Abstract

Soil drying cracking is the most common natural phenomenon affecting soil stability. Due to the complexity of the geometric shapes of soil cracks during the cracking process, it has become a major problem in engineering science. The extremely irregular and complex crack networks formed in civil engineering materials can be quantitatively investigated using fractal theory. In this paper, fractal dimension is proposed to characterize the drying cracking characteristics of composite soil by adding recycled waste brick micro-powder. At the same time, the concept of the probability entropy of cracking is introduced to quantify the ordered state of crack development. Correspondingly, the endpoint value of probability entropy was solved mathematically, and the meaning of the probability entropy of cracking was clarified. In this study, the fracture fractal characteristics of composite soil mixed with different materials were first investigated. Then, five groups of composite soil-saturated muds with added recycled waste brick micro-powder of different contents were prepared in the laboratory. Using the evaporation test under constant temperature and humidity, the change rules of the fractal dimensions, probability entropy, crack ratios, and water contents of cracks during the cracking process of the soil samples were obtained. The results show that: (1) on the whole, the fractal dimensions of the soil samples added with recycled waste brick micro-powder of different contents increased over time, and the fractal dimensions of the soil samples without recycled waste brick micro-powder were obviously larger than those of the soil samples with recycled waste brick micro-powder. With the increase in the content of recycled waste brick micro-powder, the maximum fractal dimension decreased in turn. The maximum fractal dimensions of the five groups of soil samples were 1.74, 1.68, 1.62, 1.57, and 1.45. (2) The change trends of the probability entropy and fractal dimensions were similar; both of them showed an upward trend over time, and the probability entropy of the soil samples without recycled waste brick micro-powder was greater than that of the soil samples with recycled waste brick micro-powder. With the increase in the contents of recycled waste brick micro-powder, the probability entropy decreased in turn. The maximum values of the crack probability entropy of the five groups of soil samples were 0.99, 0.92, 0.87, 0.83, and 0.80. (3) Under the action of continuous evaporation, the moisture contents of the soil samples gradually decreased over time, while the crack ratios increased over time. To sum up, both from the perspective of the development process of the cracks of the soil samples and from the perspective of the final stable crack networks of the soil samples, the geometric shapes of the cracks of the soil samples without recycled waste brick micro-powder were the most complex. With the increase in the content of recycled waste brick micro-powder, the fractal characteristics of the cracks gradually changed from complex to simple.

1. Introduction

The concept of fractals was put forward by Mandelbrot in 1975. The basic idea is to find order in disorder and reveal the laws contained in chaos, fragmentation, and other extremely irregular and complex phenomena. The introduction and improvement of fractal theory provides a powerful mathematical tool for the study of nonlinear, disordered, and extremely irregular complex problems and has a wide range of applications in the fields of physics, biology, chemistry, materials science, and so on [1]. Fractal objects that commonly exist in nature, such as curved coastlines, rough surfaces, and other issues, can be established with random models and studied using fractal theory [2,3]. In addition, fractal theory is also widely used for building materials. Under the influence of factors such as the temperature difference inside buildings, dry and wet changes of building materials, and the improper use of building materials, cracks will occur on the surface of cement, concrete, soil, etc. The gradual development of these cracks will reduce the bearing capacity of building structures and affect their safety and durability, further causing serious damage to buildings [4,5]. Many scholars at home and abroad have proven through experimental studies that many cracks that exist in nature are fractal and the characteristics of these cracks can be studied using fractal theory. Khamidulina et al. [6] studied the curing process of cement, the structure and properties of a disperse medium through fractal theory, the structural characteristics of porous materials, and the prediction of structural failure caused by various factors. Ding et al. [7] conducted an experimental study on the tensile cracks of reinforced concrete structures and analyzed the fracture morphology and mechanical properties of the tensile cracks by using the fractal geometry theory and reverse engineering. Li et al. [8] tested reinforced concrete prisms with different diameters and different corrosion rates and established the relationship between the fractal dimension and the steel bar diameter and corrosion rate, indicating that the fractal dimension is closely related to the steel bar corrosion rate and diameter. At the same time, in the research on the fractal characteristics of cracks in building materials, the measurement of crack patterns has gradually developed from field measurement to the automatic identification and quantification of fractal research using digital image technology [9]. Yao et al. [10] conducted sulfate erosion tests on concrete samples with three kinds of water–cement ratios. Using digital image-processing technology, the development law of the fractal dimensions of concrete surface cracks during corrosion was determined, and a simple theoretical model was proposed to describe the evolution of concrete micro-cracks under sulfate erosion. Li et al. [5] used the digital image processing method to analyze the cracking law and fractal characteristics of a specimen after high-temperature treatment, and thus clarified the quantitative relationship between concrete materials, temperature, and cracking characteristics. Shit et al. [11] used image-processing technology to determine the crack strength of a soil surface and studied the development degree of cracking through fractals. Wang et al. [12] used digital image-processing technology and a morphological algorithm to describe the fractal characteristics of soil crack patterns (including the crack length, average width, and fractal dimensions of the box counting method).

Soil, as a common material in the field of architecture, has received extensive attention. In order to improve the engineering geological properties of soil mass, reinforce existing buildings, and improve the bearing capacity of buildings, many scholars have studied the mechanical properties of different composite soils and the fractal characteristics of drying cracking to find composite materials that inhibit the development of soil cracks and improve the mechanical properties of soil [13,14]. Vail [15] studied the feasibility of repairing soil cracks by using bottom ash admixture and microbial-induced calcite precipitation (MICP). The experimental results showed that recycled water treatment led to more cracking, while recycled MICP treatment improved the soil strength due to calcite crystal precipitation on the surface of the soil particles and in the pores between the particles. Bordoloi [16] carried out a series of tests to monitor the suction, water content, and crack intensity factor in soil mixed with four different components (i.e., 0%, 2%, 5%, and 10%) of biochar. The results showed that the relative importance of suction and water content in determining the fracture strength factors decreased with the increase in biochar content in the soil. The optimum content of biochar was 10%. Wang [17] discussed the physical, chemical, and biological effects of biochar on expansive soil. The results showed that after five cycles of drying and wetting, the soil fracture intensity factors decreased by 33.5%, 48.5%, and 47.3% due to the introduction of 5%, 10%, and 15% biochar, respectively. It was found that 15% biochar improvement was helpful to inhibit the initiation and expansion of soil cracks. Jin [18] found that sea-buckthorn root could effectively inhibit the degree of cracking of saline alkali land. The crack ratios of saline alkali soil samples containing 0.5%, 1%, and 2% sea-buckthorn root concentration decreased by 4.87%, 11.29%, and 19.49%, respectively, compared to the samples without sea-buckthorn root concentration. Gui [19] studied the influence and sensitivity of fiber inclusions on the drying cracking behavior of clay. The results showed that the addition of fiber significantly affected the drying cracking behavior of soil. With the increase in fiber content, the cracking of the clay could be effectively reduced. However, the effect of changing the fiber length was not significant. Yang [20] believed that the fractal dimension of the rhizosphere soil of amorpha and sea-buckthorn decreased with the increase in the vertical profile depth and decreased with the increase in the soil depth; the safety factor of the slope was positively related to the fractal dimensions of the soil and root system. Fang [21] found that coral clay, Chongqing silt, and talc showed obvious crack networks under different layer thicknesses and temperatures. The area of soil blocks separated by cracks increased with the increase in the soil layer thickness, and the fractal dimension also increased with increases in layer thickness. There was a good exponential relationship between the fractal dimension and the average crack width.

In recent years, in order to reduce the loss of natural resources, reduce the emission of pollutants, and better protect the environment, the recycling of construction waste has become a hot issue in today’s society. As a kind of building material that can be recycled, waste brick has great research value and some research results. Li et al. [22] studied the influence of the particle size of recycled clay-brick powder on the pore structure of cement mixture, and found that the particle size of clay-brick powder had a significant impact on the pore size, pore volume distribution, and pore surface fractal dimension of the mixed paste. Reducing the particle size of clay-brick powder could effectively improve the pore structure of the mixed paste. Wong et al. [23] found that, due to the potential pozzolanic activity of waste brick particles and up to 20% cement substitutes, adding waste brick particles could improve the strength and durability of concrete. Li et al. [24] prepared concrete brick mortar with recycled aggregate from waste bricks and studied the bending strength of natural aggregate and recycled aggregate mortar from waste bricks. They found that in the preparation of concrete bricks, the use of recycled aggregate from waste bricks could meet the strength requirements as long as the mixing parameters and technology were reasonable. Letelier et al. [25] used waste brick powder as a cement substitute at three different grades,—5%, 10%, and 15%—and tested concrete without recycled aggregate and concrete with 30% recycled coarse aggregate. They found that 15% of cement could be replaced by waste brick powder and 30% recycled aggregate, and the material strength was not significantly lost. Fort et al. [26] assessed the potential of recycling waste brick from the perspective of the environment, and found that replacing natural aggregate with recycled waste brick only brought about minor improvement. Using recycled waste brick micro-powder to partially replace cement binder can provide substantial benefits. However, the use of alkaline activators will impair the potential of alkaline-activated materials.

Nowadays, in many studies, the additive materials of composite soil are mostly biochar and fiber, while there have been fewer studies on recycling waste bricks as additive materials of composite soil. Based on the fractal theory, through indoor experiments and digital image-processing technology, this study investigated the relationship between different contents of regenerated waste brick micro-powder and the characteristics of the dry cracking of clay soil. The fractal dimensions, crack entropy, and crack ratios of surface cracks of different samples were determined and used to characterize the structural characteristics of the surface cracks of samples. The development trend of the water loss rate and the dry cracking of soil was monitored, and it was considered that it was feasible to use waste clay brick as an additive for composite soil.

2. Materials and Methods

2.1. Materials Used in Laboratory Testing

The clay soil and waste clay bricks used in this experiment were all from Hebi City, Henan Province. Hebi City, Henan Province, has a warm climate, with an annual average temperature of 14 °C and a wide sunshine range. Under the complex hydrogeological conditions, the rock and soil have eroded and migrated for a long time, and the geology here is hard and stable. The clayey soil is light yellow, without obvious smell or inclusion. In order to avoid the influence of surface impurities on the soil samples used in the test, the depth of the sampling in this test was 0.5~1.0 m, and the soil was relatively pure. After extracting the soil sample used in the test, it was placed in a pre-prepared sealed bag to avoid water loss during transportation that would affect the determination results of the initial soil sample. The basic properties of the soil samples are shown in Table 1. The basic properties of the soil samples taken back this time were determined at the first time after being transported back to the laboratory (Table 1). The waste clay bricks used in this test were from the construction waste in the construction site in the suburb of Hebi City. Firstly, the waste clay bricks were crushed to obtain waste clay brick particles. Secondly, the large particles were removed to prevent them from affecting the test results. Finally, the prepared fine powder of the waste clay bricks were placed in a specific container and sealed for storage.

Table 1.

Physical properties of soil used in laboratory testing (before treatment).

2.2. Dry Cracking Test of Composite Soil Sample

Treatment of clay required for the experiment: Firstly, the clay was air-dried to make it easy to crush, and then the dried clay soil was crushed into particles by a crusher. Secondly, the crushed soil particles were placed in an electric oven at 105–110 °C for drying. After drying, a standard sieve with a whole diameter of 2 mm was used to sieve them. Treatment of waste clay bricks required for the experiment: Firstly, the waste clay bricks were crushed to obtain waste clay brick particles. Secondly, they were placed in an electric oven at 105–110 °C for drying. After drying, a standard sieve with a whole diameter of 2 mm was used to sieve them.

After completing the preparation of the clay and recycled waste brick micro-powder required for the test, the following amounts were weighed: 50 g of soil sample; 48.5 g of soil sample and 1.5 g of brick powder; 47.5 g of soil sample and 2.5 g of brick powder; 46.5 g of soil sample and 3.5 g of brick powder; and 45.5 g of soil sample and 4.5 g of brick powder. Then, these samples were placed in five separate circular containers (containers with an inner diameter of 20 cm and a height of 4 cm) and mixed evenly with a stirring rod. Then, water was added, and they were stirred evenly and kept at a certain humidity. After a period, the recycled waste brick micro-powder was fully mixed with the soil sample, and finally, a certain amount of water was added to prepare a saturated mud with a water content of 100%. In order to study the influence of recycled waste brick micro-powder with different contents on the fractal characteristics of clay evaporation cracking, five groups of soil samples were designed in this study. The contents of the recycled waste brick micro-powder were 0%, 3%, 5%, 7%, and 9%, and the five groups underwent parallel tests for comparison (Table 2).

Table 2.

Test design of the samples.

In the test, firstly, the prepared samples were sealed and stored in fresh bags for 48 h to precipitate. Then, the soil samples were air-dried naturally at a room temperature of 25 °C to dehydrate. During the air-drying, the masses of the soil samples were read and recorded to obtain the changes in the samples’ water contents. In order to maintain a constant temperature, this test was completed in a laboratory with shade, no sunshine, and indoor heating capable of maintaining the same room temperature. At the same time, in order to obtain the cracking characteristics of the soil samples in the evaporation process, before cracking, the samples were weighed every 3 h. After the soil samples cracked, they were weighed every 2 h, and the degree of cracking was recorded by taking a photo right above the soil sample with a digital camera. After the test, the recorded times, the masses of the round Petri dishes, the weights of the soil samples, and the images of the cracks in the soil samples at different times were imported into the computer. Then, the relevant data were calculated and the images of the cracks were processed.

2.3. Image Processing and Calculation of Related Parameters

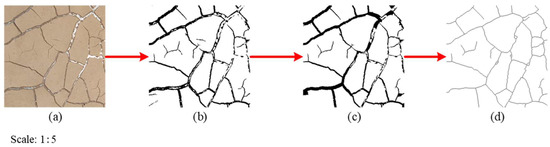

In the research on the development process and laws of cracking, in order to calculate various parameters representing the geometric morphological characteristics of the crack network, it is necessary to digitize crack images [27,28]. The processing process includes the graying of the original image, segmentation of the grayed image, a skeleton image, etc. (Figure 1). Finally, the processed image was scaled down by a factor of 5 and is shown in Figure 1.

Figure 1.

Processing of crack image. (a) Original image; (b) gray-scale image; (c) segmentation image; (d) skeleton image.

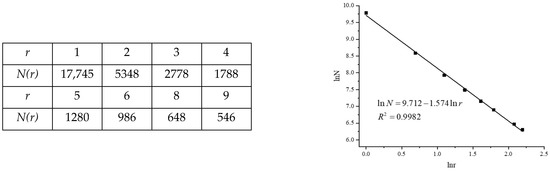

2.3.1. Fractal Dimension

Fractal dimensions can quantitatively characterize the morphological characteristics of cracking, and it is an important variable calculated after crack image processing. In this study, mainly the box dimension method was used to calculate fractal dimension: the box dimension method involves covering the square box with the side length of r on the image and calculating the total number of boxes N(r). With the change in the side length of r, the total number of boxes N(r) can be obtained. If the crack has fractal characteristics, the Hausdorff formula can be used to calculate the fractal dimension D of the crack.

In practical applications, the fractal dimension is usually not a constant, and it does not show a linear relationship in double logarithmic coordinates. The fractal dimension is often determined by Equation (2) by the ordinary least square method. In this paper, Figure 2 shows the calculation method for the fractal dimension, where, the slope D is the fractal dimension estimated, and ei is the residual of the regression equation.

Figure 2.

Calculation of fractal dimension.

2.3.2. Probability Entropy of Crack

Information entropy is a measure of the degree of system order: the lower the information entropy of a system is, the more orderly it is. On the contrary, the higher the information entropy of a system, the more disordered it is. There is a strong correlation between the probability entropy of information and the fractal dimension, which is another important parameter to describe the characteristics of crack development. Shannon [29] first introduced the concept of the information system and defined information probability entropy H as:

where Pi represents the probability of a specific type of signal i, and n represents the number of signal types. The information probability entropy H reflects the amount of information contained in each code sent by the information source.

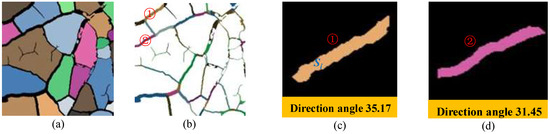

The crack image contains a lot of information. We can obtain the probability entropy of the crack by processing and calculating the crack image and analyze the development characteristics of the crack based on the research on the development law of the probability entropy of the crack. The process of obtaining the probability entropy of the crack is as follows: First, the soil blocks in the processed image are identified and segmented to complete the block analysis of the crack image (Figure 3a). Secondly, based on the information entropy theory and computer technology, the fracture network is automatically identified [30], and the crack network diagram (Figure 3b) containing different geometric information is obtained. Finally, the important calculation parameters, such as the area, length, and average width of cracks in different directions are obtained by calculation.

Figure 3.

Information on crack development. (a) Soil block segmentation. (b) Crack network identification. (c) Crack image with a direction angle of 35.17. (d) Crack image with a direction angle of 31.45.

In Figure 3b, there are cracks of different shapes in different directions. For example, the direction angles of crack ➀ and crack ➁ are 35.17 and 31.45, respectively, and their crack areas are different (Figure 3c,d). There is an extreme case: assuming that the area of crack development in each direction is the same, if the direction is disordered, then the crack development must be the most disordered state. From the test results, there are multiple intersections in the direction of crack development, and there are multiple directions from each intersection (Figure 3b), so the direction of the crack may be disordered. Another extreme case is that the cracks only develop in one direction, which makes the arrangement of the crack development the most orderly. Referring to the concept of information probability entropy, the probability entropy (K) of the crack can be de-fined as follows:

where Si represents the density or area of cracks in each direction, m is the number of cracks in different directions, n is the number of orientation intervals of crack development. The range of K values is between 0 and 1. Now, the end of the K value is solved, which can be transformed into the problem of finding the conditional maximum of multivariate function:

That is, the maximum value of function is found, and the following conditions are met:

For finding the conditional extremum with the Lagrange multiplier, constructor is as follows, where is constant:

The partial derivative of Function (7) is found and made equal to zero to obtain Equation (8).

By substituting Equation (10) into Equation (5), we can obtain: Kmax = 1.

When K = 1, the arrangement of cracks is completely random, that is, the larger the K value, the more disordered the development of cracks is on the surface of the soil sample. Therefore, K can be used as an indicator to measure the orderly development of soil cracks.

2.3.3. Crack Ratio

The crack ratio is defined as the ratio of the projected area of the crack to the total surface area on the two-dimensional plane. It represents the space occupied by the crack of the soil sample on the total surface. Rt can be used to describe the degree of cracking, as shown in Formula (10):

where Rt is the crack ratio, Scrack is the projected area of the crack, and Stotal is the total surface area of the soil sample.

3. Results

3.1. Fractal Characteristics of Cracks

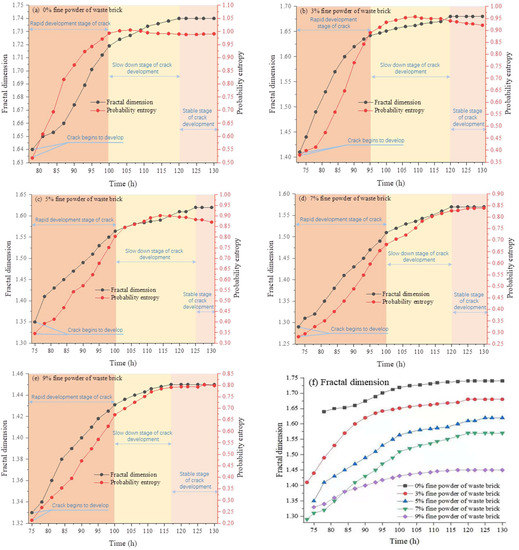

Fractal dimension is an important parameter in fractal theory, and there is a significant correlation between the fractal dimension of cracks and the structural stability index of the samples. The change rule of the fractal dimension of soil samples with different recycled waste brick micro-powder contents can reflect the influence of recycled waste brick micro-powder as an improver of the structural properties of clay to a certain extent. Therefore, the fractal dimension could be used to quantify the complex cracking mode of the samples. The larger the fractal dimension is, the more complex the crack network is [31]. From the crack initiation of the soil samples, the crack mode development can be roughly divided into three stages (Figure 4). In the first stage (rapid crack development stage), after crack initiation, the crack developed rapidly, and the fractal dimension had a rapid upward trend. The starting times and initial fractal dimensions of the drying cracks were different. The starting time of the initial crack of the soil sample without recycled waste brick micro-powder was 78 h, and the fractal dimension was1.64 (Figure 4a). The starting times of the initial cracks of the soil samples with 3%, 5%, 7%, and 9% recycled waste brick micro-powder contents were 73 h, 75 h, 73 h, and 75 h, respectively, and the fractal dimensions were 1.41, 1.35, 1.29, and 1.33, respectively (Figure 4b–e).

Figure 4.

(a–e) Changing of fractal dimension and probability entropy of crack development over time. (f): Changing of fractal dimensions of soil samples with adding different contents of recycled waste brick micro-powder over time.

As for the end time of rapid crack development, the end time of the soil sample with 3% recycled waste brick micro-powder content was 95 h, and the end times of the other four groups of soil samples were about the same, at 100 h. In the second stage (slow-down stage of crack development), compared to the first stage, the crack development speed of the soil samples was slow, and the fractal dimension increased slowly. The end time of the soil sample without recycled waste brick micro-powder was 120 h and the maximum fractal dimension was 1.74. The end times of the soil samples with 3%, 5%, 7%, and 9% recycled waste brick micro-powder content were 120 h, 125 h, 120 h, and 117 h, respectively, and the fractal dimensions were 1.68, 1.62, 1.57, and 1.45, respectively. In the third stage (stable stage of crack development), the crack network morphology did not change any more and reached a completely stable state after the cracks continued to become deeper and wider. The maximum fractal dimensions of the five groups of soil samples were 1.74, 1.68, 1.62, 1.57, and 1.45. In the three stages of crack development, the fractal dimensions of the five groups of samples show increasing trends over time, but the change law of the fractal dimension of each group of samples shows a different situation. The fractal dimension of the soil sample without adding recycled waste brick micro-powder was the largest (Figure 4f). However, the fractal dimensions of the soil samples with added 3% and 5% recycled waste brick micro-powder content decreased in turn. Due to the large particle size, rough surface, and certain activity of recycled waste brick micro-powder, its addition to soil will have a certain impact on the pore structure of the soil, thus inhibiting the randomness of soil crack development. Therefore, compared to the first three groups, the fractal dimensions of the soil samples with 7% and 9% recycled waste brick micro-powder content were smaller. Before 95 h, the fractal dimension of the soil sample with 7% recycled waste brick micro-powder content was smaller than that of the soil sample with 9% recycled waste brick micro-powder content, but after 95 h, the situation was just the opposite (Figure 4f).

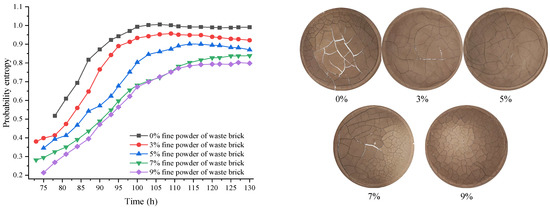

3.2. Crack Development Characteristics (Probability Entropy of Crack)

Entropy is a measure of the internal complexity of a closed system that can reflect the certainty and regularity of the system. The theory of increasing entropy is important for studying the degree of system chaos. The research shows that the larger the entropy value is, the more chaotic the system is. The theory has important applications in cybernetics, probability theory, number theory, astrophysics, life science, and other fields, but there are also more specific definitions extended to different disciplines. The probability entropy of cracks established in this paper (hereinafter referred to as probability entropy) is an important indicator of whether soil cracks will develop orderly. The range of probability entropy (K value) is between 0 and 1, and the larger the K value, the more disordered the development of surface cracks will be.

As is well known, discussion on entropy and dimension existed before the concept of fractal was proposed. Fractal dimension can be regarded as another measure of entropy, and there is a certain quantitative relationship between them. Therefore, the change law of crack probability entropy and the change law of crack fractal dimension in the process of soil crack development will have a certain similarity. Figure 5 shows that from the crack initiation of the soil samples, the crack development (probability entropy) can be roughly divided into three stages: the rapid crack development stage, the slow crack development stage, and the stable crack development stage. In general, similar to the change in the fractal dimension of crack development, the probability entropy of the five groups of soil samples had an upward trend over time, but the change law of the probability entropy of each group of soil samples also had different characteristics, indicating that the complexity of the crack development evolved into a morphology that was more complex over time. In the first stage, the probability entropy increased rapidly, which fully shows that with the rapid evaporation of water on the soil sample surface, the crack development changed rapidly to a disordered state. In the second stage, the growth rate of probability entropy slowed down. Compared to the first stage, although the crack network was more complex, the crack development speed was relatively slow. In the third stage, the crack network presented a stable state, the probability entropy reached the maximum value, and the crack morphology was more complex.

Figure 5.

Probability entropy changing over time and development characteristics of cracks of soil samples with different contents of added recycled waste brick micro-powder (pictures taken at the same time).

In the three stages of crack development, the probability entropy of the five groups of samples had an upward trend over time, and the complexity of the crack development changed to a more complex shape over time. By comparing and analyzing the development of the probability entropy of each group of samples, it was found that there were certain differences in the change law of the probability entropy of each group. The probability entropy of the soil samples without adding recycled waste brick micro-powder was the largest (Figure 5). However, the probability entropy of the soil samples with 3%, 5%, 7%, and 9% recycled waste brick micro-powder content decreased in turn, which shows that adding recycled waste brick micro-powder reduced the complexity of the cracking of the samples, and the degree of slow-down increased with the increase in the contents of recycled waste brick micro-powder.

In this study, in order to visually observe the impact of recycled waste brick micro-powder on the cracking of the samples, a group of photos taken at the same time was selected for observation (Figure 5). The research shows that the cracks of the soil sample without recycled waste brick micro-powder were wider, and there were basically no branch cracks in the middle of the soil sample. The separated blocks were larger, and the boundary cracks were small and dense, which may have been affected by the boundaries of the round vessels. However, the cracks of the soil sample containing recycled waste brick micro-powder were obviously more even, and the crack widths were smaller. Moreover, the sample with 9% content was more obvious, the cracks were more even, the number of cracks was higher, and the cracks were smaller. The above results show that the recycled waste brick micro-powder effectively inhibited the crack width growth of the soil samples, and its effect was more obvious with the increase in the contents of recycled waste brick micro-powder.

3.3. Effect of Water Content on Crack Development

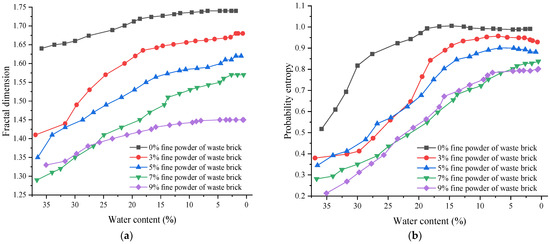

Through the study on the cracking mechanism of soil samples, it was found that the change in the fractal characteristics of the cracking of the soil samples depended on the evaporation of the soil surface water—that is, the change in water content. Under continuous evaporation, the water content of the soil sample surface had a rapid decreasing trend, resulting in a water content gradient between the different soil layers. The cracks first occurred in the surface layer with the lowest moisture content of the samples. Then, the cracks gradually developed in the form of subdivision and repeated the process, eventually forming a stable crack network [32]. In general, the fractal dimensions of the five groups of the soil samples were inversely related to the water content. With the decrease in the water content, the fractal dimensions increased continuously. When the water contents did not change (reaching the residual water content), the fractal dimension gradually tended to be stable and finally reached the maximum value (Figure 6).

Figure 6.

Fractal dimension and probability entropy image changing with water content. (a) Fractal dimension changing with water content. (b) Probability entropy changing with water content.

For the soil samples with 7% and 9% recycled waste brick micro-powder content (Figure 6a), when the water content was more than 27.6%, the fractal dimension of the former was smaller than that of the latter; when the water content was less than 27.6%, the situation was the opposite. For the soil samples with 3% and 5% recycled waste brick micro-powder content (Figure 6b), when the water content was less than 22.6%, the probability entropy of the former was greater than that of the latter; when the water content was 22.6~33.2%, the probability entropy of the former was less than that of the latter. In addition, while the water content was greater than 33.2%, the probability entropy of the former was greater than that of the latter. The change trends of the probability entropy of the soil samples with 7% and 9% recycled waste brick micro-powder content were roughly similar to their fractal dimensions.

4. Discussion

Drying cracking is caused by uneven tensile stress in the soil caused by continuous surface evaporation, which changes the hydraulic and mechanical properties of the soil [28]. With the constant evaporation of water on the surface of the samples, the soil moisture content decreased, resulting in increases in the soil suction and tensile stress. Since there is a positive correlation between tensile strength and soil suction, cracks will occur when the generated tensile stress exceeds the tensile strength of the soil [25]. The tensile stress distribution depends on the foundation friction of the soil sample and the internal defects of the soil sample [33]. The reduction of the soil stiffness at the defects of the soil samples easily caused the concentration of the tensile stress and may have become the starting points of crack development.

The cracking of the soil samples started with evaporation and the gradient change in the water content between the different soil layers. The development process of cracks can be described by the complex system of evaporation—water content changes—soil surface shrinkage—formation of a crack network. Therefore, water content is an important parameter to characterize the crack development process. The discussion on the change trend of water content is helpful to better understand the fractal characteristics of the drying cracking of the five groups of soil samples.

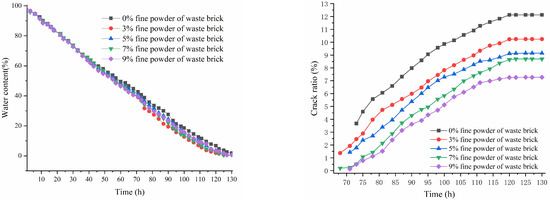

With the change in time, the free water on the soil sample surface began to evaporate first. Before 40 h, since the slopes of each curve are roughly the same (Figure 7), this indicates that the water evaporation rates of the different soil samples at the early stage were roughly the same. After 40 h, the water contents of the soil samples with different contents of recycled waste brick micro-powder began to show differences. During evaporation, the slopes of the curves changed more and more obviously. The curve of the soil samples without added recycled waste brick micro-powder decreased slowly, and the evaporation was significantly less than that of the other groups of samples. This fully shows that the recycled waste brick micro-powder can accelerate the evaporation of water in clay.

Figure 7.

Image of water contents and crack ratios changing over time.

In the process of the water evaporation of the soil samples, although the recycled waste brick micro-powder can improve the evaporation ratio of water in soil, the influence of different contents of recycled waste brick micro-powder on the evaporation ratio was also slightly different. The influence of 3% and 7% recycled waste brick micro-powder contents on evaporation was roughly the same. After 75 h, the soil sample with 3% recycled waste brick micro-powder content had the fastest evaporation ratio. The evaporation ratios of the soil samples with 5% and 9% recycled waste brick micro-powder contents were lower than that of the soil sample with 3% content. However, the final residual moisture contents of the five groups of samples were roughly the same, which were 1.85%, 0.65%, 0.93%, 0.51%, and 0.65%, respectively. This fully shows that the recycled waste brick micro-powder had little influence on the water-holding capacity of the clay.

The crack ratio is another important parameter to characterize the crack development process; the larger the crack ratio is, the more complex the crack development state is. Overall, the crack ratios of the five groups of soil samples had a positive relationship over time. The crack ratio of the soil sample without recycled waste brick micro-powder was obviously higher than that of the soil sample with recycled waste brick micro-powder. With the increase in the content of recycled waste brick micro-powder, the crack ratios of the soil samples decreased in turn (Figure 7). The maximum crack ratios of the five groups of soil samples were 12.1%, 10.2%, 9.2%, 8.7%, and 7.3%.

By comparing and analyzing the change rules of the various parameters in the process of crack development, it was found that, under the effect of continuous evaporation, the water content of the soil gradually decreased, and the shrinkage of the soil sample surface led to an increase in the crack ratio. The above changes caused two important parameters, fractal dimension and probability entropy, representing the complexity of the crack network, to increase. When the final residual water contents of the five groups of soil samples were 1.85%, 0.65%, 0.93%, 0.51%, and 0.65%, respectively, they formed stable crack networks, and the corresponding crack ratios, fractal dimension, and probability entropy values reached the maximum. According to the meaning of fractal dimensions and probability entropy, we can not only compare the complexity of the final stable crack networks of the five groups of soil samples but also monitor the complexity of the crack development of the five groups of soil samples in the process of crack development.

5. Conclusions

Soil drying cracking is a common natural phenomenon that affects the stability of soil, and the complexity of soil crack geometry in the process of cracking is a major problem in engineering science. In this study, the least square method was used to determine the fractal dimensions of the cracking, and the probability entropy values of the cracks were introduced to represent the orderliness of the crack development. The endpoint values of the probability entropy (0 ≤ K ≤ 1) were solved mathematically, thus revealing the implications of the probability entropy of the cracks.

Based on the study of fractal dimensions and probabilistic entropy theory, the variation rules of the crack parameters, such as the fractal dimension, probabilistic entropy, crack ratio, and moisture content during the evaporation cracking process of five groups of composite soil saturated mud with different contents of recycled waste brick micro-powder brick, were studied through experiments. It was concluded that the fractal dimensions, probability entropy values, and crack ratios of soil samples had a positive relationship over time and a negative relationship with the water content. The crack development process was divided into three stages, namely, the rapid crack development stage, the slow crack development stage, and the stable crack development stage.

By comparing the variety rule of the fractal dimensions, probability entropy, and crack ratios of the five groups of samples over time and the water content, it was found that the values of the fractal dimensions, probability entropy, and crack ratios of the sample without adding recycled waste brick micro-powder were all-greater than the corresponding parameter values of the samples with the added micro-powder. In addition, each parameter value decreased in turn with increases in the recycled waste brick micro-powder content.

The research and analysis on the parameters during the formation of soil cracks show that, from the perspective of both the development process of cracks and the final stable crack networks of the soil samples, the geometric shapes of the cracks of the soil samples without adding recycled waste brick micro-powder were the most complex. At the same time, it was found that with increases in the content of recycled waste brick micro-powder, the geometric shapes of the cracks gradually changed from complex to simple.

Author Contributions

Data curation, formal analysis, writing—original draft, X.Z.; supervision, resources, funding acquisition, L.L.; investigation, methodology, writing—review and editing, B.Y.; software, validation, visualization, C.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Henan (222300420281).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data, models, or code generated or used during the study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to thank all the anonymous referees for their constructive comments and suggestions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mandelbrot, B.B. The Fractal Geometry of Nature; W.H. Freeman: New York, NY, USA, 1982. [Google Scholar]

- Sun, J.J.; Ji, Z.B.; Zhang, Y.Y.; Yu, Q.P.; Ma, C.B. A Contact Mechanics Model for Rough Surfaces Based on a New Fractal Characterization Method. Int. J. Appl. Mech. 2018, 10, 18500692. [Google Scholar] [CrossRef]

- Ma, J.H.; Liu, D.X.; Chen, Y.Q. Random Fractal Characters and Length Uncertainty of the Continental Coastline of China. J. Earth Syst. Sci. 2016, 125, 1615–1621. [Google Scholar] [CrossRef]

- Zhao, X.; Cai, H.; Zhou, T.; Liu, L.; Ding, Y. Research on the factors affecting the development of shrinkage cracks of rammed earth buildings. Earthq. Struct. 2021, 20, 365–375. [Google Scholar]

- Li, L.; Zhang, Y.; Shi, Y.; Xue, Z.; Cao, M. Surface cracking and fractal characteristics of cement paste after exposure to high temperatures. Fractal Fract. 2022, 6, 465. [Google Scholar] [CrossRef]

- Khamidulina, D.D.; Nekrasova, S.A. Fractals in construction material science. IOP Conf. Ser. Mater. Sci. Eng. 2018, 451, 012026. [Google Scholar] [CrossRef]

- Ding, C.; Xu, T.; Chen, Q.; Su, C.; Zhao, P. Study on the Relationship between Fractal Characteristics and Mechanical Properties of Tensile Fracture of Reinforced Concrete Structures. KSCE J. Civ. Eng. 2022, 26, 2225–2233. [Google Scholar] [CrossRef]

- Li, W.; Wu, M.; Shi, T.; Yang, P.; Pan, Z.; Liu, W.; Liu, J.; Yang, X. Experimental Investigation of the Relationship between Surface Crack of Concrete Cover and Corrosion Degree of Steel Bar Using Fractal Theory. Fractal Fract. 2022, 6, 325. [Google Scholar] [CrossRef]

- Tang, C.S.; Cui, Y.J.; Shi, B.; Tang, A.M.; Liu, C. Desiccation and cracking behaviour of clay layer from slurry state under wetting–drying cycles. Geoderma 2011, 166, 111–118. [Google Scholar] [CrossRef]

- Yao, J.; Chen, J.; Lu, C. Fractal cracking patterns in concretes exposed to sulfate attack. Materials 2019, 12, 2338. [Google Scholar] [CrossRef]

- Shit, P.K.; Bhunia, G.S.; Maiti, R. Soil crack morphology analysis using image processing techniques. Model. Earth Syst. Environ. 2015, 1, 35. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Z.Y.; Liu, Y.; Fan, S.M. Geometric and fractal analysis of dynamic cracking patterns subjected to wetting-drying cycles. Soil Tillage Res. 2017, 170, 1–13. [Google Scholar] [CrossRef]

- Gopal, P.; Bordoloi, S.; Cai, W.L.; Liang, H.S.; Boddu, R.; Sreedeep, S.; Buragohain, P.; Garg, A. Model Development for Computing Cracking in Soil Reinforced with Fibers from Three Different Bioresources. Adv. Civ. Eng. Mater. 2018, 7, 669–693. [Google Scholar] [CrossRef]

- Lu, Y.; Gu, K.; Shen, Z.T.; Wang, X.; Zhang, Y.P.; Tang, C.S.; Shi, B. Effects of biochar particle size and dosage on the desiccation cracking behavior of a silty clay. Sci. Total Environ. 2022, 837, 155788. [Google Scholar] [CrossRef]

- Vail, M.; Zhu, C.; Tang, C.S.; Maute, N.; Montalbo-Lomboy, M.T. Desiccation Cracking Behavior of Clayey Soils Treated with Biocement and Bottom Ash Admixture during Wetting-Drying Cycles. Transp. Res. Rec. 2020, 2674, 441–454. [Google Scholar] [CrossRef]

- Bordoloi, S.; Gopal, P.; Boddu, R.; Wang, Q.H.; Cheng, Y.F.; Garg, A.; Sreedeep, S. Soil-biochar-water interactions: Role of biochar from Eichhornia crassipes in influencing crack propagation and suction in unsaturated soils. J. Clean. Prod. 2019, 210, 847–859. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, K.X.; Gan, L.; Liu, J.Q.; Mei, G.X. Expansive soil-biochar-root-water-bacteria interaction: Investigation on crack development, water management and plant growth in green infrastructure. Int. J. Damage Mech. 2021, 30, 595–617. [Google Scholar] [CrossRef]

- Jin, L.C.; Zhang, S.; Xu, Y.J. Fractal Dimension Characteristics of the Soil Cracking Process When Saline-Alkali Soil Is Mixed with Hippophae Roots. Fractal Fract. 2022, 6, 504. [Google Scholar] [CrossRef]

- Gui, Y.L.; Wong, W.Y.; Gallage, C. Effectiveness and Sensitivity of Fiber Inclusion on Desiccation Cracking Behavior of Re-inforced Clayey Soil. Int. J. Geomech. 2022, 22, 06021040. [Google Scholar] [CrossRef]

- Yang, Q.C.; Cheng, W.J.; Hao, Z.; Zhang, Q.; Yang, D.X.; Teng, D.; Zhang, Y.; Wang, X.M.; Shen, H.X.; Lei, S.Y. Study on the Fractal Characteristics of the Plant Root System and Its Relationship with Soil Strength in Tailing Ponds. Wirel. Commun. Mob. Comput. 2022, 9499465. [Google Scholar] [CrossRef]

- Fang, H.Q.; Ding, X.M.; Jiang, C.Y.; Peng, Y.; Wang, C.Y. Effects of layer thickness and temperature on desiccation cracking characteristics of coral clay. Bull. Eng. Geol. Environ. 2022, 81, 391. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Xu, Z.; Luo, X.; Gao, J. Particle-size effect of recycled clay brick powder on the pore structure of blended cement paste. Constr. Build. Mater. 2022, 344, 128288. [Google Scholar] [CrossRef]

- Wong, C.L.; Mo, K.H.; Yap, S.P.; Alengaram, U.J.; Ling, T.C. Potential use of brick waste as alternate concrete-making mate-rials: A review. J. Clean. Prod. 2018, 195, 226–239. [Google Scholar] [CrossRef]

- Li, F.; Chen, J.L.; Zhao, X.Y.; Hou, N.S. Experiment Research on the Use of Recycled Brick Aggregate in Concrete Tiles. Ad-Vanced Mater. Res. 2011, 374–377, 1912–1915. [Google Scholar] [CrossRef]

- Letelier, V.; Ortega, J.M.; Munoz, P.; Tarela, E.; Moriconi, G. Influence of Waste Brick Powder in the Mechanical Properties of Recycled Aggregate Concrete. Sustainability 2018, 10, 1037. [Google Scholar] [CrossRef]

- Fort, J.; Cerny, R. Transition to circular economy in the construction industry: Environmental aspects of waste brick recycling scenarios. Waste Manag. 2020, 118, 510–520. [Google Scholar] [CrossRef] [PubMed]

- Shin, H.; Santamarina, J.C. Desiccation cracks in saturated fine-grained soils: Particle-level phenomena and effective-stress analysis. Geotechnique 2011, 61, 961–972. [Google Scholar] [CrossRef]

- Zeng, H.; Tang, C.S.; Cheng, Q.; Zhu, C.; Yin, L.Y.; Shi, B. Drought-Induced Soil Desiccation Cracking Behavior with Consideration of Basal Friction and Layer Thickness. Water Resour. Res. 2020, 56, e2019WR026948. [Google Scholar] [CrossRef]

- Shannon, C.E. A Mathematical Theory of Communication. Bell Syst. Tech. J 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Kapur, J.N.; Sahoo, P.K.; Wong, A.K.C. A new method for gray-level picture thresholding using the entropy of the histogram. Comput. Vis. Graph. Image Process. 1985, 29, 273–285. [Google Scholar] [CrossRef]

- Preston, S.; Griffiths, B.S.; Young, I.M. An investigation into sources of soil crack heterogeneity using fractal geometry. Eur. J. Soil Sci. 1997, 48, 31–37. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, J.M.; Zhou, Z.; Shen, Z.J.; Chong, L.; Victor, C. Investigation and prediction of water infiltration process in cracked soils based on a full-scale model test. Geoderma 2021, 400, 115111. [Google Scholar] [CrossRef]

- Wang, L.; Yu, Z.; Liu, B.; Zhao, F.; Tang, S.; Jin, M. Effects of Fly Ash Dosage on Shrinkage, Crack Resistance and Fractal Characteristics of Face Slab Concrete. Fractal Fract. 2022, 6, 335. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).