Abstract

The treatment of refractory nitrogenous organic matter in industrial wastewater management poses challenges in the removal of organic matter and nitrogen. To address these issues, this study utilized a novel composite hydrodynamic cavitator, mainly consisting of spiral pipes and a step drain, which could generate cavitation twice per pass at the throat of the spiral pipe and the step drain of the cavitation cavity, thereby distinguishing it from other existing cavitators that produce cavitation only once per pass. The composite hydrodynamic cavitator, optimized using ANSYS 19.2 simulation software, offers significant advantages in energy utilization and mass transfer efficiency. Moreover, it generates a high concentration of hydroxyl free radicals, which are crucial for organic matter degradation. Batch experiments demonstrated the effective treatment of 4-aminophenol. Within 120 min, 4-aminophenol degradation efficiency reached 74.7% and total nitrogen concentration decreased slightly from 1.28 mg/L to 1.06 mg/L, while ammonia nitrogen concentration initially increased before decreasing from its peak value of 0.82 mg/L to 0.77 mg/L. During the cavitation treatment of 4-aminophenol, intermediate products, such as benzoquinone, were generated. Under the strong oxidizing action of hydroxyl radicals, nitrogen undergoes deamination to form ammonium ions, which were likely removed predominantly as nitrogen gas. The experimental results are anticipated to establish a foundation for the application of hydrodynamic cavitation technology in the treatment of refractory organic wastewater degradation and to support denitrification processes.

1. Introduction

The treatment of refractory nitrogenous organic compounds poses a significant challenge in industrial wastewater management [1]. These substances, commonly found in effluents from petroleum refining, landfill leachate, pharmaceutical manufacturing, and chemical industries, are characterized by high toxicity, poor biodegradability, and stable chemical structures [2,3,4]. Moreover, since organic compounds contain nitrogen, the nitrogen released during the degradation process enters the wastewater, increasing the nitrogen concentration and exacerbating the difficulty of nitrogen removal from the wastewater. Therefore, the treatment of wastewater containing refractory nitrogenous organic substances remains a rather challenging issue at present.

This study employs 4-aminophenol as a representative nitrogenous organic compound to investigate its degradation and nitrogen removal through hydrodynamic cavitation, aiming to provide a novel approach for the treatment of refractory nitrogenous organic wastewater. The compound 4-aminophenol, commonly used as an intermediate, is extensively applied in the synthesis of pharmaceuticals like clofibrate and paracetamol. Additionally, it is present in significant quantities in wastewater generated from dye production processes, posing challenges for conventional treatment methods due to its potent biological toxicity and chemical stability [5].

Advanced oxidation processes (AOPs) are often evaluated by researchers for the degradation of 4-aminophenol. The photocatalytic oxidation method utilizes light to irradiate specific semiconductor catalysts with band structures, inducing the production of ·OH from H2O and effectively degrading pollutants in wastewater. Mehdi A et al. [6] employed CuO-loaded wavy zeolite for catalytic degradation of 4-aminophenol using sunlight. Photocatalytically assisted electrochemical oxidation utilizing Z-TiO2 achieved an 88% degradation efficiency of 4-aminophenol [7]. In addition, a PbO2–TiO2 electrode was utilized as an anode for photoelectrocatalytic degradation treatment of simulated and real 4-aminophenol wastewaters [8], yielding favorable degradation results in all aforementioned studies. However, photocatalysts possess limitations, such as high band gaps, agglomeration tendencies, small surface areas, instability issues, and difficulties in recovery after treatment. Furthermore, the Fenton oxidation method is also commonly employed as an AOP approach. Carlos Moreno-Castill et al. [9] investigated the synthesis of highly active Fenton multiphase catalysts containing Cu2+ ions within copper ferrites to synthesize copper ferrite nanoballs (CFNSs), analyzing their effectiveness in degrading 4-aminophenol compounds. Nevertheless, treating sludge-containing Fe ions can be costly and requires significant amounts of chemicals and manpower resources. Biodegradation represents another viable option for removing 4-aminophenol compounds. Effective removal has been demonstrated through the use of organisms such as pea (Pisum sativum) shells activated with sulfuric acid [10] or Pseudomonas sp. strain ST-4 [11]. However, this method exhibits limitations when applied to wastewater treatment due to low degradation efficiency resulting from the complex compositions present in actual organic wastewaters, and long reaction times caused by high cultivation requirements for pH, a complicated reaction process, and low removal efficiency.

Cavitation is regarded as a highly efficient and promising technology that has garnered significant attention from researchers in spite of certain challenges yet to be addressed, such as cavitator scaling issues and potential clogging problems. In particular, hydrodynamic cavitation technology exhibits the most promising development prospects among these cavitation methodologies. Hydrodynamic cavitation technology requires a low inlet water pressure for the cavitator, resulting in minimal energy consumption. Furthermore, a water hammer effect system can be designed to drive water pressurization without the need for an additional booster pump, thereby avoiding extra power demand on the cavitation unit. Due to its cavitation effects, such as increased temperature, oxidation, and mechanical collision, hydrodynamic cavitation technology has been the subject of extensive research in various fields, including disinfection [12,13], degradation of refractory organics like synthetic dyes [14,15,16], pharmaceutical residues [17,18,19], pesticides [20,21], and sludge treatment [22]. Patil et al. investigated the removal of ammoniacal nitrogen from synthetic wastewater using 4-aminophenol as a model nitrogen-containing organic compound through hydrodynamic cavitation. Remarkable improvements in ammoniacal nitrogen removal were achieved by introducing air or oxygen sparging during hydrodynamic cavitation and employing solvent-assisted hydrodynamic cavitation with substances such as 1-octanol and cyclohexanol [23,24]. In this study, our objective was to enhance the cavitation effect and efficiently treat 4-aminophenol without the need for additional substances using a novel composite hydrodynamic cavitator. We examined the degradation of 4-aminophenol along with ammonia nitrogen and total nitrogen removal from the solution using this cavitator. The findings of our research will provide an innovative approach for refractory nitrogenous organic degradation through hydrodynamic cavitation, specifically addressing ammoniacal nitrogen removal.

2. Structure Design and CFD Optimization of the Composite Hydrodynamic Cavitator

2.1. The Structure of the Composite Hydrodynamic Cavitator

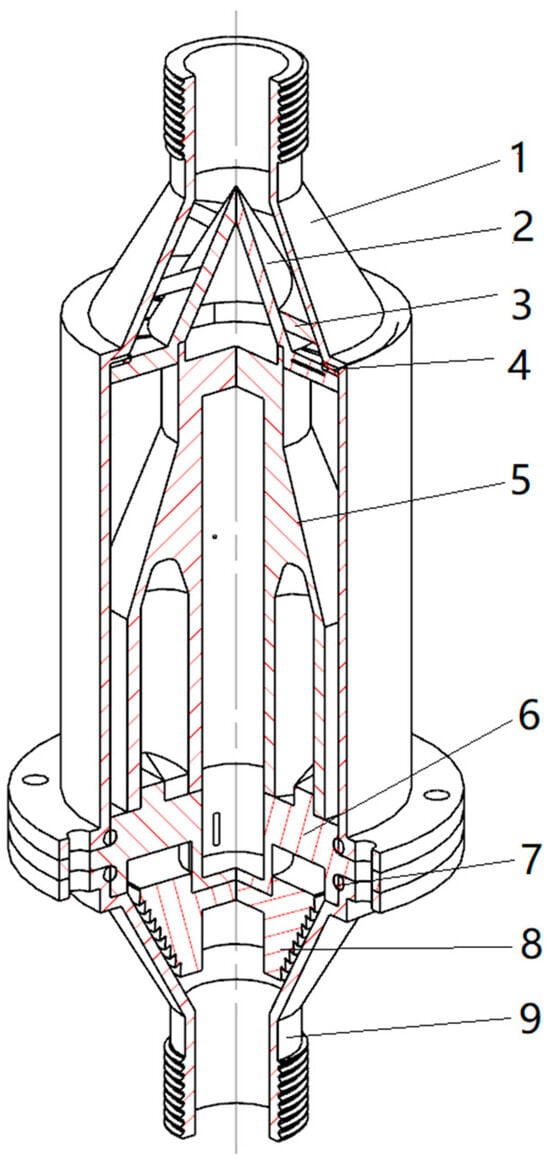

The autonomously designed composite hydrodynamic cavitator primarily comprises a shell, a spiral filter inlet, a cavitation generation chamber, a separator, a stepped drainage outlet, and an effluent outlet, as illustrated in Figure 1. Stainless steel materials were used to construct the cavitator for enhanced structural integrity. Notably, the cavitation generation chamber is equipped with four vortex chambers. The fundamental structural dimensions of the cavitator are as follows: total length of 254 mm, inlet and outlet diameters of 24 mm, and the vortex chamber has a diameter of 14 mm and a height of 50 mm.

Figure 1.

Schematic diagram of the composite hydrodynamic cavitator. 1. Outer hull. 2. Spiral channel. 3. Diverter plate. 4. Seal ring. 5. Cavitation generation chamber. 6. Dividing plate. 7. O-ring seal. 8. Step-shaped drain outlet. 9. Outlet.

2.2. Flow Field Simulation Method

The cavitator was modeled using the 3D design software UG NX 12.0. Preprocessing and volume extraction of the solid model were conducted by the preprocessing module SpaceClaim of the ANSYS 19.2 simulation software. The computational domain of the cavitator was meshed by the mesh module of the ANSYS 19.2 simulation software, and the simulation calculation of the mesh file was then carried out by the fluent module of the ANSYS 19.2 simulation software.

2.2.1. Mesh Division

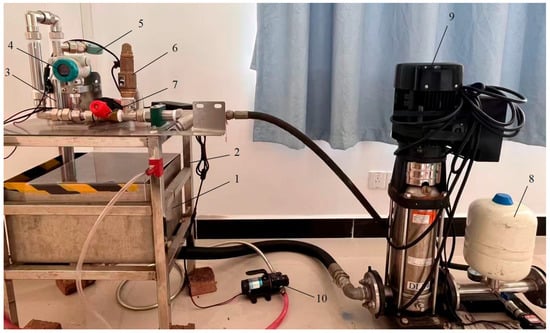

The structure of the composite hydrodynamic cavitator is relatively complex. Therefore, an adaptive unstructured mesh was employed to divide the model. According to the stress degree of the cavitator, the densities of the meshes at the throttling section, the cavitation generation section, and the boundary layer were all increased. The mesh model is shown in Figure 2.

Figure 2.

Grid model diagram.

In order to ensure the reliability of the simulation calculation, a grid generation method is used to generate four sets of grid numbers, namely 731,210, 1,191,536, 2,131,717, and 3,460,983. The inlet pressure is set to 0.4 MPa, and the velocity at the exit of the cavitation body is monitored. The velocity in the network model with 2,131,717 grid numbers tends to stabilize, indicating that the accuracy of the calculation is no longer affected by the increase in the number of network nodes. Therefore, given the calculation accuracy and simulation efficiency, we select the network model with 2,131,717 grid numbers for the fluid field simulation.

2.2.2. Simulation Conditions and Model Selection

The simulation is carried out using the pressure-based transient solver PISO algorithm, and the other variable solutions are obtained using the first-order advection scheme to ensure absolute stability. The multiphase mixture flow model and the realizable k-ε two-equation turbulence model are selected to simulate the jet cavitation phenomenon [25]. The wall treatment is selected as the non-equilibrium wall function. The Schnerr & Sauer cavitation model [26] is used to simulate the mass transport process in two-phase flow during cavitation. The velocity, pressure, and mass component variables in the flow field are solved using the continuity equation, momentum equation, turbulent kinetic energy–turbulent dissipation rate equation, and vapor phase mass transport equation.

3. Experimental Methods

3.1. The Degradation Experimental Platform

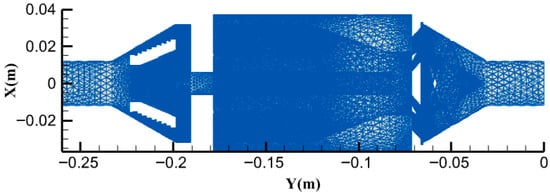

The experimental platform for the composite hydrodynamic cavitator is shown in Figure 3. The main components of the platform include the frame, water tank, composite hydrodynamic cavitator, flowmeter (DN 15 turbine flowmeter, Anhui Ruiling Measuring Instrument Manufacturing Co., Ltd., Hefei, China), manometer (Y60 manometer, Kobe Technology Co., Ltd., Wuhan, China), overflow valve, flow control valve, and booster pump (GWS-BI Vertical Integrated Fully Automatic Constant Pressure Variable Frequency Water Pump, Guangzhou Haoxiong Pump Industry Co., Ltd., Guangzhou, China), pressure tank, and various water pipes.

Figure 3.

Photograph of composite hydrodynamic cavitator test platform. 1. Water tank. 2. Frame. 3. Composite hydrodynamic cavitator. 4. Flowmeter. 5. Manometer. 6. Overflow valve. 7. Flow control valve. 8. Pressure tank. 9. Booster pump. 10. Discharge pump.

It is a closed-loop system designed to pump 10 L of pre-prepared 4-aminophenol solution from the water tank, through the overflow valve, manometer, and flowmeter, and then take it to the composite hydrodynamic cavitator and discharge the treated solution back to the water tank via the pump. The inlet pressure and flow rate of the cavitator are regulated by the booster pump, ensuring stable operational parameters throughout the cavitation process.

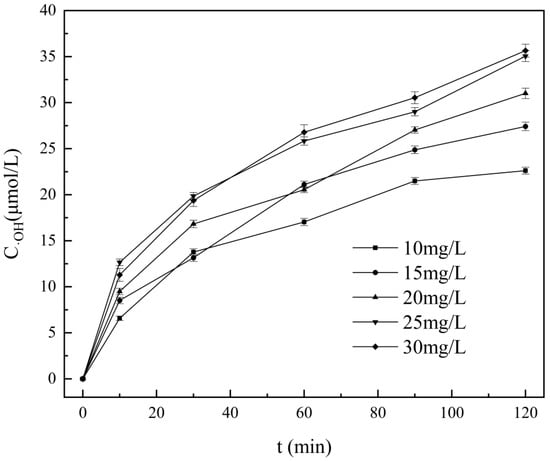

3.2. The Hydroxyl Radical Generation

The methylene blue (MB) degradation was used to indirectly determine the amount of hydroxyl radicals (·OH) generated by the composite hydrodynamic cavitator during operation [27,28].

With an inlet pressure of 0.25 MPa, initial temperature of 25 °C, and a pH of 7, 10 L solutions of MB with initial concentrations of 10 mg/L, 15 mg/L, 20 mg/L, 25 mg/L, and 30 mg/L were subjected to cavitation experiments for 120 min.

Ignoring possible secondary reactions, the reaction equation between MB and ·OH is

The amount of ·OH generated equals ΔCMB, and can be calculated as follows:

where C·OH represents the concentration of hydroxyl radicals, μmol/L. ΔCMB and ΔA are the difference in concentration of MB and that of the absorbance of MB before and after degradation by cavitation, respectively. According to the standard curve equation of MB concentration (CMB, mg/L) and its absorbance (A), A = 0.0541CMB − 0.001 (R2 = 0.9997), and ΔCMB (mg/L) approximately equals ΔA/0.0541.

By simplifying Equation (2), the amount of ·OH can be calculated as follows:

3.3. Degradation Experiment

A 10 L 4-aminophenol solution with an initial concentration of 10.0 mg/L, adjusted to pH 7.0 with 10% HCl or 10% NaOH in advance at an initial temperature of 25 °C, was placed in the water storage tank. Then the vertical booster pump was started (with the inlet pressure of the pump set to 0.25 MPa), and degradation began. After 120 min of cyclic degradation, samples were collected to determine the absorbance of 4-aminophenol, and the concentrations of ammonia nitrogen and total nitrogen. Each experiment was conducted in triplicate.

Batch experiments were conducted for the degradation of 4-aminophenol and ammonia nitrogen by the composite hydrodynamic cavitator. The experimental condition for investigating the influence of a specific factor involved altering the value of that particular factor while maintaining all other parameters consistent with the above baseline experimental conditions.

The 4-aminophenol solution samples, before and after 120 min of degradation under optimal conditions, were detected by HPLC. For this experiment, the HPLC detection instrument used was the Shimadzu-LC-2050C of Shimadzu, Kyoto, Japan, and the column used was C18. The detection conditions were as follows: the mobile phase was a mixture of methanol and water at a ratio of 50:50 (v/v), the flow rate was 1.0 L/min, the injection volume was 20 μL, the detection wavelength was 268 nm, and the column temperature was 30 °C.

4. Results and Discussions

4.1. Cavitation Characteristics Analysis of the Cavitator with Optimal Structural Parameters

Through CFD simulations of various structural parameters, the optimal composite hydrodynamic cavitator structure was determined as follows. The helical pipe is designed as a laryngeal-type pipe with a laryngeal diameter of 1.3 mm, an entrance diameter of 3 mm, an exit diameter of 3 mm, and a pipe length of 38 mm. The stepped-type drainage outlet has a nine-stage structure, with a channel width of 0.5 mm. Then, we comprehensively evaluated the cavitation performance of the aforementioned optimal cavitator by analyzing the pressure, gas content, and mass transfer cavitation characteristics of the fluid inside the cavitator at an entrance pressure of 0.6 MPa.

Figure 4 shows an XY sectional diagram of the composite hydrodynamic cavitator, which is the coordinate diagram used for the subsequent analysis. The diagram uses the entrance to the cavitator as the X-axis, with the exit represented by Y(m). The Y-axis represents the variable values of the micro-elemental bodies in the cross-section, such as absolute pressure, gas content, and mass transfer cavitation characteristics of the fluid inside the cavitator.

Figure 4.

XY cross-section of the composite hydrodynamic cavitator.

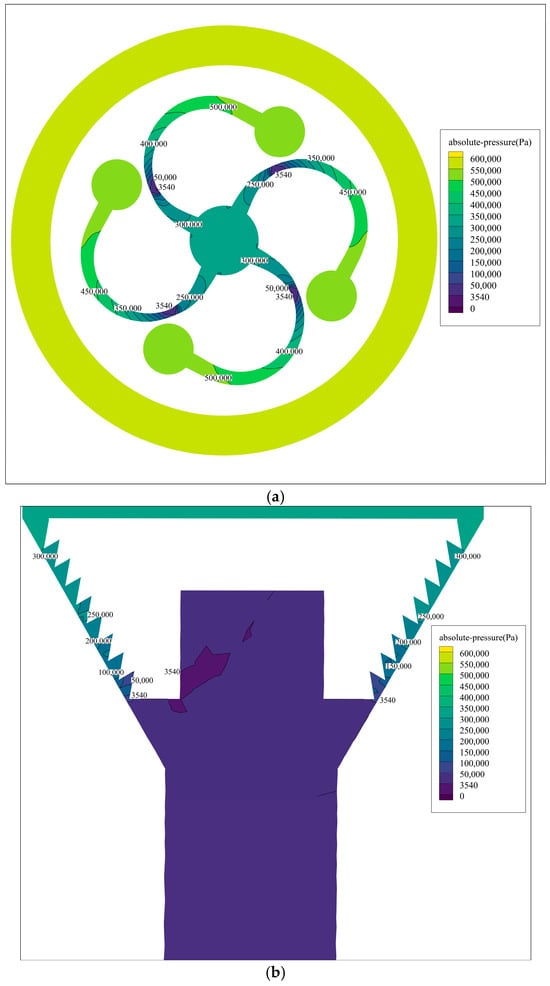

4.1.1. The Absolute Pressure of the Fluid Inside the Cavitator

Figure 5 shows the cross-sectional cloud image of the absolute pressure of fluid at two key places where cavitation occurs: the spiral pipe in the cavitation cavity (Figure 5a) and the stepped drain (Figure 5b).

Figure 5.

Cross-sectional nephogram of absolute-pressure gradient distribution at which cavitation occurs. (a) Absolute-pressure distribution of spiral pipe; (b) absolute-pressure distribution of drain outlet.

From Figure 5a, it can be seen that as the fluid flows through the helical flow passage in the front section, with the cross-sectional area decreasing gradually, the pressure drops significantly. When the fluid flows to the throat position, the absolute pressure gradually drops below the set saturated vapor pressure of 3540 Pa (for distilled water at room temperature), and then vaporization occurs to produce a vapor nucleus. After the fluid flows through the throat, the pipe’s cross-sectional area increases gradually, resulting in a pressure increase. This creates an internal and external pressure imbalance, causing the cavitation bubble to collapse and leading to cavitation. From Figure 5b, it can be seen that when the liquid flows from the cavitation generation chamber to the entrance of the stepped condensate outlet, the pressure is restored to 0.32 MPa and then gradually decreases. When the liquid flows near the stepped condensate outlet, the pressure is again lower than the saturated vapor pressure of the simulated liquid, and bubbles form. When the liquid flows to the outlet, the pressure suddenly rises and cavitation occurs. Moreover, the stepped outlet can cause cavitation bubbles that have not collapsed in the cavitation generation chamber to collapse repeatedly as they flow through multiple areas of changing cross-section, thereby improving the cavitation efficiency per pass.

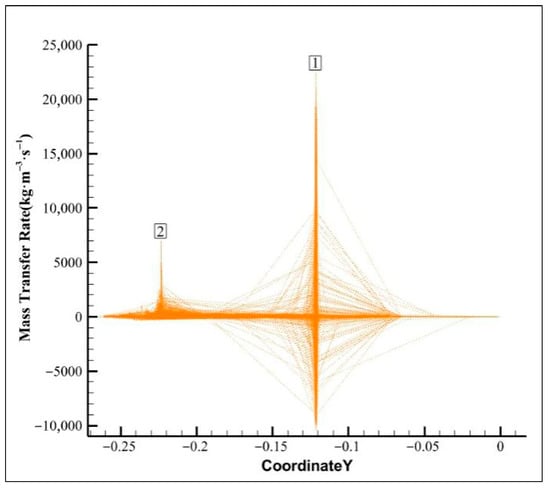

4.1.2. Mass Transfer Analysis

Figure 6 displays the mass transfer rate XY diagram of cavitation simulation from the inlet to the outlet. The mass transfer rate includes both forward and negative mass transfer. In the process of hydraulic cavitation, forward mass transfer refers to the process of gas molecules dissolved in the liquid phase moving to the gas phase, which may increase the concentration of gas in the liquid phase and promote the formation and release of bubbles, corresponding to the formation and development stage of bubbles in the process of cavitation. Negative mass transfer refers to the dissolution process of a bubble in the liquid phase; that is, the gas molecules in the bubble are redissolved into the liquid, corresponding to the collapse stage of the bubble during the cavitation process. As shown in Figure 6, peaks 1 and 2 represent the formation, development, and collapse of bubbles during the cavitation process in the spiral pipe and the stepped drain, respectively. Among them, the forward mass transfer rate of peak 1 exceeds 20,000 kg·m−3·s−1, while the negative mass transfer rate exceeds 10,000 kg·m−3·s−1. These high forward and negative mass transfer rates can promote the transfer and removal of solute. The negative mass transfer rate of peak 2 does not peak and is near the zero axis, indicating that during the cavitation process, the bubbles collapse at the exit rapidly and have no chance to transfer solute to the liquid phase.

Figure 6.

Mass transfer efficiency diagram.

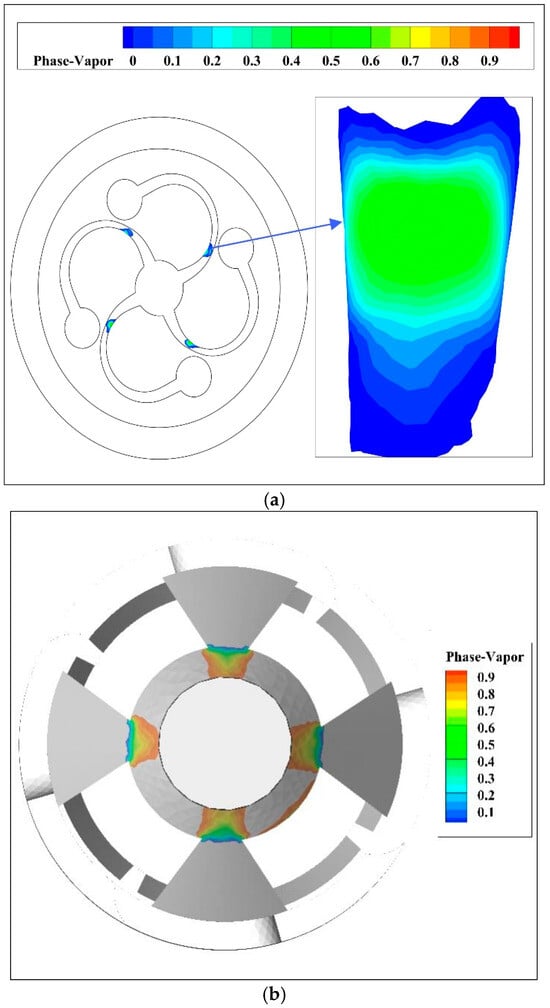

4.1.3. Gas Holdup Analysis

Gas holdup, that is, the vapor phase volume fraction, is one of the important indicators for measuring the occurrence and intensity of cavitation. Figure 7 shows the distribution of gas holdup where cavitation occurs. It was found that the distribution corresponded to the pressure distribution in which cavitation occurs, as shown in Figure 5. As shown in Figure 7a, due to the abrupt change in the pipeline through which the fluid flows, the flow velocity increases sharply, the pressure decreases significantly, and the kinetic energy increases accordingly. The pressure at the throat of the spiral channel reaches the saturated vapor pressure, causing the gas to escape from the liquid phase to form bubbles. At this spot, the gas holdup during cavitation in the spiral channel reached 63%. As shown in Figure 7b, the outlet pressure of the stepped drain is the lowest, below the liquid’s saturated vapor pressure, leading the gas in the liquid to escape and form bubbles. Therefore, the gas core generation area at the outlet has the highest gas holdup (up to 95%).

Figure 7.

Cloud diagram of gas holdup distribution at the place where cavitation occurs (a) at the spiral pipe; (b) at the drain port.

4.2. The Concentration of Hydroxyl Radical Produced During Cavitation

As shown in Figure 8, the evaluation of hydroxyl radical concentration in the composite hydrodynamic cavitator system shows that when the methylene blue concentration is low, the hydroxyl radical capture rate is also low. With the increase in methylene blue solution concentration, the capture rate increased gradually. When the concentration reached 25 mg/L, the capture rate of hydroxyl radical remained basically unchanged, indicating that the hydroxyl radical generated in the composite hydrodynamic cavitator system was fully captured by methylene blue, with a concentration of about 35 μmol/L. The numerical value is much higher than the 0.23 μmol/L (3.9 μg/L in the paper) concentration of hydroxyl radicals detected in the orifice plate hydrodynamic cavitator, as reported by Zhang et al. [28].

Figure 8.

The concentration of hydroxyl radicals produced during cavitation.

4.3. Degradation of 4-Aminophenol by the Cavitator and Nitrogen Removal Performance of the Solution

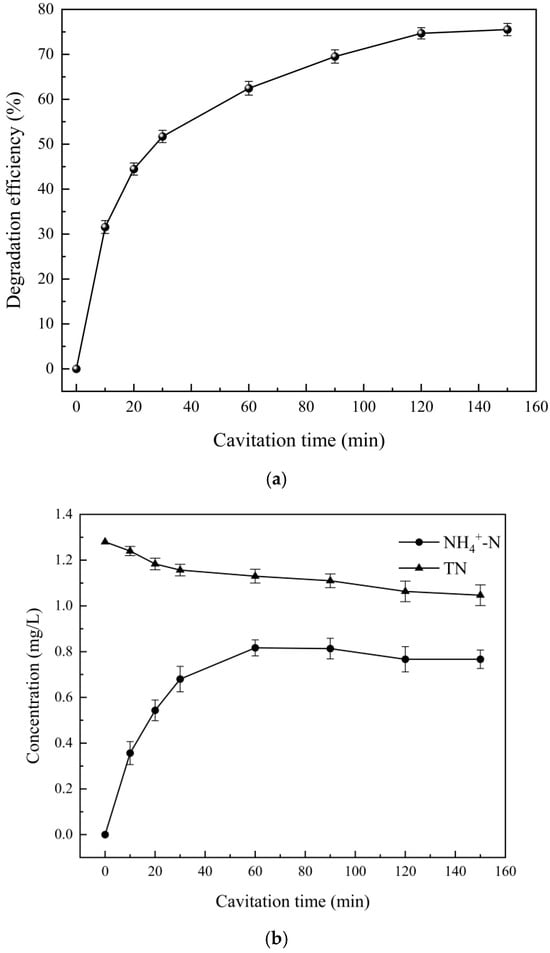

4.3.1. Influence of Cavitation Time

The degradation of 4-aminophenol and the removal of total nitrogen and ammonia nitrogen in 4-aminophenol solution with an initial concentration of 10 L of 10 mg/L under the operation time of the cavitation from 10 min to 150 min are shown in Figure 9.

Figure 9.

The degradation of 4-aminophenol (a) and the removal of total nitrogen and ammonia nitrogen (b) with cavitation time.

As shown in Figure 9a, the degradation efficiency of the 4-aminophenol solution gradually increased with the increase in cavitation time, and the degradation efficiency of 4-aminophenol tended to be stable at 120 min, reaching 74.7%. As shown in Figure 9b, the ammonia nitrogen concentration showed a trend of rising at first and then slightly falling. The concentration decreased from 0.82 mg/L (the highest value) to 0.77 mg/L. With the continuous degradation of 4-aminophenol, ammonia nitrogen was continuously generated, and its concentration increased. At the same time, the ammonia nitrogen generated was continuously oxidized by the hydroxyl radical generated by the cavitation effect until the rate of ammonia nitrogen generation was lower than that of ammonia nitrogen removal, and the concentration of ammonia nitrogen began decreasing. Throughout the cavitation process, nitrate nitrogen and nitrite nitrogen were nearly undetectable, so the generation of nitrate nitrogen or nitrite nitrogen can be disregarded. The gradual reduction in total nitrogen concentration, from 1.28 mg/L to 1.06 mg/L, can be attributed to nitrogen release as gases, such as nitrogen and nitrogen oxides, during the degradation process. The removal rate trends across the three parameters indicate that the 120 min cavitation degradation period is optimal, as it ensures high removal efficiency while preventing energy dissipation during extended processing.

4.3.2. Influence of Inlet Pressure

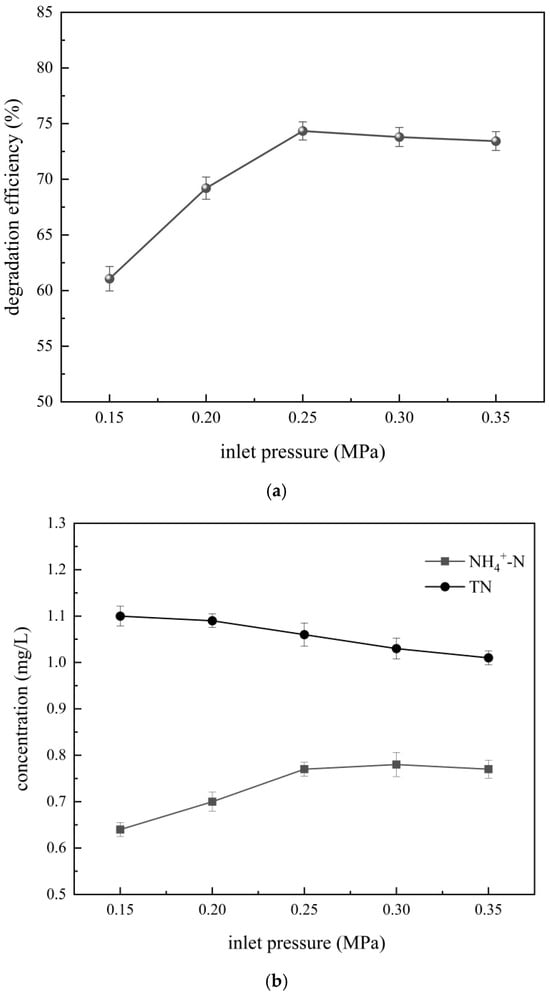

The degradation efficiency of 4-aminophenol and the removal of total nitrogen and ammonia nitrogen at different inlet pressures of 0.15–0.35 MPa for 120 min are shown in Figure 10.

Figure 10.

The degradation of 4-aminophenol (a) and the removal of total nitrogen and ammonia nitrogen (b) at different inlet pressures.

As shown in Figure 10, when the inlet pressure was in the range of 0.15–0.25 MPa, the degradation efficiency of 4-aminophenol increased significantly with the increase in the inlet pressure. The maximum degradation efficiency of 4-aminophenol was 74.7% when the inlet pressure was 0.25 MPa. The concentration of ammonia nitrogen also showed an inflection point at an inlet pressure of 0.25 MPa. However, when the inlet pressure was in the range of 0.25–0.35 MPa, the degradation efficiency of 4-aminophenol showed a slow decline with the increase in the inlet pressure, while the ammonia nitrogen concentration remained basically unchanged.

The inlet pressure has a dual effect on cavitation. First, at low inlet pressures, increasing the inlet pressure can increase the fluid flow rate and reduce the fluid pressure as it passes through the mechanically confined structure, thereby reducing the difference between the fluid pressure and the saturated vapor pressure. This facilitates the formation of the pressure drop required for cavitation, thereby improving the cavitation effect. However, when the inlet pressure is too high, the fluid’s flow rate is too high. This will significantly shorten the cavitation bubble development time, resulting in fewer effective cavitation bubbles. Moreover, a flow rate that is too high will cause the strong oxidizing free radicals generated by cavitation to pass through the cavitation region too quickly. It results in a low concentration of strong oxidizing free radicals on the outside of the cavitation region. Then it will reduce the reaction rate of 4-aminophenol and significantly affect its degradation efficiency. However, the total nitrogen concentration gradually decreases with increasing inlet pressure because gas solubility decreases at higher pressures, leading to gas release from the liquid, including nitrogen-containing gases. Therefore, the inlet pressure has an impact on the cavitation behavior of the composite hydrodynamic cavitator. Considering the energy consumption of cavitation operation, the higher the inlet pressure, the greater the energy consumption; the optimal inlet pressure is 0.25 MPa.

4.3.3. Influence of Initial pH

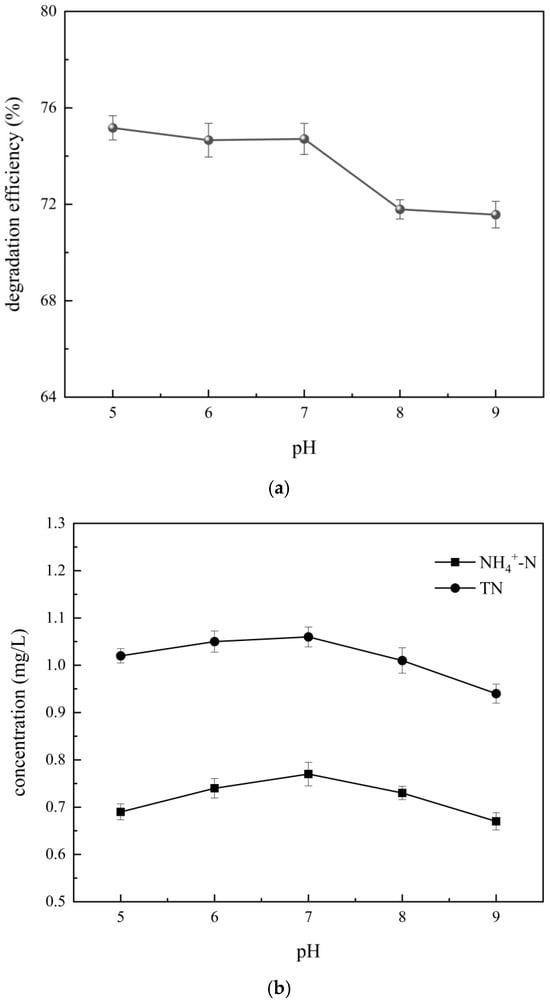

The degradation efficiency of 4-aminophenol and the removal of total nitrogen and ammonia nitrogen at a pH range of 5~9 were obtained, as shown in Figure 11.

Figure 11.

The degradation of 4-aminophenol (a) and the removal of total nitrogen and ammonia nitrogen (b) at different initial pH levels.

The degradation efficiency of 4-aminophenol decreased slightly from 75.2% to 74.7% with increasing pH from 5 to 7, as depicted in Figure 11. Simultaneously, there was a slight increase in the concentrations of total nitrogen and ammonia nitrogen, with increases of 0.04 mg/L and 0.09 mg/L, respectively. However, when pH was raised to 7–9, this increase led to a decrease in the degradation efficiency of 4-aminophenol from 75.7% to 71.6%, while causing a gradual reduction in the concentrations of total nitrogen and ammonia nitrogen; the reductions were 0.12 mg/L and 0.10 mg/L, respectively. The trends are in close agreement with the reported literature, and can be attributed to several possible reasons [29,30]. First, under acidic conditions, more hydroxyl radicals are generated, which facilitate the degradation process of 4-aminophenol [31]. Additionally, these hydroxyl radicals oxidize nitrogen-containing substances, resulting in the release of gaseous nitrogen compounds and decreasing levels of both total nitrogen and ammonia nitrogen. Second, under alkaline conditions, the generation of hydroxyl radicals may be inhibited, resulting in a decrease in the degradation efficiency of 4-aminophenol, while the concentration of ammonia nitrogen also decreases. Under alkaline conditions, more ammonium ions are converted into ammonia gas and overflow during the cavitation process, resulting in a decrease in the concentration of total nitrogen. This consequently resulted in a slight reduction in the pH value of the solution after cavitation (from an initial pH of 7.01 to 6.52 following the reaction). Third, the occurrence of cavitation is more favorable for solute molecules with higher hydrophobicity [32]. However, 4-aminophenol exhibits strong hydrophilicity under acidic and alkaline conditions. Under neutral conditions, the hydrophilicity of the amino group and hydrophobicity of the benzene ring balance each other, which is conducive to the degradation of 4-aminophenol. Therefore, considering all the above factors, pH 7 is determined to be the optimal value. However, based on the above removal variations in the pH range of 5–9, the initial pH value demonstrates minimal impact on the removal efficiencies of 4-aminophenol, total nitrogen, and ammonia nitrogen. This hydrodynamic cavitation technology exhibits robust adaptability to actual wastewater across varying pH ranges.

4.3.4. Influence on the Initial Concentration of 4-Aminophenol

In order to better compare changes in total nitrogen and ammonia nitrogen during the degradation of 4-aminophenol at different initial concentrations, concentrations are expressed in unit concentrations. The unit concentration of total nitrogen and ammonia nitrogen at different initial concentrations is defined as follows:

where Cu is the unit concentration, C is the concentration of total nitrogen or ammonia nitrogen after cavitation (mg/L), and C0 is the initial concentration of 4-aminophenol (mg/L).

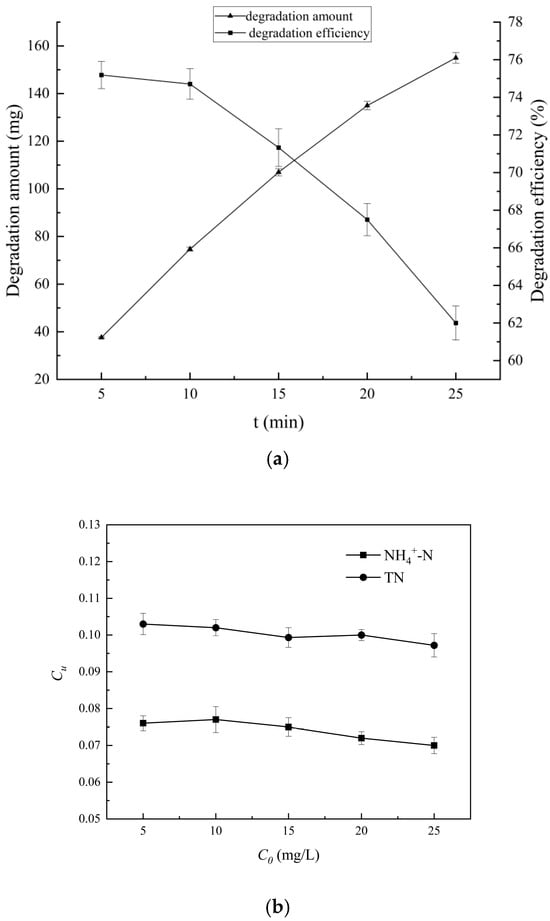

The degradation efficiency of 4-aminophenol and the concentrations of total nitrogen and ammonia nitrogen at different initial concentrations ranging from 5 mg/L to 25 mg/L are shown in Figure 12.

Figure 12.

The degradation of 4-aminophenol (a) and the removal of total nitrogen and ammonia nitrogen (b) at different initial 4-aminophenol concentrations.

As shown in Figure 12, the degradation efficiency of 4-aminophenol decreased continuously with an increase in its initial concentration, while the degradation amount gradually increased. This is because at relatively low initial concentrations of 4-aminophenol in the hydraulic cavitation system, the molecules are dispersed and difficult for hydroxyl radicals generated by cavitation to capture. Conversely, higher concentrations of 4-aminophenol are readily captured by hydroxyl radicals generated by cavitation, leading to a faster reaction.

The concentrations of total nitrogen and ammonia nitrogen exhibited a decreasing trend with increasing initial concentration of 4-aminophenol. However, the overall change was not statistically significant. At a high initial concentration of 4-aminophenol, enhanced degradation led to increased ammonia nitrogen, which was subsequently converted into more nitrogen-containing gas for release. Consequently, the total reduction was amplified without substantial alteration in unit concentrations of total nitrogen and ammonia nitrogen.

4.4. Degradation and Denitrification Chemical Reaction During Degradation

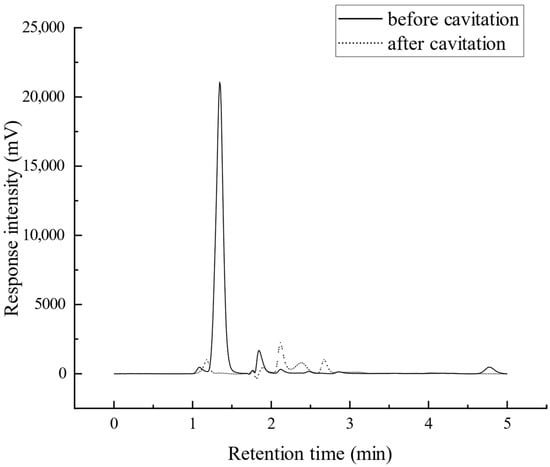

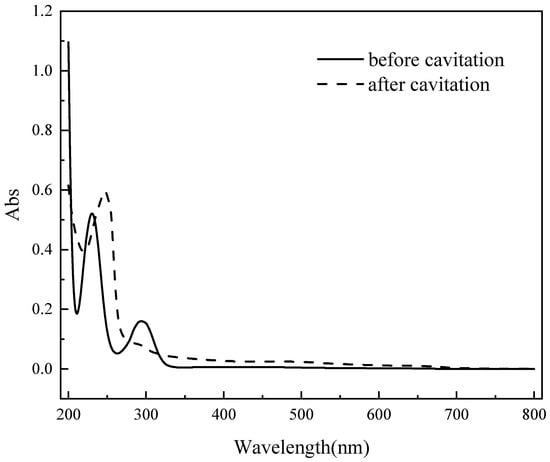

UV-Vis spectra and HPLC chromatograms before and after 120 min of cavitation were obtained, as shown in Figure 13 and Figure 14.

Figure 13.

HPLC chromatogram of 4-aminophenol solution before and after degradation.

Figure 14.

UV-Vis spectroscopy scan spectrum of 4-aminophenol solution before and after degradation.

As shown in Figure 13, compared with the two curves, the absorption peak before cavitation at 1.347 min significantly decreased, and the peak at 4.775 min disappeared, while some small miscellaneous peaks appeared after cavitation. This indicates that as the experiment progresses, the 4-aminophenol in the solution is greatly reduced, and some intermediate products are produced.

As shown in Figure 14, the original 4-aminophenol exhibits two distinct absorption peaks within the 200–800 nm range, at 231 nm and 295 nm, respectively. The molecule contains unsaturated bonds and lone-pair electrons, enabling π→π* and n→π* transitions. Furthermore, the presence of a conjugated system along with both -NH2 and -OH substituents results in a bathochromic shift in its absorption peaks. After 120 min of cavitation degradation, the absorption peaks at 295 nm and 355 nm nearly disappear, while a new characteristic peak emerges at 246 nm. This indicates a gradual reduction in 4-aminophenol content during the degradation process, accompanied by the formation of new substances [33]. The absorption at 246 nm is characteristic of benzoquinone, suggesting that benzoquinone and other intermediate products are progressively generated as degradation proceeds.

Therefore, the degradation and denitrification chemical reactions can be deduced according to the results above. The following reaction equation represents the possible reaction process. The production of hydrogen ions, deduced by the pH of the solution, decreases slightly during cavitation. The R in Equation (7) represents benzoquinone or other intermediate products. The equations show that during the cavitation treatment, intermediate products such as benzoquinone are generated, and some products are decomposed into carbon dioxide and water ultimately. Under the strong oxidizing action of hydroxyl radicals, nitrogen undergoes deamination to form ammonium ions, which are likely removed predominantly as nitrogen gas.

5. Conclusions

The composite hydrodynamic cavitator shows promising performance in cavitation. Cavitation occurs at two distinct locations: the spiral pipe throat and the stepped drain of the cavitation cavity, with maximum gas holdup rates of 63% and 95%, respectively, and both exhibiting high mass transfer rates.

The composite hydrodynamic cavitator exhibits effective degradation of 4-aminophenol and notable removal of total nitrogen and ammonia nitrogen. The experiment was conducted over a duration of 120 min. At an inlet pressure of 0.25 MPa, with an initial concentration of 10 mg/L, pH maintained at 7, and an initial temperature of 25 °C, the degradation efficiency of 4-aminophenol reached 74.7%. Concurrently, the total nitrogen concentration decreased from 1.28 mg/L to 1.06 mg/L. Nevertheless, the ammonia nitrogen concentration initially increased before subsequently decreasing, with its maximum concentration reducing from 0.82 mg/L to 0.77 mg/L. During the cavitation treatment, intermediate products such as benzoquinone are generated, and some of these products are ultimately decomposed into carbon dioxide and water. Under the strong oxidizing action of hydroxyl radicals, nitrogen undergoes deamination to form ammonium ions, which are likely removed predominantly as nitrogen gas.

Author Contributions

Methodology, B.W., R.Z., and Z.S.; Software, R.Z.; Formal analysis, Y.L.; Investigation, Z.S.; Data curation, R.Z. and Y.L.; Writing—original draft, B.W.; Writing—review & editing, B.W. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are thankful to the Department of Science and Technology of Guangdong Province for providing financial support through the Project of Agricultural Science and Technology Specialist (KTP20240964).

Data Availability Statement

The original contributions presented in this study are included in this article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Karimi-Maleh, H.; Darabi, R.; Karimi, F.; Karaman, C.; Shahidi, S.A.; Zare, N.; Baghayeri, M.; Fu, L.; Rostamnia, S.; Rouhi, J.; et al. State-of-art advances on removal, degradation and electrochemical monitoring of 4-aminophenol pollutants in real samples: A review. Environ. Res. 2023, 222, 115338. [Google Scholar] [CrossRef]

- Wu, C.W.; Li, Q.B. Characteristics of organic matter removed from highly saline mature landfill leachate by an emergency disk tube-reverse osmosis treatment system. Chemosphere 2021, 263, 128347. [Google Scholar] [CrossRef]

- Yuan, Y.; Qian, X.; Zhang, L.; Yin, W.; Chen, T.; Li, Z.; Ding, C.; Wang, B.; Liang, B.; Wang, A. Tailoring microbial redox with alternating current for efficient mineralization of refractory organic nitrogen compounds in wastewater. npj Clean Water 2025, 8, 4. [Google Scholar] [CrossRef]

- Huang, J.; Wang, C.; Zhang, S.; Han, X.; Feng, R.; Li, Y.; Huang, X.; Wang, J. Optimizing nitrogenous organic wastewater treatment through integration of organic capture, anaerobic digestion, and anammox technologies: Sustainability and challenges. Environ. Sci. Pollut. Res. 2023, 30, 76372–76386. [Google Scholar] [CrossRef] [PubMed]

- Tranchant, M.; Serrà Albert Gunderson, C.; Bertero, E.; García-Amorós, J.; Gómez, E.; Michler, J.; Philippe, L. Efficient and green electrochemical synthesis of 4-aminophenol using porous Au micropillars. Appl. Catal. A General. 2020, 602, 117698. [Google Scholar] [CrossRef]

- Nezamzadeh-Ejhieh, A.; Amiri, M. CuO supported Clinoptilolite towards solar photocatalytic degradation of p-aminophenol. Powder. Technol. 2013, 235, 279–288. [Google Scholar] [CrossRef]

- Ratiu, C.; Manea, F.; Lazau, C.; Orha, C.; Burtica, G.; Grozescu, I.; Schoonman, J. Photocatalytically-assisted electrochemical degradation of p-aminophenol in aqueous solutions using zeolite-supported TiO2 catalyst. Chem. Pap. 2011, 65, 289–298. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, N.; Xing, M.; Xu, Z.; Shen, K.; Wu, J.; Feng, Y. Photoelectrocatalysis degradation of P-aminophenol using PbO2-TiO2 heterojunction electrode: Catalytic, theoretical calculating and mechanism. J. Environ. Chem. Eng. 2024, 12, 113304. [Google Scholar] [CrossRef]

- Moreno-Castilla, C.; López-Ramón, M.V.; Fontecha-Cámara, M.Á.; Álvarez, M.A.; Mateus, L. Removal of phenolic compounds from water using copper ferrite nanosphere composites as fenton catalysts. Nanomaterials 2019, 9, 901. [Google Scholar] [CrossRef]

- Mishra, P.; Singh, K.; Dixit, U.; Agarwal, A.; Bhat, R.A. Effective removal of 4-Aminophenol from aqueous environment by pea (Pisum sativum) shells activated with sulfuric acid: Characterization, isotherm, kinetics and thermodynamics. J. Ind. Chem. Soc. 2022, 99, 100528. [Google Scholar] [CrossRef]

- Afzal Khan, S.; Hamayun, M.; Ahmed, S. Degradation of 4-aminophenol by newly isolated Pseudomonas sp. strain ST-4. Enzym. Microb. Tech. 2006, 38, 10–13. [Google Scholar] [CrossRef]

- Sun, X.; Liu, J.; Jia, L.; Wang, G.; Zhao, S.; Yoon, J.Y.; Chen, S. A review on hydrodynamic cavitation disinfection: The current state of knowledge. Sci. Total Environ. 2020, 737, 139606. [Google Scholar] [CrossRef] [PubMed]

- Hou, R.; Song, Y.; Liu, J.; Zhang, L.; Zhang, M.; Sun, X. Experimental and numerical investigation on the disinfection characteristics of a novel rotor-radial groove hydrodynamic cavitation reactor. Process Saf. Environ. 2023, 169, 260–269. [Google Scholar] [CrossRef]

- Gore, M.M.; Saharan, V.K.; Pinjari, D.V.; Chavan, P.V.; Pandit, A.B. Degradation of reactive orange 4 dye using hydrodynamic cavitation based hybrid techniques. Ultraso. Sonochem. 2014, 21, 1075–1082. [Google Scholar] [CrossRef]

- Innocenzi, V.; Prisciandaro, M.; Centofanti, M.; Vegliò, F. Comparison of performances of hydrodynamic cavitation in combined treatments based on hybrid induced advanced Fenton process for degradation of azo-dyes. J. Environ. Chem. Eng. 2019, 7, 103171. [Google Scholar] [CrossRef]

- Kore, V.S.; Manjare, S.D.; Patil, A.D.; Dhanke, P.B. A parametric study on intensified degradation of textile dye water using hydrodynamic cavitation based hybrid technique. Chem. Engin. Process.—Process Intensif. 2023, 193, 109550. [Google Scholar] [CrossRef]

- Thanekar, P.; Panda, M.; Gogate, P.R. Degradation of carbamazepine using hydrodynamic cavitation combined with advanced oxidation processes. Ultraso. Sonochem. 2018, 40, 567–576. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, R.; Li, Y.; Lian, X. CFD simulation of a swirling vortex cavitator and its degradation performance and pathway of tetracycline in aqueous solution. Int. J. Chem. React. Eng. 2022, 20, 955–963. [Google Scholar] [CrossRef]

- Roy, K.; Moholkar, V.S. Sulfadiazine degradation using hybrid AOP of heterogeneous Fenton/persulfate system coupled with hydrodynamic cavitation. Chem. Engin. J. 2020, 386, 121294. [Google Scholar] [CrossRef]

- Raut-Jadhav, S.; Saini, D.; Sonawane, S.; Pandit, A. Effect of process intensifying parameters on the hydrodynamic cavitation based degradation of commercial pesticide (methomyl) in the aqueous solution. Ultraso. Sonochem. 2016, 28, 283–293. [Google Scholar] [CrossRef]

- Patil, P.N.; Bote, S.D.; Gogate, P. Degradation of imidacloprid using combined advanced oxidation processes based on hydrodynamic cavitation. Ultraso. Sonochem. 2014, 21, 1770–1777. [Google Scholar] [CrossRef]

- Abdelrahman, A.M.; Tebyani, S.; Talabazar, F.R.; Tabar, S.A.; Berenji, N.R.; Aghdam, A.S.; Koyuncu, I.; Kosar, A.; Guven, H.; Ersahin, M.E.; et al. The flow pattern effects of hydrodynamic cavitation on waste activated sludge digestibility. Chemosphere 2024, 357, 141949. [Google Scholar] [CrossRef]

- Patil, P.B.; Bhandari, V.M.; Ranade, V.V. Improving efficiency for removal of ammoniacal nitrogen from wastewaters using hydrodynamic cavitation. Ultraso. Sonochem. 2021, 70, 105306. [Google Scholar] [CrossRef]

- Patil, P.B.; Bhandari, V.M. Solvent-assisted cavitation for enhanced removal of organic pollutants—Degradation of 4-aminophenol. J. Environ. Manag. 2022, 311, 114857. [Google Scholar] [CrossRef]

- Hong, F.; Tian, H.; Yuan, X.; Liu, S.; Peng, Q.; Shi, Y.; Jin, L.; Ye, L.; Jia, J.; Ying, D.; et al. CFD-assisted modeling of the hydrodynamic cavitation reactors for wastewater treatment—A review. J. Environ. Manag. 2022, 321, 115982. [Google Scholar] [CrossRef]

- Dastane, G.G.; Thakkar, H.; Shah, R.; Perala, S.; Raut, J.; Pandit, A.B. Single and multiphase CFD simulations for designing cavitating venturi. Chem. Eng. Res. Des. 2019, 149, 1–12. [Google Scholar] [CrossRef]

- Iwamori, S.; Nishiyama, N.; Oya, K. A colorimetric indicator for detection of hydroxyl radicals in atmosphere using a methylene blue dye based on nafion film. Polym. Degrad. Stabil. 2016, 123, 131–136. [Google Scholar] [CrossRef]

- Zhang, R.; Zhu, M.; Deng, C.; Shi, X.; Deng, Y.; Ma, J.; Liu, H.; Chen, P. Analysis on reaction kinetics of methylene blue degraded by hydrodynamic cavitation. Ind. Wat. Treat. 2018, 38, 31–34. [Google Scholar]

- Saharan, V.K.; Badve, M.P.; Pandit, A.B. Degradation of reactive red 120 dye using hydrodynamic cavitation. Chem. Engin. J. 2011, 178, 100–107. [Google Scholar] [CrossRef]

- Maršálek, B.; Zezulka, Š.; Maršálková, E.; Pochylý, F.; Rudolf, P. Synergistic effects of trace concentrations of hydrogen peroxide used in a novel hydrodynamic cavitation device allows for selective removal of cyanobacteria. Chem. Engin. J. 2019, 382, 122383. [Google Scholar] [CrossRef]

- Capocelli, M.; Prisciandaro, M.; Lancia, A.; Musmarra, D. Hydrodynamic cavitation of p-nitrophenol: A theoretical and experimental insight. Chem. Engin. J. 2014, 254, 1–8. [Google Scholar] [CrossRef]

- Kotronarou, A.; Mills, G.; Hoffmann, M.R. Ultrasonic irradiation of p-nitrophenol in aqueous solution. J. Phys. Chem. 1991, 95, 3630–3638. [Google Scholar] [CrossRef]

- Chen, W.; Gu, Z.; Wen, P.; Li, Q. Degradation of refractory organic contaminants in membrane concentrates from landfill leachate by a combined coagulation-ozonation process. Chemosphere 2019, 217, 411–422. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).