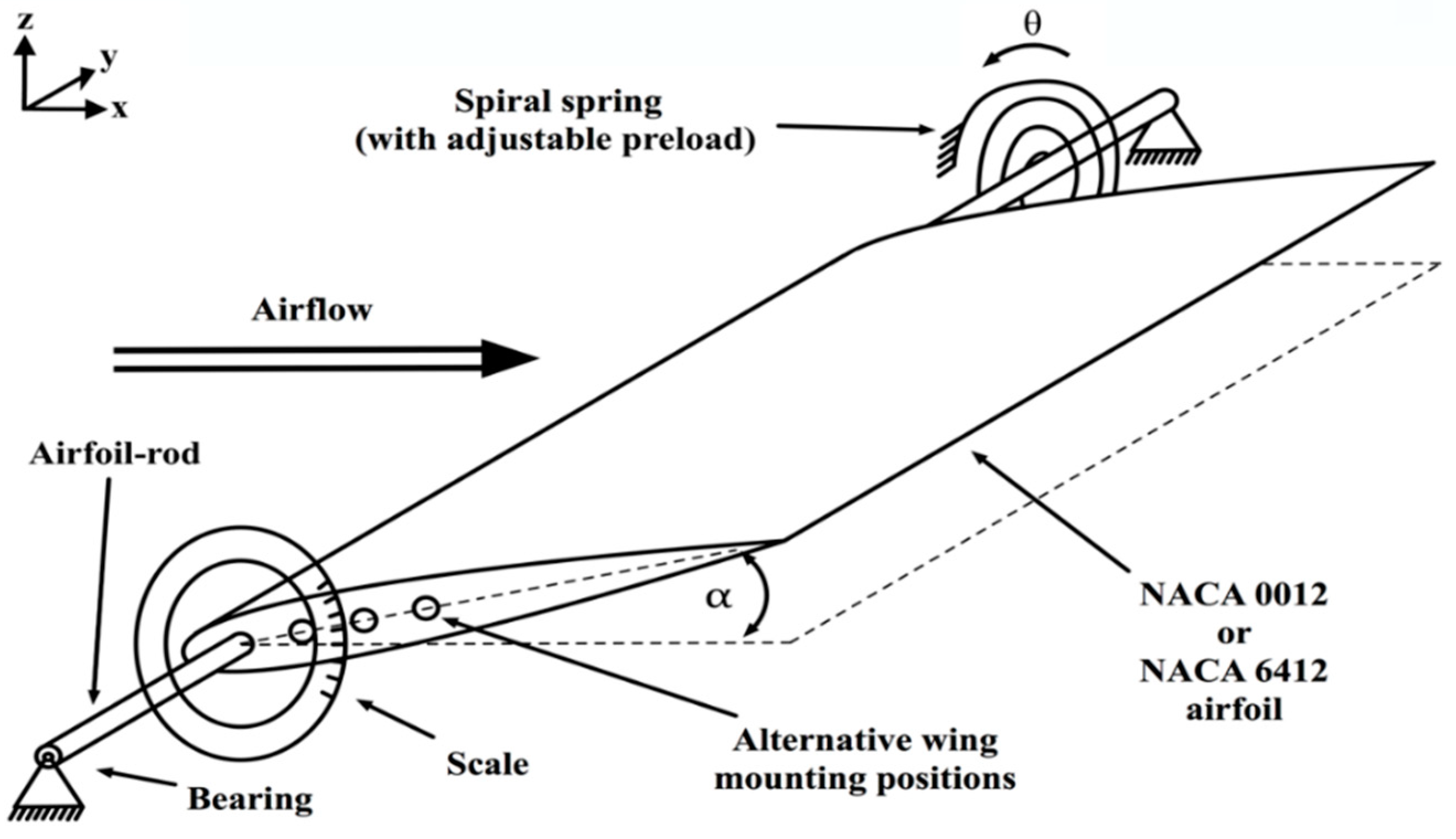

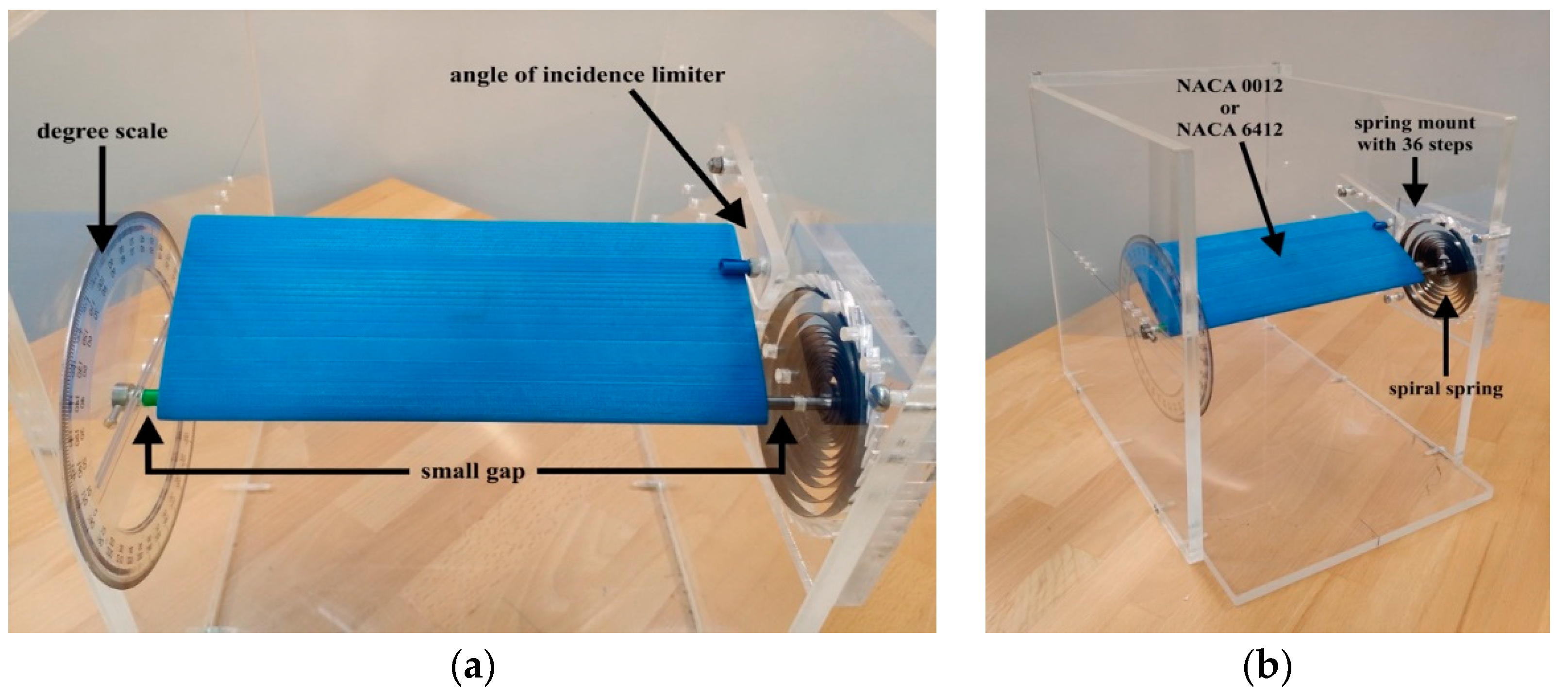

2. Methodology

2.1. System Characteristics

2.2. Experimental Setup

2.3. Airfoil Models

3. Results and Discussion

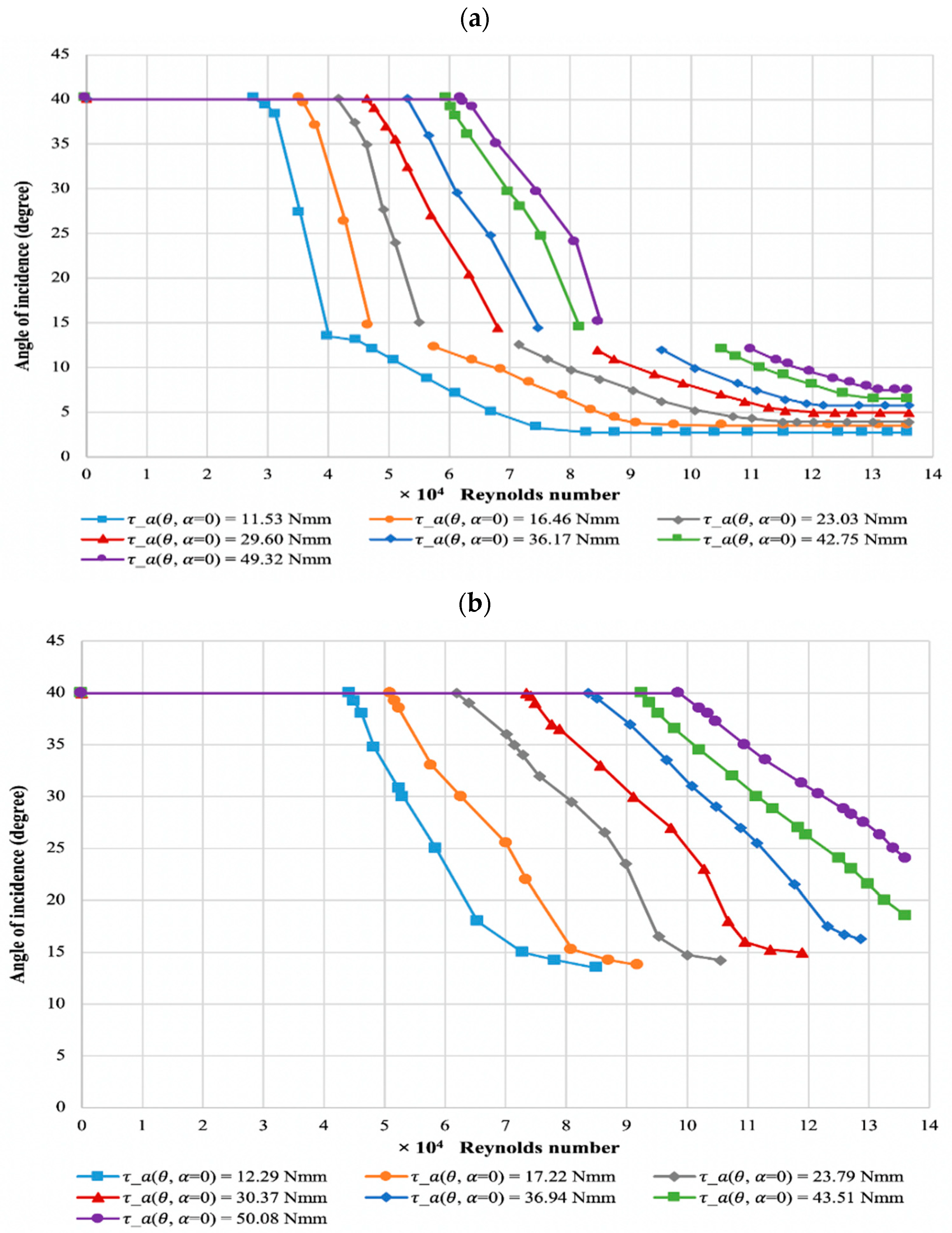

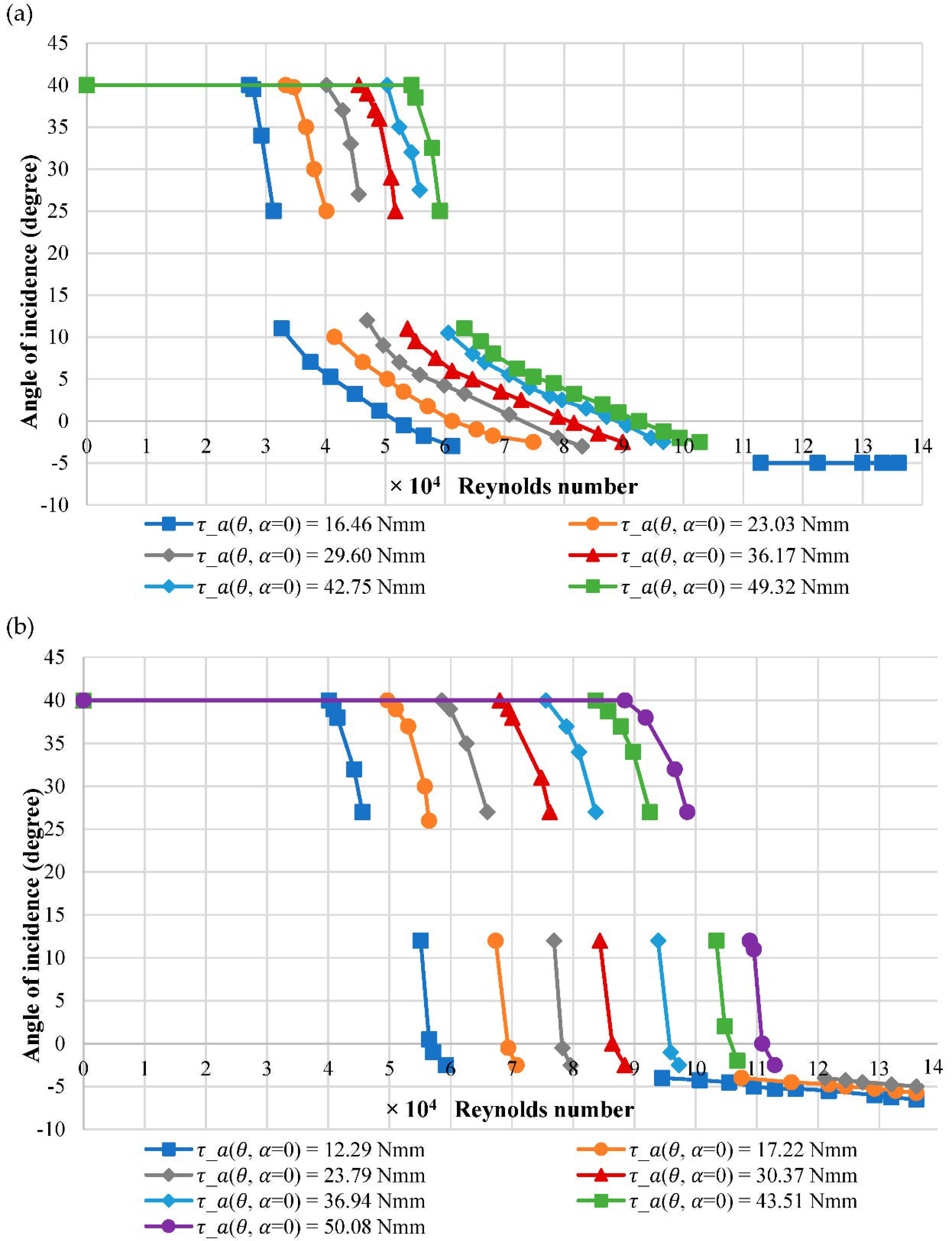

3.1. NACA 0012 at Various Pivot Point Locations and Spring Torque Settings

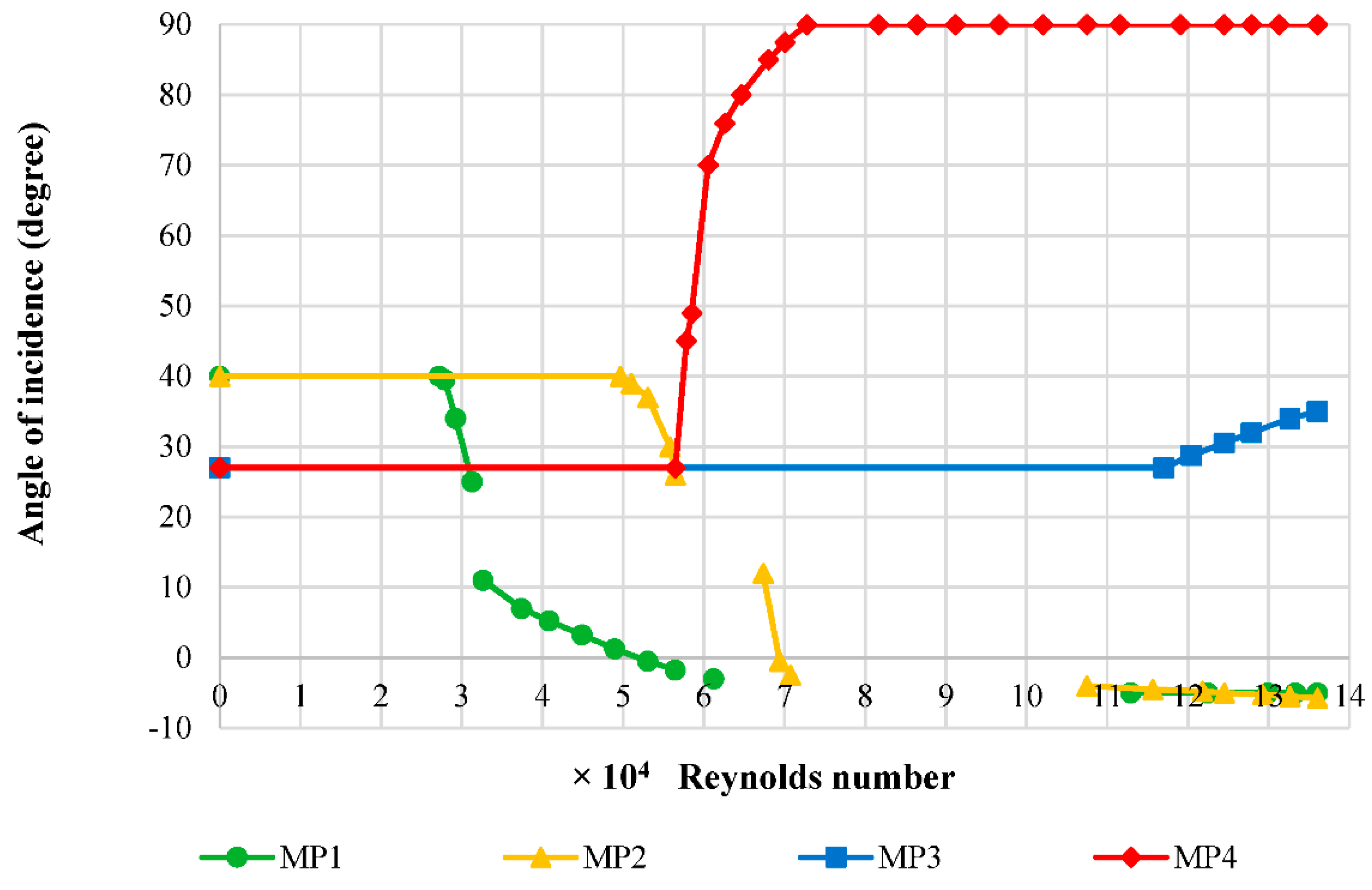

3.2. Comparison of Pivot Point Locations for NACA 0012

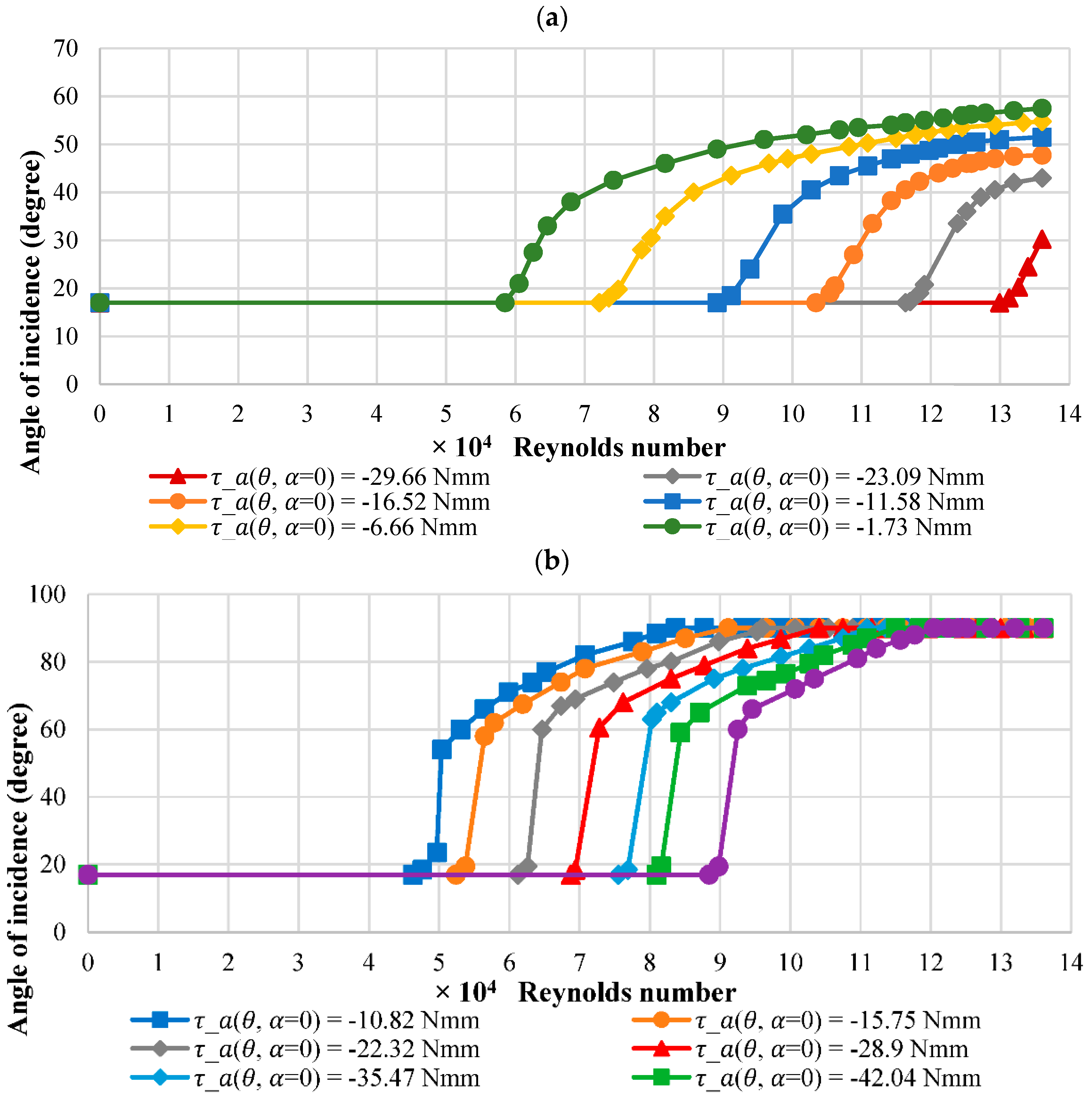

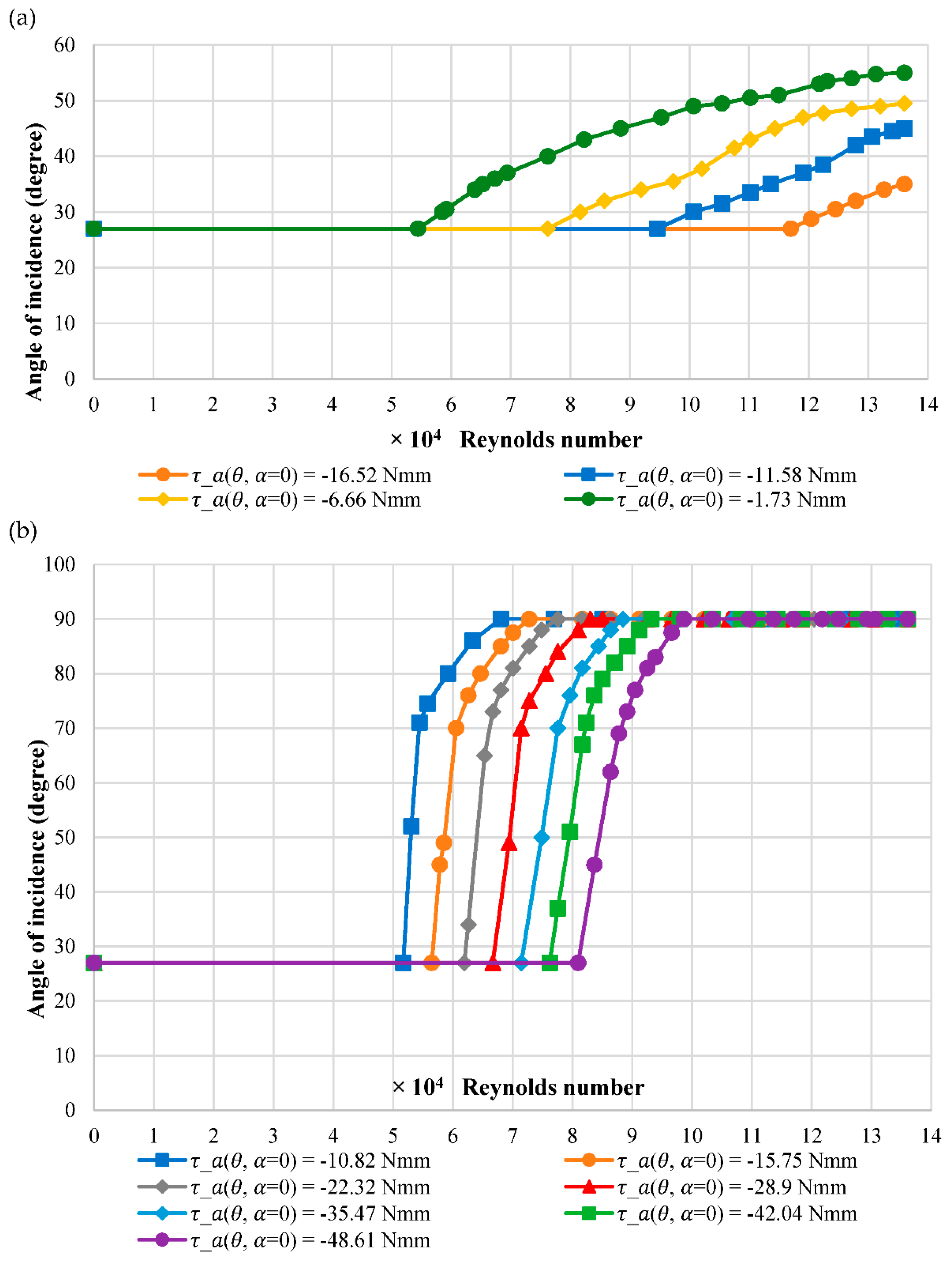

3.3. NACA 6412 at Various Pivot Point Locations and Spring Torque Settings

3.4. Comparison of Pivot Point Locations for NACA 6412

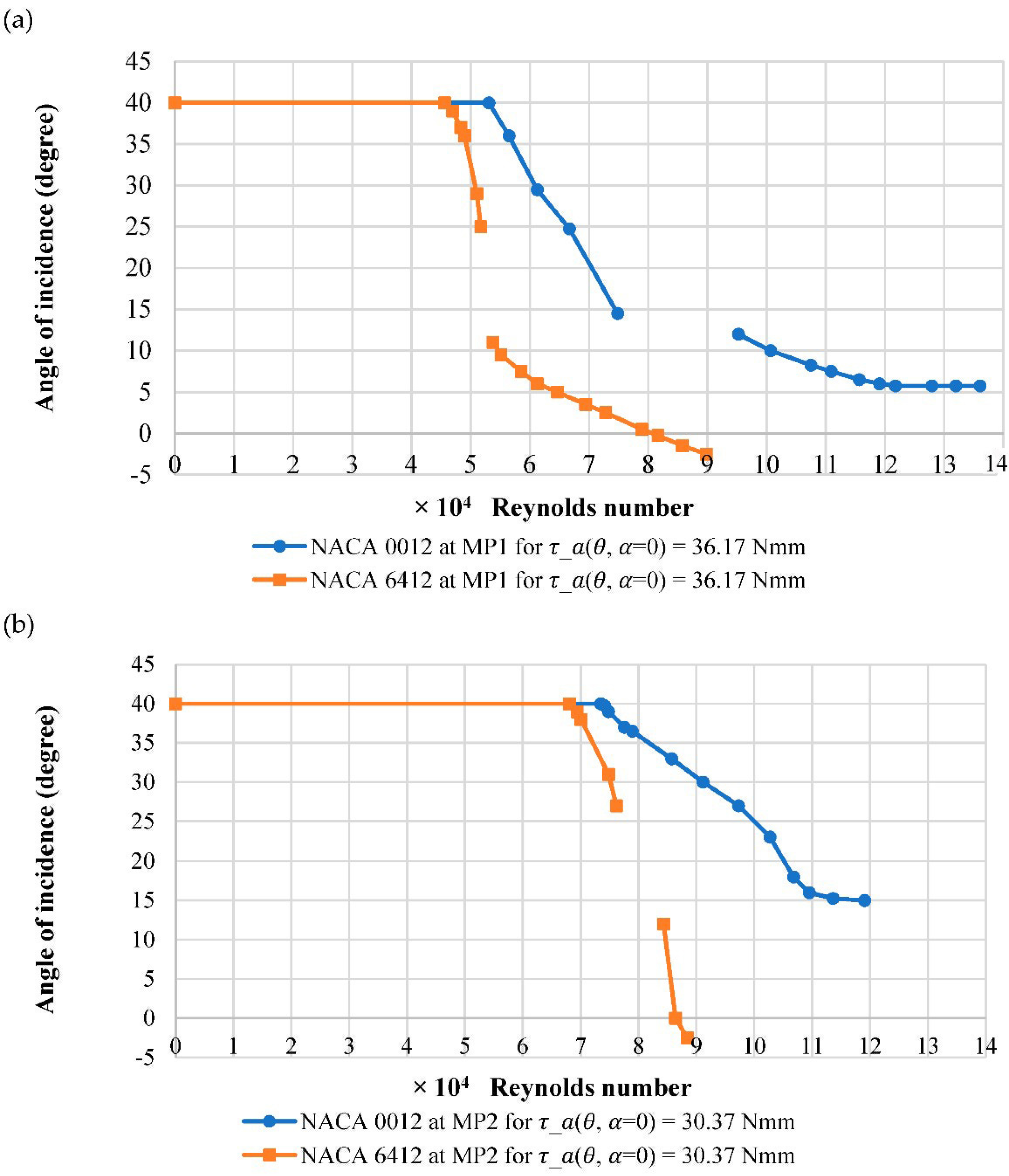

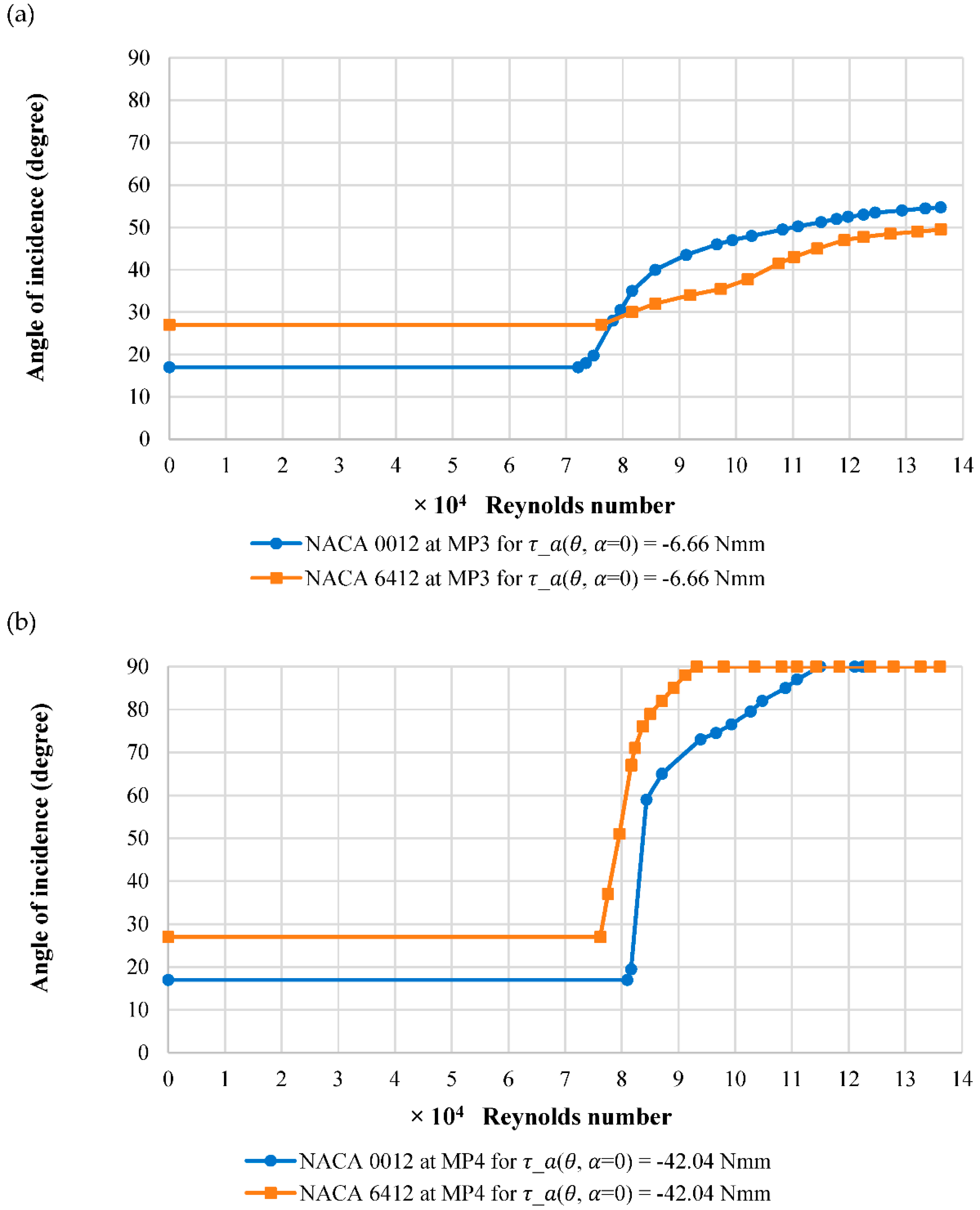

3.5. The Comparison between Cambered and Symmetrical Airfoils

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Borst, R.; Nithiarasu, P.; Tezduyar, T. Computational Fluid Structure Interaction, 1st ed.; John Wiley & Sons Ltd.: Chichester, UK, 2013. [Google Scholar]

- Dowell, E.H.; Clark, R.; Peters, D. A Modern Course in Aeroelasticity, 4th ed.; Kluwer Academic Publishers: New York, NY, USA, 2004. [Google Scholar]

- Rathore, J.; Dhingra, K.; Malik, R. Fluid structure interaction analysis of tapered wing of aircraft. Int. J. Eng. Res. Technol. 2019, 8, 307–319. [Google Scholar]

- Wang, W.; Yan, Y. Strongly coupling of partitioned fluid-solid interaction solvers using reduced-order models. Appl. Math. Model. 2010, 34, 3817–3830. [Google Scholar] [CrossRef]

- Rose, B.R.; Junu, G.R.; Manivel, M. Partly coupled fluid structure interaction analysis of an aircraft wing at subsonic speeds. Int. J. Mech. Mechatron. Eng. 2014, 14, 22–29. [Google Scholar]

- Fung, Y.C. An Introduction to the Theory of Aeroelasticity; University of California: Los Angeles, CA, USA; Dover Publications, Inc.: San Diego, CA, USA, 1993. [Google Scholar]

- Nguyen, N.; Tuzcu, I. Aeroelastic Flight Dynamics of Flexible Aircraft with Inertial and Propulsive Force Interactions. In AIAA Atmospheric Flight Mechanics Conference; American Institute of Aeronautics and Astronautics: Chicago, IL, USA, 2009; pp. 1–23. [Google Scholar]

- Collar, A. The First Fifty Years of Aeroelasticity. Aerospace 1978, 5, 12–20. [Google Scholar]

- Liauzun, C.; Piet-Lahanier, N. Aeroelasticity and Structural Dynamics. Aerosp. J. 2018, 14, 1–3. [Google Scholar]

- Chinmaya, P.; Venkatasubramani, S. Aeroelasticity—In general and flutter phenomenon. In Proceedings of the 2009 Second International Conference on Emerging Trends in Engineering & Technology, Nagpur, India, 16–18 December 2009; pp. 81–85. [Google Scholar]

- Sadraey, M. Aircraft Design, A Systems Engineering Approach, 1st ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2013. [Google Scholar]

- Afonso, F.; Leal, G.; Vale, J.; Oliveira, É.; Lau, F.; Suleman, A. Linear vs non-linear aeroelastic analysis of high-aspect-ratio wings: Effect of chord and taper-ratio variation. In Congress on Numerical Methods in Engineering; APMTAC: Lisbon, Portugal, 2015; pp. 1–9. [Google Scholar]

- Yurkovich, R. Status of unsteady aerodynamic prediction for flutter of high-performance aircraft. J. Aircr. 2003, 40, 832–842. [Google Scholar] [CrossRef]

- Rose, B.R.; Jinu, G.R. A Study on Aeroelastic Flutter Suppression and Its Control Measures—Past and Future. Int. J. Eng. Technol. 2014, 6, 960–973. [Google Scholar]

- Wang, Z.; Zhang, W.; Wu, X.; Chen, K. A novel unsteady aerodynamic Reduced-Order Modelling method for transonic aeroelastic optimization. J. Fluids Struct. 2018, 82, 308–328. [Google Scholar] [CrossRef]

- Giovanneti, L. Fluid Structure Interaction Testing, Modelling and Development of Passive Adaptive Composite Foils. Ph.D. Thesis, University of Southampton, Southampton, UK, 2017. [Google Scholar]

- Bose, C.; Badrinath, S.; Gupta, S. Dynamical stability analysis of a fluid structure interaction system using a high fidelity Navier-Stokes solver. Procedia Eng. 2016, 144, 883–890. [Google Scholar] [CrossRef][Green Version]

- Stanciu, V.; Stroe, G.; Andrei, I. Linear models and calculations of aeroelestic flutter. UPB Sci. Bull. Ser. D 2012, 74. Available online: https://www.scientificbulletin.upb.ro/rev_docs_arhiva/fullc07_145478.pdf (accessed on 26 August 2021).

- Sidlof, P.; Vlček, V.; Štěpán, M. Experimental investigation of flow-induced vibration of a pitch—Plunge NACA 0015 airfoil under deep dynamic stall. J. Fluids Struct. 2016, 67, 48–59. [Google Scholar] [CrossRef]

- Rivera, J.; Dansberry, B.; Bennett, R.; Durham, M.; Silva, W. NACA 0012 benchmark model experimental flutter results with unsteady pressure distributions. In Proceedings of the 33rd Structures, Structural Dynamics and Materials Conference, Dallas, TX, USA, 13 April 1992. [Google Scholar]

- Khatir, T.; Djillali, B.; Khatir, S.; Abdelkader, L.; Wahab, M.A. Experimental and numerical investigation of flutter phenomenon of an aircraft wing (NACA 0012). Mechanika 2017, 23, 562–566. [Google Scholar]

- Goyaniuk, L.; Poirel, D.; Benaissa, A. Pitch–Heave Symmetric Stall Flutter of a NACA0012 at Transitional Reynolds Numbers. AIAA J. 2020, 58, 3286–3298. [Google Scholar] [CrossRef]

- Thill, C.; Etches, J.; Bond, I.; Potter, K.; Weaver, P. Morphing skins. Aeronaut. J. 2008, 112, 117–139. [Google Scholar] [CrossRef]

- Gaspari, A.; Moens, F. Aerodynamic shape design and validation of an advanced high-lift device for a regional aircraft with morphing droop nose. Int. J. Aerosp. Eng. 2019, 2019, 1–21. [Google Scholar] [CrossRef]

- Basaeri, H.; Yousefi-Koma, A.; Zakerzadeh, M.R.; Mohtasebi, S.S. Experimental study of a bio-inspired robotic morphing wing mechanism actuated by shape memory alloy wires. Mechatronics 2014, 24, 1231–1241. [Google Scholar] [CrossRef]

- Barbarino, S.; Bilgen, O.; Ajaj, R.; Friswell, M.I.; Inman, D.J. A review of morphing aircraft. J. Intell. Mater. Syst. Struct. 2011, 22, 823–877. [Google Scholar] [CrossRef]

- Su, W.; Swei, S.; Zhu, G. Optimum wing shape determination of highly flexible morphing aircraft for improved flight performance. J. Aircr. 2016, 53, 1305–1316. [Google Scholar] [CrossRef][Green Version]

- Barnard, R.H. Road Vehicle Aerodynamics, 3rd ed.; Mechaero Publishing: St. Albans, UK, 2010. [Google Scholar]

- McBeath, S. Competition Car Aerodynamics, 3rd ed.; Veloce Publishing Ltd.: Poundbury, UK; Boston, MA, USA; Dorset, UK, 2017. [Google Scholar]

- Thuwis, G.A.; De Breuker, R.; Abdalla, M.M.; Gürdal, Z. Aeroelastic tailoring using lamination parameters—Drag reduction of a Formula One rear wing. Struct. Multidiscip. Optim. 2010, 41, 637–646. [Google Scholar] [CrossRef][Green Version]

- Kajiwara, S. Passive variable rear-wing aerodynamics of an open-wheel racing car. Automot. Engine Technol. 2017, 2, 107–117. [Google Scholar] [CrossRef]

- Wolf, T. The aerodynamic development of the new Porsche Cayenne. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 234, 390–408. [Google Scholar] [CrossRef]

- Knight, J.; McConnell, M.R.; Ledger, A.; Azcueta, R. Fluid structure interaction of hydrofoils. In Proceedings of the ICMET Oman 2019—International Conference on Marine Engineering and Technology, Muscat, Oman, 5–7 November 2019; Zenodo: Muscat, Oman, 2019. [Google Scholar]

- Zarruk, G.A.; Brandner, P.; Pearce, B.W.; Phillips, A.W. Experimental study of the steady fluid—Structure interaction of flexible hydrofoils. J. Fluids Struct. 2014, 51, 326–343. [Google Scholar] [CrossRef]

- Scott, S.; Capuzzi, M.; Langston, D.; Bossanyi, E.; McCann, G.; Weaver, P.; Pirrera, A. Effects of aeroelastic tailoring on performance characteristics of wind turbine systems. Renew. Energy 2017, 114, 887–903. [Google Scholar] [CrossRef]

- Abbaspour, M.; Radmanesh, A.R.; Soltani, M.R. Unsteady flow over offshore wind turbine airfoils and aerodynamic loads with computational fluid dynamic simulations. Int. J. Environ. Sci. Technol. 2016, 13, 1525–1540. [Google Scholar] [CrossRef]

- Xu, Y.Z.; Virk, M.S.; Knight, J.; Mustafa, M.Y.; Haritos, G. Factors Influencing the Performance of Porous Wind Shields. Appl. Mech. Mater. 2013, 321–324, 799–803. [Google Scholar] [CrossRef]

- Stanford, B.; Ifju, P.; Albertani, R.; Shyy, W. Fixed membrane wings for micro air vehicles: Experimental characterization, numerical modeling, and tailoring. Prog. Aerosp. Sci. 2008, 44, 258–294. [Google Scholar] [CrossRef]

- Aboelezz, A.; Hassanalian, M.; Desoki, A.; Elhadidi, B.; El-Bayoumi, G. Design, experimental investigation, and nonlinear flight dynamics with atmospheric disturbances of a fixed-wing micro air vehicle. Aerosp. Sci. Technol. 2019, 97, 105636. [Google Scholar] [CrossRef]

- Panta, A.; Fisher, A.; Mohamed, A.; Marino, M.; Xu, R.; Liu, H.; Watkins, S. Low Reynolds number aerodynamics of leading-edge and trailing-edge hinged control surfaces: Part I statics. Aerosp. Sci. Technol. 2019, 99, 105563. [Google Scholar] [CrossRef]

- Cattafesta, L.; Bahr, C.; Mathew, J. Fundamentals of Wind-Tunnel Design. In Encyclopaedia of Aerospace Engineering, 1st ed.; Blockley, R., Shyy, W., Eds.; John Wiley & Sons Ltd.: Chichester, UK, 2010; pp. 1–10. [Google Scholar]

- Poirel, D.; Harris, Y.; Benaissa, A. Self-sustained aeroelastic oscillations of a NACA0012 airfoil at low-to-moderate Reynolds numbers. J. Fluids Struct. 2008, 24, 700–719. [Google Scholar] [CrossRef]

- Knight, J.; Fels, S.; Haritos, G.; Carolus, T. Fluid-Structure Interaction of a Spring-Mounted Symmetrical Rigid Wing for Drag Reduction of Cars at Higher Wind Velocities. SAE Tech. Pap. 2020, 1, 5037. [Google Scholar]

- McAllister, K.W.; Carr, L.; McCrokskey, W.J. Dynamic Stall Experiments on the NACA 0012 Airfoil. NASA Tech. Pap. 1978, 1100. Available online: https://core.ac.uk/download/pdf/42875301.pdf (accessed on 26 August 2021).

- Akbari, M.; Price, S. Simulation of dynamic stall for a NACA 0012 airfoil using a vortex method. J. Fluids Struct. 2003, 17, 855–874. [Google Scholar] [CrossRef]

- UIUC Applied Aerodynamics Group. UIUC Airfoil Data Site. Available online: http://m-selig.ae.illinois.edu/ads/coord/n0012.dat (accessed on 26 August 2021).

- Yousefi, K.; Razeghi, A. Determination of the Critical Reynolds Number for Flow over Symmetric NACA Airfoils. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018. Session: Stability and Transition II: Shear Flows II. [Google Scholar] [CrossRef]

- Rinoie, K.; Takemura, N. Oscillating behaviour of laminar separation bubble formed on an aerofoil near stall. Aeronaut. J. 2004, 108, 153–164. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knight, J.; Fels, S.; Beazley, B.; Haritos, G.; Lewis, A. Fluid–Structure Interaction of Symmetrical and Cambered Spring-Mounted Wings Using Various Spring Preloads and Pivot Point Locations. Appl. Mech. 2021, 2, 591-612. https://doi.org/10.3390/applmech2030034

Knight J, Fels S, Beazley B, Haritos G, Lewis A. Fluid–Structure Interaction of Symmetrical and Cambered Spring-Mounted Wings Using Various Spring Preloads and Pivot Point Locations. Applied Mechanics. 2021; 2(3):591-612. https://doi.org/10.3390/applmech2030034

Chicago/Turabian StyleKnight, Jason, Simon Fels, Benjamin Beazley, George Haritos, and Andrew Lewis. 2021. "Fluid–Structure Interaction of Symmetrical and Cambered Spring-Mounted Wings Using Various Spring Preloads and Pivot Point Locations" Applied Mechanics 2, no. 3: 591-612. https://doi.org/10.3390/applmech2030034

APA StyleKnight, J., Fels, S., Beazley, B., Haritos, G., & Lewis, A. (2021). Fluid–Structure Interaction of Symmetrical and Cambered Spring-Mounted Wings Using Various Spring Preloads and Pivot Point Locations. Applied Mechanics, 2(3), 591-612. https://doi.org/10.3390/applmech2030034