Emission Factors for the Burning of Decking Slabs Made of Wood and Thermoplastic with a Cone Calorimeter

Abstract

1. Introduction

2. Materials and Methods

2.1. Fuel Sample

2.2. Experimental Methods

2.3. Chemical Analysis of Smoke and Emission Factors

3. Results

3.1. Mass Loss Rate (MLR)

3.2. Heat Release Rate and Smoke Production Rate

3.2.1. Heat Release Rate

3.2.2. Smoke Production Rate

3.2.3. Smoke Extinction Area

3.2.4. Heat Release Rate and Smoke Production Rate (HRR and SPR)

3.3. Gas, Aerosols, VOC and SVOC Released

3.3.1. Production Rates of Gas Species According to the Phases of Degradation and Combustion

3.3.2. Emission Factor of Gases and Aerosols According to the Different Imposed Heat Fluxes

3.3.3. Volatile Organic Compounds and Semi-Volatile Organic Compounds (VOC and SVOC)

3.3.4. Total Carbon Mass Balance

4. Discussion

- As combustion progresses, the pyrolysing layer is covered by residue layers, consisting of char and ash for the wood and calcium carbonate for the thermoplastic. This leads to incomplete combustion, which increases unburned gases such as CH4. The wooden slabs continue to burn in a smouldering phase, which is not the case for the thermoplastic. After the flameout, the latter continues to emit a small amount of gases until complete decomposition;

- For imposed heat fluxes lower than 20 kW/m2, a non-negligible release of smoke occurs during pyrolysis. However, most of the smoke is produced during the flame phase;

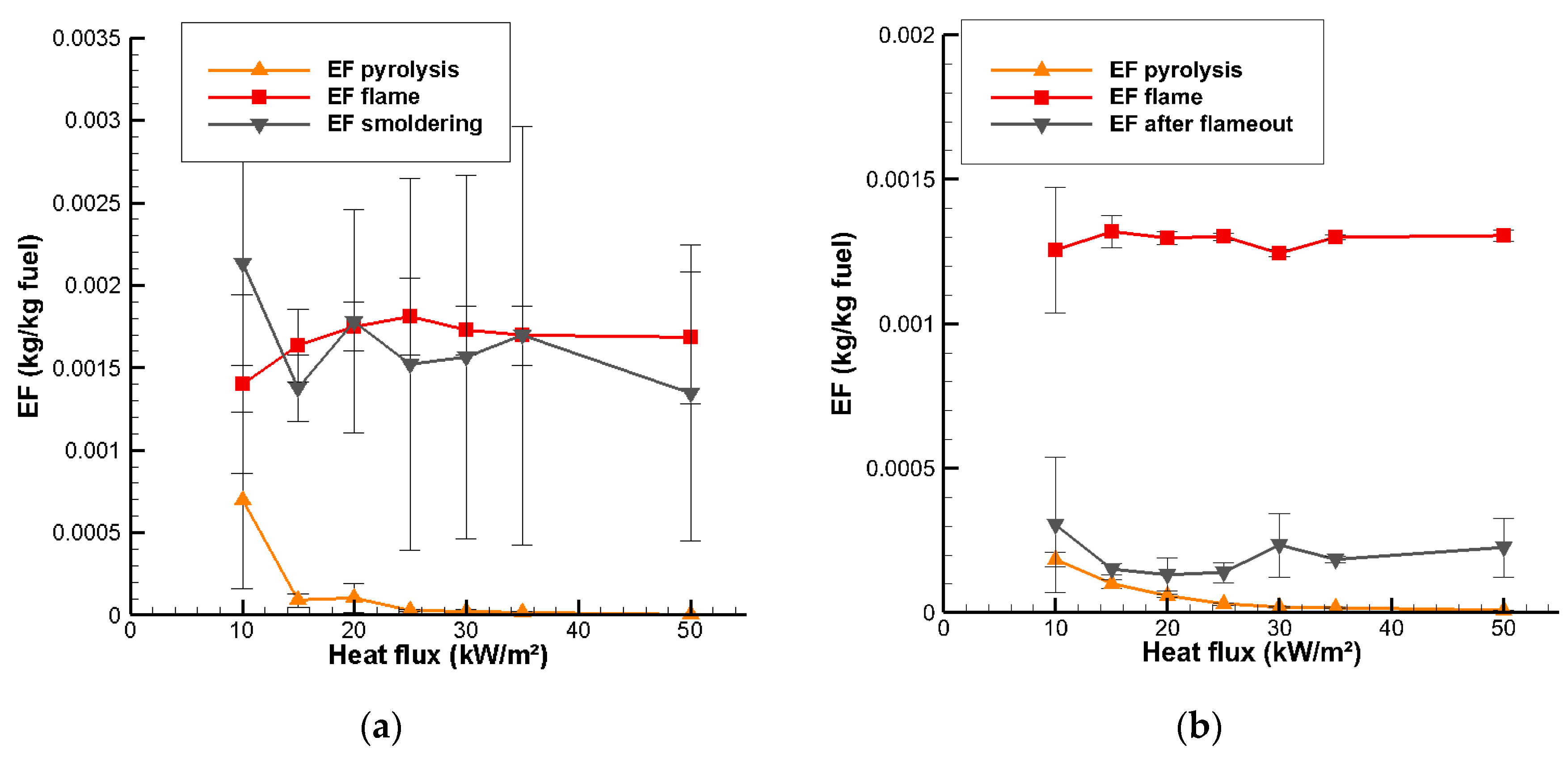

- Emission factors vary depending on the incidental heat flux, the material and the burning phase (pre-ignition, flaming, smouldering). Gas species are released with different dynamics and maximum emissions for a specific burning phase. During an actual fire, all phases of combustion are present, from the initial pyrolysis and flame phase to the smouldering phase for wood. Assessing the value of emission factors according to the phase of combustion will improve the prediction of smoke exposure for responders;

- VOCs and SVOCs have been analysed, which has quantified the main compounds as having a toxicity effect. The results found are consistent with other VOC studies conducted with different biomass fuels [22,31,43]. Wood decking releases more VOCs than thermoplastic slabs, but less HAPs, most of which are considered carcinogenic;

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | Aerosol |

| b | Burned |

| EF | Emission factor (g/kg) |

| CMB | Carbon mass balance (g/kg) |

| dry | Dry |

| EC | Elemental Carbon (µg) |

| FC | Fuel consumption (-) |

| FID | Flame ionization detector |

| FMC | Fuel moisture content on dry basis (%) |

| FTIR | Fourier transform infrared |

| HRR | Heat release rate |

| PHRR | Peak heat release rate |

| k | Light extinction coefficient (1/m) |

| m | Mass (kg) |

| ma | Aerosol mass (kg) |

| MCE | Modified combustion efficiency (-) |

| MLR | Mass loss rate (kg/s) |

| nC | Number of carbon atoms (-) |

| NMOC | Non-methane organic compounds |

| NDIR | Non-dispersive infrared |

| OC | Organic carbon (µg) |

| O2 | Oxygen |

| t | Time (s) |

| T | Temperature (K) |

| Volume flow rate in the exhaust duct (m3/s) | |

| VOC | Volatile organic compound |

| Molecular weight (kg/mol) | |

| Mass specific extinction coefficient (m2/kg) | |

| SPR | Smoke production rate |

| SEA | Specific extinction area |

| WHO | World Health Organization |

| WUI | Wildland–urban interface |

| Subscripts | |

| ign | ignition |

| flam | flaming phase |

Appendix A

| FE (kg/kg) /Flux (kW/m2) | 10 (kW/m2) | Standard Deviation | 15 (kW/m2) | Standard Deviation | 20 (kW/m2) | Standard Deviation | 25 (kW/m2) | Standard Deviation | 30 (kW/m2) | Standard Deviation | 35 (kW/m2) | Standard Deviation | 50 (kW/m2) | Standard Deviation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H2O | ||||||||||||||

| FE | 4.48 × 10−1 | 2.61 × 10−2 | 4.74 × 10−1 | 1.48 × 10−2 | 4.56 × 10−1 | 3.16 × 10−2 | 4.55 × 10−1 | 4.17 × 10−2 | 4.55 × 10−1 | 3.77 × 10−2 | 4.87 × 10−1 | 2.22 × 10−2 | 4.67 × 10−1 | 3.23 × 10−2 |

| FE pyrolysis | 2.82 × 10−2 | 2.84 × 10−2 | 5.15 × 10−3 | 3.44 × 10−3 | 1.03 × 10−2 | 7.94 × 10−3 | 3.73 × 10−3 | 2.99 × 10−3 | 4.06 × 10−3 | 3.42 × 10−3 | 2.41 × 10−3 | 9.58 × 10−4 | 6.23 × 10−4 | 4.52 × 10−4 |

| FE flame | 3.30 × 10−1 | 6.59 × 10−2 | 3.62 × 10−1 | 2.26 × 10−2 | 3.98 × 10−1 | 3.96 × 10−2 | 4.11 × 10−1 | 5.11 × 10−2 | 4.09 × 10−1 | 3.36 × 10−2 | 4.46 × 10−1 | 2.52 × 10−2 | 4.17 × 10−1 | 3.37 × 10−2 |

| FE smouldering | 9.03 × 10−2 | 6.12 × 10−2 | 1.07 × 10−1 | 3.16 × 10−2 | 4.79 × 10−2 | 3.86 × 10−2 | 4.12 × 10−2 | 2.34 × 10−2 | 4.21 × 10−2 | 2.29 × 10−2 | 3.88 × 10−2 | 1.65 × 10−2 | 4.96 × 10−2 | 7.04 × 10−3 |

| CO2 | ||||||||||||||

| FE | 1.46 × 100 | 1.79 × 10−2 | 1.48 × 100 | 5.80 × 10−2 | 1.62 × 100 | 1.92 × 10−1 | 1.69 × 100 | 1.10 × 10−1 | 1.65 × 100 | 6.47 × 10−2 | 1.62 × 100 | 5.75 × 10−2 | 1.71 × 100 | 6.55 × 10−2 |

| FE pyrolysis | 3.61 × 10−3 | 2.54 × 10−3 | 1.05 × 10−3 | 1.72 × 10−3 | 5.89 × 10−3 | 1.10 × 10−2 | 9.49 × 10−4 | 9.14 × 10−4 | 7.16 × 10−4 | 9.01 × 10−4 | 3.65 × 10−4 | 4.39 × 10−4 | 4.20 × 10−4 | 5.85 × 10−4 |

| FE flame | 1.24 × 100 | 2.49 × 10−2 | 1.28 × 100 | 1.86 × 10−2 | 1.32 × 100 | 2.37 × 10−2 | 1.40 × 100 | 3.64 × 10−2 | 1.37 × 100 | 3.29 × 10−2 | 1.36 × 100 | 7.10 × 10−3 | 1.42 × 100 | 7.32 × 10−2 |

| FE smouldering | 2.17 × 10−1 | 5.85 × 10−3 | 2.00 × 10−1 | 7.46 × 10−2 | 2.95 × 10−1 | 1.63 × 10−1 | 2.97 × 10−1 | 7.67 × 10−2 | 2.76 × 10−1 | 6.32 × 10−2 | 2.53 × 10−1 | 5.53 × 10−2 | 2.88 × 10−1 | 6.48 × 10−2 |

| CO | ||||||||||||||

| FE | 8.34 × 10−2 | 3.32 × 10−2 | 4.82 × 10−2 | 2.93 × 10−3 | 4.99 × 10−2 | 8.78 × 10−4 | 5.56 × 10−2 | 1.67 × 10−3 | 5.58 × 10−2 | 6.04 × 10−3 | 4.96 × 10−2 | 6.09 × 10−4 | 5.80 × 10−2 | 9.43 × 10−3 |

| FE pyrolysis | 3.32 × 10−3 | 4.24 × 10−3 | 2.12 × 10−4 | 3.00 × 10−4 | 5.44 × 10−4 | 6.88 × 10−4 | 8.03 × 10−6 | 7.31 × 10−6 | 4.84 × 10−6 | 4.47 × 10−6 | 5.87 × 10−7 | 6.26 × 10−7 | 0.00 × 100 | 0.00 × 100 |

| FE flame | 7.81 × 10−3 | 2.42 × 10−3 | 8.75 × 10−3 | 4.19 × 10−3 | 6.00 × 10−3 | 5.57 × 10−4 | 1.07 × 10−2 | 5.07 × 10−3 | 7.95 × 10−3 | 1.55 × 10−4 | 6.60 × 10−3 | 1.60 × 10−4 | 2.09 × 10−2 | 1.38 × 10−2 |

| FE smouldering | 7.22 × 10−2 | 3.03 × 10−2 | 3.92 × 10−2 | 6.82 × 10−3 | 4.33 × 10−2 | 3.67 × 10−4 | 4.49 × 10−2 | 6.73 × 10−3 | 4.78 × 10−2 | 5.89 × 10−3 | 4.30 × 10−2 | 4.50 × 10−4 | 3.71 × 10−2 | 4.33 × 10−3 |

| CH4 | ||||||||||||||

| FE | 4.54 × 10−3 | 9.08 × 10−4 | 3.22 × 10−3 | 2.98 × 10−4 | 2.82 × 10−3 | 2.31 × 10−4 | 2.25 × 10−3 | 2.30 × 10−4 | 1.97 × 10−3 | 3.77 × 10−4 | 1.33 × 10−3 | 1.55 × 10−4 | 7.29 × 10−4 | 2.90 × 10−4 |

| FE pyrolysis | 9.84 × 10−5 | 6.87 × 10−5 | 1.66 × 10−5 | 1.24 × 10−5 | 1.33 × 10−5 | 4.53 × 10−6 | 5.35 × 10−6 | 2.62 × 10−6 | 4.30 × 10−6 | 1.49 × 10−6 | 3.01 × 10−6 | 6.69 × 10−7 | 7.41 × 10−7 | 6.96 × 10−7 |

| FE flame | 4.25 × 10−4 | 2.93 × 10−4 | 3.91 × 10−4 | 2.63 × 10−4 | 3.05 × 10−4 | 1.43 × 10−4 | 4.41 × 10−4 | 1.62 × 10−4 | 3.25 × 10−4 | 9.48 × 10−5 | 2.64 × 10−4 | 5.56 × 10−5 | 3.69 × 10−4 | 2.96 × 10−4 |

| FE smouldering | 4.02 × 10−3 | 9.72 × 10−4 | 2.82 × 10−3 | 5.21 × 10−4 | 2.50 × 10−3 | 1.44 × 10−4 | 1.80 × 10−3 | 3.56 × 10−4 | 1.64 × 10−3 | 3.35 × 10−4 | 1.06 × 10−3 | 1.70 × 10−4 | 3.59 × 10−4 | 8.64 × 10−5 |

| NO | ||||||||||||||

| FE | 4.23 × 10−3 | 7.65 × 10−4 | 3.10 × 10−3 | 1.59 × 10−4 | 3.63 × 10−3 | 7.86 × 10−4 | 3.36 × 10−3 | 1.23 × 10−3 | 3.32 × 10−3 | 1.11 × 10−3 | 3.41 × 10−3 | 1.34 × 10−3 | 3.03 × 10−3 | 1.27 × 10−3 |

| FE pyrolysis | 6.96 × 10−4 | 5.35 × 10−4 | 8.82 × 10−5 | 4.32 × 10−5 | 1.06 × 10−4 | 8.86 × 10−5 | 2.68 × 10−5 | 6.37 × 10−6 | 2.34 × 10−5 | 1.14 × 10−5 | 1.46 × 10−5 | 5.56 × 10−6 | 5.62 × 10−6 | 2.78 × 10−6 |

| FE flame | 1.40 × 10−3 | 5.39 × 10−4 | 1.64 × 10−3 | 2.20 × 10−4 | 1.75 × 10−3 | 1.47 × 10−4 | 1.81 × 10−3 | 2.31 × 10−4 | 1.73 × 10−3 | 1.46 × 10−4 | 1.69 × 10−3 | 1.81 × 10−4 | 1.68 × 10−3 | 4.01 × 10−4 |

| FE smouldering | 2.13 × 10−3 | 6.18 × 10−4 | 1.38 × 10−3 | 2.01 × 10−4 | 1.78 × 10−3 | 6.76 × 10−4 | 1.52 × 10−3 | 1.13 × 10−3 | 1.57 × 10−3 | 1.10 × 10−3 | 1.70 × 10−3 | 1.27 × 10−3 | 1.35 × 10−3 | 8.98 × 10−4 |

| NO2 | ||||||||||||||

| FE | 1.74 × 10−4 | 1.48 × 10−4 | 2.55 × 10−5 | 3.83 × 10−5 | 8.23 × 10−5 | 1.12 × 10−4 | 1.06 × 10−4 | 1.43 × 10−4 | 6.45 × 10−7 | 6.91 × 10−7 | 2.25 × 10−7 | 2.47 × 10−7 | 2.08 × 10−7 | 3.66 × 10−7 |

| FE pyrolysis | 5.33 × 10−5 | 6.74 × 10−5 | 1.48 × 10−6 | 1.66 × 10−6 | 5.46 × 10−6 | 9.34 × 10−6 | 1.31 × 10−6 | 1.64 × 10−6 | 7.05 × 10−8 | 7.17 × 10−8 | 1.11 × 10−8 | 1.66 × 10−8 | 1.23 × 10−8 | 2.74 × 10−8 |

| FE flame | 4.83 × 10−6 | 3.18 × 10−6 | 1.30 × 10−6 | 2.44 × 10−6 | 6.12 × 10−6 | 8.30 × 10−6 | 7.77 × 10−6 | 1.05 × 10−5 | 4.74 × 10−8 | 5.86 × 10−8 | 7.87 × 10−9 | 1.31 × 10−8 | 2.65 × 10−9 | 5.93 × 10−9 |

| FE smouldering | 1.16 × 10−4 | 8.47 × 10−5 | 2.27 × 10−5 | 3.46 × 10−5 | 7.07 × 10−5 | 9.60 × 10−5 | 9.69 × 10−5 | 1.31 × 10−4 | 5.28 × 10−7 | 5.85 × 10−7 | 2.06 × 10−7 | 2.35 × 10−7 | 1.93 × 10−7 | 3.63 × 10−7 |

| C2H4 | ||||||||||||||

| FE | 4.56 × 10−4 | 1.73 × 10−4 | 2.60 × 10−4 | 9.19 × 10−5 | 3.03 × 10−4 | 1.22 × 10−4 | 3.02 × 10−4 | 1.37 × 10−4 | 2.32 × 10−4 | 4.09 × 10−5 | 2.13 × 10−4 | 2.35 × 10−5 | 2.19 × 10−4 | 1.16 × 10−4 |

| FE pyrolysis | 5.05 × 10−5 | 3.52 × 10−5 | 1.03 × 10−5 | 4.17 × 10−6 | 9.08 × 10−6 | 8.11 × 10−6 | 2.83 × 10−6 | 3.60 × 10−7 | 2.90 × 10−6 | 7.38 × 10−7 | 1.67 × 10−6 | 4.11 × 10−7 | 6.27 × 10−7 | 4.10 × 10−7 |

| FE flame | 8.93 × 10−5 | 5.71 × 10−5 | 9.56 × 10−5 | 5.33 × 10−5 | 8.82 × 10−5 | 1.51 × 10−5 | 1.09 × 10−4 | 2.56 × 10−5 | 9.23 × 10−5 | 1.76 × 10−5 | 8.57 × 10−5 | 1.89 × 10−5 | 1.26 × 10−4 | 1.08 × 10−4 |

| FE smouldering | 3.17 × 10−4 | 1.48 × 10−4 | 1.54 × 10−4 | 4.01 × 10−5 | 2.06 × 10−4 | 1.05 × 10−4 | 1.90 × 10−4 | 1.18 × 10−4 | 1.37 × 10−4 | 4.82 × 10−5 | 1.25 × 10−4 | 3.82 × 10−5 | 9.24 × 10−5 | 8.22 × 10−6 |

| SO2 | ||||||||||||||

| FE | 1.02 × 10−3 | 1.37 × 10−3 | 4.47 × 10−4 | 5.39 × 10−4 | 1.61 × 10−4 | 8.71 × 10−5 | 8.97 × 10−4 | 8.04 × 10−4 | 1.57 × 10−3 | 4.67 × 10−4 | 7.85 × 10−4 | 1.95 × 10−4 | 1.41 × 10−4 | 1.33 × 10−4 |

| FE pyrolysis | 2.07 × 10−4 | 3.98 × 10−4 | 1.61 × 10−5 | 1.69 × 10−5 | 5.79 × 10−6 | 7.21 × 10−6 | 2.10 × 10−5 | 1.92 × 10−5 | 2.20 × 10−5 | 4.58 × 10−6 | 6.86 × 10−6 | 2.63 × 10−6 | 3.71 × 10−7 | 5.06 × 10−7 |

| FE flame | 2.77 × 10−4 | 3.90 × 10−4 | 1.65 × 10−4 | 1.93 × 10−4 | 7.47 × 10−5 | 3.31 × 10−5 | 3.92 × 10−4 | 3.49 × 10−4 | 5.16 × 10−4 | 8.41 × 10−5 | 2.91 × 10−4 | 8.56 × 10−5 | 8.38 × 10−5 | 7.38 × 10−5 |

| FE smouldering | 5.33 × 10−4 | 6.27 × 10−4 | 2.66 × 10−4 | 3.34 × 10−4 | 8.08 × 10−5 | 6.54 × 10−5 | 4.83 × 10−4 | 4.38 × 10−4 | 1.04 × 10−3 | 5.15 × 10−4 | 4.87 × 10−4 | 2.14 × 10−4 | 5.73 × 10−5 | 6.04 × 10−5 |

| Aerosol | ||||||||||||||

| FE g/kg | 9.78 × 100 | 6.32 × 100 | 7.28 × 100 | 5.94 × 100 | 3.52 × 100 | 1.39 × 100 | 5.19 × 100 | 8.75 × 10−1 | 5.39 × 100 | 1.83 × 100 | 6.05 × 100 | 9.94 × 10−1 | 1.01 × 101 | 4.01 × 100 |

| FE pyrolysis | 4.70 × 100 | 4.72 × 100 | 6.58 × 10−1 | 5.14 × 10−1 | 7.63 × 10−1 | 1.28 × 100 | 8.29 × 10−2 | 4.60 × 10−2 | 9.48 × 10−2 | 6.44 × 10−2 | 6.26 × 10−2 | 2.54 × 10−2 | 3.52 × 10−2 | 2.53 × 10−2 |

| FE flame | 4.31 × 100 | 1.89 × 100 | 5.64 × 100 | 5.53 × 100 | 2.51 × 100 | 3.81 × 10−1 | 4.51 × 100 | 1.00 × 100 | 5.14 × 100 | 1.56 × 100 | 5.64 × 100 | 6.52 × 10−1 | 9.31 × 100 | 3.40 × 100 |

| FE smouldering | 7.64 × 10−1 | 6.87 × 10−1 | 9.81 × 10−1 | 8.49 × 10−1 | 2.45 × 10−1 | 5.48 × 10−1 | 5.93 × 10−1 | 1.13 × 100 | 1.61 × 10−1 | 2.18 × 10−1 | 3.48 × 10−1 | 4.29 × 10−1 | 7.37 × 10−1 | 6.59 × 10−1 |

| FE (kg/kg) /Flux (kW/m2) | 10 (kW/m2) | Standard Deviation | 15 (kW/m2) | Standard Deviation | 20 (kW/m2) | Standard Deviation | 25 (kW/m2) | Standard Deviation | 30 (kW/m2) | Standard Deviation | 35 (kW/m2) | Standard Deviation | 50 (kW/m2) | Standard Deviation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H2O | ||||||||||||||

| FE | 6.33 × 10−1 | 2.04 × 10−2 | 6.13 × 10−1 | 5.74 × 10−2 | 5.97 × 10−1 | 5.60 × 10−2 | 5.88 × 10−1 | 5.77 × 10−2 | 5.74 × 10−1 | 3.75 × 10−2 | 5.66 × 10−1 | 2.51 × 10−2 | 5.70 × 10−1 | 1.58 × 10−2 |

| FE pyrolysis | 2.90 × 10−2 | 2.39 × 10−2 | 1.19 × 10−2 | 6.42 × 10−3 | 1.06 × 10−2 | 2.40 × 10−3 | 5.99 × 10−3 | 1.39 × 10−3 | 3.36 × 10−3 | 2.02 × 10−3 | 2.96 × 10−3 | 1.25 × 10−3 | 8.89 × 10−4 | 4.80 × 10−4 |

| FE flame | 4.94 × 10−1 | 1.21 × 10−1 | 5.74 × 10−1 | 3.54 × 10−2 | 5.64 × 10−1 | 3.48 × 10−2 | 5.64 × 10−1 | 4.22 × 10−2 | 5.43 × 10−1 | 3.54 × 10−2 | 5.50 × 10−1 | 1.01 × 10−2 | 5.56 × 10−1 | 1.09 × 10−3 |

| FE smouldering | 1.10 × 10−1 | 1.45 × 10−1 | 2.71 × 10−2 | 1.58 × 10−2 | 2.30 × 10−2 | 2.45 × 10−2 | 1.80 × 10−2 | 1.57 × 10−2 | 2.70 × 10−2 | 8.40 × 10−3 | 1.29 × 10−2 | 1.41 × 10−2 | 1.30 × 10−2 | 1.55 × 10−2 |

| CO2 | ||||||||||||||

| FE | 1.74 × 100 | 2.58 × 10−2 | 1.71 × 100 | 1.34 × 10−2 | 1.75 × 100 | 3.23 × 10−2 | 1.73 × 100 | 2.69 × 10−2 | 1.72 × 100 | 1.77 × 10−3 | 1.66 × 100 | 2.14 × 10−2 | 1.59 × 100 | 6.63 × 10−3 |

| FE pyrolysis | 2.81 × 10−2 | 8.48 × 10−4 | 1.23 × 10−2 | 8.10 × 10−4 | 1.37 × 10−2 | 5.02 × 10−3 | 8.85 × 10−3 | 8.16 × 10−4 | 6.38 × 10−3 | 5.91 × 10−4 | 3.23 × 10−3 | 3.94 × 10−4 | 5.01 × 10−4 | 2.09 × 10−4 |

| FE flame | 1.66 × 100 | 2.42 × 10−2 | 1.66 × 100 | 1.18 × 10−2 | 1.68 × 100 | 1.90 × 10−2 | 1.67 × 100 | 1.86 × 10−2 | 1.63 × 100 | 2.11 × 10−2 | 1.61 × 100 | 1.80 × 10−2 | 1.56 × 100 | 2.20 × 10−3 |

| FE smouldering | 4.49 × 10−2 | 2.51 × 10−3 | 4.08 × 10−2 | 7.27 × 10−4 | 5.47 × 10−2 | 1.43 × 10−2 | 5.34 × 10−2 | 9.15 × 10−3 | 7.70 × 10−2 | 2.30 × 10−2 | 5.01 × 10−2 | 7.35 × 10−3 | 2.41 × 10−2 | 8.59 × 10−3 |

| CO | ||||||||||||||

| FE | 1.16 × 10−2 | 2.71 × 10−4 | 1.29 × 10−2 | 2.60 × 10−4 | 1.60 × 10−2 | 4.56 × 10−4 | 1.82 × 10−2 | 6.60 × 10−4 | 2.05 × 10−2 | 8.09 × 10−4 | 2.17 × 10−2 | 8.82 × 10−4 | 2.39 × 10−2 | 1.67 × 10−4 |

| FE pyrolysis | 7.45 × 10−5 | 1.77 × 10−5 | 5.89 × 10−5 | 7.62 × 10−6 | 1.96 × 10−4 | 1.50 × 10−5 | 1.07 × 10−4 | 1.94 × 10−5 | 4.98 × 10−5 | 6.41 × 10−6 | 2.16 × 10−5 | 6.06 × 10−6 | 5.02 × 10−6 | 3.82 × 10−6 |

| FE flame | 9.48 × 10−3 | 1.13 × 10−4 | 1.06 × 10−2 | 1.26 × 10−4 | 1.26 × 10−2 | 5.78 × 10−4 | 1.45 × 10−2 | 6.68 × 10−4 | 1.58 × 10−2 | 7.82 × 10−4 | 1.74 × 10−2 | 1.37 × 10−3 | 1.97 × 10−2 | 3.44 × 10−4 |

| FE smouldering | 2.03 × 10−3 | 1.41 × 10−4 | 2.24 × 10−3 | 1.27 × 10−4 | 3.17 × 10−3 | 1.11 × 10−4 | 3.66 × 10−3 | 2.11 × 10−4 | 4.68 × 10−3 | 2.98 × 10−4 | 4.33 × 10−3 | 4.83 × 10−4 | 4.24 × 10−3 | 3.58 × 10−4 |

| CH4 | ||||||||||||||

| FE | 3.29 × 10−4 | 7.36 × 10−6 | 2.93 × 10−4 | 1.49 × 10−5 | 2.13 × 10−4 | 1.06 × 10−5 | 2.55 × 10−4 | 2.48 × 10−5 | 3.26 × 10−4 | 2.70 × 10−5 | 3.62 × 10−4 | 2.47 × 10−5 | 4.54 × 10−4 | 3.33 × 10−5 |

| FE pyrolysis | 5.03 × 10−5 | 5.88 × 10−6 | 2.87 × 10−5 | 7.11 × 10−6 | 6.30 × 10−6 | 1.28 × 10−6 | 4.94 × 10−6 | 2.37 × 10−6 | 4.31 × 10−6 | 5.88 × 10−7 | 3.23 × 10−6 | 1.03 × 10−6 | 2.58 × 10−6 | 3.55 × 10−7 |

| FE flame | 1.35 × 10−4 | 3.75 × 10−5 | 1.40 × 10−4 | 6.72 × 10−6 | 1.04 × 10−4 | 1.02 × 10−5 | 1.34 × 10−4 | 1.99 × 10−5 | 1.55 × 10−4 | 9.25 × 10−6 | 2.03 × 10−4 | 4.26 × 10−5 | 2.91 × 10−4 | 1.78 × 10−5 |

| FE smouldering | 1.44 × 10−4 | 3.32 × 10−5 | 1.24 × 10−4 | 4.13 × 10−6 | 1.03 × 10−4 | 1.24 × 10−6 | 1.16 × 10−4 | 7.86 × 10−6 | 1.66 × 10−4 | 2.49 × 10−5 | 1.56 × 10−4 | 1.78 × 10−5 | 1.60 × 10−4 | 2.80 × 10−5 |

| NO | ||||||||||||||

| FE | 1.75 × 10−3 | 4.59 × 10−5 | 1.57 × 10−3 | 7.80 × 10−5 | 1.49 × 10−3 | 6.72 × 10−5 | 1.47 × 10−3 | 3.90 × 10−5 | 1.50 × 10−3 | 9.70 × 10−5 | 1.50 × 10−3 | 1.18 × 10−5 | 1.54 × 10−3 | 9.97 × 10−5 |

| FE pyrolysis | 1.86 × 10−4 | 2.51 × 10−5 | 1.01 × 10−4 | 1.54 × 10−5 | 5.94 × 10−5 | 5.67 × 10−6 | 3.12 × 10−5 | 4.08 × 10−6 | 1.97 × 10−5 | 3.30 × 10−6 | 1.72 × 10−5 | 3.34 × 10−6 | 8.09 × 10−6 | 2.18 × 10−6 |

| FE flame | 1.26 × 10−3 | 2.17 × 10−4 | 1.32 × 10−3 | 5.70 × 10−5 | 1.30 × 10−3 | 2.17 × 10−5 | 1.30 × 10−3 | 1.31 × 10−5 | 1.25 × 10−3 | 1.31 × 10−5 | 1.30 × 10−3 | 7.79 × 10−6 | 1.31 × 10−3 | 2.05 × 10−5 |

| FE smouldering | 3.04 × 10−4 | 2.35 × 10−4 | 1.52 × 10−4 | 1.89 × 10−5 | 1.33 × 10−4 | 5.68 × 10−5 | 1.40 × 10−4 | 3.48 × 10−5 | 2.34 × 10−4 | 1.10 × 10−4 | 1.84 × 10−4 | 1.14 × 10−5 | 2.26 × 10−4 | 1.02 × 10−4 |

| NO2 | ||||||||||||||

| FE | 3.58 × 10−4 | 2.42 × 10−4 | 3.70 × 10−4 | 3.19 × 10−5 | 1.32 × 10−4 | 2.52 × 10−5 | 1.16 × 10−4 | 1.02 × 10−5 | 1.56 × 10−4 | 6.19 × 10−5 | 8.54 × 10−5 | 2.03 × 10−6 | 6.70 × 10−5 | 1.70 × 10−5 |

| FE pyrolysis | 1.19 × 10−4 | 7.73 × 10−5 | 8.22 × 10−5 | 9.55 × 10−6 | 2.49 × 10−5 | 2.88 × 10−6 | 1.66 × 10−5 | 2.52 × 10−6 | 9.31 × 10−6 | 1.61 × 10−6 | 6.67 × 10−6 | 1.03 × 10−6 | 2.87 × 10−6 | 6.16 × 10−7 |

| FE flame | 1.21 × 10−4 | 9.17 × 10−5 | 1.53 × 10−4 | 8.10 × 10−6 | 5.15 × 10−5 | 1.81 × 10−6 | 4.09 × 10−5 | 3.92 × 10−6 | 3.22 × 10−5 | 1.93 × 10−6 | 1.85 × 10−5 | 2.42 × 10−6 | 7.33 × 10−6 | 2.29 × 10−6 |

| FE smouldering | 1.18 × 10−4 | 7.41 × 10−5 | 1.36 × 10−4 | 1.69 × 10−5 | 5.58 × 10−5 | 2.44 × 10−5 | 5.83 × 10−5 | 1.22 × 10−5 | 1.14 × 10−4 | 6.50 × 10−5 | 6.03 × 10−5 | 4.58 × 10−6 | 5.68 × 10−5 | 1.89 × 10−5 |

| C2H4 | ||||||||||||||

| FE | 4.31 × 10−4 | 1.51 × 10−5 | 4.27 × 10−4 | 6.35 × 10−6 | 5.28 × 10−4 | 3.29 × 10−5 | 5.66 × 10−4 | 3.25 × 10−5 | 6.74 × 10−4 | 2.97 × 10−5 | 6.84 × 10−4 | 3.69 × 10−5 | 7.12 × 10−4 | 1.94 × 10−5 |

| FE pyrolysis | 2.62 × 10−5 | 5.12 × 10−6 | 1.24 × 10−5 | 4.17 × 10−7 | 1.02 × 10−5 | 7.62 × 10−7 | 6.15 × 10−6 | 1.29 × 10−6 | 4.19 × 10−6 | 3.40 × 10−7 | 3.73 × 10−6 | 3.29 × 10−7 | 1.73 × 10−6 | 3.10 × 10−7 |

| FE flame | 1.88 × 10−4 | 9.08 × 10−5 | 2.27 × 10−4 | 8.66 × 10−6 | 2.82 × 10−4 | 3.20 × 10−5 | 2.95 × 10−4 | 2.69 × 10−5 | 3.34 × 10−4 | 3.12 × 10−5 | 3.55 × 10−4 | 4.98 × 10−5 | 4.16 × 10−4 | 4.25 × 10−5 |

| FE smouldering | 2.17 × 10−4 | 7.41 × 10−5 | 1.87 × 10−4 | 2.67 × 10−6 | 2.35 × 10−4 | 3.60 × 10−6 | 2.65 × 10−4 | 9.59 × 10−6 | 3.36 × 10−4 | 2.31 × 10−5 | 3.25 × 10−4 | 3.92 × 10−5 | 2.94 × 10−4 | 3.17 × 10−5 |

| SO2 | ||||||||||||||

| FE | 4.25 × 10−4 | 6.50 × 10−5 | 3.20 × 10−4 | 1.37 × 10−4 | 3.25 × 10−4 | 2.95 × 10−5 | 3.67 × 10−4 | 3.04 × 10−5 | 3.82 × 10−4 | 1.47 × 10−5 | 2.79 × 10−4 | 1.99 × 10−5 | 3.17 × 10−4 | 1.02 × 10−4 |

| FE pyrolysis | 6.20 × 10−5 | 1.59 × 10−5 | 2.80 × 10−5 | 2.15 × 10−5 | 2.30 × 10−5 | 4.12 × 10−6 | 1.68 × 10−5 | 1.20 × 10−6 | 7.89 × 10−6 | 2.83 × 10−6 | 5.78 × 10−6 | 7.01 × 10−7 | 2.79 × 10−6 | 1.70 × 10−6 |

| FE flame | 2.60 × 10−4 | 5.87 × 10−5 | 2.28 × 10−4 | 7.90 × 10−5 | 2.39 × 10−4 | 6.48 × 10−6 | 2.75 × 10−4 | 1.53 × 10−5 | 2.46 × 10−4 | 3.25 × 10−5 | 2.11 × 10−4 | 1.74 × 10−5 | 2.15 × 10−4 | 5.63 × 10−5 |

| FE smouldering | 1.03 × 10−4 | 5.85 × 10−5 | 6.45 × 10−5 | 3.74 × 10−5 | 6.22 × 10−5 | 2.77 × 10−5 | 7.57 × 10−5 | 1.91 × 10−5 | 1.28 × 10−4 | 4.80 × 10−5 | 6.20 × 10−5 | 2.15 × 10−6 | 9.95 × 10−5 | 5.79 × 10−5 |

| Aerosol | ||||||||||||||

| FE g/kg | 7.86 × 100 | 2.79 × 100 | 8.75 × 100 | 5.45 × 10−1 | 1.13 × 101 | 2.64 × 10−1 | 1.45 × 101 | 8.98 × 10−1 | 1.68 × 101 | 7.54 × 10−1 | 1.84 × 101 | 1.57 × 10−1 | 2.40 × 101 | 5.65 × 10−1 |

| FE pyrolysis | 9.33 × 10−1 | 1.26 × 100 | 3.63 × 10−1 | 1.72 × 10−1 | 4.21 × 10−1 | 1.77 × 10−1 | 2.29 × 10−1 | 8.19 × 10−2 | 1.52 × 10−1 | 1.17 × 10−2 | 1.22 × 10−1 | 3.84 × 10−2 | 7.69 × 10−2 | 2.62 × 10−2 |

| FE flame | 6.96 × 100 | 1.53 × 100 | 8.42 × 100 | 5.99 × 10−1 | 1.09 × 101 | 8.95 × 10−2 | 1.44 × 101 | 8.17 × 10−1 | 1.66 × 101 | 6.86 × 10−1 | 1.84 × 101 | 1.33 × 10−1 | 2.39 × 101 | 4.20 × 10−1 |

| FE smouldering | 0.00 × 100 | 0.00 × 100 | 0.00 × 100 | 0.00 × 100 | 1.00 × 10−3 | 1.73 × 10−3 | 0.00 × 100 | 0.00 × 100 | 6.74 × 10−2 | 6.11 × 10−2 | 2.06 × 10−2 | 3.56 × 10−2 | 1.10 × 10−1 | 1.86 × 10−1 |

References

- EU Wildfires Burned an Area Nearly Three Times the Size of Luxembourg. Available online: https://www.euronews.com/my-europe/2022/08/18/forest-fires-have-burned-a-record-700000-hectares-in-the-eu-this-year (accessed on 7 February 2023).

- En Corse, Une Filière Bois Peu Développée—Insee Analyses Corse—10. Available online: https://www.insee.fr/fr/statistiques/2019604 (accessed on 7 February 2023).

- What Is the WUI? Available online: https://www.usfa.fema.gov/wui/what-is-the-wui.html (accessed on 7 February 2023).

- National Interagency Coordination Center. Wildland Fire Summary and Statistics Annual Report 2020.Pdf; National Interagency Coordination Center: Boise, ID, USA, 2020; p. 8.

- International Association of Wildland Fire. Reducing the Risks of Prescribed Fire; International Association of Wildland Fire: Missoula, MT, USA, 2013. [Google Scholar]

- Wildfire and the Wildland Urban Interface (WUI). Available online: https://www.usfa.fema.gov/wui/index.html (accessed on 7 February 2023).

- Lampin-Maillet, C.; Long-Fournel, M.; Ganteaume, A.; Jappiot, M.; Ferrier, J.P. Land Cover Analysis in Wildland–Urban Interfaces According to Wildfire Risk: A Case Study in the South of France. For. Ecol. Manag. 2011, 261, 2200–2213. [Google Scholar] [CrossRef]

- Ward, D.E. Characteristic Emissions of Smoke from Prescribed Fires for Source Apportionment. In Proc Annual Meeting of the Pacific Northwest International Section; Air Pollution Control Association: Eugene, Oregon, USA, 1986; pp. 160–166. [Google Scholar]

- World Health Organization. 7 Millions De Décès Prématurés Sont Liés À La Pollution De L’air Chaque Année. Available online: https://www.who.int/fr/news/item/25-03-2014-7-million-premature-deaths-annually-linked-to-air-pollution (accessed on 24 November 2021).

- Guillaume, E. Effets Du Feu Sur Les Personnes. Synthèse Bibliographique; Laboratoire national de métrologie et d’essais (LNE): Paris, France, 2006. [Google Scholar]

- Barboni, T.; Pellizzaro, G.; Arca, B.; Chiaramonti, N.; Duce, P. Analysis and Origins of Volatile Organic Compounds Smoke from Ligno-Cellulosic Fuels. J. Anal. Appl. Pyrolysis 2010, 89, 60–65. [Google Scholar] [CrossRef]

- Miranda, A.I.; Miranda, A.I. An Integrated Numerical System to Estimate Air Quality Effects of Forest Fires. Int. J. Wildland Fire 2004, 13, 217–226. [Google Scholar] [CrossRef]

- Miranda, A.I.; Ferreira, J.; Valente, J.; Santos, P.; Amorim, J.H.; Borrego, C.; Miranda, A.I.; Ferreira, J.; Valente, J.; Santos, P.; et al. Smoke Measurements during Gestosa-2002 Experimental Field Fires. Int. J. Wildland Fire 2005, 14, 107–116. [Google Scholar] [CrossRef]

- Statheropoulos, M.; Karma, S. Complexity and Origin of the Smoke Components as Measured near the Flame-Front of a Real Forest Fire Incident: A Case Study. J. Anal. Appl. Pyrolysis 2007, 78, 430–437. [Google Scholar] [CrossRef]

- Dokas, I.; Statheropoulos, M.; Karma, S. Integration of Field Chemical Data in Initial Risk Assessment of Forest Fire Smoke. Sci. Total Environ. 2007, 376, 72–85. [Google Scholar] [CrossRef]

- Ciccioli, P.; Centritto, M.; Loreto, F. Biogenic Volatile Organic Compound Emissions from Vegetation Fires. Plant Cell Environ. 2014, 37, 1810–1825. [Google Scholar] [CrossRef]

- Aurell, J.; Hubble, D.; Gullett, B.K.; Holder, A.; Washburn, E.; Tabor, D. Characterization of Emissions from Liquid Fuel and Propane Open Burns. Fire Technol. 2017, 53, 2023–2038. [Google Scholar] [CrossRef]

- Urbanski, S.P. Combustion Efficiency and Emission Factors for Wildfire-Season Fires in Mixed Conifer Forests of the Northern Rocky Mountains, US. Atmos. Chem. Phys. 2013, 13, 7241–7262. [Google Scholar] [CrossRef]

- Soares Neto, T.G.; Carvalho, J.A.; Cortez, E.V.; Azevedo, R.G.; Oliveira, R.A.; Fidalgo, W.R.R.; Santos, J.C. Laboratory Evaluation of Amazon Forest Biomass Burning Emissions. Atmos. Environ. 2011, 45, 7455–7461. [Google Scholar] [CrossRef]

- Tihay-Felicelli, V.; Santoni, P.A.; Gerandi, G.; Barboni, T. Smoke Emissions Due to Burning of Green Waste in the Mediterranean Area: Influence of Fuel Moisture Content and Fuel Mass. Atmos. Environ. 2017, 159, 92–106. [Google Scholar] [CrossRef]

- Alves, C.A.; Gonçalves, C.; Evtyugina, M.; Pio, C.A.; Mirante, F.; Puxbaum, H. Particulate Organic Compounds Emitted from Experimental Wildland Fires in a Mediterranean Ecosystem. Atmos. Environ. 2010, 44, 2750–2759. [Google Scholar] [CrossRef]

- Evtyugina, M.; Calvo, A.I.; Nunes, T.; Alves, C.; Fernandes, A.P.; Tarelho, L.; Vicente, A.; Pio, C. VOC Emissions of Smouldering Combustion from Mediterranean Wildfires in Central Portugal. Atmos. Environ. 2013, 64, 339–348. [Google Scholar] [CrossRef]

- World Health Organization; Regional Office for Europe; Convention Task Force on the Health Aspects of Air Pollution. Health Risks of Particulate Matter from Long-Range Transboundary Air Pollution; WHO Regional Office for Europe: Copenhagen, Denmark, 2006. [Google Scholar]

- Maranghides, A.; McNamara, D.; Vihnanek, R.; Restaino, J.; Leland, C. A Case Study of a Community Affected by the Waldo Fire Event Timeline and Defensive Actions; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015.

- Babrauskas, V. Development of the Cone Calorimeter—A Bench-Scale Heat Release Rate Apparatus Based on Oxygen Consumption. Fire Mater. 1984, 8, 81–95. [Google Scholar] [CrossRef]

- Grexa, O.; Horvathova, E.; Osvald, A. Cone calorimeter studies of wood species. Proc. Korea Inst. Fire Sci. Eng. Conf. 1997, 11a, 77–84. [Google Scholar]

- Kim, J.; Lee, J.-H.; Kim, S. Estimating the Fire Behavior of Wood Flooring Using a Cone Calorimeter. J. Therm. Anal. Calorim. 2012, 110, 677–683. [Google Scholar] [CrossRef]

- Scudamore, M.J.; Briggs, P.J.; Prager, F.H. Cone Calorimetry—A Review of Tests Carried out on Plastics for the Association of Plastic Manufacturers in Europe. Fire Mater. 1991, 15, 65–84. [Google Scholar] [CrossRef]

- Cruz, M.G.; Butler, B.W.; Viegas, D.X.; Palheiro, P. Characterization of Flame Radiosity in Shrubland Fires. Combust. Flame 2011, 158, 1970–1976. [Google Scholar] [CrossRef]

- Barboni, T.; Leonelli, L.; Santoni, P.-A.; Tihay-Felicelli, V. Influence of Particle Size on the Heat Release Rate and Smoke Opacity during the Burning of Dead Cistus Leaves and Twigs. J. Fire Sci. 2017, 35, 259–283. [Google Scholar] [CrossRef]

- Andreae, M.O.; Merlet, P. Emission of Trace Gases and Aerosols from Biomass Burning. Glob. Biogeochem. Cycles 2001, 15, 955–966. [Google Scholar] [CrossRef]

- Chiaramonti, N.; Romagnoli, E.; Barboni, P.S.T. Comparison of the Thermal Degradation of Pine Species, Utilisation of Two Sizes of Calorimeter: Cone Calorimeter and LSHR. Fire Technol. 2017, 53, 741–770. [Google Scholar]

- Santoni, P.-A.; Romagnoli, E.; Chiaramonti, N.; Barboni, T. Scale Effects on the Heat Release Rate, Smoke Production Rate, and Species Yields for a Vegetation Bed. J. Fire Sci. 2015, 33, 290–319. [Google Scholar] [CrossRef]

- König, W.A.; Hochmuth, D.H.; Joulain, D. Terpenoids and Related Constituents of Essential Oils, Library of Massfinder 2.1; Institute of Organic Chemistry: Hamburg, Germany, 2001. [Google Scholar]

- Leonelli, L.; Barboni, T.; Santoni, P.A.; Quilichini, Y.; Coppalle, A. Characterization of Aerosols Emissions from the Combustion of Dead Shrub Twigs and Leaves Using a Cone Calorimeter. Fire Saf. J. 2017, 91, 800–810. [Google Scholar] [CrossRef]

- Tang, W.; Gu, X.; Jiang, Y.; Zhao, J.; Ma, W.; Jiang, P.; Zhang, S. Flammability and Thermal Behaviors of Polypropylene Composite Containing Modified Kaolinite. J. Appl. Polym. Sci. 2015, 132, 41761. [Google Scholar] [CrossRef]

- Patel, R.J.; Wang, Q. Prediction of Properties and Modeling Fire Behavior of Polyethylene Using Cone Calorimeter. J. Loss Prev. Proc. Ind. 2016, 41, 411–418. [Google Scholar] [CrossRef]

- Fateh, T.; Rogaume, T.; Luche, J.; Richard, F.; Jabouille, F. Characterization of the Thermal Decomposition of Two Kinds of Plywood with a Cone Calorimeter—FTIR Apparatus. J. Anal. Appl. Pyrolysis 2014, 107, 87–100. [Google Scholar] [CrossRef]

- Wong, S.; Hodges, J.L.; Lattimer, B.Y. Impact of Ash Layer Retention on Heat Transfer in Piles of Vegetation and Structure Firebrands. Fire Saf. J. 2022, 134, 103694. [Google Scholar] [CrossRef]

- Dietenberger, M.A.; Grexa, O. Correlation of Smoke Development in Room Tests with Cone Calorimeter Data for Wood Products. In Wood & Fire Safety, Proceedings of the 4th International Scientific Conference, Strbske Pleso, Slovak Republic, 14–19 May 2000; Forest Products Laboratory: Madison, WI, USA, 2000; pp. 45–55. [Google Scholar]

- Baan, R.; Grosse, Y.; Straif, K.; Secretan, B.; El Ghissassi, F.; Bouvard, V.; Benbrahim-Tallaa, L.; Guha, N.; Freeman, C.; Galichet, L.; et al. A Review of Human Carcinogens—Part F: Chemical Agents and Related Occupations. Lancet Oncol. 2009, 10, 1143–1144. [Google Scholar] [CrossRef]

- Neto, T.S.; Carvalho Jr, J.A.; Veras, C.A.G.; Alvarado, E.C.; Gielow, R.; Lincoln, E.N.; Christian, T.J.; Yokelson, R.J.; Santos, J.C. Biomass Consumption and CO2, CO and Main Hydrocarbon Gas Emissions in an Amazonian Forest Clearing Fire. Atmos. Environ. 2009, 43, 438–446. [Google Scholar] [CrossRef]

- Akagi, S.K.; Yokelson, R.J.; Wiedinmyer, C.; Alvarado, M.J.; Reid, J.S.; Karl, T.; Crounse, J.D.; Wennberg, P.O. Emission Factors for Open and Domestic Biomass Burning for Use in Atmospheric Models. Atmos. Chem. Phys. 2011, 11, 4039–4072. [Google Scholar] [CrossRef]

| Sample | C (%) | H (%) | O (%) | N (%) |

|---|---|---|---|---|

| Wood (pine) | 51.4 | 6.37 | 40.7 | 0.22 |

| Thermoplastic (polypropylene) | 47.4 | 7.06 | 15.7 | 0.1 |

| Wood | Thermoplastic | |

|---|---|---|

| Elemental carbon (EC) | 90.9% | 94.33% |

| Organic carbon (OC) | 9.1% | 5.66% |

| Wood | Thermoplastic | |||||

|---|---|---|---|---|---|---|

| Imposed Heat Flux (kW/m2) | PHRR (kW/m2) | tign (s) | tflam (s) | PHRR (kW/m2) | tign (s) | tflam (s) |

| 10 | 345.5 ± 83.3 | 449.5 ± 271.1 | 302.8 ± 51.7 | 435.7 ± 16.8 | 368.5 ± 31.5 | 601.2 ± 41.0 |

| 15 | 293.9 ± 38.6 | 85.6 ± 53.9 | 414.0 ± 86.3 | 486.9 ± 24.5 | 195 ± 11.4 | 587.6 ± 4.2 |

| 20 | 312.6 ± 29.4 | 67.6 ± 45.8 | 353.0 ± 24.8 | 533.2 ± 25.4 | 111 ± 5.3 | 581.6 ± 14.0 |

| 25 | 316.6 ± 17.0 | 23.6 ± 3.7 | 377.4 ± 56.3 | 562.8 ± 12.9 | 70.6 ± 4.1 | 539.0 ± 12.5 |

| 30 | 337.6 ± 21.3 | 18.4 ± 4.9 | 344.0 ± 31.5 | 562.1 ± 15.6 | 48.7 ± 2.0 | 526.7 ± 12 |

| 35 | 353.8 ± 19.4 | 12.2 ± 2.0 | 309.8 ± 11.3 | 591.0 ± 37.5 | 35.6 ± 2.6 | 496.3 ± 26.1 |

| 50 | 473.4 ± 93.0 | 6 ± 0.8 | 278.7 ± 15.9 | 701.2 ± 4.4 | 19.6 ± 0.9 | 414.3 ± 4.9 |

| N° | Compound | N° CAS | EFVOC (mg.kg−1) |

|---|---|---|---|

| 1 | Hexane (C6H14) | 110-54-3 | 64 |

| 2 | Benzene (C6H6) | 71-43-2 | 350 |

| 3 | Heptane (C7H16) | 142-82-5 | 112 |

| 4 | Toluene (C7H8) | 108-88-3 | 108 |

| 5 | Ethylbenzene (C8H10) | 100-41-4 | 42 |

| 6 | Phenylethyne (C8H6) | 536-74-3 | 125 |

| 7 | Styrene (C8H8) | 100-42-5 | 63 |

| 8 | α-Pinene (C10H16) | 80-56-8 | 88 |

| 9 | Benzaldehyde (C7H6O) | 100-52-7 | 214 |

| 10 | Benzenediethyl (C10H14) | 135-01-3 | 33 |

| 11 | p-Cymene (C10H14) | 99-87-6 | 48 |

| 12 | Limonene (C10H16) | 5989-27-5 | 138 |

| 13 | Indene (C9H8) | 95-13-6 | 93 |

| 14 | Acetophenone (C8H8O) | 98-86-2 | 133 |

| 15 | Nonanal (C9H18O) | 124-19-6 | 51 |

| 16 | Naphthalene (C10H8) | 91-20-3 | 219 |

| 17 | Decanal (C10H20O) | 112-31-2 | 44 |

| 18 | 2-Methylnaphthalene (C11H10) | 91-57-6 | 19 |

| 19 | Biphenyl (C12H10) | 92-52-4 | 22 |

| Total | 1966 |

| N° | Compound | N° CAS | EFVOC (mg.kg−1) |

|---|---|---|---|

| 1 | Benzene (C6H6) | 71-43-2 | 182 |

| 2 | 1-Heptene (C7H14) | 592-76-7 | 64 |

| 3 | Heptane (C7H16) | 142-82-5 | 36 |

| 4 | 2,4-Dimethylfuran (C6H8O) | 3710-43-8 | 63 |

| 5 | Octene (C8H16) | 111-66-0 | 72 |

| 6 | Ethylbenzene (C8H10) | 100-41-4 | 40 |

| 7 | p-Xylene (C8H10) | 106-42-3 | 99 |

| 8 | Nonane (C9H20) | 111-84-2 | 32 |

| 9 | Benzaldehyde (C7H6O) | 100-52-7 | 85 |

| 10 | Mesitylene (C9H12) | 108-67-8 | 56 |

| 11 | Undecene (C11H22) | 1002-68-2 | 108 |

| 12 | 3-Hexadecene (C16H32) | 34303-81-6 | 154 |

| 13 | Azulene (C10H8) | 275-51-4 | 87 |

| 14 | Acenaphthylene (C12H8) | 208-96-8 | 16 |

| 15 | Fluorene (C13H10) | 86-73-7 | 17 |

| 16 | Benzophenone (C13H10O) | 119-61-9 | 6 |

| 17 | Phenanthrene (C14H10) | 85-01-8 | 23 |

| Total | 1140 |

| Compounds | Carbon Mass Per Unit of Dry Fuel Burnt (gC/kg) | |

|---|---|---|

| IRND | Wood | Thermoplastic |

| CO2 (carbon monoxide) | 465.59 ± 17.87 | 433.49 ± 1.81 |

| CO (carbon dioxide) | 24.86 ± 4.04 | 7.55 ± 0.05 |

| Laser He-Ne | ||

| tars | 0.41 ± 0.16 | 0.60 ± 0.01 |

| soot | 9.17 ± 3.65 | 22.63 ± 0.53 |

| FTIR | ||

| CH4 (methane) | 0.55 ± 0.22 | 0.34 ± 0.03 |

| C3H8 (propane) | 0.78 ± 0.05 | 0.17 ± 0.04 |

| C5H12 (pentane) | 0.05 ± 0.02 | 0.04 ± 0.01 |

| C2H4 (ethene) | 0.19 ± 0.10 | 0.31 ± 0.01 |

| CH2O (formaldehyde) | 0.10 ± 0.048 | 0.03 ± 0.01 |

| C2H2 (acetylene) | 0.84 ± 0.30 | 0.65 ± 0.06 |

| Analysis by DTA/CPG-SM | ||

| Total VOC | 1.73 | 1.00 |

| Total carbon mass balance (smoke) | 504.62 ± 26.68 | 467.00 ± 2.58 |

| Carbon total (ultimate analyses) | 514.0 | 474.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinent, B.; Meerpoel-Pietri, K.; Petlitckaia, S.; Barboni, T.; Tihay-Felicelli, V.; Santoni, P.-A. Emission Factors for the Burning of Decking Slabs Made of Wood and Thermoplastic with a Cone Calorimeter. Fire 2023, 6, 162. https://doi.org/10.3390/fire6040162

Martinent B, Meerpoel-Pietri K, Petlitckaia S, Barboni T, Tihay-Felicelli V, Santoni P-A. Emission Factors for the Burning of Decking Slabs Made of Wood and Thermoplastic with a Cone Calorimeter. Fire. 2023; 6(4):162. https://doi.org/10.3390/fire6040162

Chicago/Turabian StyleMartinent, Bruno, Karina Meerpoel-Pietri, Svetlana Petlitckaia, Toussaint Barboni, Virginie Tihay-Felicelli, and Paul-Antoine Santoni. 2023. "Emission Factors for the Burning of Decking Slabs Made of Wood and Thermoplastic with a Cone Calorimeter" Fire 6, no. 4: 162. https://doi.org/10.3390/fire6040162

APA StyleMartinent, B., Meerpoel-Pietri, K., Petlitckaia, S., Barboni, T., Tihay-Felicelli, V., & Santoni, P.-A. (2023). Emission Factors for the Burning of Decking Slabs Made of Wood and Thermoplastic with a Cone Calorimeter. Fire, 6(4), 162. https://doi.org/10.3390/fire6040162