Abstract

This article presents the results of experimental studies examining the effectiveness of low-concentration nanoemulsions for enhanced oil recovery (EOR). The maximum volume concentration of diesel fuel in the emulsions did not exceed 1% by volume. The volume concentration of the emulsifier ranged from 0.05% to 0.4%. A method for preparing stable nanoemulsions was developed. The colloidal stability, viscosity, interfacial tension, wettability, and capillary imbibition rate of low-concentration nanoemulsions were studied. Filtration experiments were conducted to study oil displacement on microfluidic chips simulating a porous medium and core samples. This is the first systematic study of the properties of nanoemulsions containing diesel fuel. It was demonstrated that the developed emulsions have high potential for EOR. It was shown that increasing the emulsifier concentration reduces the contact angle from 35 to 16 degrees and halves the surface tension coefficient. Experiments studying the capillary imbibition of oil-saturated cores with nanoemulsions also confirmed their ability to reduce interfacial tension and improve rock wettability. Oil displacement efficiency during capillary imbibition increases by 22%. Filter tests on microfluidic chips and core samples confirmed the high efficiency of the developed nanoemulsions. Increasing the emulsifier concentration in the emulsion to 0.4% increases the displacement efficiency from 32% for water displacement to 57% for nanoemulsion displacement. Core tests showed that additional injection of nanoemulsions significantly increases the oil displacement efficiency by 10–14%, depending on the emulsifier concentration in the nanoemulsion. It was also established that the use of an aqueous solution of an emulsifier without a hydrocarbon phase does not provide such a significant increase in the displacement coefficient as in the emulsion composition.

1. Introduction

Hydrocarbon resources continue to play a key role in ensuring global energy security, providing stable supplies and meeting the growing global demand for energy. The global economy’s energy consumption growth trend will continue over the coming decades. According to the World Energy Outlook 2023 study [1], global energy consumption continues to show steady growth driven by fundamental factors in the development of the global economy. By 2050, the total energy supply is projected to increase by 34% under the STEPS (State Policies Scenario) and by 61% under the NZE (Net Zero Emissions Scenario). This long-term increase is due to both the growth of the world’s population and the improvement in the quality of life in developing countries, which entails an increase in demand for energy for household needs, transport and industrial production. Research works [2,3] indicate that even by 2050, demand for traditional energy sources will still be high due to population growth and the economies of developing countries, where fossil fuels remain the most affordable and reliable source of energy. Despite the increase in the share of renewable energy sources in the electric power industry, oil and gas will retain a key role in aviation, industry and petrochemicals, while coal will remain in countries with cheap resources. Infrastructure constraints and the slow transition to clean technologies are slowing the expected abandonment of hydrocarbons, especially in the context of growing global energy consumption.

Therefore, the task of increasing the energy and environmental efficiency of the extraction of traditional hydrocarbons (oil and gas) is still very relevant. Scientific research is currently underway to develop new methods for increasing oil recovery (EOR) [4,5,6]. Among the currently known ones are chemical methods that are developing most intensively. They are based on flooding the reservoir with solutions of chemical reagents to improve wetting, reduce interfacial tension (IFT) or diminish the coefficient of mobility. The most common of these methods is the injection of aqueous solutions of surfactants, polymers, and alkalis [7,8,9,10].

A relatively new approach to increase EOR, which is currently being intensively investigated, consists of the use of nanoemulsions [11,12,13]. Nanoemulsions (NE) are not strictly defined but are often referred to as emulsions containing droplets of the hydrocarbon phase in water up to 1000 nm in size. However, in our opinion, it is more correct to attribute the term “nanoemulsions” only to dispersed systems with a droplet size of about or less than 100 nm. Sometimes NE are also called ultrafine emulsions or mini-emulsions. A characteristic feature of NE is kinetic stability.

In recent years, the number of studies on the use of nanoemulsions in the oil industry has increased significantly [14,15]. NE with their unique properties have become a promising technology for industrial applications. These unique properties, including the nanometer size of droplets capable of penetrating the pores of low-permeability rocks, low IFT, wettability variation, and high stability, contribute to the use of nanoemulsions in the oil industry.

Reservoir water is used as a dispersion medium in the NE to increase EOR. Various hydrocarbons are applied as the dispersed phase: mineral oils, fuel oil, liquid paraffin, crude oil, and even industrial vegetable oils. The volume concentration of the hydrocarbon phase (HC) in emulsions can reach tens of vol.% [11,12,13,14,15].

Nanoemulsions can contribute to the increase in both residual and heavy oil due to various mechanisms. These are reducing IFT to areas with low or ultra-low one, changing the wettability of the rock, enhancing the coefficient of mobility either by increasing the viscosity of the displacing phase and/or reducing the viscosity of the displaced phase and the effect of wedging pressure.

Oil reservoirs have a heterogeneous composition of minerals that affect the wetting properties of rocks and ultimately affect the displacement of oil. The wettability of the rock surface can vary from oil wettability (oleophilicity), intermediate wettability to water wettability (hydrophilicity). Changing the wettability is the most important process in most methods of increasing EOR. It is generally assumed that during nanoemulsion flooding, NE droplets will easily penetrate into the pores of the rock and adsorb on their walls, changing the wettability [16]. When the nanoemulsion is injected, interactions of the ion pair and electron polarization occur between the adsorbed hydrocarbon phase on the rock surface and the surfactant molecules present in the aqueous phase [17,18]. This leads to an increase in the rate of capillary impregnation of NE into a porous medium and, accordingly, the displacement of oil. Here it is the very small size of the NE droplets that is very important, since it ensures penetration even into submicron channels and cracks in the rock, changing the wettability and removing capillary trapped oil.

In addition to wetting, the nanoemulsion, as noted in many studies, have rheological characteristics favorable for increasing EOR [19]. It is noted that nanoemulsions can exhibit non-Newtonian properties and have high effective viscosity, especially at high concentrations. For this reason, the injection of such nanoemulsions reduces the coefficient of mobility of the displacing liquid and, consequently, increases the area and efficiency of the pore space coverage. In some cases, polymers, which additionally stabilize the emulsion, are introduced into nanoemulsions to enhance the rheological properties [20,21]. Thus, the efficiency of oil extraction is improved by reducing IFT and increasing viscosity. The work [19] investigated the use of stable oil-in-water nanoemulsions with Tween 40 surfactants and low-viscosity mineral oil to increase EOR. The oil content in the emulsion was 5%. The size of nanoemulsion droplets was 18–31 nm. Nanoemulsions exhibited non-Newtonian properties and low IFT. The results of filtration studies on core samples have shown that injection of nanoemulsion allows extracting extra 29% of oil.

In addition to surfactants and polymers, nanoparticles of various compositions have recently been added to nanoemulsions. Firstly, nanoparticles provide additional stabilization of the nanoemulsion (the Pickering effect), and secondly, new synergistic effects from the combination of nanoparticles and nanodrops are observed to increase EOR [18,22,23]. In particular, it has been shown that nanoparticle-stabilized nanoemulsions can also reduce oil adsorption on rock surfaces by creating a wedging force between the oil and the rock surface. In [24], an experimental study on the effectiveness of nanoemulsion with various combinations of additives of ZrO2 nanoparticles was conducted. Nanoemulsions were prepared with Xylene as a dispersed phase and Triton X-100 as an emulsifier. The injection with nanoemulsion was found to lead to higher values of the recovery factor compared with injection of nanosuspensions with nanoparticles. However, in general, the combined dispersed system allows increasing the ORF by 40–107% compared to water. Similar results were obtained in [16], also examining nanoemulsions, modified with 10 nm silicon oxide nanoparticles with 10% wt.% n-heptane as a dispersed phase, stabilized with 2% Tween 40 emulsifier. As a result, it has been shown that the use of nanoemulsion allows increasing the ORF during flooding by 26.40%, and the use of nanoparticle-modified nanoemulsion provides an increase of 34.94%.

A brief literature review reveals that, despite numerous recent studies on nanoemulsion properties, further research into their application for EOR is still required. Despite the active study of nanoemulsions for enhanced oil recovery, questions regarding the synergistic contribution of individual mechanisms (viscosity, interfacial tension, and wettability) to overall displacement efficiency remain unclear. In particular, there are no systematic studies quantitatively linking emulsifier concentration to nanoemulsion stability and its ability to modify wettability, alter capillary pressure, and influence displacement efficiency. Most existing studies are limited to studying rheological properties and macroscopic displacement characteristics, without a detailed analysis of microscopic mechanisms. These studies should primarily focus on optimizing nanoemulsion composition and developing strategies to reduce the concentration of expensive components while maintaining high displacement efficiency. An example of this kind of research can be found in our recent works [25,26].

For the first time, this study provides a comprehensive evaluation of the performance of low-concentration nanoemulsions, utilizing diesel as the dispersed phase, for (EOR) applications. The colloidal stability, viscosity, interfacial tension, wettability, and capillary impregnation rate of low-concentration nanoemulsions are studied, and filtration experiments are conducted to study oil displacement on microfluidic chips simulating a porous medium and core samples. Such a study of the properties of nanoemulsions has been performed for the first time.

The main hypothesis of the study is that diesel-based nanoemulsions can significantly enhance oil recovery through the synergistic effect of reducing interfacial tension and specifically altering rock wettability. The scientific novelty of the study lies in establishing the relationship between emulsifier concentration, nanoemulsion stability, and oil displacement efficiency under conditions simulating reservoir conditions. The key objective was to quantitatively assess the contribution of individual mechanisms to overall enhanced oil recovery.

2. Emulsion Preparation Protocol

Nanoemulsions for reservoir flooding were synthesized using distilled water as the dispersion medium. Diesel fuel (DF) with a viscosity of 3.5 mPa s and a density of 830.1 kg/m3 was used as the dispersed phase; the quality of diesel fuel complies with GOST 32511—2013 (EN 590:2009) [27]. To form stable emulsion systems, we employed the commercially available emulsifier PC-501, a mixture of ethoxylated surfactants (alkyl phenols and alcohols) with 5% solvent (water) (manufactured by NPO Reagents Siberia (Tomsk, Russia). The emulsifier content was varied from 0.05% to 0.4% by volume to investigate its effect on the rheological and oil-displacing properties of the formulations. A key feature of the methodology was the use of emulsions with an ultra-low concentration of the hydrocarbon phase, set at 1 vol.% for the base case. This approach aims to minimize hydrocarbon consumption while maintaining high displacement efficiency. The selection of these low concentrations was driven by the research objective of determining the threshold values that ensure both emulsion stability and oil-displacement efficacy.

The preparation of stable nanoemulsions was achieved via two methods. The first, based on a previously established procedure, begins with the formation of a coarse dispersion. This is followed by the slow, dropwise co-addition of the hydrocarbon phase and emulsifier under continuous mechanical stirring. The process was performed using an OFITE 152-18-Prince Castle high-speed mixer (Houston, TX, USA). at 20,000 rpm for 60 min, followed by ultrasonic treatment using a Volna-M disperser (U-sonik, Biysk, Russia). (22 kHz, 400 W) for 30 min under strict temperature control. While this method, with appropriate selection of emulsifier type and dosage, yielded stable nanoemulsions, it had significant drawbacks: intensive foaming and splashing of the emulsion during mixing, the requirement for a minimum sample volume of 250 mL, and overall process complexity.

To optimize the procedure, an alternative method was developed. It utilizes mechanical dispersion with a high-speed IKA stator-rotor type disperser (IKA, Staufen, Germany), and the duration of the subsequent ultrasonic treatment was reduced to 15 min. The effectiveness of this modified technique is confirmed by achieving comparable emulsion stability with a significant reduction in processing time and reagent volumes.

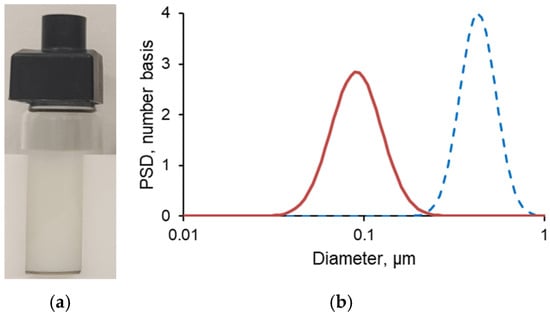

Figure 1a shows a representative emulsion system containing 1 vol.% hydrocarbon phase and 0.1 vol.% emulsifier, demonstrating visual homogeneity and stability. To quantitatively assess dispersion, acoustic spectroscopy was performed using a DT1202 analyzer (Dispersion Technologies, New York, NY, USA). This technique is based on measuring the attenuation of an ultrasonic signal as it propagates through a dispersed system. It is advantageous for analyzing concentrated and optically opaque media, as it eliminates the need for sample dilution, which can alter the initial particle size distribution.

Figure 1.

Diesel emulsion (a) and its droplet size distribution (PSD) (b). Solid line: with emulsifier; dashed line: without emulsifier.

Emulsions based on 1% diesel in water, both without emulsifier and with 0.1% emulsifier, were studied. Analysis of the ultrasound attenuation spectra enabled the calculation of the droplet size distribution functions for both systems. As shown in Figure 1b, the average droplet size of the hydrocarbon phase in the system without emulsifier was 420 nm. In contrast, the addition of 0.1% emulsifier resulted in a significant reduction in the average droplet size to 90 nm. This order-of-magnitude decrease in droplet size confirms the efficacy of the emulsifier in stabilizing the interface and suppressing coalescence. This factor is critical for ensuring the stability of the emulsion system and for forming the rheological properties that determine oil displacement efficiency in a porous medium.

3. Research Results for Emulsion Properties

3.1. Investigating the Stability of Emulsions

The experimental phase of this work focused on optimizing the formulation of stable, low-concentration emulsions. A series of tests was performed to assess emulsion stability and identify the emulsifier content that ensures maximum colloidal stability of the dispersed system. The destabilization kinetics of the formulated emulsions were analyzed using a Turbiscan LAB stability analyzer. Turbiscan LAB is capable of detecting very small changes. A signal change of ±0.1–0.2% is often considered the threshold for significance.

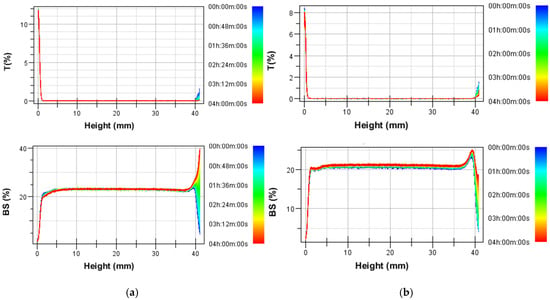

Emulsion stability studies were conducted to determine the optimal emulsifier content. A base dispersion system of 1 vol.% diesel in distilled water was used for this purpose. Figure 2 presents exemplary transmission and backscattering profiles for emulsifier concentrations of 0.05 and 0.2 vol.%. The transmission and backscattering profiles for these emulsions remained relatively stable over time. The profiles demonstrated the highest temporal stability at an emulsifier content of 0.2%. Visually, all studied emulsions appeared stable, as no significant changes compared to the initial state (Day 1) were observed during long-term storage, and the overall homogeneity of all samples was maintained.

Figure 2.

Transmission and backscattering profiles for emulsions with 1 vol.% diesel with 0.05 (a) and 0.2 vol.% (b) emulsifier.

The thermodynamic Stability Index (TSI), an integral parameter, was used to quantify the kinetics of coalescence in the emulsion systems. This index is a key metric in multiple light scattering analysis. It is calculated by mathematically integrating the differences in the light transmission or backscattering profiles over the entire height of the sample cell between two points in time. The absolute TSI value directly correlates with the intensity of sedimentation, creaming, and coalescence processes. Consequently, a lower TSI value over a given time interval indicates higher colloidal stability of the dispersed system.

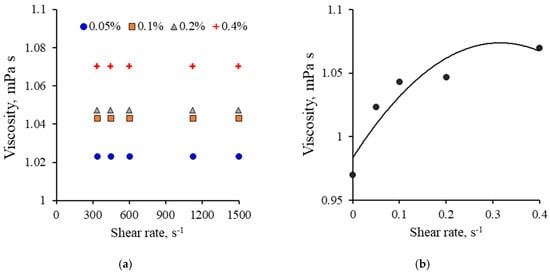

In this study, a series of experiments was conducted to monitor the change in TSI over time for emulsion samples with varying emulsifier concentrations. The resulting kinetic curves clearly demonstrate the influence of emulsifier content on the system’s destabilization rate. Analysis of the data presented in Figure 3 allows for the determination of the optimal stabilizer concentration that ensures maximum stability, as well as the identification of general patterns governing the destabilization process for this system.

Figure 3.

The effect of emulsifier concentration on the stability index TSI, (a) over time and (b) after 4 h.

The minimum of the emulsifier concentrations considered had practically no effect compared to the base emulsion; the stratification occurred monotonously with lightening at the bottom of the vial and the uniformity throughout the volume changed slightly, but more noticeably compared to the concentrations of 0.1 and 0.2 vol.%. A significant stabilizing effect was evident for emulsifier concentrations of 0.1 and 0.2 vol.% (Figure 3b), which indicates that the critical content of micelle formation is not reached at 0.05 percent of the emulsifier, i.e., the emulsifier cannot fully prevent the coalescence of droplets of the hydrocarbon phase. Since the effect is quite high at a content of 0.1 vol.%, the use of higher concentrations is impractical as leading to excessive consumption of the emulsifier.

It is obvious from Figure 3b, that the content of 0.4% has a stabilizing effect, but less impactful than the lower concentrations. This can be explained by the fact that when the critical content of micelle formation is exceeded, some of the surfactants compete at the phase interface, leading to the coalescence of phase droplets. This reduces the effectiveness of the emulsifier as a component that should increase the stability of the system.

As a result of the measurements, it has been determined that the most effective content of emulsifier is 0.1 vol.%, since it is with this amount of stabilizer that a sufficient reduction in destabilization processes is achieved. In cases of extreme points over the range of concentrations studied, the stratification processes are most intense, while even at high values of 0.4 vol.%, positive dynamics is observed to increase the stability of dispersed systems.

The analysis of the results of a series of experiments has shown that it is the ratio of the amounts of emulsifier to the HC phase rather than an increase in the emulsifier content that has the greater effect on the stability of emulsions, since excessive amounts of emulsifier may lead to the coalescence of phase droplets and accelerate the destruction of the emulsion.

3.2. Investigating the Emulsion Viscosity Coefficient

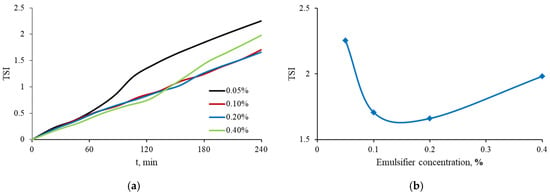

The rheological properties of the flooding fluids were investigated, with a focus on the viscosity of the synthesized nanoemulsions, as this parameter is critical for determining the efficiency of the oil displacement process under reservoir conditions.

Viscosity measurements were performed using a Brookfield rotational viscometer. This instrument operates by measuring the torque required to rotate a spindle immersed in the test fluid at a set speed. The torque is determined by the deflection of a calibrated spring, ensuring high measurement accuracy. The error in determining viscosity does not exceed 2%.

Nanoemulsions prepared with diesel (DF) and a PC-501 emulsifier were studied. The hydrocarbon phase concentration was maintained at 1 vol.% in all samples, while the emulsifier content was varied from 0.05 to 0.4 vol.% to evaluate its effect on the rheological properties. The experimental data, presented in Figure 4, reveal a key characteristic of the studied systems: their rheological behavior follows the Newtonian fluid model. This is evidenced by the constant effective viscosity, which remains independent of the shear rate across the entire range investigated. This Newtonian flow behavior indicates the absence of developed internal structures within the dispersed system and confirms the high stability of the nanoemulsions. Furthermore, the viscosity of the emulsions increases with higher emulsifier content. This trend is attributed to a reduction in droplet size and a consequent increase in the specific interfacial area as emulsifier content rises. Overall, the viscosities of the nanoemulsions were only marginally higher than that of the dispersion medium (water), with an average increase ranging from 7.5% to 9.6%.

Figure 4.

Viscosity of aqueous emulsions at different concentrations of emulsifier depending on the shear rate (a) and the viscosity coefficient dependence on the emulsifier concentration (b).

3.3. Investigating the Wetting Edge Angle and Interfacial Tension of Emulsions

The review [28] extensively discussed the issue of measuring wettability changes. Several basic wettability measurement methods are presented in the literature: contact angle measurements, spontaneous imbibition, surface imaging (scanning electron microscopy (SEM), atomic force microscopy (AFM), and nuclear magnetic resonance (NMR), and surface zeta potential measurements.

Contact angle can be used to analyze changes in surface wettability because it measures the shift in the affinity of a rock surface for one liquid to another. Contact angle measurement methods can be as simple as taking contact angle readings using photographs with a digital camera [29,30] or as complex as obtaining high-resolution images using an environmental scanning electron microscope [31]. However, there is no strictly established protocol for how to conduct contact angle measurements.

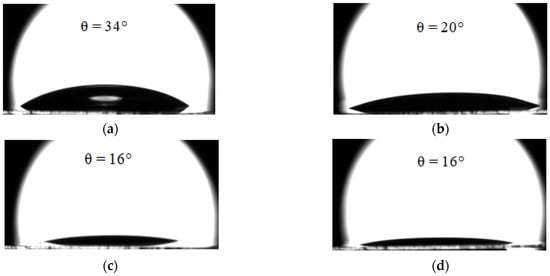

Wettability and interfacial tension measurements were performed using an IFT-820-P automated tensiometer (Temco, Inc., Minden, LA, USA), following the procedure detailed in [32]. The measurement error did not exceed ±0.2 mN/m for IFT and ±2° for contact angle. Representative droplet images are presented in Figure 5. A visual assessment clearly indicates that increasing the emulsifier content leads to a significant reduction in the contact angle on the substrate.

Figure 5.

The photos of drops of nanoemulsions with different content of emulsifier: (a) 0%, (b) 0.1%, (c) 0.2%, and (d) 0.4%.

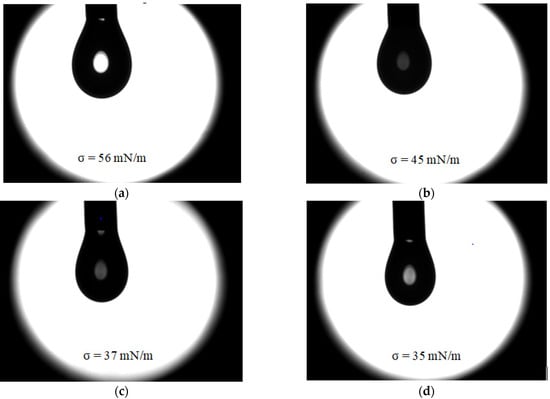

The surface tension of the studied nanoemulsions was measured by the “Pendant Drop” method. The photos is shown in Figure 6. Visualization of the drop over time corresponds to the obtained values of changes in surface tension.

Figure 6.

The photos of drops of nanoemulsions with different content of emulsifier: (a) 0%, (b) 0.1%, (c) 0.2%, and (d) 0.4% during interfacial tension measurements.

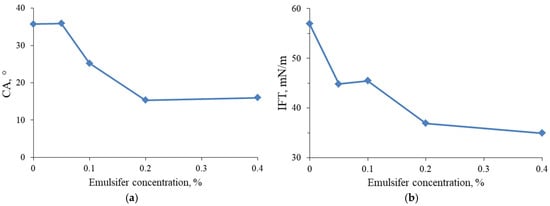

Figure 7 shows the final average values of the dependence of the surface tension coefficient and the contact angle of quartz glass plates with nanoemulsion on the emulsifier content, measured by the pending and sessile drop method. With an increase in the concentration of the emulsifier, the wettability of the emulsion is shown to improve. The wetting angle decreased from 35° to 16°, indicating a favorable shift towards water-wetting conditions that enhances oil detachment from the pore walls. Furthermore, the IFT was reduced by nearly half, which also promotes more efficient oil displacement.

Figure 7.

Effect of emulsifier concentration on (a) contact angle and (b) interfacial tension in the nanoemulsion.

Nanoemulsions can alter wettability in two ways: by surfactant molecules and by structural disjoining pressure. Surfactants in nanoemulsions can alter wettability through ion pair formation, adsorption, and micellar solubilization [33]. Another mechanism that alters wettability when using nanoemulsions is structural disjoining pressure. The concept of oil separation from a solid surface by structural disjoining pressure was first proposed in [34]. The smaller the oil droplets, the higher their concentration and structural disjoining pressure [35]; therefore, the IFT reduction effect is more pronounced. Thus, the diesel fuel nanoemulsion with the PC501 emulsifier combines both proposed IFT reduction mechanisms. Moreover, the ratio of the emulsifier and diesel fuel concentrations to the particle size of the oil phase in the emulsion determines the contribution of each mechanism to the overall enhanced oil recovery.

3.4. Investigating the Rate of Capillary Impregnation of Oil-Saturated Cores with Nanoemulsions

The objective of this article is to study the effect of the concentration of diesel and emulsifier on the rate of spontaneous displacement of oil by nanoemulsions. The spontaneous imbibition test measures the ability of a wetting phase to displace a non-wetting phase under static conditions and demonstrates the contribution of capillary and gravitational forces to wettability changes. The imbibition curve is used to interpret the wetting properties of core samples. The spontaneous imbibition rate increases with time, indicating a change in core wettability [28]. Many relevant studies of wettability change processes in enhanced oil recovery problems have been conducted using the spontaneous imbibition method [30,36].

Experiments on capillary impregnation employed emulsions prepared on the basis of water, added with diesel, with different contents of diesel and emulsifier (hereinafter EM). Based on the preliminary results of studies of the physico-chemical properties, several promising emulsion solutions were selected for considering during capillary impregnation on cores. In addition, an aqueous solution without diesel, but with the addition of 0.1% emulsifier, was considered for comparison. Table 1 provides a description and compositions of the liquids used.

Table 1.

List of displacement fluids used.

In preparation for oil displacement experiments, a comprehensive core preparation procedure was implemented. Cylindrical core plugs with a diameter of 25 mm, sourced from standard Berea sandstone blocks (Clear Birmingham Buff and Castle Gate, USA), were used as the model porous medium.

Berea Clear Birmingham Buff sandstone is a fine- to medium-grained quartz sandstone characterized by high grain sorting and roundness, resulting in isotropic flow properties. Its clay-carbonate cement influences specific interactions with reservoir fluids. The homogeneous structure of this sandstone makes it a benchmark material for studying displacement processes in high-permeability reservoirs.

Berea Castle Gate sandstone also has a quartz composition but features a more variable grain size distribution and the presence of micro-heterogeneities, making it suitable for modeling more complex reservoirs.

The use of these standardized rocks minimizes the impact of natural geological heterogeneity and ensures the comparability of results in international studies on fundamental flow processes. Core preparation included drying at 100 °C until constant mass was achieved to remove residual moisture and hydrocarbons. This was followed by precise measurement of geometric parameters, mass, and petrophysical properties (absolute porosity and gas permeability). Oil saturation was performed in a vacuum chamber for 48 h under controlled temperature and pressure. The pore volume (PV) and oil saturation level were determined gravimetrically after the process.

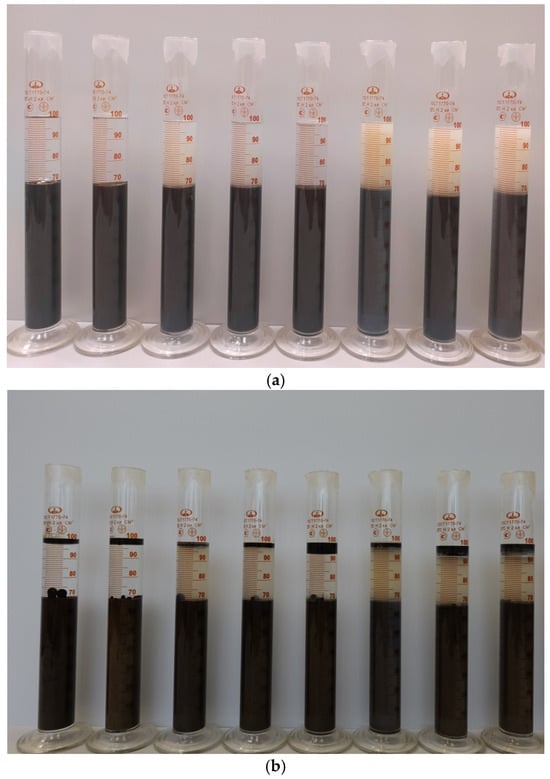

For the flooding experiments, core plugs with standardized dimensions of 2.54 cm in diameter and 15 cm in length were used. The average petrophysical properties were as follows: permeability 440 mD and porosity 21.3%. The physicochemical properties of the model oil under reservoir conditions included a viscosity of 67 mPa·s and a density of 864 kg/m3. Visual confirmation of complete saturation is provided in Figure 8.

Figure 8.

Photo of cores for the study of capillary impregnation.

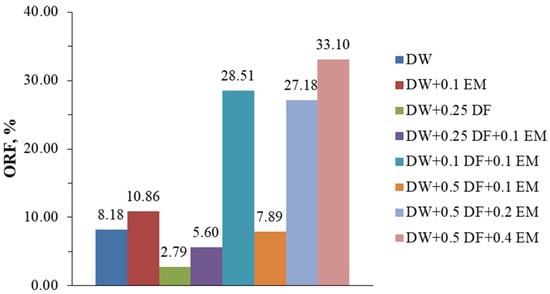

To investigate the role of capillary forces in oil displacement from the core’s pore space, a series of spontaneous imbibition experiments was conducted. The experimental procedure was as follows: a core sample, pre-saturated with oil, was immersed in the displacing fluid. Over time, capillary-driven imbibition resulted in the displacement of oil by the aqueous phase (Figure 9). The spontaneous imbibition process was visually monitored, and the volume of recovered oil was quantified. Capillary imbibition experiments are long-term (14 days) and are conducted on large individual cores, maintained at ambient temperature (25 °C) in an Amott cell. The oil recovery results from the spontaneous imbibition experiments are presented in Figure 9. Following immersion, oil droplets emerged on the core surface and subsequently migrated upwards. As shown, the cumulative oil volume recovered by the 0.5% DF + 0.4% EM and 0.5% DF + 0.2% EM nanoemulsions exceeded that of other displacing fluids. The lowest EOR was observed in the waterflooding experiment.

Figure 9.

Photographs of the oil sample displacement from the core during capillary impregnation with displacing liquids: (a) 2 h after the start of the experiment and (b) the end of the experiment.

Figure 10 presents the EOR factor for cores saturated with model oil using various displacing fluids. Capillary imbibition with water yielded an ORF of 11%. The highest ORF was achieved with diesel-based emulsifier-containing nanoemulsions, specifically reaching 33% for the 0.5% DF + 0.4% EM formulation. Thus, as a result of tests on the cores of the selected emulsion solutions, their high efficiency has been confirmed. Nanoemulsions are shown to significantly (up to 22%) increase the factor of EOR from the cores. At the same time, an increase in the content of the emulsifier in the emulsion is found to enable further increase in the ORF. With the growth of the concentration, the EOR increases monotonously. Thus, an increase in the content of emulsifier from 0.2 to 0.4% in diesel-based emulsions increases the recovery factor from 16 to 22.0%, respectively. At the same time, the use of an aqueous emulsifier solution with a content of 0.1% in an emulsion without a hydrocarbon phase increases the EOR by 4.0%. In addition, low concentrations of diesel, both with and without emulsifier, do not lead to a significant increase in the EOR as a result of capillary impregnation.

Figure 10.

ORF as a result of capillary impregnation with various displacing liquids.

The mechanism of the influence of emulsion on capillary impregnation is related to its effect on capillary pressure. Nanoemulsions can change the pore surface from oil-wet to water-wet, thereby enhancing oil displacement by spontaneous imbibition [37]. Oil is retained in the rock by capillary forces due to capillary pressure p = 2σcosθ/R, where σ is the interfacial tension, θ is the contact angle, and R is the average pore radius. As can be seen from the data in Figure 7, the nanoemulsion reduces IFT and wettability, which helps reduce capillary pressure and better displace oil during capillary impregnation.

3.5. Investigating Oil Displacement from Microfluidic Chips, Imitating Rock, Using Emulsions

This study provides the first comprehensive experimental investigation of oil displacement efficiency in a microfluidic porous medium using low-concentration diesel-based nanoemulsions. The novelty of this work lies in employing these formulations for EOR at the pore scale.

The object of study was a heavy oil, selected as a model for hard-to-recover reserves, with characteristic properties of 901.3 kg/m3 density and 79.3 mPa·s dynamic viscosity under reservoir conditions. The model porous medium was a microfluidic chip (Dolomite: 3200284) with a deterministic pore channel geometry that accurately replicates key morphological parameters of natural reservoirs, including pore space heterogeneity, a polymodal pore throat size distribution, and the presence of narrow constrictions. This platform provides a relevant physical model for screening EOR agents, as it enables the visualization and quantification of displacement mechanisms at the pore scale under controlled conditions. The microfluidic approach ensures high reproducibility of results due to precise control over the pore space geometry and experimental parameters, representing a significant advantage over the use of natural core samples.

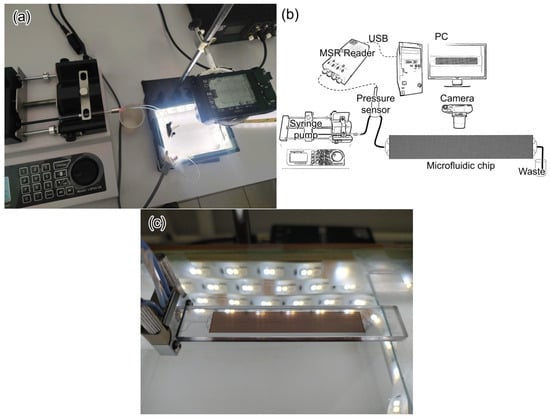

The experimental setup, schematically shown in Figure 11, comprised a suite of high-precision instruments ensuring controlled test conditions. Precise fluid delivery was achieved using a two-channel syringe pump (model LSP02-2B)(Longer Precision Pump Co., Baoding, China), which maintained a stable flow rate in the microliter-per-minute range. The injection pressure was monitored in real time by a high-precision Elveflow pressure sensor with a measurement range from −15 to 30 psi (2068.2 mbar), featuring metrological characteristics that include an accuracy of ±0.2% of the full scale and high result repeatability. All displacement experiments were performed at conducted under standard ambient conditions (atmospheric pressure, temperature 25 °C). The injections were carried out at a constant flow rate of 0.5 μL/min. Pore-scale visualization of the displacement processes was provided by a high-speed camera, which recorded the fluid dynamics and displacement fronts. A set of image analysis techniques based on color space transformation and machine vision algorithms was employed to process the experimental results, enabling quantitative evaluation of the displacement parameters with minimal error. The integrity of the flow system was verified by reference tests, which confirmed the stability of the operating parameters throughout the entire experimental series.

Figure 11.

Schematic of the experimental setup: (a) photograph of the actual equipment configuration, (b) diagram of the component connections, and (c) image of the oil-saturated microfluidic chip.

The experimental methodology, based on a previously developed and detailed protocol [18,19], was implemented as follows. The microfluidic chip was prepared by fully saturating it with the model oil to establish initial oil saturation. The chip was then mounted on a specialized backlit platform providing uniform, shadow-free illumination essential for subsequent high-resolution image analysis. The flow system was connected to the chip’s inlet port via leak-tight fittings. A calibrated pressure sensor and a 1 mL syringe filled with the displacing fluid and installed on the syringe pump were connected in series to the inlet. A critical experimental condition was maintaining a constant injection flow rate of 0.5 µL/min to ensure capillary-dominated displacement. Data acquisition from the pressure sensor and video recording were synchronized to ensure correct timing of all measured parameters for subsequent comprehensive analysis of the process dynamics.

The endpoint of each experimental run was determined based on objective criteria reflecting the conclusion of the active displacement phase. The experiment was terminated when two key conditions were met simultaneously: (1) the attainment of a plateau on the pressure curve, and (2) no observable fluid movement for at least 10 min of continuous monitoring, as confirmed by real-time analysis of the high-speed camera video stream. This approach eliminated subjectivity in determining the process completion time and ensured the comparability of results in terms of the final EOR for the entire experimental series.

The acquired video data underwent post-processing, which included decomposing the video stream into discrete frames using the FFmpeg library. The oil displacement efficiency was quantified through automated image analysis based on converting the original RGB color space to the HSV (Hue, Saturation, Value) space, which offers greater robustness to variations in lighting conditions. The analysis algorithm was implemented in the BlackBox Component Builder environment using the FreeImage computer vision library. This software package enabled accurate segmentation of the pore space, identifying areas occupied by oil and the displacing agent at each timestep. From the data obtained, the EOR was plotted against the volume of injected displacing agent, allowing for a comparative analysis of the efficiency of various nanoemulsion compositions. The accuracy of the technique was verified by calibrating the recognition system on reference images with a known phase distribution.

This work presents a comprehensive suite of flooding experiments designed to establish a correlation between the emulsifier content in nanoemulsions and the displacement efficiency of the hydrocarbon phase from a microfluidic pore space model. Filtration tests on microfluidic chips allow not only to obtain oil displacement efficiency values but also to evaluate the oil displacement process in real time, observe fluid flow in a porous medium, and observe the effects of oil washout after the breakthrough of the displacing agent and the steady-state flow regime. The use of microfluidic chips and in situ visualization of oil displacement makes it possible to elucidate, refine, and confirm the influence of the mechanisms of enhanced oil recovery by nanoemulsions at the microscopic level. The use of microfluidic chips is widely used in oil recovery studies [38,39].

The study aimed to determine the optimal formulation parameters for the displacing fluid to maximize the EOR. A baseline analysis was performed through a control experiment involving the displacement of the model oil by a conventional agent-water. This provided reference data on the displacement process and established a benchmark for an objective comparative assessment of the efficacy of the new formulations.

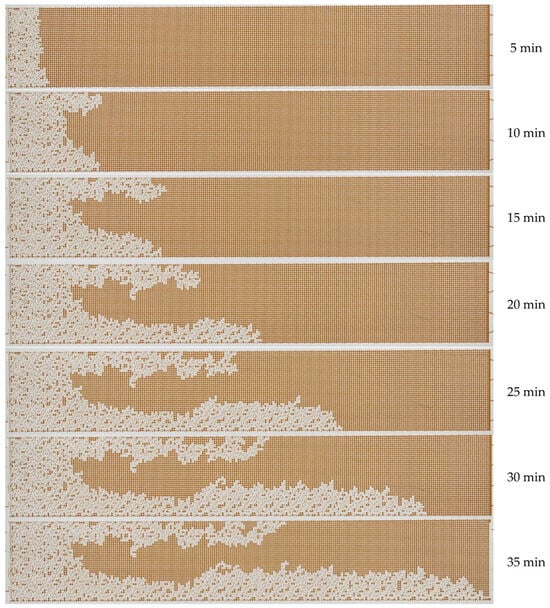

A visual analysis of the displacement kinetics is presented in Figure 12 as a series of time-lapse images showing characteristic stages of front evolution. During the initial stage of the experiment, a uniform frontal advance is observed. As the process continues, however, front instability is recorded, leading to the formation of distinct branched structures—viscous fingers. The progressive branching of these viscous fingers results in premature breakthrough of the displacing agent at the model outlet and the formation of extensive zones of capillary-trapped residual oil. A detailed analysis of the viscous finger morphology reveals two dominant development mechanisms: capillary-dominated branching at the initial stage and viscosity-dominated fingering at later stages.

Figure 12.

Visual observation results of oil displacement by an aqueous solution in a microfluidic chip.

Breakthrough of the displacing phase at the outlet occurred at approximately the 35-min mark of the experiment, after which the process dynamics did not change significantly. Subsequent displacement is characterized primarily by a droplet entrainment mechanism, involving the periodic detachment and transport of isolated residual oil droplets within the aqueous phase. However, observations indicate that this mechanism does not substantially alter the overall fluid distribution pattern or significantly reduce the volume of residual oil.

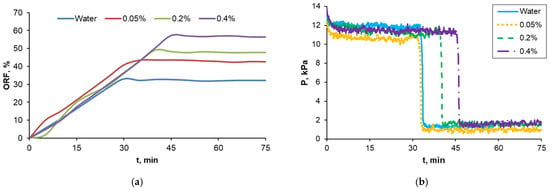

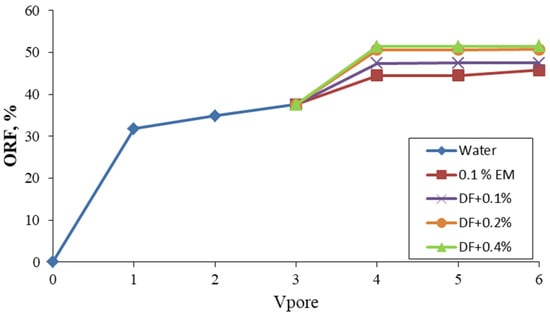

Quantification of the displacement efficiency was performed via automated image analysis based on the segmentation of regions by oil-specific color saturation. The resulting time-dependent ORF curve (Figure 15a) demonstrates linear growth during the initial stage of the process, prior to breakthrough. After aqueous phase breakthrough, the recovery factor plateaus at a constant value of approximately 32%, indicating a high residual oil saturation for conventional waterflooding. This value serves as a baseline for evaluating the effectiveness of nanoemulsions in subsequent experiments.

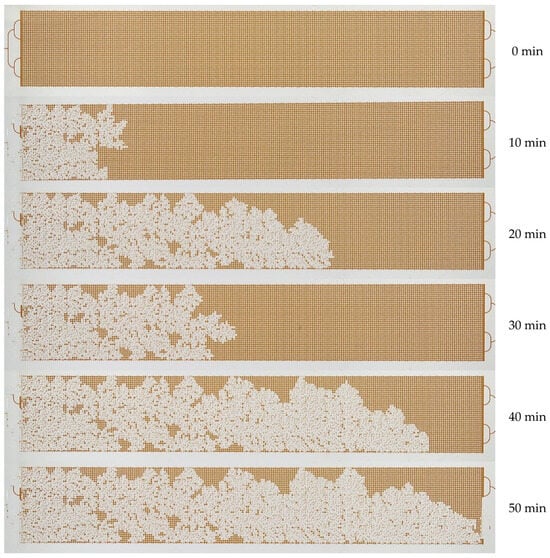

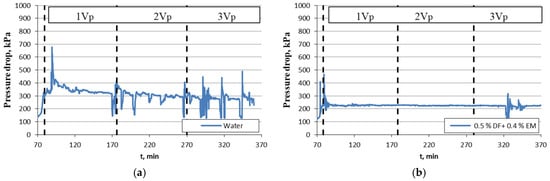

The use of nanoemulsions as a displacing agent significantly alters the flow dynamics, as clearly demonstrated in Figure 13 and Figure 14. In contrast to the base waterflooding scenario, the flow of the displacing phase is characterized by the formation of wider and more structurally complex frontal jets. A considerable increase in flow path tortuosity and pore space coverage is observed, which directly influences the displacement dynamics. A qualitative change in the displacement mechanism is confirmed by the analysis of hydrodynamic data, specifically the pressure drop profile over time (Figure 15b). A sustained pressure increase prior to breakthrough indicates a more efficient mobilization of oil and involvement of the pore volume in the flow process. The breakthrough event, identified by a sharp drop in the pressure differential, occurs significantly later than in the reference waterflood experiment. This delay correlates with increased flow path lengths and more efficient displacement. The wider frontal structures and greater areal coverage result in a substantial improvement in EOR efficiency. This is further evidenced by a reduction in the characteristic size of isolated residual oil clusters.

Figure 13.

Visualization of oil displacement by an emulsion containing 0.4% emulsifier in a microfluidic chip.

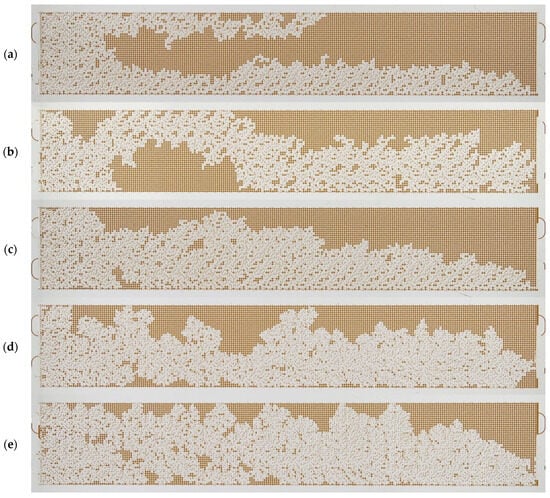

Figure 14.

Residual oil distribution in the microfluidic model after flooding with: (a) aqueous solution, and (b) nanoemulsions with emulsifier concentrations of 0.05%, (c) 0.1%, (d) 0.2%, and (e) 0.4%.

Figure 15.

Flooding performance at varying emulsifier concentrations: (a) ORF and (b) pressure drop as functions of time.

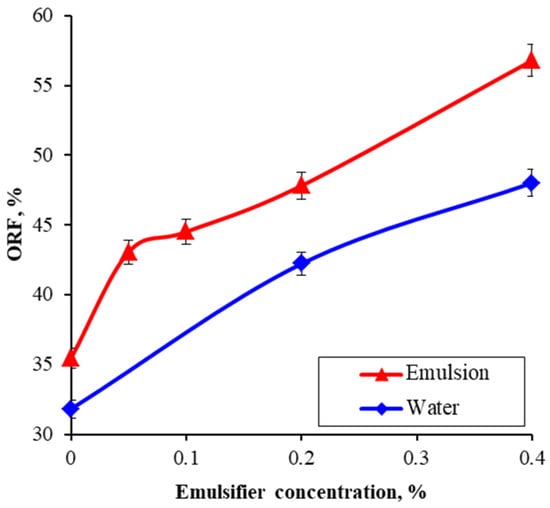

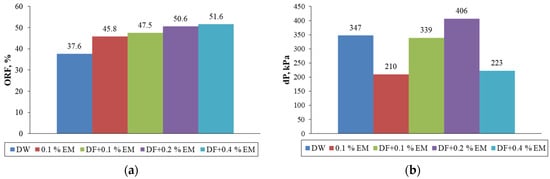

The final phase distribution in the microfluidic chip after nanoemulsion flooding at varying emulsifier concentrations is visualized in Figure 14. A quantitative analysis of the displacement efficiency, presented in Figure 15a and Figure 16, demonstrates a strong dependence of the ORF on the emulsifier content in the nanoemulsion.

Figure 16.

The dependence of ORF on the concentration emulsifier in the aqueous solution and in the emulsion.

It was found that the use of the nanoemulsion base fluid (without emulsifier) already results in a statistically significant increase in the ORF of approximately 10% compared to conventional waterflooding. The addition of an emulsifier to the nanoemulsion provides a further enhancement in recovery efficiency. Notably, as evidenced by the data in Figure 16, introducing a comparable amount of emulsifier directly into the aqueous phase does not yield a similar improvement in EOR. This observation points to a synergistic interaction between the emulsifier and the hydrocarbon phase of the nanoemulsion.

The maximum displacement efficiency (ORF = 57%) was achieved at an optimal emulsifier content of 0.4%. The underlying physicochemical mechanism is attributed to the ability of the emulsifier to reduce IFT and stabilize the dispersed structure of the nanoemulsion. This leads to a decrease in the average droplet size and modification of the displacing fluid’s rheological properties. These changes promote the overcoming of capillary barriers and improve sweep efficiency, ultimately resulting in a reduction in residual oil saturation.

Thus, this microfluidic study experimentally confirms the high efficacy of low-concentration nanoemulsions as EOR agents. It was established that employing these systems enables a significant increase in the ORF compared to conventional waterflooding. The observed effect is attributed to the multifaceted impact of nanoemulsions on flow processes in porous media, which includes modification of the pore channel surface wettability, reduction in IFT, and alteration of the displacing fluid’s rheological properties. Of particular importance is the ability of nanoemulsions to penetrate into low-permeability zones of the pore space and mobilize capillary-trapped residual oil clusters. The obtained results demonstrate the potential for developing novel enhanced EOR technologies based on low-concentration nanoemulsions.

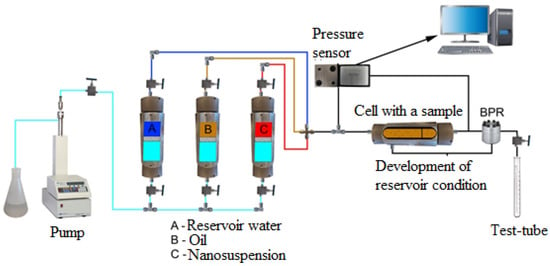

3.6. Filtration Experiments on Oil Recovery from Core Samples

According to the results of studies of capillary impregnation and microfluidic experiments, 4 solutions were selected to determine the effectiveness of total EOR from core samples: an aqueous solution of emulsifier with a content of 0.1%, and emulsions with an addition of 0.5% diesel with an emulsifier content of 0.1, 0.2, and 0.4%. Filtration tests to determine the effectiveness of flooding rocks with nanoemulsion were conducted at a filtration plant UFS-200. UFS-200 is an automatic core flooding system, which is designed for two-phase displacement of liquids in an unsteady and stable state. The scheme of the filtration plant is shown in Figure 17.

Figure 17.

A schematic diagram of the UFS-200 filtration system.

The methodology of filtration experiments with nanoemulsions is based on OST 39-195-86. The filtration experiments used composite cores drilled from the Clear Amherst Gray sandstone formation (each consisting of two individual cores) for each displacing fluid, as detailed in Table 2. This is standard practice in the oilfield (in accordance with OST 39-195-86) to account for the natural heterogeneity of the formation and to obtain representative data, since obtaining and testing multiple, perfectly identical long cores is often not feasible.

Table 2.

Description of the cores for filtration experiments with samples of the model sandstone core Clear Amherst Gray.

At the beginning, water in the amount of 3 pore volumes is pumped through a composite sample of oil-saturated core until EOR stops. The displaced liquid is collected in measuring tubes. Next, nanoemulsion is applied to displace the remaining oil from the sample. The displacing agent is pumped in an amount of at least 3 pore volumes until stopping the recovery of oil, which is collected in measuring tubes. The volume of displaced oil is determined depending on the pumped pore volume. The EOR is calculated after total displacement. The ORF dependence on the volume of the pumped liquid is shown in Figure 18. Obviously, the injection of nanoemulsion provides an additional increase in ORF by more than 10%. At the same time, pumping one pore volume is sufficient to achieve the effect.

Figure 18.

Factor of ORF from the core by the base displacing agent and total recovery by an emulsion with different concentrations of emulsifier.

The maximum increase in ORF was obtained for an emulsion with an emulsifier content of 0.4%. For it, the total EOR after water injection leads to an increase in the ORF by 14.0%, and its minimum increase of 8.2% is observed when using a 0.1% aqueous emulsifier solution without the DF. Thus, it was shown that by itself, a similar addition of an emulsifier to water increases the recovery factor, but not as significantly as in the composition of the emulsion. The effect of increased EOR is associated with the presence of a hydrocarbon phase.

At the same time, the emulsifier content affects the increment of the recovery factor: with growing concentration, a monotonous increase in the EOR occurs. Thus, an increase in the emulsifier concentration from 0.1 to 0.4% in the diesel-based emulsion provided an increase in the recovery factor from 9.95 to 14.0%, respectively.

The obtained increase in oil displacement efficiency using nanoemulsion is comparable to other methods of enhanced oil recovery. Specifically, it was shown that the addition of spherical nanoparticles leads to a maximum increase in the oil recovery coefficient of approximately 10% [40]. Modification of surfactant solutions with SiO2 nanoparticles further significantly increases the oil recovery coefficient, by 20.3% [41]. Modification of polyacrylamide solution with SiO2 nanoparticles increases the oil recovery factor by 36.4% compared to water and by 17.2% compared to a polymer solution without nanoparticles [42].

The function of the emulsifier at the injection stage is mainly to create and stabilize the nanoemulsion, which is achieved through the adsorption of its molecules at the phase boundary and an increase in the strength of the interfacial film [43,44]. A concentration of 0.1% is apparently optimal for the formation of a stable nanoemulsion in volume, since it ensures complete coverage of the interfacial surface of diesel fuel droplets and maximum film strength [44]. A further increase in the emulsifier concentration, potentially reducing the stability of the macroscopic emulsion, leads to the appearance of a significant amount of free, unadsorbed surfactant molecules in the aqueous phase. These excess molecules directly contribute to enhanced oil recovery by further reducing the interfacial tension at the oil-water interface and more actively changing the wettability of the rock through adsorption and ion pair formation [33]. In addition, nanosized diesel fuel droplets with emulsifier molecules adsorbed on the surface generate structural disjoining pressure and, at the same time, transfer surfactant molecules to the oil/rock interface. At this stage, the emulsifier, delivered to the target as part of the nanodroplets, exhibits its activity through adsorption and ion pair formation, which leads to a targeted change in wettability and a decrease in interfacial tension [33]. Thus, the dual role of the emulsifier is consistently realized at different stages of the process. First, as a stabilizer for the dispersed system, and then as an active agent modifying surface properties. Our proposed mechanism is supported by our results. The effectiveness of the emulsifier solution is lower than that of the emulsifier-stabilized diesel fuel-based nanoemulsions. However, increasing the emulsifier concentration reduces surface tension and improves oil recovery. Moreover, the proposed mechanism does not contradict, but even complements the generally accepted mechanisms for enhancing oil recovery using emulsions [12,15].

Attention should also be paid to the data in Figure 19, which shows the pressure behavior when water and then the emulsion are injected into the cores. Some studies have expressed concern that when emulsion solutions with emulsifiers are injected into the reservoir, highly viscous water-oil emulsions may form to reduce permeability. As can be seen from the graphs in Figure 19b, the pressure during injection of emulsions is stable and does not increase during filtration. There is no decrease in core permeability. It is illustrated in Figure 20a, with an increase in the concentration of the emulsifier, increase in the EOR occurs. Moreover, as it is illustrated in Figure 20b, with an increase in the concentration of the emulsifier, the pressure drop decreases. This phenomenon is due to the fact that the emulsifier addition reduces the IFT, which leads to a decrease in capillary pressure. Another important result obtained in our study is worth noting. Filtration studies of the effectiveness of emulsions on core samples have generally confirmed the results obtained by us during filtration studies on microfluidic chips. All the trends detected with the help of microfluidic chips were confirmed by core studies. This is a very important result, indicating that microfluidic research may be used for rapid assessments of the effectiveness of reservoir flooding fluids.

Figure 19.

(a) Pressure drop profile during water injection and (b) ORF during emulsion injection (0.4% emulsifier).

Figure 20.

Enhanced oil recovery performance: (a) ORF achieved by various emulsion compositions, and (b) pressure drop as a function of emulsifier concentration.

The experimental results presented in this study clearly demonstrate the high potential of low-concentration diesel-based nanoemulsions for enhancing oil recovery under the tested laboratory conditions. The observed improvements in oil displacement efficiency are attributed to the fundamental mechanisms of IFT reduction and wettability alteration towards a more water-wet state, as confirmed by our data. A key feature of the developed formulations is their ultra-low hydrocarbon phase content (<1 vol.%), which aims to minimize chemical consumption and operational costs. The Newtonian rheological behavior and negligible viscosity increase compared to water (Section 3.2) suggest that the enhanced recovery is not due to mobility control but primarily to the positive alteration of capillary forces and rock-fluid interactions.

While this research provides a systematic foundation under controlled laboratory settings, it is pertinent to discuss the potential behavior of these nanoemulsions in more complex reservoir environments. The current study intentionally utilized distilled water and ambient conditions to isolate and quantify the fundamental efficacy of the formulations. However, the influence of factors such as reservoir temperature, salinity, and geological heterogeneity is critical for field applications.

Literature data suggests that nanoemulsion systems can exhibit robustness under a range of conditions. For instance, certain surfactant-stabilized nanoemulsions have been reported to maintain or even improve their stability at elevated temperatures, with some systems becoming more transparent and stable at temperatures up to 70 °C, indicating preserved droplet size distribution [37]. This thermal stability is often associated with the kinetic nature of nanoemulsions.

Regarding salinity, the presence of salts in formation water can significantly impact emulsion stability and interfacial properties. It is well established that there exists an optimal salinity for many emulsion systems, at which minimum IFT and maximum solubilization capacity are achieved [11,37]. While salinity can increase IFT beyond this optimum, the fundamental displacement mechanisms—such as the ability to reduce IFT and alter wettability—remain valid. The sub-micron droplet size (~90 nm with emulsifier, Figure 1b) of our formulations is a critical advantage for heterogeneous formations. As noted in the literature, such small droplet sizes minimize the risk of pore throat plugging and facilitate access to low-permeability zones, thereby improving sweep efficiency [11].

Therefore, while the specific performance of our PC-501-stabilized diesel nanoemulsions under high-temperature, high-salinity, and strongly heterogeneous conditions requires further targeted investigation, the foundational mechanisms demonstrated in this work and their reported resilience in the literature provide a strong rationale for their future application.

Laboratory studies on cores and microfluidic chips are a widely accepted and necessary first step for evaluating the effectiveness of enhanced oil recovery (EOR) techniques, including the use of nanoemulsions [44]. These methods enable controlled selection of compositions and provide fundamental insights into displacement mechanisms, such as interfacial tension reduction, wettability modification, and emulsification, demonstrating the potential of this technology for reservoir stimulation.

However, extrapolating the obtained results to the full reservoir thickness requires considering the limitations of these methods. Core studies, although the gold standard, do not fully reproduce real reservoir conditions due to the limited sample volume, which negates the influence of large-scale heterogeneity and gravitational forces. Microfluidic chips, while providing pore-level visualization, have a simplified two-dimensional pore geometry and do not account for chemical interactions with the reservoir rock over long periods of time.

Therefore, the results presented in this paper should be viewed as a demonstration of the effectiveness of using nanoemulsions. Quantitative evaluation of enhanced oil recovery at the field scale requires further research, including modeling on large-scale sectional models and, ultimately, field testing.

4. Conclusions

Systematic experiments were conducted to evaluate the efficacy of low-concentration nanoemulsions for EOR. The dispersed hydrocarbon phase content was maintained at or below 1 vol.% diesel fuel, while the emulsifier content was varied from 0.05 to 0.4 vol.%. The investigated parameters included colloidal stability, viscosity, interfacial tension, wettability alteration, and spontaneous imbibition rate. Furthermore, EOR efficiency was assessed through flooding experiments on both microfluidic chips and core samples, simulating porous media conditions.

1. A method for preparing stable nanoemulsions with a diesel content not exceeding 1 vol.% was successfully developed and validated through a comprehensive experimental study. Colloidal stability analysis revealed that maximum stability is achieved at an emulsifier content of 0.1 vol.%, indicating an optimal component ratio for the dispersed system.

2. Rheological characterization confirmed that the studied low-concentration diesel-based emulsions exhibit Newtonian flow behavior. The dynamic viscosity was observed to increase with higher emulsifier concentration; however, it remained within 10% of the dispersion medium’s viscosity, indicating a negligible influence of the dispersed phase on the system’s rheological properties.

3. The study confirms that higher emulsifier concentrations enhance nanoemulsion performance by fundamentally altering interfacial properties. A measurable decrease in the contact angle from 35° to 16° indicates a favorable shift toward water-wet conditions, promoting more efficient oil detachment from rock surfaces. Simultaneously, the IFT was reduced by approximately half, further contributing to enhanced displacement efficiency. These synergistic effects-wettability alteration and IFT reduction-demonstrate the strong potential of optimized nanoemulsions for improving EOR.

4. The experimental results for capillary impregnation of oil-saturated cores with nanoemulsions have confirmed their ability to reduce IFT and improve wettability.

5. Microfluidic experiments established the dependence of the EOR on the emulsifier concentration in the nanoemulsion. It was demonstrated that using the base nanoemulsion (without emulsifier) increases the EOR by 10% compared to conventional waterflooding. A further increase in the emulsifier concentration to 0.4% yielded an additional enhancement in the EOR, reaching a maximum value of 57%.

6. Filtration tests on the cores of selected emulsion solutions have confirmed their high efficiency. The additional pumping of nanoemulsions was shown to significantly increase the factor of EOR from the cores. As the concentration of the emulsifier increases from 0.1% to 0.4%, the EOR grows monotonously from 9.95% to 14.0%. At the same time, the use of an aqueous emulsifier solution with a similar concentration without a hydrocarbon phase does not give such a significant increase in the recovery factor as in the emulsion.

7. Filtration studies on cores have generally confirmed the results obtained during filtration studies on microfluidic chips. All the trends detected with the help of microfluidic chips have been confirmed by core studies. This is a very important result, indicating that microfluidic studies can be used for rapid assessments of the effectiveness of reservoir flooding fluids.

8. Based on our research, the most likely mechanism for enhanced oil recovery using an emulsifier-stabilized nanoemulsion is as follows. Nanosized diesel fuel droplets with emulsifier molecules adsorbed on the surface generate structural disjoining pressure and, at the same time, transport surfactant molecules to the oil/rock interface. This increases the efficiency of emulsifier contact with the oil and rock and reduces surface tension, facilitating the detachment of oil droplets from the surface. This proposed mechanism is supported by our results. The effectiveness of the emulsifier solution is lower than that of nanoemulsions based on diesel fuel stabilized by the emulsifier. However, increasing the emulsifier concentration reduces surface tension and increases oil recovery.

While this study provides a comprehensive fundamental analysis of low-concentration diesel nanoemulsions for EOR, it is important to acknowledge its limitations. The experiments were conducted under ambient temperature and pressure using distilled water and model homogeneous porous media. These simplified conditions were chosen to isolate and systematically study the fundamental mechanisms of nanoemulsion action—such as wettability alteration, IFT reduction, and capillary imbibition—without the confounding effects of harsh reservoir parameters. However, we recognize that for field applications, the performance of these nanoemulsions must be evaluated under reservoir-specific conditions of temperature, salinity, pressure, and rock mineralogy. Future work will focus on testing the optimized formulations identified in this study in high-temperature/high-pressure coreflooding systems with representative brine salinities and heterogeneous core samples to directly assess their field applicability.

This research provides a foundational understanding of the nanoemulsion’s performance in EOR. However, it is critical to note that the path to industrial application requires further investigation into potential environmental impacts, such as chemical migration and long-term subsurface behavior, as well as a comprehensive economic analysis. Addressing these aspects will be a crucial next step for validating the sustainability and scalability of this technology. These studies are to be carried out in the future.

Furthermore, promising areas for further research include studying the rheological and other physicochemical properties of the compositions under reservoir conditions, as well as field testing of the technology, and assessing the economic efficiency of using nanoemulsions. Of particular interest is the study of the influence of reservoir rock mineral composition on the efficiency of oil displacement by modified nanoemulsions, such as nanoparticles.

Author Contributions

Conceptualization, V.Z. and A.M.; methodology, A.P. and M.P.; formal analysis, D.G.; investigation, A.M.; resources, V.Z.; writing—original draft preparation, A.S., S.L., A.M., A.P. and M.P.; writing—review and editing, R.V. and A.M.; visualization, D.G.; supervision, A.M.; project administration, A.M.; funding acquisition, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

The study was carried out under the state contract with the Ministry of Science and Higher Education of the Siberian Federal University, grant number FSRZ-2020-0012.

Data Availability Statement

Dataset available on request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- IEA. World Energy Outlook 2023, IEA, Paris. Licence: CC BY 4.0 (Report); CC BY NC SA 4.0 (Annex A). Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 24 October 2023).

- IEA. World Energy Outlook 2024, IEA, Paris. Licence: CC BY 4.0 (Report); CC BY NC SA 4.0 (Annex A). Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 16 October 2024).

- IEA. Global Energy Review 2025, IEA, Paris. Available online: https://www.iea.org/events/global-energy-review-2025 (accessed on 24 March 2025).

- Wang, Y.; Han, X.; Li, J.; Liu, R.; Wang, Q.; Huang, C.; Wang, X.; Zhang, L.; Lin, R. Review on Oil Displacement Technologies of Enhanced Oil Recovery: State-of-the-Art and Outlook. Energy Fuels 2023, 37, 2539–2568. [Google Scholar] [CrossRef]

- Kandiel, Y.E.; Attia, G.M.; Metwalli, F.I.; Khalaf, R.E.; Mahmoud, O. Nanoparticles in enhanced oil recovery: State-of-the-art review. J. Pet. Explor. Prod. Technol. 2025, 15, 66. [Google Scholar] [CrossRef]

- Seidy-Esfahlan, M.; Tabatabaei-Nezhad, S.A.; Khodapanah, E. Comprehensive review of enhanced oil recovery strategies for heavy oil and bitumen reservoirs in various countries: Global perspectives, challenges, and solutions. Heliyon 2024, 10, e37826. [Google Scholar] [CrossRef] [PubMed]

- Druetta, P.; Picchioni, F. Surfactant flooding: The influence of the physical properties on the recovery efficiency. Petroleum 2020, 6, 149–162. [Google Scholar] [CrossRef]

- Jinmei, B.; Kun, Q.; Xiangji, D.; Yanfeng, H. Experimental study of surfactant flooding system in low permeability reservoir. Sci. Rep. 2025, 15, 12534. [Google Scholar] [CrossRef]

- Seright, R.S.; Wang, D. Polymer flooding: Current status and future directions. Pet. Sci. 2023, 20, 910–921. [Google Scholar] [CrossRef]

- Khlaifat, A.L.; Dakhlallah, D.; Sufyan, F. A Critical Review of Alkaline Flooding: Mechanism, Hybrid Flooding Methods, Laboratory Work, Pilot Projects, and Field Applications. Energies 2022, 15, 3820. [Google Scholar] [CrossRef]

- Mariyate, J.; Bera, A. A critical review on selection of microemulsions or nanoemulsions for enhanced oil recovery. J. Mol. Liq. 2022, 353, 118791. [Google Scholar] [CrossRef]

- Li, K.; Ovsepian, M.; Xie, W.; Varfolomeev, M.A.; Luo, Q.; Yuan, C. Emulsions for enhanced oil recovery: Progress and prospect. J. Mol. Liq. 2024, 393, 123658. [Google Scholar] [CrossRef]

- Leng, K.; Guan, B.; Liu, W.; Jiang, C.; Cong, S.; Peng, B.; Tao, Y. Advance of Microemulsion and Application for Enhanced Oil Recovery. Nanomaterials 2024, 14, 1004. [Google Scholar] [CrossRef] [PubMed]

- Aljabri, N. Nanoemulsions for Oil and Gas Applications. Des. Appl. Self-Assem. Aggreg. Micelles Nanoemuls. 2024. [Google Scholar] [CrossRef]

- Hou, X.; Sheng, J.J. Properties, preparation, stability of nanoemulsions, their improving oil recovery mechanisms, and challenges for oil field applications—A critical review. Geoenergy Sci. Eng. 2023, 221, 211360. [Google Scholar] [CrossRef]

- Kumar, N.; Mandal, A. Wettability alteration of sandstone rock by surfactant stabilized nanoemulsion for enhanced oil recovery—A mechanistic study. Colloids Surf. A Physicochem. Eng. Asp. 2020, 601, 125043. [Google Scholar] [CrossRef]

- Yao, Y.; Wei, M.; Kang, W. A review of wettability alteration using surfactants in carbonate reservoirs. Adv. Colloid Interface Sci. 2021, 294, 102477. [Google Scholar] [CrossRef]

- Hamedi, H.; Zendehboudi, S.; Rezaei, N.; Azizi, A.; Shahhoseini, F. Application of Functionalized Fe3O4 Magnetic Nanoparticles Using CTAB and SDS for Oil Separation from Oil-in-Water Nanoemulsions. Langmuir 2023, 39, 7995–8007. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Mandal, A. Surfactant Stabilized Oil-in-Water Nanoemulsion: Stability, Interfacial Tension, and Rheology Study for Enhanced Oil Recovery Application. Energy AMP Fuels 2018, 32, 6452–6466. [Google Scholar] [CrossRef]

- Pal, N.; Mandal, A. Oil recovery mechanisms of Pickering nanoemulsions stabilized by surfactant-polymer-nanoparticle assemblies: A versatile surface energies’ approach. Fuel 2020, 276, 118138. [Google Scholar] [CrossRef]

- Kawaguchi, M. Silicone oil emulsions stabilized by polymers and solid particles. Adv. Colloid Interface Sci. 2016, 233, 186–199. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Dong, X.; Liu, H.; Peng, Y.; Chen, Z.; Li, Y.; Guo, Y. Fly Ash Nanoparticle-Stabilized Emulsions for Improve Mobility Control Application. In Proceedings of the SPE EuropeEC—Europe Energy Conference Featured at the 83rd EAGE Annual Conference & Exhibition, Madrid, Spain, 6–9 June 2022. [Google Scholar] [CrossRef]

- Kinra, S.; Pal, R. Rheology of Pickering Emulsions Stabilized and Thickened by Cellulose Nanocrystals over Broad Ranges of Oil and Nanocrystal Concentrations. Colloids Interfaces 2023, 7, 36. [Google Scholar] [CrossRef]

- Jalilian, M.; Tabzar, A.; Ghasemi, V.; Mohammadzadeh, O.; Pourafshary, P.; Rezaei, N.; Zendehboudi, S. An experimental investigation of nanoemulsion enhanced oil recovery: Use of unconsolidated porous systems. Fuel 2019, 251, 754–762. [Google Scholar] [CrossRef]

- Minakov, A.V.; Zhigarev, V.A.; Skorobogatova, A.D.; Guzey, D.V.; Pryazhnikov, A.I.; Stebeleva, O.P.; Lubenets, S.S. Microfluidic study of the mechanisms of oil displacement efficiency by low-concentration diesel fuel-in-water nanoemulsions. Colloids Surf. A Physicochem. Eng. Asp. 2025, 727, 138155. [Google Scholar] [CrossRef]

- Minakov, A.V.; Zhigarev, V.A.; Skorobogatova, A.D.; Guzey, D.V.; Pryazhnikov, A.I.; Lubenets, S.S.; Vaganov, R.A.; Kazanina, S.D.; Volchenko, E.N. Potential application of novel low-concentration nanoemulsion with crude oil as dispersed phase for enhanced oil recovery. Surf. Interfaces 2025, 74, 107656. [Google Scholar] [CrossRef]

- GOST 32511—2013 (EN 590:2009); EURO Diesel Fuel. Specifications. Standartinform: Moscow, Russia, 2014.

- Mohammed, M.; Babadagli, T. Wettability alteration: A comprehensive review of materials/methods and testing the selected ones on heavy-oil containing oil-wet systems. Adv. Colloid Interface Sci. 2015, 220, 54–77. [Google Scholar] [CrossRef]

- Hendraningrat, L.; Li, S.; Torsæter, O. A coreflood investigation of nanofluid enhanced oil recovery. J. Pet. Sci. Eng. 2013, 111, 128–138. [Google Scholar] [CrossRef]

- Seetharaman, G.R.; Devakumar, N.; Deshmukh, M.; Sangwai, J.S. Enhanced oil recovery by spontaneous imbibition of nanofluid assisted low saline alkali polymer in sandstone reservoir. J. Mol. Liq. 2025, 428, 127533. [Google Scholar] [CrossRef]

- Wei, Q.; Wang, X.; Mather, R.; Fotheringham, A. Fotheringham, ESEM study of size removal from ceramic fibers by plasma treatment, Applied Surface Science. Appl. Surf. Sci. 2003, 220, 217–223. [Google Scholar] [CrossRef]

- Minakov, A.V.; Pryazhnikov, M.I.; Suleymana, Y.N.; Meshkova, V.D.; Guzei, D.V. Experimental study of nanoparticle size and material effect on the oil wettability characteristics of various rock types. J. Mol. Liq. 2021, 327, 114906. [Google Scholar] [CrossRef]

- Liu, J.; Sheng, J.J.; Huang, W. Experimental investigation of microscopic mechanisms of surfactant-enhanced spontaneous imbibition in shale cores. Energy Fuels 2019, 33, 7188–7199. [Google Scholar] [CrossRef]

- Wasan, D.; Nikolov, A. Spreading of nanofluids on solids. Nature 2003, 423, 156–159. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Nikolov, A.; Wasan, D. Cleansing dynamics of oily soil using nanofluids. J. Colloid Interface Sci. 2013, 396, 293–306. [Google Scholar] [CrossRef]

- Yu, C.; Wang, M.; Chen, J.; Li, J.; Tang, Y.; Wu, Y.; Jia, Y.; Li, T. Quantitative assessment of pore-scale wettability: An approach combining alternating oil/water spontaneous imbibition and NMR. Eng. Geol. 2025, 358, 108434. [Google Scholar] [CrossRef]

- Liu, D.; Xu, J.; Zhao, H.; Zhang, X.; Zhou, H.; Wu, D.; Liu, Y.; Yu, P.; Xu, Z.; Kang, W.; et al. Nanoemulsions stabilized by anionic and non-ionic surfactants for enhanced oil recovery in ultra-low permeability reservoirs: Performance evaluation and mechanism study. Colloids Surf. A Physicochem. Eng. Asp. 2022, 637, 128235. [Google Scholar] [CrossRef]

- Dawaymeh, F.; Ayoub, E.; Khaleel, M.; Alamoodi, N. Insights into the application of microfluidic platforms in enhanced oil recovery. Petroleum 2025, 11, 422–439. [Google Scholar] [CrossRef]

- Pi, H.; Liu, S. Oil displacement in water-wet microfluidic porous media: Experimental study and image-based numerical simulation using a diffuse-interface approach. Chem. Eng. Sci. 2026, 321 Pt A, 122776. [Google Scholar] [CrossRef]

- Pryazhnikov, A.; Zhigarev, V.; Pryazhnikov, M.; Minakov, A. Microfluidic Study of Application of Nanosuspension with Aluminum Oxide Nanofibers to Enhance Oil Recovery Factor During Reservoir Flooding. Resources 2024, 13, 160. [Google Scholar] [CrossRef]

- Pryazhnikov, A.; Vaganov, R.; Lubenets, S.; Yakimov, A.; Pryazhnikov, M.; Minakov, A. Microfluidic investigation of the efficiency of oil recovery by surfactant solutions modified with nanoparticles. J. Mol. Liq. 2025, 438 Pt A, 128672. [Google Scholar] [CrossRef]

- Vaganov, R.; Zhigarev, V.; Pryazhnikov, M.; Shebeleva, A.; Nemtsev, I.; Minakov, A. Improving the efficiency of surfactant and polymer solutions by modifying them with nanoparticle additives to increase oil recovery. Chem. Eng. Sci. 2026, 321 Pt A, 122732. [Google Scholar] [CrossRef]

- Zhou, Y.; Yin, D.; Chen, W.; Liu, B.; Zhang, X. A comprehensive review of emulsion and its field application for enhanced oil recovery. Energy Sci. Eng. 2019, 7, 1046–1058. [Google Scholar] [CrossRef]

- Saadat, M.; Yang, J.; Dudek, M.; Øye, G.; Tsai, P. Microfluidic investigation of enhanced oil recovery: The effect of aqueous floods and network wettability. J. Pet. Sci. Eng. 2021, 203, 108647. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).