Abstract

Polylactic acid (PLA) is widely used in 3D printing for its biodegradability and ease of processing, but its brittleness and low impact strength often restrict its suitability for more demanding applications. The novelty of this work lies in its direct comparative approach: we systematically reinforce PLA with two distinct agricultural residues—rice husk and rice straw—under identical conditions to clarify how particle size (100 vs. 200 mesh) and NaOH surface treatment affect mechanical performance. Composite filaments containing 5–20 wt% of each fiber were produced and 3D-printed into standard tensile and flexural specimens. The results show that, although tensile strength declines at higher fiber loadings, tensile modulus, flexural strength, and impact resistance can improve significantly—particularly with 200-mesh and NaOH-treated fibers. Fourier transform infrared (FTIR) spectroscopy confirms partial lignin removal and enhanced cellulose exposure, improving fiber–matrix adhesion, which is corroborated by scanning electron microscopy (SEM) observations of reduced voids. This comparative study demonstrates that surface-treated, finely milled rice husk and rice straw significantly enhance PLA’s stiffness and toughness, offering a sustainable alternative to conventional polymeric additives. The insights gained here on fiber content, chemical treatment, and 3D printing parameters can guide the broader industrial adoption of these natural fiber-reinforced PLA composites, particularly in automotive and construction applications that require lightweight, durable materials.

1. Introduction

3D printing, also known as additive manufacturing, has transitioned from a niche technology to a fundamental component of contemporary manufacturing processes [1,2]. Its ability to precisely fabricate complex geometries with minimal material waste has made it integral to sectors such as aerospace, automotive, and healthcare. Nevertheless, polylactic acid (PLA), which is widely utilized in 3D printing, poses substantial difficulties. Although PLA is renowned for its biodegradability [3,4], and its relatively low melting point that supports easy processing, it frequently falls short in several industrial applications because of its intrinsic brittleness and low impact strength [5]. These constraints require inventive ways to improve the material characteristics of PLA in order to fulfill the demanding requirements of industrial applications. Moreover, while many natural fibers have been investigated for composite reinforcement, there is limited research that compares two different biomass residues—such as rice husk and rice straw—in a single, systematic study.

The primary motivation behind this research is to address the mechanical limitations of PLA in 3D printing. The brittleness and low impact strength of PLA limit its application in challenging industrial settings, such as the automotive and construction sectors, where materials need to endure substantial mechanical strains [4,6]. Several prior studies have demonstrated the potential of reinforcing PLA with agricultural fibers; however, they often focus on a single fiber source or lack a robust comparison across different fiber sizes and treatments. The objective of this study is to improve the mechanical characteristics of PLA by using natural fibers such as rice husk and rice straw as reinforcements. By improving these properties, this research seeks to expand the applicability of PLA in various industrial applications, offering a sustainable and high-performance alternative to traditional materials. In doing so, we aim to highlight the novelty of contrasting these two distinct fibrous residues, each of which may present unique advantages in terms of availability, cost, and mechanical contribution to PLA.

Despite advancements in composite materials, there remains a notable gap in their practical application and performance under diverse conditions. The existing literature, including studies by [7,8], often lacks a comprehensive analysis of how these materials perform in real-world scenarios. This gap is particularly critical for industries that require materials with high durability and integrity. Addressing these aspects is essential to ensure materials’ suitability for industrial use and to promote broader adoption of sustainable composites. Our work addresses this gap by systematically examining how different mesh sizes and alkaline treatments of rice husk and rice straw affect the interfacial bonding and mechanical behavior of composites—an aspect that has not been thoroughly explored.

Additionally, in comparing rice husk to rice straw, we note that rice husks often contain a higher proportion of silica, making them inherently more rigid. Rice straw, on the other hand, possesses longer fibrous structures with notable cellulose and hemicellulose content, which may offer better tensile improvements. Furthermore, cost and availability vary across regions. Rice husks, a by-product of milling, are often obtained in large volumes from rice-processing facilities, whereas rice straw is left in the fields after harvest. Understanding these compositional and practical differences is essential to tailor fibers to specific mechanical requirements.

This study makes a substantial contribution to the field of additive manufacturing by incorporating natural fibers into PLA matrices. The incorporation of rice husk and rice straw fibers is intended to enhance the mechanical characteristics of PLA, including tensile strength [9,10], flexibility [11], and impact resistance [6]. The key contributions of this study include the demonstration of enhanced material functionality, making the composites more suitable for demanding industrial applications. Unlike many previous investigations that tested only one type of fiber, we provide a comparative perspective on two agrowaste fibers, emphasizing how each interacts with the PLA matrix differently, based on both fiber dimension and surface treatment regimen.

The anticipated implications of this research are extensive. By enhancing the mechanical properties of PLA, the study encourages broader adoption of these materials in industrial applications, particularly in the automotive and construction industries [12]. These sectors demand materials that can withstand high stress and provide durability. Our comparative approach also contributes to the literature by revealing the unique advantages of each fiber type, thus guiding manufacturers in selecting the optimal reinforcement strategy. The findings are expected to drive innovation in material science and contribute to the advancement of manufacturing technologies. Furthermore, this study aims to set a benchmark for future studies and development in the field, fostering educational and industrial advancements in additive manufacturing.

In summary, this study on natural fiber-reinforced PLA composites is poised to bridge critical gaps in the current landscape of 3D printing materials, pushing the industry towards solutions that offer enhanced performance and broader applicability [13,14,15]. By systematically analyzing two different agricultural residues—rice husk and rice straw—and employing multiple treatment conditions, we provide fresh insights that can inform more efficient, sustainable, and innovative uses of PLA-based composites for real-world applications.

2. Literature Review

2.1. Evolution of 3D Printing Technology

3D printing, or additive manufacturing, originated in the early 1980s and has experienced transformative growth due to improvements in speed, resolution, and material compatibility [1,2]. The rapid prototyping stage of 3D printing has evolved into an industrial-grade manufacturing process, with applications in aerospace, automotive, biomedical, and consumer goods [16,17,18].

2.2. Advantages of 3D Printing

One of the key benefits of 3D printing is its capacity to create intricate, customized designs without excessive material waste. Complex geometries can be realized with minimal manufacturing steps, facilitating a faster time-to-market. Additionally, its layer-by-layer approach inherently reduces waste compared to subtractive manufacturing [19,20]. These advantages align well with modern sustainability goals, particularly when used in tandem with biodegradable polymers such as PLA.

2.3. Expanded Review: Natural Fiber–Reinforced PLA

Natural fibers have been explored extensively as reinforcements for polymer matrices, including PLA, due to their biodegradability, abundance, and cost-effectiveness [21,22,23,24]. In many studies, fibers such as jute, sisal, bamboo, and hemp have been shown to enhance the mechanical properties of PLA, especially when surface treatments (e.g., alkaline treatment) are applied to improve fiber-matrix adhesion.

Although numerous natural fibers have been studied, two byproducts of rice production—rice husk and rice straw—have garnered attention more recently [25]. However, the literature often focuses on one material at a time (e.g., only rice husk), leaving a gap in direct comparisons of how both residues might perform within the same experimental framework. As agricultural waste, both resources are abundant and inexpensive. Rice husks removed during milling often have higher silica content, which can contribute to stiffness in composites [26]. In contrast, rice straw tends to be more fibrous, containing long cellulose strands that can improve tensile performance. Indeed, cost and availability can differ by geographic region: rice husk is typically available at milling facilities, while rice straw may be left in the field and require gathering and potential pretreatment.

These differences in composition suggest that rice husk and rice straw might impart distinct mechanical behaviors when incorporated into PLA. Despite some scattered research on each fiber individually, a comprehensive side-by-side evaluation of husk vs. straw—particularly incorporating mesh size variations and alkaline treatments—remains sparse in recent literature.

2.4. Uniqueness of This Study

The present study addresses this gap by systematically examining both rice husk and rice straw as reinforcements in PLA filaments intended for 3D printing, using two distinct mesh sizes (100 and 200) and incorporating alkaline (NaOH) treatments to enhance fiber-matrix bonding. Our approach differs from previous work by providing a direct comparison of these two residues under identical processing conditions. This comparative perspective clarifies which waste stream (or combination thereof) best suits the specific mechanical requirements in PLA composites.

2.5. Additional Considerations in Fiber Reinforcement

Successful reinforcement also depends on factors such as fiber loading, dispersion, and alignment [22,23]. Excessive fiber content can cause void formation and inferior mechanical performance. Similarly, alkaline treatment parameters (temperature, duration, and NaOH concentration) can profoundly influence final composite properties [27]. Hence, a systematic variation in mesh size, fiber content, and chemical treatment is critical for identifying optimal formulations that balance tensile strength, flexural properties, and impact resistance.

2.6. Research Contribution and Implications

By integrating two different agricultural residues into PLA, this work demonstrates a sustainable route to enhanced polymer performance while valorizing biomass that would otherwise be disposed of or burned. This addresses a critical ecological need by potentially reducing waste and lowering carbon emissions, aligning with broader sustainability targets in additive manufacturing. The automotive and construction sectors, in particular, may benefit from higher-performing PLA composites due to weight reduction, improved mechanical resilience, and the resulting environmental advantages [12]. Therefore, the study’s outcomes can guide manufacturers, researchers, and policymakers in choosing suitable natural fiber sources for diverse industrial applications.

3. Research Methodology

3.1. Materials and Preparation

3.1.1. Polylactic Acid (PLA)

In this study, PLA 3D850 (NatureWorks, Minneapolis, MN, USA) was used as the base polymer. It was selected for its higher crystallization rate and thermal stability compared to standard-grade PLA, thus making it more suitable for 3D printing processes [28]. The basic properties of PLA 3D850, as provided by the manufacturer, include a density of approximately 1.24 g/cm3, a glass transition temperature of about 60 °C, and a melt flow index ranging from 6 to 10 g/10 min (measured at 210 °C, 2.16 kg).

3.1.2. Rice Husk and Rice Straw

The rice husk and rice straw used in this study were obtained from the Khlong Luang Agricultural Cooperative Limited (Khlong Luang, Pathum Thani, Thailand) as post-harvest agricultural residues. Prior to milling, both materials were air-dried and inspected to remove foreign matter. The dried fibers were then milled and passed through two different sieve sizes (100 mesh and 200 mesh), thereby controlling the overall particle dimensions. This process was designed to ensure that the fibrous reinforcements were neither excessively large—causing extrusion difficulties—nor too short, which can undermine mechanical performance [23].

Subsequent to milling, the fibers were subjected to a 5 wt% NaOH treatment at 50 °C for 2 h to remove impurities, waxes, and a portion of the lignin content, as described previously [13]. Following this alkaline treatment, the fibers were thoroughly rinsed with distilled water until neutral pH was reached and then dried in an oven at 60 °C for 6 h. Representative fiber morphologies were examined via scanning electron microscopy (SEM, JEOL JSM-IT200, Tokyo, Japan), confirming that the length distributions fell within an optimal range for effective reinforcement, as detailed in Section 4.2.

3.2. Optimized Ratio Selection

Although multiple ratios of rice husk and rice straw were initially tested, the optimal ratio for filament production was found to be 5 wt% rice husk and 10 wt% rice straw, based on preliminary mechanical tests (tensile and impact) and ease of filament extrusion.

Table 1 summarizes the compositions of the PLA composites formulated in this study, highlighting the weight percentage of PLA, rice husk, and rice straw in each sample.

Table 1.

Summary of PLA composite formulations (wt%).

3.3. Composite Pellet and Filament Production

3.3.1. Composite Pellet Formation

The PLA pellets were dried at 60 °C for 6 h to reduce moisture content. Subsequently, they were compounded with the treated rice husk (5 wt%) and rice straw (10 wt%) using a twin-screw extruder (Coperion ZSK-18, Niederbiegen, Germany) set at a temperature of 180 °C along the barrel zones, with a screw speed of 100 rpm. The molten blend was then cooled and pelletized into uniform composite pellets.

3.3.2. Filament Extrusion

These composite pellets were then re-extruded using a single-screw extruder (Felfil Evo, Turin, Italy) at 180 °C to form 3D-printable filaments. The filament diameter was carefully maintained at 1.75 mm (± 0.05 mm) by adjusting the pulling speed and monitoring with a laser gauge. The single-screw extruder was operated at approximately 15 rpm to ensure consistent flow and prevent fiber agglomeration.

3.4. 3D Printing of Test Specimens

3.4.1. Printing Parameters and Build Orientation

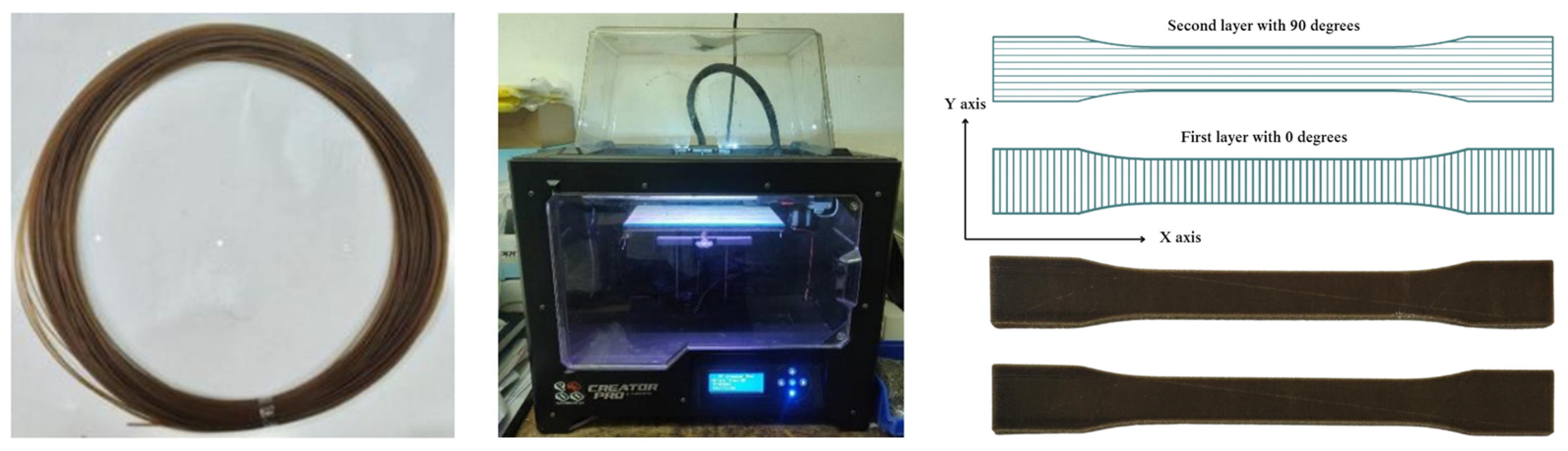

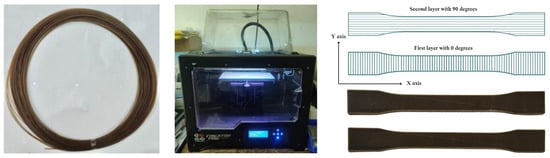

An FDM (fused deposition modeling) 3D printer (FlashForge Creator Pro, Hangzhou, China) was used to fabricate the test specimens. The nozzle temperature was set to 220 °C, and the build-plate temperature was 50 °C to ensure adequate adhesion without excessive warping. The layer height was 0.2 mm, and the print speed was 50–60 mm/s.

Specimens were printed using a 0°/90° raster pattern (Figure 1) to evaluate material behavior in both the longitudinal and transverse directions. This method better reflects real-world loading scenarios and establishes a standardized basis for comparing outcomes with existing data on 3D-printed composites [25].

Figure 1.

Printing specimens from the prepared composite filaments.

3.4.2. Specimen Geometry

Standard dog-bone tensile specimens (Type I) were designed according to ASTM D638, while rectangular flexural bars were printed following ASTM D790 specifications [9]. The overall dimensions (width, thickness, gauge length) conformed to each relevant standard.

3.5. Mechanical Testing

3.5.1. Tensile and Flexural Tests

Tensile tests were performed on a universal testing machine (Instron 5567, Norwood, MA, USA) at a crosshead speed of 5 mm/min, in accordance with ASTM D638 [29]. Flexural properties were examined via three-point bending tests following ASTM D790, using a crosshead speed of 1.35 mm/min [30]. Each test group consisted of seven replicate specimens (n = 7) to ensure statistical robustness.

3.5.2. Impact Strength

Izod impact tests were carried out (ASTM D256) using a 2 J pendulum [31]. Notched samples were prepared to a standardized depth and geometry prior to testing.

3.5.3. Data Analysis

All mechanical property measurements were performed with seven replicate specimens (n = 7) per formulation, in line with the recommended practice for polymer composite studies. The number of replicates reflects a balance between reducing statistical uncertainty and addressing practical constraints (e.g., availability of fibers and filament stability). The test fixtures and equipment were calibrated at regular intervals, and the specimens were produced under standardized printing conditions to minimize extrinsic sources of variability.

Once the tests were completed, the mean values and standard deviations were calculated for each property measured (tensile strength, tensile modulus, flexural strength, flexural modulus, and impact energy). These results are presented in the form of bar charts and tables, with explicit error bars indicating ±1 standard deviation. Although natural fiber reinforcements often increase heterogeneity in the composite microstructure, such transparent reporting of variability provides a realistic view of each formulation’s performance range. Furthermore, the moisture content of both PLA and natural fibers was controlled prior to compounding, and the fiber-size distribution was rigorously maintained to mitigate sample-to-sample inconsistencies.

3.6. Microstructural and Chemical Analysis

3.6.1. Scanning Electron Microscopy (SEM)

A JEOL JSM-IT200 SEM was utilized to examine the fracture surfaces of selected tensile specimens, focusing on fiber pull-out, interfacial bonding, and void formations.

3.6.2. FTIR Analysis—Methodology

Fourier transform infrared (FTIR) spectroscopy was conducted to elucidate the chemical structure of untreated and alkali-treated rice husk and rice straw fibers. Spectra were obtained using an FTIR spectrometer (PerkinElmer Spectrum Two, Waltham, MA, USA) over the range of 4000–400 cm−1 with a resolution of 4 cm−1 and 16 scans per sample. Each sample was mixed with KBr (spectroscopic grade) and pressed into pellets prior to measurement. The key diagnostic bands for lignocellulosic components were monitored, particularly

- 1720 cm−1 (C = O stretching of carbonyl group)

- 1050 cm−1 (C–O stretching in cellulose)

- 897 cm−1 (C–O–C stretching in cellulose).

All spectra were baseline-corrected to minimize artifacts and allow for direct comparison. To assess the extent of lignin removal and cellulose exposure, peak intensities and relative changes in these wavenumber regions were carefully compared between the untreated and NaOH-treated fibers.

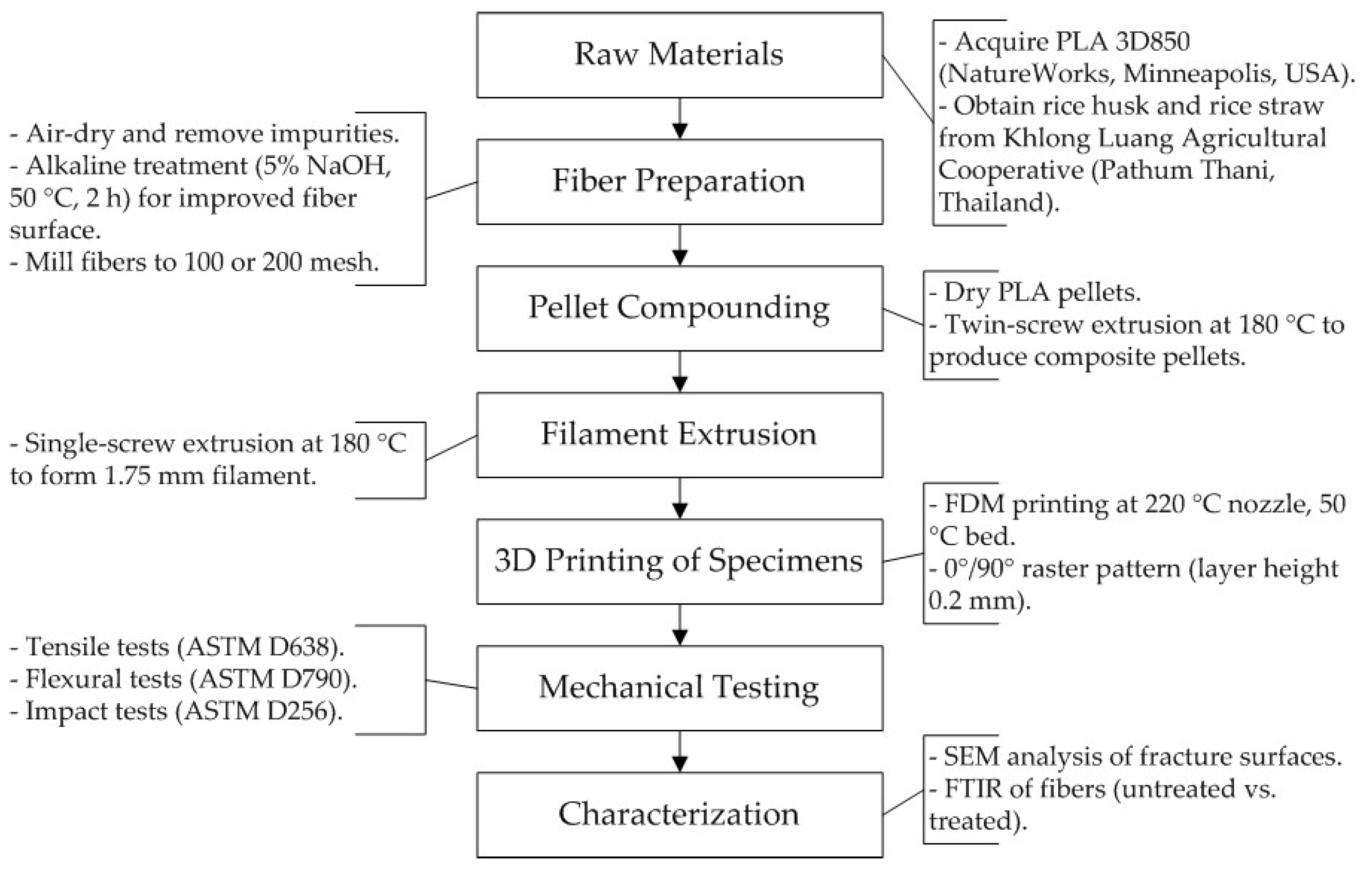

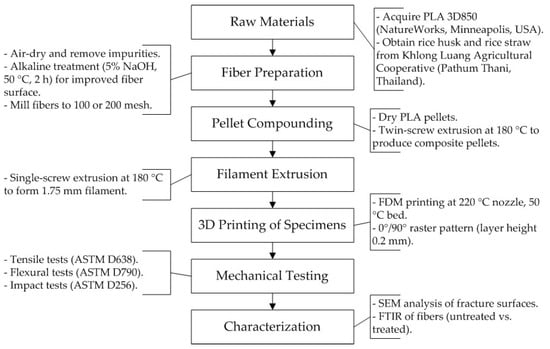

3.7. Overall Experimental Workflow

Figure 2 provides a concise overview of the entire experimental sequence, from raw material collection and fiber pretreatment through filament production, 3D printing, and final testing.

Figure 2.

Experimental workflow of PLA composite processing.

4. Results

4.1. Mechanical Properties of PLA Composites

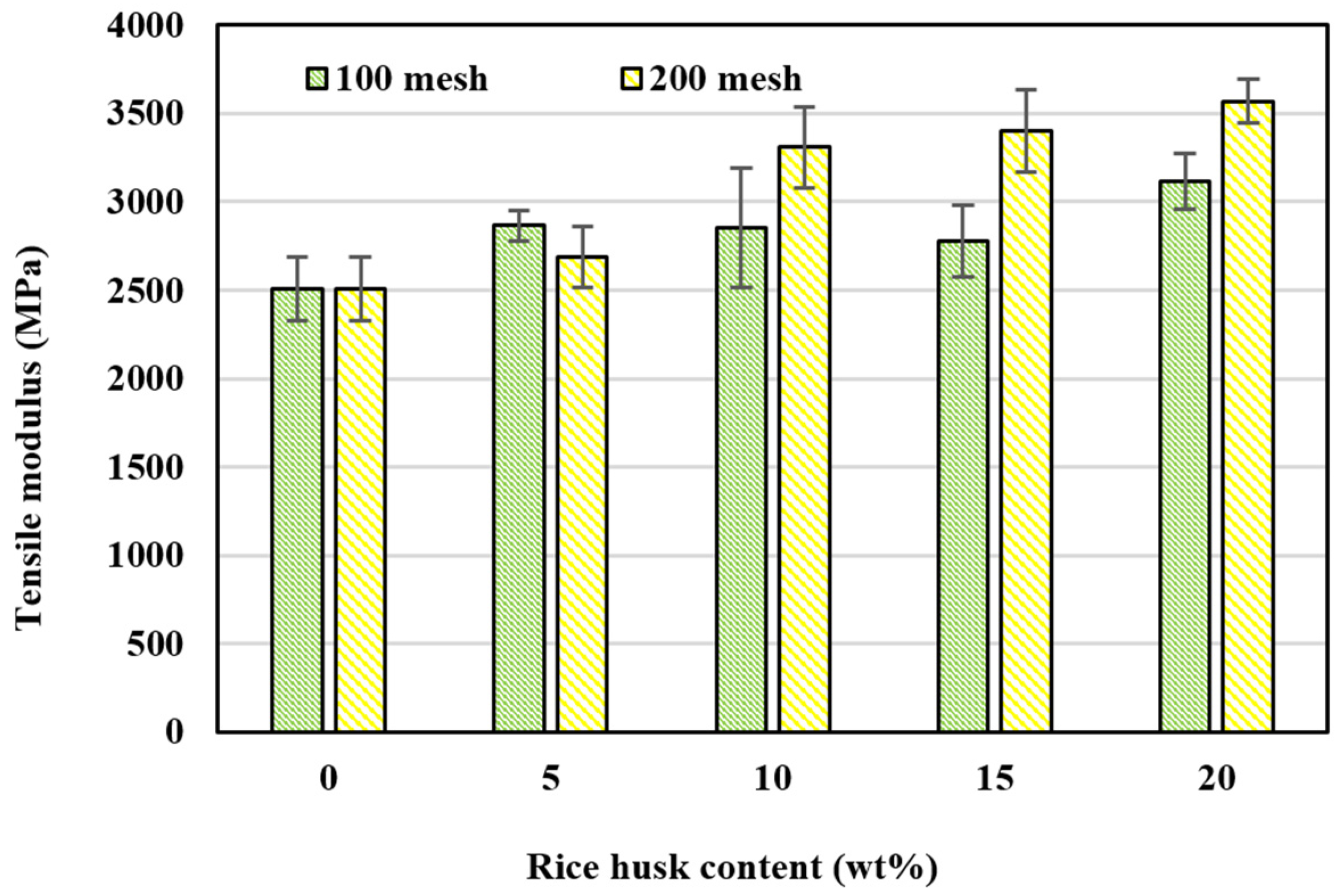

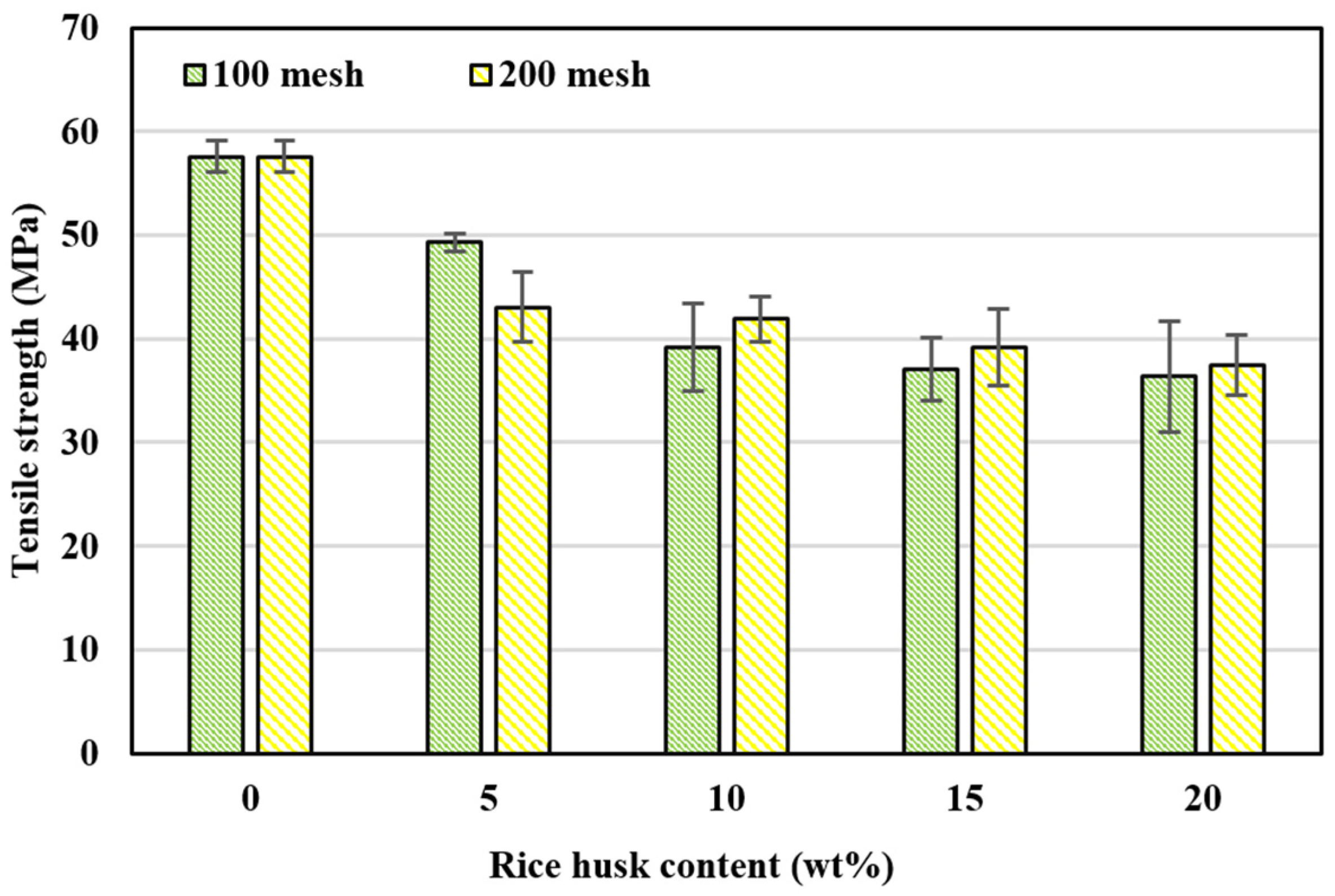

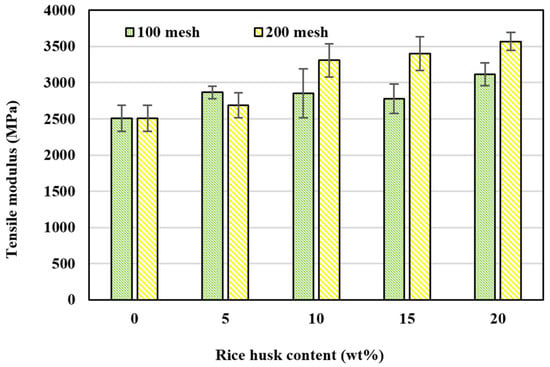

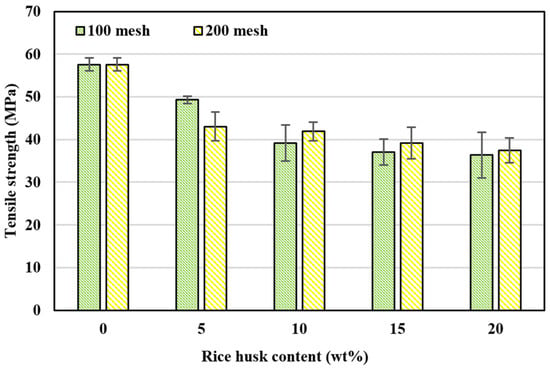

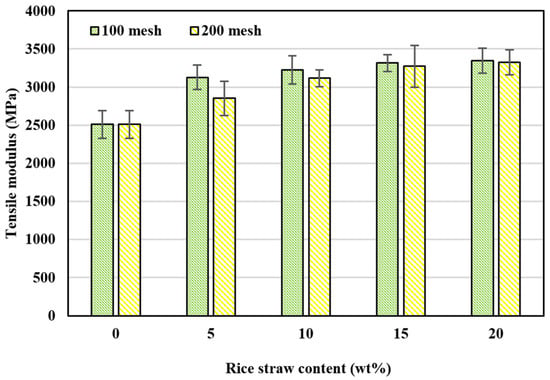

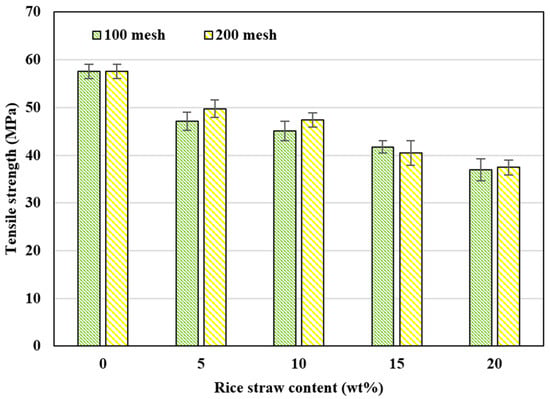

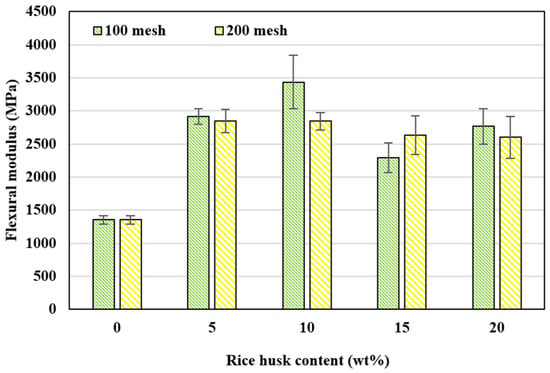

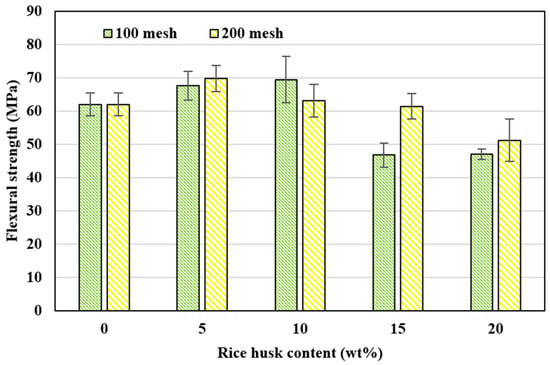

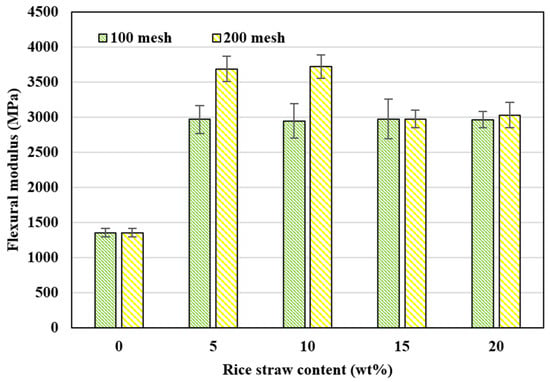

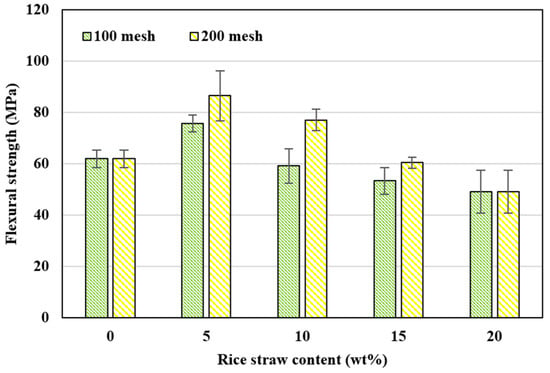

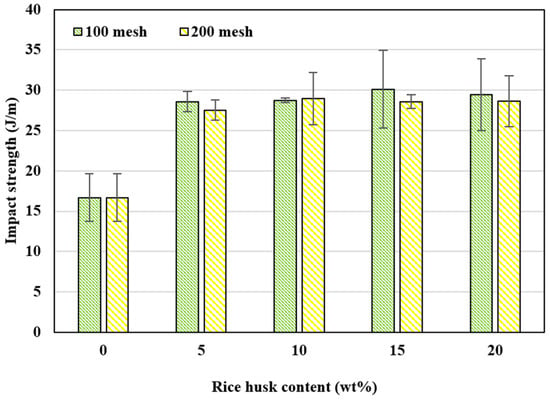

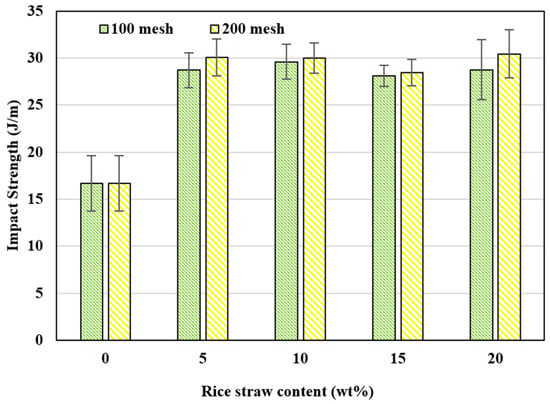

Mechanical testing focused on the tensile, flexural, and impact behaviors of 3D-printed PLA composites containing rice husk and rice straw at varying mesh sizes (100 mesh vs. 200 mesh). Figure 3, Figure 4, Figure 5, Figure 6, Figure 7, Figure 8, Figure 9, Figure 10, Figure 11 and Figure 12 present average values for each property, alongside error bars denoting ±1 standard deviation. While the data exhibit some variability—partly due to the inherent heterogeneity of natural fibers—the overall trends confirm that fiber incorporation can substantially alter the material’s stiffness, impact strength, and load-bearing capacity.

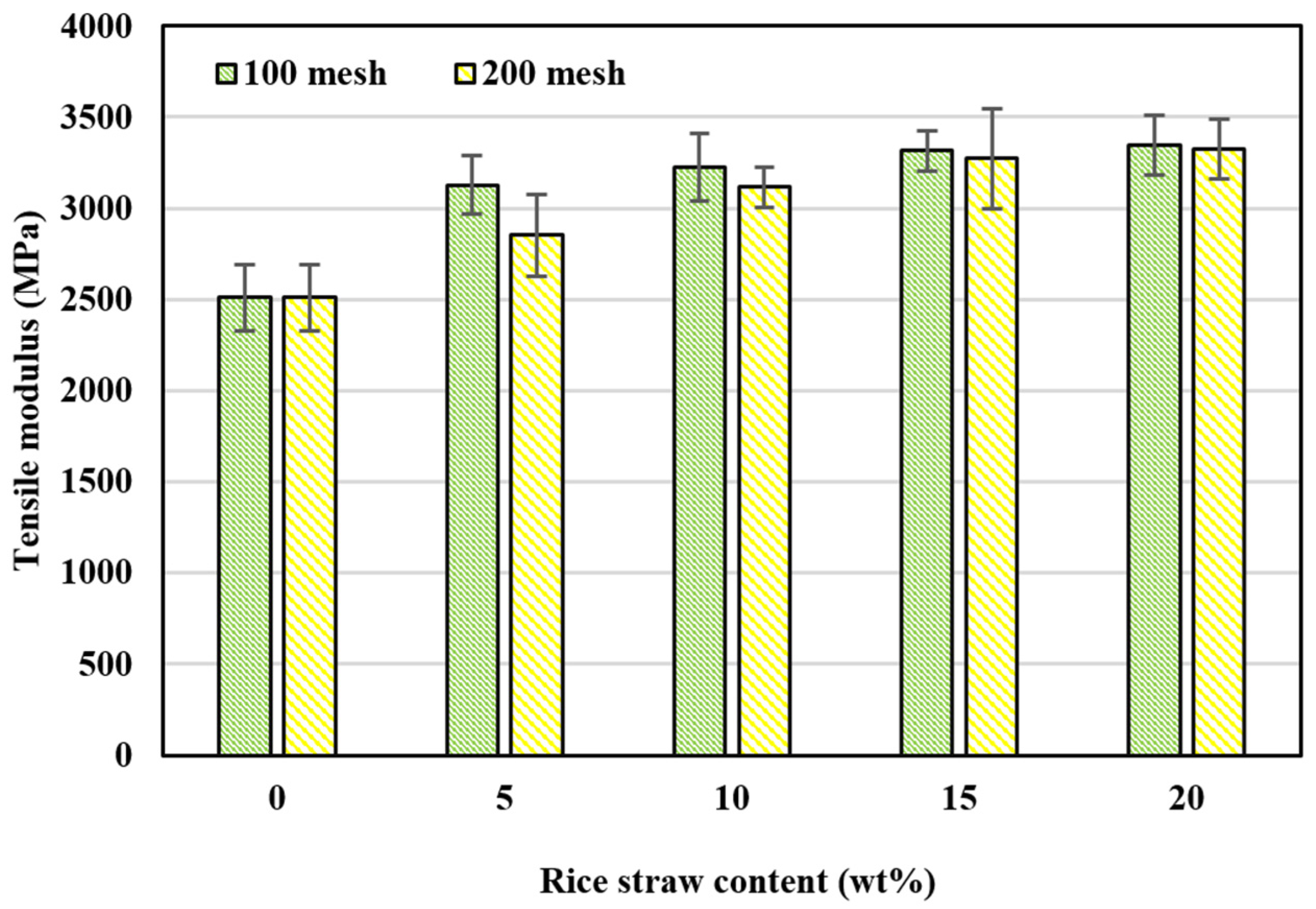

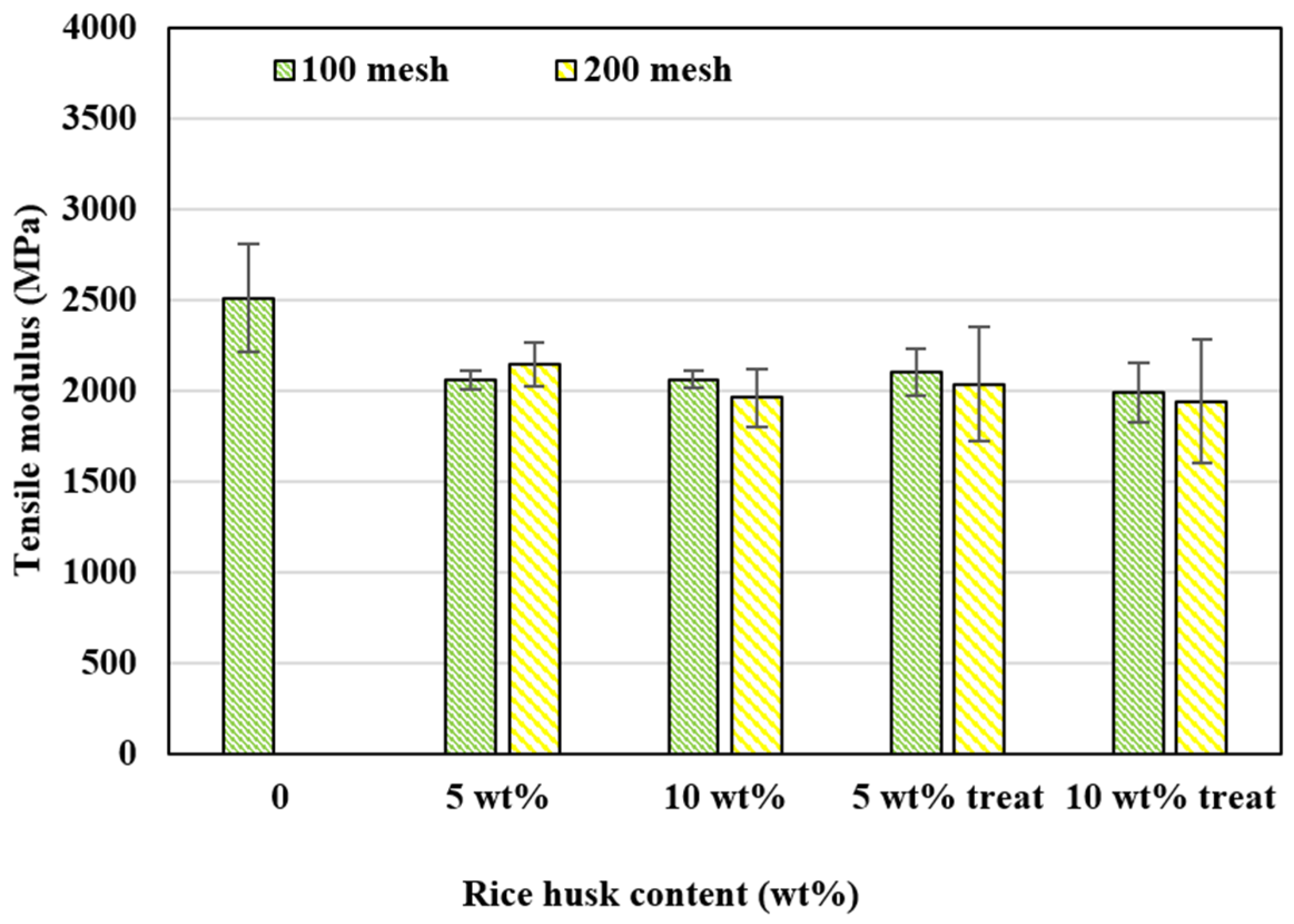

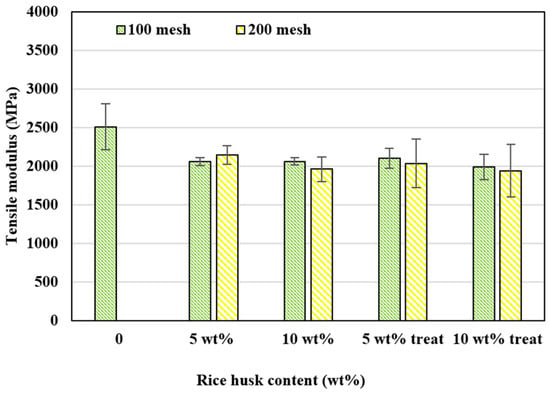

Figure 3.

Tensile modulus of PLA composites reinforced with rice husk.

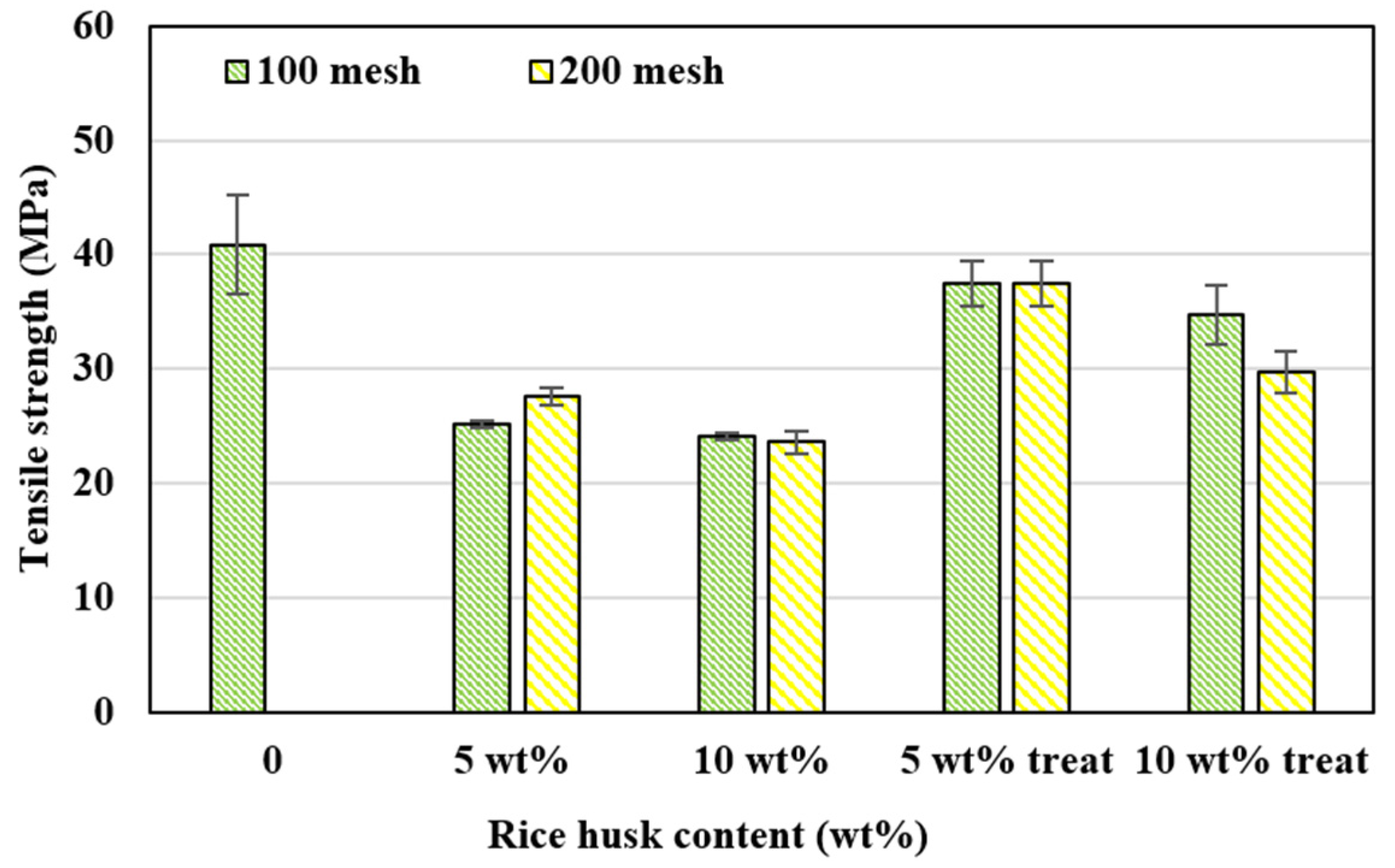

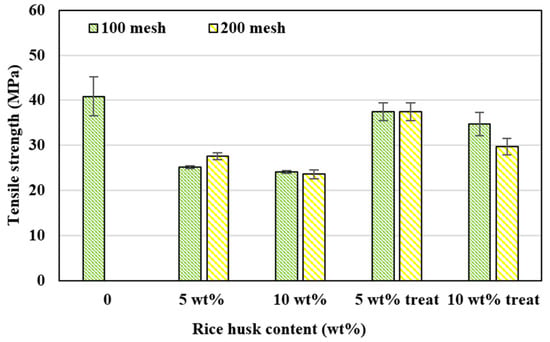

Figure 4.

Tensile strength of PLA composites reinforced with rice husk.

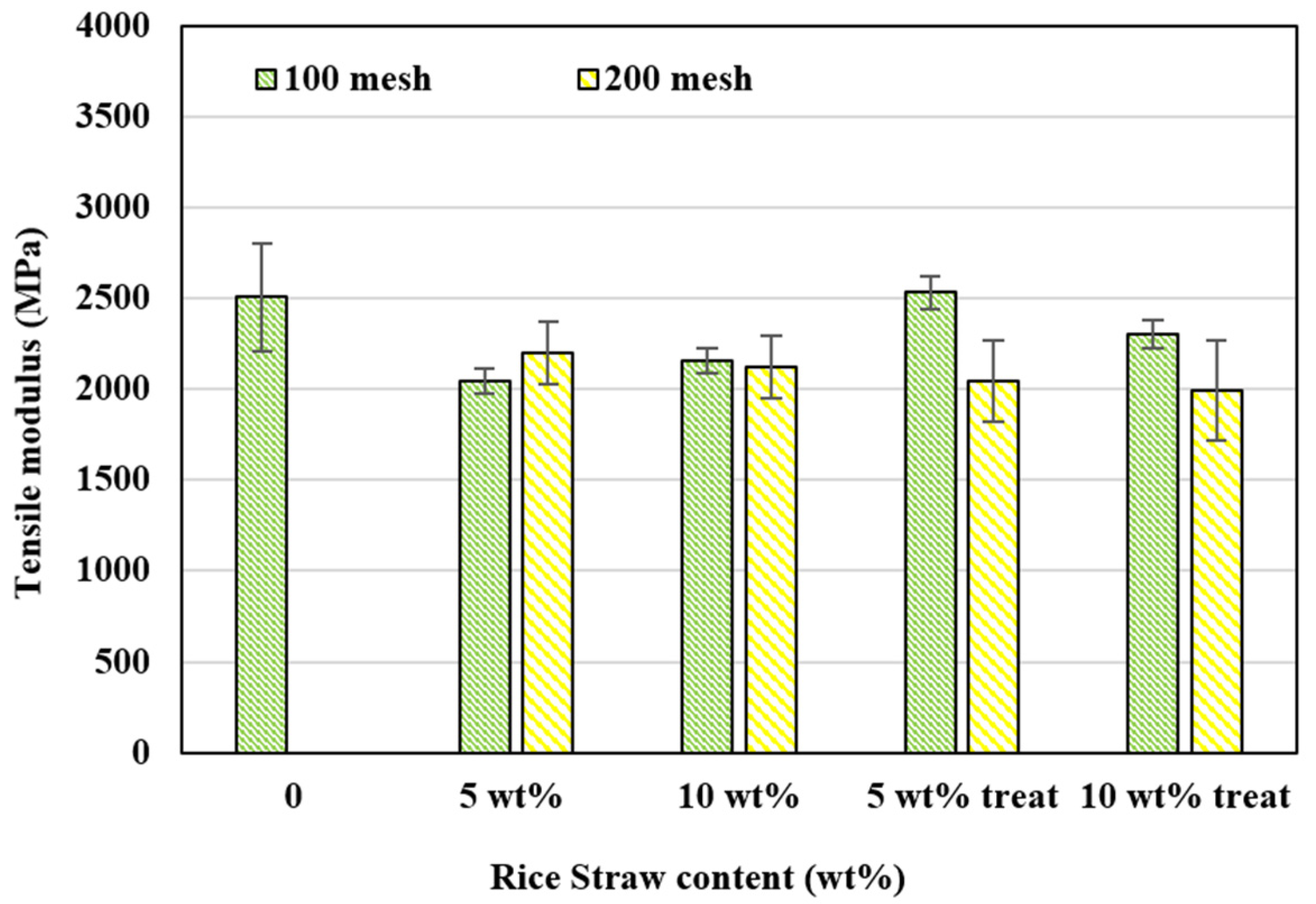

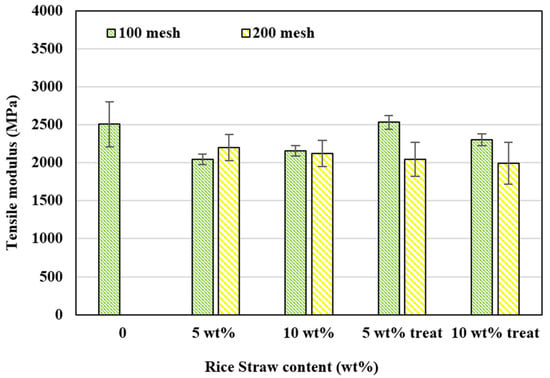

Figure 5.

Tensile modulus of PLA composites reinforced with rice straw.

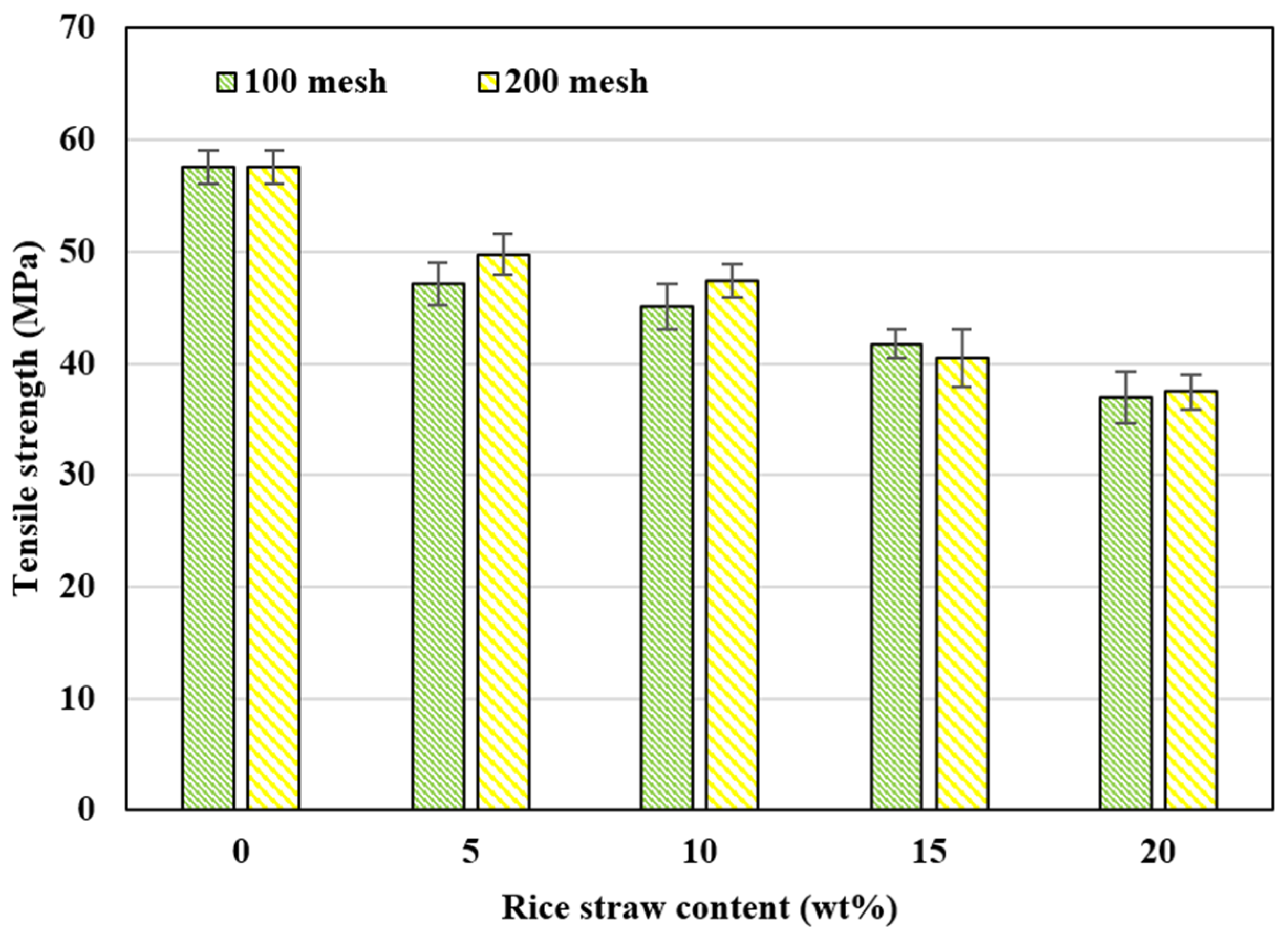

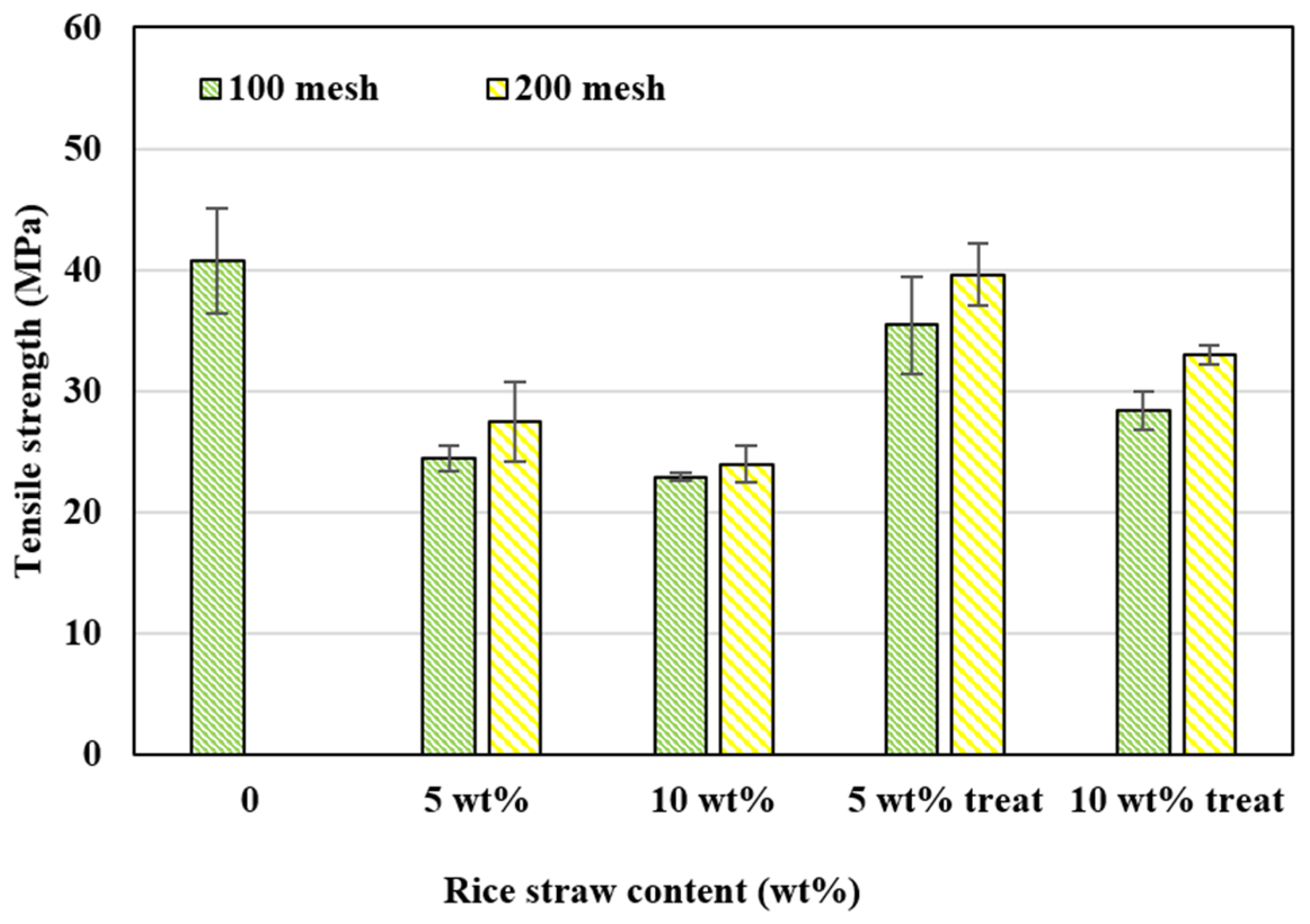

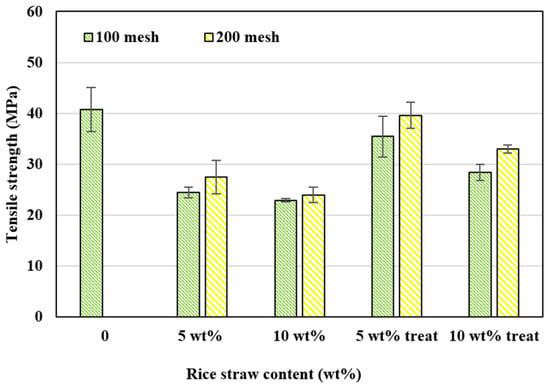

Figure 6.

Tensile strength of PLA composites reinforced with rice straw.

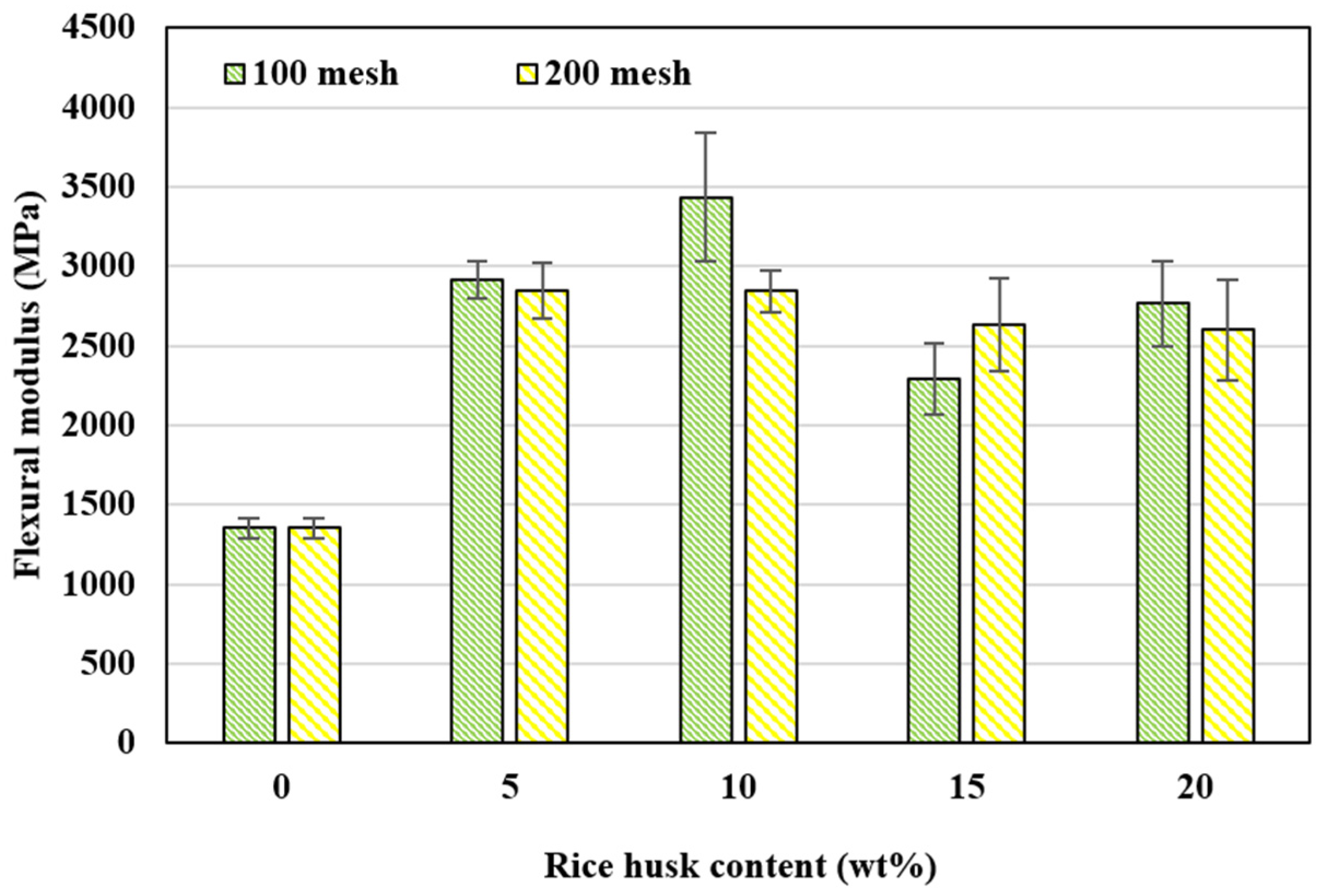

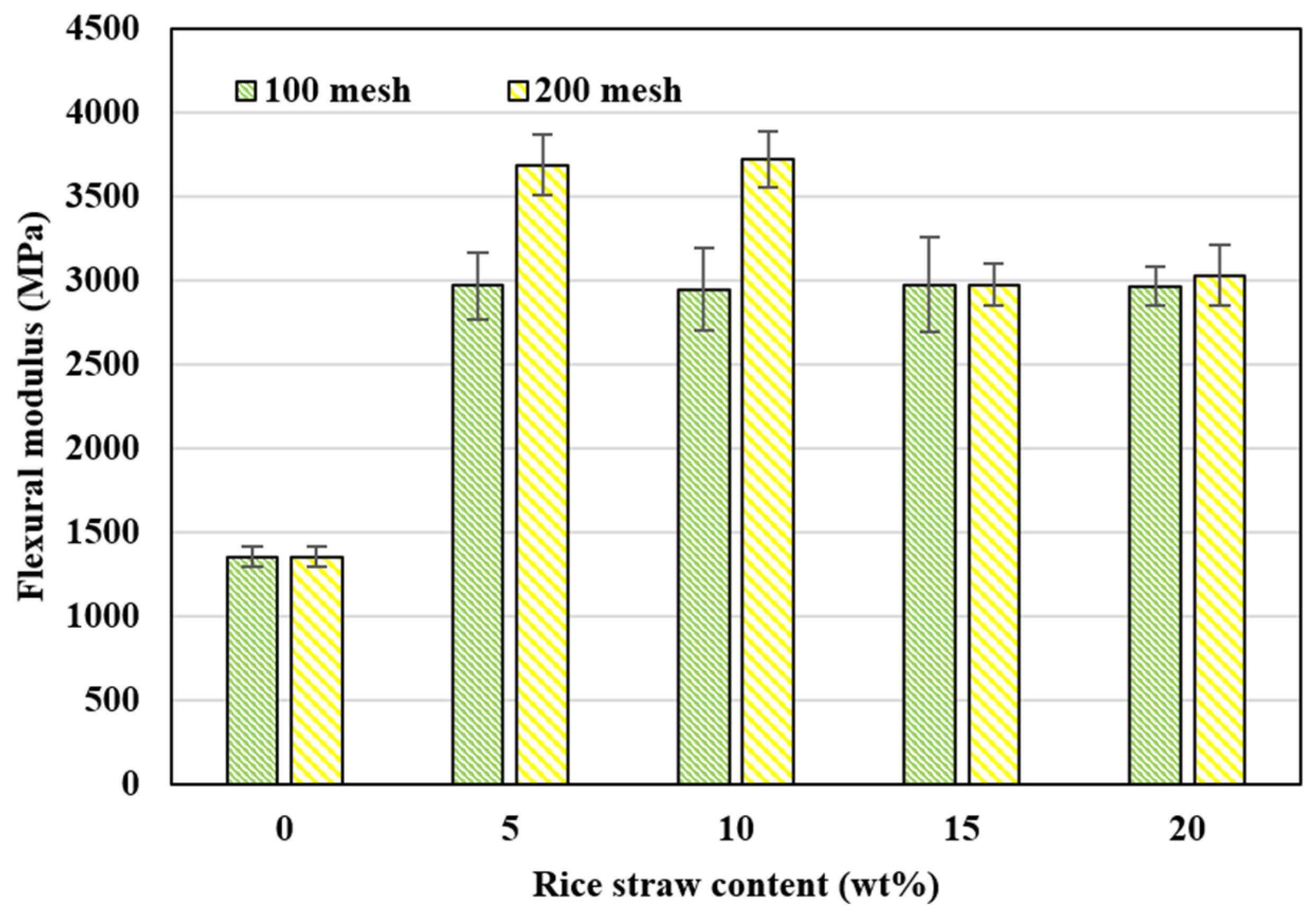

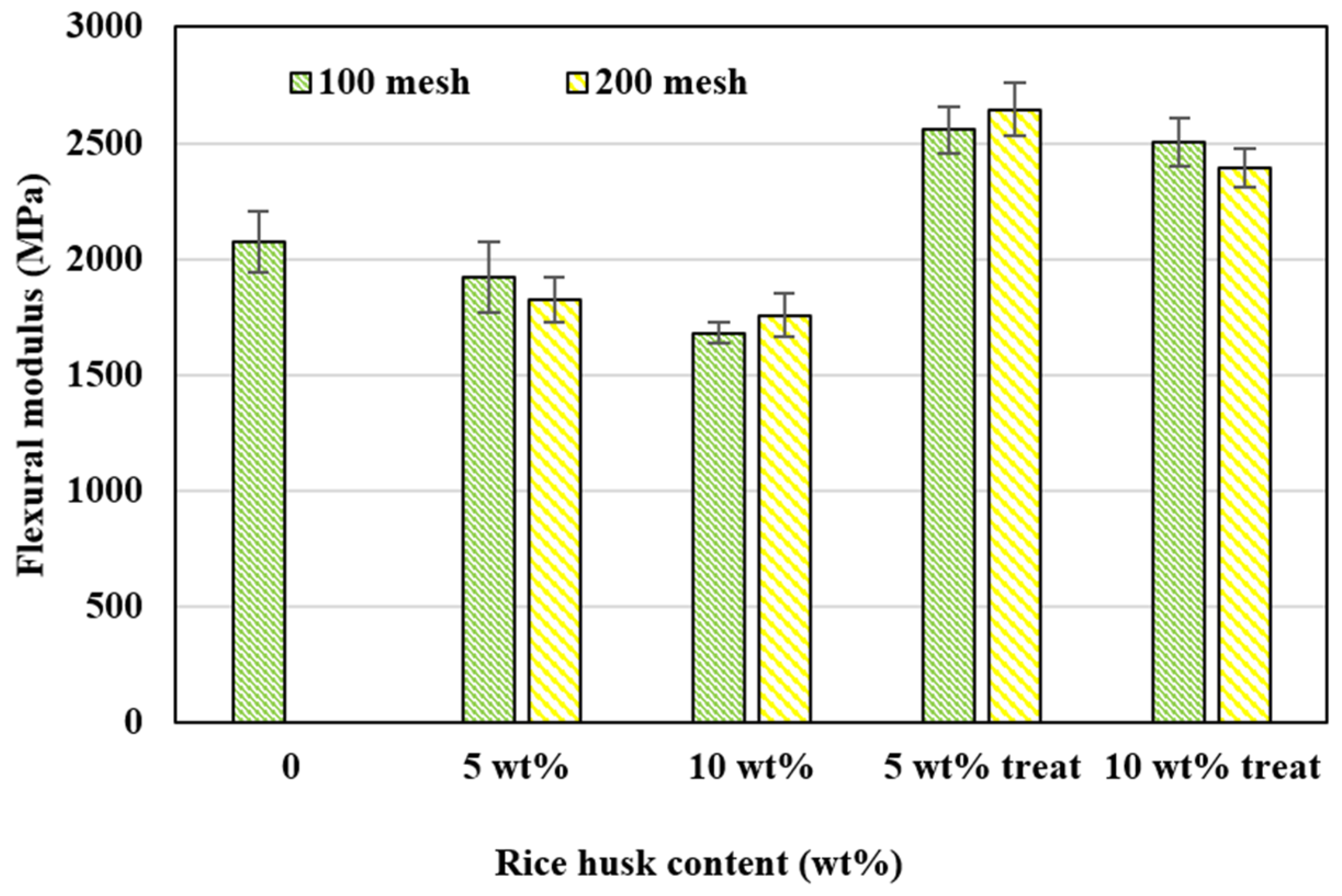

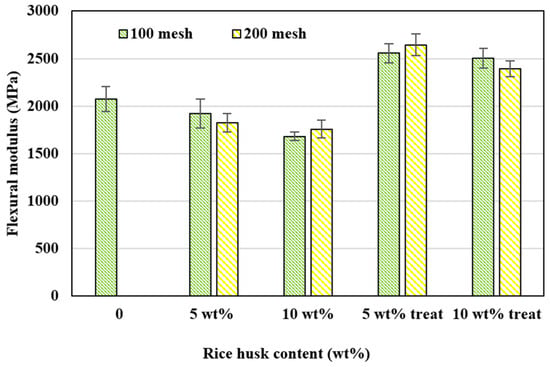

Figure 7.

Flexural modulus of PLA composites reinforced with rice husk.

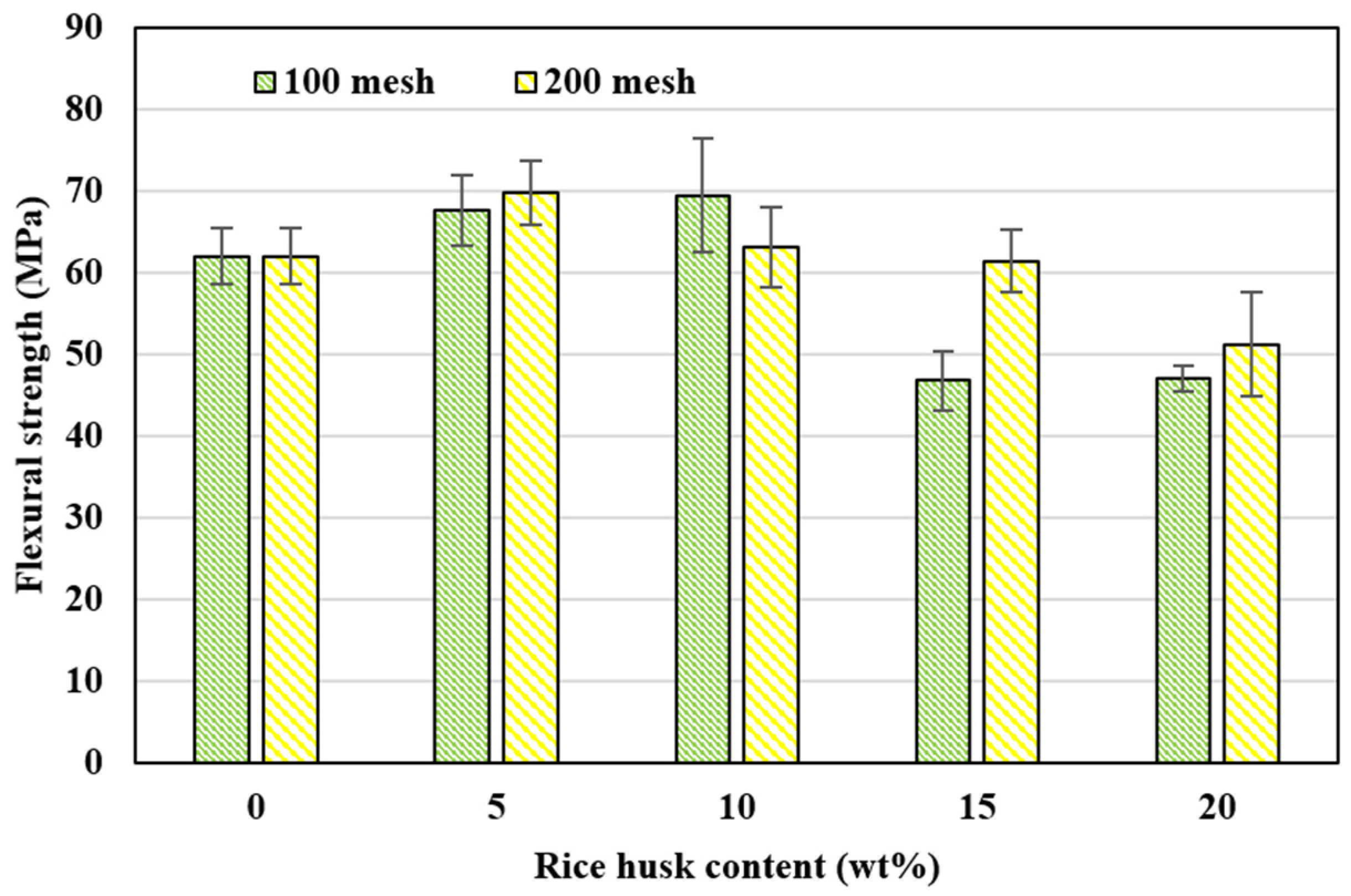

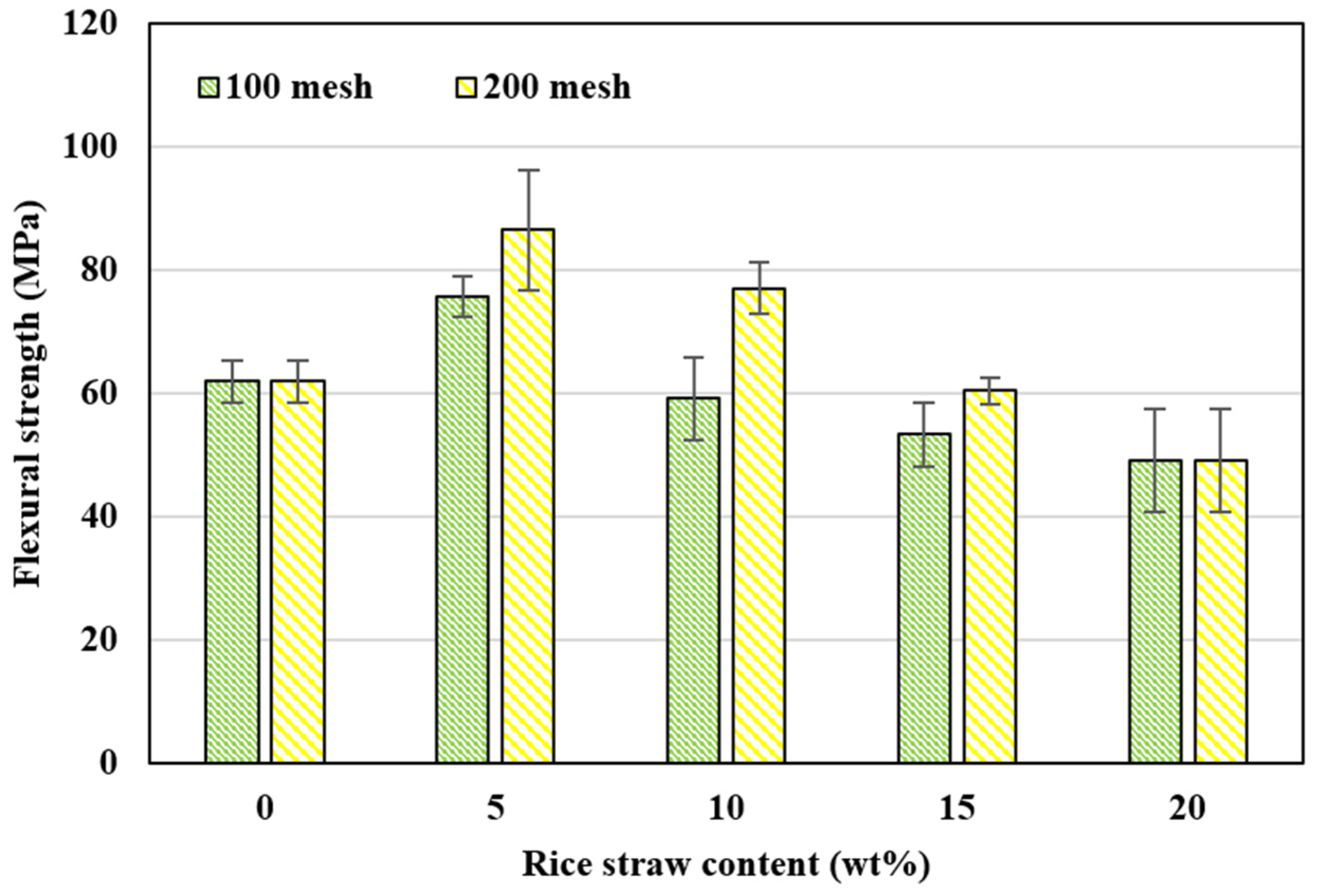

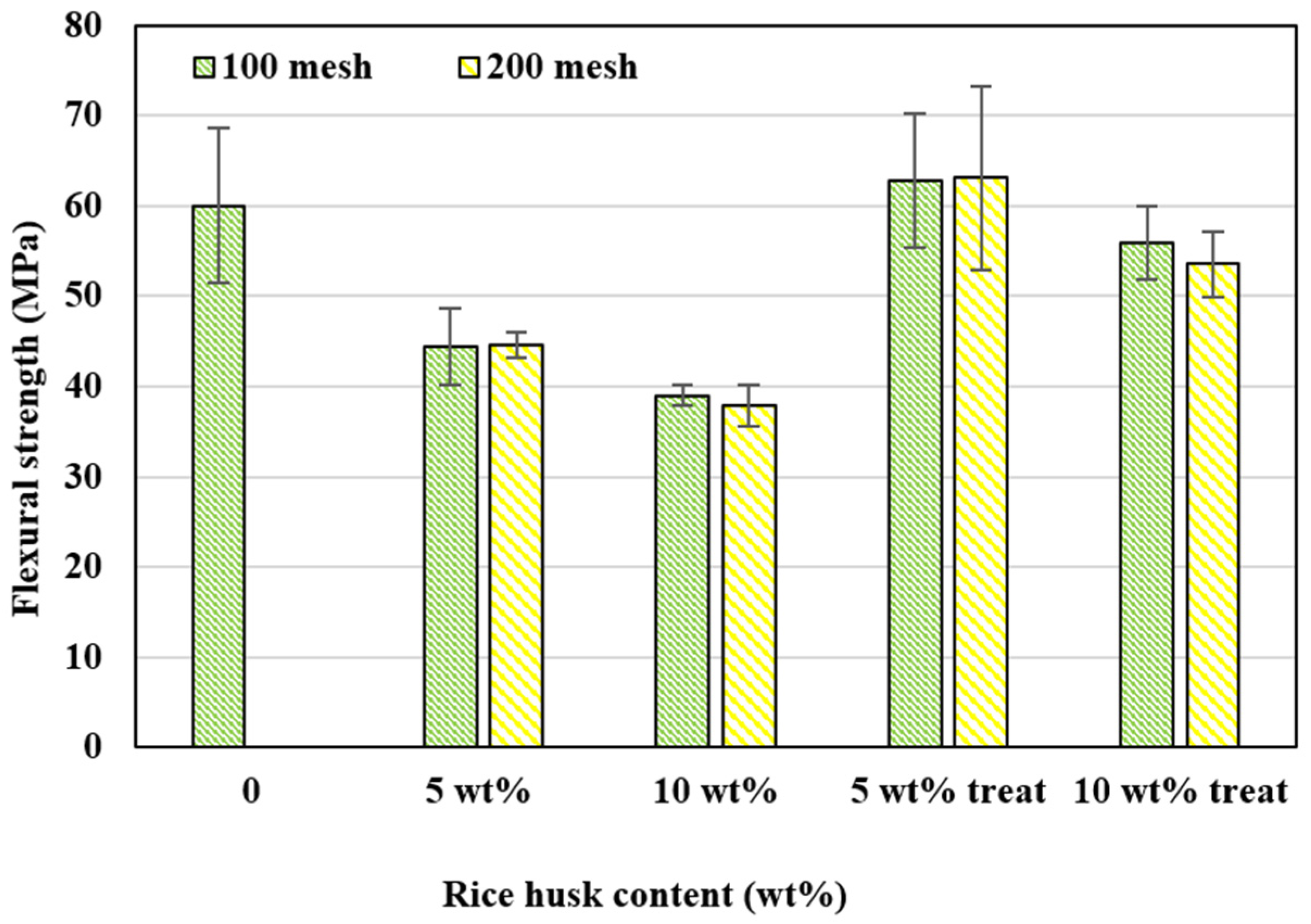

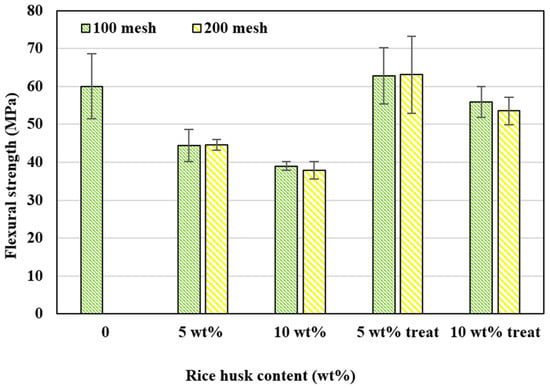

Figure 8.

Flexural strength of PLA composites reinforced with rice husk.

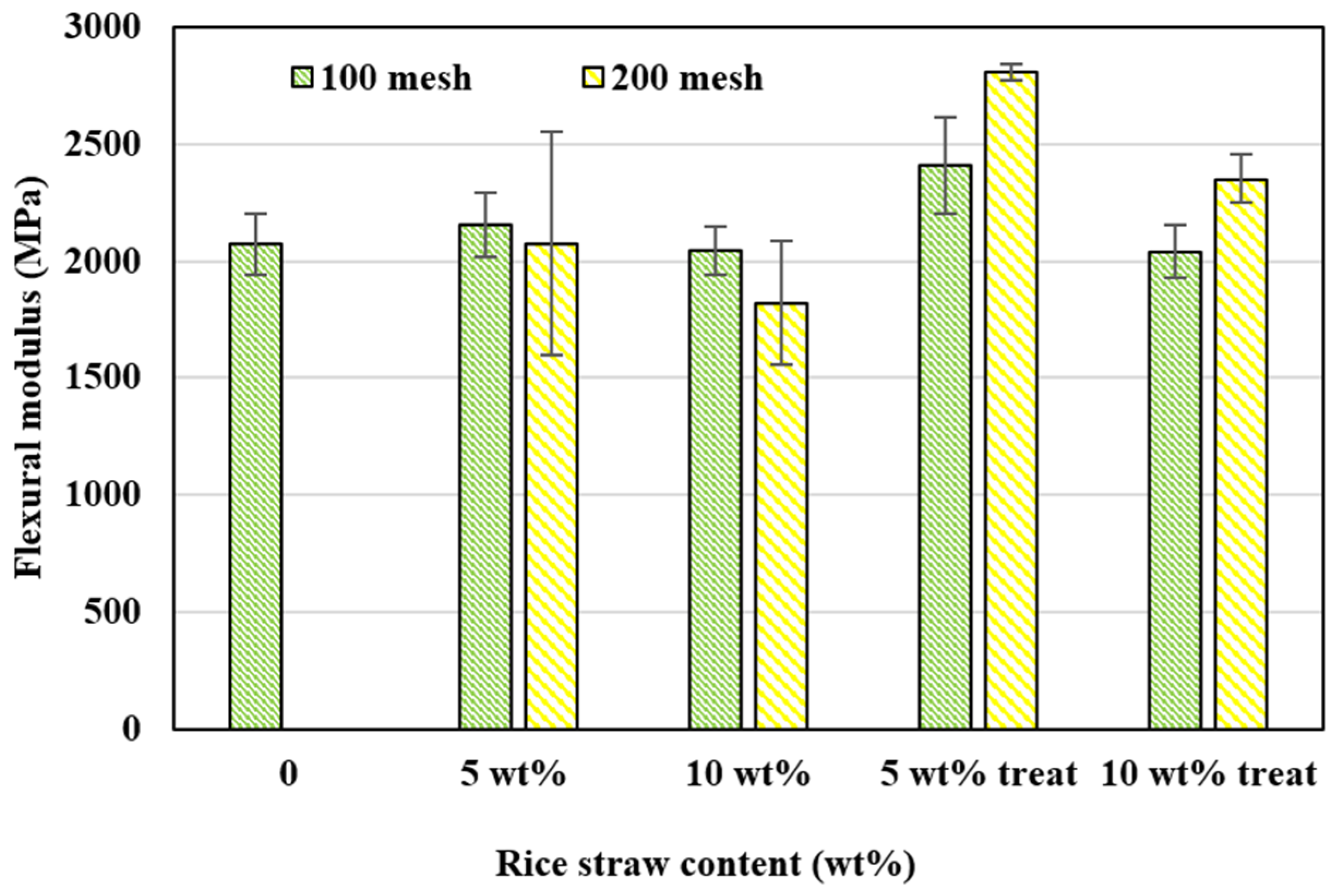

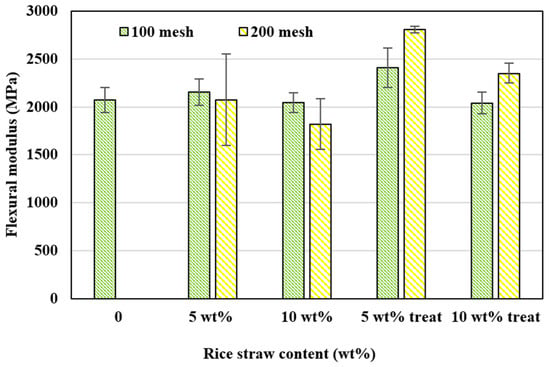

Figure 9.

Flexural modulus of PLA composites reinforced with rice straw.

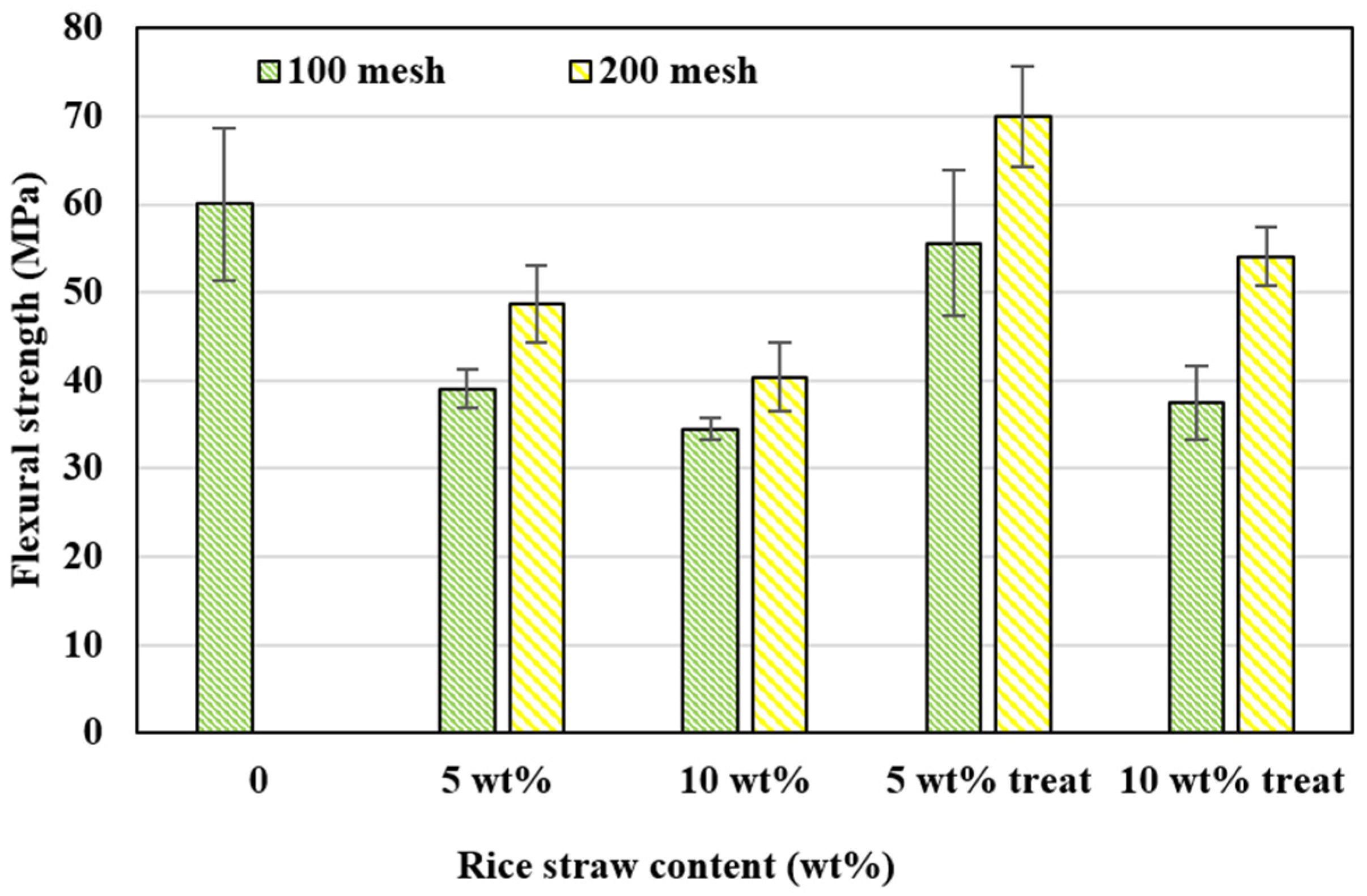

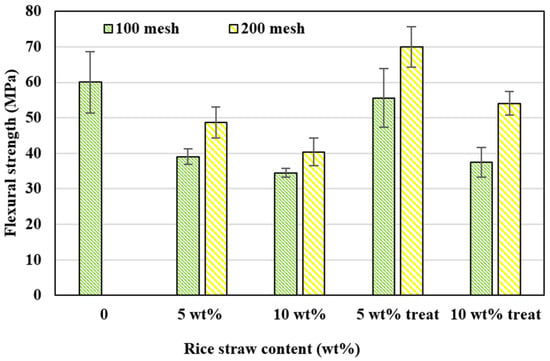

Figure 10.

Flexural strength of PLA composites reinforced with rice straw.

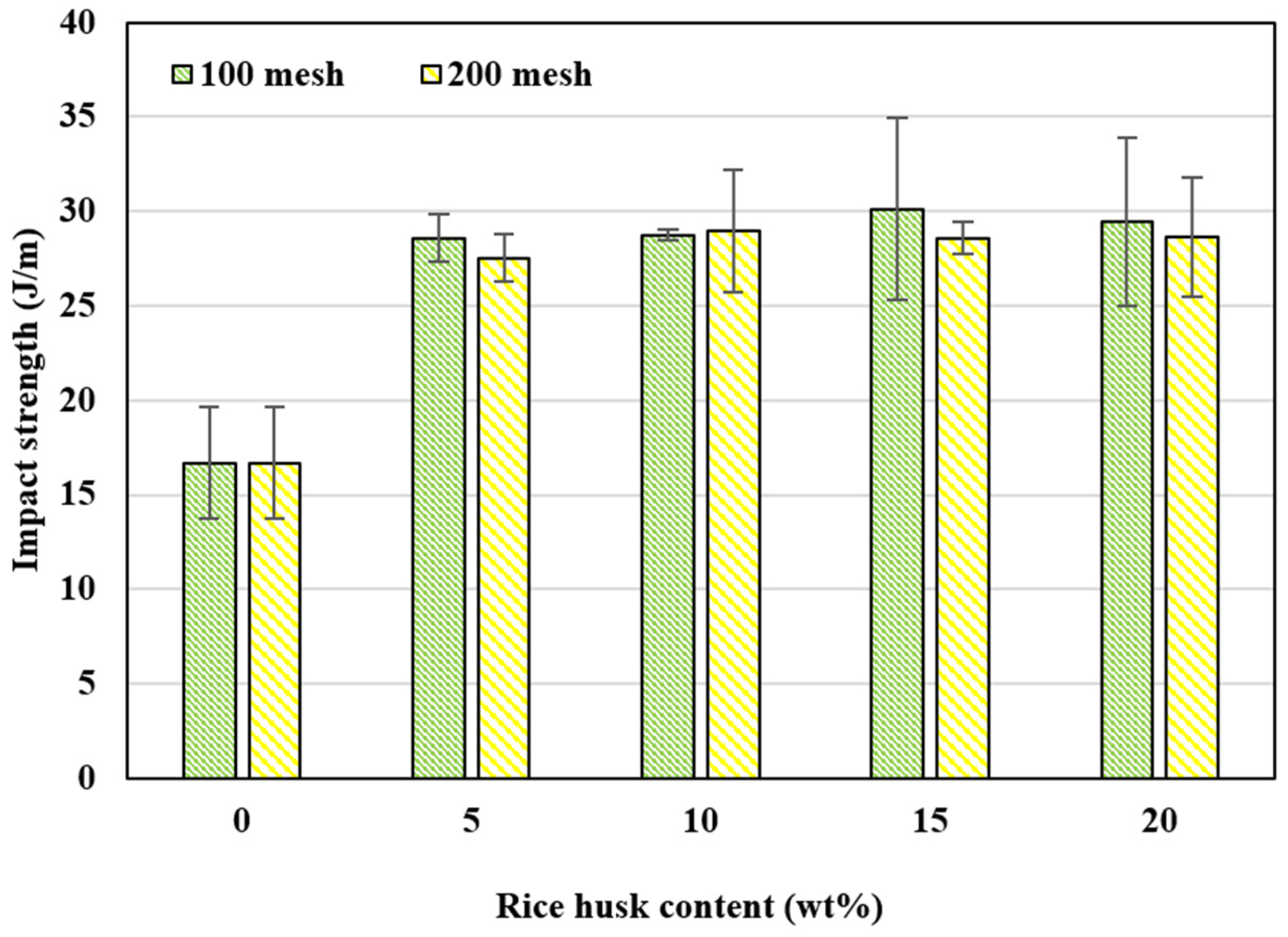

Figure 11.

Impact strength of PLA composites reinforced with rice husk.

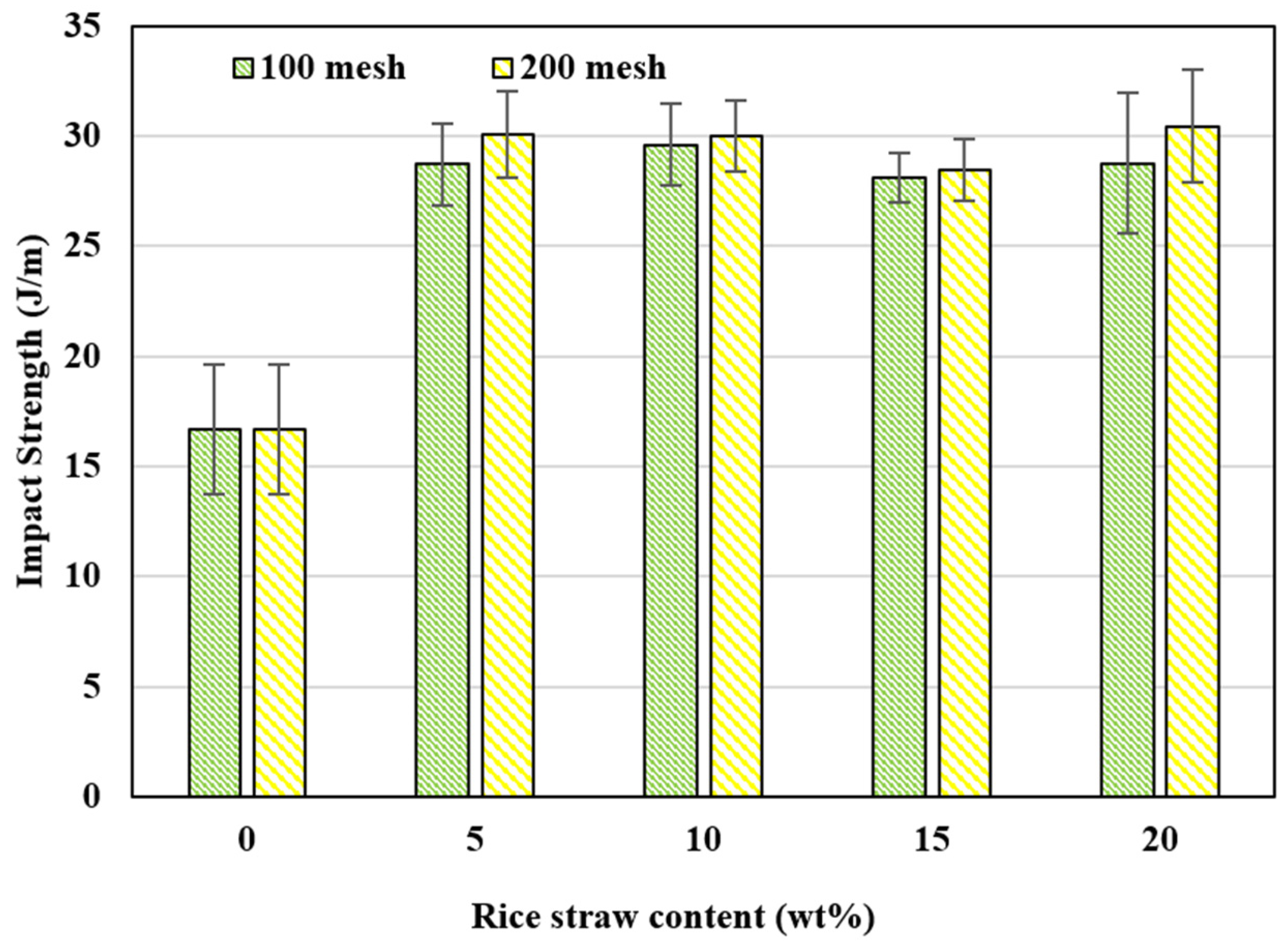

Figure 12.

Impact strength of PLA composites reinforced with rice straw.

Standardized fabrication and testing protocols were employed to mitigate extrinsic sources of variability, including strict control of printing temperature, filament production consistency, and specimen geometry. Nevertheless, minor fluctuations in fiber distribution or interfacial bonding remain possible. In practice, these variations underscore the importance of using multiple replicates per condition to reliably capture the performance envelope of each composite formulation.

4.1.1. Tensile Properties

Figure 3 illustrates that the tensile modulus of PLA/rice husk composites increases proportionally with fiber content. This rise is attributable to the stiffening effect imparted by natural fibers, which curtails chain mobility in the polymer matrix. At higher fiber loadings, however, the improvement remains moderate rather than substantial. Notably, the200-mesh NaOH-treated fibers tend to yield more pronounced modulus gains, likely due to better dispersion and stronger interfacial bonding.

As shown in Figure 4, the tensile strength of PLA/rice husk composites declines at elevated fiber content. Poor stress transfer at the matrix–fiber interface remains a key factor contributing to this behavior. The SEM images depict fiber pull-out and voids, further indicating suboptimal interfacial adhesion. Although fiber treatment moderately improves compatibility, the inherent brittleness of rice husk particles and the discontinuous nature of short fibers may still limit their ability to carry tensile loads.

A similar trend emerges for PLA/rice straw (Figure 5), where finer (200-mesh) and NaOH-treated fibers deliver incrementally higher tensile modulus values. Consistent fiber distribution and reduced agglomeration favor an uptick in stiffness. Nevertheless, the overall magnitude of the improvement remains moderate, underscoring the importance of other factors (e.g., fiber loading, further surface modifications) to maximize stiffness gains.

Figure 6 indicates that tensile strength generally decreases as fiber content increases. Although the NaOH treatment partially enhances bonding, the use of higher fiber contents appears to introduce additional weak points via fiber agglomeration or micro-voids. Smaller, well-treated fibers can mitigate this effect to an extent by promoting more uniform dispersion and stable load transfer; however, excessively short fibers can also undermine strength if they fail to bridge stress concentrations effectively [23].

Overall, the results emphasize that while mesh size and chemical treatment improve tensile modulus and offer modest gains in tensile strength at lower fiber contents, the complex interplay of fiber geometry, matrix adhesion, and overall dispersion continues to be pivotal.

Tensile Modulus of PLA/Rice Straw Composites: Similar to the rice husk composites, the tensile modulus of PLA/rice straw composites showed an increase with fiber loading, as seen in Figure 5. The reinforcing effect of rice straw fibers led to an improvement in stiffness, particularly when finer 200-mesh fibers and NaOH treatment were applied. However, as with rice husk composites, the improvement should be characterized as moderate rather than substantial, and further enhancement may require advanced surface treatments or compatibilizers to maximize fiber–matrix interactions.

Tensile Strength of PLA/Rice Straw Composites: The tensile strength of PLA/rice straw composites exhibited a declining trend with increasing fiber content, as presented in Figure 6. This reduction is attributed to limited interfacial bonding and inefficient stress transfer, particularly at higher fiber concentrations. The SEM images confirm the presence of fiber pull-out and micro-voids, which contribute to premature failure under tensile loading. Although NaOH treatment improved interfacial adhesion, the inherent differences in mechanical compatibility between the PLA matrix and natural fibers still resulted in strength reduction. Future studies could explore alternative fiber modifications, such as silane coupling agents or hybrid reinforcement strategies, to mitigate this limitation.

4.1.2. Flexural and Impact Properties

The flexural modulus and impact strength of PLA composites reinforced with rice husk and rice straw generally demonstrated clear improvements compared to neat PLA, as expected for fiber-reinforced materials. Figure 7, Figure 8, Figure 9 and Figure 10 illustrate that the addition of natural fibers contributes to an increase in flexural stiffness, particularly in 200-mesh NaOH-treated fibers, which exhibited the highest flexural modulus. However, it is important to note that beyond a certain fiber loading, the modulus exhibited a slight decline due to fiber aggregation and potential stress concentration points.

Similarly, impact strength increased with fiber reinforcement (Figure 11 and Figure 12), reaching the highest values at 15 wt% fiber loading, which suggests that the presence of natural fibers enhances energy absorption and resistance to sudden impact forces. This improvement is consistent with previous findings in fiber-reinforced PLA composites, where fibers contribute to crack deflection and energy dissipation. However, the effect may be limited at excessive fiber loadings due to potential fiber pull-out and weak interfacial bonding, as observed in the SEM images.

These findings align with the expected trends in natural fiber-reinforced composites, reinforcing the role of proper fiber dispersion and matrix interaction in determining mechanical performance. Future research should further explore the balance between fiber content and processing conditions to optimize flexural and impact properties for various industrial applications.

4.2. Chemical and Microstructural Analysis

4.2.1. FTIR Analysis—Results

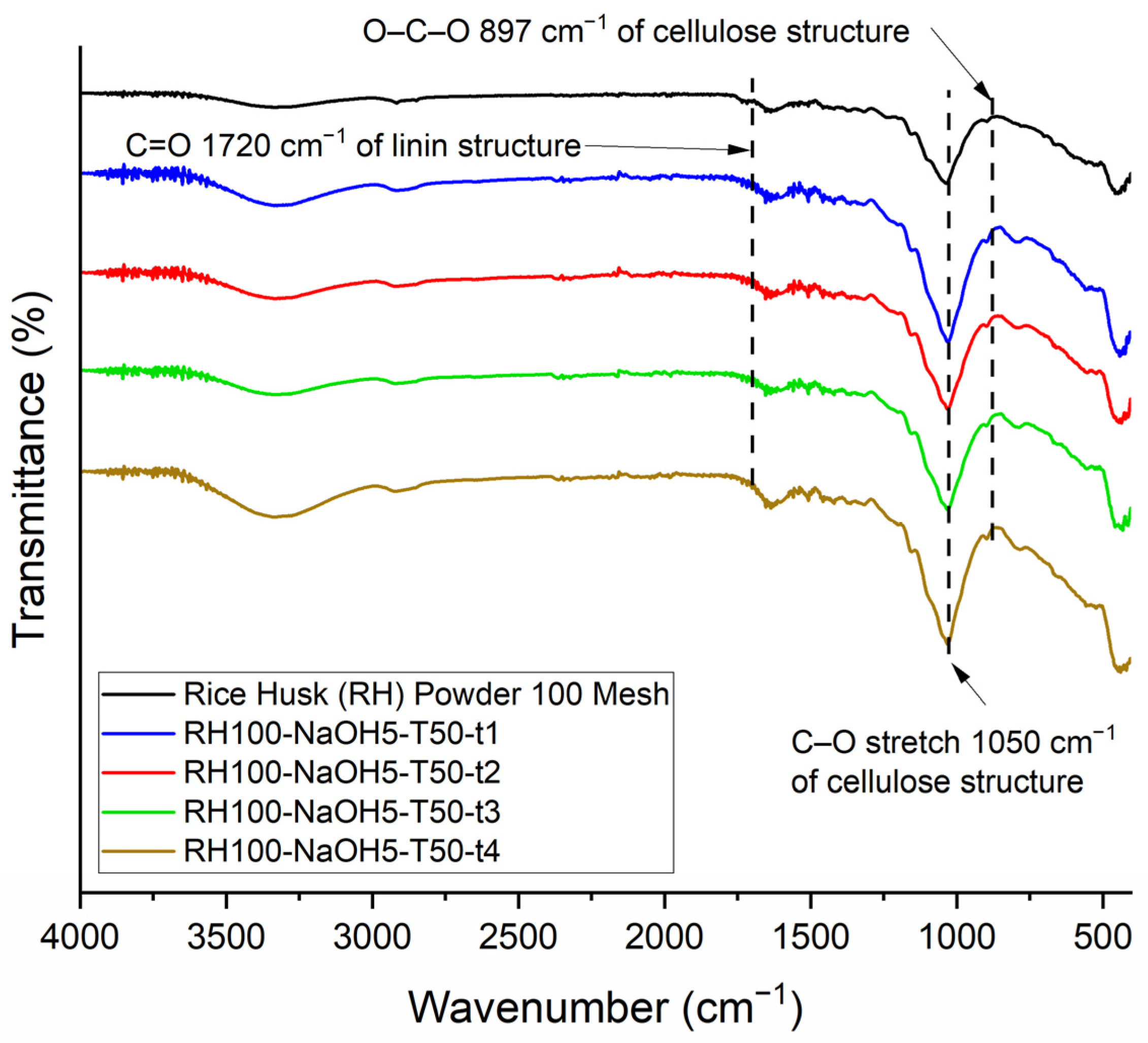

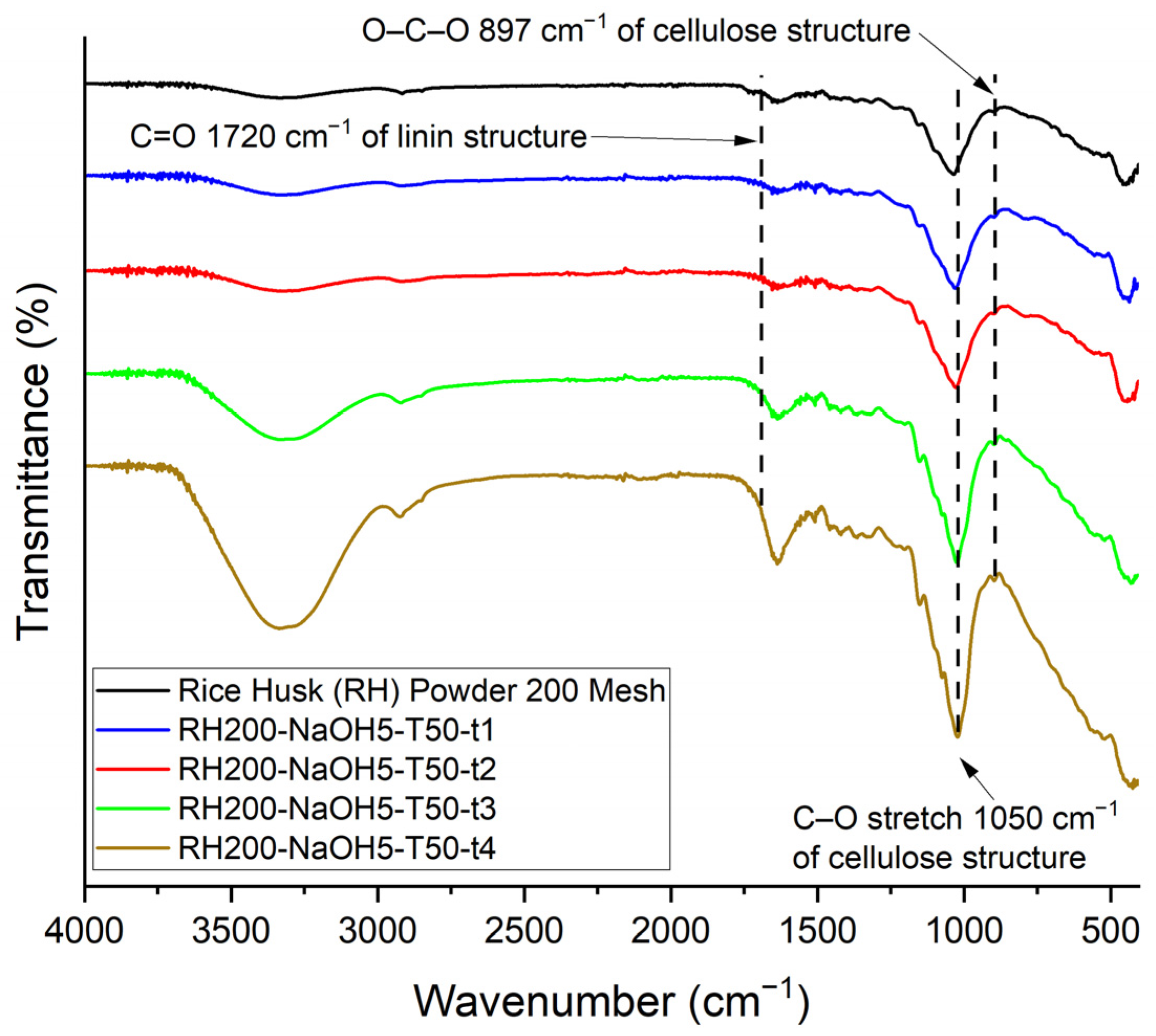

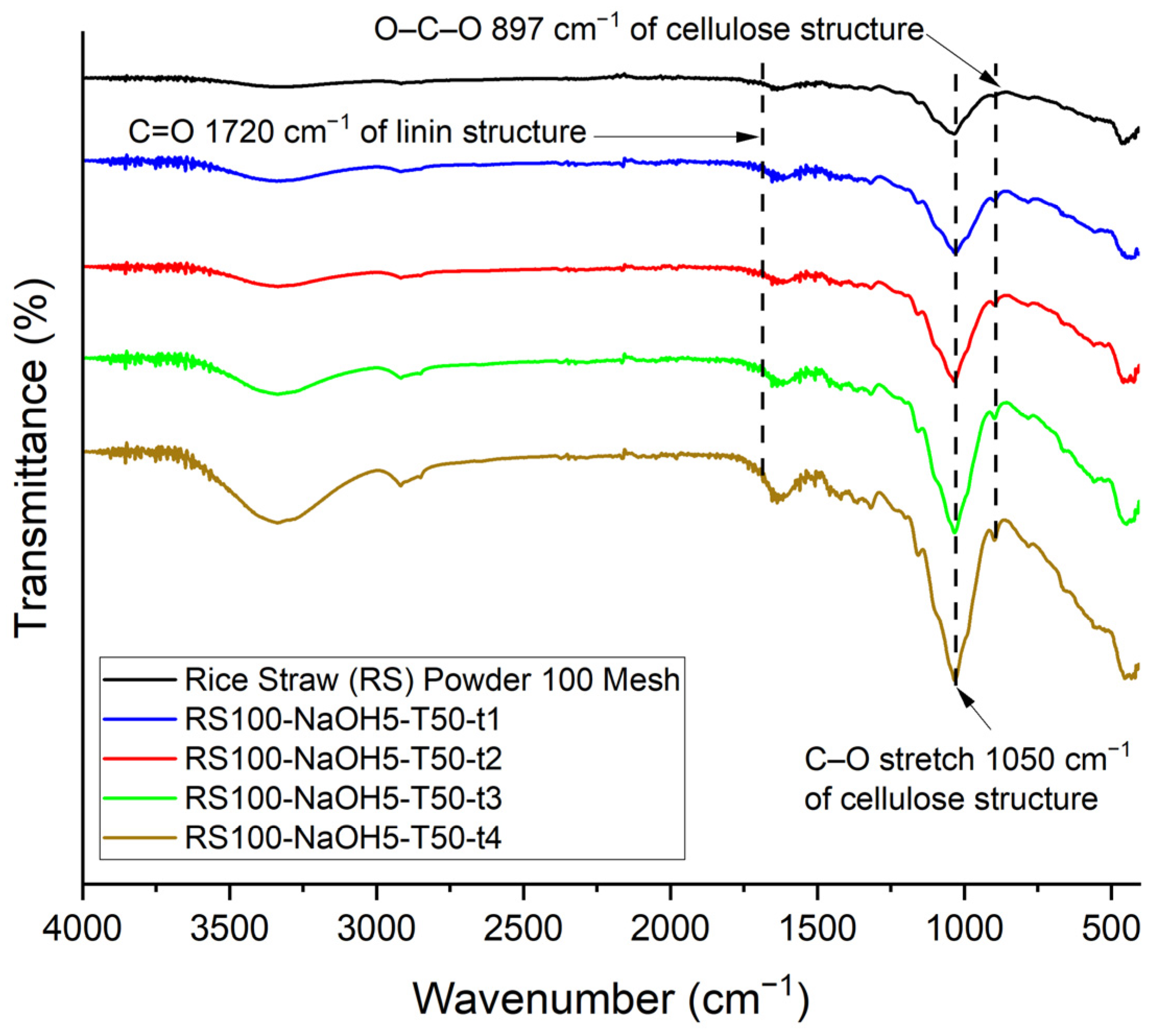

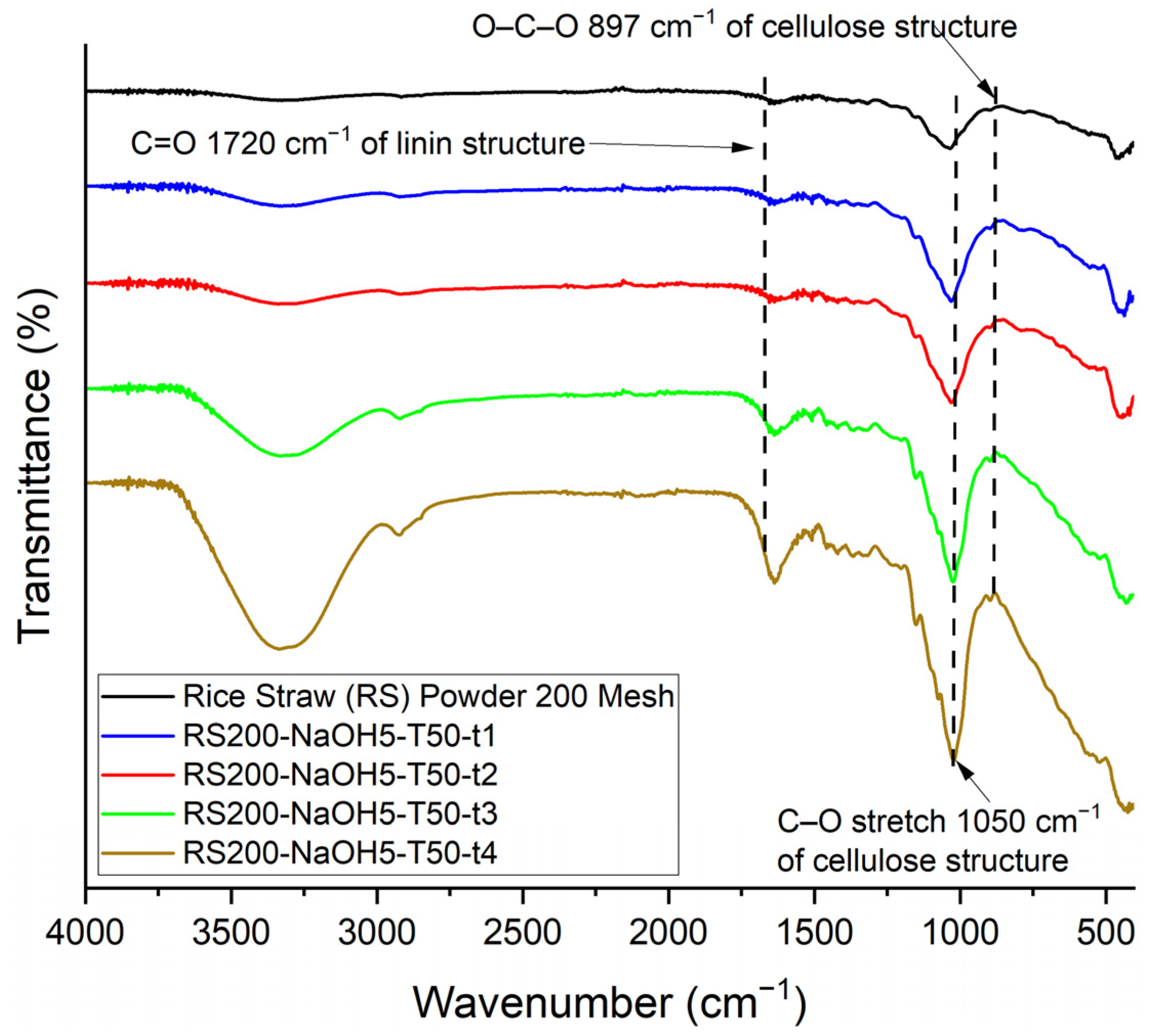

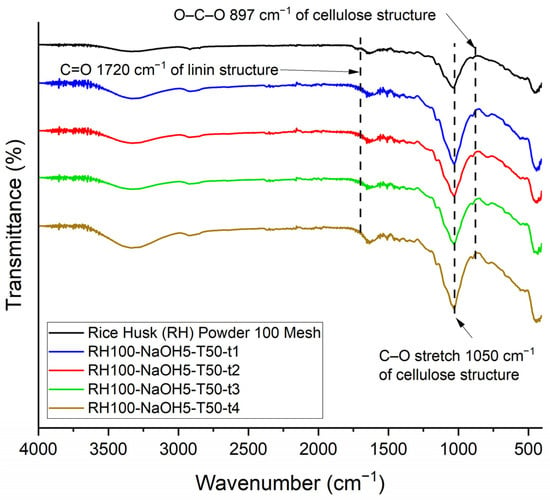

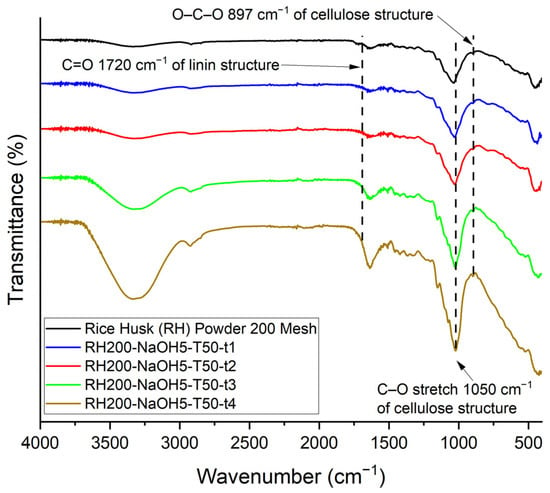

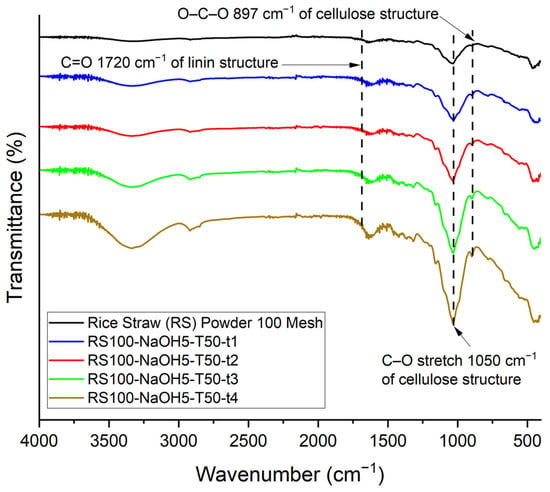

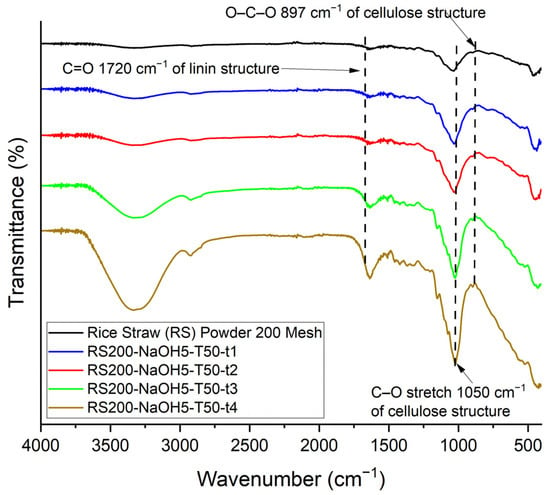

Figure 13, Figure 14, Figure 15 and Figure 16 present the FTIR spectra for (i) untreated rice husk or rice straw powder and (ii) fibers treated with 5 wt% NaOH at 50 °C for 1–4 h. Several characteristic peaks confirm the lignocellulosic nature of the samples:

Figure 13.

FTIR spectrum of 100-mesh rice husk powder, untreated and treated with 5% NaOH at 50 °C for 1–4 h.

Figure 14.

FTIR spectrum of 200-Mesh rice husk powder, untreated and treated with 5% NaOH at 50 °C for 1–4 h.

Figure 15.

FTIR spectrum of 100-mesh rice straw powder, untreated and treated with 5% NaOH at 50 °C for 1–4 h.

Figure 16.

FTIR spectrum of 200-mesh rice straw powder, untreated and treated with 5% NaOH at 50 °C for 1–4 h.

- A small but identifiable band near 1720 cm−1 corresponds to the C=O stretching vibration of carbonyl groups found in lignin.

- A peak around 1050 cm−1 corresponds to the C–O stretching of cellulose and hemicellulose.

- A peak around 897 cm−1 corresponds to the β-glycosidic C–O–C stretching vibrations in cellulose.

In the untreated fibers, the relative intensity of the lignin-related band at 1720 cm−1 is more prominent, whereas the NaOH-treated samples show a noticeable reduction in this band. These trends align with commonly reported chemical modifications observed when lignocellulosic fibers undergo mild alkali treatment [13,32]. Simultaneously, the bands near 1050 cm−1 and 897 cm−1 (associated with cellulose) become comparatively more pronounced, suggesting that partial lignin removal or disruption of non-cellulosic layers has enhanced cellulose exposure on the fiber surface. This improved exposure promotes more effective interfacial interactions with the PLA matrix [14,23].

Implications for Composite Reinforcement: By reducing lignin content (and possibly waxes), NaOH treatment roughens the fiber surface and exposes more cellulose. The SEM images corroborate this, showing fewer voids and enhanced fiber–matrix contact in treated samples. Consequently, these chemical and morphological changes translate into improved bonding with the PLA matrix, as further discussed in Section 4.1 and Section 4.3.

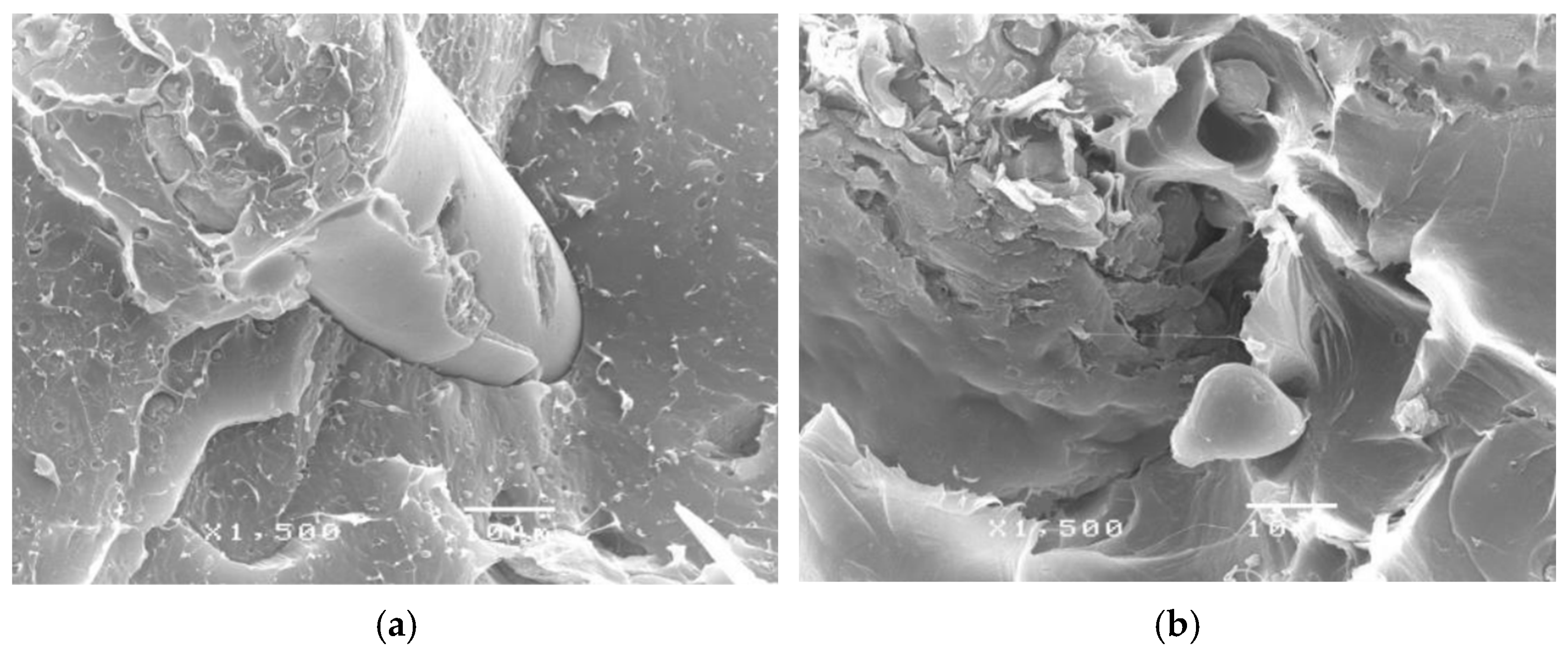

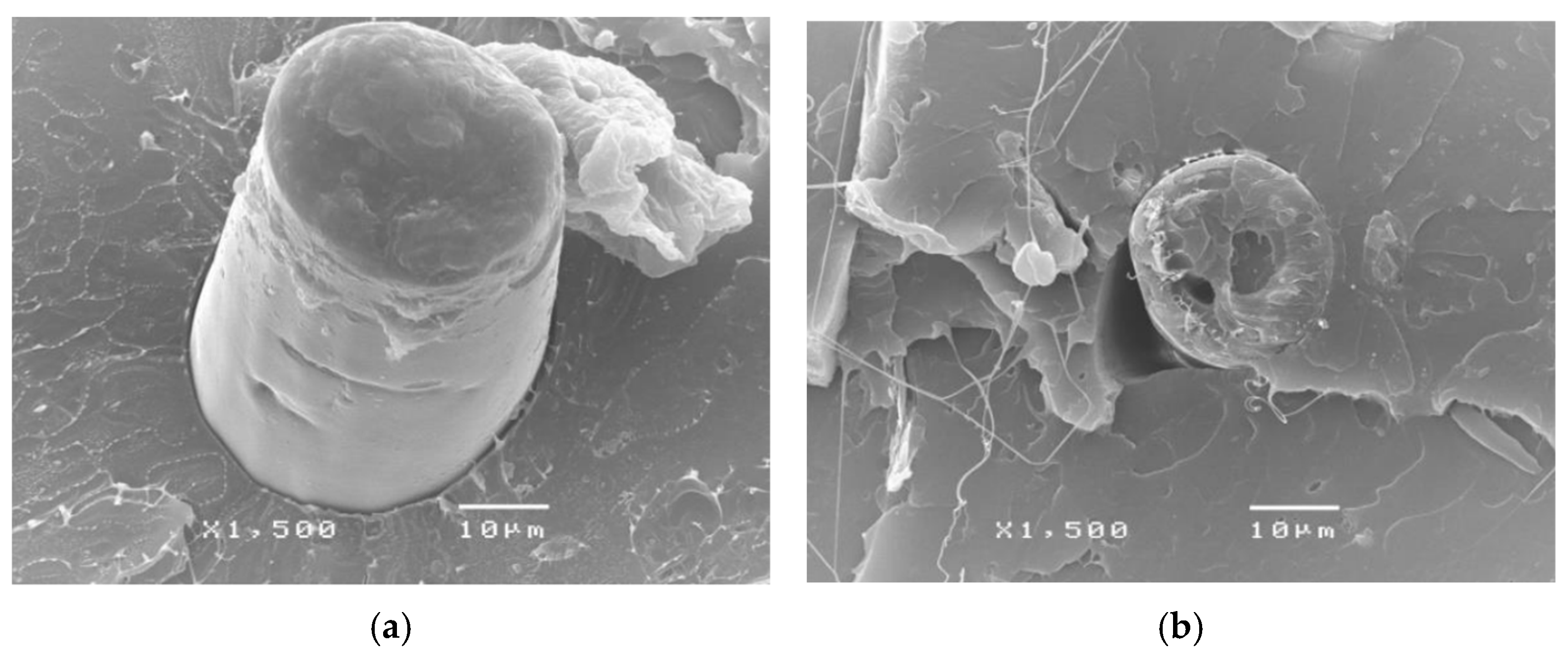

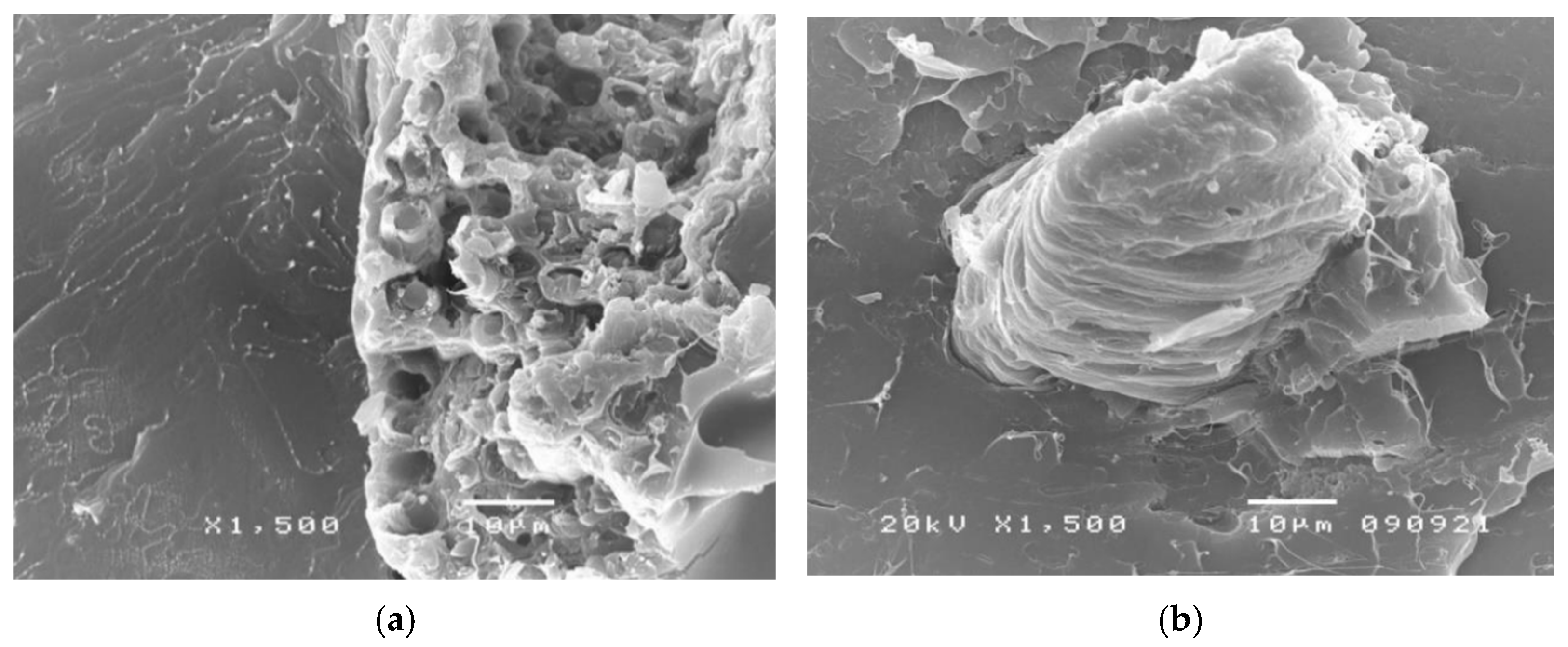

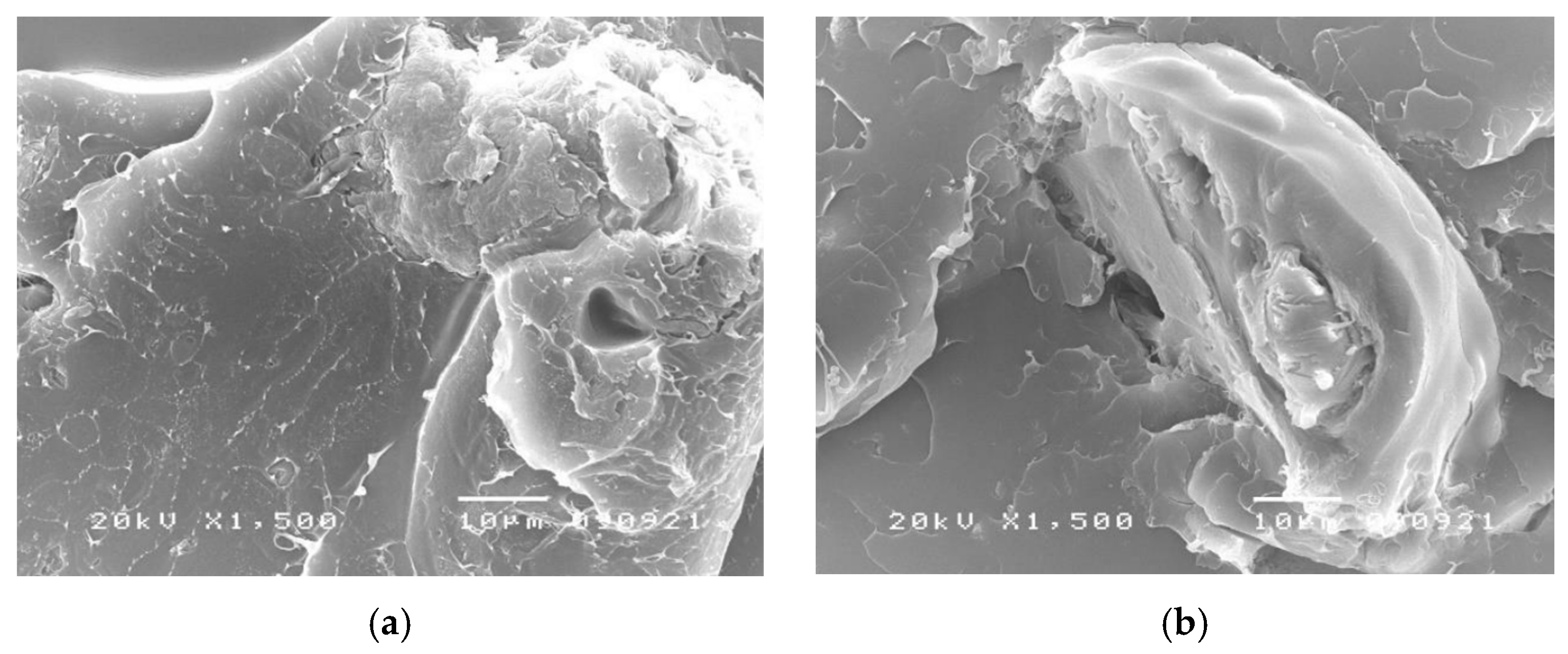

4.2.2. SEM Microstructure

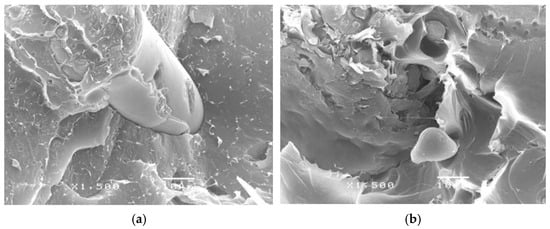

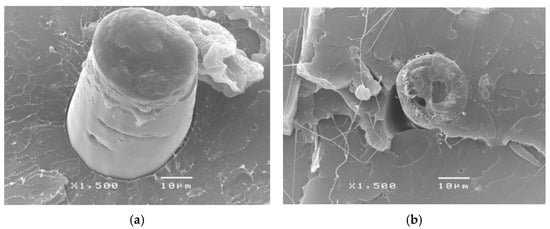

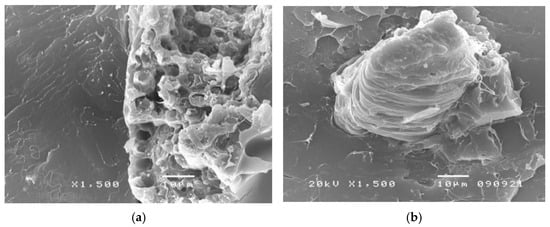

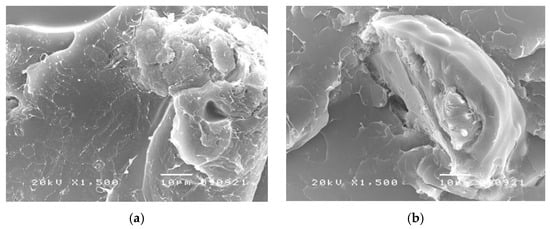

Figure 17, Figure 18, Figure 19 and Figure 20 provide representative SEM images of the composite fracture surfaces. Untreated fibers often exhibit gaps at the fiber–matrix interface, whereas fibers treated in 5% NaOH solution display more consistent bonding and fewer voids. Finer fiber sizes (200 mesh) further enhance the uniformity of dispersion within the PLA matrix. While such dispersion increases flexural and impact performance, high fiber loadings may still create stress concentrations that hinder tensile strength.

Figure 17.

SEM images of PLA/RH100 composites at 5 wt% fiber loading: (a) untreated; (b) alkali-treated. Scale bar = 10 μm.

Figure 18.

SEM images of PLA/RH200 composites at 5 wt% fiber loading: (a) untreated; (b) alkali-treated.

Figure 19.

SEM images of PLA/RS100 composites at 5 wt% fiber loading: (a) untreated; (b) alkali-treated.

Figure 20.

SEM images of PLA/RS200 composites at 5 wt% fiber loading: (a) untreated; (b) alkali-treated. Scale bar = 10 μm.

Figure 17 shows the fiber fragments exhibiting a typical length distribution associated with 100-mesh processing, which provides sufficient reinforcement for load transfer. However, occasional voids are observed near the fiber–matrix interface.

Figure 18 shows that 200-mesh milling produces finer and more uniformly dispersed fibers. The corresponding micrographs reveal reduced void formation and improved interfacial contact, consistent with enhanced reinforcement.

Figure 19 shows that 100-mesh straw fibers exhibit moderate aspect ratios, with localized gaps at the fiber–matrix interface still present.

Figure 20 shows that the 200-mesh straw fibers retain a sufficient length for effective reinforcement, contributing to a more compact microstructure with reduced fiber pull-out.

4.3. Mechanical Properties of 3D-Printed PLA Composites Reinforced with Natural Fibers

An additional set of tensile, flexural, and impact tests was conducted on the 3D-printed samples. Figures 21, 23, 25, and 27 illustrate the performance of rice husk composites, whereas Figures 22, 24, 26, and 28 do the same for rice straw under similar conditions.

4.3.1. Tensile Performance of 3D-Printed Composites

Figure 21 and Figure 22 show that tensile modulus benefits somewhat from the inclusion of treated and finer mesh fibers, whereas Figure 23 and Figure 24 confirm that tensile strength tends to decrease with fiber loading. This behavior parallels the observations in hot-pressed samples, underscoring the importance of matrix–fiber interface quality and the potential for micro-voids to reduce load-bearing efficiency.

Figure 21.

Tensile modulus of 3D-printed PLA composites reinforced with 100-mesh and 200-mesh rice husk at various contents and treatment conditions.

Figure 22.

Tensile modulus of 3D-printed PLA composites reinforced with 100-mesh and 200-mesh rice straw at various contents and treatment conditions.

Figure 23.

Tensile strength of 3D-printed PLA composites reinforced with 100-mesh and 200-mesh rice husk at various contents and treatment conditions.

Figure 24.

Tensile strength of 3D-printed PLA composites reinforced with 100-mesh and 200-mesh rice straw at various contents and treatment conditions.

4.3.2. Flexural and Impact Behavior of 3D-Printed Composites

Figure 25, Figure 26, Figure 27 and Figure 28 reveal that flexural modulus and flexural strength remain improved relative to neat PLA, especially with alkaline-treated fibers at 200 mesh. Impact strength also shows positive gains when fiber content is moderate and well-dispersed. These improvements highlight the role of both fiber mesh size and surface treatment in reinforcing 3D-printed parts.

Figure 25.

Flexural modulus of 3D-printed PLA composites reinforced with 100-mesh and 200-mesh rice husk at various contents and treatment conditions.

Figure 26.

Flexural modulus of 3D-printed PLA composites reinforced with 100-mesh and 200-mesh rice straw at various contents and treatment conditions.

Figure 27.

Flexural strength of PLA composites reinforced with 100-mesh and 200-mesh rice husk at various contents and treatment conditions.

Figure 28.

Flexural strength of 3D-printed PLA composites reinforced with 100-mesh and 200-mesh rice straw at various contents and treatment conditions.

4.4. Results with Key Findings Summarized and Comparison

Table 2 compiles representative findings, highlighting improved flexural modulus and impact strength, but a general decline in tensile strength with increased fiber loading. The table focuses on tensile modulus, tensile strength, flexural modulus, and flexural strength, as well as qualitative interfacial bonding inferred from SEM images.

Table 2.

Comparative mechanical performance of natural fiber-reinforced PLA composites.

The data emphasize that flexural modulus and impact strength consistently show greater improvement than tensile strength, which often declines with higher fiber loading due to incomplete stress transfer. FTIR analyses indicate a partial removal of lignin, confirmed by SEM evidence of improved adhesion when fibers are treated with NaOH. Finer mesh sizes (200) typically enhance these effects further.

5. Discussion

5.1. Effect of Natural Fiber Reinforcement on Mechanical Properties

The comparison between treated and untreated fibers shows moderate improvements in the mechanical properties of PLA composites when treated fibers are used. Figure 21 and Figure 23 depict the tensile modulus and strength of PLA composites reinforced with rice husk. The composites incorporating treated fibers exhibit a higher tensile modulus, suggesting enhanced stiffness due to improved interfacial adhesion. However, the tensile strength does not show a significant increase, as stress transfer remains limited despite fiber treatment. The SEM images (Figure 17 and Figure 18) indicate that fiber pull-out and micro-voids are still present, supporting the interpretation that interfacial bonding issues persist at higher fiber loadings.

Figure 22 and Figure 24 display the tensile characteristics of PLA composites reinforced with rice straw. The treated rice straw fibers contribute to a moderate enhancement in tensile modulus, consistent with the behavior observed in rice husk composites. However, the tensile strength decline at higher fiber loadings remains evident, reinforcing the conclusion that further improvements in fiber–matrix interactions are required. The findings are supported by SEM images (Figure 19 and Figure 20), which reveal better bonding in treated composites compared to untreated ones, though voids and weak interfaces are still visible. Future research should focus on developing alternative fiber treatments, such as silane coupling agents, and optimizing fiber dispersion to further enhance stress transfer efficiency.

The size of the fibers’ mesh is a critical factor in influencing the mechanical characteristics of the composites. The data from Figure 21 and Figure 22 indicate that composites reinforced with 200-mesh fibers have a greater tensile modulus in comparison to those reinforced with 100-mesh fibers. The finer fibers result in a more even distribution inside the PLA matrix, which improves the mechanical characteristics by boosting stress distribution and reducing the creation of empty spaces [24]. However, excessively small particles may lead to agglomeration, creating stress concentration points and reducing mechanical performance. In addition, preparing small particle sizes is difficult.

The flexural modulus for PLA composites with various mesh sizes is depicted in Figure 25 and Figure 26. Consistently, 200-mesh fibers demonstrate superior performance compared to 100-mesh fibers, regardless of whether they are treated or untreated. Smaller fiber diameters have a positive impact on reinforcing because they have a larger surface area, which improves bonding with the matrix [25].

Maximizing the mechanical performance of PLA composites requires determining the ideal fiber content. The data shown in Figure 21, Figure 22, Figure 23, Figure 24, Figure 25, Figure 26, Figure 27 and Figure 28 indicate that a fiber concentration of 5 wt% achieves an optimal equilibrium between reinforcing and matrix integrity. Increased fiber concentrations often lead to the formation of clumps and empty spaces, which can have a detrimental effect on the mechanical characteristics of the composite material [33].

The flexural characteristics, as shown in Figure 25, Figure 26, Figure 27 and Figure 28, demonstrate that the greatest flexural modulus and strength are attained when the fiber concentration is 5 wt%, particularly when using treated fibers. This ideal composition guarantees adequate dispersion of fibers and efficient transmission of stress, all while preserving the structural integrity of the PLA matrix.

This research fills the gap described in the current literature by effectively resolving the mechanical limits of typical PLA composites by surface treatments and adjusting fiber amount and size. The improved mechanical characteristics of the processed PLA composites, including natural fibers, indicate their potential for wider utilization in many industries. This fulfills the study goals and provides significant knowledge to the area of additive manufacturing [7,8].

In addition, the presence of natural fibers inevitably introduces some degree of heterogeneity, as variations in fiber length, orientation, or interfacial compatibility can affect local stress transfer. The standard deviations reported in Figure 3, Figure 4, Figure 5, Figure 6, Figure 7, Figure 8, Figure 9, Figure 10, Figure 11 and Figure 12 reflect this inherent variability. By testing multiple replicates and meticulously controlling the preparation parameters (i.e., drying, extrusion, and printing conditions), the results capture a statistically reliable range of mechanical performance. Although the error bars appear relatively larger than those commonly observed in neat polymers, they are consistent with literature reports on natural fiber-reinforced systems [32].

5.2. Implications for Industrial Applications

The results of this study have important consequences for the automotive and construction sectors, which have a strong need for materials that have excellent mechanical qualities and environmental advantages. Integrating natural fibers like rice husk and rice straw into PLA matrices has shown significant improvements in mechanical characteristics, including tensile strength, flexural strength, and modulus. These improvements render the composites especially well-suited for applications that necessitate materials capable of enduring high levels of stress and maintaining long-lasting durability.

In the automobile sector, there is a crucial need for materials that are both light-weight and sturdy in order to enhance fuel economy and minimize emissions. The PLA composites that underwent treatment, particularly those reinforced with 200-mesh fibers, demonstrated superior mechanical qualities that are crucial for the pro-duction of components, including interior panels, bumpers, and structural supports. The enhanced tensile and flexural characteristics of these components guarantee their ability to withstand the mechanical stresses experienced during vehicle operation, thereby improving safety and performance [19,34].

Similarly, in the construction industry, it is imperative for materials to possess exceptional durability and stability in order to guarantee the long-lasting and secure nature of construction. The improved mechanical characteristics of PLA composites with treated fibers suggest their possible application in construction materials, such as panels, beams, and reinforcements. The enhanced flexural strength and modulus, as depicted in Figure 25 and Figure 26, indicate that these composites possess the ability to withstand substantial loads without undergoing deformation. Consequently, they are very suitable for structural applications [25,35].

The progress in using natural fiber-reinforced PLA composites shows significant potential for wider use of these materials in 3D printing applications. The study demonstrates that treated fibers improve compatibility and bonding with the PLA matrix, leading to better mechanical performance. This enhancement is vital for 3D printing applications, where accuracy and the integrity of materials are of utmost importance.

The advent of 3D printing technology has transformed the manufacturing industry by allowing the creation of intricate and personalized parts while minimizing material waste. Integrating natural fibers into PLA not only improves the mechanical characteristics but also corresponds with the increasing focus on sustainability. The ecologically benign characteristics of PLA, together with the biodegradability of rice husk and rice straw fibers, render these composites a sustainable substitute for conventional petrochemical-based plastics [20,36].

The results of the study indicate that composites containing treated 200-mesh fibers exhibit improved performance. This suggests that these materials can be successfully utilized in 3D printing to manufacture components that require exceptional strength and endurance. These applications encompass medical devices, aircraft components, and consumer products, where the mechanical integrity of printed parts is of utmost importance [24,37].

This discovery has broader implications that go beyond simply enhancing the mechanical characteristics of PLA composites. These materials have the potential to be used in important industrial areas, which would promote sustainability and innovation in manufacturing techniques. Treated natural fiber-reinforced PLA composites have improved characteristics that make them a practical and competitive choice for a wide range of challenging applications. This addresses the existing research gap and sets the stage for future progress in material science and 3D printing technology.

5.3. Addressing the Research Gap

This work focuses on overcoming the mechanical constraints of PLA by enhancing its strength through the use of natural fibers, including rice husk and rice straw. The mechanical testing results indicated moderate improvements in tensile properties and notable enhancements in flexural performance, reflecting the beneficial influence of fiber reinforcement on composites.

The use of rice husk and rice straw in PLA composites resulted in an increase in the tensile modulus. The data shown in Figure 21 and Figure 22 indicate that composites reinforced with 200-mesh fibers had a greater tensile modulus in comparison to composites reinforced with 100-mesh fibers. The application of surface treatment to the fibers resulted in a further increase in the tensile modulus, suggesting that the use of finer and treated fibers leads to higher stiffness. Moreover, the treated composites exhibited a significant enhancement in their tensile strength, as evidenced by the data presented in Figure 23 and Figure 24. The improvement is ascribed to enhanced adhesion between the fiber and matrix, resulting in a decrease in fiber pull-out under load and thus increasing tensile strength.

The flexural characteristics exhibited a comparable pattern. The figures, namely Figure 25 and Figure 26, demonstrate that the flexural modulus of composites containing 200-mesh fibers was greater than that of composites containing 100-mesh fibers. The fibers that underwent treatment consistently exhibited increased flexural modulus and strength, as shown in Figure 27 and Figure 28. This emphasizes the significance of treating the fiber surface to improve the composite’s ability to resist bending. The composites containing treated 200-mesh fibers exhibited the greatest flexural strength, highlighting the synergistic impact of both fiber fineness and surface treatment in optimizing the strength of the composite when subjected to flexural pressures.

The investigation of the SEM microstructure provides a more profound understanding of the interaction between the fiber and matrix. The untreated fibers exhibit inadequate adherence to the PLA matrix, resulting in visible empty spaces and openings at the interface between the fibers and matrix (Figure 17a, Figure 18a, Figure 19a, and Figure 20a). Conversely, the treated fibers had a significantly stronger connection with the matrix, as seen by the decreased presence of empty spaces and the more consistent arrangement of fibers (Figure 17b, Figure 18b, Figure 19b, and Figure 20b). Enhanced adherence is a direct consequence of the surface treatment, which improves the compatibility between the hydrophilic natural fibers and the hydrophobic PLA matrix.

Significant changes in the microstructure were observed when comparing natural fibers with different mesh sizes, namely, 100 mesh and 200 mesh. The 200-mesh fibers, as depicted in Figure 18 and Figure 20, exhibited superior dispersion within the matrix and had fewer instances of agglomeration in comparison to the 100-mesh fibers shown in Figure 17 and Figure 19. The enhanced dispersion of the finer particles led to the overall enhancement of mechanical characteristics in the treated composites containing 200-mesh fibers.

This work effectively fills the research gap concerning the mechanical limits of standard PLA composites by showcasing the enhancements in fiber–matrix adhesion resulting from alkaline treatment and smaller fiber diameters. The increased interfacial bonding of these composites demonstrates their ability to satisfy more rigorous application requirements due to their better mechanical characteristics. This method not only addresses the main study topic but also strengthens the wider implications of using these advanced composites in many industrial applications.

5.4. Limitations and Future Research

While this study highlights the potential of natural fiber-reinforced PLA composites, certain limitations must be acknowledged:

- Interfacial bonding issues: The observed tensile strength reduction suggests that future research should explore stronger coupling agents or fiber modifications to enhance stress transfer.

- Surface treatment optimization: Advanced chemical treatments, such as silane coupling agents, could further enhance interfacial adhesion and improve mechanical properties.

- Hybrid fiber reinforcement strategies: The introduction of hybrid fibers, combining different natural fibers or synthetic reinforcements, could help balance tensile strength and stiffness.

- Environmental durability: The long-term performance of these composites under humidity, UV exposure, and thermal cycling remains unexplored and should be investigated in future work [23].

- Process optimization: The study did not focus on optimizing 3D printing parameters (e.g., raster orientation, infill density), which could further impact mechanical performance.

Future research should focus on refining fiber content, processing conditions, and surface treatments to further enhance flexural and impact properties while addressing potential limitations such as fiber aggregation and interfacial bonding efficiency. Optimizing hybrid fiber reinforcements, alternative fiber treatments, and durability testing will be essential for improving the practical applicability of natural fiber-reinforced PLA composites for industrial use [27].

6. Conclusions

This study investigated the mechanical and microstructural behavior of 3D-printed PLA composites reinforced with rice husk and rice straw fibers. The objective was to enhance the mechanical properties of PLA by reinforcing it with natural fibers and optimizing fiber characteristics through mesh size refinement and NaOH surface treatment. Several key findings emerged from this study:

- Optimal Fiber Characteristics: Finer fibers (200 mesh) exhibited better dispersion and interfacial contact within the PLA matrix, leading to notable improvements in flexural modulus and impact strength compared to coarser fibers (100 mesh). NaOH treatment further modified the fiber surface, reducing voids and fiber pull-out, as confirmed by SEM analysis.

- Tensile Performance: While a moderate increase in tensile modulus was observed for treated and finely milled fibers, tensile strength tended to decrease at higher fiber loadings. This decline is attributed to local stress concentrations and insufficient stress transfer at the fiber–matrix interfaces. Balancing fiber content and improving interfacial bonding are critical factors for achieving better tensile performance.

- Flexural and Impact Strength Improvements: The 3D-printed PLA composites exhibited enhanced flexural modulus and impact resistance, particularly in composites incorporating well-dispersed and chemically pretreated fibers. These improvements are attributed to efficient load distribution under bending and energy absorption during impact, confirming the effectiveness of fiber reinforcement in PLA-based composites.

- Microstructural and Spectroscopic Validation: FTIR analysis revealed partial lignin removal, with spectral shifts indicating increased cellulose exposure after NaOH treatment. SEM images corroborated these findings, showing improved interfacial adhesion in the treated fiber composites, which contributed to enhanced mechanical properties.

- Industrial Implications: These composites hold potential in automotive interiors, construction panels, and consumer products, where biodegradability, strength, and impact performance are priorities. Harnessing agricultural residues in PLA supports sustainability goals while providing improved mechanical robustness.

In conclusion, rice husk and rice straw fibers exhibit complementary reinforcing behaviors in 3D-printed PLA composites, particularly when subjected to alkaline treatment and refined to smaller mesh sizes. These findings contribute to the development of sustainable, high-performance biocomposites, supporting broader adoption of natural fiber-reinforced PLA for eco-friendly industrial applications.

Author Contributions

Conceptualization, N.S. and A.M.; methodology, A.M. and P.T.; software, P.T.; validation, S.P., B.C., and P.T.; formal analysis, A.M. and N.S.; investigation, A.M. and N.S.; resources, A.M.; data curation, A.M., P.T., and N.S.; writing—original draft preparation, N.S.; writing—review and editing, A.M. and P.T.; visualization, S.P. and B.C.; supervision, N.S.; project administration, A.M. and N.S.; funding acquisition, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors express their gratitude to the Department of Industrial Engineering, Faculty of Engineering, Rajamangala University of Technology, Thanyaburi, Thailand, for granting permission to use its laboratory equipment for this research.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Rath, K.C.; Chatterjee, P.; Patro, P.M.; Bojja, P.; Kumar, A.; Das, R.P. 3D printing technology in smart manufacturing systems for efficient production process. Intell. Manuf. Manag. Syst. 2023, 85, 85–111. [Google Scholar] [CrossRef]

- Mateti, T.; Jain, S.; Ananda Shruthi, L.; Laha, A.; Thakur, G. An overview of the advances in the 3D printing technology. 3D Print. Technol. Water Treat. Appl. 2023, 1, 1–37. [Google Scholar] [CrossRef]

- Trivedi, A.K.; Gupta, M.; Singh, H. PLA based biocomposites for sustainable products: A review. Adv. Ind. Eng. Polym. Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Kuru, Z.; Kaya, M.A. Improving the properties of biodegradable PLA via blending with polyesters for industrial applications. Eur. J. Res. Dev. 2022, 2, 299–318. [Google Scholar] [CrossRef]

- Ding, S.; Wang, X.; Wang, Z. Supertoughened polylactide via the addition of low content poly(ε-caprolactone) and tensile deformation above the glass transition temperature. Macromolecules 2023, 56, 5089–5100. [Google Scholar] [CrossRef]

- Paulo, A.; Santos, J.; Da Rocha, J.; Lima, R.; Ribeiro, J. Mechanical properties of PLA specimens obtained by additive manufacturing process reinforced with flax fibers. J. Compos. Sci. 2023, 7, 27. [Google Scholar] [CrossRef]

- Pop, M.A.; Cosnita, M.; Croitoru, C.; Zaharia, S.M.; Matei, S.; Spîrchez, C. 3D-printed PLA molds for natural composites: Mechanical properties of green wax-based composites. Polymers 2023, 15, 2487. [Google Scholar] [CrossRef] [PubMed]

- Dey, A.; Rahman, M.M.; Gupta, A.; Yodo, N.; Lee, C.W. A performance study on 3D-printed bioplastic pots from soybean by-products. Sustainability 2023, 15, 10535. [Google Scholar] [CrossRef]

- Kumar, A.M.; Jayakumar, K.; Shalini, M. Enhancing the performance of polylactic acid (PLA) reinforcing with sawdust, rice husk, and bagasse particles. J. Polym. Mater. 2023, 39, 269–281. [Google Scholar] [CrossRef]

- Mahdy, M.M.; Mahfouz, S.Y.; Tawfic, A.F.; Ali, M.A.E.M. Performance of rice straw fibers on hardened concrete properties under effect of impact load and gamma radiation. Fibers 2023, 11, 42. [Google Scholar] [CrossRef]

- Taha, M.; Fouly, A.; Abdo, H.S.; Alnaser, I.A.; Abouzeid, R.; Nabhan, A. Unveiling the potential of rice straw nanofiber-reinforced HDPE for biomedical applications: Investigating mechanical and tribological characteristics. J. Funct. Biomater. 2023, 14, 366. [Google Scholar] [CrossRef] [PubMed]

- Hajdek, K.; Smoljan, B.; Sarkanj, B.; Sitek, W. Processing technologies, properties and application of poly(lactic acid) (PLA). Int. J. Mod. Manuf. Technol. 2023, 15, 87–97. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Ishak, M.R.; Mohammad Taha, M.; Mustapha, F.; Leman, Z. A review of natural fiber-based filaments for 3D printing: Filament fabrication and characterization. Materials 2023, 16, 4052. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Sinha, A.K.; Rao, K.R.; Soni, V.K.; Chandrakar, R.; Sharma, H.K. A review on mechanical properties of natural fibre reinforced PLA composites. Curr. Mater. Sci. 2023, 16, 365–375. [Google Scholar] [CrossRef]

- Sözen, A.; Doğru, A.; Demir, M.; Özdemir, H.N.; Seki, Y. Production of waste jute doped PLA (polylactic acid) filament for FFF: Effect of pulverization. Int. J. 3d Print. Technol. Digit. Ind. 2023, 7, 124–128. [Google Scholar] [CrossRef]

- Asfak, S.A.; Arif, T.F.; Uday, T.S.; Singh, M.P. Rapid prototyping: Advancements in manufacturing technologies. Int. J. Eng. Appl. Sci. Technol. 2020, 5, 254–260. [Google Scholar] [CrossRef]

- Mukherjee, T. Special issue: The science and technology of 3D printing. Materials 2021, 14, 6261. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Tamimi, Z.A.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive manufacturing: A comprehensive review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, X. The application of 3D printing technology in the field of science and technology and art in the future. In Proceedings of the International Conference on Modeling and Simulation in Mechanical Engineering (ICMSME), Belgrade, Serbia, 7–8 July 2017. [Google Scholar]

- Salve, M.; Amreen, K.; Pattnaik, P.K.; Goel, S. Chapter-II: 3D printing; A state of the art approach in electrochemical sensing. In CRC Book on Microelectronics and Signal Processing: Advanced Concepts and Applications; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Kim, M.; Jeong, J.H.; Lee, J.Y.; Capasso, A.; Bonaccorso, F.; Kang, S.H.; Lee, Y.K.; Lee, G.H. Electrically conducting and mechanically strong graphene–polylactic acid composites for 3D printing. ACS Appl. Mater. Interfaces 2019, 11, 11841–11848. [Google Scholar] [CrossRef]

- Baran, E.; Erbil, H. Surface modification of 3D printed PLA objects by fused deposition modeling: A review. Colloids Interfaces 2019, 3, 43. [Google Scholar] [CrossRef]

- Chen, X.; Chen, G.; Wang, G.; Zhu, P.; Gao, C. Recent progress on 3D-printed polylactic acid and its applications in bone repair. Adv. Eng. Mater. 2019, 22, 1901065. [Google Scholar] [CrossRef]

- Fontana, L.; Minetola, P.; Iuliano, L.; Rifuggiato, S.; Khandpur, M.S.; Stiuso, V. An investigation of the influence of 3D printing parameters on the tensile strength of PLA material. Mater. Today Proc. 2022, 57, 657–663. [Google Scholar] [CrossRef]

- Rajpurohit, S.R.; Dave, H.K. Impact strength of 3D printed PLA using open-source FFF-based 3D printer. Prog. Addit. Manuf. 2020, 6, 119–131. [Google Scholar] [CrossRef]

- Jogur, G.; Khan, A.N.; Das, A.; Mahajan, P.; Alagirusamy, R. Impact properties of thermoplastic composites. Text. Prog. 2018, 50, 109–183. [Google Scholar] [CrossRef]

- Li, X.; Ni, Z.; Bai, S.; Lou, B. Preparation and mechanical properties of fiber-reinforced PLA for 3D printing materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 322, 022012. [Google Scholar] [CrossRef]

- NatureWorks LLC. Ingeo™ PLA 3D850 Technical Data Sheet; NatureWorks LLC: Minnetonka, MN, USA, 2022; Available online: https://natureworksllc.com/Ingeo-in-Use/3D-Printing (accessed on 16 August 2024).

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D790; Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- Huda, M.S.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Wood-fiber-reinforced poly(lactic acid) composites: Evaluation of the physicomechanical and morphological properties. J. Appl. Polym. Sci. 2011, 119, 2221–2229. [Google Scholar] [CrossRef]

- Benamira, M.; Benhassine, N.; Ayad, A.; Dekhane, A. Investigation of printing parameters effects on mechanical and failure properties of 3D printed PLA. Eng. Fail. Anal. 2023, 148, 107218. [Google Scholar] [CrossRef]

- Hao, B.; Lin, G. 3D printing technology and its application in industrial manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 782, 022065. [Google Scholar] [CrossRef]

- Kolář, K.; Litoš, J.; Reiterman, P.; Petrtýl, M. Dynamic stability of multi-functional composite developed for application in permanent way of Prague underground. Key Eng. Mater. 2018, 760, 147–151. [Google Scholar] [CrossRef]

- Yang, S. Introduction and future outlook of the 3D printing technology. In Proceedings of the International Conference on Mechanical Design and Simulation (MDS 2022), Wuhan, China, 20 September 2022. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Zhang, N.; Wang, T.; Hao, M.Y. Short review of polymer composites for 3D printing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 758, 012046. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).