Abstract

For years, concentrated solar power (CSP) has been considered an emerging technology that could disrupt the energy production sector. The possibility to store the electricity generated during the sunny operating hours in the form of heat enhances energy dispatchability and gives CSP a unique value proposition that conventional renewable energies cannot provide cost-efficiently since it requires the integration of costly large-scale battery systems. CSP is a cleaner technology compared to photovoltaics, but photovoltaics currently has lower overall capital costs, making it more attractive to investors and stakeholders who want to spend less money upfront. This is one of the main reasons why CSP has never really led either the electricity market or the heating one, even if its combined generation capability (heat and electricity) is globally recognized as a great advantage for a renewable technology. In this study, we analyze the reasons why CSP is not as widespread as it could be; at the same time, we look at the opportunities and the enablers for a further deployment of this technology, focusing on the European region.

1. Introduction

Renewable energy technologies are gaining importance in the global electricity grid mix, and Concentrated Solar Power (CSP) is one of the most debated [1,2,3,4,5,6]. The Strategic Energy Technology (SET) Plan targets the deployment of low-carbon technologies in a fast and cost-competitive way to boost the transition towards a climate-neutral energy system [7]. In its Activity 5 of Research and Innovation (R&I) activities, the SET Plan urges as a priority the development of “Improved central receiver molten salt technology”. Wind and photovoltaics (PV) have reached an outstanding installed capacity of more than 1000 GW worldwide [8], achieving reliable and cost-competitive green energy. However, both technologies are not dispatchable, which is an increasingly important feature for the electrical grid, and therefore limits their penetration [9]. CSP concentrates the sun’s energy into high-temperature heat used to (i) produce electricity via thermodynamic cycles at high efficiency, (ii) hybridize with heat from other sources such as fossil or renewable fuels, and (iii) store it cost-effectively to be delivered when required by the grid. These are the reasons why CSP is a flexible and dispatchable renewable energy technology (RET) that must become a key element for a sustainable energy transition balancing the grid scenarios in a wise way and allowing maximum penetration to other RETs.

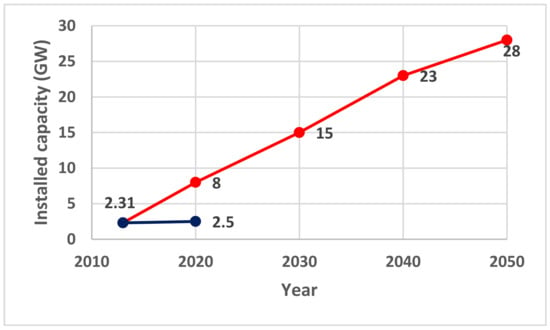

According to a study of the International Energy Agency (IEA) in 2014, the forecast regarding worldwide electricity production should see 11% of penetration of CSP in 2050 reaching 954 GW of installed capacity [10]. In 2020, the percentage covered by this technology was 0.5%, which is just around 6 GW of CSP power capacity installed. In Figure 1, the forecast for CSP installation in the EU is shown, demonstrating that in 2020 the European capacity should have been close to 8 GW, while at the moment it is just around 2.5 GW [6,11].

Figure 1.

Forecast of installed capacity in GW for CSP projects in EU (red line) and current installed capacity in 2020 (in blue).

To boost the growth of CSP and get back on the path to make the 2050 target, the CSP sector must (i) enhance its storage capacity and (ii) promote those materials with the greatest potential to reduce costs in the short term. These two items combine and multiply in one type of CSP plant—the central receiver tower (CR), which is considered as having the highest cost reduction potential. Cost reduction potential comes from the fact that it is the type of CSP that can more efficiently produce large amounts of high-temperature (high-quality) heat [7]. The first CSP power plants built around the world did not have any storage to provide flexibility of operation, while nowadays it is very difficult to find CSP power plants without molten salt tanks able to store consistent quantities of energy (until 18 h of storage capacity). Considering the last 20 projects put in operation worldwide, 16 of them have storage capacity [12].

In any case, currently, only around 450 MW out of the 6155 MW CSP capacity in operation are towers with molten-salt thermal energy storage (TES) technology [11]. Regarding the type of technology, parabolic troughs (PTs) are the most used in Europe, being the most mature and the first to be installed in the first decade of the 21st century (45 plants out of 51). Worldwide, the tendency includes more CR and linear fresnel (LF), especially in the USA, where four out of five recent plants constructed are CR, and in China, where five out of eight operating projects are CR [11].

On economic terms, the CR levelized cost of electricity (LCOE) is lower than other CSP technologies, giving it better possibilities to achieve the cost-related target from the SET Plan [8]. Therefore, CSP towers are becoming the preferred option for many CSP plant promoters.

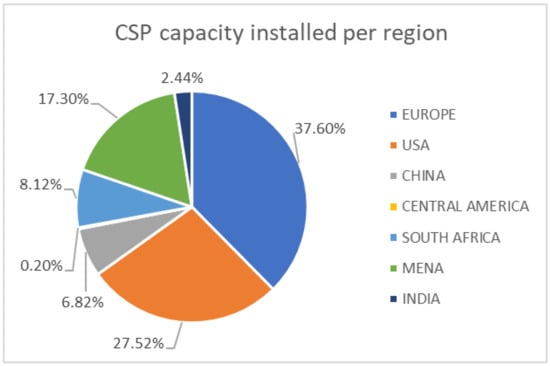

In terms of geographical localization, of the seven regions analyzed, the EU is the one with the highest capacity installed (2314 MW), where Spain is the leading country, with almost the totality in the south of the country, as depicted in Figure 2. Greece and Cyprus have given approval for their first CSP projects, the MINOS 50 MW project to be located in Crete and the Eos Green Energy CSP project (50 MW) to be implemented in southern Cyprus [13,14]. Both projects will make use of tower technology in combination with molten salt storage.

Figure 2.

CSP capacity installed per region. Own analysis.

Europe is followed by the USA (1694 MW) and the MENA region (1065 MW). This last one, together with South Africa (500 MW) and China (420 MW) are the regions that have the highest number of new projects in operation in the last two years (16 out of 18 projects worldwide from 2018) [11]. In 2019, the new CSP capacity was installed outside of Spain and the United States with Israel leading the market, followed by China, South Africa, Kuwait and France [15]. Furthermore, China will surely assume the role of leader in CSP plants in the future because it currently has seven projects under construction (for a total of 414 MW of capacity) and one more under development (a 100 MW thermal oil PT with molten salts to be installed in Guliang). In Dubai, the Noor Energy power plants under construction will increase the MENA CSP capacity of 700 MW in 2021. Chile and Australia are becoming new players with the Cerro Dominador plant in Atacama (110 MW CR with MS) and the Aurora Solar project, which is expected to reach 150 MW of capacity with a solar power plant coupled with molten-salt storage technology [11].

2. Economic Considerations of Grid-Connected CSP Towers and the Business Opportunity for Thermal Energy Storage

According to the IEA Sustainable Development Scenarios (SDS) [10], CSP electricity generation should increase annually by 26% through 2030, to reach a value of 183.8 TWh. Nowadays, the total production worldwide is just of 11.9 TWh. Even if 2018 has been the second year with the largest addition of CSP capacity since 2013, with 600 MW installed [11], the growth rhythm is still too slow to catch the sustainability goals imposed by the Paris Conference of Parties (COP 21).

CR systems are highly suitable for Europe’s “sun belt” (e.g., Spain, Italy and Greece), with the potential of providing a considerable amount of renewable and clean electric energy. According to ESTELA, the estimation of the installed capacity of solar thermal energy (therefore including both electricity and heat production) in southern Europe in 2050 will be 120 GW, based on the existing technologies [16]. The European solar industry is working on developing better components and thermal cycles, leading to more efficient technologies; therefore, the long-term estimations will probably be revised upward. The first generation of commercial CSP tower projects using molten salt technology have been operational for many years now. However, failed projects such as the Crescent Dunes project, the first large-scale CR project with molten salt storage in the USA, where technical problems prevented the plant from delivering according to expectations, impacted investor confidence in CSP [14,17]. With the learnings and experiences and technology maturation, the costs for building the second generation of CSP tower plants were reduced, and plants now operate more efficiently.

With investor’s tendency to favor PV and wind deployments, it is important to mention the importance of energy storage systems in the robustness and stability of the future grid, which, when introduced into the equation, will allow CSP to become competitive with PV and wind.

It is well-known that by increasing the fraction of RES in the European power grid, the electricity price will be subject to higher fluctuations and periods of very low, even negative electricity prices will become longer and more frequent. This is simply due to the fact that during high wind power generation and/or high PV output, conventional fossil-fired power plant operators prefer to pay and stay connected to the grid instead of shutting down the plant (as a complete shutdown and restart would imply higher costs). Storage systems are therefore necessary and, in different geographical contexts, solar PV and/or wind power are being combined with CSP and TES capacity in innovative hybrid plants to decrease production costs and increase energy generation. Nowadays, in different regions of the world, renewables are the lowest-cost source of new power generation. Onshore wind and solar PV can consistently offer a cheaper source of new electricity projects, compared to the lowest cost fossil fuel alternative, not considering any financial aid [18]. The cost of electricity from CSP has declined 26% year-on-year since 2018, the highest cost reduction of all renewable energy sources. With an LCOE of 0.066 €/kWh, CSP is at the low end of the fossil fuel cost range and in the same cost range as offshore wind [7,10], [18]. Nevertheless, it should be remembered that CSP has an important competitive advantage on the other renewable energies, since the increased penetration of non-dispatchable RES reduces the grid flexibility and increases the need for systems that allow to decouple weather-driven generation from demand. By adding thermal-to-electricity storage to CSP plants, new business opportunities arise for CSP with TES to offer such services to the network operators. If the LCOE of PV power plants and onshore wind farms would incorporate an additional storage system with large scale batteries, it would result that the CSP with the LCOE of TES would be lower, because the thermal storage in CSP plants is already considered in the LCOE of CSPs [16]. At the end of 2019, an estimated 21 GWh of TES operated together with CSP plants [19].

This TES capacity optimum is a compromise with the objective to collect as much energy as possible during the summer months (when CSP production is higher than the demand) but at the same time limiting total investment of the TES system, such that less solar production in winter months (TES never fully charged) does not jeopardize the LCOE. The TES capacity optimum differs between each type of plant. Current CSP plants have between 4 and 18 h of storage. When plants require shorter TES times, such as one hour of storage of the 20% of the nominal plant capacity as required by the Portuguese second solar auction, CSP cannot compete with solar PV with battery storage [20].

Thus, in any CSP plant with TES, there is significant TES capacity available, especially during the winter months. The CSP plant can store cheap off-peak electricity and sell it later during peak times, increasing its economic viability. Around 5.5% of the CSP plants in operation worldwide (i.e., 45.1% of the total installed capacity) are connected to TES systems and 95.6% of them (i.e., 99.8% of the total installed capacity) use liquid sensible heat storage elements due to their reliability, low cost and simple operation [21]. Research on alternative energy storage techniques such as solid particle energy storage or thermochemical energy storage show that the cost of storage can be reduced while maintaining storage effectiveness and thermal efficiency [22,23]. As reported in Section 1, of the total CSP projects under various stages of development in 2019, 95.8% of the upcoming capacity has storage. The trend for the under-development of CSP capacity is to increase the number of hours, where 63% have storage of 10 to 13 hours, compared to active plants where only 5% have over 10 h storage [24].

Another approach to fairly compare CSP plants with other renewable and conventional power plants is to consider different indicators, such as the levelized avoided cost of electricity (LACE). The LACE represents the potential cost of providing electricity to the grid through a new power plant project, and it is calculated as the weighted average cost of the marginal cost of electricity dispatch [25]. In order to make the right calculations, LACE takes into account different territorial indicators, such as daily and seasonal variation in demand, the existing grid mix generation, the heat produced, the fuel cost and the ability to dispatch on-demand power [26]. In simple terms, since the avoided cost can be seen as the potential revenues of the candidate project and the LCOE as the cost to produce electricity, if the LACE is higher than the LCOE, the related plant is considered as economically attractive. Thanks to the fact the LACE considers many different local and dispatchable parameters to calculate its final value, if considered when comparing CSP plants to other options, it can boost the CSP option among the others (especially when the thermal/electrical storage is included in the analysis) [27].

To foster this implementation of new CSP, one of the most promising and applicable solutions is the hybridization of CSP and PV power plants. While large scale batteries coupled with renewable energy power plants only have few hours of storage capacity, the TES of a CSP plant can reach up to 18 h of high-quality thermal storage, depending on the size of the tanks [9,28,29,30]. Furthermore, the heat can be stored at a fraction of the cost of electrical batteries and can be dispatched in the form of electricity via turbine or direct heat whenever is needed, avoiding PV curtailment and improving water savings [29]. This concept, called “sector coupling”, needs to be taken into account when feasibility analysis of integrated storage systems for renewable energies are performed. Being an innovative concept based on mature and validated technologies, ways to substantially reactivate the commercial deployment of CSP should be incorporated in the solutions [29,31]. Hybrid CSP-PV plants are cost-effective, sustainable and based on proven technologies, so much that the Noor Energy I facility project, which counts on a hybrid 700 MW CSP using tower technology and a 250 MW PV plant, witnessed a new world record of LCOE at 0.066 €/kWh (0.0073 USD/kWh) [18].

3. High Temperature Concentrating Solar Heat for Industrial Applications

CSP can be used to provide energy and/or process heat to industries. Many industries require heat for their production processes. Current solar heat generators for industrial processes focus on industries using low to medium temperatures, up to 400 °C. Typical processes suitable for the integration of solar heat are the drying of food or products, cleaning, fermentation, and steam generation.

The very-high-temperature solar plant opens the way for using concentrating solar heat (CSH) also for high-temperature industrial processes or for the pre-heating phase of very-high-temperature processes. Examples of high-temperature industrial processes (300 °C to 700 °C) are distillation, nitrate melting or forced air drying. Examples of very-high temperature processes (>700 °C) are chemical processing and material transformation processes as used in the cement, steel, or glass industry. All these industries are confronted with increasing costs for fossil fuels and emission rights and an increasing pressure from stakeholders and society to reduce their greenhouse gas (GHG) emissions.

CSH is already used for low to medium temperature processes with the most developed market being the district heating market. The use of CSH for industrial processes continues to be a growing niche market worldwide. At least 741 solar heat systems for industry, totaling a 662,648 m2 collector area (567 MWth), were in operation at the end of the year 2018 globally [32].

The next paragraphs describe the most promising areas for using CSP or CSH in industrial applications and applicable business models.

3.1. Steel, Chemical and Cement Industries

CSP energy-intensive industries, such as steel, chemicals and cement, are key to Europe’s economy, but they account for 20% of the EU’s greenhouse gas emissions. For example, making steel accounts for around 8% of global CO2 emissions, according to the World Steel Association [33]. To reduce its emissions by 80 to 95% by 2050, the European steel sector will need around 400 TWh/year of CO2-free electricity. Of this, about 230 TWh would be used to produce around 5.5 million tons of hydrogen to replace fossil fuels [34]. One of the eleven proposed focus areas for the European Green Deal Call is “Industry for a clean and circular economy” [35]. The research mission in this area is to close the carbon cycle in industry, reducing CO2 emissions through renewable-energy-driven innovative catalytic materials and technologies. What these heavy industries have in common is that they require permanent, steady, very high temperatures for their production processes. The majority of the process heat in these industries is currently being produced using coal, oil and natural gas. When considering applying concentrated solar technologies for these heavy industries, the capital costs and integration in existing production processes should be considered carefully. Investments in kilns are typically for 20 to 50 years. This calls for two types of solutions containing solar technologies: retrofit solutions for existing installations that are not end-of-life and solutions for newly built factories.

3.2. Desalination

A growing world population with an increasing demand for clean drinking water and a global shift towards a carbon-neutral world boosts the demand for solar desalination plants. The World Bank affirmed it is urgently important that the desalination industry makes efforts to shift away from polluting energy sources. Driven by the geographical coincidence of consistent water scarcity and high direct normal irradiation (DNI) potential, CSP-driven desalination shows a great capability to tackle water insufficiency. Since CSP can generate both electricity and thermal energy, it is an excellent candidate to drastically improve desalination services [36]. One project that could be a gamechanger for solar-powered desalination is NEOM, a metropolis under development in Saudi Arabia which will be 33 times the size of New York City [37]. NEOM has selected Britain’s Solar Water Plc to provide their solar-enhanced greenhouse technology but it can open the way for other CSP-based desalination solutions. In order to promote the efficiency of desalination procedures through the use of solar thermal plants, indicators such as the levelized cost of water (LCOW) and the levelized avoided cost of water (LACW) can be used. The LCOW is a twin indicator of LCOE while the LACW is a twin indicator of LACE, but both are focused on the cost of water (€/m3). There are different studies that highlight the importance of taking into account LACW and LCOW in thermal desalination plants [38,39,40,41]. The capital expenditure to build a CSP plant is seen as the major obstacle for coupling it with desalination plants, according to Alhaj et al. [38]. In this simulation study, based on a previous literature review, the LCOW varies from $0.94/m3 to $4.31/m3, considering different technology combinations (e.g., use of a natural gas boiler coupled with the CSP plant to increase the operating hours and therefore decrease the LCOW). Mata-Torres et al. analyzed the potential combination of PV and existing CSP, together with a Multi-Effect Distillation (MED) plant for the mining industry, correlating the size of the plant as a function of the LCOW, obtaining optimal configurations depending on different parameters (thermal energy storage hours, PV and MED capacity) [39]. Caceres Gonzalez et al. [40] concluded that a CSP supercritical CO2 recompression Brayton cycle with MED can potentially approach $1.25/m3 for the LCOW, affirming that the studied solar-desalination can compete with fossil-based alternatives. A slightly higher value for the LCOW, equal to $1.48/m3, was the objective to achieve for Cekirge et al. [41] in their study on solar desalination plants, specifically focused on central towers. To support the initial hypothesis, this study utilized an alternative approach based on the modified levelized cost of water (MLCOW), a modified methodology to assess the cost of the water, considering the capital expenditure (CAPEX) and operating expenditure (OPEX) after the payback period of the CSP plant. The conclusion is based on the fact that, using minor- or zero-interest rates compared to the current market conditions, LCOW and MLCOW will be lower, shortening the payback period and empowering the use of CSP CT for desalination purposes.

3.3. Green Hydrogen Production Plants

Being one of the most critical industrial processes of the near future, applicable to different industry segments (e.g., district heating, energy storage, power generation), hydrogen generation is becoming of high interest in the energy sector. Nowadays, the hydrogen generation technologies are used for the production of ammonia and methanol, as well as for different on-site oil refining processes. Hydrogen produced with the use of renewable energies is expected to play a key role in the decarbonization of the aforementioned sectors, in which the alternatives are more expensive or more polluting. While currently hydrogen uses are limited, for it to make a significant contribution to the energy transition, it also needs to be adopted in fields where it is not common at the moment, such as transportation, building and electricity production [42].

Currently, hydrogen is mainly produced using natural gas, with a process that generates significant CO2 emissions. This type of hydrogen is known as “grey”. A cleaner version is “blue” hydrogen, for which the carbon emissions are captured and stored; this is being considered as an intermediate solution. The cleanest form of hydrogen production is “green” hydrogen, which is produced by renewable energy sources, avoiding carbon emissions during the process. Different techniques exist to produce green hydrogen. In thermochemical water-splitting cycles, high-temperature heat is used to drive a series of chemical reactions that produce hydrogen. One such cycle is the so-called hybrid sulfur cycle or Westinghouse cycle, consisting of two steps using high-temperature heat to reduce sulfuric acid and electrolysis to oxidize SO2, restoring the original oxidation state of the cycle. Another method for producing green hydrogen is the use of photolytic processes where light energy is used to split water into hydrogen and oxygen. Today, the most promising and well-developed method for producing green hydrogen is water electrolysis, where H2O molecules are decomposed into separate hydrogen and oxygen gases using renewable energy.

There are three main parameters to take into account for the economic viability of hydrogen generation from renewables: the electrolyzer capital expenditure, the LCOE of the used electricity and the number of operating hours (load factor) on a yearly basis [43]. Next to these parameters, the efficiency of the electrolyzer and energy utilization factor impact the competitiveness of green hydrogen production compared to grey hydrogen production. Proton membrane electrolyzers (PEM), which can operate more flexibly and reactively than alkaline electrolyzers, are approaching technical maturity and economies of scale. PEM electrolyzers allow flexible operation to obtain additional revenues from different electricity markets without sacrificing available production capacity [44]. CSP with storage could, in combination with PV solar, provide the clean energy needed to create green hydrogen.

New initiatives in the steel industry focus on using green hydrogen for the replacement of natural gas as the primary fuel source and to make the use of cokes in the production process redundant. Swedish company HYBRIT announced in August 2020 that it started test-operations at a pilot “fossil-free” steel manufacturing plant [45]. In the same period, Germany’s largest steelmaker, Thyssenkrupp, revealed plans to create a factory able to produce carbon neutral steel by using green hydrogen instead of coal [33]. Both companies expect to have the first fossil-free steel on the market by 2026 but expect prices to be 20 to 30% higher because of the high energy costs for hydrogen production.

3.4. Business Models for CSP in Industrial Appliances

Three different models for financing solar power plants can be distinguished.

- Purchasing model: The solar energy provider acts as a contractor and is responsible for the design, dimensioning and installation of the solar energy generator. The solar energy generator is installed on the premises of the industrial customer. The client pays for the installation upon delivery and thus carries the initial investment.

- Rent/lease model: To avoid high upfront investments, industries can decide to rent or lease a solar power plant. In the lease model, the customer obtains the solar power plant on lease from a financing partner by agreeing for a down payment and an agreed lease rental for a fixed period. Leasing does not lead to an increase in liability as the asset stays off the balance sheet of customers. At the end of the lease period, the customer has the option to purchase the investment at the residual value and enjoy free solar power for the remaining lifetime of the plant. In the case of mobile solar power plants, a rental model is also possible. This would allow for maximum flexibility for the client and easy adaptation of the customer’s local energy generation capacity when demand is changing.

- PPA/HPA model: A new financial instrument that would reduce the risk for businesses of adopting a CSH-based solution for their industrial processes is the heat purchase agreement (HPA). The idea of the HPA is similar to the power purchase agreement (PPA) which was introduced to create a level playing field for renewable energy providers. The long-term PPAs protect buyers and sellers from fluctuating energy prices. “With HPAs, utility-scale solar heat producers could set up large CSH utilities and sell heat to multiple smaller firms clustered in industrial parks”, stated World Bank energy consultant Elena Cuadros in an interview with SolarPACES [46]. This would reduce the need for businesses to make capital costs and would give the heat producer a stable revenue stream over the longer term.

4. Materials, the Technological Challenge for CSP Uptake

4.1. Materials for Focal Point Receivers

One of the main concerns regarding the efficiency of CSP is the performance of the materials used to manufacture all the different components of the power plant (receiver, storage system, heat exchangers, etc.) [23]. In fact, to reach temperatures up to 900 °C, the receiver should be manufactured to accomplish a high absorption of solar radiation (and this can be done through selective coatings) but at the same time minimizes the thermal losses [47,48]. In general, working at such a high temperature is a challenge for all the materials involved in the thermodynamic cycle. The R&D of innovative CSP plants is often focused on the creation of materials that can work and maintain at elevated temperatures, needed for high efficiency of the cycle. Composite materials can, for example, help to improve the energy conversion in the heat exchangers, and they can help to develop new mechanically tough and highly thermally conductive ceramic receivers [48,49].

Another innovation for improving the performance of the CSP materials is to use specific coatings and surface treatments to improve emissivity and thermomechanical properties, such as the use of plasmonic technology based on nanoparticles and the integration of metal-oxide coating by sol-gel deposition on the solar receiver [47,49]. The state-of-the-art tower receivers are usually coated with a high sunlight absorptivity layer (Pyromark 2500, around 40€/l) [50], directly applied on the receiver tubes. Up to now, there is no commercially available process to deposit high-temperature stable absorbers on central receivers, and these have to be recoated every few years with a strong investment. Aluminum nitride (AlN) as a protective coating in extreme environments could be used in its polycrystalline form because R&D projects have demonstrated its low fabrication cost [51]. The infiltration of SiC matrix lattices through high-temperature chemical vapor deposition is an innovation oriented towards all those applications in high-temperature conditions (transfer knowledge to pressure/temperature sensors market) [52].

4.2. Heat Transfer Fluids (HTFs)

An additional important matter is related to the thermal energy storage materials: usually the heat transfer fluid is molten salts or, more rarely, synthetic oil [28]. To increase the working temperature of the energy storage application, new materials, for example, liquid metals (sodium or lead), currently used in nuclear reactors [31], are being investigated to prove the validity of heat transfer fluids that can work with temperatures up to 900 °C [21]. Zarza et al. [53] stated in their study that an improvement in HTF and storage solution can lead to a reduction in the LCOE of 2.3% in central tower CSP plants. Previous experiences with liquid metals in CT plants showed that using liquid sodium as a cooler can lower the cost of the thermal storage, piping and pumps because of the potential smaller tank size to have the same energy density [21,54]. Liquid lead is safer than other liquid metals that react fast with air and has competitive advantages compared to molten salt for storage purposes (higher energy storage density and 50% lower cost) [54]. The parametric analysis of these studies showed that the optimal results would be achieved at a high temperature compared to the set one, but because of a lack of qualified materials that work at the optimal temperature, the HTF’s temperature is usually reduced.

4.3. Materials for Heat Transfer Fluid and Energy Storage Containers

In parallel with innovative heat transfer fluids, the testing of materials with good corrosion resistance, minor oxidation and better self-healing properties than reference commercial ones are currently ongoing [55]. This is the case for some alloys, such as the FeCrAl steels, materials whose properties can be useful for the lead-cooled fast reactor (LFR) community, creating a knowledge transfer that can speed up the technology’s development. In any case, on the energy storage side, the use of lead as an HTF requires innovations in the field of advanced steels. According to Weinstein et al. [56], aluminum-coated steels show good compatibility with liquid lead, and this affinity is studied in other publications [57,58]. Innovative FeCrAl-alloy corrosion-creep-resistant steels for high-temperature thermal storage using liquid lead at 750° allow minor oxidation and better self-healing properties than reference commercial steels, obtaining as a plus a raw material reduction [58]. The FeCrAl alloy is used to manufacture the composite tubes. FeCrAls, ferritic alumina-forming steels, are the only viable solution to date to be used in CSP plants using lead or lead alloys as an HTF, because at the moment, there are no other solutions on the market that can operate in molten lead at elevated temperatures that at the same time have high creep strength [59]. The oxidation resistance is excellent for those steels but the mechanical integrity at 1000 to 1300 °C (creep) is weak. Therefore, an oxygen-dispersed strengthening (ODS) grade is needed [38]. At the moment, there is only one commercial ODS-FeCrAl, Kanthal APMT, which is available in different tube sizes [60,61].

4.4. Materials Outlook

In order to achieve the desired performance, each cited material should be validated through tests that are usually expensive to make, especially when these materials have to be applied on real-sized pilot sites [62]. To partially solve this problem, advanced laboratory tests that properly simulate the real conditions of high-temperature environments are constantly improving. Furthermore, to physically test the materials that will be further implemented in CSP design, innovative testing procedures are being implemented. For example, X-ray tomography helps to observe whether damage has developed or not in the microstructure at the predicted locations in the analyzed material. This process helps organizations who are designing high-performance ceramic absorbers. The research in the solar thermal field is focused on X-ray tomography to analyze the deformation and damage that innovative materials have after being tested [63,64,65,66]. Observing the subsurface microstructure without destructive sectioning and the introduction of damage avoids performing destructive tests on the materials to adjust the microstructure parameters.

As for CSP purposes, the studied materials can work for other different applications related to high temperatures (e.g., nuclear reactors).

5. Policy Enablers for CSP

In Section 2, Section 3 and Section 4, different economic and technological enablers for a wider CSP inclusion in the energy sector have been described, focusing on the industrial applications. Nevertheless, CSP plants face political and legislative barriers that can block their development. The clarity and availability of policy instruments is seen as the fundamental driver to support the development of solar thermal energy applications and CSP by many insiders and professionals [63,66]. In this section, examples of currently available policy instruments are:

- Feed in tariffs: premium/tariff/payment for newly installed renewable energy sources.

- Net metering: the sales of excess electricity generated by solar systems from households and commercial establishments to the grid.

- Investment tax credits: a percentage of the investments on solar projects, businesses or individuals are allowed to deduct from their taxes.

- Subsidies: a direct monetary aid supplied by a government to a private industrial actor.

- Financing facilitation: financial services such as a renewable energy financing portfolio, low-interest loans or micro-credits, offered by financial institutes to businesses and/or individuals.

- Renewable energy portfolio: penetration targets for renewable energy in the overall electricity supply mix.

- Public investment: government and/or donor-funded projects to support solar energy.

- Government mandates and regulatory provisions: government laws and regulations supporting transmission companies and electricity utilities to supply or purchase electricity generated from renewable energy plants.

According to the REN21 Policy Database [19], the number of countries with renewable energy policies has grown from 90 in 2010 to 143 in 2019, while 166 countries had targets for renewable power production at the end of the same year. The impact of such instruments can be significant, as shown by the abandoning of the so-called ‘sun tax’ in Spain which was introduced in 2015 to tax the installation of PVs and self-consumption. In October 2018, the Spanish government approved a Royal Decree that set the new rules in this area, encouraging collective self-consumption and establishing a simplified mechanism for self-produced and unconsumed energy compensation [67]. As a result, Spain became Europe’s largest solar market in 2019 [68].

Climate change mitigation policies and related activities help support renewable energy development by establishing the phasing out from fossil fuels, increasing their costs compared to renewable energies to reduce or eliminate any greenhouse gas emissions. Examples such as carbon pricing and emissions trading schemes are supporting the creation of climate change policies too [69]. The EU’s Clean Energy for All Europeans legislation that passed in 2019 supports solar and energy storage and targets 32% renewable electricity production by 2030. Some member states have set an even more ambitious target, such as Spain, who committed to an economy-wide renewable energy target of 42% of final energy consumption by 2030, or Denmark, who has set a target of 50% renewable energy in 2030 and 100% renewable energy in 2050 [70]. With the announcement of the European Green Deal, the European Commission expressed its ambition to make Europe the world’s first carbon-neutral continent by 2050, creating a favorable climate for all solar applications [31,34].

6. Barriers, Obstacles and Framework Conditions

All new technologies, especially renewable energies, can face different barriers in order to be developed in a structured and well-functioning energy system. Although utilities, which appreciate the CSP dispatchability, are really glad to give it access to the grid [3,9,71,72], planning and permitting processes can be slow in many countries since authorities are familiar with PV and other renewables but not with CSP [73]. This issue has delayed grid access as well as permissions or access to water or gas networks for many CSP plants. Furthermore, previous to permit confirmation, the related environmental impacts must be analyzed, taking into account the loss of animal habitat, water use, visual impacts and the effects on endangered species. In fact, the pace of the permitting process has been one of the most frequent problems for CSP installation [74]. Apart from the bureaucratic concerns, some of the barriers facing the CSP industry are included in the following subsections.

6.1. Political

The competitiveness of CSP technology is highly related to local solar resources [75]. Thus, at the EU level, CSP generation needs to be supported in Europe’s sun belt (south of Spain, Italy and Greece) with the opportunity to export electricity to other EU countries. The future achievements of CSP depend on suitable countries, producers and consumers sharing a common vision of a sustainable future. According to ESTELA [31], the problem is political: the LCOE should not be considered as the only important parameter to compare different renewable energies. Other factors, such as the added flexibility that CSP provides and the reduction in CO2 and GHG emissions, the hidden externalized costs should also be considered when comparing the possible technologies to be installed for power generation to offer support in a way that does not discriminate against CSP. Similar to the MLCAW approach explained in Section 3.2, Cekirge et al. suggest using the modified levelized cost of electricity (MLCOE) and the modified levelized avoidable cost of electricity (MLACE) [76], taking into account a CAPEX equal to zero after the payback period of the CSP plant, leading to zero fuel costs and enhancing the competitiveness of CSP plants compared to the alternatives.

According to [73], one of the major challenges for the sector are the political and economic uncertainties of the most invested countries, which can lead to the instability of renewable energy policies and the eventual exit of large CSP players, slowing down the deployment of research in the field. Furthermore, according to IEA data [77], the total value of global fossil fuel consumption subsidies in 2018 was $400 billion, with oil as the most heavily subsidized energy carrier, which represents more than double the estimated subsidies to renewables and is a key barrier to the transition to a clean energy system which includes the CSP sector.

6.2. Economic

CSP capacity development does not depend only on its LCOE, but on other renewable energies too. If solar PV and wind energy become even cheaper than today’s levels, CSP would probably no longer represent an effective alternative for electricity production, considering the IRENA data [18]. Molten-salt central receiver plants report LCOE values between 10.2 c€/kWh (Cerro Dominador) and 0.66 €/kWh (Dewa CSP complex) depending on many different factors [18,31]. Alternative indicators such as the MLCOE, the LACE and the MLACE could be taken into account for a fairer comparison between renewable alternatives [25,27,76]. Even the cost of storing electricity with large-scale batteries will be an indicator for the future development of CSP installations [21]. If it is high, alternative solutions to store energy (such as stored heat that can be converted to electricity) can take their portion of the market. Although the dispatchability of CSP would justify elevated costs with respect to non-dispatchable RES, it is not yet seen as fundamental by energy investors. Other specific economic constraints regard: (i) the destructive testing methods, seen as a waste of money and materials from the industrial partners, which is restraining the growth of the material testing market; (ii) the costs of designing and constructing a solar furnace suitable for high and very high temperatures are massive compared to concentrated solar heat (CSH) installations for low- and mid-temperature processes; (iii) CSH for high-temperature processes requires a tower-based collector and the use of resistant materials, which requires a higher initial investment compared to collector technologies such as concentrated dish, parabolic trough or linear Fresnel collectors [78].

6.3. Social

CSP technology is not generally known to the public. Solar-energy-based power generation is typically perceived as photovoltaic power generation [79]. Thus, the great potential of thermal energy storage, and hence, the dispatchable nature of CSP is not sufficiently present in the public opinion [31].

Due to the COVID-19 crisis, global energy demand declined by 3.8% in the first quarter of 2020, especially in Europe and North America, considering the confinement measures enforced in March. Although renewable energy has been the energy source most resilient to COVID-19 lockdown measures, it is expected that the growth of renewables would be smaller than anticipated before the COVID-19 crisis [80].

A good example of the lack of investor confidence comes from the Crescent Dunes tower plant in Nevada, which was the first CSP tower plant using molten-salt storage in the USA. The plant lost its only customer, NV Energy Inc., which cited the plant’s lack of reliability. The plant opened in 2015 but could not compete with the increased efficiency of cheap solar panels and was shut down in April 2019. Financers invested $140 million in the plant and the US government offered loan guarantees with a total value of $737 million [14,17].

Various studies have demonstrated the barrier represented by the not-in-my-backyard (NIMBY) syndrome for the deployment of large-scale renewable energy installations [81,82].

6.4. Technological

Currently, commercial molten-salt tower plants are experiencing many technological challenges (durability issues of the receivers and TES tanks, non-optimal solar flux control, limited heliostat calibration possibilities), which result in lower electricity production, and hence, lower productivity compared to the expected ones [20,21]. The technological challenges more related to the R&D of new materials for CSP that we already depicted in Section 3 are:

- Coating treatments and their high costs, difficulties in the scalability of synthesis, and durability at high temperatures in oxidizing environments. Presently, employing glass-ceramic and organic interlayers can be applied just on SiC-based materials [47].

- Lead as the fluid to use for thermal storage has good characteristics, including good stability and a high boiling point, but it also has a lower thermal conductivity and is more corrosive and more expensive than sodium [21].

- Testing and certification schemes are an obstacle in the replacement of old but functional materials in exchange for innovative and better performing ones. To convince companies of the long term goodness of the innovative solutions available at the R&D stage is a challenge that can be overcome with innovative fast-testing procedures and by making the testing certification easier. An alternative is to include in the provider contracts warranties related to the materials used [51].

- Difficulties in manufacturing large quantities of advanced materials and competition in mass volumes of low-cost products are still an obstacle for the CSP material manufacturers. Lower performances compared to those recorded in a testing environment and high costs can be unattractive for the investors [51].

The CSH technology used for very-high-temperature processes is not a conventional technology and is being considered as a business risk by industries. CSH technologies are not plug and play, and therefore, the integration with the industrial process and the conventional heating equipment requires thorough analysis in the pre-planning phase [46,83].

6.5. Environmental

Probably the most severe environmental concern is the relatively high water consumption of CSP plants [84,85,86]. Water is needed for the cleaning of the mirrors and for wet cooling of the condenser. Whereas the water consumption for the condenser can be avoided by using dry-cooling, water consumption for mirror cleaning will remain. Increasing the efficiency of the cleaning system and improved control methods, such as monitoring mirror dirtiness and advanced scheduled cleaning measures, can drastically reduce the water usage in CSP plants.

Another important environmental aspect to take into account is the land use [87]. The collector field and the tower both require a large area of land space to be made available. For example, it is estimated that a typical CSP plant requires from 5 to 10 acres of land per MW of capacity. In industrial areas, such areas are either not available or are expensive to purchase or lease [69].

6.6. Legal

CSP is a very young technology when compared to more mature RES [1]. Therefore, although the concept of CSP is very promising as it provides dispatchability (TES), it is still considerably more expensive than PV or wind power [2,3,4,5,72]. Therefore, legal incentives would be required in order to boost the deployment of CSP until economic competitiveness is reached [73]. Subsidies and incentives such as preferential loans, zero land cost and tax support are useful in decreasing the CSP plant LCOEs by almost 20% [25].

Permits and planning processes should be developed at a European level to make investors rely on the technology and to optimize the planning and schedule times of the construction processes [31].

Environmental impact assessments are of fundamental importance for gaining the trust of society [78], but they should be regulated as well as the testing measures [88]. For example, many European countries are setting stricter regulations in the use of ceramics and their workplace, because of their carcinogenic nature, which is going in the expected direction.

7. Conclusions and Recommendations

The future of CSP technology is uncertain and it will depend on the various factors described in this publication. CSP has the potential to increase its penetration in the European electricity grid mix and the use of the produced heat for industrial processes, but it faces especially technological, political and economic challenges. Table 1 provides a summary of the main enablers and obstacles for a wider development of CSP in Europe.

Table 1.

Enablers and barriers for a wider deployment of CSP in Europe.

The review of the current CSP market, focusing on solar tower technology, evidenced present and future challenges, collecting information and data from researchers in the field, manufacturers, energy agencies and all those figures’ experts in the field. This analysis gives an overview of the main barriers and drivers the CSP technology has to face to finally become a valuable asset in the electric grid of tomorrow. The main recognized advantage lies in the dispatchability available at a low cost and low environmental impact thanks to the thermal energy storage. If this competitive advantage was not recognized in the past [73], nowadays it is the main point the CSP market is leveraged on. The potential hybridization with photovoltaics is seen as a valuable and mature way to introduce more CSP capacity in the electricity production in the EU. In any case, and for every application, its LCOE must decrease to provide a substantial reason to raise the interest of the investors, and the forecasted cost reduction potential [7] is one of the highest in the renewable energies context. If policies would take into account other parameters (apart from the LCOE) and if the administrative procedures were made simpler to connect this kind of power plant to access the grid, the potential of CSP in the future would be immensely higher than the current one [26,41,76].

This review demonstrates that the most attractive markets to implement CSP plants in are for the production of green hydrogen, for desalination purposes and to create hybrid power plants with photovoltaics. Regarding the development of green hydrogen, its popularity will increase in the future, and since the electrolysis should be triggered with renewable energies, the CSP can be a valuable resource to use. An increasing request for drinkable water would push the development of clean desalination techniques, and the CSP has the requested features to be implemented in this field. The combination of PVs and CSP is seen as the most effective way to boost CSP installations, reducing the overall LCOE of the hybrid power plant without influencing the efficiency of the power produced.

The cost of planning and the complex integration raises challenges for industrial solar heat and energy projects. By adopting a modular approach and using pre-assembled plug-in systems, the costs for the design, manufacturing and installation of local solar heat generators can be reduced. Next to that, creating an industrial energy segmentation that will allow to identify any industrial customers to a fitting segment (categories) can shorten the planning time from months to a few days. For each of these segments, the optimal and most efficient configuration based on predefined KPIs can be developed. Here, it is a matter of grouping the industry into segments and categories based on different parameters, finding a representative load profile for each group. For the segmentation, the following parameters could be used: the industrial sector, location, available area for the solar collector field, total energy demand, heat demand (yearly, monthly, weekly, daily), conventional heat source (oil, gas burner etc.) and price (€/kWh), connection or possibility to connect to the district heating network, use of waste heat, heat distribution medium (hot water, steam, etc.) and temperature, types of processes and load profiles, etc.

Many different projects in the R&D stage, cited throughout this paper, are widely working on many different innovations that can help CSP technology to improve its efficiency and decrease its overall costs. New materials for the solar receiver and the thermal storage are currently tested at a laboratory level and on site. Furthermore, the focus at a regulation level, proposing to revise the current standardization measures for testing procedures is strongly taken into account (e.g., ISO 18,755—fine ceramics (advanced ceramics, advanced technical ceramics)), aiming to have a single standard to fully characterize innovative materials. CSP R&D projects can become a point of reference for experts in the field and the results achieved until now reveal that a more efficient and less costly technology is possible to develop in the next future.

Further research should be focused on analyzing the political, environmental and economic constraints for the other types of CSP power plants, namely PT and LF, to understand if the problems met for the development of solar towers are the same, or if instead it results in it being easier or harder to implement CSP projects if based on alternative technologies. This could give policy makers and investors a wider understanding of CSP technology trends. A further study could focus on describing the drivers and barriers in the most suitable regions for CSP that were not included in this study (especially MENA, China and the USA) to understand if the CSP market could have any advantages if implemented in those areas.

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 721045. This paper exclusively reflects the authors’ considerations on the treated topic. The European Commission is not responsible for any use that can be made out of the information contained in this paper.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ko, N.; Lorenz, M.; Horn, R.; Krieg, H.; Baumann, M. Sustainability Assessment of Concentrated Solar Power (CSP) Tower Plants—Integrating LCA, LCC and LCWE in One Framework. Proc. CIRP 2018, 69, 395–400. [Google Scholar] [CrossRef]

- Fernández, R.; Ortiz, C.; Chacartegui, R.; Valverde, J.; Becerra, J. Dispatchability of solar photovoltaics from thermochemical energy storage. Energy Convers. Manag. 2019, 191, 237–246. [Google Scholar] [CrossRef]

- McPherson, M.; Mehos, M.; Denholm, P. Leveraging concentrating solar power plant dispatchability: A review of the impacts of global market structures and policy. Energy Policy 2020, 139, 111335. [Google Scholar] [CrossRef]

- Dale, M. A Comparative Analysis of Energy Costs of Photovoltaic, Solar Thermal, and Wind Electricity Generation Technologies. Appl. Sci. 2013, 3, 325–337. [Google Scholar] [CrossRef]

- Awan, A.B.; Zubair, M.; Praveen, R.; Bhatti, A.R. Design and comparative analysis of photovoltaic and parabolic trough based CSP plants. Sol. Energy 2019, 183, 551–565. [Google Scholar] [CrossRef]

- Corona, B.; Miguel, G.S. Environmental analysis of a Concentrated Solar Power (CSP) plant hybridised with different fossil and renewable fuels. Fuel 2015, 145, 63–69. [Google Scholar] [CrossRef]

- European Commission, Initiative for Global Leadership in Concentrated Solar Power—Implementation Plan. 2017. Available online: https://setis.ec.europa.eu/system/files/set_plan_-_csp_initiative_implementation_plan.pdf (accessed on 19 September 2020).

- International Renewable Energy Agency (IRENA). Renewable Energy Statistics; Renewable Energy Agency: Abu Dhabi, UAE, 2019. [Google Scholar]

- Denholm, P.; Mehos, M. Enabling Greater Penetration of Solar Power via the use of CSP with Thermal Energy Storage. In Solar Energy: Application, Economics and Public Perception; Apple Academic Press: Oakland, CA, USA, 2014. [Google Scholar]

- OECD. Technology Roadmap: Concentrating Solar Power; OECD: Paris, France, 2010. [Google Scholar]

- Protermo Solar, Proyectos en el Exterior: Centrales en Operación, Construcción y en Fase de Desarrollo. Available online: https://www.protermosolar.com/proyectos-termosolares/proyectos-en-el-exterior (accessed on 18 August 2020).

- New Energy Update. CSP Today Global Tracker. Available online: http://tracker.newenergyupdate.com/tracker/projects (accessed on 18 August 2020).

- SolarPACES. SolarPACES Database. Available online: https://www.solarpaces.org/csp-technologies/csp-projects-around-the-world/ (accessed on 18 August 2020).

- Focal Line Solar Inc. Crescent Dunes Owner Files for Bankruptcy, Cyprus Starts to Build First CSP Plant. Available online: https://flsnova.com/2020/08/19/crescent-dunes-owner-files-bankruptcy-cyprus-starts-build-first-csp-plant (accessed on 11 September 2020).

- US National Renewable Energy Laboratory (NREL). Concentrating Solar Power Projects. Available online: https://solarpaces.nrel.gov (accessed on 10 June 2020).

- Crespo, L. Status of STE Industry and Markets and ESTELA’s Solar European Industry Initiative. In Proceedings of the ASTRI 2015 Symposium Cost Reduction Status of Concentrating Solar Thermal (CST) Technologies, Melbourne, VIC, Australia, 20 February 2015. [Google Scholar]

- Martin, C.; Querolo, N. A $1 Billion Solar Plant was Obsolete before It Ever Went Online. Available online: https://www.bloomberg.com/news/articles/2020-01-06/a-1-billion-solar-plant-was-obsolete-before-it-ever-went-online (accessed on 10 January 2020).

- International Renewable Energy Agency (IRENA). Renewable Power Generation Costs in 2019; Renewable Energy Agency: Abu Dhabi, UAE, 2020. [Google Scholar]

- REN 21. Renewables 2020—Global Status Report. Available online: https://www.ren21.net/gsr-2020 (accessed on 18 August 2020).

- Unknown. How Spain’s Auction Can Achieve the 5 GW of Concentrated Solar Power It Wants. Available online: https://www.evwind.es/2020/09/17/xavier-lara-on-how-spains-q4-auction-can-achieve-the-5-gw-of-concentrated-solar-power-it-wants/77226 (accessed on 23 September 2020).

- Achkari, O.; El Fadar, A. Latest developments on TES and CSP technologies—Energy and environmental issues, applications and research trends. Appl. Therm. Eng. 2020, 167. [Google Scholar] [CrossRef]

- Kerskes, H. Thermochemical Energy Storage; Elsevier: Amsterdam, The Netherlands, 2016; pp. 345–372. [Google Scholar]

- Ma, Z.; Glatzmaier, G.C.; Mehos, M. Development of Solid Particle Thermal Energy Storage for Concentrating Solar Power Plants that use Fluidized Bed Technology. Energy Proc. 2014, 49, 898–907. [Google Scholar] [CrossRef]

- GlobalData. Power Database. Available online: https://www.globaldata.com/industries-we-cover/power (accessed on 21 February 2020).

- Shen, W.; Chen, X.; Qiu, J.A.; Hayward, J.; Sayeef, S.; Osman, P.; Meng, K.; Dong, Z.Y. A comprehensive review of variable renewable energy levelized cost of electricity. Renew. Sustain. Energy Rev. 2020, 133, 110301. [Google Scholar] [CrossRef]

- Colla, M.; Ioannou, A.; Falcone, G. Critical review of competitiveness indicators for energy projects. Renew. Sustain. Energy Rev. 2020, 125, 109794. [Google Scholar] [CrossRef]

- Mulongo, N.Y.; Kholopane, P.A. An economic assessment of South African electricity supply systems. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Paris, France, 26–27 July 2018; pp. 77–85. [Google Scholar]

- Py, X.; Sadiki, N.; Olives, R.; Goetz, V.; Falcoz, Q. Therpmal energy storage for CSP (Concentrating Solar Power). EPJ Web Conf. 2017, 148, 00014. [Google Scholar] [CrossRef]

- Liu, H.; Zhai, R.; Fu, J.; Wang, Y.; Yang, Y. Optimization study of thermal-storage PV-CSP integrated system based on GA-PSO algorithm. Sol. Energy 2019, 184, 391–409. [Google Scholar] [CrossRef]

- Powell, K.M.; Rashid, K.; Ellingwood, K.; Tuttle, J.; Iverson, B.D. Hybrid concentrated solar thermal power systems: A review. Renew. Sustain. Energy Rev. 2017, 80, 215–237. [Google Scholar] [CrossRef]

- Fraunhofer Institute for Solar Energy Systems ISE. From Green Deal to Green Recovery: An Initiative of the European Solar Thermal Industry; Fraunhofer Institute for Solar Energy Systems ISE: Freiburg, Germany, 2020. [Google Scholar]

- Weiss, W.; Spörk-Dür, M. Global Market Development and Trends in 2018; AEE Institute for Sustainable Technologies: Gleisdorf, Austria, 2019. [Google Scholar]

- Reuters. Thyssenkrupp Presents Plan for Carbon Neutral Steel Plant. Available online: https://www.reuters.com/article/thyssenkrupp-steel-hydrogen-idUSL8N2FU1JN2020 (accessed on 18 August 2020).

- European-Green-Deal-Communication_en. Available online: https://ec.europa.eu/info/publications/communication-european-green-deal_en (accessed on 10 September 2020).

- Low Carbon Roadmap Pathways to a CO2-Neutral European Steel Industry. 2019. Available online: www.eurofer.eu (accessed on 8 January 2020).

- Mohammadi, K.; Saghafifar, M.; Ellingwood, K.; Powell, K. Hybrid concentrated solar power (CSP)-desalination systems: A review. Desalination 2019, 468, 114083. [Google Scholar] [CrossRef]

- HELIOCSP. Neom to Build Desal Plant with Solar Dome technology. Available online: http://helioscsp.com/neom-to-build-desal-plant-with-solar-dome-technology (accessed on 10 June 2020).

- Alhaj, M.; Al-Ghamdi, S.G. Why is powering thermal desalination with concentrated solar power expensive? Assessing economic feasibility and market commercialization barriers. Sol. Energy 2019, 189, 480–490. [Google Scholar] [CrossRef]

- Mata-Torres, C.; Escobar, R.A.; Cardemil, J.M. Techno-economic analysis of CSP+PV+MED plant: Electricity and water production for mining industry in Northern Chile. AIP Conf. Proc. 2018, 2033, 180007. [Google Scholar] [CrossRef]

- Gonzalez, R.A.C.; Zheng, Y.; Hatzell, K.B.; Hatzell, M.C. Optimizing a Cogeneration sCO2 CSP-MED Plant using Neural Networks. ACS ES&T Eng. 2021, 1, 393–403. [Google Scholar] [CrossRef]

- Cekirge, H.M.; Erturan, S.E.; Thorsen, R.S. CSP (Concentrated Solar Power)—Tower Solar Thermal Desalination Plant. Am. J. Mod. Energy 2020, 6, 51. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). The Future of Hydrogen Executive Summary and Recommendations; International Renewable Energy Agency (IRENA): Abu Dhabi, UAE, 2019. [Google Scholar]

- Gielen, D.; Taibi, E.; Miranda, R. Hydrogen: A Renewable Energy Perspective; International Renewable Energy Agency (IRENA): Abu Dhabi, UAE, 2018. [Google Scholar]

- International Renewable Energy Agency. Hydrogen from Renewable Power: Technology Outlook for the Energy Transition; International Renewable Energy Agency (IRENA): Abu Dhabi, UAE, 2018. [Google Scholar]

- Scott Carpenter. Swedish Steelmaker uses Hydrogen Instead of Coal to Make Fossil-Free Steel. Available online: https://www.forbes.com/sites/scottcarpenter/2020/08/31/swedish-steelmaker-uses-hydrogen-instead-of-coal-to-make-fossil-free-steel/#609fd33d2c8b (accessed on 18 August 2020).

- Kraemer, S. Concentrated Solar Heat Could Decarbonize Industrial Heat Globally. Available online: https://helioscsp.com/concentrated-solar-power-could-decarbonize-industrial-heat/ (accessed on 22 September 2020).

- Casalegno, V.; Balerna, S.G.E.; Balerna, L.F.E.; Ferraris, M.; Calendario, V.M. New high performance SiC-based solar receivers for CSP. In Proceedings of the EEEIC Conference, Madrid, Spain, 9–12 June 2020. [Google Scholar]

- Ho, C.K. Advances in central receivers for concentrating solar applications. Sol. Energy 2017, 152, 38–56. [Google Scholar] [CrossRef]

- Hoffschmidt, B. Receivers for Solar Tower Systems; DLR: Font Romeu, France, 2014. [Google Scholar]

- Ho, C.K.; Mahoney, A.R.; Ambrosini, A.; Bencomo, M.; Hall, A.; Lambert, T.N. Characterization of Pyromark 2500 for High-Temperature Solar Receivers. In Energy Sustainability; American Society of Mechanical Engineers: New York, NY, USA, 2012; pp. 509–518. [Google Scholar]

- Smit, S.; Sterling, R. Report on market analysis and impacts, NEXTOWER project.Partner responsible for the deliverable: R2M Solution Spain SL. Available online: https://www.h2020-nextower.eu/ (accessed on 20 October 2020).

- Chen, D.; Colas, J.; Mercier, F.; Boichot, R.; Charpentier, L.; Escape, C.; Balat-Pichelin, M.; Pons, M. High temperature properties of AlN coatings deposited by chemical vapor deposition for solar central receivers. Surf. Coatings Technol. 2019, 377, 124872. [Google Scholar] [CrossRef]

- KIC-Inno Energy. Future Renewable Energy Costs: Solar-Thermal Electricity Renewable Energies; KIC-Inno Energy: Eindhoven, The Netherlands, 2018. [Google Scholar]

- Pacio, J.; Fritsch, A.; Singer, C.; Uhlig, R. Liquid Metals as Efficient Coolants for High-intensity Point-focus Receivers: Implications to the Design and Performance of Next-generation CSP Systems. Energy Proc. 2014, 49, 647–655. [Google Scholar] [CrossRef]

- Kribus, A. Concentrated Solar Power: Components and materials. EPJ Web Conf. 2017, 148, 00009. [Google Scholar] [CrossRef]

- Weinstein, L.A.; Loomis, J.; Bhatia, B.S.; Bierman, D.M.; Wang, E.N.; Chen, G. Concentrating Solar Power. Chem. Rev. 2015, 115, 12797–12838. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.; Hwang, I.S.; Kim, J.H. Design of alumina forming FeCrAl steels for lead or lead–bismuth cooled fast reactors. J. Nucl. Mater. 2013, 441, 650–660. [Google Scholar] [CrossRef]

- Dömstedt, P.; Ejenstam, J.; Szakalos, P. High Temperature Corrosion of a Lean Alloyed FeCrAl-steel and the Effects of Impurities in Liquid Lead. In Proceedings of the EEEIC Conference, Madrid, Spain, 9–12 June 2020. [Google Scholar]

- Dömstedt, P.; Lundberg, M.; Szakalos, P. Corrosion Studies of Low-Alloyed FeCrAl Steels in Liquid Lead at 750 °C. Oxid. Met. 2019, 91, 511–524. [Google Scholar] [CrossRef]

- Li, N.; Parker, S.S.; Wood, E.S.; Nelson, A.T. Oxide Morphology of a FeCrAl Alloy, Kanthal APMT, Following Extended Aging in Air at 300–600 °C. Met. Mater. Trans. A 2018, 49, 2940–2950. [Google Scholar] [CrossRef]

- KANTHAL® APMT. Description of the Product. Available online: https://www.kanthal.com/en/products/material-datasheets/tube/kanthal-apmt (accessed on 15 June 2020).

- Coventry, J.S. Performance of a concentrating photovoltaic/thermal solar collector. Sol. Energy 2005, 78, 211–222. [Google Scholar] [CrossRef]

- Buffiere, J.-Y.; Maire, E.; Adrien, J.; Masse, J.-P.; Boller, E. In Situ Experiments with X ray Tomography: An Attractive Tool for Experimental Mechanics. Exp. Mech. 2010, 50, 289–305. [Google Scholar] [CrossRef]

- Salvo, L.; Suéry, M.; Marmottant, A.; Limodin, N.; Bernard, D. 3D imaging in material science: Application of X-ray tomography. Comptes Rendus Phys. 2010, 11, 641–649. [Google Scholar] [CrossRef]

- Salvo, L.; Cloetens, P.; Maire, E.; Zabler, S.; Blandin, J.; Buffière, J.; Ludwig, W.; Boller, E.; Bellet, D.; Josserond, C. X-ray micro-tomography an attractive characterisation technique in materials science. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2003, 200, 273–286. [Google Scholar] [CrossRef]

- Barhli, S.; Saucedo-Mora, L.; Jordan, M.; Cinar, A.; Reinhard, C.; Mostafavi, M.; Marrow, T. Synchrotron X-ray characterization of crack strain fields in polygranular graphite. Carbon 2017, 124, 357–371. [Google Scholar] [CrossRef]

- Duffield, J.S. The politics of renewable power in Spain. Eur. J. Gov. Econ. 2020, 9, 5–25. [Google Scholar] [CrossRef]

- SolarPower Europe EU Market Outlook. Available online: https://www.solarpowereurope.org/european-market-outlook-for-solar-power-2020-2024 (accessed on 22 June 2020).

- Solar Energy Industry Application (SEIA). Concentrating Solar Power. Available online: https://www.seia.org/initiatives/concentrating-solar-power (accessed on 18 August 2020).

- Office of the European Union. Clean Energy for all Europeans Energy; Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Jorgenson, J.; Denholm, P.; Mehos, M. Estimating the Value of Utility-Scale Solar Technologies in California Under a 40% Renewable Portfolio Standard; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2014. [Google Scholar]

- Mehos, M.; Turchi, C.; Jorgenson, J.; Denholm, P.; Ho, C.; Armijo, K. On the Path to SunShot: Advancing Concentrating Solar Power Technology Performance and Dispatchability; United States Department of Energy: Washington, DC, USA, 2016.

- Kiefer, C.P.; Del Río, P. Analysing the barriers and drivers to concentrating solar power in the European Union. Policy implications. J. Clean. Prod. 2020, 251, 119400. [Google Scholar] [CrossRef]

- Simsek, Y.; Watts, D.; Escobar, R. Sustainability evaluation of Concentrated Solar Power (CSP) projects under Clean Development Mechanism (CDM) by using Multi Criteria Decision Method (MCDM). Renew. Sustain. Energy Rev. 2018, 93, 421–438. [Google Scholar] [CrossRef]

- Viebahn, P.; Lechon, Y.; Trieb, F. The potential role of concentrated solar power (CSP) in Africa and Europe—A dynamic assessment of technology development, cost development and life cycle inventories until 2050. Energy Policy 2011, 39, 4420–4430. [Google Scholar] [CrossRef]

- Cekirge, H.M.; Erturan, S.E.; Thorsen, R.S. The CSP (Concentrated Solar Power) Plant with Brayton Cycle: A Third Generation CSP System. Am. J. Mod. Energy 2020, 6, 43. [Google Scholar] [CrossRef]

- Matsumura, M.W. Latest Data on Fossil-Fuel Consumption Subsidies. 2018. Available online: https://www.iea.org/weo/energysubsidies (accessed on 12 February 2020).

- Abbas, R.; Montes, M.; Rovira, A.; Martínez-Val, J. Parabolic trough collector or linear Fresnel collector? A comparison of optical features including thermal quality based on commercial solutions. Sol. Energy 2016, 124, 198–215. [Google Scholar] [CrossRef]

- Woersdorfer, J.S.; Kaus, W. Will nonowners follow pioneer consumers in the adoption of solar thermal systems? Empirical evidence for northwestern Germany. Ecol. Econ. 2011, 70, 2282–2291. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Global Energy Review The Impacts of the COVID-19 Crisis on Global Energy Demand and CO 2 Emissions; IEA: Paris, France, 2020. [Google Scholar]

- Sæþórsdóttir, A.D.; Ólafsdóttir, R. Not in my back yard or not on my playground: Residents and tourists’ attitudes towards wind turbines in Icelandic landscapes. Energy Sustain. Dev. 2020, 54, 127–138. [Google Scholar] [CrossRef]

- Bell, D.; Gray, T.; Haggett, C. The ‘Social Gap’ in Wind Farm Siting Decisions: Explanations and Policy Responses. Environ. Politi 2005, 14, 460–477. [Google Scholar] [CrossRef]

- SolarPACES. CSP Could Decarbonize Industrial Heat Globally. Available online: https://csp-eranet.eu/new/concentrated-solar-heat-could-decarbonize-industrial-heat-globally (accessed on 15 June 2020).

- Macknick, J.; Newmark, R.; Turchi, C. Operational Water Consumption and Withdrawal Factors for Electricity Generating Technologies: A Review of Existing Literature. In Proceedings of the AWRA 2011 Spring Specialty Conference: Managing Climate Change Impacts on Water Resources: Adaptation Issues, Options and Strategies, Golden, CO, USA, 18 April 2011. [Google Scholar]

- Carter, N.T.; Campbell, R.J. CRS Report for Congress Water Issues of Concentrating Solar Power (CSP) Electricity in the U.S. Southwest Specialist in Natural Resources Policy. 2009. Available online: www.crs.gov (accessed on 15 January 2020).

- Liqreina, A.; Qoaider, L. Dry cooling of concentrating solar power (CSP) plants, an economic competitive option for the desert regions of the MENA region. Sol. Energy 2014, 103, 417–424. [Google Scholar] [CrossRef]

- Klein, S.J.; Rubin, E.S. Life cycle assessment of greenhouse gas emissions, water and land use for concentrated solar power plants with different energy backup systems. Energy Policy 2013, 63, 935–950. [Google Scholar] [CrossRef]

- Sánchez, A.M. Towards the market through Standards. In Proceedings of the EEEIC Conference, Madrid, Spain, 9–12 June 2020. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).