Biocompatible Optical Fibers Made of Regenerated Cellulose and Recombinant Cellulose-Binding Spider Silk

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Dissolution of MCC

2.2.2. Wet-Spinning of Regenerated Cellulose Fibers

2.2.3. Processing of eADF4(C16)-CBD

2.2.4. Production of Recombinant Spider Silk Films

2.2.5. Coating with eADF4(C16)

2.2.6. Coating with eADF4(C16)-CBD

2.2.7. Ultraviolet and Visible Light Spectroscopy

Optical Characterization of Recombinant Spider Silk Films

Attenuation Determination via Cut-Back Method

2.2.8. Calculation of the Maximum Data Rate according to the Nyquist Rule

2.2.9. Infrared Spectroscopy

2.2.10. Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Analysis (EDX)

3. Results and Discussion

3.1. Characterization of Optical Properties of eADF4(C16) Films and Coatings

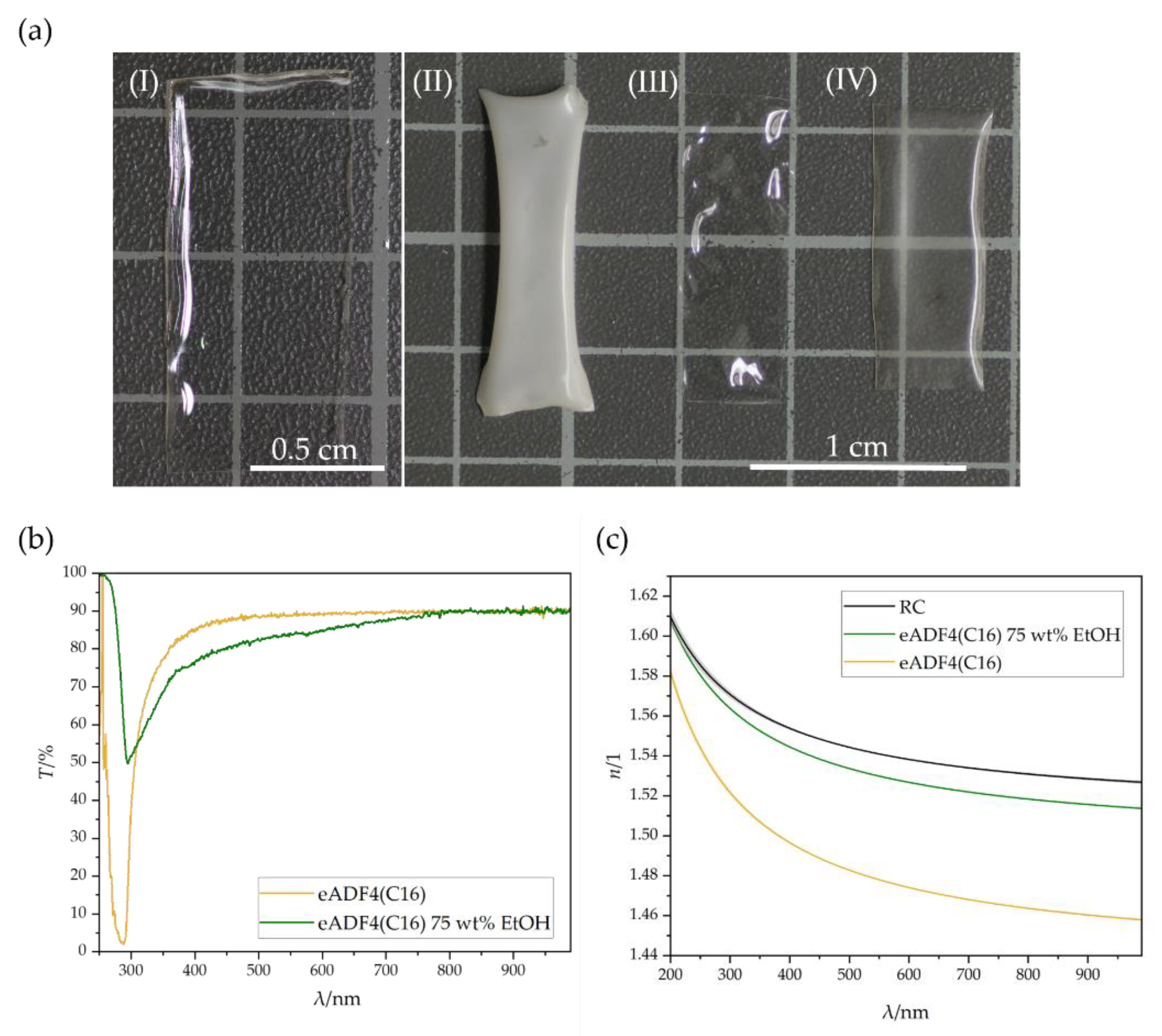

3.1.1. Fabrication of eADF4(C16) Films and Determination of Optical Properties

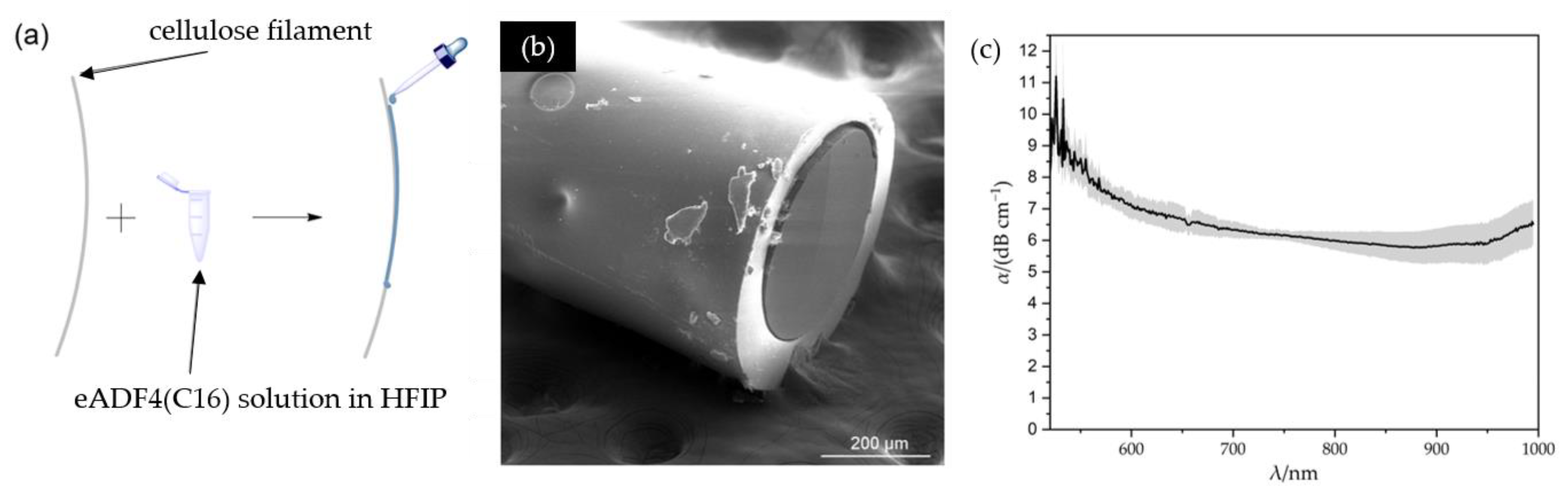

3.1.2. Processing of Optical Fibers and Attenuation Determination

3.2. Processing of eADF4(C16)-CBD for Improved Optical Fiber Properties

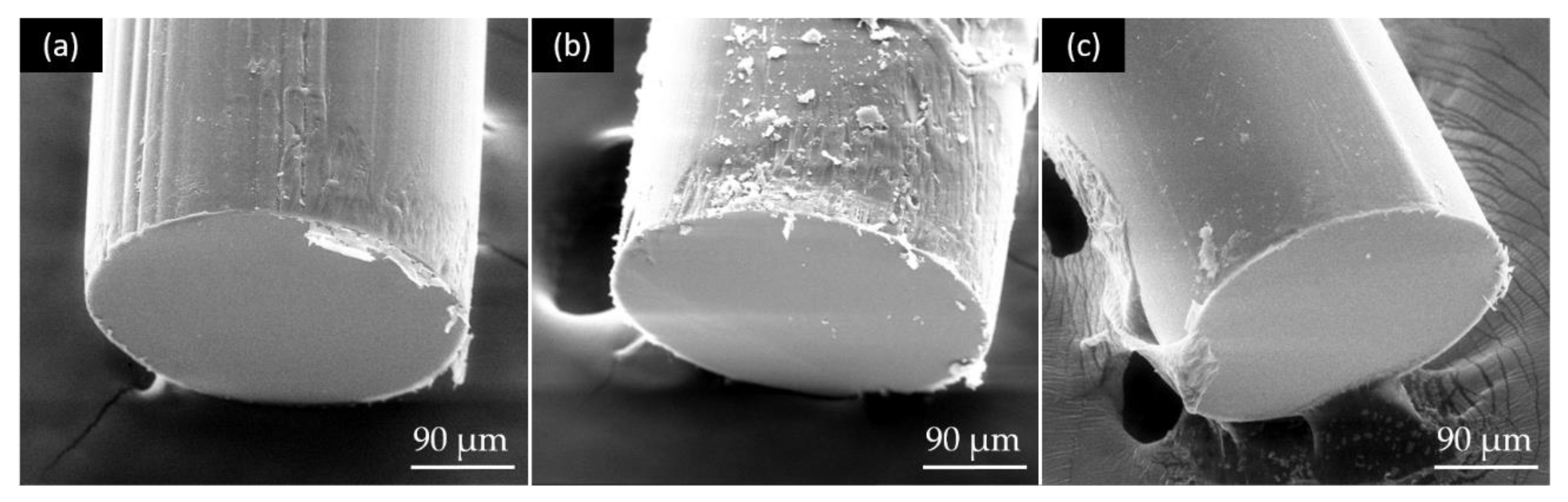

3.2.1. Optimization of the Optical Fibers via Cellulose Binding Domain

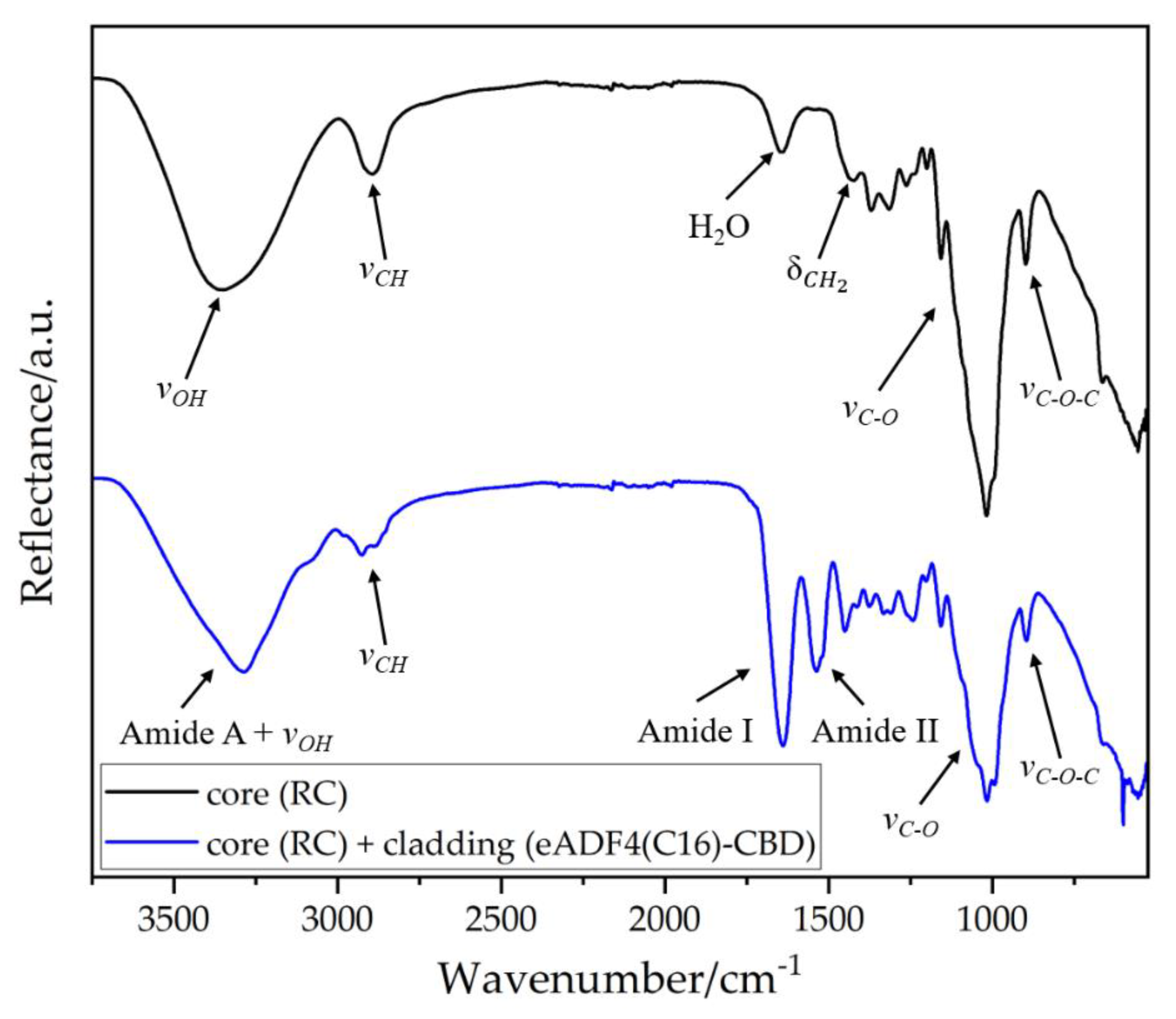

3.2.2. Determination of the Optical Properties of eADF4(C16)-CBD Films

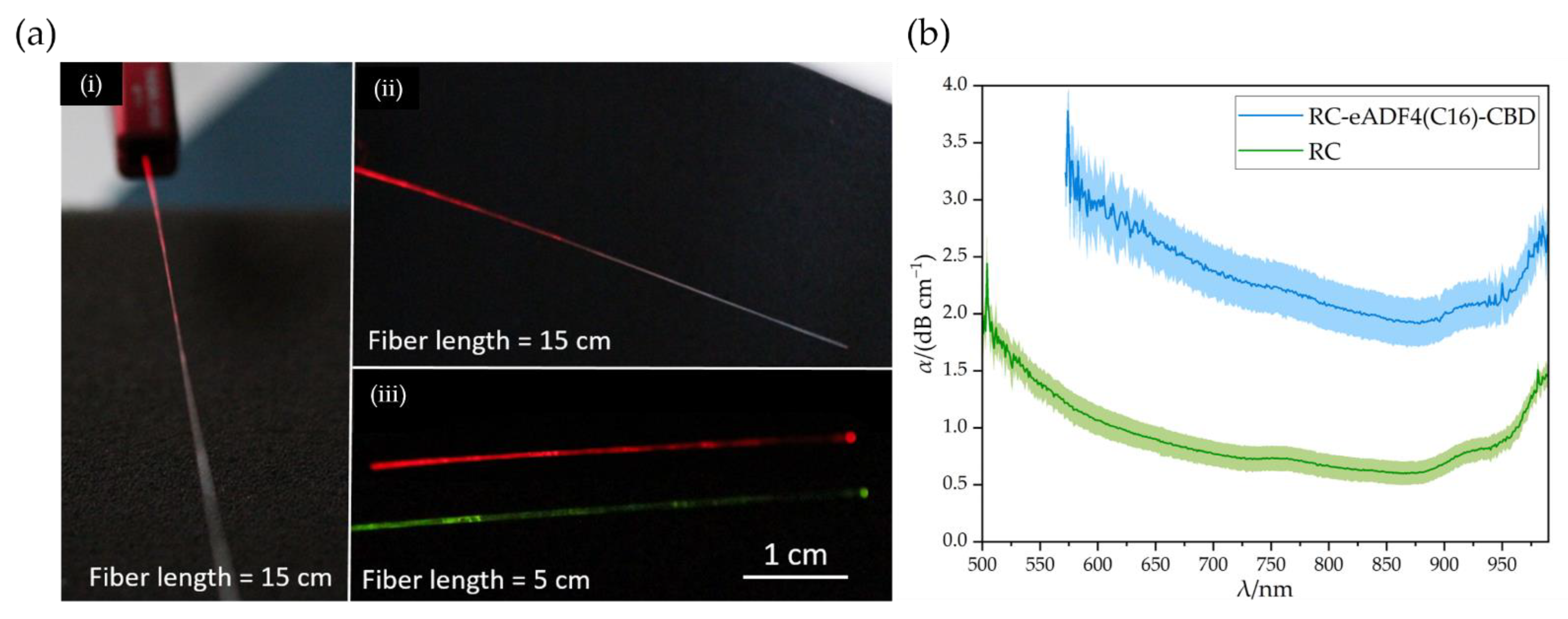

3.2.3. Fabrication of Core-Cladding Optical Fibers and Attenuation Determination

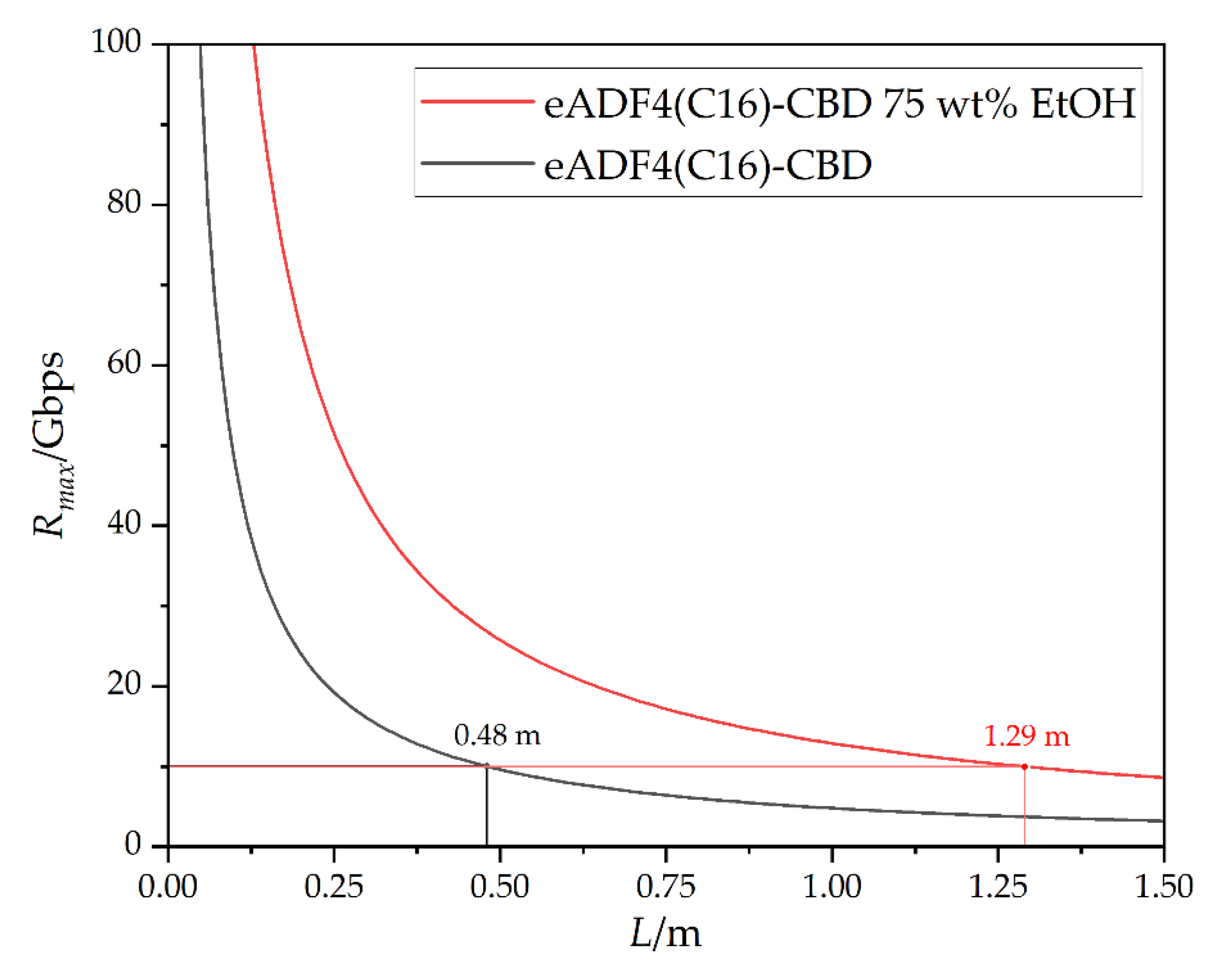

3.3. Calculation of the Maximum Data Rate according to the Nyquist Rule

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bunge, C.A.; Beckers, M.; Gries, T. Polymer Optical Fibres: Fibre Types, Materials, Fabrication, Characterisation and Applications; Elsevier: Duxford, UK, 2017. [Google Scholar]

- Cochrane, C.; Mordon, S.R.; Lesage, J.C.; Koncar, V. New design of textile light diffusers for photodynamic therapy. Mater. Sci. Eng. C Mater. Biol. Appl. 2013, 33, 1170–1175. [Google Scholar] [CrossRef] [PubMed]

- Quandt, B.M.; Pfister, M.S.; Lübben, J.F.; Spano, F.; Rossi, R.M.; Bona, G.-L.; Boesel, L.F. POF-yarn weaves: Controlling the light out-coupling of wearable phototherapy devices. Biomed. Opt. Express 2017, 8, 4316–4330. [Google Scholar] [CrossRef] [PubMed]

- Moslan, M.S.; Othman, M.H.D.; Samavati, A.; Salim, M.A.M.; Rahman, M.A.; Ismail, A.F.; Bakhtiar, H. Fabrication of polycarbonate polymer optical fibre core via extrusion method: The role of temperature gradient and collector speed on its characteristics. Opt. Fiber Technol. 2020, 55, 102162. [Google Scholar] [CrossRef]

- Scheibel, T. Spider silks: Recombinant synthesis, assembly, spinning, and engineering of synthetic proteins. Microb. Cell Fact 2004, 3, 14. [Google Scholar] [CrossRef] [PubMed]

- Miyamoto, T.; Takahashi, S.; Ito, H.; Inagaki, H.; Noishiki, Y. Tissue biocompatibility of cellulose and its derivatives. J. Biomed. Mater. Res. 1989, 23, 125–133. [Google Scholar] [CrossRef]

- Helenius, G.; Bäckdahl, H.; Bodin, A.; Nannmark, U.; Gatenholm, P.; Risberg, B. In vivo biocompatibility of bacterial cellulose. J. Biomed. Mater. Res. A 2006, 76, 431–438. [Google Scholar] [CrossRef]

- Torres, F.G.; Commeaux, S.; Troncoso, O.P. Biocompatibility of bacterial cellulose based biomaterials. J. Funct. Biomater. 2012, 3, 864–878. [Google Scholar] [CrossRef]

- Sommer, C.; Bargel, H.; Raßmann, N.; Scheibel, T. Microbial repellence properties of engineered spider silk coatings prevent biofilm formation of opportunistic bacterial strains. MRS Commun. 2021, 11, 356–362. [Google Scholar] [CrossRef]

- Zeplin, P.H.; Maksimovikj, N.C.; Jordan, M.C.; Nickel, J.; Lang, G.; Leimer, A.H.; Römer, L.; Scheibel, T. Spider Silk Coatings as a Bioshield to Reduce Periprosthetic Fibrous Capsule Formation. Adv. Funct. Mater. 2014, 24, 2658–2666. [Google Scholar] [CrossRef]

- Borkner, C.B.; Elsner, M.B.; Scheibel, T. Coatings and Films Made of Silk Proteins. ACS Appl. Mater. Interfaces 2014, 6, 15611–15625. [Google Scholar] [CrossRef]

- Reimer, M.; Zollfrank, C. Cellulose for Light Manipulation: Methods, Applications, and Prospects. Adv. Energy Mater. 2021, 11, 2003866. [Google Scholar] [CrossRef]

- Dupuis, A.; Guo, N.; Gao, Y.; Godbout, N.; Lacroix, S.; Dubois, C.; Skorobogatiy, M. Prospective for biodegradable microstructured optical fibers. Opt. Lett. 2007, 32, 109–111. [Google Scholar] [CrossRef]

- Orelma, H.; Hokkanen, A.; Leppänen, I.; Kammiovirta, K.; Kapulainen, M.; Harlin, A. Optical cellulose fiber made from regenerated cellulose and cellulose acetate for water sensor applications. Cellulose 2020, 27, 1543–1553. [Google Scholar] [CrossRef]

- Reimer, M.; Van Opdenbosch, D.; Zollfrank, C. Fabrication of Cellulose-Based Biopolymer Optical Fibers and Their Theoretical Attenuation Limit. Biomacromolecules 2021, 22, 3297–3312. [Google Scholar] [CrossRef]

- Omenetto, F.G.; Kaplan, D.L. A new route for silk. Nat. Photonics 2008, 2, 641. [Google Scholar] [CrossRef]

- Parker, S.T.; Domachuk, P.; Amsden, J.; Bressner, J.; Lewis, J.A.; Kaplan, D.L.; Omenetto, F.G. Biocompatible Silk Printed Optical Waveguides. Adv. Mater. 2009, 21, 2411–2415. [Google Scholar] [CrossRef]

- Applegate, M.B.; Perotto, G.; Kaplan, D.L.; Omenetto, F.G. Biocompatible silk step-index optical waveguides. Biomed. Opt. Express 2015, 6, 4221–4227. [Google Scholar] [CrossRef]

- Mittal, N.; Jansson, R.; Widhe, M.; Benselfelt, T.; Hakansson, K.M.O.; Lundell, F.; Hedhammar, M.; Soderberg, L.D. Ultrastrong and Bioactive Nanostructured Bio-Based Composites. ACS Nano 2017, 11, 5148–5159. [Google Scholar] [CrossRef]

- Meirovitch, S.; Shtein, Z.; Ben-Shalom, T.; Lapidot, S.; Tamburu, C.; Hu, X.; Kluge, J.A.; Raviv, U.; Kaplan, D.L.; Shoseyov, O. Spider Silk-CBD-Cellulose Nanocrystal Composites: Mechanism of Assembly. Int. J. Mol. Sci. 2016, 17, 1573. [Google Scholar] [CrossRef]

- Mohammadi, P.; Aranko, A.S.; Landowski, C.P.; Ikkala, O.; Jaudzems, K.; Wagermaier, W.; Linder, M.B. Biomimetic composites with enhanced toughening using silk-inspired triblock proteins and aligned nanocellulose reinforcements. Sci. Adv. 2019, 5, eaaw2541. [Google Scholar] [CrossRef]

- Heidebrecht, A.; Scheibel, T. Recombinant production of spider silk proteins. Adv. Appl. Microbiol. 2013, 82, 115–153. [Google Scholar] [PubMed]

- Doblhofer, E.; Scheibel, T. Engineering of recombinant spider silk proteins allows defined uptake and release of substances. J. Pharm. Sci. 2015, 104, 988–994. [Google Scholar] [CrossRef] [PubMed]

- Humenik, M.; Mohrand, M.; Scheibel, T. Self-Assembly of Spider Silk-Fusion Proteins Comprising Enzymatic and Fluorescence Activity. Bioconjug. Chem. 2018, 29, 898–904. [Google Scholar] [CrossRef] [PubMed]

- Ong, E.; Gilkes, N.R.; Miller, R.C., Jr.; Warren, R.A.J.; Kilburn, D.G. The cellulose-binding domain (CBDCex) of an exoglucanase from Cellulomonas fimi: Production in Escherichia coli and characterization of the polypeptide. Biotechnol. Bioeng. 1993, 42, 401–409. [Google Scholar] [CrossRef] [PubMed]

- Huemmerich, D.; Helsen, C.W.; Quedzuweit, S.; Oschmann, J.; Rudolph, R.; Scheibel, T. Primary Structure Elements of Spider Dragline Silk and Their Contribution to Protein Solubility. Biochemistry 2004, 43, 13604–13612. [Google Scholar] [CrossRef]

- Acquaroli, L.N. Matrix method for thin film optics. arXiv 2018, arXiv:1809.07708. [Google Scholar]

- Daum, W.; Krauser, J.; Zamzow, P.E.; Ziemann, O. Light propagation in optical fibers. In POF-Polymer Optical Fibers for Data Communication, 1st ed.; Springer: Heidelberg, Germany, 2002; Chapter 1. [Google Scholar]

- Takezawa, Y.; Taketani, N.; Tanno, S.; Ohara, S. Empirical estimation method of intrinsic loss spectra in transparent amorphous polymers for plastic optical fibers. J. Appl. Polym. Sci. 1992, 46, 1835–1841. [Google Scholar] [CrossRef]

- Cai, D.; Heise, H.M. Spectroscopic Aspects of Polydimethylsiloxane (PDMS) Used for Optical Waveguides. In Molecular Spectroscopy—Experimentand Theory-From Molecules to Functional Materials, 1st ed.; Leszczynski, J., Koleżyński, A., Król, M., Eds.; Springer Nature: Cham, Switzerland, 2019; Chapter 13. [Google Scholar]

- Voges, E.; Petermann, K. Vielmodenfasern. In Optische Kommunikationstechnik, 1st ed.; Freude, W., Ed.; Springer: Heidelberg, Germany, 2002; Chapter 5. [Google Scholar]

- Huemmerich, D.; Slotta, U.; Scheibel, T. Processing and modification of films made from recombinant spider silk proteins. Appl. Phys. A 2006, 82, 219–222. [Google Scholar] [CrossRef]

- Aigner, T.; Scheibel, T. and Scheibel, T. Self-Rolling Refillable Tubular Enzyme Containers Made of Recombinant Spider Silk and Chitosan. ACS Appl. Mater. Interfaces 2019, 11, 15290–15297. [Google Scholar] [CrossRef]

- Spiess, K.; Ene, R.; Keenan, C.D.; Senker, J.; Kremer, F.; Scheibel, T. Impact of initial solvent on thermal stability and mechanical properties of recombinant spider silk films. J. Mater. Chem. 2011, 21, 13594. [Google Scholar] [CrossRef]

- Perotto, G.; Zhang, Y.; Naskar, D.; Patel, N.; Kaplan, D.L.; Kunud, S.C.; Omenetto, F.G. The optical properties of regenerated silk fibroin obtained from different sources. Appl. Phys. Lett. 2017, 111, 103702. [Google Scholar] [CrossRef]

- Little, D.J.; Kane, D.M. Image contrast immersion method for measuring refractive index applied to spider silks. Opt. Express 2011, 19, 19182–19189. [Google Scholar] [CrossRef]

- Vehovec, T.; Gartner, A.; Planinšek, O.; Obreza, A. Influence of different types of commercially available microcrystalline cellulose on degradation of perindopril erbumine and enalapril maleate in binary mixtures. Acta Pharm. 2012, 62, 515–528. [Google Scholar] [CrossRef]

- Ciolacu, D.; Ciolacu, F.; Popa, V.I. Amorphous cellulose–structure and characterization. Cellulose Chem. Technol. 2011, 45, 13–21. [Google Scholar]

- Slotta, U.; Tammer, M.; Kremer, F.; Koelsch, P.; Scheibel, T. Structural Analysis of Spider Silk Films. Supramol. Chem. 2006, 18, 465–471. [Google Scholar] [CrossRef]

- Sindhu, K.A.; Prasanth, R.; Thakur, V.K. Medical Applications of Cellulose and its Derivatives: Present and Future. In Nanocellulose Polymer Nanocomposites; Thakur, V.K., Ed.; Scrivener Publishing: Beverly, MA, USA, 2014. [Google Scholar] [CrossRef]

- Holland, C.; Numata, K.; Rnjak-Kovacina, J.; Seib, F.P. The Biomedical Use of Silk: Past, Present, Future. Adv. Healthcare Mater. 2019, 8, 1800465. [Google Scholar] [CrossRef]

- Kröplin, P.; Dieling, C.; Beckers, M.; Schrank, V.; Beer, M.; Gries, T.; Seide, G.; Bunge, C.-A. Overview of the POF market. In Polymer Optical Fibres, 1st ed.; Bunge, C.-A., Gries, T., Beckers, M., Eds.; Woodhead Publishing: Duxford, UK, 2017; Chapter 11. [Google Scholar]

- Polishuk, P. Plastic optical fibers branch out. IEEE Commun. Mag. 2006, 44, 140–148. [Google Scholar] [CrossRef]

- Zubia, J.; Arrue, J. Plastic Optical Fibers: An Introduction to Their Technological Processes and Applications. Opt. Fiber Technol. 2001, 7, 101–140. [Google Scholar] [CrossRef]

- Francisco, M.D.; Chen, W.-F.; Pan, C.-T.; Lin, M.-C.; Wen, Z.-H.; Liao, C.-F.; Shiue, Y.-L. Competitive Real-Time Near Infrared (NIR) Vein Finder Imaging Device to Improve Peripheral Subcutaneous Vein Selection in Venipuncture for Clinical Laboratory Testing. Micromachines 2021, 12, 373. [Google Scholar]

- Kaberniuk, A.A.; Shemetov, A.A.; Verkhusha, V.V. A bacterial phytochrome-based optogenetic system controllable with near-infrared light. Nat. Methods 2016, 13, 591–597. [Google Scholar] [CrossRef]

- Kim, M.M.; Darafsheh, A. Light Sources and Dosimetry Techniques for Photodynamic Therapy. Photochem. Photobiol. 2020, 96, 280–294. [Google Scholar] [CrossRef] [PubMed]

- Béguin, P.; Aubert, J.-P. The biological degradation of cellulose. FEMS Microbiol. Rev. 1994, 13, 25–58. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Wang, B. Biodegradation of Silk Biomaterials. Int. J. Mol. Sci. 2009, 10, 1514–1524. [Google Scholar] [CrossRef] [PubMed]

| Sample | nF | nD | nC | νD | A/1 | B/1 | C/nm |

|---|---|---|---|---|---|---|---|

| RC [15] | 1.5454 ± 0.0002 | 1.5388 ± 0.0002 | 1.5357 ± 0.0004 | 55.65 ± 3.34 | 1.37 ± 0.05 | 0.91 ± 0.04 | 50.6 ± 0.7 |

| eADF4(C16) | 1.4843 ± 0.0002 | 1.4749 ± 0.0001 | 1.4705 ± 0.0002 | 34.25 ± 1.06 | 1.12 ± 0.05 | 0.94 ± 0.05 | 64.0 ± 2.5 |

| eAD4(C16) 75 wt% EtOH | 1.5349 ± 0.0001 | 1.52741 ± 0.00008 | 1.5239 ± 0.0001 | 47.76 ± 0.84 | 1.185 ± 0.009 | 1.050 ± 0.008 | 49.990 ± 0.006 |

| Scheme 1. | nF | nD | nC | νD | A/1 | B/1 | C/nm |

|---|---|---|---|---|---|---|---|

| eADF4(C16)-CBD | 1.49574 ± 0.00006 | 1.48643 ± 0.00003 | 1.48210 ± 0.00006 | 35.66 ± 0.32 | 1.174 ± 0.005 | 0.922 ± 0.005 | 64.61 ± 0.21 |

| eAD4(C16)-CBD 75 wt% EtOH | 1.5326 ± 0.0004 | 1.5227 ± 0.0002 | 1.5182 ± 0.0005 | 36.18 ± 2.22 | 1.20 ± 0.04 | 1.00 ± 0.03 | 64.7 ± 1.5 |

| Elements | Core-Material | Cladding-Material |

|---|---|---|

| C | 87.44 | 62.80 |

| N | - | 17.40 |

| O | 11.67 | 19.13 |

| Na | 0.12 | 0.18 |

| Pd | 0.16 | 0.09 |

| Au | 0.61 | 0.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reimer, M.; Mayer, K.; Van Opdenbosch, D.; Scheibel, T.; Zollfrank, C. Biocompatible Optical Fibers Made of Regenerated Cellulose and Recombinant Cellulose-Binding Spider Silk. Biomimetics 2023, 8, 37. https://doi.org/10.3390/biomimetics8010037

Reimer M, Mayer K, Van Opdenbosch D, Scheibel T, Zollfrank C. Biocompatible Optical Fibers Made of Regenerated Cellulose and Recombinant Cellulose-Binding Spider Silk. Biomimetics. 2023; 8(1):37. https://doi.org/10.3390/biomimetics8010037

Chicago/Turabian StyleReimer, Martin, Kai Mayer, Daniel Van Opdenbosch, Thomas Scheibel, and Cordt Zollfrank. 2023. "Biocompatible Optical Fibers Made of Regenerated Cellulose and Recombinant Cellulose-Binding Spider Silk" Biomimetics 8, no. 1: 37. https://doi.org/10.3390/biomimetics8010037

APA StyleReimer, M., Mayer, K., Van Opdenbosch, D., Scheibel, T., & Zollfrank, C. (2023). Biocompatible Optical Fibers Made of Regenerated Cellulose and Recombinant Cellulose-Binding Spider Silk. Biomimetics, 8(1), 37. https://doi.org/10.3390/biomimetics8010037