Abstract

Recycling of construction and demolition waste is a central point of discussion throughout the world. The application of recycled concrete as partial replacement of mineral aggregates in concrete mixes is one of the alternatives in the reduction of pollution and savings in carbon emissions. The combined influence of the recycled crushed concrete, lime, and natural pozzolana on the mechanical and sustainable properties of concrete materials is firstly proposed in this study. In this research, unconventional construction materials are employed to produce concrete: the recycled crushed concrete is used as coarse aggregate, while lime and natural pozzolana are used as a partial replacement for cement. Substitutions of 10%, 20%, 50% of gravel are made with recycled aggregates, and 2%, 5%, 10% of cement with lime and natural pozzolan. Tests on the fresh and hardened properties, destructive (compressive strength) and non-destructive tests (sclerometer rebound and ultrasound) of mixtures are carried out. It is shown that the use of recycled materials can provide an increase in compressive strength of up to 34% with respect to conventional concrete. Life cycle cost and sustainability assessments indicate that concrete materials incorporating recycled aggregate possess good economic and environmental impacts.

1. Introduction

Interactions between concrete materials and alternative fillers such as hydrated lime and natural pozzolana have been investigated in the past decades [1,2]. With the former, it provides compacting capabilities to concrete since its particles are finer than those of conventional cement [2]. The addition of hydrated lime increases the mechanical strengths and ductility of concrete mixes at the same time. For the latter, pozzolana is a siliceous material that is reactive in the presence of water and calcium hydroxide [3]. The reaction products of pozzolanas and alkali solutions possess cementitious properties, leading to low-permeability concrete which has high durability and improvement in resistance to chemical attacks. Pozzolans correspond to materials that are also used as an alternative component to elaborate Portland cement [4]. By using hydrated lime and natural pozzolana materials with crushed recycled aggregates, it will generate an improvement in the mix design [5]. By making concrete with partial dosages of recycled aggregates concrete (RAC) [6,7], lime, and natural volcanic pozzolan, it is expected to obtain more sustainable concretes for use in civil engineering projects [8]. The elaboration of concrete with recycled aggregates, lime, and natural pozzolana faces the search for optimal dosages to achieve the highest mechanical performance and thus comply with the phases and tests applied for its responsible use in civil works.

The application of recycled concrete as a partial or complete replacement of natural mineral aggregates in concrete mixes has drawn significant research interests in the past few decades. Recent research points to a processing value of 25,000 million tons per year, which is equivalent to about 6000 million trucks of mortar per day [9]. Studies have pointed out that the use of recycled concrete comes with the intervention of recycled aggregates that in their composition will differ from natural aggregates, mainly since they will demonstrate an increase in water absorption, lower resistance, lower density, lower hardness, and these properties they will directly affect the new concrete in question [9,10,11]. Standardised guidance, such as ASTMD692, has also included crushed concrete as part of coarse aggregates accepted for its construction use fulfilling the due specifications [12]. Previous studies have also reported that the recycled aggregates of crushed concrete consist of 70% by volume of natural original aggregate and 30% by volume of cementitious mass [13].

As discussed, partial replacement of mineral aggregates with recycled concrete aggregates (RA) leads to the potential reduction in mechanical properties and fresh properties of concrete mixes [9,10]. It has been shown that the reduction in the mechanical strength is a function of the amount of RCA used [14,15]. Regardless of the reduction in mechanical strengths, studies have also reported that due to the lower density of RA compared to natural aggregate, RA shows a clear advantage in the application of lightweight concrete [16]. Detailed studies have also shown that the sources of RA have a clear influence on the mechanical properties of concrete mixes. RA from high strength concrete processes low water absorption and behaves similar to natural aggregates. Whereas concrete mixes using RCA from low strength concrete with high water absorption show lower elastic modulus [15].

Studies on the performance of concrete structural members using RA have also been reported in the past decades. It is shown that with the increase of RA content, the load-bearing capacities of RAC members decrease accordingly, while the failure mechanisms of RAC structural beams, columns, and slabs are the same as those with conventional concrete, and the behaviour of reinforcement and stirrups are also comparable to those in conventional reinforced concrete members [17,18,19]. Studies on the hysteretic behaviour indicate that the energy dissipation capacity of RAC members is lower than that of conventional RC members [17]. Although the addition of RAC causes the reduction of yielding and ultimate strengths of structures under seismic loads, the reduction is proved to be less than that of the mechanical properties of RAC materials. In addition, the energy dissipation and stiffness degradation properties of RAC members are also comparable to reinforced concrete structures [17,20,21]. It can be noted that although the replacement of natural aggregates with RA causes the strength reductions of reinforced concrete structural members, the RAC structural performance under static and seismic loadings are both comparable to conventional RC members.

Studies have also focused on the enhancement in binding properties of cement and recycled aggregates [22,23,24]. Although previous studies have shown that lime and pozzolana can be regarded as reactive binders to improve the strengths and durability of concrete materials, and the mechanical properties of recycled concrete have been reported in the literature, the combination of recycled aggregate and these fillers received limited research attention even though they can provide enhanced strengths and sustainability of concrete materials. Moreover, due to the little practice with this recycled material in Ecuador, detailed studies on the properties of concrete materials incorporating natural lime and pozzolana are limited.

To this end, a series of experimental investigations are proposed in this study to examine the performance of concrete materials incorporating recycled aggregates and a range of the amount of hydrated lime and natural volcanic pozzolan. As a collection process for this project, discarded concrete cylinders from the university lab were used as recycled concrete aggregate. Slump tests and mechanical strength tests are performed to evaluate the influence of the above-mentioned binders and recycled aggregates on concrete materials. The combined influence of recycled aggregate, lime, and pozzolan on the mechanical properties of concrete mixes are investigated, while the mix design of RAC with alternative binders is also proposed based on the experimental findings. The outcomes provide key information on the fundamental properties of the sustainable concrete material and potential ways of reducing the environmental impact caused by the manufacturing of conventional concrete.

2. Materials and Methods

The recycled concrete material described in this paper contains Portland Cement, lime, and volcanic pozzolana as binders. Aside from binders, the mixes included Anropevi sand as fine aggregate, limestone with the maximum aggregate size of 19 mm, and recycled crush concrete. The latter material was obtained from the crushing of cylinders in the laboratory.

The properties of pozzolans depend on their chemical composition and structure. They mainly have three oxides: silicic oxide (SiO2), aluminium oxide (Al2O3), and ferric oxide (Fe2O3). The chemical analysis of the pozzolan employed in this research work fulfils the specifications of the ASTM C-618 [25]. There it states that that the minimum content of the total components of silicic oxide, aluminium oxide, and ferric oxide should be at least 70%. For this analysis, the pozzolana employed has a content of 80%.

The pozzolana can be described by its colour. This can generally be greyish or brown, depending on the origin and the concentrations of silicon oxides. There are also other types of natural colours such as red or black due to the presence of other oxides. For its part, the particle size depends on the origin and the grinding that is carried out on the material.

Another typical material added to the concrete is limestone. Calcium carbonate comprises most of the limestone, which at temperatures around 900 °C decomposes and forms the oxide of lime and carbon dioxide. When the lime is hydrated, it mixes with water to generate calcium hydroxide. During this process of converting the lime, the material is heated. This is why it expands, and it is converted into a very fine powder. This powder is ready to be used as cement in construction. The results obtained from the analyses of this powder from the producer were compared with the established materials from the standards [26,27], where the chemical analysis in the X-ray refractometer is showing 80.32% of CaO.

The chemical characteristics of this compound are detailed below as stated by some researchers and the technical sheet from the manufacturer:

- May react with strong acids generating carbon dioxide.

- Colour: white when they are pure, but changes colour between grey and black because of the carbonaceous impurities they contain.

- Resistance: presents resistance to the compression factor, the value ranges between 98.4–583.5 kg per square centimetre.

- Density: 2.65–2.75 kg per litre

- It can react with water.

Table 1.

Chemical Components Cement.

Table 2.

Physical and Chemical Properties of HOLCIM Cement.

The details such as the origin of the materials used in this study are listed in Table 3.

Table 3.

Materials used in the experimental part.

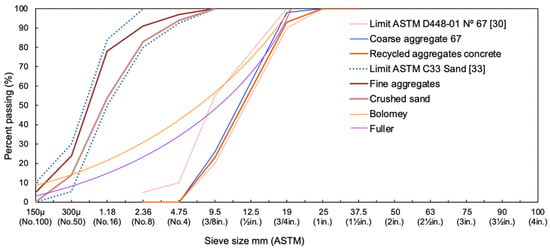

A previous step to the design of the concrete mix was to perform the granulometric analysis of the materials involved, such as the sieving analysis, rodded volumetric weight, loose volumetric weight, dry surface density, absorption, humidity, fineness modulus. In the granulometric analysis [28] for the materials is by the coding by size of the different fractions, the responsibility of UNE EN 933-2: 96 [29] is prescribed, which establishes as a basic sequence of sieves the one formed by the following: 0.063–0.125–0.250–0.500–1–2–4–8–16–31.5–63–125 mm. For fine aggregate, only sieves of the series are used. For coarse aggregate, use the 10–20–40 mm sieves together, which are included in the complementary R 20 series admitted by the indicated Standard [28,30].

The properties will allow us to correctly understand the functionality of concrete, which will allow us to define the proportions that will be used in the project (Figure 1 and Table 4). Figure 1 highlights the optimum curves obtained by using Bolomey’s and Fuller’s design methods.

Figure 1.

Grain size distribution curve of fine and coarse aggregate.

Table 4.

Coarse aggregate Absorption from San Eduardo Plant.

The aim is to use tests and to be able to correctly analyse the product and be able to foresee any prior anomaly or inconsistency. The tests will be carried out with different dosages of material to compare their different behaviours, because each percentage will affect the strength, appearance, durability, and functionality of the new concrete. Likewise, the tests, granulometric designs, granulometric curves, concrete mix designs, will be carried out based on the corresponding regulations.

Among the methods and processes involved for the development of the project were: obtaining materials, mainly discarded concrete, crushing discarded concrete in 3/4 “, obtaining natural volcanic lime, and pozzolana, obtaining cement, sand, stone 19 mm, and clean water. Other necessary analyses are to establish the percentage of air included, determine the water and cement ratio, volume of coarse aggregate.

Also, the determination of the water and cement ratio, the volume of coarse aggregate, and the percentage of air included are among the additional analyses required (Table A1).

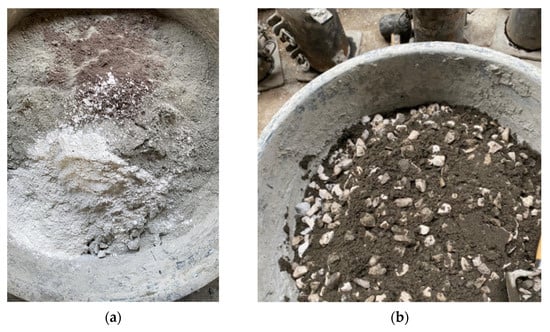

The strength of reference conventional concrete mix was designed to be fc = 28 MPa. A total of 7 concrete mixes were prepared, as shown in Figure 2. Apart from the conventional concrete mix NC, three mixes with partial replacement of 10%, 20%, and 50% of coarse aggregates with recycled concrete were prepared (RC10-0LV, RC20-0LV, and RC50-0LV respectively). Three additional mixes with recycled concrete were prepared with 2%, 5%, and 10% of cement replaced with lime and volcanic pozzolan in equal weights. Details of all the mix designs are listed in Table 5.

Figure 2.

(a) Dosing of materials, (b) Preparation of the mixture.

Table 5.

Mix proportions of RAC mixtures (kg/m3).

Specimens were prepared to investigate the fresh properties and compressive strength of each mix design on 7, 14, and 28 days. Non-destructive tests were performed to examine the flexural-compressive strength ratios of recycled concrete specimens. The experimental study and data analysis process embedded in this study started from the test planning, review of materials and equipment, obtaining materials, specimen tests, analysis of data obtained, and finally, the discussion.

3. Results

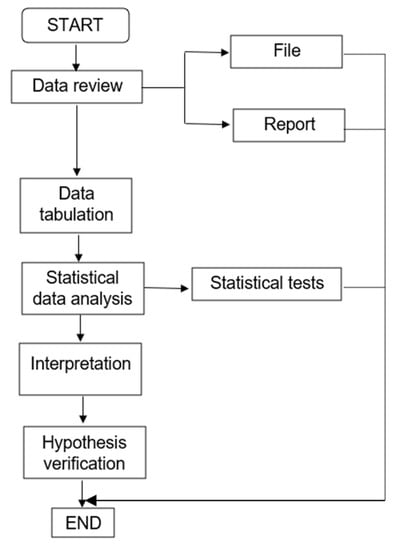

In the data analysis process, the activities are structured from the review of the sources of information provided by the trials (Figure 3).

Figure 3.

Data analysis process.

In this study, the fresh properties of conventional concrete mix (NC) and mixes with recycled concrete (RC10-0LV, RC20-LV, RC50-0LV, and RC10-5LV) were investigated, Figure 4. The slump test results for mixes containing different ratios of recycled concrete are listed in Table 6. As expected, the recycled crushed concrete has the same constituents. It can be noted that the recycled aggregate concrete does not influence the workability of the mixtures. Due to the same constituents in the crushed recycled concrete and the designed mixes, the slumps of concrete mixtures with and without recycled concrete are similar. The different mix designs fulfil the tolerances of the slump according to the Ecuadorian standard (INEN 1855 para 5.1.2.1) in which mentions that is required to maintain the workability at least for 30 min [31]. In the mix designs, the average values measured for the air content and the density were 1.9% and 2320 kg/m3, respectively.

Figure 4.

Slump test conventional concrete mix (NC).

Table 6.

Slump test results.

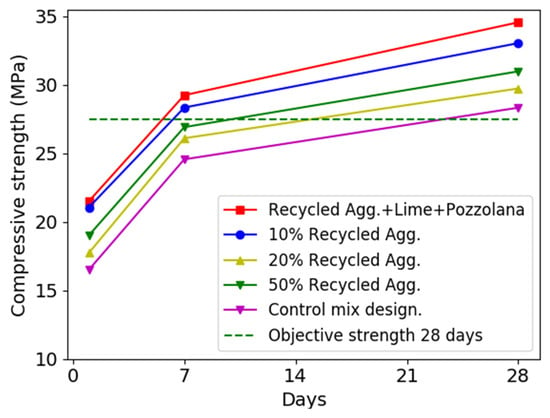

The compressive strengths of mixes NC, RC10-0LV, RC20-0LV, RC50-0LV, and RC10-5LV on 7, 14, and 28 days were investigated through cylindrical specimens with the size of Φ100 × 200 mm. The curing dates for the specimens were 7, 14, and 28 days. This test is described in ASTM C39 [32]. The test results are shown in Figure 5, and it is observed that recycled concretes have greater resistance compared to natural ones for the same water-cement ratio. It can be concluded that the partial replacement of coarse aggregates with crushed recycled concrete improves the compressive of the mixture. As shown in Figure 4, the compressive strength of the mix was increased by 18% as 10% of the aggregates were replaced. Further increase of the recycled concrete reduces the compressive strength of the mixtures. The main difference between the RAC and the natural aggregates is the amount of mortar included that the former incorporate due to the mortar from which they come. The dose of mortar included makes the RAC present different properties from the natural ones that are reflected in their properties, such as an increase in water permeability, and lower consistency. The concrete made with these aggregates will be directly restricted by these properties [33]. There is no regulated way to value these amounts, although methods that try to remove it from the outside of the aggregate are often used to establish the proportion by weight that corresponds to the mortar attached to the aggregate. Another representation to evaluate it consists of making a concrete mix design with RAC and with coloured cement. The specimens made are cut and polished, from there, the exteriority of the mortar is measured with a planimeter, distinguishing itself from the original by its tonality [33]. In all the studies available from the literature, it has been seen that the increase in the amount of mortar has a negative impact on its mechanical properties [33,34,35]. A higher strength was obtained with the mix RC10-5LV (35.7 MPa), indicating that the lime and volcanic pozzolan improve the binding between cement pastes and aggregates.

Figure 5.

Compressive strength of different mixes at different curing ages.

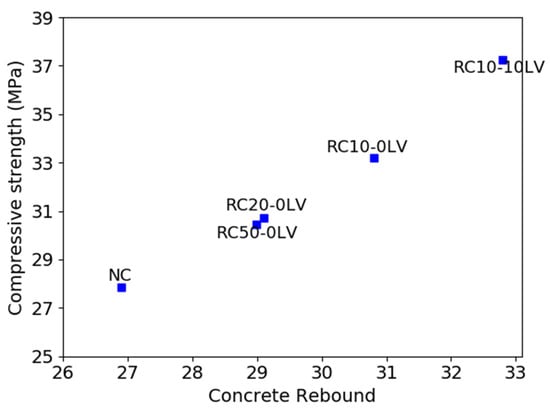

Additionally, a study to correlate the resistance of the concrete both in compression as well as for bending was carried out. These non-destructive tests are known as sclerometer rebound and ultrasound [36]. This is important since, as it is known, concrete is used in multiple works such as buildings, houses, and bridges where the focus is on the behaviour of concrete in compression as well as on pavements [36]. The following results for the sclerometer and ultrasound test show the results from two specimens of each mix, cured in water for 28 days. Figure 6 shows how the concrete rebound increases when lime and pozzolana are included in the mix design. However, it can be noticed that the concrete rebound is higher in all the measures, which means that the concrete is uniform in all the mix designs.

Figure 6.

Concrete rebound vs. Compressive strength.

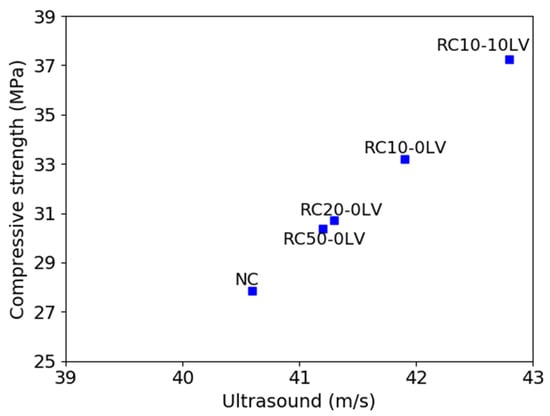

Figure 7 shows the ultrasound versus the compressive strength. This non-destructive test is a tool that helps to determine the concrete quality. It has been used in many countries instead of performing destructive tests such as compressive or flexural strength. It can be noticed that the concrete in all the mix designs presents a good condition according to the ultrasound test [37].

Figure 7.

Ultrasound vs. Compressive strength.

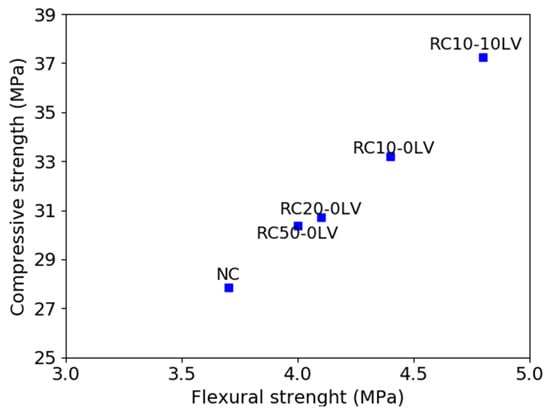

As can be seen in Figure 8, there is an increase in the flexural strength of concrete. Also, it can be concluded that it can also be used in pavements where the range of resistance to flexure was between 3 to 4.5 MPa.

Figure 8.

Flexural strength vs. Compression strength.

4. Life Cycle Analysis

The Life Cycle Analysis is a process that allows the evaluation of the environmental quality of a product or its components in a global way. This will focus on the environmental aspects and potential impacts in the stages of its corresponding life cycle. One of the fundamental objectives of this analysis is to help during the making decision process, especially, to understand the environmental consequences that can be generated by using the product or its components [38]. Therefore, the Life Cycle Analysis is a tool that helps to quantify the impact of the construction of buildings since it is based on objectively studying the different environmental impacts, analysing in-depth the environmental behaviour of aspects such as energy, raw materials, and water used (inputs) and its outputs (general waste and emissions transmitted to the atmosphere) [39].

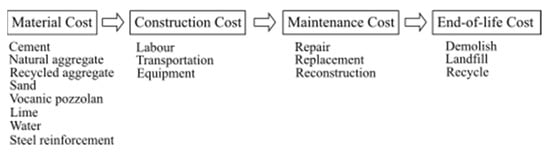

In this study, a life cycle cost analysis (LCCA) was carried out to investigate the benefits of using recycled concrete as alternatives to replace mineral aggregates in structural concrete. Considering the practical application of RAC, a prototype of reinforced concrete structure is accounted for in the LCCA. The LCCA model embedded in this study comprises the costs of four phases as shown in Figure 9. According to ISO 15686-5 [40], LCCA needs to cover a long enough period of time for the consideration of maintenance and end-of-life cost. A reinforcement ratio of 2% in the structural concrete prototype was chosen in order to assess the influence of recycled aggregate on each phase of the LCCA model.

Figure 9.

Life cycle cost analysis.

The material cost of each component used in this study is listed in Table 7. It can be noted that compared to natural aggregate, the recycled aggregate concrete aggregate had a lower cost in the local area. The cost of reinforcement was taken as the cost of black steel bars [41], and total costs of 1 m3 of mix NC, RC50-0LV, and RC10-10LV (with reinforcement) are listed in Table 7 according to the mix design as shown in Table 5. It can be noted that replacing natural aggregates with recycled concrete shows a minor influence on the material price of structural concrete.

Table 7.

Material cost analyses.

Construction cost includes transportation, labour, and equipment for the manufacturing of reinforced concrete structures, while maintenance cost mainly comprises the expenses of repairs, replacements, or reconstructions during the service life of RC structures. The end-of-life cost refers to the demolish and landfill of the materials. In common practice, the construction, maintenance, and end-of-life costs are evaluated as a percentage of the material cost directly [42,43]. Consequently, the LCCA of RC structures shows that although the addition of recycled materials (recycled concrete, lime, and volcanic pozzolan) has a positive influence on the mechanical strengths of the material, the life cycle cost of RC structures with RAC are similar to those with NC materials.

In addition to the life cycle cost consideration, the extraction of natural aggregates and the consumption of non-renewable energies are leading us to a non-reversible situation [44]. The use of materials such as recycled concrete, lime, and natural pozzolana along with others. Although all recycled or discarded materials are not going to be suitable for use in the construction industry, public and private support is necessary for the analysis and research of new unconventional construction materials present in our surroundings. This is in order to raise awareness of people seeking to take care of the environment without the need to reduce the development of the construction field, rather than being able to find a synergy between both fields, the environment, and construction.

The excessive environmental impact caused by the life cycle of concrete materials is one of the major concerns of sustainable development. Conventional concrete is one of the largest consumers of natural resources, as well as the main source of construction demolish waste [6,45]. In addition, the manufacturing of concrete materials consumes a high level of total primary energy and causes severe greenhouse gas (GHG) emissions, which account for approximately 5% of the world’s CO2 emissions [46,47]. Amongst the constituents of the conventional concrete mixes, Portland cement is the primary source of GHG emissions and embodied energy (EE) (up to more than 80% of total emissions of concrete) [48,49,50]. Replacing the main constituents, such as cement and aggregates, with more sustainable materials is effective to reduce the environmental impact generated by conventional concrete.

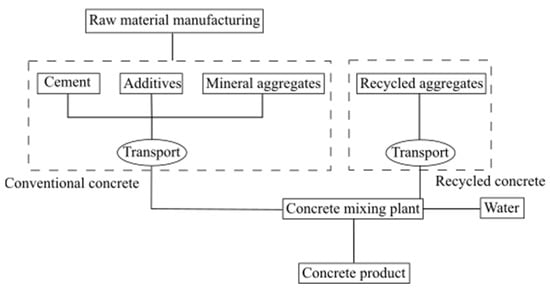

In this study, recycled crushed concrete was acquired directly from the university lab to partially replace the coarse aggregate of conventional concrete. Figure 10 demonstrates the system boundaries of the concrete production system. In general, the average GHG emission of mineral aggregates is between 14–40 kg CO2 eq./t, which contributes to approximately 14% of the total GHG emission of concrete mixes [51,52]. Consequently, the reduction of GHG emission of concrete materials due to partial replacement of mineral aggregates with recycled concrete is insignificant [6,52]. Nevertheless, the major difference in environmental impact caused by conventional concrete and recycled aggregate concrete lies in the transportation aspect. In general, the transport distance of natural mineral aggregate is between 0.3 and 280 km, whereas recycled aggregate concrete has a significantly lower transportation distance between 0 and 40 km [53]. It can be noted that in addition to alleviating the problem of construction and demolition waste caused by wasted concrete materials, the application of crushed concrete as recycled aggregate has a clear impact on the reduction of transportation loads of materials.

Figure 10.

System boundaries of concrete production.

5. Conclusions

This paper examined the performance of concrete materials incorporating recycled aggregates, hydrated lime, and natural volcanic pozzolan. Fresh and mechanical properties were evaluated to assess the influence of the mix constituents, as well as a life cycle cost and environmental impacts were determined. Overall results indicate that materials such as recycled concrete aggregates can be used as a partial replacement for the natural aggregate and local lime or natural pozzolana can replace part of the binders. The main key findings are listed below.

- A good relationship between the workability and the satisfactory mechanical behaviour that the concrete was obtained with the presence of these three unconventional materials for concrete designs.

- The introduction of recycled aggregates, lime, and volcanic pozzolan (replacement 10% crushed aggregate + 10% binder) leads to an increase of up to 34% in compressive strength compared to the conventional concrete mix.

- The non-destructive tests show a good performance in the concrete’s quality where the concrete rebound increases when lime and pozzolana are included in the mix design.

- The life-cycle-cost analysis indicates that partial replacement of mineral aggregates with recycled aggregates shows a minor reduction in the total cost of concrete mixes.

- The sustainable investigation shows that although recycled concrete aggregates possessed similar greenhouse gas emissions with natural mineral aggregates, the low transport distance of recycled concrete contributes significantly to the environmental impact of the concrete manufacturing system.

From this research, several investigative branches can start for new methodologies, environmentally friendly construction materials, knowing the contamination that occurs in the manufacture of the raw material for cement and concrete, not to mention the immense energy consumption at which all days we are protagonists; seeking to know, experiment and work with new materials allowing progressively to reduce the environmental impact that is generally attacked by the construction field and its activities related to construction.

Author Contributions

Conceptualization, W.P.-P. and N.G.-T.; methodology, W.P.-P. and N.G.-T.; validation, W.P.-P. and N.G.-T.; formal analysis, W.P.-P.; investigation, W.P.-P. and N.G.-T.; resources, W.P.-P. and N.G.-T.; writing—original draft preparation, W.P.-P., N.G.-T. and B.X.; writing—review and editing, W.P.-P., N.G.-T. and B.X.; visualization, N.G.-T.; supervision, N.G.-T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors gratefully acknowledge the support provided by the Universidad Espiritu Santo for provision of facilities to undertake the experimental work. The support of Ing. Jorge Flores Rada from Holcim Ecuador S.A through the provided materials is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Conventional concrete mix design.

Table A1.

Conventional concrete mix design.

| Compressive Strength f’c (MPa): | 28 | |||||

| Slump | 10 | cm | ||||

| Coarse aggregate | Fine aggregate | |||||

| P.V.V. = | 1491.11696 | kg/m3 | P-V.S. = | 1480.14 | kg/m3 | |

| P.V.S. = | 1345.133482 | kg/m3 | Ds.s.s. = | 2662 | kg/m3 | |

| D.s.s.s.= | 2599 | kg/m3 | M.F. = | 2.4 | ||

| Absorption = | 1.2 | % | Absorption = | 3.71 | % | |

| Abs. real = | 1.4 | % | Abs.real = | 3.91 | % | |

| a/c = | 0.6 | |||||

| water (litres) | 205 | cement (kg/m3): | 359.8091667 | # bags/m3: | 7196 | |

| Air (%): | 1.8 | |||||

| Water content: | 215.89 | |||||

| Concrete 1 m3 | ||||||

| CEMENT | 0114 | m3 | ||||

| WATER: | 0216 | m3 | ||||

| COARSE AGG.: | 0379 | m3 | ||||

| AIR: | 0.02 | m3 | ||||

| SAND: | 0271 | m3 | ||||

References

- Quiñonez, E.A.; Pozo, L.I. Elaboración de Bloque a Base de Escombros de Hormigón, cal y Puzolana Para Viviendas del Cantón Durán. Bachelor’s Thesis, Universidad Laica Vicente Rocafuerte, Guayaquil, Ecuador, 2019. [Google Scholar]

- Ávila, A.S.; Cabrera, M.U. Caracterización de la Ceniza Volcánica del Tungurahua Para la Fabricación de un Aglomerante Cal-puzolana. Bachelor’s Thesis, Universidad de Cuenca, Cuenca, Ecuador, 2010. [Google Scholar]

- Bompa, D.V.; Elghazouli, A.Y. Mechanical properties of hydraulic lime mortars and fired clay bricks subjected to dry-wet cycles. Constr. Build. Mater. 2021, 303, 124458. [Google Scholar] [CrossRef]

- Gargiani, R. Concrete from Archeology to Invention, 1700–1769: The Renaissance of Pozzolana and Roman Construction Techniques; EPFL Press: Lausanne, Switzerland, 2013. [Google Scholar]

- Moreno-Anselmi, L.A.; Garcia, M.A.O.; Polo, K.A.R. Mechanical properties of concrete made with recycled aggregates extracted from debris of baked clay masonry. Rev. Espac. 2019, 40, 12. [Google Scholar]

- Sabău, M.; Bompa, D.V.; Silva, L.F.O. Comparative carbon emission assessments of recycled and natural aggregate concrete: Environmental influence of cement content. Geosci. Front. 2021, 12, 101235. [Google Scholar]

- Sabău, M.; Remolina, D.J. Prediction of Compressive Strength of General-Use Concrete Mixes with Recycled Concrete Aggregate. Int. J. Pavement Res. Technol. 2021. [Google Scholar] [CrossRef]

- Zapana, D.V. Estudio de la Influencia de la Pureza de la Caliza, Tamaño de Partícula y Temperatura Para Obtener Oxido de Calcio de alta Reactividad Mediante un Diseño Experimental 2K. Bachelor’s Thesis, Universidad Nacional de San Agustín de Arequipa, Arequipa, Perú, 2019. [Google Scholar]

- Topcu, I.B. Physical and mechanical properties of concretes produced with waste concrete. Cem. Concr. Res. 1997, 27, 1817–1823. [Google Scholar] [CrossRef]

- Bedoya, C.; Dzul, L. El Concreto con Agregados Reciclados Como Proyecto de Sostenibilidad Urbana. Rev. Ing. Construcción 2015, 30, 99–108. Available online: https://scielo.conicyt.cl/pdf/ric/v30n2/art02.pdf (accessed on 14 March 2021). [CrossRef] [Green Version]

- Garcia-Troncoso, N.; Li, L.; Cheng, Q.; Mo, K.H.; Ling, T.-C. Comparative study on the properties and high temperatures resistance of self-compacting concrete with various types of recycled aggregates. Case Stud. Constr. Mater. 2021, 15, e00678. [Google Scholar]

- ASTM D692. Standard Specification for Coarse Aggregate for Asphalt Paving Mixtures US; American Society of Testing Materials: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Meddah, M.S.; Al-Harthy, A.; Ismail, M.A. Recycled Concrete Aggregates and Their Influences on Performances of Low and Normal Strength Concretes. Buildings 2020, 10, 167. [Google Scholar]

- Kang, T.H.K.; Kim, W.; Kwak, Y.K.; Hong, S.G. The choice of recycled concrete aggregates for flexural members. In Proceedings of the 18th International Association for Bridge and Structural Engineering Congress on Innovative Infrastructures, Seoul, Korea, 19–21 September 2012. [Google Scholar]

- Yang, K.H.; Chung, H.S.; Ashour, A.F. Influence of type and replacement level of recycled aggregates on concrete properties. ACI Mater. J. 2008, 105, 289–296. [Google Scholar]

- Rao, M.C.; Bhattacharyya, S.K.; Barai, S.V. Influence of filed recycled coarse aggregate on properties of concrete. Mater. Struct. 2011, 44, 205–220. [Google Scholar]

- Xiao, J. Recycled Aggregate Concrete Structures; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Sogo, M.; Sogabe, T.; Maruyama, I.; Sato, R.; Kawai, K. Shear behavior of reinforced recycled concrete beams. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona, Spain, 8 November 2004; pp. 610–618. [Google Scholar]

- Xiao, J.; Sun, Y.D.; Falkner, H. Seismic performance of frame structures with recycled aggregate concrete. Eng. Struct. 2006, 28, 1–8. [Google Scholar] [CrossRef]

- Yang, Y.; Han, L. Experimental behavior of recycled aggregate concrete filled steel tubular columns. J. Constr. Steel Res. 2006, 62, 1310–1324. [Google Scholar]

- Yang, Y.; Han, L.; Zhu, L. Experimental performance of recycled aggregate concrete-filled circular steel tubular columns subjected to cyclic flexural loadings. Adv. Struct. Eng. 2009, 12, 183–194. [Google Scholar] [CrossRef]

- Omrane, M.; Rabehi, M. Effect of natural pozzolan and recycled concrete aggregates on thermal and physico-mechanical characteristics of self-compacting concrete. Constr. Build. Mater. 2020, 247, 118576. [Google Scholar]

- Beka, I.A.; Motta, R.; Bernucci, L.B. Application of recycled aggregates from construction and demolition waste with Portland cement and hydrated lime as pavement subbase in Brazil. Constr. Build. Mater. 2020, 258, 119520. [Google Scholar]

- Kanellopoulos, A.; Nicolaides, D.; Petrou, M.F. Mechanical and durability properties of concretes containing recycled lime powder and recycled aggregates. Constr. Build. Mater. 2014, 53, 253–259. [Google Scholar] [CrossRef]

- ASTM C-618. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- INEN 246:2010. Cal Hidráulica Hidratada para Construcción; Requisitos Norma Técnica Ecuatoriana; Instituto Ecuatoriano de Normalización: Quito, Ecuador, 2008. [Google Scholar]

- ASTM C25. Standard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTMC C33/C33M. Standard Specification for Concrete Aggregates US.; American Society of Testing Materials: West Conshohocken, PA, USA, 2008. [Google Scholar]

- UNE EN 9933:2 96. Methods of Test for Dense Shaped Refractory Products—Part 2; Determination of True Density, Spanish Standard, AENOR: Madrid, Spain, 1996. [Google Scholar]

- ASTM D448. Standard Classification for Sizes of Aggregate for Road and Bridge Construction US.; American Society of Testing Materials: West Conshohocken, PA, USA, 2001. [Google Scholar]

- INEN 1855. Hormigones. Hormigón Premezclado; Requisitos Norma Técnica Ecuatoriana; Instituto Ecuatoriano de Normalización: Quito, Ecuador, 2001. [Google Scholar]

- ASTM C39. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. Standard Specification for Concrete Aggregates US; American Society of Testing Materials: West Conshohocken, PA, USA, 2008. [Google Scholar]

- López Gayarre, F. Influencia de la Variación de los Parámetros de Dosificación y Fabricación de Hormigón Reciclado Estructural Sobre sus Propiedades Físicas y Mecánicas. Ph.D. Thesis, Universidad de Oviedo, Gijón, España, 2008. [Google Scholar]

- de Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar contento n the properties of recycled aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Sánchez De Juan, M. Estudio sobre la utilización de Árido Reciclado para la Fabricación de Hormigón Estructural. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2005. [Google Scholar]

- Garcia-Troncoso, N.; Crespo-León, K. Correlaciones Entre Ensayos no Destructivos y Destructivos para Hormigón de alta Resistencia Usando Agregados Calcáreos. Bachelor’s Thesis, Escuela Superior Politécnica del Litoral, Guayaquil, Ecuador, 2009. Available online: http://www.dspace.espol.edu.ec/handle/123456789/7961 (accessed on 20 May 2021).

- ASTM C78. Standard Test Method for Flexural Strength of Concrete US; American Society of Testing Materials: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Rodriguez, B.I.R. El Análisis de Ciclo de Vida y la Gestión Ambiental; Boletin IIE Tendencias tecnológicas Julio-Septiembre del 2003; Instituto Nacional de Electricidad y Energías Limpias: Cuernavaca, México, 2003; pp. 91–97. [Google Scholar]

- Curran, M.A. Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable; Wiley: Hoboken, NJ, USA, 2012; ISBN 978-1-118-09972-8. [Google Scholar]

- ISO/TC59/SC14. Committee, ISO 15686-5:2008: Buildings and Constructed Assets-Service-Life Planning-Part 5: Life-Cycle Costing; International Organisation for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- RSMeans, Construction and Cost Estimating Data. 2017. Available online: https://www.rsmeans.com/ (accessed on 15 December 2020).

- Val, D.V.; Stewart, M.G. Life-cycle cost analysis of reinforced concrete structures in marine environments. Struct. Saf. 2003, 25, 343–362. [Google Scholar]

- Ali, M.M.; Kyoung, S.M. Structural developments in Tall Buildings: Current trends and future prospects. Archit. Sci. Rev. 2007, 50. [Google Scholar] [CrossRef]

- Tsai, C.-H.; Shen, Y.-H.; Tsai, W.-T. Reuse of the Materials Recycled from Renewable Resources in the Civil Engineering: Status, Achievements and Government’s Initiatives in Taiwan. Materials 2021, 14, 3730. [Google Scholar] [CrossRef]

- EC (European Commission). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Roadmap to a Resource Efficient Europe; COM (2011) 571 final; EC: Brussels, Belgium, 2011; 25p. [Google Scholar]

- Nazzari, A.; Sanjayan, J.G. Handbook of Low Carbon Concrete; Elsevier Science: Cambridge, MA, USA, 2016. [Google Scholar]

- WBCSD World Business Council for Sustanaible Development, International Energy Agency: ‘Cement Technology Roadmap 2009: Carbon Emissions Reductions up to 2050’, Geneva/Paris. 2009. Available online: https://cement.mineralproducts.org/documents/wbcsd-iea%20cement%20roadmap%202009.pdf (accessed on 23 October 2021).

- Flower, D.J.M.; Sanjayan, J.G. Green House Gas Emissions Due to Concrete Manufacture. Int. J. Life Cycle Assess 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Wolf, C.D.; Chin, S.; Ochsendorf, J.; Hajiah, A.E.; Al-Mumin, A.; Buyukozturk, O. Impact of Embodies Energy on Materials/Buildingss with Partial Replacement of Ordinary Portland Cement (OPC) by Natural Pozzolanic Volcanic Ash. J. Clean. Prod. 2018, 177, 547–554. [Google Scholar]

- Xu, B.; Li, H.; Bompa, D.V.; Elghazouli, A.Y.; Chen, J. Performance of Polymer Cementitious Coatings for High-Voltage Electrical Infrastructure. Infrastructures 2021, 6, 125. [Google Scholar]

- Abdelmonim, A.; Bompa, D.V. Mechanical and Fresh Properties of Multi-Binder Geopolymer Mortars Incorporating Recycled Rubber Particles. Infrastructures 2021, 6, 146. [Google Scholar] [CrossRef]

- Jimenez, L.F.; Dominguez, J.A.; Vega-Azamar, R.E. Carbon Footprint of Recycled Aggregate Concrete. Adv. Civ. Eng. 2018, 2018, 7949741. [Google Scholar]

- Oliveira, L.S.; Pacca, S.A.; John, V.M. Variability in the Life Cycle of Concrete Block CO2 Emissions and Cumulative Energy Demand in the Brazilian Market. Constr. Build. Mater. 2016, 114, 588–594. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).