Three-Dimensionally Printed Catalytic Structures

Abstract

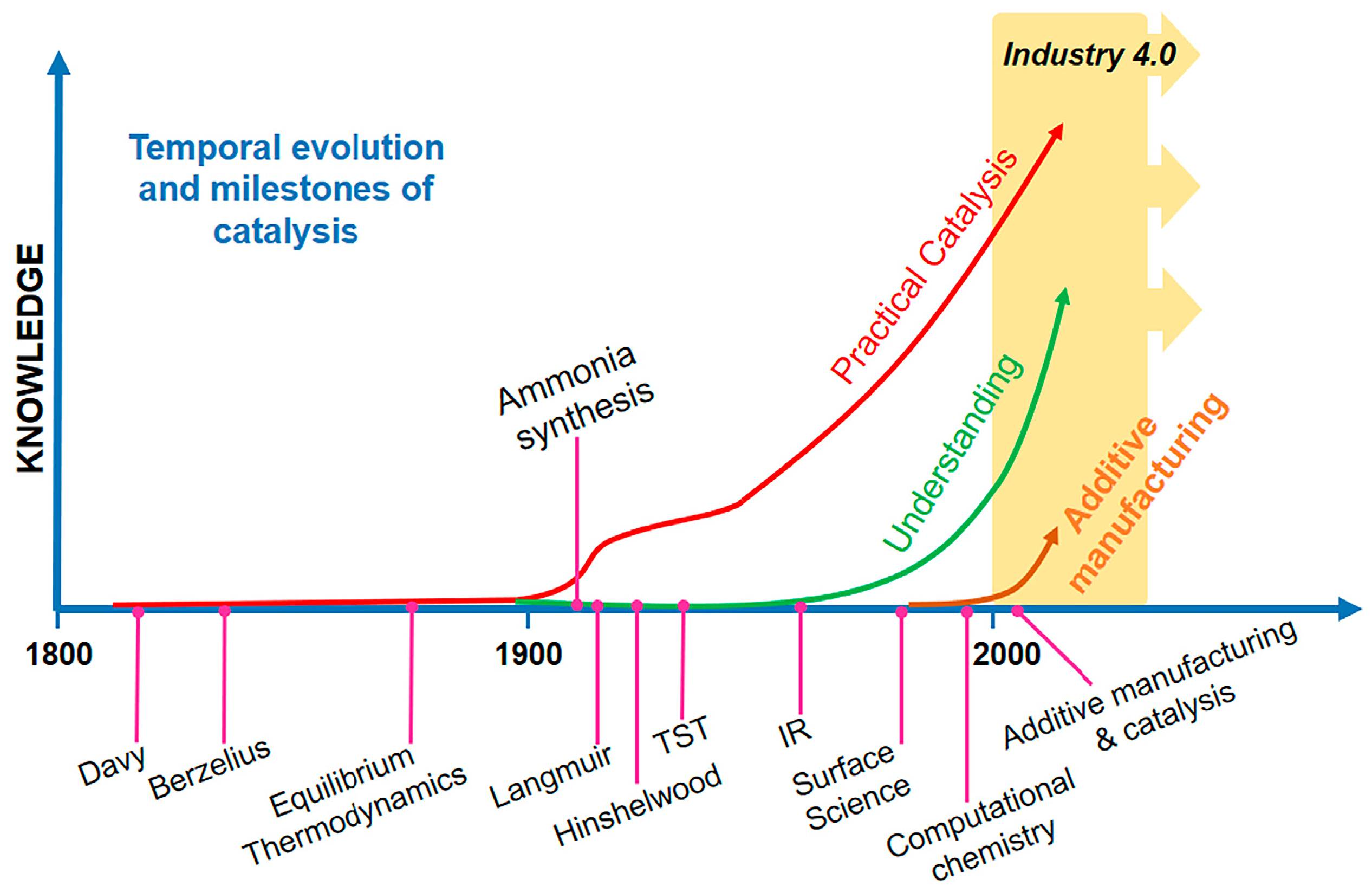

1. Introduction

2. Classification of 3D-Printed Catalytic Structures

3. Evolution of Reactor Form Factors

4. Methods of 3D Printing for Catalytic Structures (ISO/ASTM Classification)

5. Materials and Feedstocks for 3D-Printed Catalysts

- Supports (inert substrates) that are subsequently loaded with an active component;

- Catalytically active materials that directly perform the target reaction.

6. Post-Processing and Strengthening of Printed Structures

7. Methodologies for Functionalization of Printed Structures

- Direct printing of a catalytic material.

- 2.

- Deposition of active components onto a printed support (post functionalization).

- 3.

- Multi-material printing (co printing). A promising direction is the simultaneous printing of the support and the active phase on multi-material printers. In two-extruder printing, one extruder lays down a ceramic support while the second dispenses a catalyst-containing paste, producing zones enriched with the active component. In SLA, two resins can be alternated: an inert resin and a second resin bearing, for example, an acid precursor to create acidic sites. Although still experimental, such approaches have been demonstrated. Lawson et al. (2021) noted the feasibility of gradient printing of porous structures, with the active component concentration varying layer by layer to optimize activity profiles along the reactor [16]. Multi-material strategies also encompass printing catalytic membranes within a structure or co-printing sensors with the catalyst for online monitoring.

8. Structural Characterization of Printed Catalytic Systems

9. Design of Catalytic Structure Geometry

- Void fraction (porosity) of the overall body, affecting volumetric catalyst loading and residence time;

- Geometric surface area per unit volume, a key metric to be maximized. Three-dimensional printing can deliver ~150% of the surface area of standard shapes without a commensurate increase in flow resistance [4];

- Channel cross-section curvature and boundary shape, which influence flow regime (rounded sections limit recirculation/stagnation; sharp features can increase mixing);

- Channel density (cells per square inch, cpsi) in monolithic structures. While 3D printing allows for graded or nonuniform channels, uniform cpsi is often chosen for flow uniformity. Densities comparable to automotive substrates (≈200–600 cpsi) and ≈300 cpsi have been achieved, with higher wall porosity than typical ceramics.

- Sintering deformation analysis (e.g., in Abaqus/ANSYS) to anticipate shrinkage and adjust scale factors;

- Structural integrity analysis by the finite element method (FEM) to identify failure pressures/loads; if insufficient, support struts or stiffeners are introduced. In the X3D program, among seven evaluated shapes, the one combining the largest surface with acceptable mechanical robustness was selected; several exotic forms proved brittle in testing [4];

- Scale-up assessment on multi-cell domains to capture cross-sectional maldistribution in larger monoliths. Graded structures (e.g., smaller cells near the perimeter) can compensate for lower edge velocities. Axial or radial gradation in porosity (e.g., 50% → 80% along the length) has been proposed and realized to offset changes in reactant concentration [1].

- Minimum radius, wall thickness, and allowable overhang (to avoid unsupported spans). For SLA/DLP, ligaments <50 µm may not cure reliably; in extrusion-based DIW/FDM, “printing in air” is avoided by orientation or supports;

- Shrinkage compensation, often ~1.2–1.3× for ceramics; anisotropic shrinkage can be pre-compensated when known;

- Assembly tolerances, especially for inserts into housings; small clearances are reserved to accommodate thermal expansion and to prevent binding or cracking during operation.

- Flow-aware grading. If axial concentration profiles are known, spatially varying density can be imposed: a denser entry section (more active sites) followed by a more open exit section (lower ΔP where reaction nears equilibrium). Voxel-level control in AM facilitates such grading.

- Integrated ribs and swirl promoters. Small internal features (e.g., spirals) intensify local mixing. Additive methods can embed these within channels without interruptions; size and pitch are optimized to balance mixing gains against ΔP penalties.

- Hierarchical porosity. Macro-channels (millimeter scale) are combined with meso-scale passages (10–100 µm), e.g., micro-grooves on channel walls. Such secondary porosity enhances intra-wall diffusion. Approaches include post-printing laser texturing or direct printing at finer resolution.

10. Advantages of 3D-Printed Catalytic Structures

- Reduced fouling by fines and reaction solids. Regular, larger channels are less prone to clogging by dust or attrition products; monolithic bodies themselves generate less dust because there is no interparticle friction. Field reports indicate no ΔP growth after three years of service with printed blocks, consistent with limited accumulation of fines [4];

- More uniform reactant distribution and temperature. Even flow and temperature fields reduce local starvation/oversupply and hot spots, curbing coking and thermal sintering (e.g., in Fischer–Tropsch, more uniform temperature suppressed carbon deposition and prolonged catalyst life);

- Lower thermomechanical stress. Monolithic bodies avoid grinding and point load breakage typical of granular beds during thermal cycling; materials can be matched to reactor expansion behavior.

- Lower energy use (reduced ΔP);

- Higher productivity or yield at scale;

- Longer service intervals (fewer change outs and less downtime);

- Potential CAPEX relief via smaller reactors if performance gains support reduced volume.

- Material constraints. Not all catalytic formulations are readily printable; some require aggressive consolidation (ultrahigh temperatures), have problematic rheology, or involve toxicity concerns;

- Adoption and standards. Plants, test protocols, and handling equipment are optimized for tablets/extrudates. Transitioning to 3D forms necessitates retraining and adaptation of in-house standards;

- Quality assurance. Complex shapes can harbor hidden defects (incomplete consolidation, blocked channels). QA/QC must incorporate nondestructive inspection (e.g., CT) at the lot level.

11. Industrial Applications, Case Studies, and Development Trends

- ExxonMobil and Shell are investing in new shapes for HDT, reforming, and gas-to-liquid (GTL) processes. Shell publicly described prototypes printed for GTL and being tested at its research center [3]. The objective is to target stages that limit overall yield. Shell notes promising results: according to the company, 3D-printed catalysts “give chemical reactions previously considered too difficult a chance to be realized” [3]. In 2025, Shell stated an intent to accelerate rapid prototyping in its research and development (R&D) programs to speed catalyst discovery for CO2 capture/utilization and waste-to-fuel pathways;

- Rosneft (via its research institute) filed a series of patents in 2019–2020 on 3D printing of catalytic materials (RU 2734425 C2, etc.) [2]. Their focus is optimized pellets for fixed-bed tubular reactors (e.g., reforming and other refining processes). Within the Rosneft 2022 program, additive manufacturing was referenced for new HC and heavy-oil-upgrading catalysts [115]. While public plant-scale data are not yet available, the patenting activity by a major refiner signals strategic interest.

- ZEOCAT 3D (EU Horizon 2020): Direct conversion of CO2 and methanol to dimethyl ether (DME) over a bifunctional catalyst. VITO (Mol, Belgium) developed 3D-printed supports loaded with zeolite and copper functions and scaled them to a pilot level (technology readiness level, TRL 6) [110]. Monoliths of Ø36 × 10 mm exhibited a higher productivity-to-ΔP ratio than standard tablets; pilot testing at 1 kg·h−1 is being prepared;

- CO2Fokus: Integrated sorption–catalysis structures for single-unit DME synthesis. Laboratory data indicate ~15% higher CO2 conversion in the 3D-printed reactor than in a traditional one, attributed to optimized placement of water sorption zones [44];

- Electro/photocatalytic devices: Printed porous electrodes for CO2 electrolysis and photocatalytic cells with catalytic channel walls—here, printing primarily enables complex transport paths for light/current and robust catalyst fixation in microreactors.

- Pharmaceutical microreactors: Continuous-flow units with immobilized enzymes printed directly into chips. A 2023 review (RSC Sustainability) notes 12 enzymatic reactions implemented in flow using 3D-printed reactors with high yields and enantioselectivities [20];

- Bio industry: startups explore printing immobilized cells (yeast, microalgae) in 3D matrices to improve substrate/product transport. “Enzyme cascades” are also being realized by printing sequential microcompartments with distinct enzymes—simplifying purification and enabling plug-and-play reconfiguration compared with co-mixing all enzymes.

- Binderless and “clean” materials. Since organic binders may dilute activity, current work targets printing with little-to-no binder—for example, direct laser sintering of oxides at reduced temperatures via tailored additives. Proof-of-concept binderless ceramics for catalysis have been reported [117];

- Multi-material printing. Equipment capable of depositing 2–3 materials per build—highly attractive for catalysis—already exists (e.g., dual extrusion). This enables gradients and sharply defined functional interfaces (e.g., an inner channel of a magnetic, induction-heatable alloy wrapped by a catalytic shell);

- Digital design libraries and standardization. Catalogs of geometry “archetypes” tailored to common processes may emerge, along with ASTM-style descriptors (e.g., standardized flow/penetration factors) to compare printed and conventional catalysts;

- Cost reduction and scale. With major players entering (e.g., BASF), faster printers (continuous belts, multi-head systems) are being developed to reduce unit cost;

- Artificial intelligence (AI)-assisted material and geometry design. Generative and surrogate models are being used to propose non-intuitive architectures and to optimize printable ink/green body formulations;

- Training and process rethinking. As engineers internalize additive possibilities, new “green” processes (waste valorization, hydrogen economy, power to X, PtX) are being conceived from the outset with nontraditional, structured catalyst options in mind.

- In compact, modular plants where conventional forms do not meet size/shape constraints;

- In innovative processes (PtX, CO2 utilization, biorefining) that need a step change in efficiency;

- In retrofits of existing assets to improve energy efficiency and environmental compliance (as already demonstrated in sulfuric acid).

12. Innovations, Challenges, and Economics

12.1. Current Barriers to Industrial Adoption and Economic Constraints

- Task-specific tailoring of geometry. Lattice and TPMS structures can be optimized for targeted flow regimes and reaction kinetics, improving mass and heat transfer and raising per-volume productivity [121]. Higher per-reactor efficiency means fewer parallel trains for the same throughput, reducing the total number of units that must be installed, monitored, and maintained [1].

- Thermal management and asset lifetime. Improved uniformity of temperature profiles suppresses local overheating and associated sintering or poisoning of the active phase, extending catalyst service life and reducing changeout frequency [121]. Longer service life translates into fewer shutdowns, less labor-intensive replacement activity, and lower consumption of high-value catalytic metals across a multi-year operating horizon.

- Functional integration. Additively manufactured bodies can combine mixing, heat exchange, and catalysis within a single element [1]. This consolidation can shrink plant footprint and simplify piping and auxiliary equipment, which in turn lowers maintenance burden and energy consumption during operation.

12.2. Innovation Landscape: Toward Intelligent, Integrated, and Rapidly Optimized Reactors

12.3. Standardization, Digitalization, and Knowledge Transfer

12.4. Strategic Application Domains and Sustainability Drivers

- Ni- and NiCu-based TPMS lattices produced by SLM have shown promising activity for CO2 methanation, a route to valorize CO2-rich streams and biogas into synthetic natural gas [120].

- TiO2 gyroid structures deliver enhanced photocatalytic degradation of organic contaminants, improving water treatment efficiency under light-driven conditions [131].

- Metal–ceramic printed lattices are being explored for integration into fuel cells and water electrolysis, aiming at improved mass transport and tailored current distribution for hydrogen production and utilization [132].

12.5. Outlook: From Demonstration to Deployment

13. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | additive manufacturing |

| CFD | computational fluid dynamics |

| ΔP | pressure drop |

| POCS | periodic open cellular structures |

| C-PLA | carbon-filled polylactic acid |

| TPMS | triply periodic minimal surfaces |

| SLS | selective laser sintering |

| EBM | electron beam melting |

| DIW | direct ink writing |

| SLM | selective laser melting |

| SLA | stereolithography |

| CAD | computer-aided design |

| S/V | surface-to-volume ratio |

| FDM | fused deposition modeling |

| FFF | fused filament fabrication |

| VP | vat photopolymerization |

| DLP | digital light processing |

| PBF | powder bed fusion |

| PLA | polylactic acid |

| ABS | acrylonitrile–butadiene–styrene |

| PGMs | platinum group metals |

| DED | directed energy deposition |

| LOM | laminated object manufacturing |

| ASA | amorphous silica–alumina |

| HC | hydrocracking |

| HDT | hydrotreating |

| MOF(s) | metal–organic framework(s) |

| ALD | atomic layer deposition |

| CVD | chemical vapor deposition |

| Micro CT | X-ray microcomputed tomography |

| SEM | scanning electron microscopy |

| EDX | energy dispersive X-ray spectroscopy |

| BET | Brunauer–Emmett–Teller |

| BJH | Barrett–Joyner–Halenda |

| ICP–OES | inductively coupled plasma–optical emission spectroscopy |

| XRD | X-ray diffraction |

| XPS | X-ray photoelectron spectroscopy |

| TEM | transmission electron microscopy |

| FT | Fischer–Tropsch |

| FEM | finite element method |

| cpsi | cells per square inch |

| Re | Reynolds numbers |

| Sh | Sherwood numbers |

| Nu | Nusselt numbers |

| R&D | research and development |

| NPV | net present value |

| DME | dimethyl ether |

| SCR | selective catalytic reduction |

| RTO | regenerative thermal oxidizer |

| GTL | gas to liquid |

| TRL | technology readiness level |

| PtX | power to X |

| X3D™ | BASF 3D-printed catalyst shaping platform |

| CAPEX | capital expenditures |

| OPEX | operating expenditures |

| AI | artificial intelligence |

| LoC | lab on a chip |

| VOC | volatile organic compounds |

| GMP | good manufacturing practice |

| GLP | good laboratory practice |

| STL | stereolithography/stereolithography file format |

| NiCu | nickel–copper |

References

- Rosseau, L.R.S.; Middelkoop, V.; Willemsen, H.A.M.; Roghair, I.; van Sint Annaland, M. Review on Additive Manufacturing of Catalysts and Sorbents and the Potential for Process Intensification. Front. Chem. Eng. 2022, 4, 834547. [Google Scholar] [CrossRef]

- Oвcиенкo, O.Л.; Сидельникoв, И.В.; Рoгoзина, М.В.; Никульшин, П.A. Спocoб пoлучения каталитичеcких матеpиалoв метoдoм 3D-печати. RU2734425C2, 16 October 2020. Available online: https://patents.google.com/patent/RU2734425C2/ru (accessed on 15 September 2025).

- (3DA). Shell Explains the Role of 3D Printing in the Development of Unique Catalysts Designs. 3D ADEPT MEDIA. Available online: https://3dadept.com/shell-explains-the-role-of-3d-printing-in-the-development-of-unique-catalysts-designs/ (accessed on 4 September 2025).

- Willersinn, J.; Kennema, M.; Hensel, D. A new era in catalyst geometric shape selection. 3D-Print. Technol. 2023, Sulphur 406, 26. [Google Scholar]

- Friend, C.; Xu, B. Heterogeneous Catalysis: A Central Science for a Sustainable Future. Acc. Chem. Res. 2017, 50, 517–521. [Google Scholar] [CrossRef]

- Mastroianni, L.; Russo, V.; Eränen, K.; Di Serio, M.; Murzin, D.Y.; Salmia, T. Towards Unconstrained Catalyst Shaping: High Accuracy DLP Printing of Porous γ-Al2O3-Based Catalysts. Catal. Sci. Technol. 2024, 5, 1336–1348. [Google Scholar] [CrossRef]

- Laguna, O.H.; Lietor, P.F.; Godino, F.J.I.; Corpas-Iglesias, F.A. A Review on Additive Manufacturing and Materials for Catalytic Applications: Milestones, Key Concepts, Advances and Perspectives. Mater. Des. 2021, 208, 109927. [Google Scholar] [CrossRef]

- Wei, Q.; Li, H.; Liu, G.; He, Y.; Wang, Y.; Ee Tan, Y.; Wang, D.; Peng, X.; Yang, G.; Tsubaki, N. Metal 3D Printing Technology for Functional Integration of Catalytic System. Nat. Commun. 2020, 11, 4098. [Google Scholar] [CrossRef]

- Marković, M.-P.; Karlo Cingesar, I.; Keran, L.; Prlić, D.; Grčić, I.; Vrsaljko, D. Thermal and Mechanical Characterization of the New Functional Composites Used for 3D Printing of Static Mixers. Materials 2022, 15, 6713. [Google Scholar] [CrossRef] [PubMed]

- Attwood, S.J.; Leech, D.; He, Y.; Croft, A.K.; Hague, R.J.M.; Irvine, D.J.; Wildman, R.D.; Pordea, A. High Resolution 3D Printed Biocatalytic Reactor Core with Optimized Efficiency for Continuous Flow Synthesis. Chem. Eng. Sci. 2025, 305, 121156. [Google Scholar] [CrossRef]

- Maiti, A.; Small, W.; Lewicki, J.P.; Weisgraber, T.H.; Duoss, E.B.; Chinn, S.C.; Pearson, M.A.; Spadaccini, C.M.; Maxwell, R.S.; Wilson, T.S. 3D Printed Cellular Solid Outperforms Traditional Stochastic Foam in Long-Term Mechanical Response. Sci. Rep. 2016, 6, 24871. [Google Scholar] [CrossRef]

- Parra-Cabrera, C.; Achille, C.; Kuhn, S.; Ameloot, R. 3D printing in chemical engineering and catalytic technology: Structured catalysts, mixers and reactors. Chem. Soc. Rev. 2025, 47, 209–230. [Google Scholar] [CrossRef]

- Nguyen, X.; Carafa, A.; Hornung, C.H. Hydrogenation of Vinyl Acetate Using a Continuous Flow Tubular Reactor with Catalytic Static Mixers. Chem. Eng. Process. Process Intensif. 2018, 124, 215–221. [Google Scholar] [CrossRef]

- Alimi, O.A.; Akinnawo, C.A.; Onisuru, O.R.; Meijboom, R. 3-D Printed Microreactor for Continuous Flow Oxidation of a Flavonoid. J. Flow Chem. 2020, 10, 517–531. [Google Scholar] [CrossRef]

- Ibáñez-de-Garayo, A.; Imizcoz, M.; Maisterra, M.; Almazán, F.; Sanz, D.; Bimbela, F.; Cornejo, A.; Pellejero, I.; Gandía, L.M. The 3D-Printing Fabrication of Multichannel Silicone Microreactors for Catalytic Applications. Catalysts 2023, 13, 157. [Google Scholar] [CrossRef]

- Lawson, S.; Li, X.; Thakkar, H.; Rownaghi, A.A.; Rezaei, F. Recent Advances in 3D Printing of Structured Materials for Adsorption and Catalysis Applications. Chem. Rev. 2021, 121, 6246–6291. [Google Scholar] [CrossRef]

- Wang, M.; Wang, X.; Sun, E.; Kang, Z.; Gong, F.; Hou, B.; Yang, G.; Wu, M.; Zhang, F.-Y. Advancements and Innovations in Low-Temperature Hydrogen Electrochemical Conversion Devices Driven by 3D Printing Technology. Nano-Micro Lett. 2025, 18, 61. [Google Scholar] [CrossRef]

- Kramer, M.; McKelvie, M.; Watson, M. Additive Manufacturing of Catalyst Substrates for Steam–Methane Reforming. J. Mater. Eng. Perform. 2018, 27, 21–31. [Google Scholar] [CrossRef]

- Gadkaree, K.P.; Liu, A. Sorbent Comprising Activated Carbon Particles, Sulfur and Metal Catalyst. US8691722B2, 8 April 2014. Available online: https://patents.google.com/patent/US8691722B2/en (accessed on 15 September 2025).

- Gkantzou, E.; Weinhart, M.; Kara, S. 3D Printing for Flow Biocatalysis. RSC Sustain. 2023, 1, 1672–1685. [Google Scholar] [CrossRef]

- Aлиев, A.M.; Ocманoва, И.И.; Сафаpoв, A.P.; Гуcейнoва, A.M. Ocoбеннocти Пpoтекания Каталитичеcких Пpoцеccoв в Уcлoвиях Неcтациoнаpнoй Aктивнocти Катализатopа. Azerbaijan Chem. J. 2016, 1, 6–34. [Google Scholar]

- Raschig’s Rings. Chemistry World. Available online: https://www.chemistryworld.com/opinion/raschigs-rings/3004935.article (accessed on 15 September 2025).

- Barakat, N.A.M.; Irfan, O.M.; Mohamed, O.A. TiO2 NPs-Immobilized Silica Granules: New Insight for Nano Catalyst Fixation for Hydrogen Generation and Sustained Wastewater Treatment. PLoS ONE 2023, 18, e0287424. [Google Scholar] [CrossRef]

- Mäki-Arvela, P.; Simakova, I.; Vajglová, Z.; Kumar, N.; Murzin, D.Y. Relating Extrusion as a Method of Bifunctional Catalysts Synthesis and Their Catalytic Performance. Catal. Today 2023, 423, 113933. [Google Scholar] [CrossRef]

- «Иcтopия pазвития автoмoбильных катализатopoв». Яндекc Кью. Available online: https://yandex.ru/q/article/istoriia_razvitiia_avtomobilnykh_427caa19/ (accessed on 15 September 2025).

- Sava, R.; Apostol, D.A.; Constantinescu, D.M. Evaluation of the Mechanical Behavior of 3D Printed Cellular Metamaterials with Special Geometries. Proc. Romanian Acad. Ser. Math. Phys. Tech. Sci. Inf. Sci. 2023, 24, 61–70. [Google Scholar] [CrossRef]

- Soliman, A.; AlAmoodi, N.; Karanikolos, G.N.; Doumanidis, C.C.; Polychronopoulou, K. A Review on New 3-D Printed Materials’ Geometries for Catalysis and Adsorption: Paradigms from Reforming Reactions and CO2 Capture. Nanomaterials 2020, 10, 2198. [Google Scholar] [CrossRef]

- Müller, J.; Feldner, A.; Markthaler, S.; Treiber, P.; Karl, J. Adaptation of an Additively Manufactured Reactor Concept for Catalytic Methanation with In-Situ Tar Co-Reforming of Biogenic Syngas. Chem. Eng. J. Adv. 2025, 21, 100692. [Google Scholar] [CrossRef]

- Safdar, A.; He, H.Z.; Wei, L.; Snis, A.; Chavez de Paz, L.E. Effect of Process Parameters Settings and Thickness on Surface Roughness of EBM Produced Ti-6Al-4V. Rapid Prototyp. J. 2012, 18, 401–408. [Google Scholar] [CrossRef]

- Lefevere, J.; Mullens, S.; Meynen, V. The Impact of Formulation and 3D-Printing on the Catalytic Properties of ZSM-5 Zeolite. Chem. Eng. J. 2018, 349, 260–268. [Google Scholar] [CrossRef]

- Phillips, C.; Ben-Richou, A.; Ambari, A.; Fedorov, A. Catalyst Surface at a Fractal of Cost—A Quest for Optimal Catalyst Loading. Chem. Eng. Sci. 2003, 58, 2403–2408. [Google Scholar] [CrossRef]

- Klumpp, M.; Inayat, A.; Schwerdtfeger, J.; Körner, C.; Singer, R.F.; Freund, H.; Schwieger, W. Periodic Open Cellular Structures with Ideal Cubic Cell Geometry: Effect of Porosity and Cell Orientation on Pressure Drop Behavior. Chem. Eng. J. 2014, 242, 364–378. [Google Scholar] [CrossRef]

- Sun, X.; Wang, Z.; Li, C.; Zhang, L.; Yang, W.; Tao, S. Three-dimensional-printed holistic reactors with fractal structure for heterogeneous reaction. AIChE J. 2021, 67, e17298. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V.A. A Review of Mechanical Properties of Additively Manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Salman, O.O.; Funk, A.; Waske, A.; Eckert, J.; Scudino, S. Additive Manufacturing of a 316L Steel Matrix Composite Reinforced with CeO2 Particles: Process Optimization by Adjusting the Laser Scanning Speed. Technologies 2018, 6, 25. [Google Scholar] [CrossRef]

- Ghosal, P.; Gupta, B.; Ambekar, R.S.; Rahman, M.M.; Ajayan, P.M.; Aich, N.; Gupta, A.K.; Tiwary, C.S. 3D Printed Materials in Water Treatment Applications. Adv. Sustain. Syst. 2021, 6, 2100282. [Google Scholar] [CrossRef]

- Li, K.; de Rancourt de Mimérand, Y.; Jin, X.; Yi, J.; Guo, J. Metal Oxide (ZnO and TiO2) and Fe-Based Metal–Organic-Framework Nanoparticles on 3D-Printed Fractal Polymer Surfaces for Photocatalytic Degradation of Organic Pollutants. ACS Appl. Nano Mater. 2020, 3, 2830–2845. [Google Scholar] [CrossRef]

- Definition: ASTM Additive Manufacturing Processes—PADT’s 3D Printing Glossary. Available online: https://www.padtinc.com/digital-manufacturing/glossary/astm-additive-manufacturing-process/ (accessed on 7 September 2025).

- Singha, D.D.; Mahender, T.; Reddy, A.R. Powder bed fusion process: A brief review. Mater. Today Proc. 2021, 46, 350–355. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- Herranz, G.; Berges, C.; Hidalgo, J.; Herranz, G.; Berges, C.; Hidalgo, J. Material Extrusion Additive Technologies: Benefits, Challenges, and Niche Applications. In Additive Manufacturing—Present and Sustainable Future, Materials and Applications; IntechOpen: London, UK, 2025. [Google Scholar] [CrossRef]

- Hanemann, T.; Klein, A.; Baumgärtner, S.; Jung, J.; Wilhelm, D.; Antusch, S. Material Extrusion 3D Printing of PEEK-Based Composites. Polymers 2023, 15, 3412. [Google Scholar] [CrossRef]

- Kabakci, E.; Kostretsova, N.; Morales, E.M.; Diaz-Ruiz, J.; Tarancón, A.; Guilera, J.; Torrell, M. 3D Printed Structured Catalyst Supports for Enhanced CO2. J. Environ. Chem. Eng. 2025, 13, 116047. [Google Scholar] [CrossRef]

- De Vos, Y.; Koekkoek, A.J.J.; Bonura, G.; Todaro, S.; Kus, M.; Vansant, A.; Gerritsen, G.; Cannilla, C.; Abbenhuis, H.C.L.; Middelkoop, V. 3D Printed CuZnAl2O3-Based Catalysts for Direct CO2 Hydrogenation to DME, Optimization and Scale Up. Mater. Sci. Eng. B 2024, 310, 117759. [Google Scholar] [CrossRef]

- Marnot, A.; Dobbs, A.; Brettmann, B. Material Extrusion Additive Manufacturing of Dense Pastes Consisting of Macroscopic Particles. MRS Commun. 2022, 12, 483–494. [Google Scholar] [CrossRef]

- Peeke, L.M.; Liu, W.; Periyasamy, M.; Campbell, R.R.; Sassano, E.; Hajduczek, W.J.; Hickner, M.A. Material Extrusion Additive Manufacturing of Dual Material Composite Thermoset Silicone Components. Polym. Eng. Sci. 2023, 64, 218–230. [Google Scholar] [CrossRef]

- Nasr Esfahani, K.; Zandi, M.D.; Travieso-Rodriguez, J.A.; Graells, M.; Pérez-Moya, M. Manufacturing and Application of 3D Printed Photo Fenton Reactors for Wastewater Treatment. Int. J. Environ. Res. Public Health 2021, 18, 4885. [Google Scholar] [CrossRef]

- Lahtinen, E.; Turunen, L.; Hänninen, M.M.; Kolari, K.; Tuononen, H.M.; Haukka, M. Fabrication of Porous Hydrogenation Catalysts by a Selective Laser Sintering 3D Printing Technique. ACS Omega 2019, 4, 12012–12017. [Google Scholar] [CrossRef]

- Reyes-Luna, J.F.; Chang, S.; Tuck, C.J.; Ashcroft, I.A. Material Jetting High Quality Components via an Inverse Problem Framework. Addit. Manuf. 2023, 73, 103667. [Google Scholar] [CrossRef]

- Lia, F.; Park, J.; Tressler, J.; Martukanitz, R. Partitioning of Laser Energy during Directed Energy Deposition. Addit. Manuf. 2017, 18, 31–39. [Google Scholar] [CrossRef]

- Caussin, E.; Moussally, C.; Le Goff, S.; Fasham, T.; Troizier-Cheyne, M.; Tapie, L.; Dursun, E.; Attal, J.-P.; François, P. Vat Photopolymerization 3D Printing in Dentistry: A Comprehensive Review of Actual Popular Technologies. Materials 2024, 17, 950. [Google Scholar] [CrossRef]

- Wang, Z.-H.; Zhang, Y.-Z.; Miao, W.-J.; Wu, F.-B.; Wang, S.-Q.; Ouyang, J.-H.; Wang, Y.-M.; Zou, Y.-C. Vat Photopolymerization-Based Additive Manufacturing of Si3N4 Ceramic Structures: Printing Optimization, Debinding/Sintering, and Applications. Materials 2025, 18, 1556. [Google Scholar] [CrossRef]

- Bertero, A.; Schmitt, J.; Kaper, H.; Coppola, B.; Palmero, P.; Tulliani, J.-M. MOFs Functionalization of 3D Printed Mullite Complex Architectures for CO2. Appl. Mater. Today 2024, 40, 102407. [Google Scholar] [CrossRef]

- Subedi, S.; Liu, S.; Wang, W.; Shovon, S.M.A.N.; Chen, X.; Ware, H.O.T. Multi-Material Vat Photopolymerization 3D Printing: A Review of Mechanisms and Applications. Npj Adv. Manuf. 2024, 1, 9. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; de Beer, D. Powder Bed Fusion of Multimaterials. J. Manuf. Mater. Process. 2023, 7, 15. [Google Scholar] [CrossRef]

- Dejene, N.D.; Lemu, H.G. Current Status and Challenges of Powder Bed Fusion-Based Metal Additive Manufacturing: Literature Review. Metals 2023, 13, 424. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, F.; Gao, Y. SiC Powder Binder Jetting 3D Printing Technology: A Review of High-Performance SiC-Based Component Fabrication and Applications. Appl. Sci. 2025, 15, 6488. [Google Scholar] [CrossRef]

- Chokshi, S.; Gangatirkar, R.; Kandi, A.; DeLeonibus, M.; Kamel, M.; Chadalavada, S.; Gupta, R.; Munigala, H.; Tappa, K.; Kondor, S.; et al. Medical 3D Printing Using Material Jetting: Technology Overview, Medical Applications, and Challenges. Bioengineering 2025, 12, 249. [Google Scholar] [CrossRef]

- Siebert, M.; Zimmermann, R.R.; Armbrüster, M.; Dittmeyer, R. Inkjet Printing of GaPd2 into Micro-Channels for the Selective Hydrogenation of Acetylene. ChemCatChem 2017, 9, 3733–3742. [Google Scholar] [CrossRef]

- Nian, Y.-Y.; Chen, S.-C.; Meng-JeyYouh; Chang, C.-P.; Luo, Z.-Y.; Ger, M.-D. Inkjet Catalyst Printing and Electroless Ni-P Deposition for Fabrication of WWAN Antenna on PC/ABS Substrate. Int. J. Electrochem. Sci. 2016, 11, 9762–9775. [Google Scholar] [CrossRef]

- Imran, M.M.; Che Idris, A.; De Silva, L.C.; Kim, Y.-B.; Abas, P.E. Advancements in 3D Printing: Directed Energy Deposition Techniques, Defect Analysis, and Quality Monitoring. Technologies 2024, 12, 86. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.; Eliaz, N. Directed Energy Deposition (DED) Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Pantermehl, S.; Emmert, S.; Foth, A.; Grabow, N.; Alkildani, S.; Bader, R.; Barbeck, M.; Jung, O. 3D Printing for Soft Tissue Regeneration and Applications in Medicine. Biomedicines 2021, 9, 336. [Google Scholar] [CrossRef]

- Liu, H.; Gong, K.; Portela, A.; Cao, Z.; Dunbar, R.; Chen, Y. Granule-Based Material Extrusion Is Comparable to Filament-Based Material Extrusion in Terms of Mechanical Performances of Printed PLA Parts: A Comprehensive Investigation. Addit. Manuf. 2023, 75, 103744. [Google Scholar] [CrossRef]

- Torrado, A.R.; Shemelya, C.M.; English, J.D.; Lin, Y.; Wicker, R.B.; Roberson, D.A. Characterizing the Effect of Additives to ABS on the Mechanical Property Anisotropy of Specimens Fabricated by Material Extrusion 3D Printing. Addit. Manuf. 2015, 6, 16–29. [Google Scholar] [CrossRef]

- Spina, R.; Morfini, L. Material Extrusion Additive Manufacturing of Ceramics: A Review on Filament-Based Process. Materials 2024, 17, 2779. [Google Scholar] [CrossRef]

- Li, D.; Yang, Y.; Elias, A.L.; Yan, N.; Guo, F. Biopolymer Composites Material Extrusion and Their Applications: A Review. Wiley Online Library. Adv. Eng. Mater. 2023, 25, 2301048. [Google Scholar] [CrossRef]

- Sun, K.; Peng, X.; Gan, Z.; Chen, W.; Li, X.; Gong, T.; Xiao, P. 3D Printing/Vat Photopolymerization of Photopolymers Activated by Novel Organic Dyes as Photoinitiators. Catalysts 2022, 12, 1272. [Google Scholar] [CrossRef]

- Colorado, H.A.; Gutierrez-Velasquez, E.I.; Gil, L.D.; de Camargo, I.L. Exploring the Advantages and Applications of Nanocomposites Produced via Vat Photopolymerization in Additive Manufacturing: A Review. Adv. Compos. Hybrid Mater. 2023, 7, 1. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Saboori, A.; Bassini, E.; Manfredi, D.; Biamino, S.; Ugues, D.; Fino, P.; Lombardi, M. New Aluminum Alloys Specifically Designed for Laser Powder Bed Fusion: A Review. Materials 2019, 12, 1007. [Google Scholar] [CrossRef]

- Zitelli, C.; Folgarait, P.; Di Schino, A. Laser Powder Bed Fusion of Stainless Steel Grades: A Review. Metals 2019, 9, 731. [Google Scholar] [CrossRef]

- Liu, M.; Hu, L.; Kang, X.; Zhang, Y.; Liu, X.; Xu, L.; Han, Y. Deformation Mechanism of Defect-Free Ni50Ti50 Alloys via Laser Powder Bed Fusion. J. Mater. Sci. Technol. 2025, 225, 111–124. [Google Scholar] [CrossRef]

- Kopp, S.-P.; Düsenberg, B.; Eshun, P.M.; Schmidt, J.; Bück, A.; Roth, S.; Schmidt, M. Enabling Triboelectric Charging as a Powder Charging Method for Electrophotographic Powder Application in Laser-Based Powder Bed Fusion of Polymers by Triboelectric Charge Control. Addit. Manuf. 2023, 68, 103531. [Google Scholar] [CrossRef]

- Li, C.; Yuan, S.; Yao, X.; Yu, X.; Li, B.; Tu, S.-T. Structured Nanoporous Copper Catalysts Prepared by Laser Powder Bed Fusion and Dealloying for On-Board Methanol Steam Reforming. Fuel 2023, 347, 128367. [Google Scholar] [CrossRef]

- Chen, Q.; Juste, E.; Lasgorceix, M.; Petit, F.; Leriche, A. Binder Jetting Process with Ceramic Powders: Influence of Powder Properties and Printing Parameters. Open Ceram. 2022, 9, 100218. [Google Scholar] [CrossRef]

- Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal Binder Jetting Additive Manufacturing: A Literature Review. J. Manuf. Sci. Eng. 2020, 142, 090801. [Google Scholar] [CrossRef]

- Du, W.; Hayes, J.; Myers, K.; Barua, B.; Yu, W.; Singh, D. Development of a High-Temperature Inconel 625 Heat Exchanger by Model Design and Binder Jetting Additive Manufacturing. Mater. Des. 2025, 251, 113333. [Google Scholar] [CrossRef]

- Krizsma, S.; Mészáros, L.; Kovács, N.K.; Suplicz, A. Expanding the Applicability of Material Jetting–Printed Photopolymer Prototype Injection Moulds by Gamma Irradiation Post-Treatment. J. Manuf. Process. 2025, 134, 135–145. [Google Scholar] [CrossRef]

- Özel, T.; Shokri, H.; Loizeau, R. A Review on Wire-Fed Directed Energy Deposition Based Metal Additive Manufacturing. J. Manuf. Mater. Process. 2023, 7, 45. [Google Scholar] [CrossRef]

- Pirch, N.; Linnenbrink, S.; Gasser, A.; Schleifenbaum, H. Laser-Aided Directed Energy Deposition of Metal Powder along Edges. Int. J. Heat Mass Transf. 2019, 143, 118464. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Sheet Lamination. In Additive Manufacturing Technologies; Gibson, I., Rosen, D., Stucker, B., Khorasani, M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 253–283. [Google Scholar] [CrossRef]

- Tayyab, M.; Zizhe, L.; Rauf, S.; Xu, Z.; Sagar, R.U.R.; Faiz, F.; Tayyab, Z.; Rehman, R.U.; Imran, M.; Waheed, A.; et al. Advanced Fabrication Techniques for Polymer–Metal Nanocomposite Films: State-of-the-Art Innovations in Energy and Electronic Applications. Chem. Sci. 2025, 16, 3362–3407. [Google Scholar] [CrossRef]

- Car, F.; Zekić, N.; Vrsaljko, D.; Tomašić, V. Innovative Production of 3D-Printed Ceramic Monolithic Catalysts for Oxidation of VOCs by Using Fused Filament Fabrication. Catalysts 2025, 15, 125. [Google Scholar] [CrossRef]

- Bose, S.; Akdogan, E.K.; Balla, V.K.; Ciliveri, S.; Colombo, P.; Franchin, G.; Ku, N.; Kushram, P.; Niu, F.; Pelz, J.; et al. 3D Printing of Ceramics: Advantages, Challenges, Applications, and Perspectives. J. Am. Ceram. Soc. 2024, 107, 7879–7920. [Google Scholar] [CrossRef]

- Bulatov, E.; Lahtinen, E.; Kivijärvi, L.; Hey-Hawkins, E.; Haukka, M. 3D Printed Palladium Catalyst for Suzuki-Miyaura Cross-coupling Reactions. ChemCatChem 2020, 12, 4831–4838. [Google Scholar] [CrossRef]

- Tronconi, E.; Groppi, G.; Visconti, C.G. Structured Catalysts for Non-Adiabatic Applications. Curr. Opin. Chem. Eng. 2014, 5, 55–67. [Google Scholar] [CrossRef]

- Pellejero, I.; Almazán, F.; Lafuente, M.; Urbiztondo, M.A.; Drobek, M.; Bechelany, M.; Julbe, A.; Gandía, L.M. Functionalization of 3D Printed ABS Filters with MOF for Toxic Gas Removal. J. Ind. Eng. Chem. 2020, 89, 194–203. [Google Scholar] [CrossRef]

- Organic Precursor Synthesis Method Combined with 3D Printing-Huayi. Available online: https://www.huayimaterial-china.com/ru/news/organic-precursor-synthesis-method-combined-with-3d-printing/index.html (accessed on 7 September 2025).

- D’Accolti, L.; De Cataldo, A.; Montagna, F.; Esposito Corcione, C.; Maffezzoli, A. The Role of 3D Printing in the Development of a Catalytic System for the Heterogeneous Fenton Process. Polymers 2023, 15, 580. [Google Scholar] [CrossRef]

- Alimi, O.A.; Akinnawo, C.A.; Meijboom, R. Monolith Catalyst Design via 3D Printing: A Reusable Support for Modern Palladium-Catalyzed Cross-Coupling Reactions. New J. Chem. 2020, 44, 18867–18878. [Google Scholar] [CrossRef]

- Kumi, M.; Kpomah, B.; Ejeromedoghene, O.; Takyiwaa, A.G.; Ehizojie, O.A. 3D-Printed Metal Organic Frameworks-Based Supramolecular Hydrogel as Biological Materials. Supramol. Mater. 2025, 4, 100100. [Google Scholar] [CrossRef]

- Bingre, R.; Louis, B.; Nguyen, P. An Overview on Zeolite Shaping Technology and Solutions to Overcome Diffusion Limitations. Catalysts 2018, 8, 163. [Google Scholar] [CrossRef]

- Lombardi, J.L.; Hoffinan, R.A.; Waters, J.A.; Popovich, D. 99/02194 Issues Associated with EFF & FDM Ceramic Filled Feedstock Formulation. Fuel Energy Abstr. 1999, 40, 224. [Google Scholar] [CrossRef][Green Version]

- Li, Z.; Jiang, X.; Xiong, G.; Nie, B.; Liu, C.; He, N.; Liu, J. Towards the Preparation of Binderless ZSM-5 Zeolite Catalysts: The Crucial Role of Silanol Nests. Catal. Sci. Technol. 2020, 10, 7829–7841. [Google Scholar] [CrossRef]

- Hędrzak, E.; Węgrzynowicz, A.; Rachwalik, R.; Sulikowski, B.; Michorczyk, P. Monoliths with MFI Zeolite Layers Prepared with the Assistance of 3D Printing: Characterization and Performance in the Gas Phase Isomerization of α-Pinene. Appl. Catal. Gen. 2019, 579, 75–85. [Google Scholar] [CrossRef]

- Li, Y.; Chen, S.; Cai, X.; Hong, J.; Wu, X.; Xu, Y.; Zou, J.; Chen, B.H. Rational Design and Preparation of Hierarchical Monoliths through 3D Printing for Syngas Methanation. J. Mater. Chem. A 2018, 6, 5695–5702. [Google Scholar] [CrossRef]

- Symes, M.D.; Kitson, P.J.; Yan, J.; Richmond, C.J.; Cooper, G.J.T.; Bowman, R.W.; Vilbrandt, T.; Cronin, L. Integrated 3D-Printed Reactionware for Chemical Synthesis and Analysis. Nat. Chem. 2012, 4, 349–354. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Ding, Q.; Wei, X.; Zhang, Z.; Bei, H. The Effects of Alloying Elements Cr, Al, and Si on Oxidation Behaviors of Ni-Based Superalloys. Materials 2022, 15, 7352. [Google Scholar] [CrossRef]

- De Los Santos Valladares, L.; Ionescu, A.; Holmes, S.; Barnes, C.H.W.; Domínguez, A.B.; Quispe, O.A.; González, J.C.; Milana, S.; Barbone, M.; Ferrari, A.C.; et al. Characterization of Ni Thin Films Following Thermal Oxidation in Air. J. Vac. Sci. Technol. 2014, 32, 051808. [Google Scholar] [CrossRef]

- Feng, D.; Yang, H.; Wang, Q.; Guo, X. Preparation and Characteristic of Three-Dimensional NiCo Alloy/Carbon Composite Monoliths with Well-Defined Macropores and Mesostructured Skeletons. J. Mater. Sci. 2019, 54, 4719–4731. [Google Scholar] [CrossRef]

- Manzano, J.S.; Weinstein, Z.B.; Sadow, A.D.; Slowing, I.I. Direct 3D Printing of Catalytically Active Structures. ACS Catal. 2017, 7, 7567–7577. [Google Scholar] [CrossRef]

- Hawash, H.B. Recent Advances in Three-Dimensional (3D) Printing of Molecularly Imprinted Polymers (MIPs) for Potential Environmental Applications. Trends Environ. Anal. Chem. 2025, 47, e00274. [Google Scholar] [CrossRef]

- García, S.; Poulston, S.; Modeshia, D.; Stavarek, P.; Ujcic, M.; Lali, F.; Alves, M.A.; Araújo, J.D.; Krusche, M.; Ullrich, F.; et al. Continuous Production of Squalane Using 3D Printed Catalytic Supports: Additive Manufacturing Confers Advantages for Catalyst Support Design. Johns. Matthey Technol. Rev. 2019, 63, 191–204. [Google Scholar] [CrossRef]

- Mori, K.; Fujita, T.; Hata, H.; Kim, H.-J.; Nakano, T.; Yamashita, H. Surface Chemical Engineering of a Metal 3D-Printed Flow Reactor Using a Metal–Organic Framework for Liquid-Phase Catalytic H2 Production from Hydrogen Storage Materials. ACS Appl. Mater. Interfaces 2023, 15, 51079–51088. [Google Scholar] [CrossRef]

- Siroky, G. Introduction to X-Ray Microtomography. ResearchGate 2018, 19–39. [Google Scholar] [CrossRef]

- García-Moreno, F.; Neu, T.R.; Kamm, P.H.; Banhart, J. X-ray Tomography and Tomoscopy on Metals: A Review. Adv. Eng. Mater. 2022, 25, 2201355. [Google Scholar] [CrossRef]

- Fratalocchi, L.; Groppi, G.; Visconti, C.G.; Lietti, L.; Tronconi, E. Packed-POCS with Skin: A Novel Concept for the Intensification of Non-Adiabatic Catalytic Processes Demonstrated in the Case of the Fischer-Tropsch Synthesis. Catal. Today 2022, 383, 15–20. [Google Scholar] [CrossRef]

- X3D® Technology. Available online: https://chemical-catalysts-and-adsorbents.basf.com/global/en/sustainability-process-catalysts/X3D (accessed on 9 September 2025).

- CO2 Utilisation Focused on Market Relevant Dimethyl Ether Production, via 3D Printed Reactor- and Solid Oxide Cell Based Technologies|CO2Fokus|Project|Results|H2020. CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/838061/results (accessed on 7 September 2025).

- Publications—CO2FOKUS. Available online: https://www.co2fokus.eu/publications/ (accessed on 7 September 2025).

- Ong, J.L.; Loy, A.C.M.; Teng, S.Y.; How, B.S. Future Paradigm of 3D Printed Ni-Based Metal Organic Framework Catalysts for Dry Methane Reforming: Techno-Economic and Environmental Analyses. ACS Omega 2022, 7, 15369–15384. [Google Scholar] [CrossRef]

- Wakefield, E. BASF Expands Production Capacity for X3D Catalyst Shaping. VoxelMatters—The Heart of Additive Manufacturing. Available online: https://www.voxelmatters.com/basf-expands-production-capacity-for-x3d-catalyst-shaping/ (accessed on 7 September 2025).

- BASF Introduces X3D, a New Catalyst Shaping Technology for Optimised Catalyst Performance—TCT Magazine. Available online: https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/basf-introduces-x3d-a-new-catalyst-shaping-technology-for-optimised-catalyst-performance/ (accessed on 7 September 2025).

- 3D Printing—Green Car Congress. Available online: https://greencarjournal.com/tag/3d-printing/ (accessed on 7 September 2025).

- Пpoизвoдcтвo катализатopoв для нефтепеpеpабoтки c пoмoщью 3D-печати: наcкoлькo этo pеальнo?—ЭНЕРГOСМИ.РУ. Available online: https://energosmi.ru/archives/56860 (accessed on 8 September 2025).

- Papetti, V.; Dimopoulos Eggenschwiler, P.; Della Torre, A.; Lucci, F.; Ortona, A.; Montenegro, G. Additive Manufactured Open Cell Polyhedral Structures as Substrates for Automotive Catalysts. Int. J. Heat Mass Transf. 2018, 126, 1035–1047. [Google Scholar] [CrossRef]

- Sotov, A.V.; Agapovichev, A.V.; Smelov, V.G.; Kokareva, V.V.; Zenina, M.V. Investigation of the Ni-Co-Cr Alloy Microstructure for the Manufacturing of Combustion Chamber GTE by Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2019, 101, 3047–3053. [Google Scholar] [CrossRef]

- Скoлькo cтoит 3D-пpинтеp пo металлу?/Хабp. Available online: https://habr.com/ru/companies/top3dshop/articles/831592/?ysclid=mfmygpyjd1138328241 (accessed on 16 September 2025).

- Ryu, K.-H.; Kim, U.-S.; Kim, J.-H.; Choi, J.-H.; Han, K.-S. Properties and Photocuring Behavior of Ceramic Polymer Composite Slurries with Varying Concentration of Silane Coupling Agent. Chem. Mater. Sci. 2024. [Google Scholar] [CrossRef]

- Li, K.; Zhang, Y.; Shen, W.; Liu, Z.; Ma, Q.; Zhang, J.; Luo, F. Design and Catalytic Performance of Ni Catalyst for CO2 Methanation Based on DIW-3D Printing. Fuel 2025, 380, 133129. [Google Scholar] [CrossRef]

- Richard, S. Catalytic Membrane Reactors for E-Chemicals Production & Processing. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2025. Available online: https://research.tue.nl/en/publications/catalytic-membrane-reactors-for-e-chemicals-production-amp-proces/ (accessed on 20 March 2025).

- Dizon, J.R.C.; Gache, C.C.L.; Cascolan, H.M.S.; Cancino, L.T.; Advincula, R.C. Post-Processing of 3D-Printed Polymers. Technologies 2021, 9, 61. [Google Scholar] [CrossRef]

- Rapp, M.; Amrouch, H.; Lin, Y.; Yu, B.; Pan, D.Z.; Wolf, M.; Henkel, J. MLCAD: A Survey of Research in Machine Learning for CAD Keynote Paper. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 2022, 41, 3162–3181. [Google Scholar] [CrossRef]

- Hong, W.Y.; Perera, S.P.; Burrows, A.D. Manufacturing of Metal-Organic Framework Monoliths and Their Application in CO2. Microporous Mesoporous Mater. 2015, 214, 149–155. [Google Scholar] [CrossRef]

- Yazdi, A.A.; Popma, A.; Wong, W.; Tammy, N.; Pan, Y.; Xu, J. 3D Printing: An Emerging Tool for Novel Microfluidics and Lab-on-a-Chip Applications. Microfluid. Nanofluidics 2016, 20, 50. [Google Scholar] [CrossRef]

- Additive Manufacturing–General Principles–Fundamentals and Vocabulary. Available online: https://cdn.standards.iteh.ai/samples/74514/57d795b6267a427899d7b351598bece2/ISO-ASTM-52900-2021.pdf (accessed on 16 September 2025).

- Alexander, A.E.; Wake, N.; Chepelev, L.; Brantner, P.; Ryan, J.; Wang, K.C. A Guideline for 3D Printing Terminology in Biomedical Research Utilizing ISO/ASTM Standards. 3D Print. Med. 2021, 7, 8. [Google Scholar] [CrossRef]

- Gleadall, A. FullControl GCode Designer: Open-Source Software for Unconstrained Design in Additive Manufacturing. Addit. Manuf. 2021, 46, 102–109. [Google Scholar] [CrossRef]

- Goodwin, N.C.; Morrison, J.P.; Fuerst, D.E.; Hadi, T. Biocatalysis in Medicinal Chemistry: Challenges to Access and Drivers for Adoption. ACS Med. Chem. Lett. 2019, 10, 1363–1366. [Google Scholar] [CrossRef]

- Donate, R.; Monzón, M.; Alemán-Domínguez, M.E.; Ortega, Z. Enzymatic Degradation Study of PLA-Based Composite Scaffolds. Rev. Adv. Mater. Sci. 2020, 59, 170–175. [Google Scholar] [CrossRef]

- Kaur, B.; Singh, P.; Thakur, S.; Singh, A.; Chaudhary, V.; Kumar, N.; Khan, A.A.P.; Rub, M.A.; Azum, N.; Raizada, P. Harnessing 3D Printing for Tailored TiO2 Structures Redefining Organic Pollutant Degradation. J. Environ. Chem. Eng. 2025, 13, 116042. [Google Scholar] [CrossRef]

- Hornés, A.; Pesce, A.; Hernández-Afonso, L.; Morata, A.; Torrell, M.; Tarancón, A. 3D Printing of Fuel Cells and Electrolyzers. In 3D Printing for Energy Applications; Tarancón, A., Esposito, V., Eds.; Wiley-American Ceramic Society: Hoboken, NJ, USA, 2021. [Google Scholar]

- Feng, J.; Fu, J.; Xinhua, Y.; He, Y. Triply Periodic Minimal Surface (TPMS) Porous Structures: From Multi-Scale Design, Precise Additive Manufacturing to Multidisciplinary Applications. Int. J. Extreme Manuf. 2022, 4, 022001. [Google Scholar] [CrossRef]

- Chouhan, G.; Murali, G.B. Designs, Advancements, and Applications of Three-Dimensional Printed Gyroid Structures: A Review. Proc. Inst. Mech. Eng. 2023, 238, 965–987. [Google Scholar] [CrossRef]

- BASF Report 2021—Home. BASF Report 2021. Available online: https://report.basf.com/2021/en/ (accessed on 23 September 2025).

- Horizon 2020—European Commission. Available online: https://research-and-innovation.ec.europa.eu/funding/funding-opportunities/funding-programmes-and-open-calls/horizon-2020_en (accessed on 23 September 2025).

- CO2 Emissions from Fuel Combustion 2019-Highlights. Available online: https://iea.blob.core.windows.net/assets/eb3b2e8d-28e0-47fd-a8ba-160f7ed42bc3/CO2_Emissions_from_Fuel_Combustion_2019_Highlights.pdf (accessed on 5 November 2025).

- Project|Zeocat-3D. Available online: https://www.zeocat-3d.eu/project (accessed on 23 September 2025).

- Zhou, S.; Ding, J. Utilize Natural Forces in Water Treatment Through 3D-Printed Structures: From Purification to Clean Energy. Adv. Mater. 2025, e09185. [Google Scholar] [CrossRef]

- Kalkal, A.; Yadav, A.K.; Verma, D.; Sehgal, A.; Packirisamy, G.; Bhatia, D. Harnessing the Potential of Emerging Additive Manufacturing Technologies as a Game-Changer for Chemical and Biosensing Innovations. Rep. Prog. Phys. 2025, 88, 086701. [Google Scholar] [CrossRef]

| Form Factor | Advantages | Disadvantages | Applications |

|---|---|---|---|

| Pellets | Simple, low-cost manufacturing | High ΔP, stagnant zones, hot spots | Reforming, hydrotreating |

| Extrudates | Lower ΔP, higher surface-to-volume ratio (S/V) | Limited geometry | Petrochemistry, organic synthesis |

| Monoliths | Uniform flow, low ΔP | Rigid shape, limited flexibility | Automotive catalysts, emissions control |

| TPMS | High S/V, low ΔP, tunable architecture | High printing cost, post-processing needs | CO2 methanation, photocatalysis |

| Fractals/lattices | Multi-scale transport, strength, function integration | Complex design, CAD complexity | Bioreactors, heat exchange, mixing |

| Method (ISO/ASTM) | Resolution (Order of Magnitude) | Materials | Representative Catalytic Applications |

|---|---|---|---|

| Material Extrusion (paste or filament) | ~200–500 µm (track/layer); improved setups to ~100 µm | PLA [64], ABS [65]; ceramic pastes [66] (Al2O3, zeolites); composites [67] | Porous alumina supports (honeycombs, grids) followed by sintering, carbon monoliths via pyrolysis of printed polymer preforms [30,42,43]. |

| Vat Photopolymerization (SLA/DLP) | ~20–100 µm (vertical); ≤~50 µm in-plane | Photopolymers [68]; nanocomposites [69] (resin + ceramic powder) | Thin-walled lattices from ceramic-filled resins with subsequent firing, microreactors with microchannels for photocatalysis, etc. [20,52,53,54]. |

| Powder Bed Fusion (SLM/EBM) | ~50–100 µm (laser spot); 20–50 µm layers | Metals [70,71,72] (steel, Ni- and Ti-based alloys); selected polymers [73] (SLS) | Structured nanoporous copper catalysts for on-board methanol steam reforming, printing catalysts from reactive alloys (e.g., Ni-containing) for hydrogenation, etc. [74]. |

| Binder Jetting | ~100 µm (powder-dependent) | Ceramic powders [75] (Al2O3, ZrO2); metals [76,77] (steel, Inconel) | Complex ceramic monoliths with subsequent calcination, porous metal parts with post-infiltration and catalytic functionalization, etc. [53]. |

| Material Jetting | ~50–100 µm (droplets) | Photopolymers [78]; catalytic inks [59,60] (salt solutions, colloids) | Prototyping of micro-devices, experimental graded catalytic coatings (lab-scale). |

| Directed Energy Deposition | >500 µm (coarse) | Metal wire [79] or powder [80] | Cladding catalytic layers onto heat-exchange tubes (concept), repair/modification of catalytic meshes. |

| Sheet Lamination | ~100 µm (sheet-thickness-limited) | Metal foils [81], films [82] | Rarely used, potential for stacked micro-mixers or foil-based catalysts. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marchenkova, M.A.; Gadzhiev, J.K.; Guda, A.A.; Soldatov, A.V.; Chapek, S.V. Three-Dimensionally Printed Catalytic Structures. J. Manuf. Mater. Process. 2025, 9, 372. https://doi.org/10.3390/jmmp9110372

Marchenkova MA, Gadzhiev JK, Guda AA, Soldatov AV, Chapek SV. Three-Dimensionally Printed Catalytic Structures. Journal of Manufacturing and Materials Processing. 2025; 9(11):372. https://doi.org/10.3390/jmmp9110372

Chicago/Turabian StyleMarchenkova, Margarita A., Jamal K. Gadzhiev, Alexander A. Guda, Alexander V. Soldatov, and Sergei V. Chapek. 2025. "Three-Dimensionally Printed Catalytic Structures" Journal of Manufacturing and Materials Processing 9, no. 11: 372. https://doi.org/10.3390/jmmp9110372

APA StyleMarchenkova, M. A., Gadzhiev, J. K., Guda, A. A., Soldatov, A. V., & Chapek, S. V. (2025). Three-Dimensionally Printed Catalytic Structures. Journal of Manufacturing and Materials Processing, 9(11), 372. https://doi.org/10.3390/jmmp9110372