A Full Assistance System (FAS) for the Safe Use of the Tractor’s Foldable Rollover Protective Structure (FROPS)

Abstract

1. Introduction

- The development of a full assistance system (FAS) by means of strength analysis;

- The development of a system that can automatically lock the FROPS when it is unfolded without making the folding operations strenuous;

- The constructive and dynamic integration of this automatic locking device (ALD) with the FAS;

- The physical testing of the prototype.

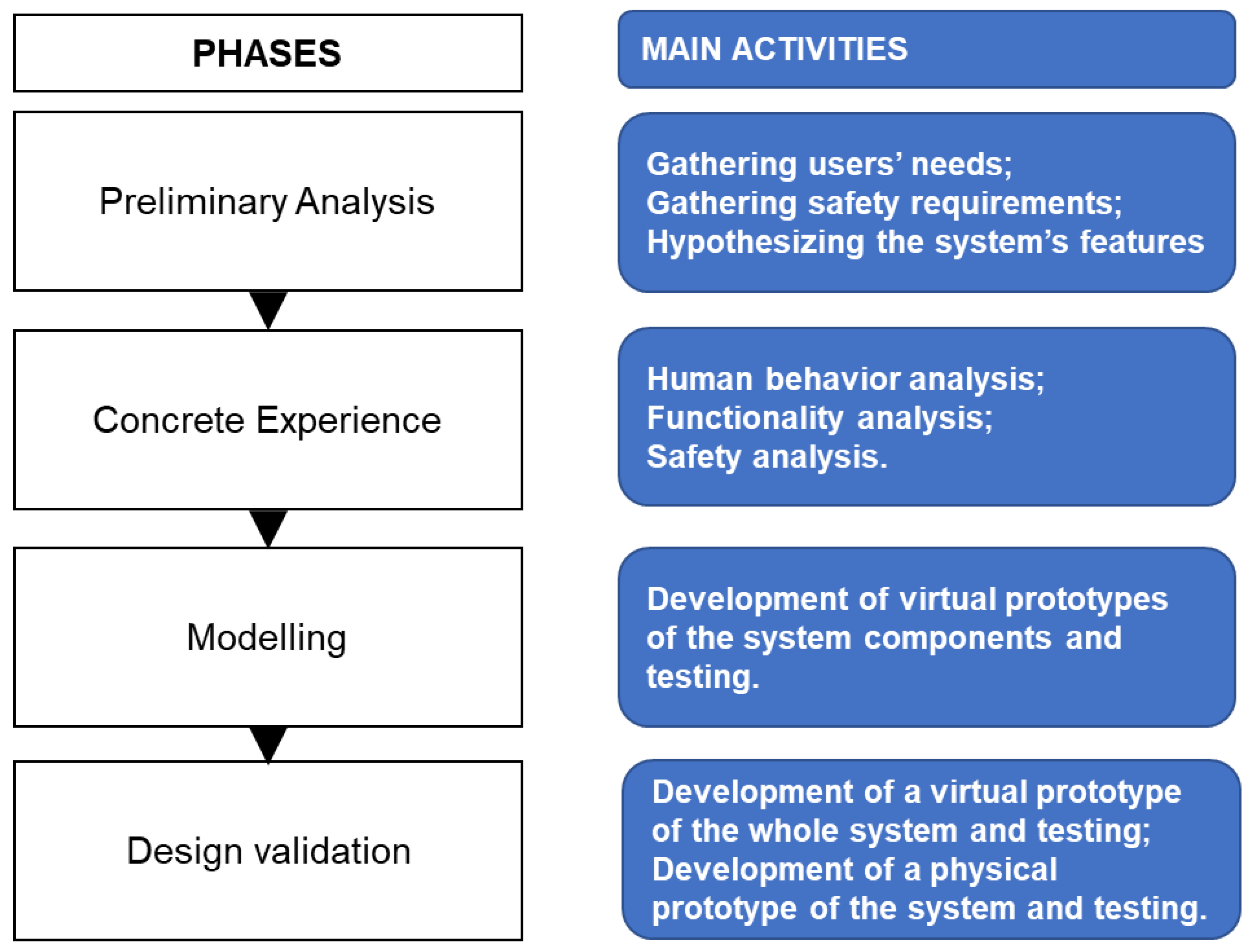

2. Research Approach

- Predicting the system behavior;

- Predicting human behavior;

- Analyzing the system functions;

- Analyzing the users’ behavior;

- Developing solution principles and the associated functions of the system;

- Developing a virtual model and validating it;

- Developing a physical prototype and validating it.

3. Preliminary Analysis

- A ground clearance not higher than 600 mm considering the lowest points of the axles;

- A minimum track width with one of the axles less than 1150 mm when the tractor is equipped with tires or tracks of the largest size recommended by the manufacturer;

- The unladen mass of the tractor, which can vary from 400 kg up to 3500 kg.

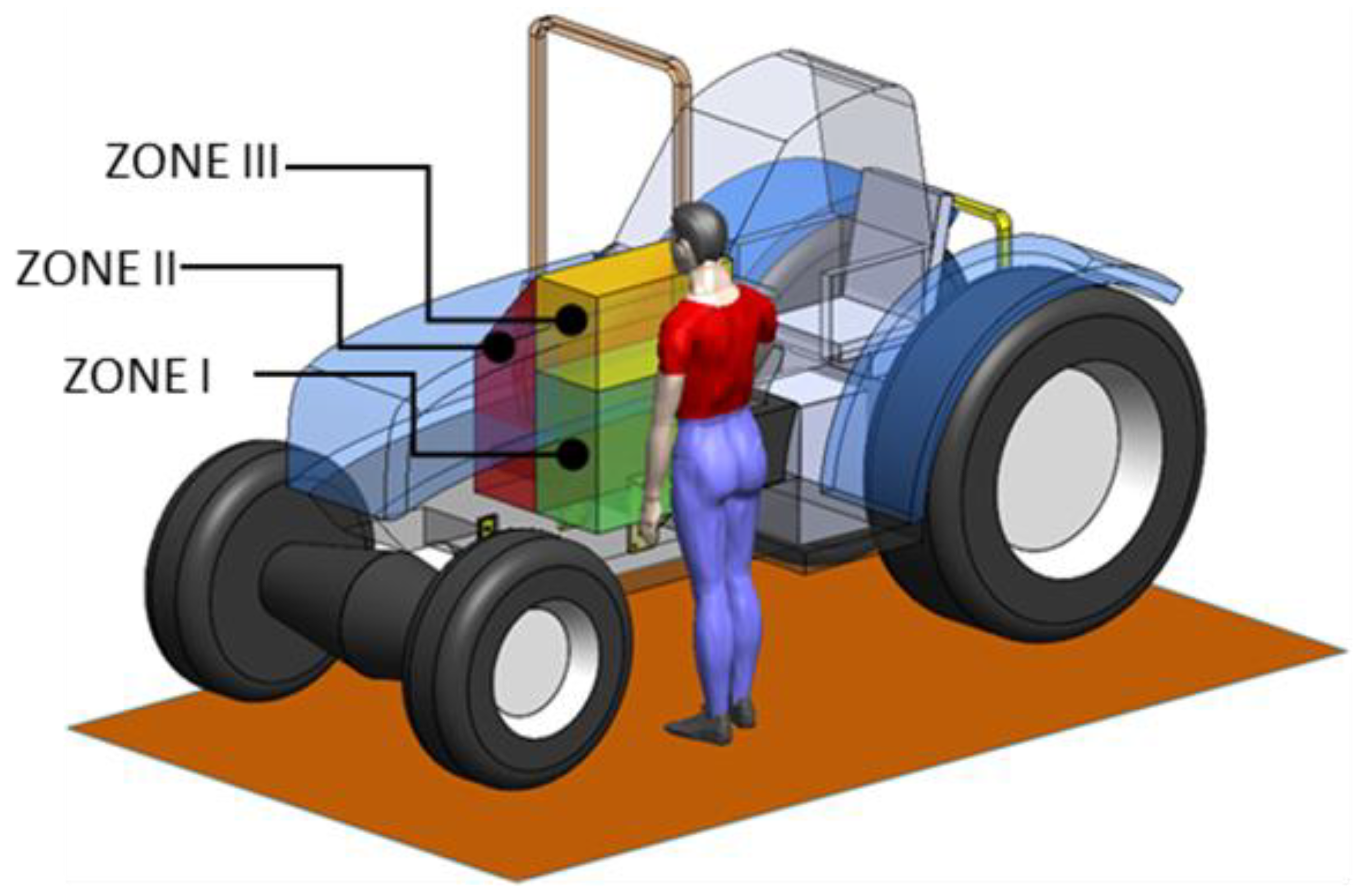

- “Grasping area”, which is the part of the FROPS used by the operator to raise/lower the bar;

- “Accessible part of the grasping area”, which represents the area that can be reached by the operator when raising/lowering the FROPS;

- “Accessible zone”, consisting of the volume occupied by a standing operator when raising/lowering the FROPS.

- For zone I, 100 N;

- For zone II, 75 N;

- For zone III, 50 N.

4. Concrete Experience

5. Modeling the Full Assistance System

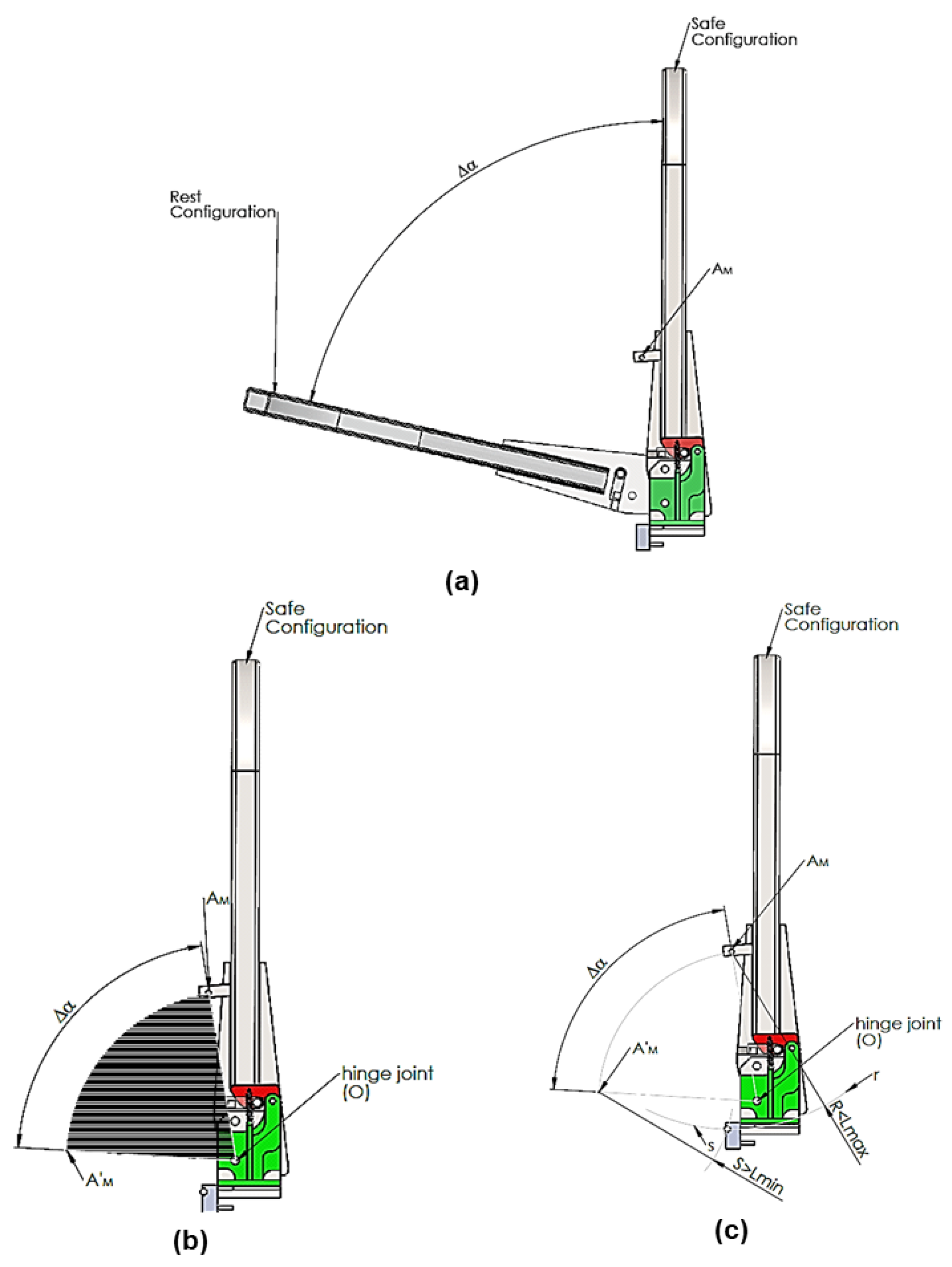

- MW is the moment of the weight force of the FROPS: this moment varies depending on the horizontal distance of the center of gravity (GOC) from the axis of the hinge joint;

- MACT represents the moment of the actuator, which varies on the basis of both the actuator type and the forces it can exert on the FROPS, considering the distance between the anchorage points AF (fixed anchorage point) and AM (mobile anchorage point) on the one hand, and the hinge axis to determine the arm lever on the other.

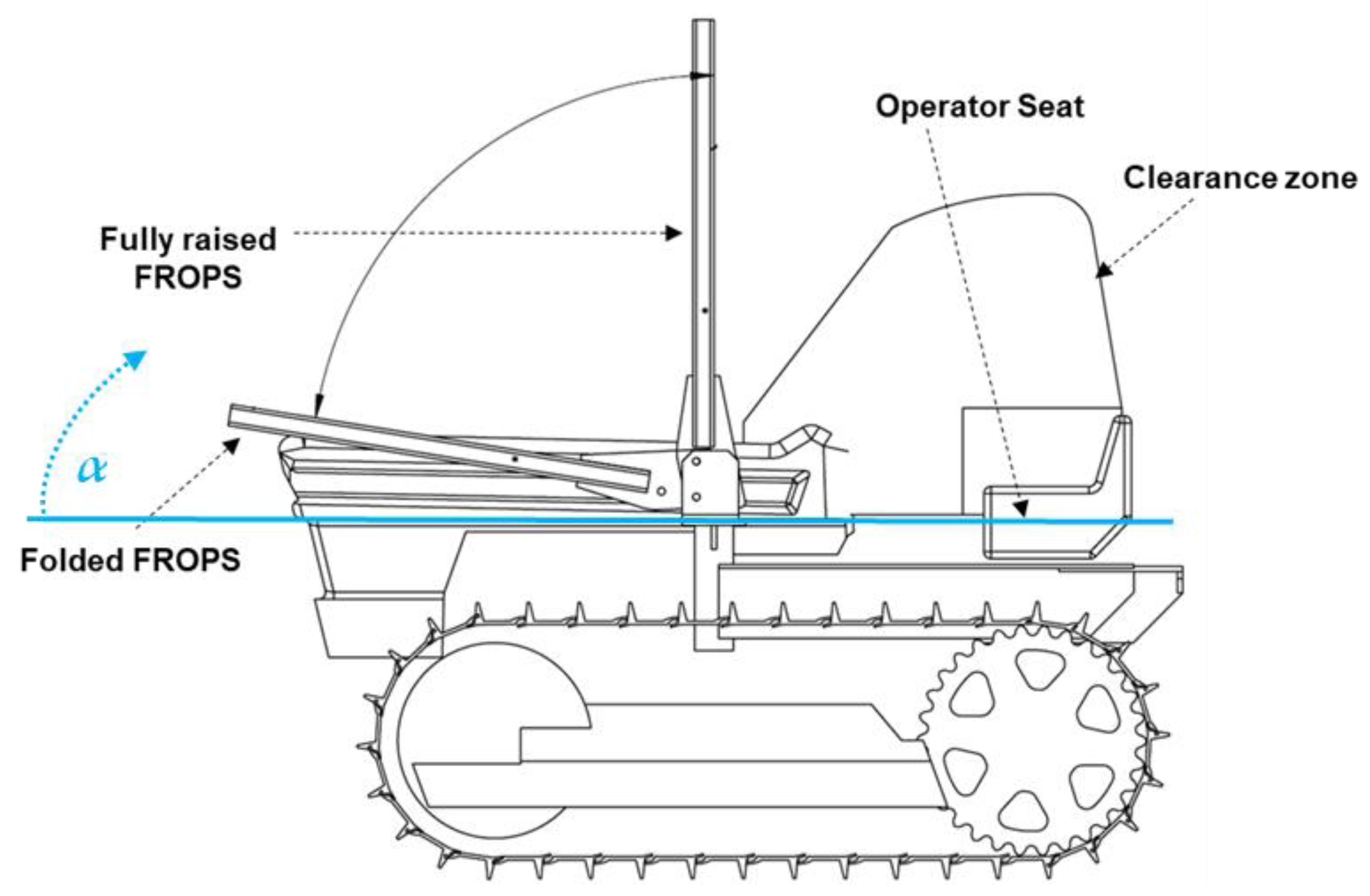

- where P is the weight force of the FROPS, b is the arm of the weight force, and α represents the inclination of the FROPS (i.e., the folding angle), as schematized in Figure 5. It must be noted that MW reaches its maximum value in the rest configuration, and based on the data provided by [27], this value is about 187 Nm for each side.

- The design of a suitable FAS requires an iterative procedure consisting of three main steps:

- Step 1—identification of the actuator model in terms of strength (FACT) and stroke (i.e., the maximum and minimum distance between AF and AM allowed by the system);

- Step 2—definition of the AF point on the FROPS’s fixed part and of AM on the FROPS’s mobile part;

- Step 3—analysis of the load capability condition (MACT (α) ≥ MW).

- Phase 1: Evaluation of the angular range of motion of the FROPS, i.e., the span between the rest configuration (FROPS folded down) and safety configuration (FROPS fully raised); definition of the point AM;

- Phase 2: Definition of the position of AM in the rest configuration (A’M) considering the sector of the circumference with the center corresponding to the projection of the hinge joint O (the amplitude corresponds to the angle ∆α);

- Phase 3: Point AF of the actuator can be obtained as the intersection between the two circular arcs r and s, where s is the circumference arc centered at point AM (radius S), while r is the circumference arc centered in A’M (radius R). The anchorage points comply with the actuator range of motion only if R is smaller than the maximum elongation of the actuator Lmax and S is smaller than the minimum elongation of the actuator Lmin. If the actuator length and elongation do not meet these geometrical requirements, the AM point or/and the AF point should be changed iteratively.

- Nominal stroke: 152.4 mm;

- Voltage: 12 V DC;

- Current draw: 20 Amp;

- Speed: 33 mm/sec;

- Load: up to 18,000 N.

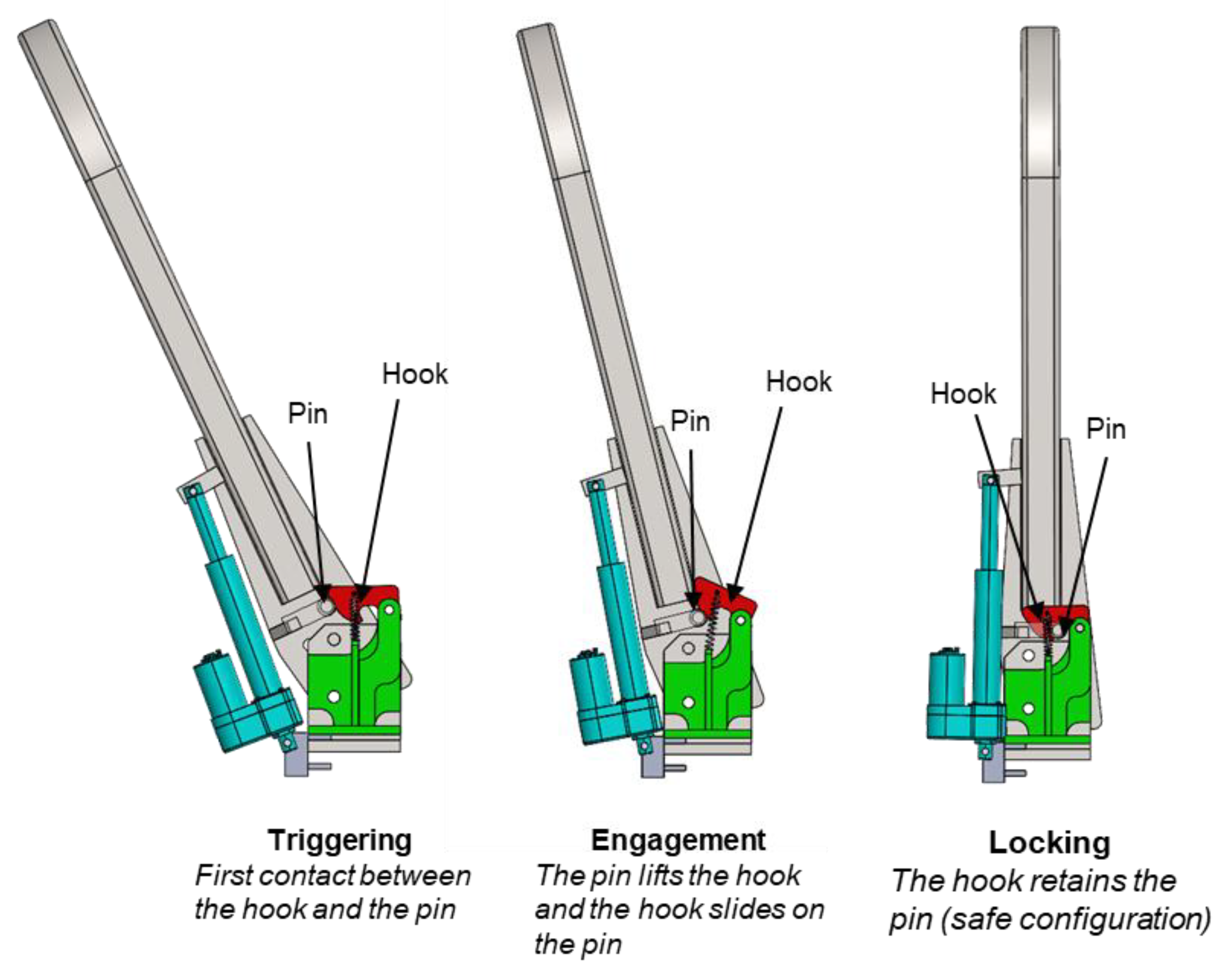

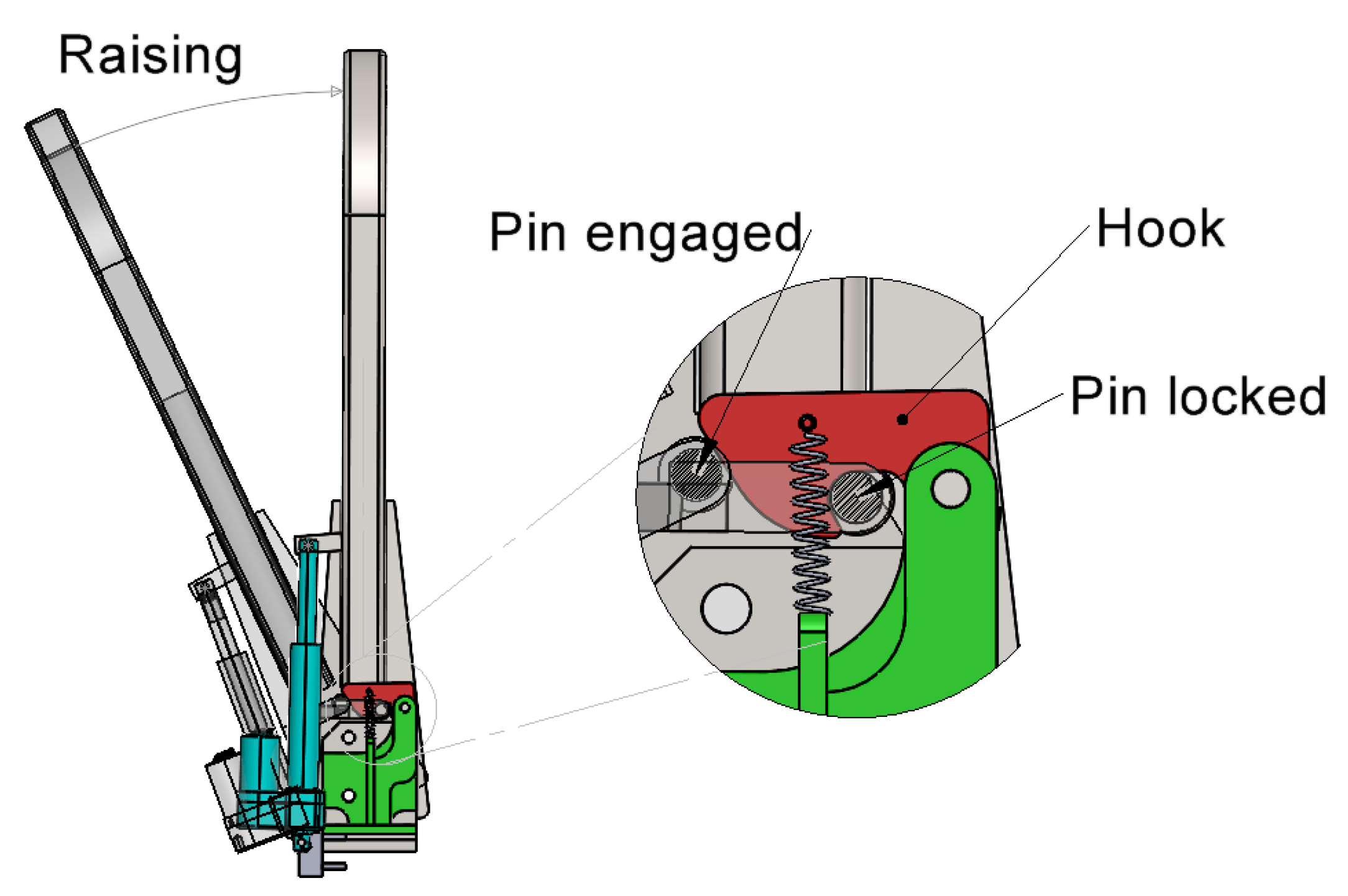

6. Modeling the Automatic Locking Device

- Triggering;

- Engagement;

- Locking.

7. Validation

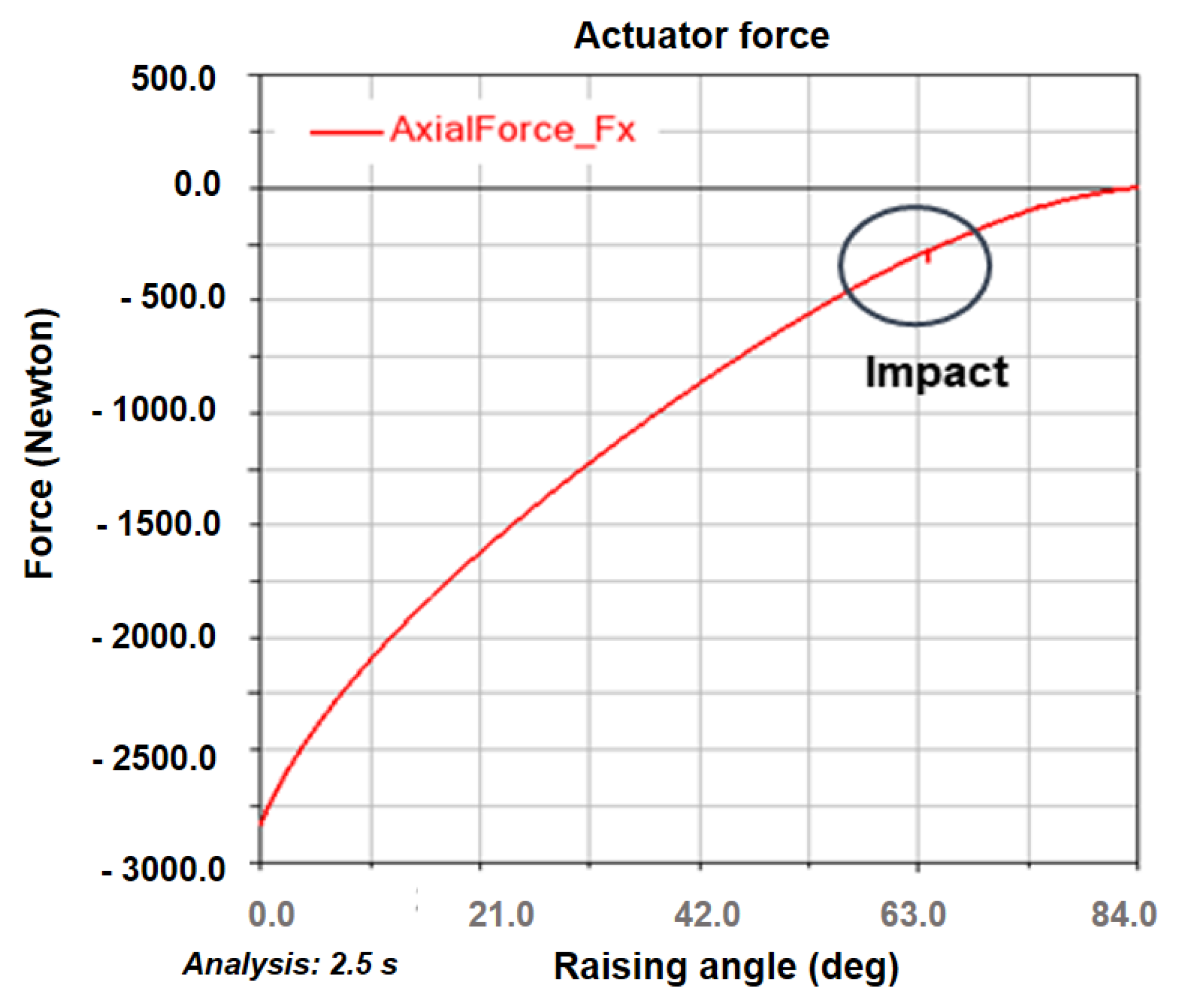

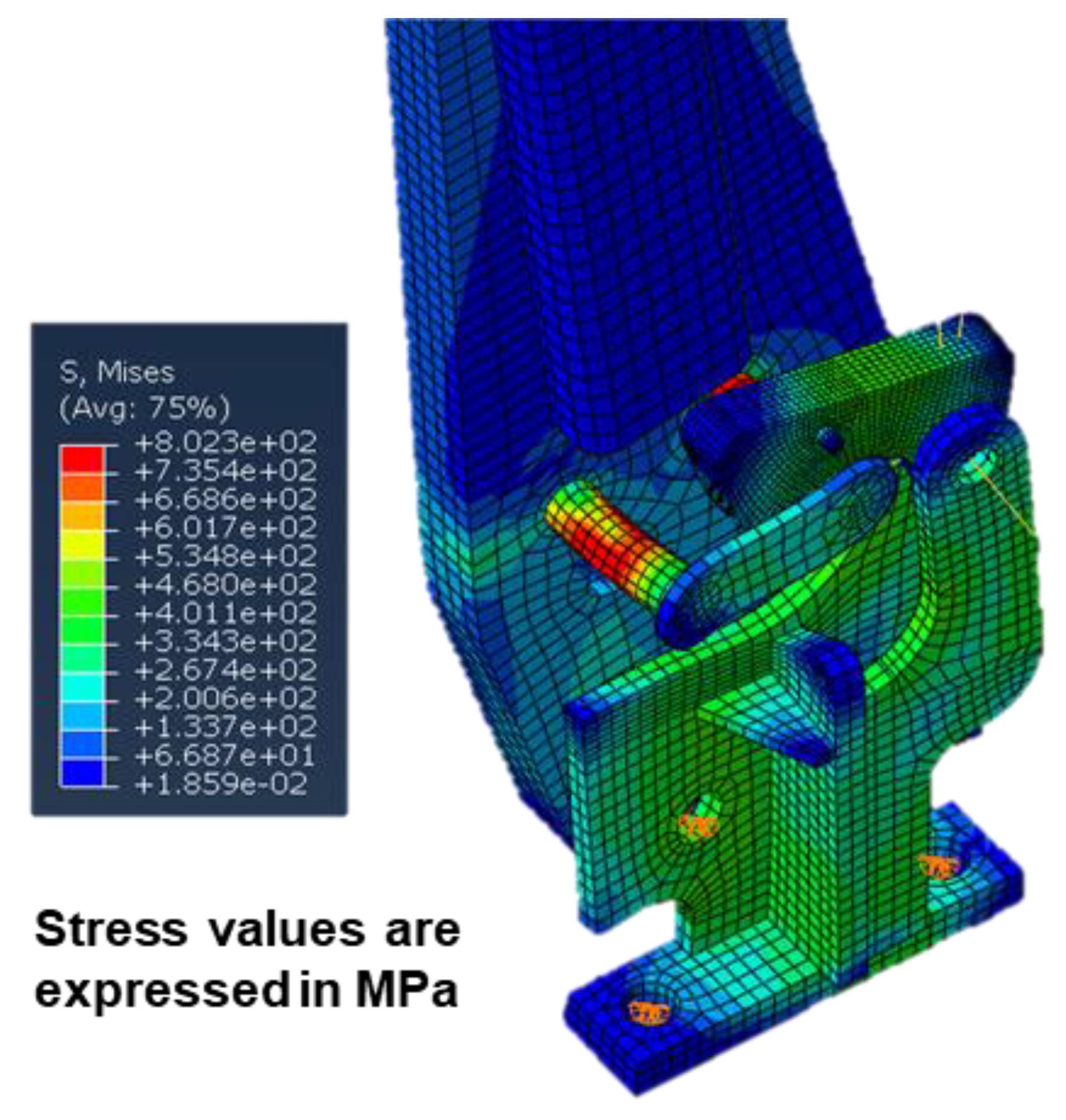

7.1. Virtual Testing

- One second, which is in line with the time of the tractor’s rollover;

- Five seconds, which corresponds to the time needed by the chosen actuators to fully raise the FROPS;

- Two and a half seconds, which is an intermediate value between 1 and 5 s that can add information on the effects of the impact on the ALD.

- The roll bar and plate material is S275 JR steel;

- The locking pins were obtained from calibrated bolts of 10.9 grade (yield strength 940 MPa).

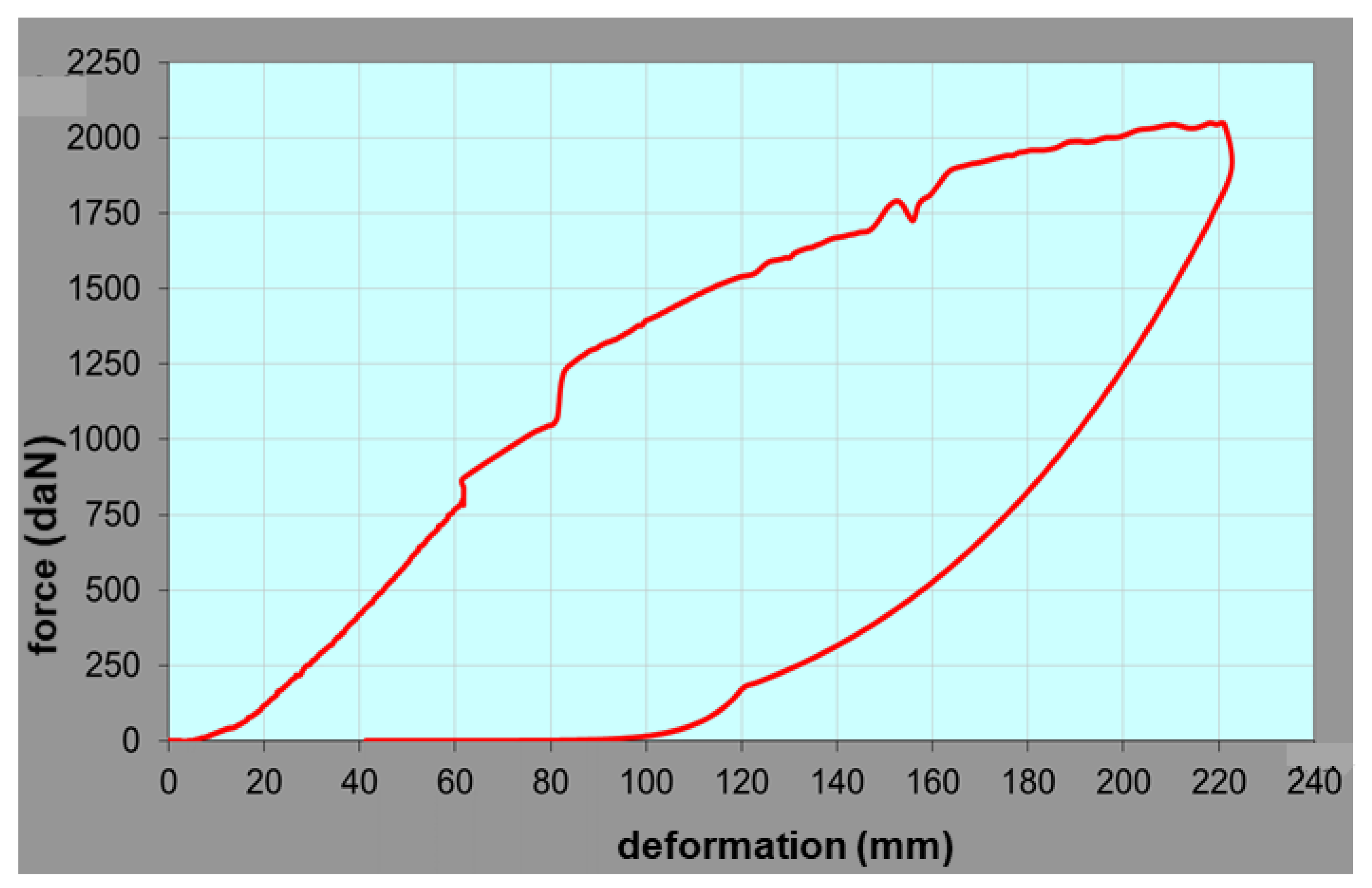

7.2. Physical Testing

8. Discussion

- The system can be easily adapted to existing FROPS models, even if, in this case, an additional structural test is necessary to verify the compliance of the modified model of the protective structure with the OECD Codes;

- The implementation costs are very low considering that the two electric actuators (one for each side of the FROPS) can be connected to the tractor’s battery for the energy supply;

- Lowering/raising and locking operations can be carried out by the operator from the driving seat.

- The physical tests of the FROPS equipped with the ALD to verify compliance with the OECD Codes;

- The completion of the practical implementation of both systems on the tractor.

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nawaz, W.; Linke, P.; Koҫ, M. Safety and sustainability nexus: A review and appraisal. J. Clean. Prod. 2019, 216, 74–87. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M. NOSACQ-50 for safety climate assessment in agricultural activities: A case study in Central Italy. Int. J. Environ. Res. Public Health 2020, 17, 9177. [Google Scholar] [CrossRef] [PubMed]

- Barneo-Alcántara, M.; Díaz-Pérez, M.; Gómez-Galán, M.; Carreño-Ortega, Á.; Callejón-Ferre, Á.J. Musculoskeletal disorders in agriculture: A review from Web of Science core collection. Agronomy 2021, 11, 2017. [Google Scholar] [CrossRef]

- International Labour Office (ILO). Safety and Health at Work, A Vision for Sustainable Prevention. Available online: https://www.ilo.org/wcmsp5/groups/public/@ed_protect/@protrav/@safework/documents/publication/wcms_301214.pdf (accessed on 19 November 2022).

- Facchinetti, D.; Santoro, S.; Galli, L.E.; Pessina, D. Agricultural tractor roll-over related fatalities in Italy: Results from a 12 years Analysis. Sustainability 2021, 13, 4536. [Google Scholar] [CrossRef]

- Pochi, D.; Fornaciari, L.; Vassalini, G.; Grilli, R.; Fanigliulo, R. Levels of whole-body vibrations transmitted to the driver of a tractor equipped with self-levelling cab during soil primary tillage. AgriEngineering 2022, 4, 695–706. [Google Scholar] [CrossRef]

- Vita, L.; Gattamelata, D.; Pessina, D. Retrofitting agricultural self-propelled machines with roll-over and tip-over protective structures. Safety 2021, 7, 46. [Google Scholar] [CrossRef]

- Pinzke, S.; Svennefelt, C.A.; Lundqvist, P. Occupational injuries in Swedish agriculture–development and preventive actions. J. Agric. Saf. Health 2018, 24, 193–211. [Google Scholar] [CrossRef]

- Myers, J.R.; Hendricks, K.J. Agricultural tractor overturn deaths: Assessment of trends and risk factors. Am. J. Ind. Med. 2010, 53, 662–672. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M. Safety vision of agricultural tractors: An engineering perspective based on recent studies (2009–2019). Safety 2020, 6, 1. [Google Scholar] [CrossRef]

- Sorensen, J.A.; Jenkins, P.; Bayes, B.; Clark, S.; May, J.J. Cost-effectiveness of a ROPS social marketing campaign. J. Agric. Saf. Health 2010, 16, 31–40. [Google Scholar] [CrossRef]

- Hard, D.L.; McKenzie, E.A.; Cantis, D.; May, J.; Sorensen, J.; Bayes, B.; Madden, E.; Stone, B.; Maass, J. The NIOSH CROPS demonstration project: A study in New York and Virginia with an emphasis on youth. J. Agric. Saf. Health 2016, 22, 173–186. [Google Scholar] [CrossRef]

- Cavallo, E.; Langle, T.; Bueno, D.; Tsukamoto, S.; Görücü, S.; Murphy, D. Rollover protective structure (ROPS) retrofitting on agricultural tractors: Goals and approaches in different countries. J. Agromed. 2014, 19, 208–209. [Google Scholar] [CrossRef]

- European Agency for Safety and Health at Work (EU-OSHA). Maintenance in Agriculture—A Safety and Health Guide; Publications Office of the European Union: Luxembourg, 2011; Available online: https://data.europa.eu/doi/10.2802/54188 (accessed on 19 November 2022).

- Gattamelata, D.; Puri, D.; Vita, L.; Fargnoli, M.; Lombardi, M. Retrofitting agricultural tractors with aftermarket weather cabins: Safety issues for manufacturers and users. In Proceedings of the International Conference on Industrial Engineering and Operations Management (IEOM), Rome, Italy, 2–5 August 2021; pp. 339–350. Available online: http://ieomsociety.org/proceedings/2021rome/306.pdf (accessed on 19 November 2022).

- Mann, A.J.; Jepsen, S.D. Using expert panel data to guide youth agricultural safety and health training resources in the US. Safety 2017, 3, 4. [Google Scholar] [CrossRef]

- Silleli, H.; Dayıoglu, M.A.; Gültekin, A.; Saranlı, G.; Yıldız, M.A.; Akay, E.; Ekmekçi, K. Anchor mechanism to increase the operator clearance zone on narrow-track wheeled agricultural tractors: Static and field upset test results. Biosyst. Eng. 2008, 99, 196–204. [Google Scholar] [CrossRef]

- Ballesteros, T.; Arana, I.; Ezcurdia, A.P.; Alfaro, J.R. E2D-ROPS: Development and tests of an automatically deployable, in height and width, front-mounted ROPS for narrow-track tractors. Biosyst. Eng. 2013, 116, 1–14. [Google Scholar] [CrossRef]

- Ballesteros, T.; Arana, J.I.; De Ezcurdia, A.P.; Alfaro, J.R. Development and validation of automatically deployable ROPS based on airbag inflator technology. Biosyst. Eng. 2015, 130, 92–105. [Google Scholar] [CrossRef]

- Cremasco, M.M.; Caffaro, F.; Giustetto, A.; Vigoroso, L.; Paletto, G.; Cavallo, E. Tractor rollover protection: Is the incorrect use of foldable rollover protective structures due to human or to technical issues? Hum. Factors J. Hum. Factors Ergon. Soc. 2020, 62, 64–76. [Google Scholar] [CrossRef]

- Vigoroso, L.; Caffaro, F.; Micheletti Cremasco, M.; Cavallo, E. Improving tractor safety: A comparison between the usability of a conventional and enhanced rear-mounted foldable ROPS (FROPS). Int. J. Environ. Res. Public Health 2022, 19, 10195. [Google Scholar] [CrossRef]

- Molari, G.; Rondelli, V. On the definition of narrow-track wheeled agricultural tractors. Biosyst. Eng. 2004, 88, 75–80. [Google Scholar] [CrossRef]

- Micheletti Cremasco, M.; Vigoroso, L.; Caffaro, F.; Paletto, G.; Cavallo, E. Considering human variability in the design of safe interaction with agricultural machinery: The case of foldable roll-over protective structure (FROPS) manual handling. Agronomy 2021, 11, 1303. [Google Scholar] [CrossRef]

- Etherton, J.; McKenzie, J.E.A.; Lutz, T.; Cantis, D.; Kau, T.Y. An initial farmer evaluation of a NIOSH AutoROPS prototype. Int. J. Ind. Ergon. 2004, 34, 155–165. [Google Scholar] [CrossRef]

- Alkhaledi, K.; Means, K.; McKenzie, J.E.; Smith, J. Reducing occupational fatalities by using NIOSH 3rd generation automat-ically deployable rollover protective structure. Saf. Sci. 2013, 51, 427–431. [Google Scholar] [CrossRef]

- Pessina, D.; Facchinetti, D. A survey on fatal accidents for overturning of agricultural tractors in Italy. Chem. Eng. Trans. 2017, 58, 79–84. [Google Scholar] [CrossRef]

- Gattamelata, D.; Vita, L.; Fargnoli, M. Machinery safety and ergonomics: A case study research to augment agricultural tracklaying tractors’ safety and usability. Int. J. Environ. Res. Public Health 2021, 18, 8643. [Google Scholar] [CrossRef] [PubMed]

- Fargnoli, M.; Vita, L.; Gattamelata, D.; Laurendi, V.; Tronci, M. A reverse engineering approach to enhance machinery design for safety. In Proceedings of the DESIGN 2012, the 12th International Design Conference, Dubrovnik, Croatia, 21–24 May 2012; Marjanovic, D., Storga, M., Pavkovic, N., Bojcetic, N., Eds.; International Design Conference: Dubrovnik, Croatia, 2012; pp. 627–636, ISBN 978-953-7738-17-4. [Google Scholar]

- Wood, K.L.; Jensen, D.; Bezdek, J.; Otto, K.N. Reverse engineering and redesign: Courses to incrementally and systematically teach design. J. Eng. Educ. 2001, 90, 363–374. [Google Scholar] [CrossRef]

- Organisation for the Economic Co-Operation and Development (OECD). Tractors standard Codes 4, 6, 7, 8. Organisation for the Economic Co-Operation and Development Paris, France. Available online: https://www.oecd.org/agriculture/tractors/codes/ (accessed on 19 November 2022).

- Pessina, D.; Facchinetti, D.; Giordano, D.M. Narrow-track agricultural tractors: A survey on the load of the hand-operated foldable rollbar. J. Agric. Saf. Health 2016, 22, 275–284. [Google Scholar] [CrossRef]

- Franceschetti, B.; Rondelli, V. Models to predict the force to operate front foldable rollover protective structures for narrow-track tractors. Biosys. Eng. 2019, 185, 126–134. [Google Scholar] [CrossRef]

- Vigoroso, L.; Caffaro, F.; Cremasco, M.M.; Giustetto, A.; Paletto, G.; Cavallo, E. A bottom-up approach to tractor safety: Improving the handling of foldable roll-over protective structures (FROPS) through user-centred design. In Innovative Bio-Systems Engineering for Sustainable Agriculture, Forestry and Food Production, Lecture Notes in Civil Engineering 67, Proceedings of the International Mid-Term Conference of the Italian Association of Agricultural Engineering, Matera, Italy, 12–13 September 2019; Coppola, A., Di Renzo, G., Altieri, G., D’Antonio, P., Eds.; Springer Nature: Geneve, Switzerland, 2020; pp. 645–652. [Google Scholar] [CrossRef]

- Vigoroso, L.; Caffaro, F.; Cavallo, E.; Cremasco, M.M. User-centred design to promote the effective use of rear-mounted foldable roll-over protective structures (FROPSs): Prototype evaluation among novice and expert farmers. Span. J. Agric. Res. 2021, 19, e0207. [Google Scholar] [CrossRef]

- MSC Adams Software. Available online: https://hexagon.com/it/products/product-groups/computer-aided-engineering-software/adams (accessed on 19 November 2022).

- Italian Workers’ Compensation Authority (INAIL). L’installazione dei Dispositivi di Protezione in Caso di Ribaltamento nei Trattori Agricoli o Forestali. Linee Guida: (Installation of Protection Devices in the Event of Overturning of Agricultural or Forestry Tractors. Guidelines). Available online: https://www.inail.it/cs/internet/comunicazione/pubblicazioni/catalogo-generale/linstallazione-dei-dispositivi-di-protezione.html (accessed on 19 November 2022).

- Fargnoli, M. Design for safety and human factors in industrial engineering: A review towards a unified framework. In Proceedings of the 11th Annual International Conference on Industrial Engineering and Operations Management, Singapore, 7–11 March 2021; pp. 7511–7522. [Google Scholar]

- Urquhart, L.; Wodehouse, A.; Loudon, B.; Fingland, C. The application of generative algorithms in human-centered product development. Appl. Sci. 2022, 12, 3682. [Google Scholar] [CrossRef]

- Kim, H.; Lee, K.; Räsänen, K. Agricultural injuries in Korea and errors in systems of safety. Ann. Agric. Environ. Med. 2016, 23, 432–436. [Google Scholar] [CrossRef]

- Irwin, A.; Poots, J. Investigation of UK farmer go/no-go decisions in response to tractor-based risk scenarios. J. Agromed. 2018, 23, 154–165. [Google Scholar] [CrossRef]

- Caffaro, F.; Cremasco, M.M.; Roccato, M.; Cavallo, E. Drivers of farmers’ intention to adopt technological innovations in Italy: The role of information sources, perceived usefulness, and perceived ease of use. J. R. Stud. 2020, 76, 264–271. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M.; Haber, N. A fuzzy-QFD approach for the enhancement of work equipment safety: A case study in the agriculture sector. Int. J. Reliab. Saf. 2018, 12, 306–326. [Google Scholar] [CrossRef]

- Sadeghi, L.; Dantan, J.Y.; Mathieu, L.; Siadat, A.; Aghelinejad, M.M. A design approach for safety based on product-service systems and function–behavior–structure. CIRP J. Manuf. Sci. Technol. 2017, 9, 44–56. [Google Scholar] [CrossRef]

- Keskin, S.G.; Keskin, M.; Soysal, Y. Assessing farm tractor incidents and awareness levels of operators for tractor safety issues in the Hatay province of Turkey. J. Agric. Saf. Health 2012, 18, 113–128. [Google Scholar] [CrossRef]

- Kogler, R.; Quendler, E.; Boxberger, J. Occupational accidents with agricultural machinery in Austria. J. Agromed. 2016, 21, 61–70. [Google Scholar] [CrossRef]

- Casazza, C.; Martelli, R.; Rondelli, V. Evaluation of a commercial tractor safety monitoring system using a reverse engineering procedure. J. Agric. Saf. Health 2016, 22, 215–225. [Google Scholar] [CrossRef]

- Urbanic, R.J.; ElMaraghy, W. A design recovery framework for mechanical components. J. Eng. Des. 2009, 20, 195–215. [Google Scholar] [CrossRef]

- Tinc, P.J.; Gadomski, A.; Sorensen, J.A.; Weinehall, L.; Jenkins, P.; Lindvall, K. Applying the consolidated framework for implementation research to agricultural safety and health: Barriers, facilitators, and evaluation opportunities. Saf. Sci. 2018, 107, 99–108. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gattamelata, D.; Puri, D.; Vita, L.; Fargnoli, M. A Full Assistance System (FAS) for the Safe Use of the Tractor’s Foldable Rollover Protective Structure (FROPS). AgriEngineering 2023, 5, 218-235. https://doi.org/10.3390/agriengineering5010015

Gattamelata D, Puri D, Vita L, Fargnoli M. A Full Assistance System (FAS) for the Safe Use of the Tractor’s Foldable Rollover Protective Structure (FROPS). AgriEngineering. 2023; 5(1):218-235. https://doi.org/10.3390/agriengineering5010015

Chicago/Turabian StyleGattamelata, Davide, Daniele Puri, Leonardo Vita, and Mario Fargnoli. 2023. "A Full Assistance System (FAS) for the Safe Use of the Tractor’s Foldable Rollover Protective Structure (FROPS)" AgriEngineering 5, no. 1: 218-235. https://doi.org/10.3390/agriengineering5010015

APA StyleGattamelata, D., Puri, D., Vita, L., & Fargnoli, M. (2023). A Full Assistance System (FAS) for the Safe Use of the Tractor’s Foldable Rollover Protective Structure (FROPS). AgriEngineering, 5(1), 218-235. https://doi.org/10.3390/agriengineering5010015