Abstract

This study evaluated the impact of mill scale (MS), a steel manufacturing waste product, as a replacement for natural fine aggregate (up to 100% by volume) in high-calcium fly ash-based geopolymer concrete (GC) and ordinary Portland cement concrete (CC). We compared the workability, compressive strength, splitting tensile strength, modulus of elasticity, density, water absorption, porosity, ultrasonic pulse velocity, thermal conductivity, acid resistance, chloride penetration, and radiation attenuation (gamma rays and fast neutrons) of the resulting materials. Results showed that GC and CC with 100% MS achieved 28-day compressive strengths of 23.6 MPa and 35.2 MPa, respectively, representing 58% and 90% of the strengths of plain GC and CC. MS-modified GC exhibited superior acid and chloride resistance compared to CC. Importantly, MS enhanced radiation shielding, with GC and CC containing 100% MS, demonstrates the best performance, suggesting its potential use in radiation-shielding construction materials.

1. Introduction

It has been known for decades that the process of cement production is not environmentally friendly because it produces a large amount of greenhouse gas, accounting for 4–7% of CO2 emissions worldwide [1,2,3], and up to 0.7–1.0 tons of CO2 per ton of cement [2,4,5]. Therefore, to reduce CO2 emissions from the cement industry, geopolymer has been developed as an alternative binder material in concrete. Geopolymers are produced by mixing alkaline solutions with aluminosilicate materials such as fly ash, metakaolin, and bottom ash [6,7,8]. The reaction between alkaline solutions and aluminosilicate materials (i.e., geopolymerization) causes the formation of three-dimensional polymeric structures of silica and alumina, including Si-O-Al-O bonds [9]. Compared with traditional concrete, geopolymer concrete exhibits excellent durability under acid and sulfate attacks [10,11,12]. Moreover, recent studies reported that the corrosion of reinforcement due to chloride penetration into geopolymer concrete was lower than that of cement concrete at a similar strength [13].

Mill scale is a by-product of the hot-rolling process in the steel manufacturing industry. A previous study had shown that nearly 10–20 kg of mill scale was generated for each ton of steel produced [14]. Generally, they can be recycled in a sintering plant. However, owing to the large amount of steel produced worldwide, the mill scale eliminated by the sintering process is much less than the amount produced [15]. As a result, a substantial amount of mill scale is still disposed of in landfills, causing serious environmental impacts. Therefore, several studies have shed light on the utilization of mill scale to produce more sustainable materials for construction. For example, Ozturk et al. [16] showed that mill scale can be used up to 15% in cement mortar without compromising its compressive strength while having better electromagnetic wave shielding properties than conventional cement mortar. Sharma et al. [17] showed that mill scale and bismuth trioxide can effectively shield radiation when used as aggregates in fly ash and slag-based geopolymer composites. Nongnuang et al. [18] showed that the use of an electromagnetic field to cure geopolymer paste containing 5% waste iron powder results in higher strength than a specimen cured at 60 °C. The proposed electromagnetic field curing method can help reduce energy consumption by 99.7% compared to the oven curing method. Furthermore, the effects of mill scale on the surface of steel bars have been studied in a few studies. Doi et al. [19] suggested that the presence of mill scale on the surface of steel rebars deteriorates the corrosion resistance of the steel rebars because initial defects result in a non-uniform surface condition at the mill scale. This causes crevice corrosion between the mill scale and the steel substrate, which can induce more Cl− ions to penetrate through the initial defects of the mill scale. In contrast, if the mill scale is present uniformly on the surface of the steel bar, it can enhance the corrosion resistance of the steel rebar. This is because the uniform surface condition of the mill scale can act as the first barrier preventing the steel rebar from being attacked by Cl− ions [20]. Additionally, corrosion-induced defects in structural steel components, such as pitting, have been shown to significantly reduce fatigue life and compromise structural safety [21,22]. Ozturk and Karabulut [23] investigated the effects of substituting crushed stone aggregate with mill scale at 10%, 20%, and 30% by volume in cement mortar. Their results demonstrated that as the proportion of mill scale increased from 0% to 30%, the compressive strength declined significantly from about 70 MPa to 30 MPa. At the same time, the material’s ability to shield against electromagnetic interference improved considerably. Siriwattanakarn et al. [24] examined the incorporation of mill scale waste as a partial replacement for natural fine aggregate in cement mortar at 5%, 10%, 15%, and 20% by volume. Their findings indicated that a 20% replacement led to a reduction in compressive strength. Additionally, increasing the mill scale content resulted in lower workability and thermal conductivity, along with a slight increase in porosity. Ahmed and Kamal [25] studied the replacement of natural sand with steel slag and the partial substitution of steel slag with mill scale in cement mortar. They reported that a full replacement of sand with steel slag enhanced compressive strength by 4.6%, while incorporating mill scale at levels up to 8% in place of steel slag further boosted compressive strength by 13.8%. Nawaz et al. [26] investigated the use of steel-scale waste as a replacement for sand in high-performance concrete. The sand was replaced by steel-scale waste at varying proportions by mass: 20%, 40%, 50%, 60%, 80%, and 100%. The results showed that flowability improved with increasing steel-scale waste content up to 40%, after which it began to decline. An increase in steel-scale waste content also led to higher dry density and enhanced compressive strength, with optimal results observed at a 50% replacement level. Beyond this point, compressive strength began to decrease. Additionally, higher steel-scale waste content significantly reduced water absorption.

Ionizing radiation, particularly gamma rays and neutrons, poses serious health hazards due to its ability to ionize atoms and alter molecular structures [27,28]. Concrete is widely used in radiation shielding due to its availability, cost-effectiveness, structural strength, and capacity to attenuate gamma and neutron radiation [29,30,31]. The effectiveness of concrete in shielding gamma rays is primarily influenced by its density and the atomic number of its constituents; materials with higher density and heavier elements are more effective at absorbing or scattering gamma radiation [30]. Neutron shielding requires concrete to be rich in elements with high neutron interaction cross-sections, such as hydrogen or boron, which facilitate energy loss for every scattering [32,33,34,35].

Over the past decade, researchers have studied the utilization of mill scale as a fine aggregate replacement in Portland cement concrete, but only a few have investigated its utilization in geopolymers. However, no studies have investigated the radiation shielding performance of GC incorporating mill scale as a fine aggregate against fast neutrons and gamma rays emitted by Cobalt-60. Considering this gap, an attempt was made in this work to study the effect of mill scale on the GC properties. Additionally, the effect of mill scale on ordinary Portland cement (OPC) concrete was examined for comparison.

2. Materials and Methods

2.1. Materials

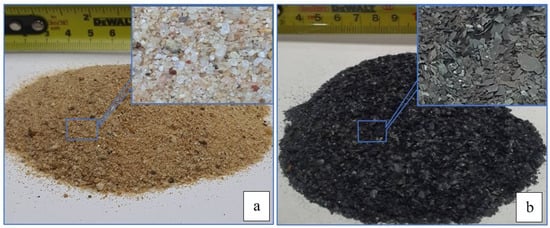

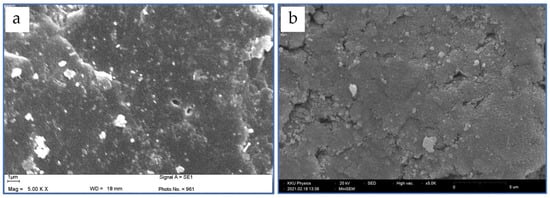

High-calcium fly ash (FA) obtained from the Mae Moh power plant in northern Thailand was used as the aluminosilicate material. The specific gravity of the FA was 2.24. The OPC used in this study has a specific gravity of 3.15. The chemical compositions of FA, OPC, and mill scale (MS) are analyzed using an X-ray fluorescence spectrometer, as listed in Table 1. The high CaO content (22.95%) in FA promoted early strength development by facilitating the formation of calcium silicate hydrate (C-S-H) gel, which modified the microstructure, densified the matrix, improved compressive strength, and reduced porosity [36,37]. A sodium silicate solution (Na2SiO3, SS) and sodium hydroxide solution (NaOH, SH) at a concentration of 10 M were used as alkaline activators. The chemical composition of SS is presented in Table 1. River sand (RS) and MS were used as fine aggregates. RS and MS have maximum particle sizes of 4.75 mm and 2.36 mm, respectively. MS containing 98.74% Fe2O3 was obtained from a supplier (Klang Wiremesh KhonKaen Co., Ltd.) in Khon Kaen Province, Thailand. The physical appearances and scanning electron microscope (SEM) images of the RS and MS are shown in Figure 1 and Figure 2, respectively. Crushed limestone with a maximum particle size of 19.0 mm, obtained from the local millstone plant in northeast Thailand, was used as the natural coarse aggregate.

Table 1.

Chemical compositions of FA, OPC, MS, and SS.

Figure 1.

Physical appearances of fine aggregates: (a) RS; (b) MS.

Figure 2.

SEM images of the surface of fine aggregates: (a) RS; (b) MS.

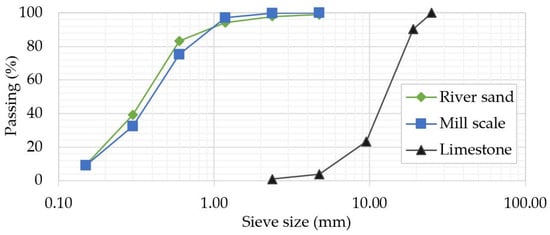

The specific gravity, abrasion, water absorption, and fineness modulus of all aggregates are listed in Table 2. According to the data, the specific gravity of MS (5.26) was significantly higher than that of river sand (2.64), implying that the density of the concrete matrix could increase when MS is used. However, the dry unit weight of MS was lower than that of river sand, suggesting that under dry compaction conditions and for the same volume, the mill scale results in a lower mass despite its higher specific gravity. This discrepancy could be attributed to the flat and flaky nature of mill scale particles, which leads to a looser packing arrangement and the entrapment of more voids, resulting in poor packing density. The particle size distribution of the aggregates is shown in Figure 3. River sand and crushed limestone were washed to remove contaminants and then prepared under saturated surface dry (SSD) conditions before use.

Table 2.

Properties of aggregates.

Figure 3.

Particle size distributions of aggregates.

2.2. Mix Proportions and Specimen Preparation

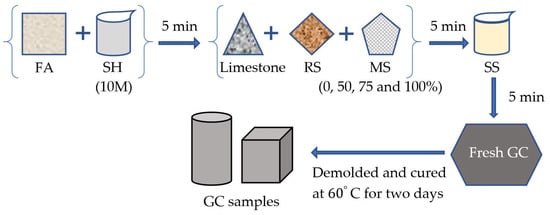

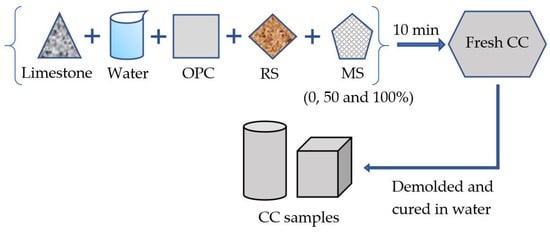

Geopolymer concrete (GC) was prepared using a liquid-to-binder ratio (L/B) of 0.67 and an SS/SH ratio of 1.0, and RS was replaced with MS at 0%, 50%, 75%, and 100% by volume. To prepare ordinary Portland cement concrete (CC), a water-to-cement ratio (W/C) of 0.48 was used, and RS was replaced with MS at 0%, 50%, and 100% by volume. The mix proportions of the GC and CC are listed in Table 3. To prepare GC, FA was mixed with SH for 5 min. Coarse and fine aggregates were then added, and the mixture was further mixed for 5 min. Finally, SS was added, and the mixture was mixed for another 5 min. The mixture was then cast into molds and hardened at room temperature for 1 h. One hour after demolding, the GC samples were wrapped with plastic sheets and cured in an oven at 60 °C for two days; these were optimal curing conditions following the recommendation of Chindaprasirt et al. [38]. After heat curing, the samples were kept in a controlled room at 23 ± 2 °C and 50% relative humidity until testing. For CC, the specimens were prepared according to ASTM C192-07 [39] and cured in tap water. Flowcharts of the sample preparation for GC and CC are illustrated in Figure 4 and Figure 5, respectively.

Table 3.

Mix proportions (kg/m3).

Figure 4.

Flowchart of the sample preparation for GC.

Figure 5.

Flowchart of the sample preparation for CC.

2.3. Testing

2.3.1. Physical and Mechanical Properties

The slump (ASTM C143-08) [40] and slump flow (ASTM C1611-05) [41] of both types of concrete were tested immediately after mixing. The compressive strength (ASTM C39-05) [42] was tested on cylindrical samples with a diameter of 10 cm and a height of 20 cm at 7, 28, and 90 days of age. The modulus of elasticity (ASTM C469-04) [43] and splitting tensile strength (ASTM C496-04) [44] were tested. A testing machine with a load capacity of 2000 kN was used to test the compressive strength and modulus of elasticity with a constant loading rate of 0.20 MPa/s, while a constant loading rate of 1.0 MPa/min was applied for the splitting tensile strength test.

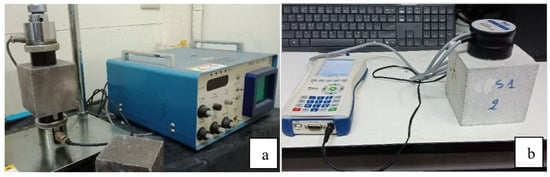

Cubic samples with dimensions of 10 cm × 10 cm × 10 cm were prepared for density, water absorption, and porosity tests according to ASTM C642-06 [45]. Ultrasonic pulse velocity (ASTM C597-02) [46] and thermal conductivity (ASTM D5930-17) [47] were also investigated. To determine the ultrasonic pulse velocity (Figure 6a) and thermal conductivity (Figure 6b), the specimens were dried in an oven at 110 °C for 24 h before testing. It is important to note that, for each test in this study, three samples from each mix were evaluated to obtain the average value, and all tests were conducted at 28 days of age, except for the compressive strength test.

Figure 6.

(a) Ultrasonic pulse velocity test; (b) thermal conductivity test.

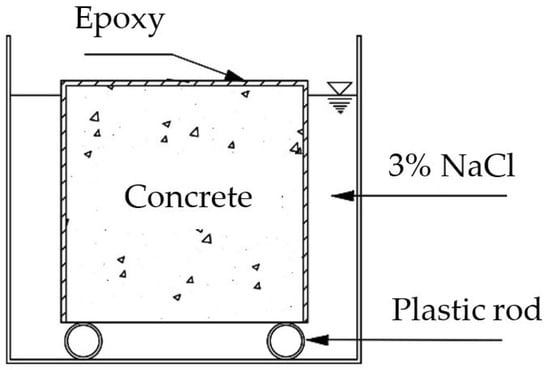

2.3.2. Durability Tests

To test the acid resistance (ASTM C267-01) [48] of concrete, the specimens were immersed in a plastic tank containing 3% H2SO4 for 7, 14, 28, 56, 84, and 120 days. The weight loss after immersion was determined. The chloride penetration test (Figure 7) was conducted on cylindrical samples with a diameter of 10 cm and a height of 10 cm, which were cut from their original size (10 cm diameter and 20 cm height). After cutting, the samples were air-dried for 24 h. Then, they were surface-coated with non-shrinkage epoxy, leaving the cut surface non-coated to control the direction of chloride ion penetration. The specimens were subsequently left air-dried for 24 h before immersion in a plastic container filled with 3% NaCl solution, as described by Nuaklong et al. [49]. The NaCl solution was replaced every month. The chloride penetration depth was measured after 90 d of immersion by spraying a 0.1 N silver nitrate solution (AgNO3) on the freshly split surface of the specimen.

Figure 7.

Test setup for chloride penetration depth.

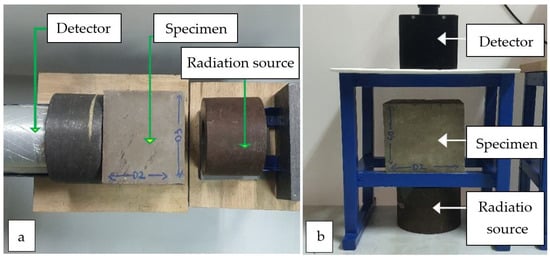

2.3.3. Radiation-Shielding Properties

Gamma rays and fast neutrons were used to test the radiation-shielding properties of concrete in this study. The specimens were irradiated by gamma rays produced from 96 μCi Cesium-137 (Cs-137) with photon energy of 662 keV and 47 μCi Cobalt 60 (Co-60) with photon energies of 1173 keV and 1332 keV, detected by a 3″ × 3″ NaI (Tl) detector. The fast neutrons emitted from a 100 mCi Americium-241/Beryllium (241Am-Be) neutron source were detected by a proton recoil neutron detector. The gradual attenuation test setups for the gamma rays and fast neutrons are shown in Figure 8. Cubic specimens with a dimension of 15 cm × 15 cm × 15 cm were tested at 28 days of age. The specimens were oven-dried at 105 °C for 24 h before testing. For the gamma radiation-shielding experiment, the linear attenuation coefficient and half-value layer were calculated according to Lambert’s law [29] using Equations (1) and (2). For the fast neutron radiation-shielding experiment, the fast neutron removal cross-section and half-value layer were calculated according to Equations (3) and (4). The half-value layer is defined as the thickness of concrete that reduces the intensity of radiation to half of its original value.

Figure 8.

(a) Test setup for gamma rays; (b) test setup for fast neutrons.

HVL = ln2/μ,

3. Results and Discussion

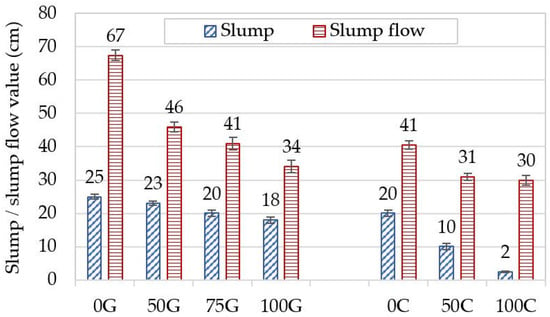

3.1. Slump and Slump Flow

Figure 9 shows the values of the slump and slump flows of GC and CC. The results indicate that the slump and slump flow values decrease with increasing MS replacement content in both GC and CC. In the case of slump values, the replacement of fine aggregates with MS causes a significant reduction in the slump of CC compared to GC. The slump values of CC declined from 10 cm in the 50C sample to 2 cm in the 100C sample, accounting for a >50% reduction. In contrast, slump values of GC only decrease from 25 cm for the 0G sample to 18 cm for the 100G sample (28% reduction), suggesting less effect of MS replacement in GC than in CC. The reduction in the slump value of concretes due to MS replacement was attributed to the flat, flaky, and porous structure of mill scale particles, as shown in Figure 1 and Figure 2. The irregular particles of the MS required greater external force to enable flow, while its porous structure increased water demand, thereby reducing the slump value. This finding is consistent with the findings of Parvathikumar et al. [50], which reported a 50% decrease in the slump value of OPC concrete when river sand was replaced with 100% steel mill scale.

Figure 9.

Slump and slump flow values of concrete.

Conversely, the influence of MS on the slump flow values was more profound in GC than in CC. In this respect, there was a reduction of slump flow of nearly 50% when 100% MS (100G) was replaced in GC, whereas there was only a 27% reduction when the same MS replacement content was applied in CC. The reduction in the slump flow values observed in this study could also be attributed to the highly irregular particles of MS with cavities, as described above. This result is consistent with a previous study by Siriwattanakarn et al. [24], who also reported a decreasing trend in the flow value of cement mortar when mill scale waste was used as a fine aggregate replacement.

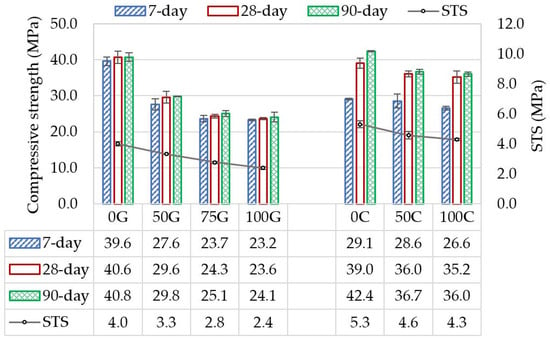

3.2. Compressive Strength and Splitting Tensile Strength

The compressive strength and splitting tensile strength (STS) results are shown in Figure 10. The compressive strengths of both GC and CC decreased with increasing MS replacement content, regardless of the curing age. The CG containing MS exhibits lower compressive strength than the CC containing MS at the same level of MS replacement. The greater reduction in the compressive strength of GC containing MS compared to CC can be attributed to a more significant increase in the porosity of GC compared to CC, as evidenced in Section 3.4, which reduces its compressive strength. In the case of GC, when 50% MS replacement was used, the compressive strength of 28–30 MPa was observed, which is significantly reduced compared to the 0GC sample of 40–41 MPa. Nevertheless, when the replacement with mill scale increased to 75% and 100%, only a decrease in the compressive strength was observed. Furthermore, a longer curing period of 90 d did not produce a noticeably higher compressive strength compared to the early age strength (7 d) in all GC samples. This implies that the heat-curing process promotes relatively complete geopolymerization, and leads to rapid strength development, with little strength development at later ages.

Figure 10.

Compressive and splitting tensile strengths of concrete.

Although there was a discernible loss of strength of CC when 50% MS was employed, the strength remained relatively unchanged when MS replacement was increased to 100%. Moreover, the strength reduction became more profound when the curing period was prolonged to 90 days. In this regard, the 28-day strength of the control CC was approximately 39 MPa, and those containing 50% and 100% MS were approximately 35–36 MPa. Nevertheless, a further curing period of up to 90 days did not have a significant effect on the compressive strength of MS-containing CC (50C and 100C). The 28 d and 90 d strengths of both 50C and 100C leveled off at approximately 35–36 MPa. Remarkably, the 90 d strengths of both 50C and 100C are comparable (36–37 MPa) even though the MS replacement content is doubled. This suggests that a curing time of 28 d is sufficient to achieve a sufficiently high compressive strength of MS-containing CC. Furthermore, because of the equal compressive strengths of the 50C and 100C samples, the implementation of MS as a complete substitute for natural fine aggregates in CC is promising without further compromising its compressive strength. The reduction in compressive strength of the concrete with the addition of MS was due to the weak mechanical properties of MS, which caused a weak interfacial transition zone (ITZ) between the paste and MS aggregate. Moreover, the reduction could be attributed to the porous structure of MS, which increases the mixture’s water demand, negatively affects workability, hinders the formation of a well-compacted, dense structure [23], and interferes with the development of a cohesive matrix, leading to internal voids and structural weak points that further reduce compressive strength [16]. This finding agrees with the report of Alwaeli and Nadziakiewicz [51], who found that when the OPC concrete was mixed with scale waste by more than 25%, the compressive strength deteriorated. In addition, Siriwattanakarn et al. [24] reported that substituting fine aggregate with 20% mill scale waste by volume resulted in a reduction in compressive strength.

The effect of MS replacement on the splitting tensile strength (STS) of both GC and CC was also investigated (Figure 10). The results showed that the STS of GC and CC gradually decreased with increasing MS replacement content. The lowest STS was found in 100G (2.4 MPa), accounting for a 40% reduction compared with that of the 0G (4.0 MPa) sample. Like the compressive strength, an increase in MS content in CC tends to cause lower levels of STS reduction than in GC. For the 100C sample, the STS is 4.3 MPa, which is only 19% lower than that of the 0C sample. Moreover, the STS of 4.3 MPa of the 100% substitution of MS for fine aggregates (100C) was only slightly reduced compared to 4.6 MPa of the mixture with 50% MS substitution (50C). The reduction in the STS of the concretes incorporating MS was also attributed to the weak ITZ between the binder and MS aggregate, as well as the increased porosity in the concrete matrix, as evidenced in Section 3.4.

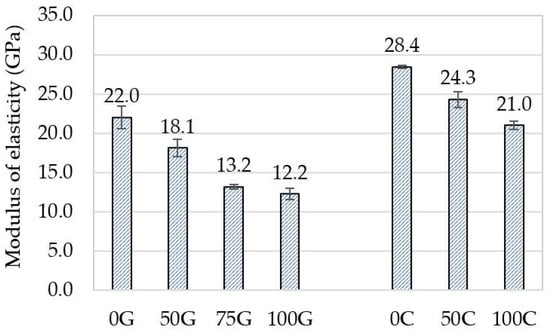

3.3. Modulus of Elasticity

Figure 11 illustrates the modulus of elasticity of GC and CC at the age of 28 days. The results show that the modulus of elasticity decreases with an increasing MS replacement level. The reduction was attributed to the inherently weak mechanical properties of MS, which led to the formation of a weak ITZ, negatively affecting stress transfer between the binder and aggregates and resulting in a lower modulus of elasticity. In agreement with the compressive strength, the MS content had a greater effect on the modulus of elasticity of GC than that of CC. There was a considerable reduction in the modulus of elasticity from 22.0 GPa for the 0G sample to 12.2 GPa for the 100G sample. In contrast, the modulus of elasticity of CC slightly drops from 28.4 GPa of 0C to 21.0 of 100C. Moreover, the modulus of elasticity of GC is notably lower than that of CC, even though their compressive strengths are relatively within the same range. The lower elastic modulus of geopolymer concrete compared with that of cement concrete is attributed to the lower elastic modulus of the geopolymer paste itself [52]. Furthermore, Yost et al. [53] found that the elastic modulus of fly ash-based geopolymer concrete was approximately 11% to 16% less than the value obtained from ACI 318-08 [54]. The findings of this study are in line with those of previous works. For example, Hardjito et al. [55] suggested that the modulus of elasticity of fly ash geopolymer concrete increases with compressive strength. Furthermore, heat curing has a strong influence on the elastic modulus, which can help stiffen the geopolymer matrix, thus increasing the elastic modulus [56,57].

Figure 11.

Modulus of elasticity.

3.4. Bulk Density, Porosity, and Water Absorption

The density, porosity, and water absorption of GC and CC are listed in Table 4. The bulk densities of GC and CC increased with increasing MS content. In the case of GC, the density increased from 2356 kg/m3 (0G) to 2377 kg/m3 and 2467 kg/m3 when using MS at ratios of 50% and 100%, respectively. Likewise, the density of CC increased from 2331 kg/m3 to 2356 kg/m3 and 2435 kg/m3 when MS replacement content increased from 0% to 50% and 100%. The increase in density is mainly due to the higher specific gravity of MS compared to that of river sand. This finding is consistent with the results of Ismail and Al-Hashmi [58], who revealed that the use of waste iron to replace river sand could increase the density of concrete. Similarly, Nawaz et al. [26] also observed that increasing the content of steel-scale waste led to higher concrete density, attributed to the higher specific gravity of steel-scale waste compared to natural sand, resulting in denser concrete mixtures.

Table 4.

Density, porosity, and water absorption.

An increase in the MS content caused a higher volume of porosity and an increase in the water absorption of both GC and CC (Table 4). There is ~40% increase in the porosity of GC when 100% MS replacement is used, whereas there is only ~14% more pore space in CC at the same MS replacement level. This suggests that MS is more compatible with the cement matrix than with the geopolymer paste. The increase in porosity is due to the flat particles of the MS particles, which allow more air bubbles to be trapped within the matrix during specimen preparation. A previous report [24] also found that the porosity of cement mortar slightly increased with higher mill scale waste content. This result agrees with previous research [59] showing that the porosity of the high-calcium fly ash-based geopolymer mortar was higher than that of the OPC mortar. In addition, a significant reduction in workability can affect the compaction of the specimen, leading to a larger volume of voids [16,60]. Likewise, the water absorption of GC increased with increasing MS content at a more intense level than that found in CC. In this regard, the water absorption of GC varied between 4.4% and 6.7%, while that of CCs was 3.4% and 3.9%. Although the water absorption of MS (0.04%) is much lower than that of RS (0.62%), the increasing porosity in concrete with higher MS content can lead to increased water absorption.

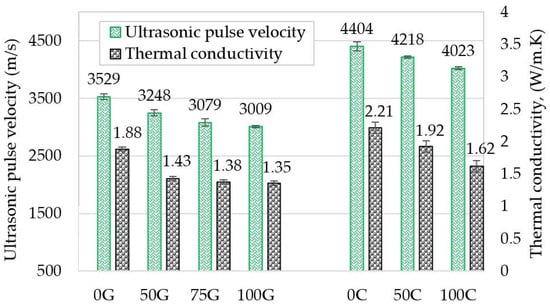

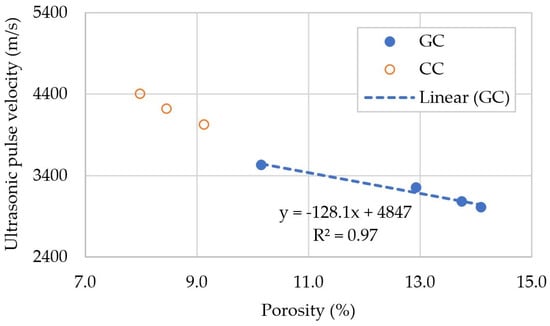

3.5. Ultrasonic Pulse Velocity and Thermal Conductivity

Ultrasonic pulse velocity (UPV) and thermal conductivity results for GC and CC are shown in Figure 12. The results indicated that both GCs and CCs containing MS had reduced UPV values. The UPV values for samples 0G, 50G, 75G, and 100G were 3529, 3248, 3079, and 3009 m/s, respectively. Meanwhile, samples 0C, 50C, and 100C exhibited higher ranges of UPV values of 4404, 4218, and 4023 m/s, respectively. This indicates that MS-containing CCs have fewer air voids within the matrix, thus implying better quality than MS-containing GCs. The relationship between the porosity and the UPV value in both types of concrete was also investigated (Figure 13). This finding illustrates a negative linear correlation between UPV and porosity, confirming that a higher UPV value results from a lower level of porosity in the concrete. The results were in line with a previous report by Esen and Doğan [61], which suggested that a lower UPV value of concrete was obtained in concrete with higher porosity.

Figure 12.

Ultrasonic pulse velocity and thermal conductivity.

Figure 13.

Relationship between ultrasonic pulse velocity and porosity.

The thermal conductivities of both GC and CC decreased when MS was used to replace the fine aggregates (Figure 12). It is noticed that the thermal conductivity of GC slightly decreases with increasing MS content, whereas this effect is more profound in CC. In the case of GC, thermal conductivity decreased by <6% when MS content was doubled from 50% (50G) to 100% (100G). In contrast, there is a ~16% decrease in the thermal conductivity of CC when MS content increases from 50% (50C) to 100% (100C). Nevertheless, the thermal conductivity of 50G was significantly lower than the control (24% reduction), whereas that of 50C was only slightly lower (13% lower than 0C). Although a partial replacement of MS for fine aggregates causes a greater level of reduction in the thermal conductivity of GC than that of CC, a complete substitution decreases the thermal conductivity of both GC and CC in relatively the same range of ~27–28% when compared to their corresponding controls. The reduced values of the thermal conductivity of GC and CC containing MS could be attributed to the increased porosity within the matrix, despite a slight increase in density. In this study, it appears that the influence of increased porosity outweighed the impact of increased density on thermal performance. When the MS replacement ratio increased from 0% to 100%, GC exhibited a 38.2% increase in porosity compared to only a 4.7% increase in density. Similarly, CC showed a 13.75% increase in porosity and a 4.5% increase in density. This disparity could suggest that the elevated porosity had a more significant effect in reducing thermal conductivity than the minor gains in density. This finding is consistent with a previous study by Siriwattanakarn et al. [24], which also reported a decrease in thermal conductivity of cement mortar with increasing mill scale waste content, despite an observed increase in density. Therefore, the use of MS as a replacement for fine aggregates in either GC or CC is beneficial for producing concrete with thermal insulation properties.

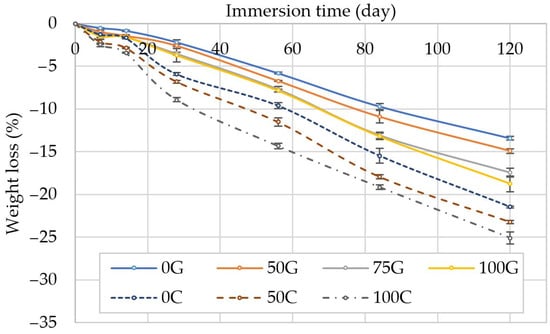

3.6. Acid Resistance

The resistance of concrete to sulfuric acid attack is one of the most important characteristics for assessing its durability. The results in Figure 14 show that the weight loss of both GC and CC due to acid attack increased with increasing MS contents. Furthermore, it was found that CC has lower resistance to acid attack than GC, in which the 0C sample shows ~60% higher corrosion than the 0G sample after 120 d of testing duration. This can be explained by the fact that there is a higher amount of calcium compounds in CC than in GC, which is a major component that can be easily attacked by sulfuric acid. When calcium compounds react with sulfuric acid, calcium sulfate is produced, which causes expansion, cracking, and weight loss in the materials [62]. The reduced resistance to sulfuric acid attack in concretes incorporating MS as a fine aggregate can be attributed to the increased porosity, making it more susceptible to acid attack.

Figure 14.

Weight loss due to sulfuric acid attack.

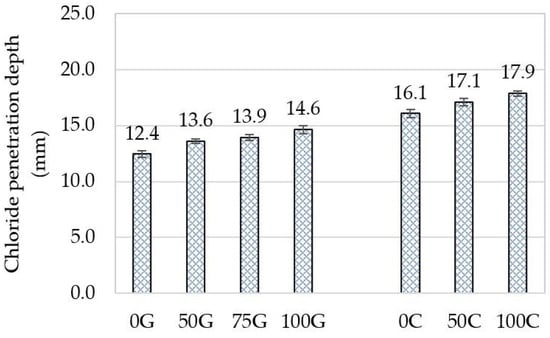

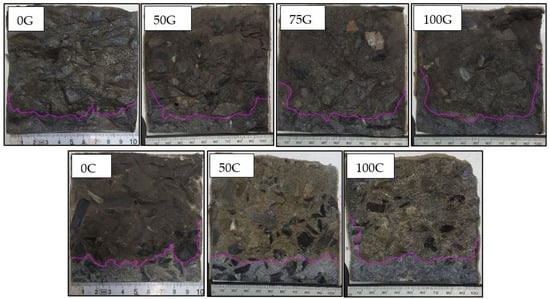

3.7. Chloride Penetration Depth

Figure 15 and Figure 16 show the chloride penetration depths of GC and CC after 90 d of immersion in a 3% NaCl solution. The results indicate that the chloride solution can penetrate deeper when the MS content increases in both the GC and CC. An increased penetration depth was attributed to the higher porosity in the concrete [49,63], resulting from the increased MS content. Furthermore, rust can occur when chloride ions come into contact with MS and consequently lead to crack formation between MS and pastes, allowing chloride to penetrate even more easily [19].

Figure 15.

Chloride penetration depth.

Figure 16.

Chloride penetration depth after 90 d of immersion in 3% NaCl solution.

Moreover, CC was less resistant to chloride penetration than GC, regardless of the MS replacement content. Considering this, the chloride penetration depths of GCs are in the range of 12–15 mm, while that of CCs ranges from 16 to 18 mm. This result is consistent with Tennakoon et al. [64], who reported that geopolymer concrete immersed in NaCl solution shows a significantly lower apparent chloride penetration depth than OPC concrete. This was due to the cross-linked structure of C-A-S-H in the geopolymer, which prevented chloride ingression. In addition, Ismail et al. [65] showed that geopolymer concrete exhibits more resistance to chloride penetration than OPC concrete, although it has a higher porosity. This is because of the C-A-S-H formation in the geopolymer, which is a denser gel-like structure than C-S-H in OPC. Likewise, Gunasekara et al. [13] reported that the lower chloride penetration depth of geopolymer concrete compared to cement concrete can be attributed to the three-dimensional structure of the N-A-S-H and C-A-S-H gels in geopolymers, which helps decrease chloride diffusion.

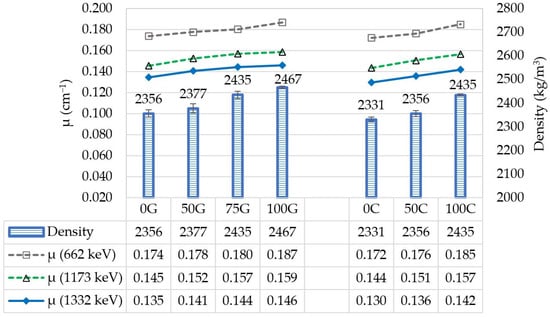

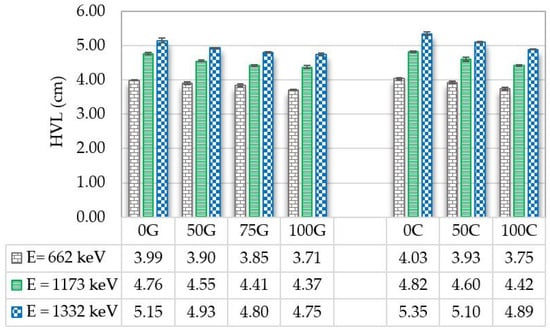

3.8. Radiation-Shielding Properties Against Gamma Rays

The linear attenuation coefficients (µ) of GC and CC at the three photon energies emitted from Cs-137 and Co-60, concerning their densities, are presented in Figure 17. The results showed that increasing the MS content improved the radiation absorption properties of GC and CC at all photon energy levels. This is consistent with Ozturk et al. [16], who reported that the utilization of MS to partially replace river sand in OPC mortar could provide better shielding against electromagnetic waves. In addition, µ is positively correlated with the density of concrete. This agrees with previous research suggesting that a better attenuation coefficient against gamma rays can be obtained using high-density materials [66]. Similarly, Sharma et al. [17] demonstrated that the µ of geopolymer composite incorporating mill scale as aggregate increased with the geopolymer composite’s density. Furthermore, both GC and CC in the present work exhibited better-shielding properties against radiation at lower photon energies (662 keV), as evidenced by the higher μ at this photon energy than at the others. This shows that μ increases with a decrease in the photon energy, as presented in previous studies [67,68].

Figure 17.

Linear attenuation coefficients and density of concretes.

Because the radiation shielding property of a material is usually presented in terms of HVL, which is crucial for designing the wall thickness for radiological protective materials, the HVL of concrete under gamma ray radiation was evaluated, as shown in Figure 18. The results indicated that the HVL of GC and CC slightly decreased with increasing MS content, whereas it increased with increasing photon energy. At 1332 keV photon energy, the HVL of GC reduces from 5.15 cm at 0G to 4.93 cm, 4.80 cm, and 4.75 cm at 50G, 75G, and 100G, respectively. At the same photon energy, CCs have HVLs of 5.35 cm, 5.10 cm, and 4.89 cm at 0C, 50C, and 100C, respectively. This is because both GC and CC become denser when the MS is used. Therefore, they require less thickness to be shielded against radiation. This result was confirmed by Saca et al. [68], who reported that the increased density of concrete positively affected its HVL.

Figure 18.

HVL under gamma ray radiation shielding of concretes.

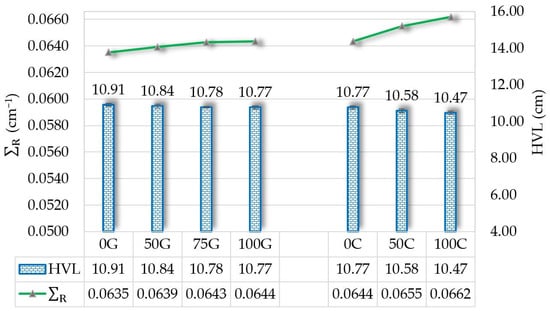

3.9. Radiation-Shielding Properties Against Fast Neutrons

Because fast neutrons have a higher penetrating power than gamma rays, the and HVL for fast neutron beams of GCs and CCs were also investigated, as shown in Figure 19. The results indicate that both GC and CC containing MS have better radiation absorption properties for fast neutrons than their corresponding references (0G and 0C). There was a slight decrease in the HVL, especially in the case of CC, when the MS content increased. It can be noticed that correlates with HVL, in which the better the shielding property of the material, the thinner the material is required to protect against incoming radiation.

Figure 19.

and HVL under neutron particle shielding of concretes.

In addition, CCs showed a better shielding property against fast neutrons than GCs, as evidenced by the higher and lower HVL of CC at all MS replacement contents. For instance, when MS content increases from 0% to 100%, the of GC increases from 0.0635 cm−1 to 0.0644 cm−1, while that of CC increases from 0.0644 cm−1 to 0.0662 cm−1. This may be due to the higher water content in CC production, resulting in more hydrogen atoms interacting with the fast neutrons. Consequently, fast neutrons elastically scatter and lose energy to penetrate the material [29]. Moreover, the presence of iron atoms in MS can cause fast neutrons to scatter inelastically and lose their penetration power. In contrast to gamma ray attenuation, neutron attenuation not only depends on the density of the shielding material but also on the chemical composition within it [69]. Neutrons have no charge and can interact only with the nuclei of low-atomic-number substances, and the addition of chemicals with low atomic numbers, such as hydrogen or boron, can favor neutron attenuation of the shielding material [32,33,34,35]. Furthermore, inelastic scattering of neutrons when interacting with atomic nuclei of high-inelastic scattering cross-section elements, such as iron, can also play an important role in attenuating the neutron radiation of the shielding material. In comparison with a previous study [29] that utilized a different type of aggregate (barite and cut steel bar), the value of cement concrete incorporating cut steel bars as coarse aggregate ranged from 0.0700 cm−1 to 0.0737 cm−1, which is relatively higher than the values observed in the current study (0.0635 cm−1 to 0.0644 cm−1 for GC and 0.0644 cm−1 to 0.0662 cm−1 for CC). However, while cut steel bars demonstrated higher values, the cost-effectiveness of the material should also be considered when compared to MS. Additionally, the same study [29] reported values below 0.0700 cm−1 in samples that did not contain cut steel bars. This highlights the potential of iron-rich materials, such as MS, in enhancing fast neutron radiation attenuation in concrete.

4. Conclusions

This study presents the use of mill scale in GC as a fine aggregate replacement by volume in comparison with CC. Based on the properties of MS-containing GC, including mechanical, physical, and durability properties, and radiation shielding against gamma rays and fast neutrons, the following conclusions can be drawn:

- Substitution of river sand with MS remarkably decreases the slump, slump flow, compressive strength, splitting tensile strength, and modulus of elasticity of the concretes. The 28-day compressive strength of GC containing 100% MS was reduced by 42% compared to the control sample, and the modulus of elasticity of GC was notably lower than that of CC.

- The use of MS as a fine aggregate replacement increases the density, porosity, and water absorption of concrete. The ultrasonic pulse velocity and thermal conductivity values of the concrete decreased with increasing MS content. A reduction in the thermal conductivity of concrete incorporating MS can result in better insulation.

- A reduction in acid resistance was found in concretes containing MS, in which CC was more affected than GC. The presence of MS in the concrete increased chloride penetration after exposure to a 3% NaCl solution. GC showed better resistance to chloride ion penetration than CC.

- Replacement of river sand with MS in geopolymers and cement concretes enhances the shielding properties against gamma rays (emitted from Cs-137 and Co-60) and fast neutron radiation. In the case of GC, as the MS content increases from 0% to 100%, the HVL decreases from 5.15 cm to 4.75 cm when exposed to Co-60 at a photon energy of 1332 keV, while the increased from 0.0635 cm−1 to 0.0644 cm−1.

All these findings suggest that the utilization of MS to replace river sand in GC offers an alternative approach to upcycling MS waste for producing sustainable materials with radiation-shielding properties against gamma rays and fast neutrons. MS is a viable candidate for a novel construction material for radiation shielding purposes. However, MS availability, cost, and corrosion risk in aggressive environments should be carefully considered due to potential impacts on long-term concrete durability. Additionally, further studies should explore the combination of MS with other heavyweight coarse aggregates to further enhance their radiation shielding properties.

Author Contributions

Conceptualization, L.S. and V.S.; investigation, L.S.; methodology, L.S., A.W. and C.Y.; data curation, L.S. and C.Y.; writing—original draft preparation, L.S.; validation, A.W., C.Y., J.E., U.R. and P.C.; writing—review and editing, C.Y., J.E., V.S., U.R. and P.C.; supervision, V.S.; resources, V.S.; funding acquisition, V.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fundamental Fund of Khon Kaen University. “The use of heavyweight aggregate in geopolymer composites” has received funding support from the National Science, Research and Innovation Fund (NSRF). The first author would like to acknowledge the support of the KKU Scholarship for ASEAN & GMS Countries Personnel from Khon Kaen University.

Data Availability Statement

Research data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Gartner, E. Industrially interesting approaches to “low-CO2” cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Meyer, C. The Greening of the Concrete Industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Humphreys, K.; Mahasenan, M. Towards a Sustainable Cement Industry: Climate Change. Substudy 8; World Business Council for Sustainable Development: Geneva, Switzerland, 2002. [Google Scholar]

- Josa, A.; Aguado, A.; Heino, A.; Byars, E.; Cardim, A. Comparative analysis of available life cycle inventories of cement in the EU. Cem. Concr. Res. 2004, 34, 1313–1320. [Google Scholar] [CrossRef]

- de Amorim Júnior, N.S.; Neto, J.S.A.; Santana, H.A.; Cilla, M.S.; Ribeiro, D.V. Durability and service life analysis of metakaolin-based geopolymer concretes with respect to chloride penetration using chloride migration test and corrosion potential. Constr. Build. Mater. 2021, 287, 122970. [Google Scholar] [CrossRef]

- Bezabih, T.; Kanali, C.; Thuo, J. Effects of teff straw ash on the mechanical and microstructural properties of ambient cured fly ash-based geopolymer mortar for onsite applications. Results Eng. 2023, 18, 101123. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Zhong, W.L.; Fan, L.F. Long-term durability investigation of basalt fiber-reinforced geopolymer concrete in marine environment. J. Mater. Res. Technol. 2024, 31, 593–605. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Wallah, S.E.; Hardjito, D.; Sumajouw, D.M.J.; Rangan, B.V. Sulfate and Acid Resistance of Fly Ash-Based Geopolymer Concrete. In Australian Structural Engineering Conference 2005; Engineers Australia: Sydney, NSW, Australia, 2005. [Google Scholar]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Salem, H.A. Effect of cement addition, solution resting time and curing characteristics on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 123, 581–593. [Google Scholar] [CrossRef]

- Part, W.K.; Ramli, M.; Cheah, C.B. An Overview on the Influence of Various Factors on the Properties of Geopolymer Concrete Derived from Industrial Byproducts. Constr. Build. Mater. 2015, 77, 370–395. [Google Scholar] [CrossRef]

- Gunasekara, C.; Law, D.; Bhuiyan, S.; Setunge, S.; Ward, L. Chloride induced corrosion in different fly ash based geopolymer concretes. Constr. Build. Mater. 2019, 200, 502–513. [Google Scholar] [CrossRef]

- Ma, N.; Houser, J.B.; Wood, L.A. Production of cleaner mill scale by dynamic separation of the mill scale from the fast-moving flume water at a hot rolling mill. J. Clean. Prod. 2018, 176, 889–894. [Google Scholar] [CrossRef]

- Umadevi, T.; Brahmacharyulu, A.; Karthik, P.; Mahapatra, P.C.; Prabhu, M.; Ranjan, M. Recycling of steel plant mill scale via iron ore sintering plant. Ironmak. Steelmak. 2012, 39, 222–227. [Google Scholar] [CrossRef]

- Ozturk, M.; Depci, T.; Bahceci, E.; Karaaslan, M.; Akgol, O.; Sevim, U.K. Production of new electromagnetic wave shielder mortar using waste mill scales. Constr. Build. Mater. 2020, 242, 118028. [Google Scholar] [CrossRef]

- Sharma, R.; Hussain, S.; Seetala, N.; Matthews, J.; Edwards, R.; Amritphale, S.; Matthews, E. Simultaneous use of bismuth trioxide and mill scale for ternary blended geopolymer composite in radiation shielding applications. Prog. Nucl. Energy 2024, 172, 105213. [Google Scholar] [CrossRef]

- Nongnuang, T.; Jitsangiam, P.; Rattanasak, U.; Chindaprasirt, P. Novel electromagnetic induction heat curing process of fly ash geopolymer using waste iron powder as a conductive material. Sci. Rep. 2022, 12, 9530. [Google Scholar] [CrossRef]

- Doi, K.; Hiromoto, S.; Shinohara, T.; Tsuchiya, K.; Katayama, H.; Akiyama, E. Role of mill scale on corrosion behavior of steel rebars in mortar. Corros. Sci. 2020, 177, 108995. [Google Scholar] [CrossRef]

- Ming, J.; Shi, J.; Sun, W. Effect of mill scale on the long-term corrosion resistance of a low-alloy reinforcing steel in concrete subjected to chloride solution. Constr. Build. Mater. 2018, 163, 508–517. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, H.; Deng, Y.; Cao, Y.; He, Y.; Liu, Y.; Deng, Y. Fatigue behavior of high-strength steel wires considering coupled effect of multiple corrosion-pitting. Corros. Sci. 2025, 244, 112633. [Google Scholar] [CrossRef]

- Zhang, H.; Deng, Y.; Cao, Y.; Chen, F.; Luo, Y.; Xiao, X.; Deng, Y.; Liu, Y. Field testing, analytical, and numerical assessments on the fatigue reliability on bridge suspender by considering the coupling effect of multiple pits. Struct. Infrastruct. Eng. 2024, 1–16. [Google Scholar] [CrossRef]

- Ozturk, M.; Karabulut, A. Electromagnetic Interference Shielding Properties of Carbon Fiber Mortars with Mill Scale and Red Mud: A Comparative Study. Constr. Build. Mater. 2024, 451, 138827. [Google Scholar] [CrossRef]

- Siriwattanakarn, A.; Wongsa, A.; Eua-Anant, N.; Sata, V.; Sukontasukkul, P.; Chindaprasirt, P. Utilization of Mill Scale Waste as Natural Fine Aggregate Replacement in Mortar: Evaluation of Physical, Mechanical, Durability, and Post-Fire Properties. Recycling. 2025, 10, 20. [Google Scholar] [CrossRef]

- Ahmed, S.M.; Kamal, I. Electrical resistivity and compressive strength of cement mortar based on green magnetite nanoparticles and wastes from steel industry. Case Stud. Constr. Mater. 2022, 17, e01712. [Google Scholar] [CrossRef]

- Nawaz, A.; Hussain, S.; Tufail, R.F.; Iqbal, H.W.; Mehmood, T.; Saingam, P.; Alattyih, W.; Ahmad, J. Performance evaluation of high-performance concrete mixes incorporating recycled steel scale waste as fine aggregates. Results Eng. 2024, 24, 103079. [Google Scholar] [CrossRef]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric composite materials for radiation shielding: A review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef] [PubMed]

- Sayyed, M.I.; El-Mesady, I.A.; Abouhaswa, A.S.; Askin, A.; Rammah, Y.S. Comprehensive study on the structural, optical, physical and gamma photon shielding features of B2O3-Bi2O3-PbO-TiO2 glasses using WinXCOM and Geant4 code. J. Mol. Struct. 2019, 1197, 656–665. [Google Scholar] [CrossRef]

- Daungwilailuk, T.; Yenchai, C.; Rungjaroenkiti, W.; Pheinsusom, P.; Panwisawas, C.; Pansuk, W. Use of barite concrete for radiation shielding against gamma-rays and neutrons. Constr. Build. Mater. 2022, 326, 126838. [Google Scholar] [CrossRef]

- Awadeen, M.; Amin, M.; Bakr, R.H.; Tahwia, A.M. Mechanical properties, attenuation coefficient, and microstructure of ultra high-performance heavyweight concrete for radiation shielding applications. J. Build. Eng. 2024, 82, 108395. [Google Scholar] [CrossRef]

- Azreen, N.M.; Rashid, R.S.M.; Amran, Y.H.M.; Voo, Y.L.; Haniza, M.; Hairie, M.; Alyousef, R.; Alabduljabbar, H. Simulation of ultra-high-performance concrete mixed with hematite and barite aggregates using Monte Carlo for dry cask storage. Constr. Build. Mater. 2020, 263, 120161. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Antolik, A.; Gawlicki, M. Evaluation of compatibility of neutron-shielding boron aggregates with Portland cement in mortar. Constr. Build. Mater. 2018, 164, 731–738. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Yalçınkaya, Ç.; Tuyan, M. Optimization of reactive powder concrete by means of barite aggregate for both neutrons and gamma rays. Constr. Build. Mater. 2018, 189, 470–477. [Google Scholar] [CrossRef]

- Piotrowski, T. Neutron shielding evaluation of concretes and mortars: A review. Constr. Build. Mater. 2021, 277, 122238. [Google Scholar] [CrossRef]

- Prochon, P.; Piotrowski, T. The effect of cement and aggregate type and w/c ratio on the bound water content and neutron shielding efficiency of concretes. Constr. Build. Mater. 2020, 264, 120210. [Google Scholar] [CrossRef]

- Temuujin, J.; van Riessen, A.; Williams, R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. J. Hazard. Mater. 2009, 167, 82–88. [Google Scholar] [CrossRef]

- Dombrowski, K.; Buchwald, A.; Weil, M. The influence of calcium content on the structure and thermal performance of fly ash based geopolymers. J. Mater. Sci. 2007, 42, 3033–3043. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chareerat, T.; Hatanaka, S.; Cao, T. High-Strength Geopolymer Using Fine High-Calcium Fly Ash. J. Mater. Civ. Eng. 2011, 23, 264–270. [Google Scholar] [CrossRef]

- ASTM C192-07; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C143-08; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C1611-05; Standard Test Method for Slump Flow of Self-Consolidating Concrete. ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM C39-05; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens 1. ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM C469-04; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM C496-04; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM C642-06; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM C597-02; Standard Test Method for Ultrasonic Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM D5930; Standard Test Method for Thermal Conductivity of Plastics by Means of a Transient Line-Source Technique. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C267-01; Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer Concretes. ASTM International: West Conshohocken, PA, USA, 2001.

- Nuaklong, P.; Sata, V.; Wongsa, A.; Srinavin, K.; Chindaprasirt, P. Recycled aggregate high calcium fly ash geopolymer concrete with inclusion of OPC and nano-SiO2. Constr. Build. Mater. 2018, 174, 244–252. [Google Scholar] [CrossRef]

- Parvathikumar, G.; Sahadevan, B.; Palanisamy, C. Scrap steel mill scale as river sand replacement in cement concrete: Effect on durability characteristics. J. Mater. Cycles Waste Manag. 2024, 26, 1490–1504. [Google Scholar] [CrossRef]

- Alwaeli, M.; Nadziakiewicz, J. Recycling of scale and steel chips waste as a partial replacement of sand in concrete. Constr. Build. Mater. 2012, 28, 157–163. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.; Rangan, B. Fracture properties of geopolymer paste and concrete. Mag. Concr. Res. 2011, 63, 763–771. [Google Scholar] [CrossRef]

- Yost, J.R.; Radlińska, A.; Ernst, S.; Salera, M. Structural behavior of alkali activated fly ash concrete. Part 1: Mixture design, material properties and sample fabrication. Mater. Struct. 2013, 46, 435–447. [Google Scholar] [CrossRef]

- ACI 318-08; Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2008.

- Hardjito, D.; Wallah, S.; Sumajouw, D.M.J.; Rangan, B. Fly Ash-Based Geopolymer Concrete. Aust. J. Struct. Eng. 2005, 6, 77–86. [Google Scholar] [CrossRef]

- Nasvi, M.M.C.; Gamage, R.P.; Sanjayan, J. Geopolymer as well cement and variation of its mechanical behavior with curing temperature. Greenh. Gases Sci. Technol. 2012, 2, 46–58. [Google Scholar] [CrossRef]

- Noushini, A.; Castel, A. The effect of heat-curing on transport properties of low-calcium fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 464–477. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; AL-Hashmi, E.A. Reuse of waste iron as a partial replacement of sand in concrete. Waste Manag. 2008, 28, 2048–2053. [Google Scholar] [CrossRef]

- Kunthawatwong, R.; Sylisomchanh, L.; Pangdaeng, S.; Wongsa, A.; Sata, V.; Sukontasukkul, P.; Chindaprasirt, P. Recycled Non-Biodegradable polyethylene terephthalate waste as fine aggregate in fly ash geopolymer and cement mortars. Constr. Build. Mater. 2022, 328, 127084. [Google Scholar] [CrossRef]

- Tawfik, T.A.; Slaný, M.; Palou, M.T. Influence of heavyweight aggregate on the fresh, mechanical, durability, and microstructural properties of self-compacting concrete under elevated temperatures. J. Build. Eng. 2023, 80, 108104. [Google Scholar] [CrossRef]

- Esen, Y.; Doğan, Z.M. Evaluation of physical and mechanical characteristics of siderite concrete to be used as heavy-weight concrete. Cem. Concr. Compos. 2017, 82, 117–127. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U.; Sompop, T. Resistance to acid and sulfate solutions of microwave-assisted high calcium fly ash geopolymer. Mater. Struct. 2012, 46, 375–381. [Google Scholar] [CrossRef]

- Somna, R.; Jaturapitakkul, C.; Made, A.M. Effect of ground fly ash and ground bagasse ash on the durability of recycled aggregate concrete. Cem. Concr. Compos. 2012, 34, 848–854. [Google Scholar] [CrossRef]

- Tennakoon, C.; Shayan, A.; Sanjayan, J.G.; Xu, A. Chloride ingress and steel corrosion in geopolymer concrete based on long-term tests. Mater. Des. 2017, 116, 287–299. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Brice, D.G.; Kilcullen, A.R.; Hamdan, S.; Van Deventer, J.S.J. Influence of fly ash on the water and chloride permeability of alkali-activated slag mortars and concretes. Constr. Build. Mater. 2013, 48, 1187–1201. [Google Scholar] [CrossRef]

- Gharieb, M.; Mosleh, Y.A.; Alwetaishi, M.; Hussein, E.E.; Sultan, M.E. Effect of using heavy aggregates on the high-performance concrete used in nuclear facilities. Constr. Build. Mater. 2021, 310, 125111. [Google Scholar] [CrossRef]

- Lotfi-Omran, O.; Sadrmomtazi, A.; Nikbin, I.M. The influences of maximum aggregate size and cement content on the mechanical and radiation shielding characteristics of heavyweight concrete. Prog. Nucl. Energy 2020, 121, 103222. [Google Scholar] [CrossRef]

- Saca, N.; Radu, L.; Fugaru, V.; Gheorghe, M.; Petre, I. Composite materials with primary lead slag content: Application in gamma radiation shielding and waste encapsulation fields. J. Clean. Prod. 2018, 179, 255–265. [Google Scholar] [CrossRef]

- Demir, I.; Gümüş, M.; Gökçe, H.S. Gamma ray and neutron shielding characteristics of polypropylene fiber-reinforced heavyweight concrete exposed to high temperatures. Constr. Build. Mater. 2020, 257, 119596. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).