Optimization of Process Parameters for Minimum Kerf Taper Angle and Surface Roughness in the Abrasive Water Jet Machining of a Hybrid Composite

Abstract

1. Introduction

2. Methodology

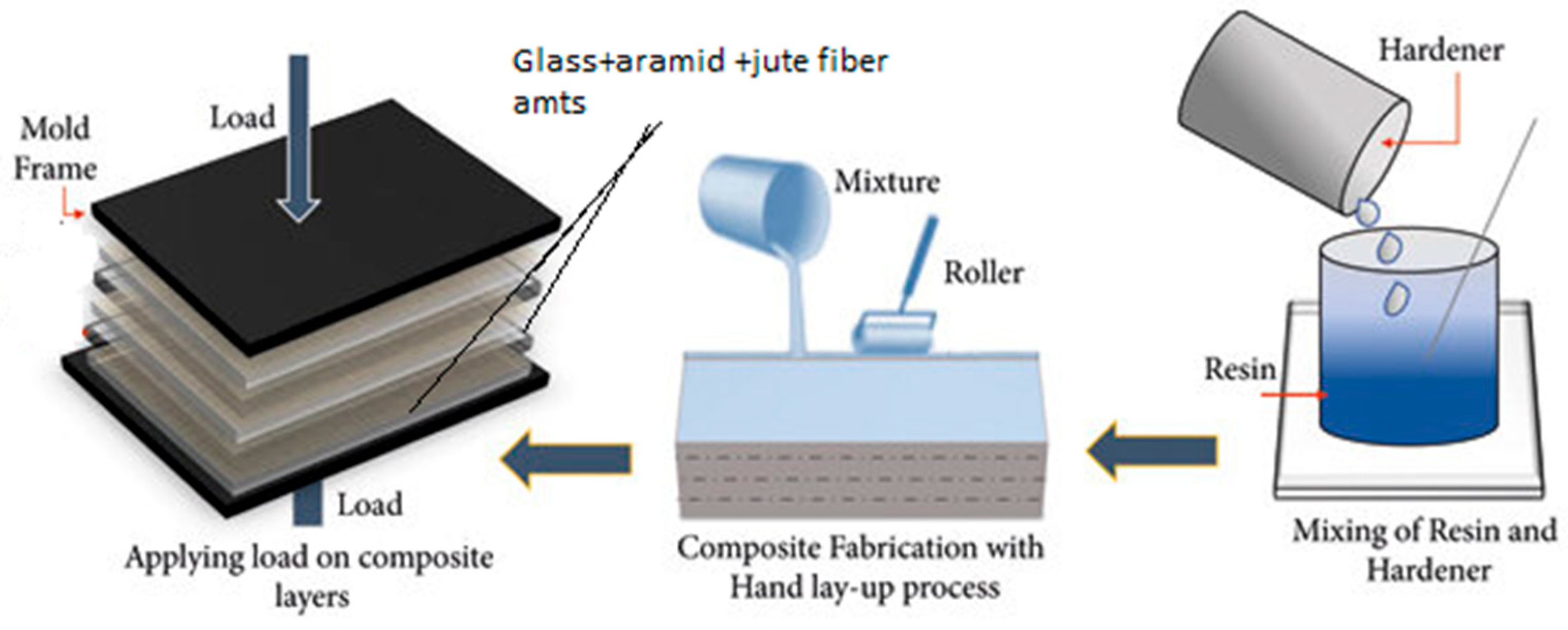

2.1. Preparation of Hybrid Composite Specimen

2.2. Abrasive Water Jet Machining

2.3. Selection of Machining Parameters and Their Levels

2.4. Measurement of Kerf Taper Angle and Surface Roughness

2.5. Design of Experiments (DOE)

3. Results and Discussion

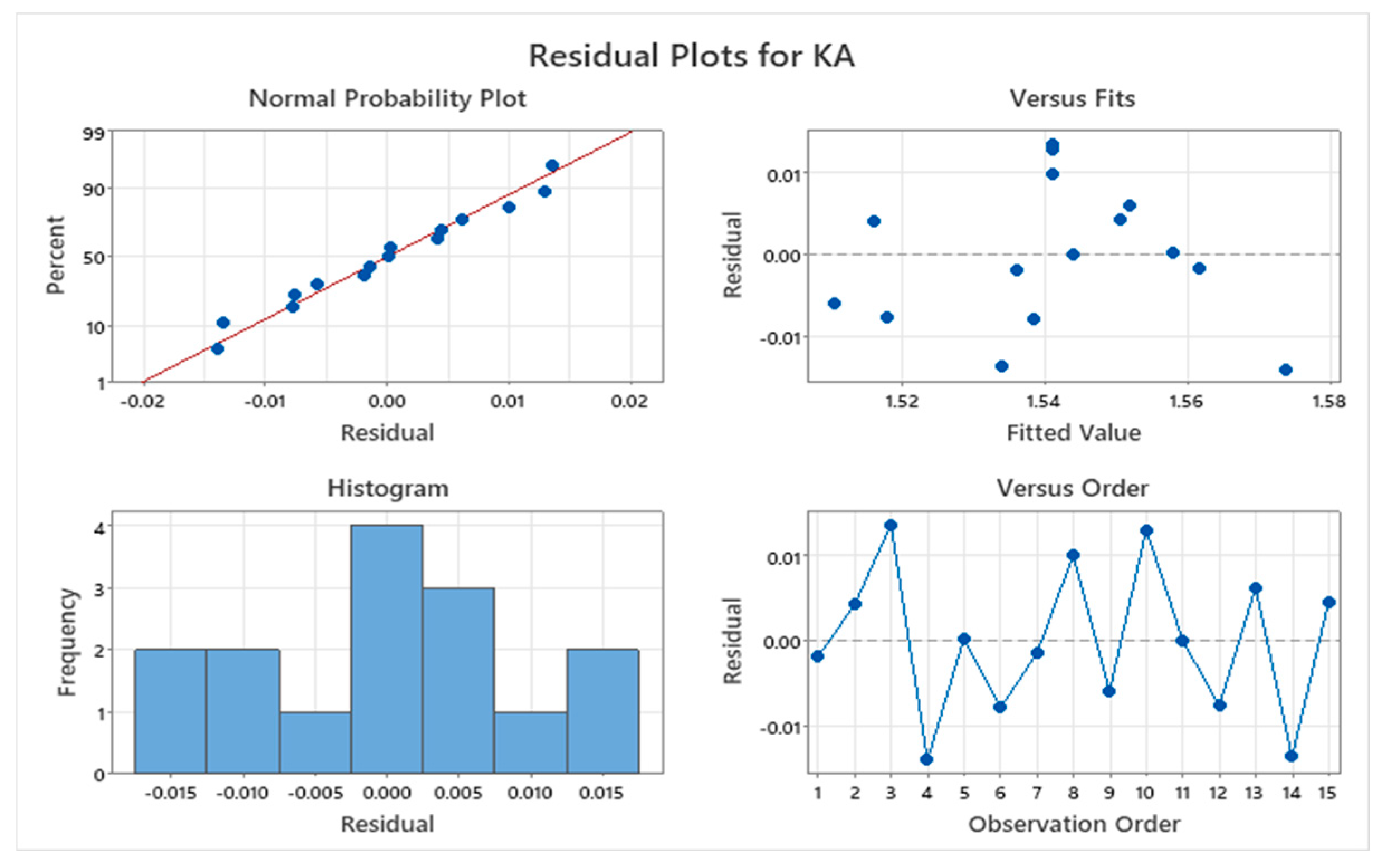

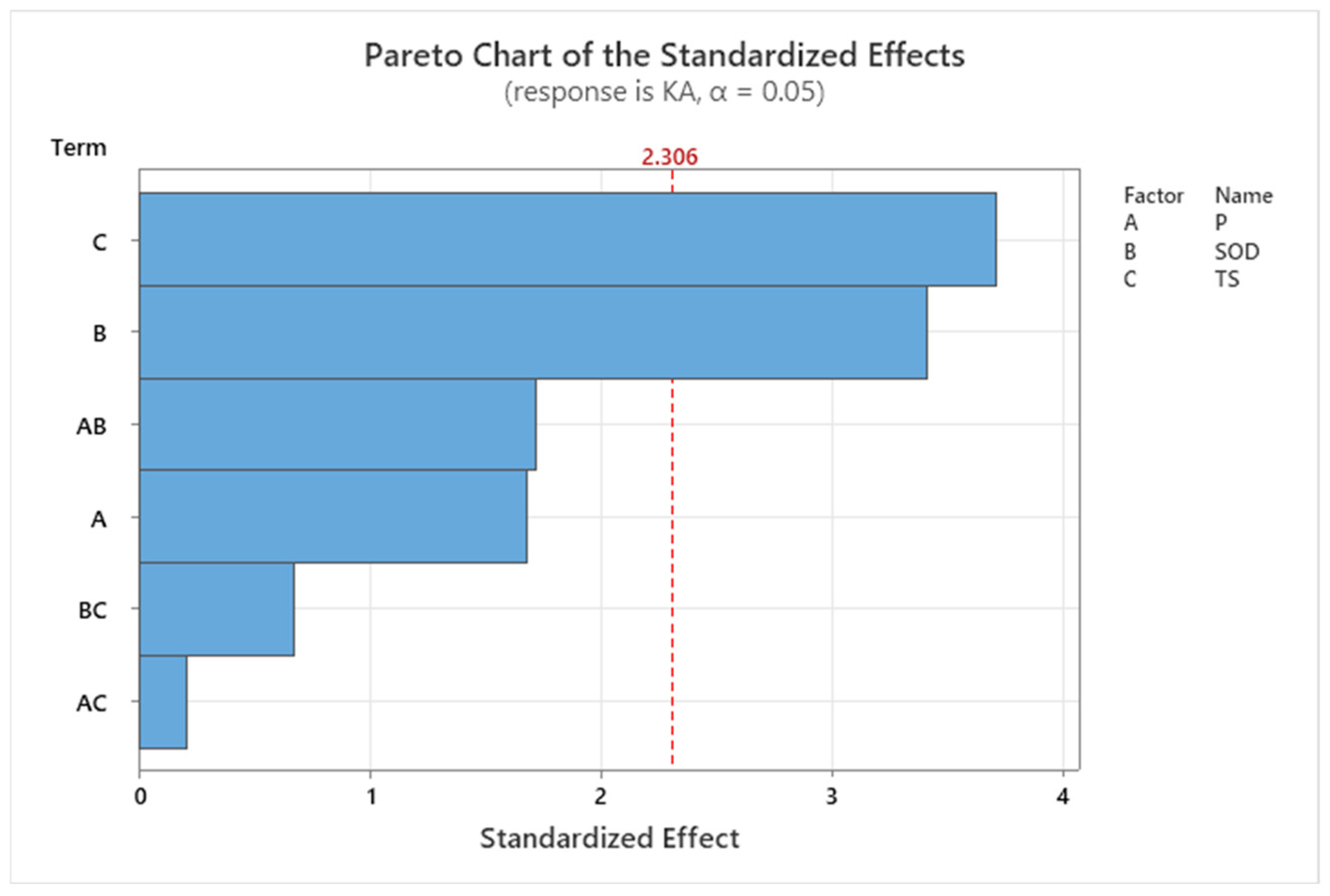

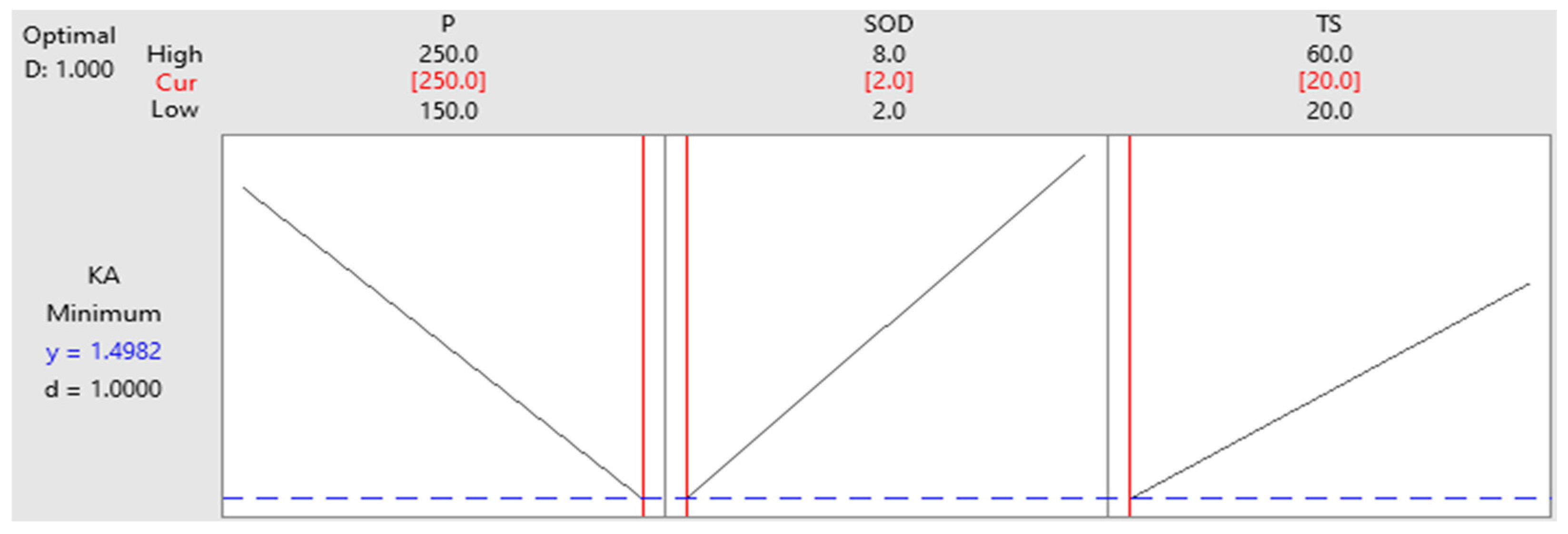

3.1. Analysis of Kerf Taper Angle (KT)

3.1.1. Regression Equation for Kerf Angle

+ 0.000064 SOD × TS

3.1.2. ANOVA for Kerf Angle (KT)

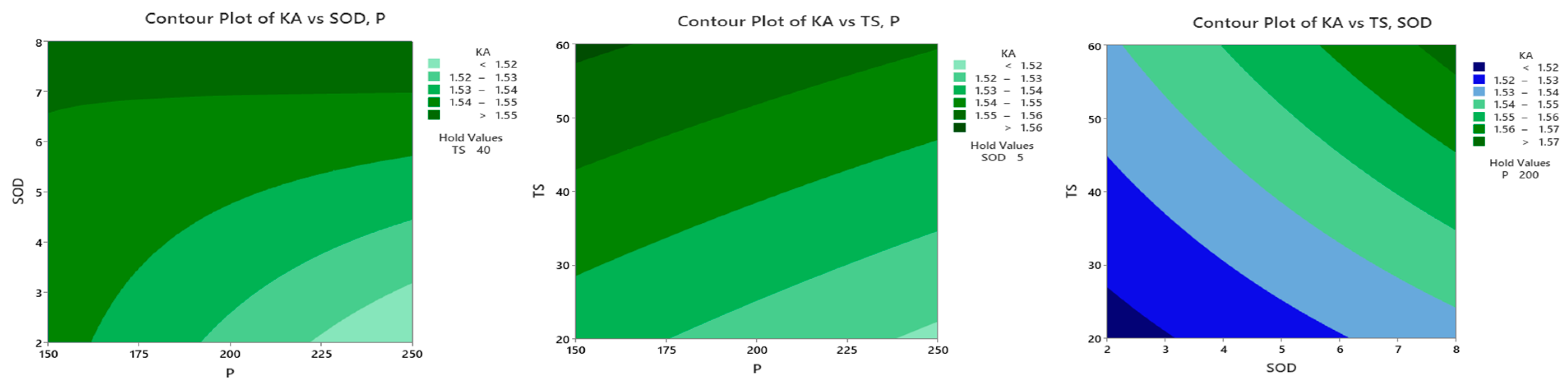

3.1.3. Effect of Process Parameters on the Kerf Taper Angle

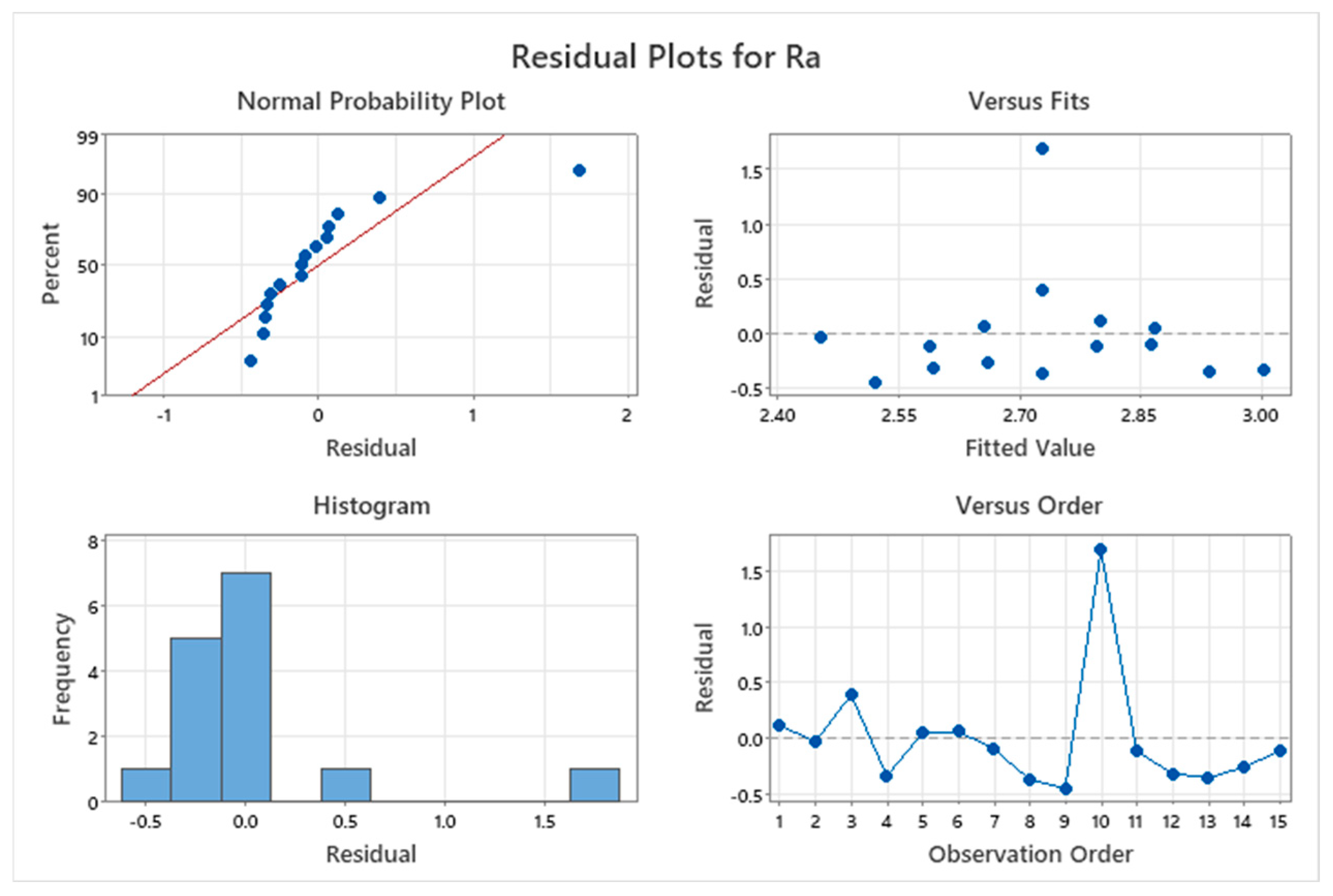

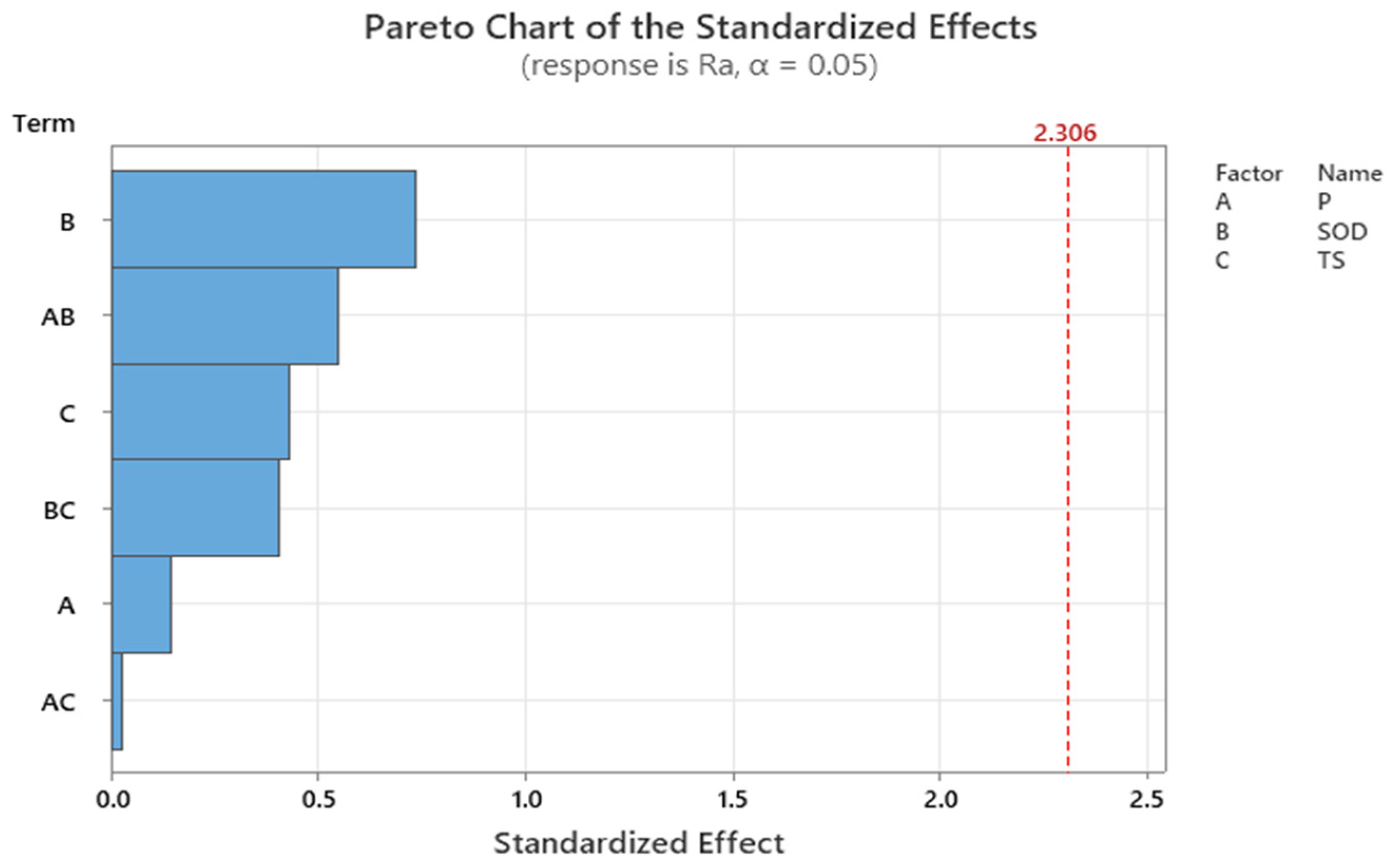

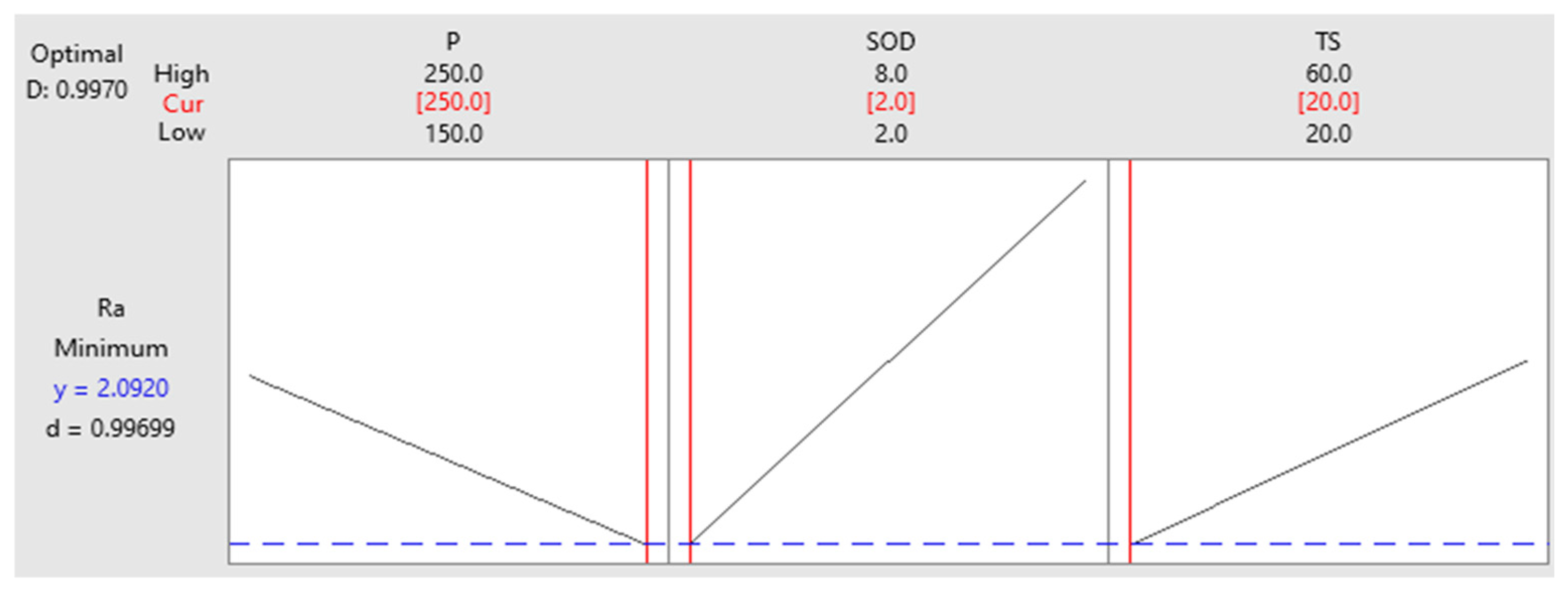

3.2. Analysis of Surface Roughness

3.2.1. Regression Equation for Surface Roughness

3.2.2. ANOVA for Surface Roughness

3.2.3. Effect of Process Parameters on the Surface Roughness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nassar, M.M.A.; Arunachalam, R.; Alzebdeh, K.I. Machinability of natural fiber reinforced composites: A review. Int. J. Adv. Manuf. Technol. 2017, 88, 2985–3004. [Google Scholar] [CrossRef]

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Banea, M.D. A review of recent advances in hybrid natural fiber reinforced polymer composites. J. Renew. Mater. 2022, 10, 561–589. [Google Scholar] [CrossRef]

- Ramesh, M.; Gopinath, A.; Deepa, C. Machining characteristics of fiber reinforced polymer composites: A review. Indian. J. Sci. Technol. 2016, 9, 1–7. [Google Scholar] [CrossRef]

- Dahiya, A.K.; Bhuyan, B.K.; Acharya, V.; Kumar, S. Optimization of process parameters for machining defects of glass fibre reinforced polymer composite machined by AWJM. In Materials Today: Proceedings; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Ergene, B.; Bolat, Ç. A review on the recent investigation trends in abrasive waterjet cutting and turning of hybrid composites. Sigma J. Eng. Nat. Sci. 2019, 37, 989–1016. [Google Scholar]

- Chichane, A.; Boujmal, R.; El Barkany, A. Bio-composites and bio-hybrid composites reinforced with natural fibers. Mater. Today Proc. 2023, 72, 3471–3479. [Google Scholar] [CrossRef]

- Pathapalli, V.R.; Pittam, S.R.; Sarila, V.; Burragalla, D.; Gagandeep, A. Multi-objective parametric optimization of AWJM process using Taguchi-based GRA and DEAR methodology. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 238, 2845–2853. [Google Scholar] [CrossRef]

- Palanikumar, K.; Prabhudass, J.M.; Prabha, P.S.; Senthilkumar, N. Sustainable optimization of abrasive water jet machining for MWCNT/bamboo/Kenaf hybrid polymer composites. Int. J. Interact. Des. Manuf. 2025, 19, 3765–3782. [Google Scholar] [CrossRef]

- Virk, G.S.; Singh, B.; Singh, Y.; Sharma, S.; Ilyas, R.A.; Patyal, V. Abrasive water jet machining of coir fiber reinforced epoxy composites: A review. Funct. Compos. Struct. 2022, 4, 014001. [Google Scholar] [CrossRef]

- Ramalingam, T.; Bhaskar, S.; Seshumadhav, K.; Allamraju, K.V. Optimization of process parameters in bi-directional carbon fiber composite using AWJM. Mater. Today Proc. 2018, 5, 18933–18940. [Google Scholar] [CrossRef]

- Dahiya, A.K.; Bhuyan, B.K.; Kumar, S. Abrasive water jet machining of glass fibre reinforced polymer composite: Experimental investigation, modelling and optimization. Int. J. Interact. Des. Manuf. 2023, 17, 1933–1947. [Google Scholar] [CrossRef]

- Ram, K.; Bajpai, P.K. Water Jet Machining of Hybrid Fiber-Reinforced Polymer Composites. In Forming and Machining of Polymers, Ceramics, and Composites; CRC Press: Boca Raton, FL, USA, 2024; pp. 134–143. [Google Scholar]

- Sajan, S.M. Investigation of the Effect of Abrasive Water Jet Machining Parameters on Fiber-Reinforced Epoxy Composite. Master’s Thesis, Kaunas University of Technology, Kaunas, Lithuania, 2025. [Google Scholar]

- Ficko, M.; Begic-Hajdarevic, D.; Cohodar Husic, M.; Berus, L.; Cekic, A.; Klancnik, S. Prediction of surface roughness of an abrasive water jet cut using an artificial neural network. Materials 2021, 14, 3108. [Google Scholar] [CrossRef] [PubMed]

- Sambruno, A.; Bañon, F.; Salguero, J.; Simonet, B.; Batista, M. Kerf taper defect minimization based on abrasive waterjet machining of low thickness thermoplastic carbon fiber composites C/TPU. Materials 2019, 12, 4192. [Google Scholar] [CrossRef] [PubMed]

- Azmir, M.A.; Ahsan, A.K. A study of abrasive water jet machining process on glass/epoxy composite laminate. J. Mater. Process. Technol. 2009, 209, 6168–6173. [Google Scholar] [CrossRef]

- Gopal, P.M.; Kavimani, V.; Arunkumar, K. Multi-objective optimization on abrasive water jet machining of epoxy/glass fiber/grinding wheel particle composite through hybrid optimization technique. Multiscale Multidiscip. Model. Exp. Des. 2023, 6, 697–707. [Google Scholar] [CrossRef]

- Nyaboro, J.N.; Ahmed, M.A.; El-Hofy, H.; El-Hofy, M. Numerical and experimental characterization of kerf formation in abrasive waterjet machining. In Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition, Volume 2: Advanced Manufacturing, Pittsburgh, PA, USA, 9–15 November 2018; Volume 52019, p. V002T02A050. [Google Scholar] [CrossRef]

- Madhu, S.; Balasubramanian, M. Challenges in abrasive jet machining of fiber-reinforced polymeric composites–a review. World J. Eng. 2021, 18, 251–268. [Google Scholar] [CrossRef]

- Deepak, D.; Davim, J.P. Multi-response optimization of process parameters in AWJ machining of hybrid GFRP composite by grey relational method. Procedia Manuf. 2019, 35, 1211–1221. [Google Scholar] [CrossRef]

- Saravanakumar, S.; Sathiyamurthy, S.; Vinoth, V. Enhancing machining accuracy of banana fiber-reinforced composites with ensemble machine learning. Measurement 2024, 235, 114912. [Google Scholar] [CrossRef]

- Jagadish; Bhowmik, S.; Ray, A. Prediction and optimization of process parameters of green composites in AWJM process using response surface methodology. Int. J. Adv. Manuf. Tech. 2016, 87, 1359–1370. [Google Scholar] [CrossRef]

- Jani, S.P.; Senthil Kumar, A.; Adam Khan, M.; Uthayakumar, M. Surface roughness and morphology studies on machining hybrid composite material using abrasive water jet cutting process. In Surface Engineering of Modern Materials; Gupta, K., Ed.; Springer: Cham, Switzerland, 2020; pp. 125–148. [Google Scholar] [CrossRef]

- Yang, X.; Lin, X.; Li, M.; Jiang, X. Experimental study on surface integrity and kerf characteristics during abrasive waterjet and hybrid machining of CFRP laminates. Int. J. Precis. Eng. Manuf. 2020, 21, 2209–2221. [Google Scholar] [CrossRef]

- Peržel, V.; Hloch, S.; Tozan, H.; Yagimli, M.; Hreha, P. Comparative analysis of abrasive waterjet (AWJ) technology with selected unconventional manufacturing processes. Int. J. Phys. Sci. 2011, 6, 5587–5593. [Google Scholar] [CrossRef]

- Subramanian, M.; Selvam, R.; Balasubramanian, T.; Madhusuthan, A.V. Optimum cutting performance of AWJM for Fiber/Metal hybrid composites using GRA-ANN methods. In Materials Today: Proceedings; Elsevier: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Karthikeyan, R.; Madhu, S.; Geo Varuvel, E.; Pethuthraj, M. Influence of brown algae filler and process parameters on the surface roughness and MRR of jute fiber polymeric composite machined by abrasive water jet. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 09544089241288069. [Google Scholar] [CrossRef]

- Manjunath Patel, G.C.; Jagadish; Kumar, R.S.; Swamy Naidu, N.V. Optimization of abrasive water jet machining for green composites using multi-variant hybrid techniques. In Optimization of Manufacturing Processes; Springer International Publishing: Cham, Switzerland, 2019; pp. 129–162. [Google Scholar] [CrossRef]

- Pragadish, N.; Kaliappan, S.; Natrayan, L.; Selvam, M.; Patil, P.P.; Arvinda Pandian, C.K. A short review on AWJM of natural fibre reinforced composite materials. Appl. Mech. Mater. 2023, 912, 123–139. [Google Scholar] [CrossRef]

- Murthy, B.R.N.; Makki, E.; Potti, S.R.; Hiremath, A.; Bolar, G.; Giri, J.; Sathish, T. Optimization of process parameters to minimize the surface roughness of abrasive water jet machined jute/epoxy composites for different fiber inclinations. J. Compos. Sci. 2023, 7, 498. [Google Scholar] [CrossRef]

- Kumar, J.; Soota, T.; Rajput, S.K. Optimization and measurement of kerf width and surface roughness of AISI 316L. Forces Mech. 2022, 6, 100071. [Google Scholar] [CrossRef]

- Khan, M.A.; Soni, H.; Mashinini, P.M.; Uthayakumar, M. Abrasive water jet cutting process form machining metals and composites for engineering applications: A review. Eng. Res. Express 2021, 3, 022004. [Google Scholar] [CrossRef]

- Niranjan, C.A.; Srinivas, S.; Ramachandra, M. Experimental investigations on depth of penetration and surface integrity in AZ91/Al2O3 nano-composites cut by abrasive water jet. Int. J. Adv. Manuf. Technol. 2020, 107, 747–762. [Google Scholar] [CrossRef]

- Vijayananth, K.; Muthukutti, G.P.; Ramakrishnan, S.K.; Venkatesan, S.; Zhou, W. An integrated CRITIC-COPRAS approach for multi-response optimization on AWJM of hybrid filler–reinforced polymer composite and its surface integrity. Int. J. Adv. Manuf. Technol. 2024, 131, 4965–4980. [Google Scholar] [CrossRef]

| Variable Parameters | |||

|---|---|---|---|

| Parameters | Water Pressure (P) | Traverse Speed (TS) | Stand of Distance (SOD) |

| Units | MPa | Mm/min | mm |

| Level 1 | 150 | 20 | 2 |

| Level 2 | 200 | 40 | 5 |

| Level 3 | 250 | 60 | 8 |

| Constant parameters | |||

| Garnet size | MESH | 60 | |

| Mass flow rate (MFR) | g min−1 | 100 | |

| Orifice diameter | mm | 0.35 | |

| Angle of target | Degree | 90 | |

| Exp No. | P (MPa) | SOD (mm) | TS (mm/min) | Ra1 | Ra2 | Ra (Avg) | Top Kerf | Bottom Kerf | KA | Kerf Taper (θ) | Kerf Taper (Radians) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 200 | 8 | 20 | 2.922 | 3.016 | 2.969 | 2208.54 | 1602.24 | 1905.390 | 61.8673 | 1.5546 |

| 2 | 200 | 2 | 20 | 2.434 | 2.570 | 2.502 | 1320.18 | 1074.46 | 1197.320 | 25.0735 | 1.5309 |

| 3 | 200 | 5 | 40 | 3.126 | 2.812 | 2.969 | 1715.65 | 1109.36 | 1412.505 | 61.8663 | 1.5546 |

| 4 | 200 | 8 | 60 | 2.675 | 1.924 | 2.300 | 2013.71 | 1105.00 | 1559.355 | 92.7255 | 1.5600 |

| 5 | 250 | 8 | 40 | 2.926 | 2.423 | 2.675 | 2212.90 | 1427.77 | 1820.335 | 80.1153 | 1.5583 |

| 6 | 200 | 2 | 60 | 2.727 | 2.634 | 2.681 | 1280.92 | 1036.66 | 1158.790 | 24.9245 | 1.5307 |

| 7 | 150 | 5 | 60 | 2.777 | 2.773 | 2.775 | 1699.66 | 1132.62 | 1416.140 | 57.8612 | 1.5535 |

| 8 | 200 | 5 | 40 | 2.369 | 3.136 | 2.753 | 1782.53 | 1285.28 | 1533.905 | 50.7398 | 1.5603 |

| 9 | 250 | 2 | 40 | 2.085 | 2.163 | 2.124 | 1353.62 | 1205.32 | 1279.470 | 15.1327 | 1.5048 |

| 10 | 200 | 5 | 40 | 4.418 | 2.557 | 3.488 | 1772.36 | 1187.87 | 1480.115 | 59.6418 | 1.5540 |

| 11 | 150 | 2 | 40 | 2.482 | 3.239 | 2.861 | 1424.86 | 1058.47 | 1241.665 | 37.3867 | 1.5441 |

| 12 | 250 | 5 | 20 | 2.288 | 2.577 | 2.433 | 1865.41 | 1375.43 | 1620.420 | 49.9980 | 1.5508 |

| 13 | 150 | 8 | 40 | 2.593 | 2.989 | 2.791 | 2057.33 | 1286.74 | 1672.035 | 78.6316 | 1.5581 |

| 14 | 150 | 5 | 20 | 2.411 | 2.104 | 2.258 | 1785.44 | 1294.01 | 1539.725 | 50.1459 | 1.5509 |

| 15 | 250 | 5 | 60 | 2.691 | 2.652 | 2.672 | 1651.68 | 1180.60 | 1416.140 | 48.0694 | 1.5549 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 6 | 0.004170 | 0.000695 | 5.27 | 0.018 |

| Linear | 3 | 0.003715 | 0.001238 | 9.40 | 0.005 |

| P | 1 | 0.000370 | 0.000370 | 2.81 | 0.132 |

| SOD | 1 | 0.001533 | 0.001533 | 11.63 | 0.009 |

| TS | 1 | 0.001812 | 0.001812 | 13.75 | 0.006 |

| 2-Way Interaction | 3 | 0.000455 | 0.000152 | 1.15 | 0.386 |

| P*SOD | 1 | 0.000390 | 0.000390 | 2.96 | 0.124 |

| P*TS | 1 | 0.000006 | 0.000006 | 0.04 | 0.841 |

| SOD*TS | 1 | 0.000059 | 0.000059 | 0.45 | 0.521 |

| Error | 8 | 0.001054 | 0.000132 | ||

| Lack-of-Fit | 6 | 0.001047 | 0.000175 | 48.56 | 0.020 |

| Pure Error | 2 | 0.000007 | 0.000004 | ||

| Total | 14 | 0.005224 | |||

| Model Summary | |||||

| S | R-sq | R-sq(adj) | R-sq(pred) | ||

| 0.0592776 | 97.90% | 96.33% | 90.32% | ||

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 6 | 0.53963 | 0.089938 | 0.96 | 0.505 |

| Linear | 3 | 0.33316 | 0.111054 | 1.19 | 0.374 |

| P | 1 | 0.00932 | 0.009316 | 0.10 | 0.760 |

| SOD | 1 | 0.24082 | 0.240818 | 2.57 | 0.147 |

| TS | 1 | 0.08303 | 0.083028 | 0.89 | 0.374 |

| 2-Way Interaction | 3 | 0.20647 | 0.068822 | 0.74 | 0.560 |

| P*SOD | 1 | 0.13323 | 0.133225 | 1.42 | 0.267 |

| P*TS | 1 | 0.00034 | 0.000342 | 0.00 | 0.953 |

| SOD*TS | 1 | 0.07290 | 0.072900 | 0.78 | 0.403 |

| Error | 8 | 0.74870 | 0.093588 | ||

| Lack-of-Fit | 6 | 0.36818 | 0.061363 | 0.32 | 0.881 |

| Pure Error | 2 | 0.38052 | 0.190262 | ||

| Total | 14 | 1.28833 | |||

| Model Summary | |||||

| S | R-sq | R-sq(adj) | R-sq(pred) | ||

| 0.305921 | 41.89% | 90.00% | 88.00% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bekal, S.M.; Hiremath, A.; B. R. N., M.; K., S.; S. R., H.; B. M., G.; M. C., G.S. Optimization of Process Parameters for Minimum Kerf Taper Angle and Surface Roughness in the Abrasive Water Jet Machining of a Hybrid Composite. J. Compos. Sci. 2025, 9, 604. https://doi.org/10.3390/jcs9110604

Bekal SM, Hiremath A, B. R. N. M, K. S, S. R. H, B. M. G, M. C. GS. Optimization of Process Parameters for Minimum Kerf Taper Angle and Surface Roughness in the Abrasive Water Jet Machining of a Hybrid Composite. Journal of Composites Science. 2025; 9(11):604. https://doi.org/10.3390/jcs9110604

Chicago/Turabian StyleBekal, Sathvik M., Anupama Hiremath, Murthy B. R. N., Suhas K., Harisha S. R., Gurumurthy B. M., and Gowri Shakar M. C. 2025. "Optimization of Process Parameters for Minimum Kerf Taper Angle and Surface Roughness in the Abrasive Water Jet Machining of a Hybrid Composite" Journal of Composites Science 9, no. 11: 604. https://doi.org/10.3390/jcs9110604

APA StyleBekal, S. M., Hiremath, A., B. R. N., M., K., S., S. R., H., B. M., G., & M. C., G. S. (2025). Optimization of Process Parameters for Minimum Kerf Taper Angle and Surface Roughness in the Abrasive Water Jet Machining of a Hybrid Composite. Journal of Composites Science, 9(11), 604. https://doi.org/10.3390/jcs9110604