Abstract

Plastic contamination is a burning issue costing the global cotton and textile industries billions of dollars annually. Any time plastics from different sources end up in a cotton lint bale, the value to the textile mills plummets significantly. Various industry players have therefore made a concerted effort to find lasting solutions to the menace posed by plastic to cotton profitability and sustainability. Nevertheless, until now, there have been no up-to-date comprehensive documents detailing the numerous and ever-growing efforts committed to solving this challenge. Therefore, this article provides a detailed yet compact review of this highly dynamic subject matter. First, it puts into perspective plastic contamination in the cotton and textile industries. Then, the cotton value chain is subdivided into phases from pre-cultivation to textile mills. The root causes of plastic contamination are discussed in each stage, followed by discussions of some already developed and emerging solutions in response to the challenge by the affected industries and researchers. Concluding from the author’s perspective, the paper makes projections for the future directions of plastic mitigation efforts within the cotton and textile industries. This article also infers from the reviewed literature that research on finding alternative materials to plastic as module wrap, the development of new, effective, and all-condition plastic sensing techniques for ginning and spinning equipment, and standardized protocols for UAV in-field surveys of plastic trash are some of the areas that will be beneficial to finding a permanent solution to the challenge.

1. Introduction

Cotton (Gossypium hirsutum L.) is a globally significant agricultural crop from which numerous products (including lint used in making yarns and fabrics, cottonseed oil used for human consumption and animal feed production, and linters used in making ice cream, toothpaste, filters, currency and securities, solid rocket propellants, etc.) originate. Cotton lint is the most important economic product from cotton crop plants, and the value of cotton lint strongly correlates with the level of foreign matter present in the bale [1,2,3,4,5]. In the past decade, of notorious interest to the global cotton and textile industries is the issue of plastic extraneous matters that have been on the upward trend in the cotton supply chain, and which has been taking both financial and reputational tolls on the industries [1,4,5,6,7,8,9,10]. Plastic contaminants come from diverse sources; they include agricultural mulch films, fertilizer bags, plastic shopping bags disposed at or air-blown to the fringes of cotton fields and picked together with seed cotton during harvesting, and cylindrical (popularly known as “round”) cotton module wraps [3,11,12,13,14,15,16]. Of these plastic contamination sources, the round module wraps of different colors are one of the biggest culprits, especially in countries that have widely adopted John Deere mechanical harvesters with onboard module-building capability [17]. For example, in the US, yellow, pink, and black color module wraps account for about 60–70%, 15–25%, and 5–10%, respectively, of the total plastic found in officially tracked US-produced cotton bales by USDA-AMS C&T [18].

When these plastics end up in the final lint bales produced from commercial cotton gins, significantly higher effort is required from the textile mills to add value to the lint and manufacture textiles, if they are at all useful for production. Furthermore, contaminants, such as plastic, can lead to the downgrading of garments or fabrics or their total rejection, which may cause permanent friction among growers, ginners, and textile mills [19,20,21].

To this end, the global (and more importantly, US, which is the global largest exporter of cotton lint bales) cotton and textile industries have responded to this plastic contamination menace with numerous approaches focused on different stages along the cotton value chain from the fields to the textile mills [3,4,5,22,23,24]. From various cotton fields where plastic contamination potential starts—especially in cotton-producing countries such as Australia, the US, Israel, and Brazil, where there are high adoption rates of John Deere (Deere and Company, Moline, IL, USA) automatic module-building spindle harvesters (popularly known as “pickers”) that use plastic material to wrap seed cotton module—to the various textile mills which convert cotton lint into fine apparels that customers gladly want to invest their money in, the commercial industries cannot leave any stage without guards against plastic contamination [7,25,26].

However, until now, there have been no up-to-date comprehensive documents capturing the ever-growing efforts of different individual researchers, groups, agencies, and industries at tackling plastic contamination challenges. All that exists are scanty, scattered, and often country-specific documents that are difficult to sift through and sometimes cumbersome to reference by new entrants and even some old hands in the sector. Some other works, such as [21], cover the general topic of cotton contamination but focus only focus on plastic contamination as one type of cotton contamination. Moreover, the article [21,27] is many years old and does not cover the recent developments that have taken place in the past couple of years. Hence, there is a gap in this area of knowledge that needs filling with a comprehensive review of the state-of-the-art of global plastic contamination issues and both the historical and most recent efforts that researchers and the two industries involved are making to tackle the challenge which has been taking significant economic and reputational tolls on cotton.

Therefore, this paper anticipates being beneficial to the larger cotton-related research community, particularly those working on cotton quality studies, by showcasing the new possible future research directions based on the trajectory of the previous works by various researchers. Furthermore, the paper will contribute to finding lasting solutions to the challenge posed by plastic contamination to the revenue of cotton growers globally and enhance cotton’s claim to sustainability and a contamination-free nature, which is one of its competitive edges over other natural and synthetic fibers.

1.1. Objectives

Therefore, the main objective of this review is to fill the identified gaps stated above. It aims to highlight the main issues with plastic contamination within the cotton value chain and build connections/links among the various research publications on the topic while highlighting major technological solutions that have been invented/adopted, deployed, or are still in the proposition or developmental phases but have significant prospects for mitigating or solving the problem. The review also discusses some of the sensitization efforts by agricultural extensionists and other players in the cotton and textile industries. Finally, some areas that may be suitable for future studies by researchers in the field are presented.

1.2. Adopted Approach

Toward the objectives, this review adopts the following approach. First, the cotton value chain is divided into different stages according to the valorization phases, starting from the in-field pre-harvesting phase to the textile milling phase. At each stage, the sources and causes of plastic contamination are discussed, followed by an elaboration of the existing and emerging technologies and ideas created to solve this challenge. This review also includes narrations of the regulatory, extension, and sensitization services and efforts made by different entities in the world at each phase.

1.3. Materials

The objectives of this paper are achieved by extensively consulting different print and electronic materials, journal articles, conference publications and talks, expert opinions, and directives from national and international regulatory agencies and professional bodies interested in (or saddled with) the responsibility of ensuring quality within the cotton supply chain.

Finally, according to all the reviewed past events and efforts, projections for the future trends of plastic contamination mitigation research efforts and technologies within the cotton and textile industries are made in the closing remarks.

1.4. Paper Flowchart

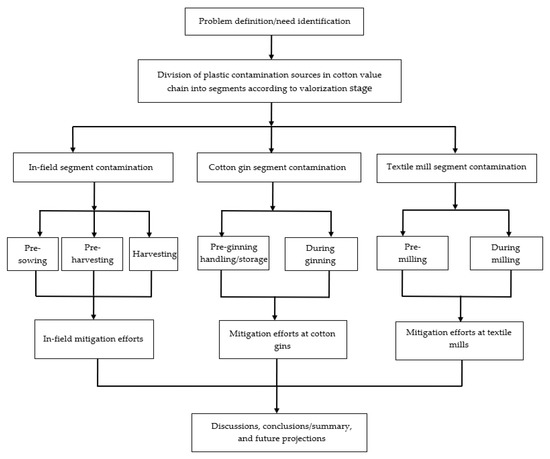

Figure 1 shows a graphical representation of the structure of this review article. It provides a summary of both the approach and materials used in the paper.

Figure 1.

A flowchart summarizing the framework/workflow adopted in this review article.

2. Discussions

As earlier briefly stated, cotton is the most significant natural fiber in the world which has an annual average global production volume of about 25.9 million tons which is produced mainly in India, China, USA, Brazil, Australia, Pakistan, Turkey, Burkina Faso, and Uzbekistan [27,28,29,30]. It has long enjoyed a good reputation among the fibers used in textile and apparel production [27]. Recently, however, this reputation has come under considerable challenges from increasing general contamination levels, particularly plastic contaminants, within the entire cotton value chain [27,31].

Types of contamination include organic and inorganic matters like metal, wires, rubber, tar, sand, grease, jute, leaves, feathers, paper, plastic films from diverse sources, nylon, animal and human hair, and leather [27,31,32]. Thus, plastics are just one of the numerous contaminants usually found in finished lint bales. However, plastic contamination is unique in that, while almost all these other cotton contaminants are spinnable and/or dyeable, plastic contamination is neither; plastic has far more detrimental effects on cotton fiber quality and, indirectly, the fabric quality produced from them than most other contaminant types, and therefore deserves special attention. Hence, this paper is specially focused on the topic of plastic contamination within the cotton value chain to highlight the primary sources of plastic contamination and the most recent efforts made by different players in the industries affected to mitigate and eliminate the threat of plastic on cotton quality and profitability.

Generally, cotton contaminants do not grow in cotton bolls in the field as deducible in the examples of contaminants previously listed. Instead, however, contaminants enter the cotton value chain at different stages between the farms and the final stages of processing cotton into fabric products at spinning and textile mills. For instance, to identify sources of plastic contamination found in cotton in the United States, where plastic contamination is estimated to cause over USD 750 million in lost revenue annually [33], some researchers conducted a time and quality study of round cotton modules from cotton fields to ginning stage on the assumption that the increasing rate of plastic contamination within the US cotton value chain correlates with the recent widespread adoption of harvesting technology that builds freshly harvested seed cotton into plastic-wrapped round modules [34]. In the study, the researchers combined an RFID scanning system and video recordings of the modules as they were loaded for transportation from the field to the gins, arriving, and getting unwrapped before ginning. They recorded the videos from perspectives revealing the undersides of the seed cotton modules; these were the most susceptible to damage, being the portion that often directly interfaces with the handling machines and the ground. Their research outcome suggested a strong correlation between module wrap flaws/damages (and thus cotton contamination) and the number of handling events and time or distance that modules encounter between the fields and the cotton gins. Round module damage events resulting from module truck chain, which pushes plastics into the cotton modules, are significant potential causes of plastic contamination in cotton.

Similarly, despite the cleanliness reputation accorded to the cotton of Australian origin by the ITMF, it is reported that strings and fabrics made from plastic constitute the second most damaging contamination source in Australian cotton [32]. Plastic films from seed cotton module covers are identified as the lead contributor because there has been a decreasing (e.g., 34% in 2007 to 16% in 2005) trend in the level of jute/hessian contamination and an increasing plastic contamination trend in Australian cotton since the industry significantly changed from using jute/hessian to plastic module covers [32]. Specifically, a 3-year joint study conducted by the Australian cotton industry and P. T. Apac Inti Corpora (a large cotton spinning mill in Indonesia) to extend the findings of the ITMF’s survey—which has some inherent limitations—indicated an increasing trend in plastic contamination levels from the beginning to the conclusion of the study. The study suggested that if caution is taken in handling/transportation and unwrapping the plastic bale covers, which have significantly replaced jute/hessian module covers, there should be minimal risk of contamination [32]. In addition, the report revealed that most of the contamination in Australian cotton occurs during picking, and only a minimal amount occurs at the ginning phase because the characteristics of the contaminants found in the cotton bales show that they originated from the stages before ginning [32].

Furthermore, in a country such as Pakistan, where cotton is a significant contributor to national export earnings and is still manually harvested, it is reported that cotton contamination is responsible for a loss of between USD 1.4 (according to All Pakistan Textile Mills Association—APTMA) and USD 3 billion (according to Pakistan Textile Journal) in export revenue losses annually [32,35]. Plastic is a significant constituent of the contamination. Moreover, reports show that plastic contaminations mainly occur when the polypropylene (PP) and plastic bags commonly used during cotton picking by rural women manual cotton pickers tear down and get mixed with cotton [35,36,37]. In addition, the potential for plastic contamination persists at all the subsequent phases of the seed cotton value chain, starting from farm picking to the ginning facilities. For instance, because of the general practice of paying the wages of cotton pickers in the form of cotton, the cotton pickers in Pakistan often keep the cotton they pick at their respective homes until they amass a substantial quantity to sell in the commodity market. So, during the storage at the pickers’ homes and when transporting the cottons in PP bags sewed with jute twines, the cotton becomes contaminated with plastic from the sewn PP bags and other contaminants [35,36].

The following subsections give elaborate—i.e., both general and specific—discussions about plastic contamination in each phase into which the cotton value chain is divided as discussed and illustrated in Figure 1.

2.1. Plastic Contamination in the Pre-Sowing, Pre-Harvesting, and Harvesting Phases

2.1.1. Pre-Sowing and Pre-Harvesting Phases

The potential entrance of plastic into the cotton value chain starts with the management practices adopted by cotton growers. For instance, in some parts of the US states of Georgia and Texas, growers practice a double cropping system in which watermelon and other crops like cotton are planted together on black plastic mulch which blocks photosynthetically active radiation and prevents weed growth [38]. In other countries, too, many cotton growers use plastic films/mulch in their production management to meet the demand for early planting of full-season cotton [39]. The practice has been scientifically proven to improve seed cotton yields by as much as 295 to 430 kg (650 to 950 lbs.) with or without irrigation in different countries, and it also significantly increases the amount of cotton that can be harvested early, preventing lint quality deterioration in the field after boll opening [39,40,41]. These improvements are a result of the capabilities of plastic film mulching to regulate soil temperature, defeat weed growth, and reduce soil water loss, therefore increasing cotton water use efficiency [42]. However, despite the proven advantages of the agricultural practice of mulching with plastic films, the resulting residual plastics in the field are recognized as a common soil pollutant that has been reported to impair soil quality in different world regions, thus cancelling out the economic benefits of the practice [42,43,44,45,46,47,48,49,50,51,52,53]. Moreover, during cotton harvesting, the residual plastics are sometimes picked up together with the seed cotton leading to plastic contamination in cotton.

Other sources of plastic contamination in cotton fields before harvesting are plastic garbage disposed close to cotton fields and/or air-blown into the edges of the cotton lots, fertilizer bags which were not correctly handled during application and ended up in the fields, busted irrigation plastic pipes during the season, etc. [3,54].

Traditionally, many cotton growers make attempts to retrieve these plastics from their fields before harvesting seed cotton (e.g., removing mulch materials after they have served their purpose), despite this being laborious and cost-intensive work. However, it is often impossible to retrieve all the plastics because some break down into smaller fragments that evade retrieval/get buried in the soil. Sometimes it is impractical to manually remove all the plastic because of the large farm size, hence the necessary labor. These plastic residuals get picked up by automatic harvesters (which are mainly of two types: spindle pickers and cotton strippers) in countries that have automated cotton harvesting. However, the risk of picking them up is minimal in other countries like India, China, and some African countries, where mechanical harvesters are yet to penetrate the market and manual harvesting is still the norm [26,55].

2.1.2. Harvesting and Post-Harvesting Handling Phases

As discussed in the previous sub-section—Pre-sowing and Pre-harvesting Phases—the first risk of plastic contamination within the cotton supply chain may be traced to the pre-planting farming management practices adopted by cotton growers. Those plastic pieces that are not removed from the field before the commencement of harvesting operation with mechanical harvesters, whether stripper- or picker-type, have a significant likelihood to progress through the value chain and become confirmed contaminants when packed with the harvested seed cotton. Depending on the type of mechanical harvester used, the amount of trash generally may be very significant in the harvested seed cotton module. While the picker-type mechanical cotton harvesters are more selective in removing seed cotton from the pods (called “bolls”) using a set of spindles, the stripper-type mechanical harvesters are less selective or gentle in harvesting the seed cotton from cotton plant stands; thus, they create more trash contents (including plastic mulch residues, shopping bags, etc.) in the value chain compared with picker-type harvesters [26,56,57].

Furthermore, since the 2006 season when Case IH introduced their first Module Express 625 cotton picker, followed by John Deere releasing their own model 7760 mechanical picker harvester during the 2008 growing season, modern mechanical cotton harvesters have been able to form/build modules onboard while harvesting is still in progress, a scenario that enhances cotton harvesting efficiency by eliminating the need for the investment in boll buggies, a module builder, tractors, and crew members required in the conventional module building approach [58,59,60]. More specifically, the John Deere model 7760 and its successors, CP690, CP770, and CS770, gained wide market acceptance among cotton growers because, unlike Case IH’s onboard module builders, they form seed cotton into round modules that are approximately one-fourth the size of a conventional rectangular module. In addition, research has shown that the round modules have a faster processing rate at gins compared with the other module types and produce seed cotton with improved moisture levels and lint with higher color rating [61,62]. A unique feature of the round modules is the automatic covering of seed cotton modules with a specially engineered plastic material (made of linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), or PP that is water resistant and protects the seed cotton from the elements of weather, i.e., rain, ultraviolet (UV) radiations from the sunlight, and wind), whereas other module types require additional labor to manually cover them up with tarpaulins or coated plastic which, unfortunately, may retain water from the rain because of their flat tops and raise the moisture level of the stored seed cotton [62,63].

Despite these advantages of the round module builders that made them the hallmark of modern mechanized cotton harvesting, they bring a new challenge to the industry: the risk of plastic contamination in the supply chain. Although the plastic module cover applied by the John Deere onboard module builder to cover harvested seed cotton has been engineered for tear-resistance [64], wear and tear of the plastic cover is possible because of incorrect handling by the machine operators during harvesting and transportation of modules from the field to the gin, creating plastic foreign materials in the seed cotton that may contaminate countless lint bales down the value chain. For example, unloading the finished round module from an onboard module builder in the field where there are lots of stalks may create punctures in the plastic covers from where numerous pieces break off and mix with the seed cotton; likewise, burs and sharp edges in module trucks could impair the integrity of the plastic module cover [65,66,67], just like improper replacement of a run-out module wrap during harvest. Furthermore, some inferior plastic module-wrap brands, which are not as durable as the Tama Group’s TamaWrap™ (Tama USA Inc., Dubuque, IA, USA), originally designed and patented for round module covering, have infiltrated the cotton industry, especially in the United States [68,69,70]. Given that the patent held by Tama Group on the module wrap will expire soon [71], if no prompt actions are taken, these inferior module wraps will become more widespread.

On the other hand, although there is a very minimal probability of hand-picking the plastic residues and trash in the field together with manually harvested seed cotton in countries where cotton harvesting is unautomated, there are other sources of plastic contamination that may need attention. For instance, manually picked cotton is usually dropped into woven baskets or plastic bags (see Figure 2). With constant usage over many seasons, those bags wear and tear and may terminate as plastic foreign matter in the seed cotton [35,36,37].

Figure 2.

Manual Seed cotton harvesting: an example mode of transporting such harvested seed cotton to the gin (adopted with permission from [63]).

2.2. Plastic Contamination in the Ginning Phase

Ginning Phase

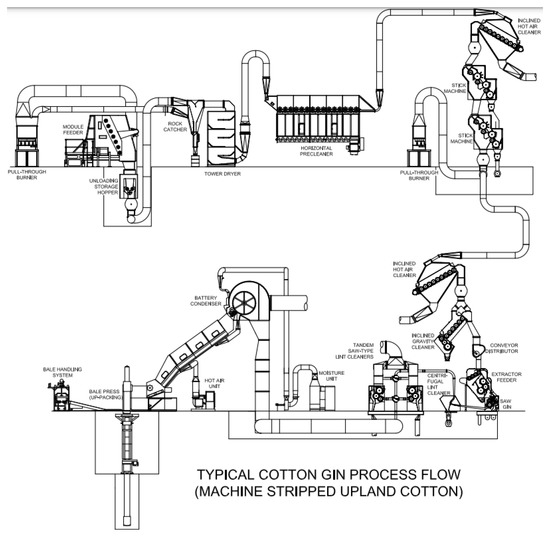

To a large extent, some research works have shown that eliminating most plastic contamination risks in the cotton value chain is possible if harvesting and post-harvest pre-ginning material flow activities are cautiously executed [32,67,72]. However, there are still instances of plastic contamination initiation during seed cotton unloading at cotton gin module feeders (see Figure 3 for the general sequence and layout of a typical cotton gin machinery). These contamination incidents occur when cotton gin workers disobey manufacturer-recommended cutting techniques for round seed cotton module covers (see Appendix A) and the plastic wraps get caught by module feeder floor rollers, causing them to flow into the module feeder with seed cotton and, if big enough, to get trapped on the dispersing cylinders as depicted in Figure 4.

Figure 3.

A typical sequence/layout of cotton gin equipment (Provided by Lummus Corporation, Savannah, GA, USA).

Figure 4.

An example module cover trapped on dispersing cylinders of a cotton gin module feeder [73].

When such an incident occurs at the module feeder, the plastics break up into smaller fragments that contaminate uncountable lint bales if they are not promptly removed [3,74]. Conventional gin cleaning equipment (cylinder cleaners) are undesigned for removing plastic, and research has shown that they are ineffective in ejecting thick module wrap pieces from ginning operations [74]. Hence, small plastic pieces from module covers left for too long on the module feeder dispersing cylinders end up in the final lint bales and create plastic call scenarios for such bales, implying financial loss to the primary producers and friction between different stakeholders. Article [75] estimates that 15% of total contamination originated from the cotton gins (both before and during ginning process).

The International Textile Manufacturers Federation (ITMF), in its most recent survey (2007–2019) released in the year 2020 [31], reported different plastic-based contaminants found in cotton supplied to textile mills. From the report: contaminants tagged “strings made of plastic film” and “fabrics made of plastic film” each affected 39% of all evaluated cotton samples delivered to textile mills by cotton gins across the world; “strings made of woven plastic” and “fabrics made of woven plastic” affected 36% and 31% of the cotton samples analyzed, respectively.

2.3. Contamination at the Textile Mills

Handling at Textile Mills

For many decades, the issue of contamination has been a subject of discussion in the textile industry. One of the foci is usually on having cotton value models that avoid PP or generally plastic packaging materials [75]. However, despite this focus, there has been a general uptrend in foreign matter contaminations within the global textile industry, and this is unrestricted to cotton textile milling lines alone; it affects those that mill other fibers as well [31,75,76].

Plastic contamination is of particular interest among other contamination types at spinning/textile mills—dead and immature fibers, threads, old pieces of fabrics, feathers, white PP, jute, etc.—because, while most of these other contaminant types are spinnable and/or dyeable, cotton is neither spinnable nor dyeable [77]. Thus, plastic contamination is very critical to quality at textile mills.

According to an estimate by Uster® Technologies (Uster, Switzerland), only a total of about 10% of all contaminants in the cotton value chain get initiated during spinning operations (bale stocking and the actual process), compared to the 40% and 20% introduced in the pre-harvesting and harvesting phases of seed cotton, respectively [75]. Given that plastic is only a fraction of the total contaminants, the amount of plastic contamination originating during the spinning process/textile milling may be small; however, even a minute piece of plastic in cotton fiber may result in substantial cost and quality loss implications in the finished products (yarn or fabrics/garments).

The main factor contributing to the origination of contaminants at textile mills is the significant level of automation that has taken place within the textile industry globally over the past few decades [14,31]. That is the scenario because, while process automation has brought significant improvements to the spinning and milling processes by reducing labor costs and minimizing human interventions, the replacement of humans by machines at different stages has resulted in all kinds of foreign materials that were hitherto detected and removed manually by human inspectors going undetected until after they have been torn into smaller fragments and contaminated numerous yarns, i.e., at a stage when it is late to remedy the damage because automated machines limited capabilities to detect and eject foreign matter [31,78].

2.4. Plastic Mitigation Efforts: Pre-Planting, Pre-Harvesting, and Harvesting Phases

Numerous efforts have been committed to controlling plastic contamination in the field. First, because awareness is necessary for tackling the menace, various industry stakeholders have made several sensitization/awareness campaigns. In the USA, for example, despite the report that the cotton industry produces one of the very cleanest cotton bales in the world [31], the industry regulators are leaving no stone unturned to ensure that the country maintains the high reputation of its cotton, which has enjoyed premium prices in the international commodity market for many decades because of their contamination-free quality. For instance, important cotton industry governing/regulating councils (National Cotton Council—NCC; Georgia Cotton Council—GCC) in the country made free educational videos and printed materials to educate growers, and particularly machinery operators, on the best practices to adopt before and during mechanical cotton harvesting [78,79,80]. Growers are advised to practice good housekeeping in their cotton fields and around handling equipment, i.e., to check their farms and retrieve trash that may contaminate seed cotton before harvesting starts, to routinely clean their cotton harvesters’ heads, to always ensure proper replacement of run-out module wraps on the onboard module builders with industry-standard module wrap during harvesting, and, in cases where seed cotton are packaged into conventional modules, farmers are encouraged to replace torn module covers promptly and use module chords instead of plastics to tie down modules during transportation. It is recommended that round modules should be transported at least 15 cm above the ground surface to prevent damaging the underside of the module wrap. Communication between growers/harvesting crew and the gin managers is emphasized because, when round modules with issues during harvesting are flagged and communicated ahead of delivery to ginners, the gin managers are more prepared to mitigate plastic contamination risk from the damaged module cover.

Furthermore, in Australia, a country also rated by the ITMF as a producer of one of the cleanest-quality cotton globally, various efforts are ongoing to maintain and improve their contamination-free cotton quality. Although, the issue of plastic contamination seems not to be as severe relative to the US cotton industry, which generally adopted the onboard module builder-type harvesters later than the Australians did. The early adoption of the onboard module builder in Australia ensured that the teething problems associated with the new technology adoption were largely resolved earlier than in a country like the USA, which is now just overcoming the issue of plastic contamination associated with automatic cotton harvesting and module building. The Australian cotton industry response has also aimed at implementing best management practices (BMP) during harvesting to minimize in-field contamination [32]. Moreover, in Australia, there has been some research success in the development of thin biodegradable plastic films for mulching which do not remain on the soil surface at harvest; this may eliminate an important source of plastic contamination which enters the cotton value chain in the field when fully available for growers’ use [47]. Since 2017, the new biodegradable films have been commercially evaluated across many states in the US with significant yield and water use efficiency benefits reported.

In Pakistan, a major cotton-producing nation, in realization of the adverse impact of contamination, particularly plastics, on the quality of the country’s cotton, which contributes significantly to the national agricultural GDP, many industry players have taken to sensitization and awareness campaign for the cotton pickers through whom most of the contamination originates [35,36,37].

Finally, across different countries that cultivate cotton, there have been studies aimed at detecting diverse types of plastic trash in cotton fields using remote sensing and image processing techniques [42,81,82,83,84]. These techniques, which majorly use images taken from unmanned aerial vehicles (UAVs) with a single or multiple multispectral camera(s) on board, have shown good prospects for detecting plastic in cotton fields at different stages of crop physiological maturity and have thus been proposed for in-field management/mitigation of plastic contamination of seed cotton to create maps of plastic locations within cotton fields that can aid retrieval before harvesting [84]. However, most of the techniques have the disadvantage of being largely dependent on finding the right atmospheric conditions to capture the aerial image dataset.

2.5. Plastic Mitigation Efforts: Ginning Phase

Cotton gins are mainly responsible for ensuring that their lint bales are as clean as possible to maintain a good reputation and ensure cordial relationships with their textile industry customers. Thus, even if plastic contaminants arrive in the cotton modules from the field, it is the responsibility of the gin to ensure that they get removed without ending up in the final produced lint bales. In the USA, the USDA has introduced additional plastic contamination codes 71 and 72 on the permanent bale identification (PBI) system, which serves as an accountability scheme for every bale produced in the country and classed by the USDA [85]. The USDA does not permit changing the plastic contamination classification of any bale from which samples were collected, even when new cotton samples are sent in for review classification, because the distribution of plastic foreign matter is usually non-uniformly in the plastic-contaminated bale. Thus, ginners are bound to be more circumspect in handling the seed cotton they process to reduce the possibility of having a permanent plastic code—which causes discounted prices—for their cotton bales.

Furthermore, some research efforts aimed at mitigating plastic contamination at the cotton gin include the development of a machine vision-based plastic detection–ejection system by researchers at the USDA-ARS Gin Lab, Lubbock (in collaboration with Bratney Companies, Des Moines, IA, USA, a leading company in industrial optical sorting and cleaning operation), which detects incoming plastic materials at the gin-stand apron and puffs them out with air produced by a set of solenoid-controlled air-knives. This system has been tested with satisfactory performance in-house at the USDA and some commercial gins during multiple seasons [33]. The success of the tested prototype has led to the production of a commercial model marketed as Visual Imaging Plastic Removal (VIPR™) by Lummus Ag Technology (Savanna, GA, USA) and Bratney Companies [86]. The reported demonstrated aggregate accuracy detection and ejection efficiency of the system is about 90%, and the system has been made available to commercial gins on a selective basis since the 2021 ginning year. Generally, the gins at which the system was pilot tested witnessed a significant decrease in the plastic calls for their bales relative to previous years.

Another promising research effort towards mitigating plastic contamination at cotton gins is the optical inspection system for module feeders that the USDA developed, which relies on video streams from one or numerous network IP camera(s) installed at the back wall of well-lit module feeders [73,87]. This solution shifts the plastic mitigation focus further upstream of the ginning line, relative to the VIPR™, thereby ensuring that ginners can promptly detect plastic pieces caught on the module feeder before they break into smaller fragments that require a system like the VIPR™ system to remove or end up in the final lint bales downstream. Subsequent development of this system incorporated a custom software that pauses the module feeder floor on a user-defined frequency and captures a few still images of the module feeder (for a few seconds), which is usable in detecting the presence of plastic on the module feeder [22].

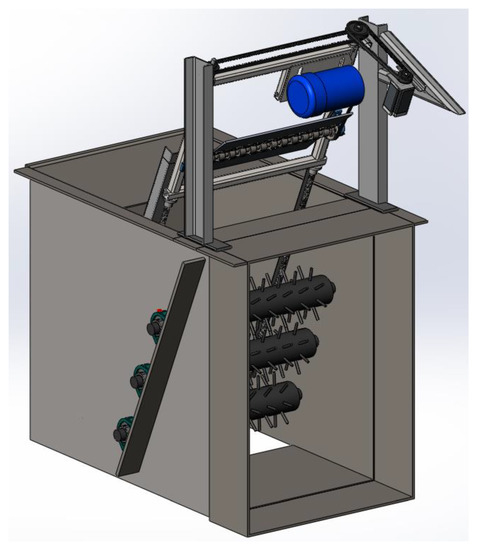

Moreover, researchers at Texas A&M University who hold the paradigm that plastic contamination can be better mitigated at the gin if plastics are intercepted and eliminated earlier in the ginning line proposed, designed, and fabricated a brush-based plastic removal mechanism for installation at cotton gin module feeder [3]. The conceptualized idea is to have a brush mechanism which is integrable with the USDA’s automatic module feeder inspection system and is automatically deployable to run against plastic pieces detected on any of the module feeder’s dispersing cylinders and to remove them by abrasive forces. The brush system (see Figure 5) has been designed, fabricated, installed on a micro gin module feeder at Texas A&M University, and optimized for maximum plastic removal efficiency based on some identified explanatory factors [88]. Efforts are ongoing to fully integrate the optimized brush mechanism and the optical sensor for plastics—the USDA’s automatic module feeder inspection system—to form an optimized closed-loop plastic detection removal system. Successful completion of this system will ensure earlier detection and removal of plastics upstream of the ginning operation with minimal human intervention.

Figure 5.

3D model of the Texas A&M University-designed brush-based plastic removal mechanism installed on a mini module feeder.

Because most plastic contamination events initiated at the ginning phase of the cotton supply chain relate to improper handling of round module wraps, most educational materials produced by relevant industry agencies/regulators have emphasized the training of the ginning crew on the appropriate handling/unwrapping technique of the module wrap at module feeders to prevent plastic contamination events [79,80]. Moreover, to assist correct unwrapping of cylindrical module covers, Tama Group, the manufacturer of the module wrap, created a set of recommendations and guidelines, as shown in Figure A1 in Appendix A, for handling the modules at various types of cotton gin. In addition, since the 2018 season, a cutting zone indicator (Tama Cut Indicator™) has been included on the module wraps to assist gin workers in properly unwrapping the plastic at gins in a manner that minimizes the risk of plastic contamination [63].

Noteworthy is the development of a seed cotton contamination and leaf cleaner, available in two models, MZQ-7A and MZQ-10, by Handan GoldenLion Cotton Machinery (Handan City, China), specifically for cleaning hand-picked seed cotton. The product is commercially available, and the manufacturer claims it can remove about 40 to 60% trash content in seed cotton. However, this machine is inefficient for removing thick plastic materials and other rigid trash contents in seed cotton, as confirmed by a group of researchers from the USDA and Cotton Incorporated (Cary, NC, USA) [89]. It may, however, be beneficial in some cotton-producing regions of the world, i.e., those where cotton harvesting is not yet automated and the main risk of plastic contamination comes from thin mulch films.

Some previous studies have also investigated using ion mobility spectroscopy (IMS) techniques for detecting plastic contamination in seed cotton. The idea started with gas chromatograph–mass spectroscopy (GC–MS) identification of voltaic organic chemicals (VOC) released by typical plastic contaminants (PP, LLDPE, or HDPE) found in cotton when subjected to an elevated temperature of around 100 °C, which is typical during ginning operation and within the tolerable recommended limit for cotton drying. The technique showed promising results in detecting even small concentrations of plastic matter in seed cotton [90]. In the future, this technique may serve as a viable basis for developing a plastic sensing system that can be an alternative to the optical sensors (cameras) needed by computer vision algorithms like the VIPR and USDA’s module feeder inspection systems.

2.6. Plastic Mitigation Efforts: Textile Mills

As stated earlier, the increased level of automation in the textile milling industry led to the late detection of plastics in the textile milling process [32]; hence, for many years, the textile mills suffered significant losses because contaminants, especially plastic trash, were not detected earlier in the textile production procedure. The industry initially responded by boycotting and penalizing cotton lint gins and suppliers/regions from which contaminated lint bales were supplied [32]; hence, as discussed in the previous sub-sections, the action stimulated cotton growers and ginners to be more careful in their production and cotton module management and processing strategies. Some advancements are being made by the global cotton industry toward producing and supplying clean lint bales, devoid of plastic and other non-lint materials, to the textile industry.

Other than the textile industry boycotting or discounting the prices of cotton lint from some regions of the world that are notorious for supplying plastic-contaminated lint bales, some leading textile machinery manufacturers have made significant efforts leading to technological solutions which assist the spinning and textile mills in detecting and removing contaminants at various stages of spinning (i.e., blowroom, carding and comber, draw frame and lappers, ring frame, and winding), especially in the early stages before they get shredded into fragments capable of degrading yarn/fabric quality [35,91]. These solutions are divided into two broad categories: removal systems (or sorting machines) in the blowroom and electronic yarn clearers equipped with a suitable foreign fiber channel. The removal system types are designed for handling bulk contamination with substantial sizes, while the yarn clearers are designed to eliminate small-size contaminants. It may be possible to use only yarn cleaners when the level of non-fiber contents like plastic is minimal, but not when there are significant contaminants in the cotton [92].

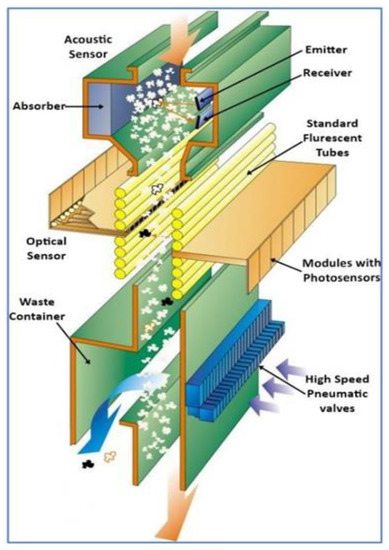

The first of these commercial solutions, known as Loptex Sorter (Loptex SRL, Como, Italy), shown in Figure 6, came in many years ago with significant success and improvements afterward [93,94]. Loptex’s system uses pneumatic valves (see Figure 7 for detailed schematics of the system’s parts) at the start of the spinning process, i.e., before carding machinery, and is integrable into existing and new blowroom lines. The system is modular in design and has a high detection resolution and accuracy afforded by a combination of a camera and ultrasonic sensor systems, multiple light sources, and bespoke software, which synergistically detect contaminants as being darker than cotton fiber as shown by the dark-colored substances in Figure 7. It removes hazardous trash, including plastic (PP), upon detection by activating the variable electronic control signals for the pneumatic valves—which depend on the contaminant size—to enhance the spinnability and dyeability of cotton fibers [92]. The Loptex Sorter was successful because of these unique features, which made other competing manufacturers adopt a similar approach. The other technological solutions (e.g., Barco Vision Cotton Sorter, Premier Fiber Eye, Uster Optiscan, and Vision Shield) are installed in the blowroom to detect and remove contaminants that are detectable by spectral (color) characteristics.

Figure 6.

Example Loptex sorter that uses both optical and ultrasonic sensors (adopted with permission from [95]).

Figure 7.

Internal structure and arrangement of components of the Loptex sorter. The black and dark-colored substances are detected as contaminants (adopted with permission from [95]).

Uster offers some effective commercial contamination control technologies. For instance, installing the Uster’s fiber cleaners inline at the blowroom just after the opener but before carding gives spinners control over the contamination level in the carded fleece and the final product (the yarn). The Uster’s Jossi Vision Shield N relies on high-sensitivity imaging spectroscopy technology to rapidly detect contaminants, particularly plastics, at higher resolution (and over a large wavelength spectrum) than most other systems, including the Loptex Sorter, because the fiber tufts are uncluttered at the stage of fiber processing at which it is integrated [96]. Upon detection, the contaminants are ejected similarly to the Loptex Sorter using precision valves to perfectly time every ejection of only the contaminant. The system comes in different width sizes to meet customers’ specific needs.

2.7. Plastic Mitigation Efforts, Application Regions, Advantages, and Limitations: Summary

Table 1 below summarizes some of the above-discussed plastic mitigation efforts, their current geographical regions of adoption and application, and advantages and disadvantages or limitations in their uses. The applications span different geographical extents, and while some are fully commercialized, others are in experimental phases.

Table 1.

A summary of some plastic mitigation efforts within the cotton and textile industries, regions of current adoption and application, advantages, and limitations.

3. Conclusions

Cotton aims to maintain its reputation and competitive edges as the fiber of choice over other competing natural and synthetic fibers. So, based on the previous efforts by the affected industries and various researchers reviewed above, the author envisages that there would continually be significant substitution of the conventional PE mulch films with biodegradable plastic mulches (BDMs) already penetrating the global agricultural markets. A high adoption rate of such BDMs in countries like China, India, Pakistan, etc., where mulching is an intensive cotton agronomy cultural practice and manual harvesting remains the norm, will ensure the minimization of plastic contamination risk within the cotton value chain and thus increase the supply of more contamination-free cotton to the textile mills.

Furthermore, it is the author’s opinion that the adoption rate of onboard module builder cotton harvesters will continue to increase globally due to the machines becoming more affordable to growers in some parts of the world (Asia and Africa) where the prices of the new harvesters are currently prohibitive. In a few years, some of the current mechanical cotton harvester models with onboard module building in the US, Australia, Brazil, Israel, and other countries where cotton harvesting is already significantly automated will be sold to growers in other climes where the prices of the new machines are currently unaffordable. That will surely help reduce the general trend of plastic contamination in the cotton value chain because the new owners of the mechanized harvesters would have a global archive of materials from which to learn plastic mitigation practices. As shown by various studies in literature, such an anticipated trend is typical for the adoption rate of high-end commercial agricultural technologies in developing economies.

There would also continue to be significant efforts from cotton growers, researchers, regulatory agencies, and commercial equipment manufacturers to ensure that methods and systems for mitigation, detection, and removal/elimination of plastic (and other contaminants) across the cotton value chain from field to textile mills are continuously developed, optimized, and enforced. An example of such efforts is the recent development of a new standard for cotton module wrap/cover (ASABE S615.2) by the ASABE [99,100].

Moreover, the author anticipates that soon, the current TamaWrap™ material may get replaced with a novel non-plastic material (just as plastic module covers have replaced jute/hessian in places like Australia) which will offer the same protection against the elements of weather, but which is easier to detect and remove from cotton processing lines in the cases of wear and tear. An enabling condition for this projection to materialize is the soon-to-expire Tama Group patent on the module wrap products discussed earlier. Upon the patent expiration, there would be opportunities for other industry players to (likely in collaboration with Tama Group) research this significant aspect of plastic contamination mitigation and likely come up with feasible, sustainable replacement material. That is not an uncommon trend, and the anticipation of this likelihood is also partly responsible for the introduction of ASABE Standard S615.2 mentioned above.

Likewise, some methods of plastic detection which may need further investigation to perfect their significant potential in the detection of plastic materials in cotton include the IMS, which some researchers broached earlier. Successfully perfecting the IMS technique for sensing plastic foreign material in cotton will offer a strong alternative or companion method to the camera-based detection technique, which is sensitive to ambient lighting conditions and currently used in the USDA systems and adopted in the Texas A&M brush-based plastic detection-and-removal system. Because the IMS relies only on non-spectral characteristics to detect plastics, its performance is unaffected by the lighting condition in the cotton gin. Similarly, ultrasonic sensing techniques for the same application of plastic detection in cotton gin module feeders where lighting conditions are naturally poor may be an open research topic. Ultrasonic sensing techniques have found some largely successful applications in the textile milling industries but have not yet gained any significant usage on the cotton ginning side of the supply chain.

In addition, towards more efficient plastic detection within the cotton value chain, and as the use of UAV technologies in agriculture is becoming more affordable and popular, there should be more committed efforts towards the standardization of techniques and protocols for performing large-scale pre-harvest in-field plastic surveys of cotton fields using remotely sensed imagery collected with drones.

On the Textile mill industry side, the cotton spinning industry has always engaged in investments in equipment that would reduce its heavy reliance on human labor and technologies that can enhance the quality of their products which compete with other synthetic fibers. The industry does not rely only on sourcing raw cotton from trusted and reliable contamination-free suppliers and boycotting others but is also proactive in collaborating with major commercial manufacturers of quality monitoring and enhancement technologies to develop improved sorting and clearing systems that can better handle emerging contaminant types. However, most publicly available evaluation data and performance indices for these commercialized technological solutions have been collected solely by the manufacturers or with their significant involvements. Thus, an independent evaluation of some of the most popular commercial sorting and yarn clearer technologies may be a path for the research community to investigate in the future to ascertain the exact value they offer to the textile industry.

4. Summary

For the past few years, plastic contamination, especially plastic extraneous matter found in cotton lint bales used as the raw materials at spinning/textile mills, has continued to burden the global cotton value chain. Numerous efforts have been committed to solving this challenge which affects the reputation and profitability of cotton as the natural fiber of choice. While some mitigation efforts and methods have been experimented with and successfully commercialized, others are still in the developmental phases. Moreover, the potential of each of the attempted and proposed solutions differ; while some are significantly effective and easy to implement, others are less effective, costly, or not practical on a large scale.

Thus, despite the efforts committed to solving the plastic contamination issue in cotton, there still exists a lacuna in the solution to the problem. From the findings of this literature review, it is appropriate to summarize that future research focusing on finding alternative materials that can serve the same protective function as plastic for cotton modules, but with no associated contamination risk linked with plastics will be highly beneficial. Moreover, the development and standardization of an all-weather UAV protocol for pre-harvest in-field inspection of cotton fields on a large scale may be of significant interest to industries and national regulatory agencies seeking to mitigate plastic contamination right from the cotton fields. Furthermore, researchers aiming to further develop effective plastic sensing techniques, such as the IMS and others, for detecting/sensing plastic materials in cotton ginning and spinning equipment, will be highly interesting stakeholders in this field.

Overall, as cotton competes with other natural and synthetic fibers, there is no doubt that successfully implementing some of these technological solutions, recommendations, and research outcomes will go a long way in restoring the reputation of cotton as a contamination-free, sustainable fiber of choice. Successes in these suggested research activities will benefit the cotton producers in the US, Australia, Pakistan, India, some west African countries, and other cotton-producing nations, as well as textile manufacturers across the world whose revenues are persistently threatened by plastic contamination.

Funding

This research received financial support from Cotton Incorporated under agreement No. 22-560TX.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The author would like to thank everyone whose critiques of the work have contributed to its evolution into its final form.

Conflicts of Interest

The author declares no conflict of interest.

Disclaimer

The author declares that the mention of a trade name, proprietary product, or specific equipment does not constitute a guarantee or warranty by Texas A&M University and does not imply approval of the product to the exclusion of others that may be available in lieu.

Appendix A

Figure A1.

Round module cover manufacturer recommendations and guidelines for handling round seed cotton modules at gins to minimize plastic contamination (adapted from [63]).

References

- Zhang, R.; Li, C. Detection of synthetic foreign matter in cotton lint by shortwave infrared hyperspectral imaging. In Proceedings of the ASABE Annual International Meeting, New Orleans, LA, USA, 26–29 July 2015. Paper No. 152189878. [Google Scholar] [CrossRef]

- Funk, P.A.; Armijo, C.B.; Whitelock, D.P.; Delhom, C.D.; Holt, G.A.; Wanjura, J.D.; Pelletier, M.G. Thermal contact, a passive approach to plastic removal from seed cotton. In Proceedings of the ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019. Paper 1901898. [Google Scholar]

- Adeleke, A.A.; Hardin, R.G., IV; Pelletier, M.G. Design of a Plastic Removal Mechanism for Cotton Gin. In Proceedings of the Beltwide Cotton Conferences, Virtual, 5–7 January 2021. [Google Scholar]

- Whitelock, D.P. USDA and University Researchers Work to Prevent U.S. Cotton Contamination. Cotton Farming, 1 December 2017; 23–25. [Google Scholar]

- Whitelock, D.P.; Armijo, C.B.; Delwiche, S.R.; Kim, M.S.; Hughs, S.E.; Byler, R.K. Development of a prototype sensor to detect plastic contamination in seed cotton at the gin. In Proceedings of the ASABE Annual International Meeting, Orlando, FL, USA, 17–20 July 2016. Paper No. 162461827. [Google Scholar]

- Whitelock, D.P.; Armijo, C.B.; Delwiche, S.R.; Kim, M.S.; Hughs, S.E. Continued work to develop a low-cost sensor to detect plastic contamination in seed cotton at the gin. In Proceedings of the Beltwide Cotton Conferences, Dallas, TX, USA, 4–6 January 2017. [Google Scholar]

- Whitelock, D.P.; Byler, R.K.; Pelletier, M.G.; Thomasson, A. What research is happening to help prevent contamination of U.S. cotton? In Proceedings of the National Cotton Council Beltwide Cotton Conference, Dallas, TX, USA, 4–6 January 2017. [Google Scholar]

- Whitelock, D.P. Contamination Sources, Prevention, and Research. International Cotton Advisory Committee Recorder. 2017. Available online: https://www.icac.org/getattachment/mtgs/Plenary/76th/Agenda-(Reports-Minutes)/1_OS8_Whitelock.pdf (accessed on 10 October 2022).

- Whitelock, D.P.; Jiang, W.; Armijo, C.B.; Rayson, G.; Byler, R.K.; Hughs, S.E.; Pelletier, M.G.; Baker, K.D.; Fortier, C.A. Current research to maintain contamination-free U.S. cotton. In Proceedings of the ASABE Annual International Meeting, New Orleans, LA, USA, 26–29 July 2015. Paper No. 152188755. [Google Scholar]

- Wenbin, J.; Whitelock, D.P.; Hughs, S.E.; Rayson, G. Low-resolution mid-infrared reflection analysis for discernment of contaminants in seed cotton. Int. J. Anal. Bioanal. Methods 2018, 1, 1–13. [Google Scholar]

- Vollin, T. Clean Cotton MAFES Researcher Tackles Plastic in Cotton. MAFES Discovers. 2020. Available online: https://www.mafes.msstate.edu/discovers/article.asp?id=197#:~:text=Plastic%20contamination%20of%20cotton%20is,bales%20or%20modules%20of%20cotton (accessed on 29 September 2022).

- Blomquist, G. We can stop Contamination-This is how to do it. In Proceedings of the Beltwide Cotton Conference, New Orleans, LA, USA, 6–10 January 1997. [Google Scholar]

- Jordan, J.G. Lint Contamination—A Serious Threat to U.S. Cotton. In Proceedings of the Beltwide Cotton Conference, San Antonio, TX, USA, 5–9 January 2004. [Google Scholar]

- Van Nimmen, E.; Van Langenhove, L. Spinners Tools to Deal with Cotton Contamination. In Proceedings of the Beltwide Cotton Conferences, San Diego, CA, USA, 5–9 January 1998. [Google Scholar]

- Simpson, S. Contamination: Educating the Ginner and Grower. In Proceedings of the Beltwide Cotton Conference, San Diego, CA, USA, 5–9 January 1998. [Google Scholar]

- Plains Cotton Growers. Best Practices to Prevent Plastic Contamination. Available online: https://www.plainscotton.org/best-practices-to-prevent-plastic-contamination/ (accessed on 7 October 2022).

- Huguley, S.E. STCGA Surveys Gins to Identify Plastic Contamination Issues. Southwest FarmPress. 2020. Available online: https://www.farmprogress.com/cotton/stcga-surveys-gins-identify-plastic-contamination-issues (accessed on 29 September 2022).

- USDA-AMS C&T. Available online: https://content.govdelivery.com/attachments/USDAAMS/2020/07/24/file_attachments/1502672/2%20-Plastic%20Contamination%20Remains%20Industry-Wide%20Focus,%20final%20Plastic%20article%20with%20header,%207-7-20.pdf (accessed on 29 September 2022).

- Huguley, S.E. Plastic Contamination: Who Bears the Cost? Southwest FarmPress. Available online: https://www.farmprogress.com/cotton/plastic-contamination-who-bears-cost (accessed on 29 September 2022).

- Van der Sluijs, M. Contaminants in Cotton—Still a Major Issue for High Quality Products. In Proceedings of the 35th International Cotton Conference, Bremen, Germany, 17–18 March 2021. [Google Scholar]

- Van der Sluijs, M.H.J.; Hunter, L. Cotton contamination. Text. Prog. 2018, 49, 137–171. [Google Scholar] [CrossRef]

- Wanjura, J.D.; Pelletier, M.G.; Holt, G.A.; Barnes, E.M.; Wigdahl, J.; Doron, N. An Integrated Plastic Contamination Monitoring System for Cotton Module Feeders. AgriEngineering 2021, 3, 907–923. [Google Scholar] [CrossRef]

- USDA AMS. New Extraneous Matter Code for Plastic Contaminants in Cotton Samples. 2018. Available online: https://content.govdelivery.com/accounts/USDAAMS/bulletins/1fd9f69 (accessed on 30 September 2022).

- Barnhardt Purified Cotton. USDA Addresses Plastic Contamination in US Cotton. 2018. Available online: https://barnhardtcotton.net/blog/usda-addresses-plastic-contamination-in-us-cotton/ (accessed on 30 September 2022).

- Van der Sluijs, M.H.J.; Krajewski, A. Contamination Detection using Module Hood Feeder Sensors. In Proceedings of the Beltwide Cotton Conferences, San Antonio, TX, USA, 5–7 January 2015. [Google Scholar]

- Barnes, E.; Morgan, G.; Hake, K.; Devine, J.; Kurtz, R.; Ibendahl, G.; Sharda, A.; Rains, G.; Snider, J.; Maja, J.M.; et al. Opportunities for Robotic Systems and Automation in Cotton Production. AgriEngineering 2021, 3, 339–362. [Google Scholar] [CrossRef]

- Adamu, B.F.; Wagaye, B.T. Cotton Contamination. In Cotton Science and Processing Technology; Textile Science and Clothing Technology; Wang, H., Memon, H., Eds.; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Khan, M.A.; Wahid, A.; Ahmad, M.; Tahir, M.T.; Ahmed, M.; Ahmad, S.; Hasanuzzaman, M. World cotton production and consumption: An overview. In Cotton Production and Uses, 1st ed.; Ahmad, S., Hasanuzzaman, M.M., Eds.; Springer Nature: Singapore, 2020; pp. 1–7. [Google Scholar]

- DNFI. Available online: https://dnfi.org/cotton-fibres (accessed on 10 October 2022).

- Australian Cotton. Available online: https://australiancotton.com.au/supply_chain/the-features-and-benefits-of-cotton (accessed on 10 October 2022).

- International Textile Manufacturers Federation. Cotton Contamination Survey (2007–2019). Available online: https://www.itmf.org/images/dl/publications/CCS-Vol15-2019.pdf (accessed on 3 October 2022).

- Van der Sluijs, M.H.J. Contamination and its significance to the Australian cotton industry. In Cotton Catchment Communities; CRC: Boca Raton, FL, USA, 2009; Volume 185, pp. 1–34. [Google Scholar]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D. Cotton Gin Stand Machine-Vision Inspection and Removal System for Plastic Contamination: Software Design. AgriEngineering 2021, 3, 494–518. [Google Scholar] [CrossRef]

- Mitchell, L.C.; Ward, J.K. A Time and Quality Study of Round Cotton Modules from Field to Ginning. In Proceedings of the ASABE AIM, Omaha, NE, USA, 12–15 July 2020. [Google Scholar] [CrossRef]

- State-Bank-of-Pakistan. Available online: https://www.sbp.org.pk/reports/quarterly/FY05/first/Special_1.pdf (accessed on 10 October 2022).

- Dawn. Available online: https://www.dawn.com/news/11783/contamination-of-cotton-sources-remedies (accessed on 10 October 2022).

- Business-Recorder. Available online: https://www.brecorder.com/news/565576 (accessed on 10 October 2022).

- UGA. Available online: https://extension.uga.edu/publications/detail.html?number=B996&title=commercial-watermelon-production (accessed on 10 October 2022).

- Qi, J.; Zhang, Y.; Dai, J.; Xu, S.; Zhang, D.; Nie, J.; Sun, X.; Dong, H. Late-planted short-season cotton without plastic mulching is an alternative to early-planted mulched full-season cotton. Ind. Crops Prod. 2021, 163, 113325. [Google Scholar] [CrossRef]

- Bennett, O.L.; Ashley, D.A.; Doss, B.D. Cotton Responses to Black Plastic Mulch and Irrigation. Agron. J. 1966, 58, 57–60. [Google Scholar] [CrossRef]

- Dong, H.; Weiji, L.; Tang, W.; Zhang, D. Early plastic mulching increases stand establishment and lint yield of cotton in saline fields. Field Crops Res. 2009, 111, 269–275. [Google Scholar] [CrossRef]

- Zhai, Z.; Chen, X.; Zhang, R.; Qiu, F.; Meng, Q.; Yang, J.; Wang, H. Evaluation of residual plastic film pollution in pre-sowing cotton field using UAV imaging and semantic segmentation. Front. Plant Sci. 2022, 13, 991191. [Google Scholar] [CrossRef]

- Dai, J.; Dong, H. Intensive cotton farming technologies in China: Achievements, challenges, and countermeasures. Field Crops Res. 2014, 155, 99–110. [Google Scholar] [CrossRef]

- Yan, C.R.; Mei, X.R.; He, W.Q.; Zheng, S.H. Present situation of residue pollution of mulching plastic film and controlling measures. Trans. CSAE 2006, 22, 269–272, (in Chinese, with English abstract). [Google Scholar]

- Zhang, Z.; Cui, Q.; Chen, L.; Zhu, X.; Zhao, S.; Duan, C.; Zhang, X.; Song, D.; Fang, L. A critical review of microplastics in the soil-plant system: Distribution, uptake, phytotoxicity and prevention. J. Hazard. Mater. 2022, 424, 127750. [Google Scholar] [CrossRef]

- Yan, C.; Liu, E.; Shu, F.; Liu, Q.; Liu, S.; He, W. Review of agricultural plastic mulching and its residual pollution and prevention measure in China. J. Agric. Res. Environ. 2014, 31, 95–102. [Google Scholar]

- Braunack, M.; Price, J. The potential for thin biodegradable film in the Australian cotton industry. In Proceedings of the 16th ASA Conference, Armidale, Australia, 14–18 October 2012. [Google Scholar]

- Mancl, K. The Dirt on Agricultural Plastic Pollution of the Soil in the U.S. and China. New Security Beat. Available online: https://www.newsecuritybeat.org/2022/03/dirt-agricultural-plastic-pollution-soil-u-s-china/ (accessed on 2 October 2022).

- Xiao, J.; Zhao, J.B. Farmland plastic film pollution and its countermeasures. Sichuan Environ. 2005, 24, 102–1055. [Google Scholar]

- Wang, J.G. Utilization and Pollution Control of Agricultural Chemicals; Beijing Press: Beijing, China, 2001; pp. 73–74. [Google Scholar]

- Jiang, Y.J.; Zheng, D.M.; Zhu, Z.Y. Effects of remnant plastic film in soil on growth and yield of cotton. Agro-Environ. Prot. 2001, 20, 177–179. [Google Scholar]

- Zhi, J.H.; Zheng, D.M.; Zhu, Y.J. Effects of leftover film contamination on cotton production and its administration. J. Tarim Univ. 2007, 19, 66–70. [Google Scholar]

- Li, Q.J.; Wei, C.Z.; Lei, Y.W.; Wang, J.; Wu, T.L.; Wang, X.S. Influence of white pollute on root growth of cotton. Xinjiang Agric. Sci. 2008, 45, 769–775, (In Chinese, with English abstract). [Google Scholar]

- O’Hanlon, M. With Cotton Harvest Underway, Farmers Fear Grocery Bags, Plastic Contamination. Available online: https://www.victoriaadvocate.com/news/local/with-cotton-harvest-underway-farmers-fear-grocery-bags-plastic-contamination/article_9f8c90b0-c438-11e9-9c61-03c92ae351a7.html (accessed on 2 October 2022).

- Ramkumar, S. Cotton Contamination, Particularly Plastics, Now a Global Issue. Available online: https://www.depts.ttu.edu/agriculturalsciences/news/posts/2018/10/pss-in-press-cotton-contamination.php (accessed on 2 October 2022).

- Choi, A.B. How Is Cotton Harvested? Available online: https://www.thefutonshop.com/blog/what-is-the-difference-between-a-cotton-picker-and-a-cotton-stripper#:~:text=Cotton%20picker%20vs%20cotton%20stripper,longer%20fibers%20(higher%20qualities) (accessed on 2 October 2022).

- Cotton Incorporated. Available online: https://www.cottoninc.com/cotton-production/ag-resources/harvest-systems/stripper-harvesting/background-of-cotton-harvesting/ (accessed on 2 October 2022).

- Forrest Laws. Case Introduces First Module-Building Cotton Picker. Southwest Farm Press. 2006. Available online: https://www.farmprogress.com/case-introduces-first-module-building-cotton-picker (accessed on 2 October 2022).

- Forrest Laws. Deere Unveils Self-Propelled Round-Module Cotton Picker. 2007. Available online: https://www.farmprogress.com/deere-unveils-self-propelled-round-module-cotton-picker (accessed on 2 October 2022).

- The Agriculturist. Available online: https://ttuagriculturist.com/2018/03/30/4-advantages-of-the-new-round-bale-cotton-picker/ (accessed on 3 October 2022).

- Byler, R.K.; Willcutt, M.H.; Buschermohle, M.J.; Mayfield, W.D.; Barnes, E.M. The Effects of Three Module Types on Cotton Ginning and Fiber Quality; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2009. [Google Scholar]

- Cotton Incorporated. Available online: https://www.cottoninc.com/cotton-production/ag-resources/harvest-systems/seed-cotton-handling-storage/a-brief-history-of-cotton-modules/ (accessed on 3 October 2022).

- TamaWrap. Available online: https://www.cotton-wrap.com/ginning-process/ (accessed on 3 October 2022).

- TamaWrap. Available online: https://www.tama-usa.com/wp-content/uploads/2015/02/Tama_RMW_for_John_Deere_7760_CP690_CS690_Cotton_Harvesters.pdf (accessed on 3 October 2022).

- Cotton Incorporated. Available online: https://www.cottoninc.com/cotton-production/ag-resources/harvest-systems/seed-cotton-handling-storage/john-deere-round-modules/ (accessed on 3 October 2022).

- Cotton Incorporated. Available online: https://www.cottoninc.com/cotton-production/ag-resources/harvest-systems/seed-cotton-handling-storage/module-covers/ (accessed on 3 October 2022).

- National Cotton Council of America. Available online: https://www.cotton.org/tech/quality/upload/CERTIFICATES-OF-ANALYSIS-AND-APPROVED-LIST-DRAFT-LK.pdf (accessed on 3 October 2022).

- National Cotton Council. Available online: https://www.cotton.org/tech/quality/upload/Plastics-in-Cotton-TAMU-5-11-22.pdf (accessed on 3 October 2022).

- Cotton Farming. Available online: https://www.cottonfarming.com/ginning-marketplace/module-wrap-performance-can-affect-plastic-contamination/ (accessed on 3 October 2022).

- RPX Insight. Available online: https://insight.rpxcorp.com/litigation_documents/13846421 (accessed on 3 October 2022).

- Google Patents. Available online: https://patents.google.com/patent/US6787209B2/en (accessed on 3 October 2022).

- Cotton Incorporated. Available online: https://cottoncultivated.cottoninc.com/wp-content/uploads/2020/08/PreventionOfContamination-HaulingModules-19Aug2020.pdf (accessed on 3 October 2022).

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D. A cotton module feeder plastic contamination inspection system. AgriEngineering 2020, 2, 280–293. [Google Scholar] [CrossRef]

- Hardin, R.G.; Byler, R.K. Removal of sheet plastic materials from seed cotton using a cylinder cleaner. J. Cotton Sci. 2016, 20, 375–385. [Google Scholar] [CrossRef]

- Biermann, I. Contamination Control in Spinning. Available online: https://baumwollboerse.de/wp-content/uploads/2018/03/Biermann_Iris_Uster-Technologies_2018_01.pdf (accessed on 2 October 2022).

- Biradar, M.M. Contamination in PV Fiber Dyed Spinning—A Big Threat to Yarn and Fabric Quality. Fiber2fashion. 2011. Available online: https://www.fibre2fashion.com/industry-article/pdfdownload.asp?filename=3471&article=3471&status=new (accessed on 3 October 2022).

- Loptex. The most comprehensive and accurate system for the detection and removal of contamination. Available online: https://www.loptex.it/spinning.html (accessed on 4 October 2022).

- National Cotton Council of America. Available online: https://www.youtube.com/watch?v=5Pja_HbMElA&list=PLQmOxrncMDTFWZYPn1hon6GToAswAlIWX&index=2 (accessed on 4 October 2022).

- National Cotton Council of America. Available online: https://www.cotton.org/tech/quality/cont-free-cotton-video.cfm (accessed on 5 October 2022).

- Georgia Cotton Council. Available online: https://georgiacottoncommission.org/prevention-of-plastic-contamination/ (accessed on 5 October 2022).

- Xiong, Y.; Zhang, Q.; Chen, X.; Bao, A.; Zhang, J.; Wang, Y. Large scale agricultural plastic mulch detecting and monitoring with multi-source remote sensing data: A case study in Xinjiang, China. Remote Sens. 2019, 11, 2088. [Google Scholar] [CrossRef]

- Hardin IV, R.G.; Huang, Y.; Poe, R. Detecting plastic trash in a cotton field with a UAV. In Proceedings of the Beltwide Cotton Conferences, San Antonio, TX, USA, 3–5 January 2018. [Google Scholar]

- Zhang, Q.; Hua, L.; Yao, J. Development of Detection System for Cotton Plastic Covering Using Ultrasonic. Appl. Mech. Mater. 2013, 411–414, 1439–1444. [Google Scholar] [CrossRef]

- Southwest Farm Press. Available online: https://www.farmprogress.com/cotton/drones-and-ai-technology-could-help-fight-plastic-contamination (accessed on 4 October 2022).

- USDA-AMS. Cotton Classification: Understanding the Data. Available online: https://www.ams.usda.gov/sites/default/files/media/CottonDBUnderstandingtheData.pdf (accessed on 7 October 2022).

- Rutherford, R. VIPR—Battling Contamination with Technology. Cotton Farming. 2020. Available online: https://www.cottonfarming.com/feature-story/vipr-battling-contamination-with-technology/ (accessed on 7 October 2022).

- National Cotton Council. Available online: https://www.cotton.org/ncga/upload/ModuleFeeder_Inspection-Simple-Camara-System.pdf (accessed on 7 October 2022).

- Adeleke, A.A.; Hardin, R.G., IV. Parameter optimization of a plastic removal mechanism for cotton gins. In Proceedings of the Beltwide Cotton Conferences, San Antonio, TX, USA, 4–6 January 2022. [Google Scholar]

- Whitelock, D.P.; Armijo, C.B.; Pelletier, M.G.; Funk, P.A.; Holt, G.A.; Wanjura, J.D.; Kothari, N.; Martin, V. Evaluation of the Goldenlion Contamination Cleaner. In Proceedings of the Beltwide Cotton Conferences, Austin, TX, USA, 8–10 January 2020. [Google Scholar]

- Funk, P.A.; Eiceman, G.A. Applications of ion mobility spectroscopy to the cotton ginning industry. In Proceedings of the ASAE Annual International Meeting, Chicago, IL, USA, 28–31 July 2002. [Google Scholar]

- Kakde, M.V.; Shah, H.R. Cotton Contamination—Its Sources & Remedial Measures. Textile Review Magazine, Saket Projects, Ltd, Ahmedabad, India. March 2013. Available online: http://textilesworldwide.blogspot.com/2013/04/cotton-contamination-its-sources.html?m=1 (accessed on 9 October 2022).

- Textilesindepth. Available online: https://textilesindepthcom.typepad.com/blog/2010/09/detection-and-removal-of-contaminations.html (accessed on 9 October 2022).

- Loptex SRL. Available online: https://www.loptex.it/ (accessed on 9 October 2022).

- Machinesitalia. Available online: https://www.machinesitalia.org/sites/default/files/company_pdf/brochure6-11.pdf (accessed on 9 October 2022).

- Kiron, M.I. Loptex: An Optosonic Sorter. Textile Learner. 2022. Available online: https://textilelearner.net/loptex-an-optosonic-sorter/ (accessed on 10 October 2022).

- Uster. Available online: https://www.uster.com/nonwovens-zero-tolerance-contamination-control/ (accessed on 9 October 2022).

- Innovation in Textiles. Available online: https://www.innovationintextiles.com/industrial/chinese-spinner-puts-uster-yarn-clearers-to-the-test/ (accessed on 10 October 2022).

- Knitting Industry. Available online: https://www.knittingindustry.com/new-loepfe-tool-for-more-efficient-yarn-clearing/ (accessed on 10 October 2022).

- ASABE. Available online: https://www.asabe.org/Portals/0/aPubs/S615.pdf (accessed on 7 October 2022).

- Wanjura, J.D.; Ankeny, M.; Martin, V.; Barnes, E.; Holmes, S.; Farrell, M.; Delhom, C.D.; Ashley, H.; Holt, G.A.; Pelletier, M.G. Updates to ASABE X615.2 cotton module cover material performance. In Proceedings of the National Cotton Council Beltwide Cotton Conferences, San Antonio, TX, USA, 4–6 January 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).