Abstract

This work aims to evaluate how the particle size of a waste filler in the form of eggshells changes the mechanical properties of biopoly(ethylene terephthalate) (bioPET). BioPET was modified with three different waste fractions: 1.60–3 mm—large particles; 1.60–1 mm—medium particles; 1 mm–200 μm—small particles. Waste filler was added to the biopolymer matrix in the amount of 10 wt.%. Static tensile tests, as well as bending and impact tests, were carried out to assess the strength properties of the waste-enriched materials. Dissipation energy changes and relaxation processes were observed and evaluated by means of a low-cycle dynamic test. Waste particles were shown to be an effective modifier of bioPET by increasing its stiffness (all particle sizes) and strength (the smallest ones). Studies of the wetting angle and mechanical energy dissipation in the first hysteresis loops indicate the better adhesion of small particles to the biopolymer and their greater ability to dissipate mechanical energy.

1. Introduction

Material recycling is a promising way to meet the requirements of the European Green Deal, and the sustainable development of plastics is in line with the goal of achieving climate neutrality by 2050. Many initiatives are being undertaken, including replacing petroleum-based raw materials with renewable raw materials in the synthesis of plastics and using waste in their synthesis, following the idea of a circular economy [1].

Recently, the interest of researchers in environmentally friendly engineering materials modified with waste as a filler has increased. One such waste filler is eggshells (EG). The Environmental Protection Agency in the USA has classified EG waste in the 15th position on the list of food industries causing pollution problems. One of the methods to mitigate utilization problems is to find new applications for waste materials. The chemical composition of EG comprises mainly calcium carbonate (94–97%) and 3–4.5% of organic matter [2,3,4,5]. Calcium carbonate obtained from EG could be applied again as a filler for the polymer matrix in composite materials [2]. Moreover, trace amounts of other elements have been found, such as MgO (0.83%), SO3 (0.66%), P2O5 (0.43%), Al2O3 (0.15%), K2O (0.08%), SiO2 (0.07%), Cl2O3 (0.06%), and SrO (0.04%). The density of EG ranges from 2.50 g/cm3 to 2.62 g/cm3 [2].

The influence of the application of waste EG fillers on polymer properties has been studied by several authors [6,7,8,9]. I. C. C. Iloabachie et al. have looked into the impact of EG on epoxy resins. They concluded that the flexural strength reached a maximum of 12 MPa at 25 wt.% eggshell particles, while the greatest hardness corresponded to 20 wt.% eggshell particles [9]. K.S. AJAO et al. analyzed the influence of wood dust and EG particles on the properties of epoxy resins. The tensile and flexural strengths increased when the share of reinforcement polymers was greater. A composite comprising 3 wt.% wood dust and 10 wt.% EG particles exhibited the highest tensile strength of 34.87 MPa, whereas a composite with 10 wt.% wood dust and 10 wt.% eggshell particles had the highest flexural strength. The hardness of the material increased with an increase in the amount of the reinforcement additive, reaching the highest level at 5 wt.% wood dust and 10 wt.% EG particles. The researchers concluded that composites with favourable mechanical properties can be obtained if the composition of wood dust and EG is optimally designed [10].

Helen Obianuju Ofor analyzed the influence of EG on the properties of thermoplastic polymers such as polypropylene, high-density polyethylene, acrylonitrile–butadiene–styrene, and polystyrene. The results revealed substantial improvements in the mechanical characteristics of the EG. The study of Helen Obianuju Ofor resulted in thermoplastic polymer composites with various eggshell waste/eggshell residue contributions and potential applications in the automobile and building construction industries [8]. EG could also serve as an effective filler for poly(vinyl chloride) (PVC) composites [11].

Biocomposites are both polymers of petrochemical origin modified with natural fillers and biopolymers modified with non-renewable fillers. However, biocomposites whose polymer matrix is synthesized from biomonomers where filler is derived from renewable sources are the most environmentally friendly materials. So far, the literature has described the influence of EG on the properties of biopolyethylene [12], biopolyurethanes [13], and polylactic acid [14,15].

Leszczyńska et al. modified rigid polyurethane foams synthesized from rapeseed oil-based polyol with EG as a natural filler. The researchers looked into the structure as well as the physico-mechanical, thermal, and biological performance of the modified foams. They concluded that a proper decision regarding the type and content of the renewable raw material, as well as the reasonable development of a recipe for a rigid polyurethane foam, led to environmentally friendly materials being produced. The resulting material exhibited unimpaired or even more advantageous properties with respect to the reference materials derived from petrochemical substrates only [13].

Hanumantharaju H G et al. prepared composites based on polylactic acid and EG. The bio-composites were obtained by adding eggshells in the form of powder into a PLA polymer matrix. Different filler weights were introduced using 3D printing. Next, the mechanical properties and biodegradability of the composites based on PLA and EG were studied. The EG-reinforced bio-composites were biodegradable, but their mechanical properties were found to have deteriorated compared to those of PLA [14].

Biopolymers derived from natural raw materials are becoming increasingly important in the face of limited oil resources as well as the need to reduce greenhouse gas emissions. BioPET is a polymer that is made from renewable raw materials. A biopathway for the synthesis of terephthalic acid offers the potential to obtain bioPET from 100% renewable raw materials. Currently, the content of biocomponents in bioPET corresponds to the presence of ethylene glycol, constituting about 30% of the biocontent [16]. BioPET is characterized by properties similar to those of PET made from petrochemical raw materials. A disadvantage of bioPET is its higher price compared to PET [17]. In order to reduce costs, the polymer mass can be reduced by introducing a waste filler. The size of the filler particles used in polymer modification plays a vital role.

To the best of our knowledge, studies on the influence of EG particle size on the mechanical properties of bioPET/eggshell biocomposites have not been published yet. In particular, the use of eggshells as fillers is especially promising when there is a need for greater rigidity. Since eggshells are cheap waste materials, their use seems even more feasible. With the hope of reducing the cost of biocomposites, we undertook studies to understand the influence of EG particle size on the mechanical properties of bioPET.

2. Results and Discussion

2.1. Properties of Modified EG

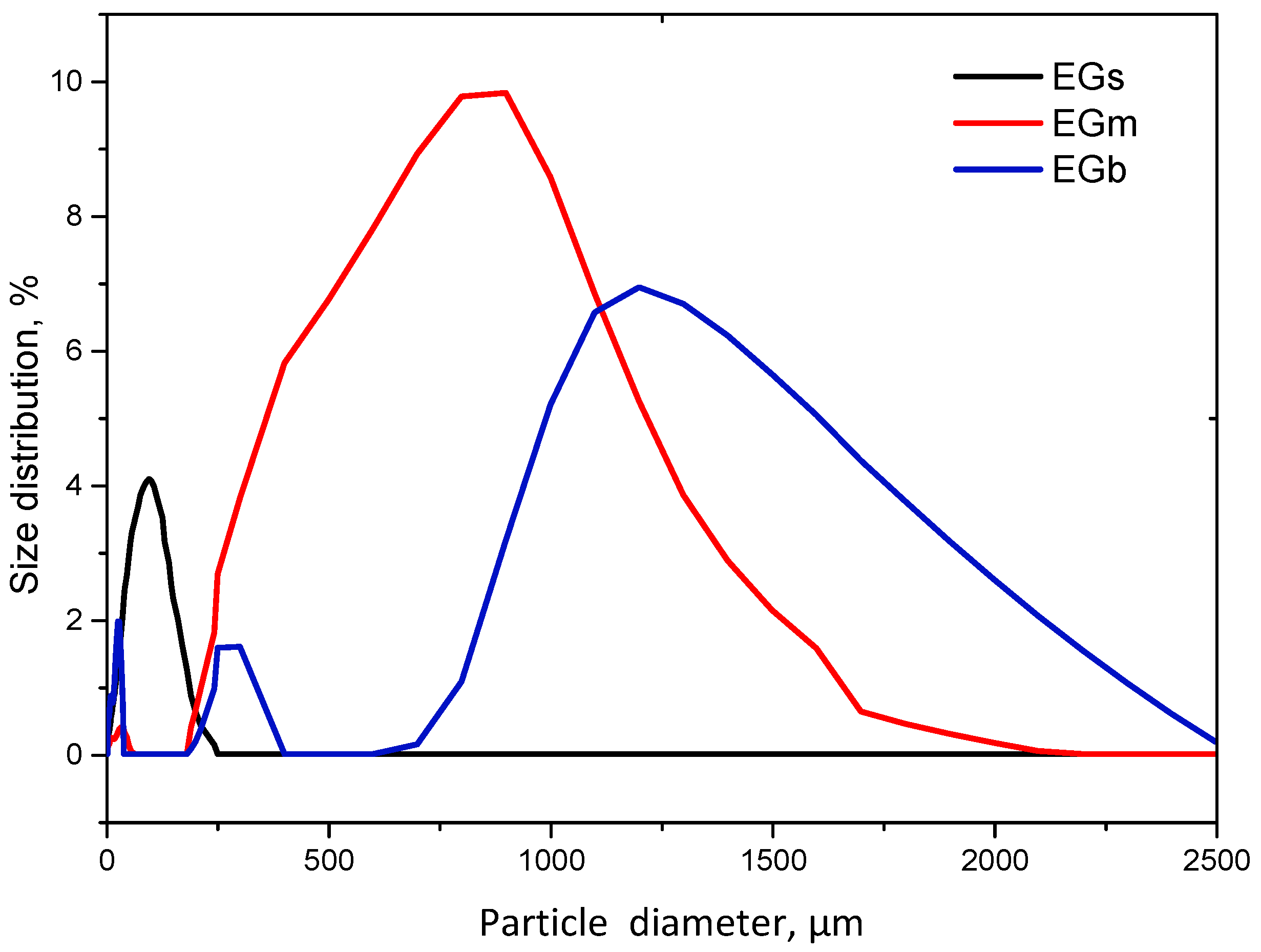

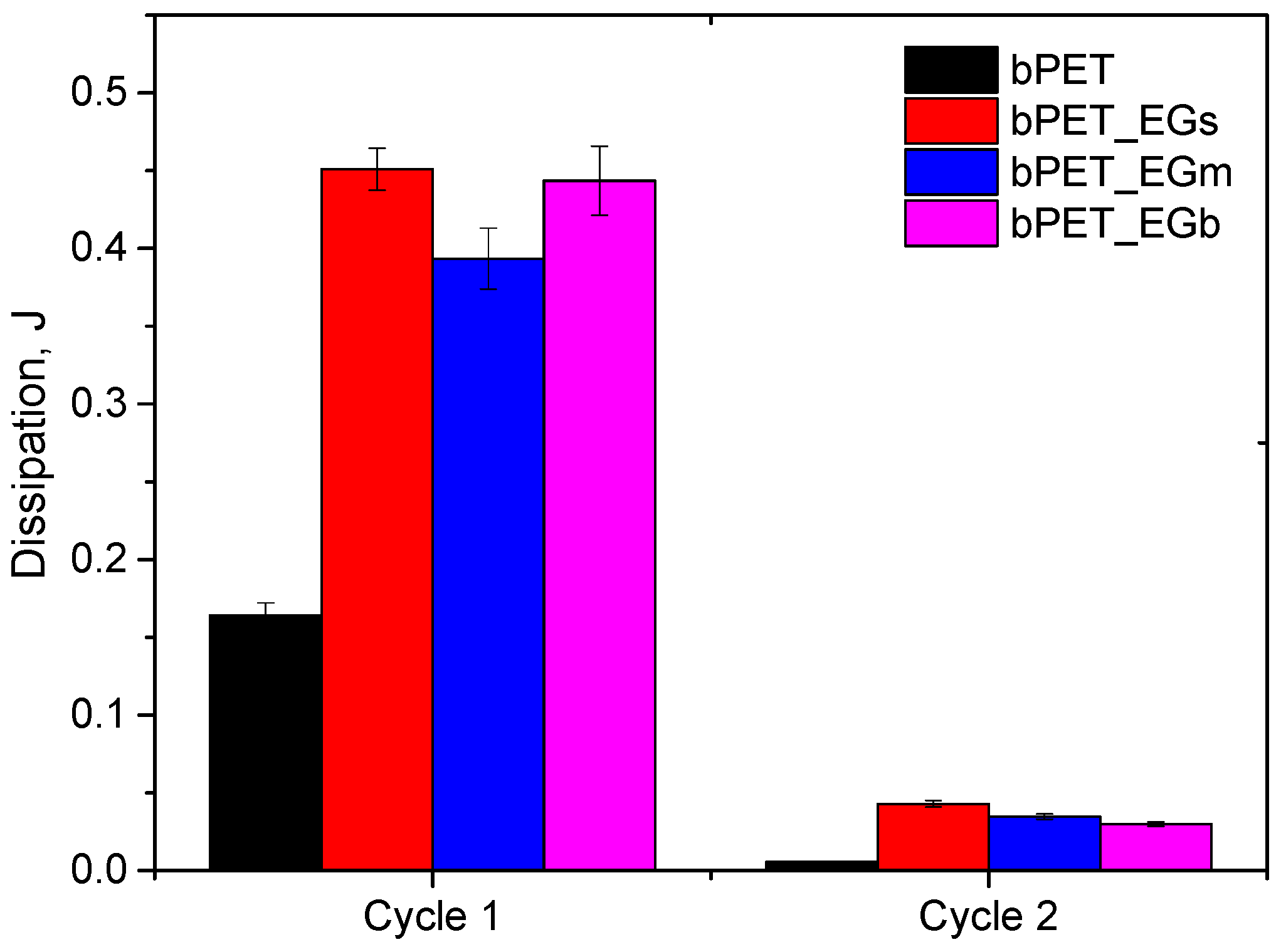

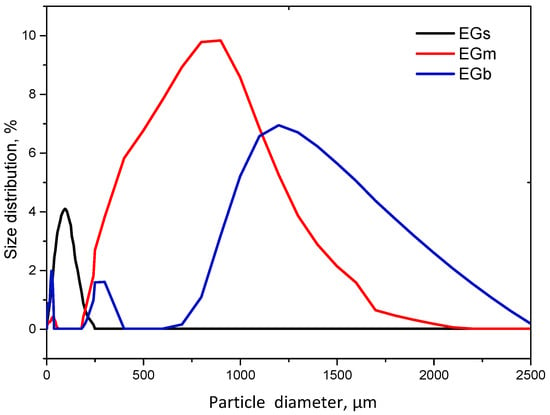

Three fractions of ground EG were used to modify bioPET: small (EGs), medium (EGm), and large (EGb). Table 1 presents the results of an analysis of particle sizes, while Figure 1 displays the EG particle size distribution curves.

Table 1.

Eggshell particle sizes.

Figure 1.

EG particle size distribution curves.

EGs, EGm, and EGl were characterized by average particle sizes of 67, 711, and 747 µm, respectively. The particle distributions shown in Figure 1 reveal significant differences in particle sizes.

Differences in particle sizes were also confirmed by optical microscope photographs (Figure 2).

Figure 2.

Optical microscopy images of modified EG.

2.2. Mechanical Properties of the Biocomposites

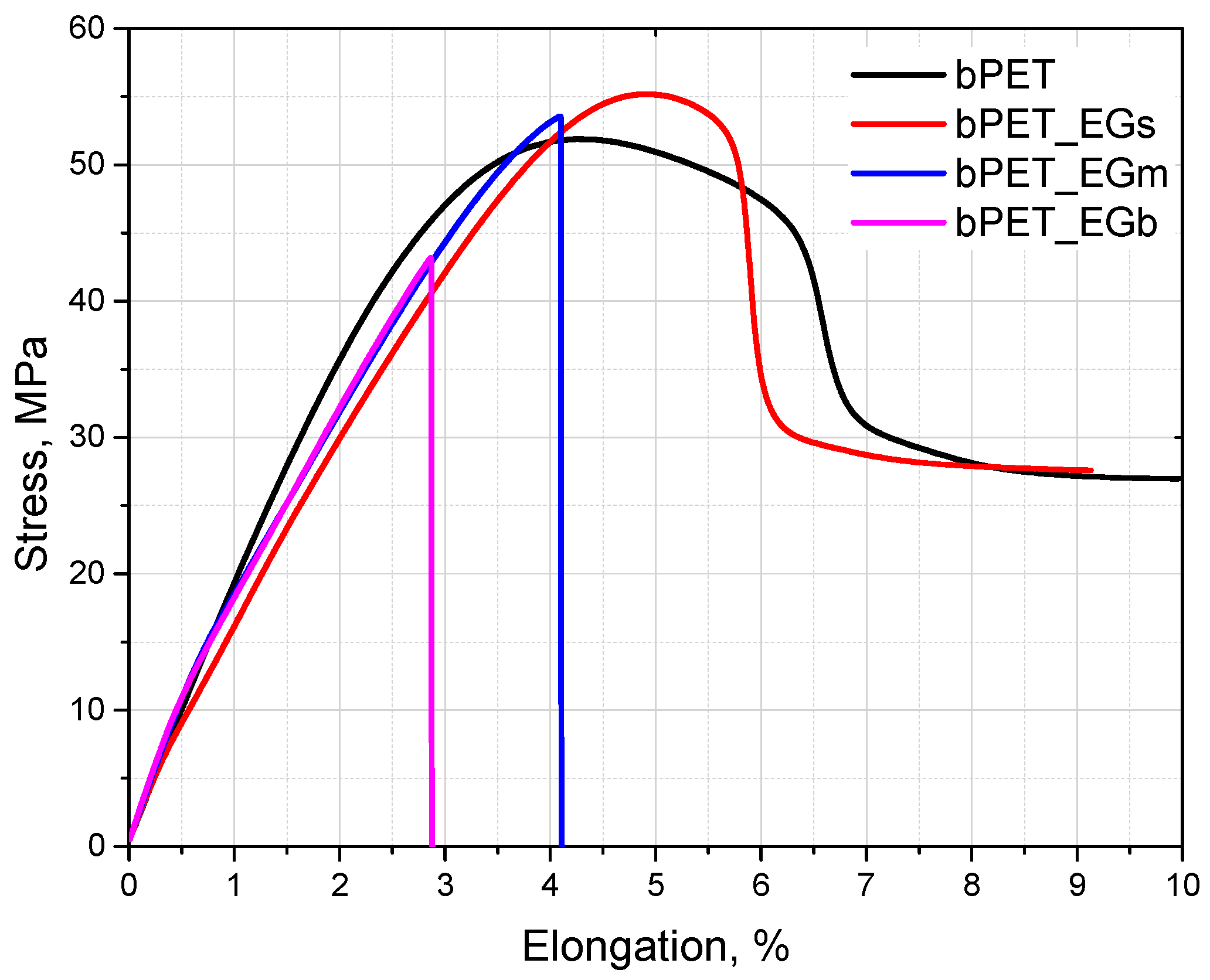

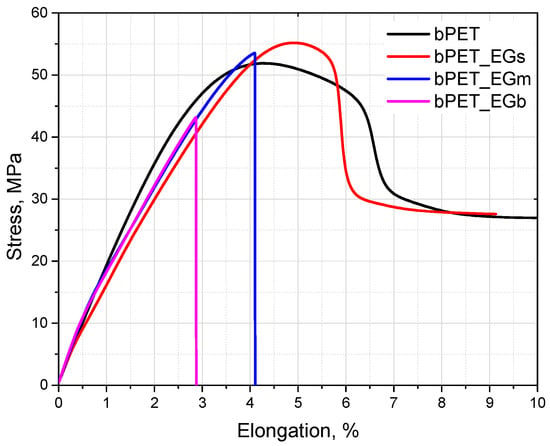

Figure 3, Figure 4 and Figure 5, as well as Table 2 and Table 3, present the results concerning the mechanical characteristics based on static tensile and three-point bending tests.

Figure 3.

Tensile strength curves of bioPET composites.

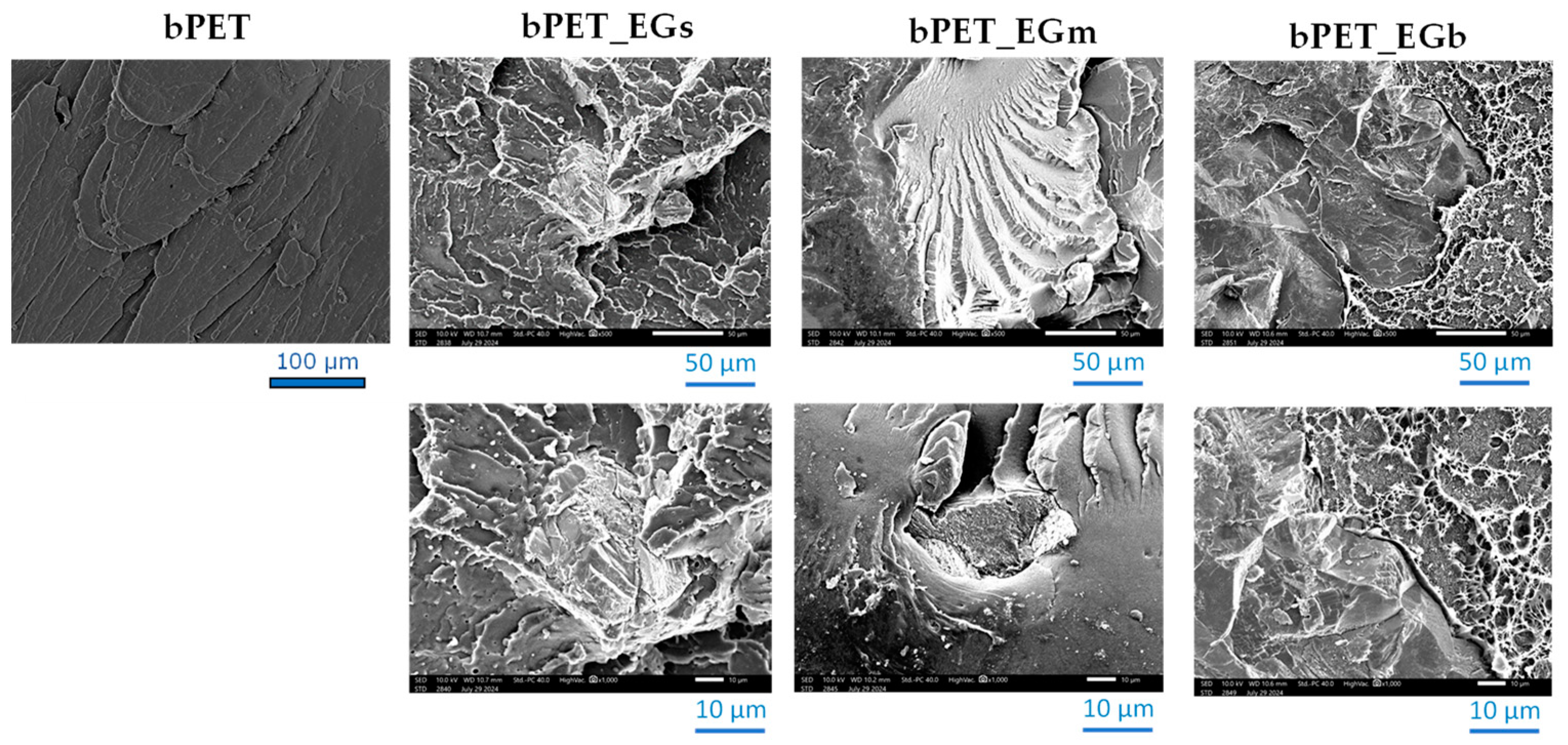

Figure 4.

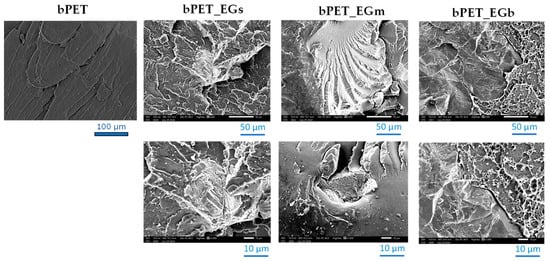

SEM images of the biocomposites.

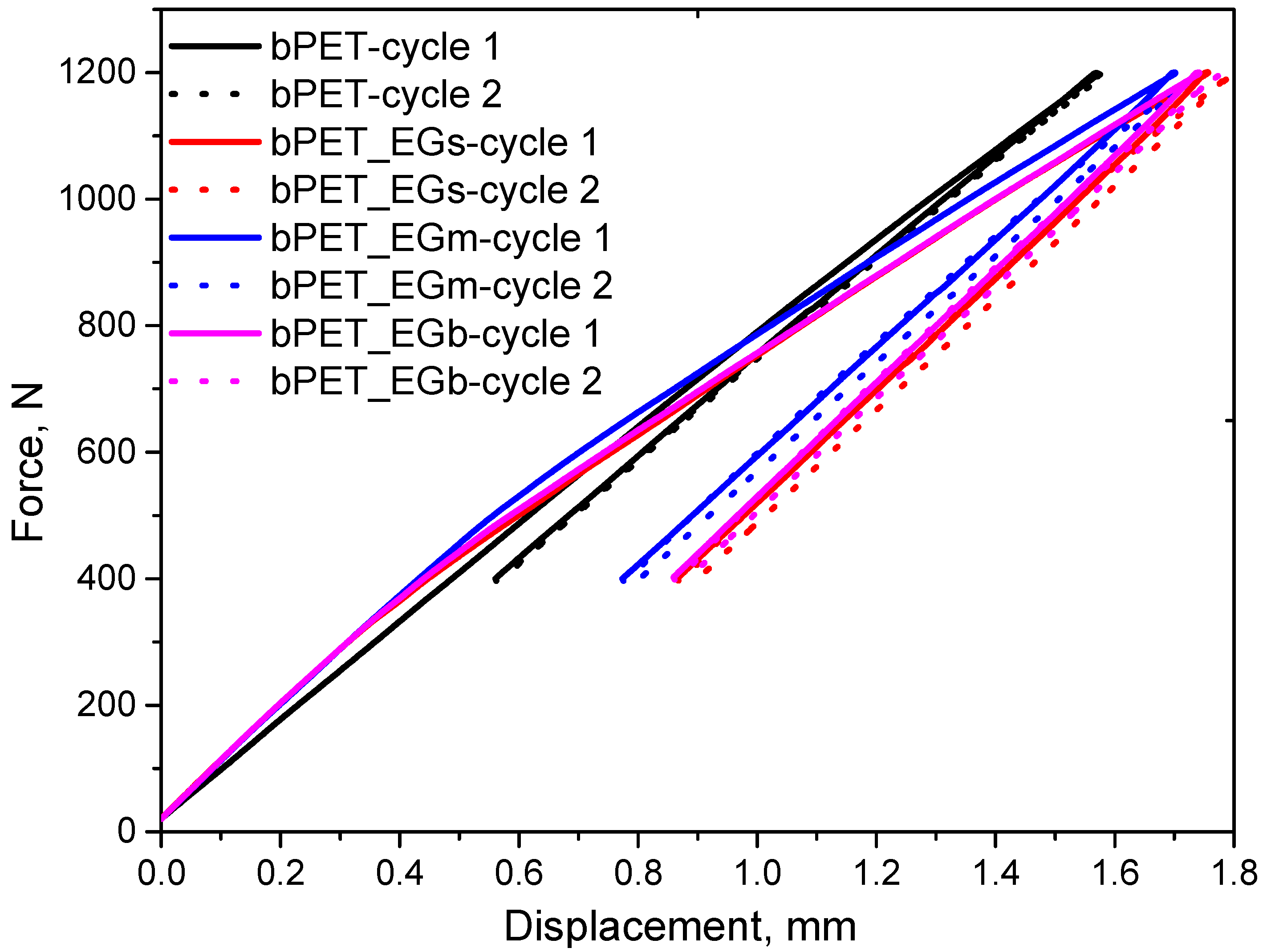

Figure 5.

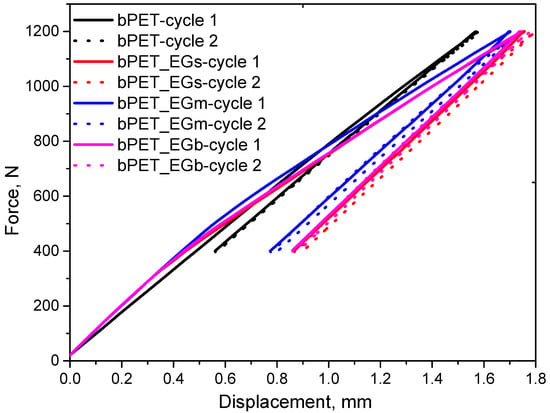

Mechanical hysteresis loops for cycle 1 (solid line) and cycle 2 (dashed line).

Table 2.

Tensile strength properties of biobased PET composites with the addition of organic fillers.

Table 3.

Bending strength properties of the biobased PET composites with the addition of organic fillers.

The addition of EG increased the stiffness of the bioPET-based composites regardless of the particle size of the waste filler. In the case of the smallest particles, an increase in tensile strength was observed. A clear dependence between the particle size and the strength of the biocomposites was observed. Cree and Soleimani manufactured PLA composites via injection moulding with waste eggshell (63 μm and 32 μm) contents of 5, 10, and 20 wt.% [18]. The composite tensile strengths and flexural strengths were the best when the filler loadings were 5 wt.% and 10 wt.%, respectively, for both filler types. However, these values were lower than those of the unmodified material. Both the tensile modulus and flexural modulus increased with an increase in filler loading. The highest impact strength for the composites was obtained at a filler loading of 5 wt.% for both filler types and was slightly better for smaller particles sizes. In the case of the bPET modification in this work, a slight increase in strength from 52 to 55 MPa was obtained after adding 10% of the smallest filler fraction. This is a promising result because of the possibility of reducing the polymer matrix while maintaining appropriate mechanical properties. The modification of bPET with the use of EGs increased the stiffness by about 35%, but large flat particles, as shown in Figure 3, reduced the strength to about 30%. This is probably related to the lower adhesion of large flat shell waste due to areas with lower wettability. Some large particles could have been arranged perpendicularly to the sample axis during the injection process, which would have significantly increased the stiffness but weakened the strength of the biocomposite as the tensile forces would act transversely to the surface of large flat shells. SEM images of the biocomposites modified with EG are shown in Figure 4.

SEM images show that fine particles are better embedded within the polymer matrix, while those with greater grain sizes often fall off, creating characteristic areas of reflections. In the third picture from the left at the top of the top row, the morphological structure of an eggshell particle is shown, in the form of characteristic smaller and spreading microlayers with a width of approximately 40 μm.

The analysis of the three-point bending test results revealed that large-sized biofiller particles were arranged along the sample axis. This caused an increase in the bending stress compared to the use of small particles by 12%, while reducing the elastic modulus by 38%, below the value of the bending modulus of the unmodified bioPET. This result confirms the very weak adhesion between large eggshell particles and the polymer matrix, and it may be necessary to use appropriate compatibilizers in future studies.

Based on the juxtaposition of the first and second hysteresis loops, it was found that the addition of EG increased the stiffness of the biocomposites in the first parts of the hysteresis loop (for smaller deformations), when the interactions between the fibre and the matrix were more active. Later, the loop slope decreased, indicating that the processes related to the matrix deformation began to dominate. The largest deformations in the first parts of the hysteresis loop correspond to the biocomposites with smaller particles.

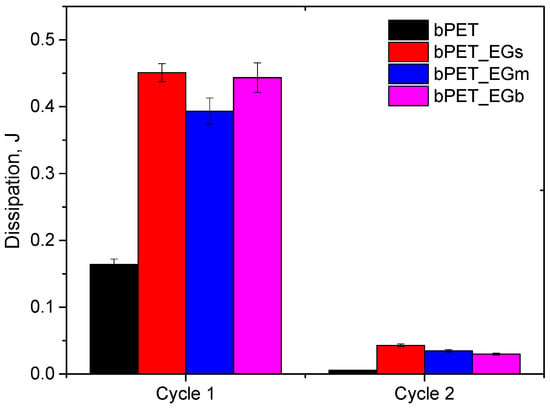

It was found that the addition of EG waste increased the mechanical energy dissipation in the first hysteresis loop almost by a factor of three (Figure 6). With the progressive process of the low-cycle fatigue of the tested samples, the dissipation values decreased almost tenfold after 20 cycles. In both the first and the twentieth cycles, the highest dissipation values were achieved by the composite with the smallest EG addition. This indicates better adhesion of the smallest EG particles to the polymer matrix compared to the other EG fractions.

Figure 6.

Comparison of mechanical energy dissipation values for cycles 1 and 2.

Neat bioPET exhibits moderate hydrophobicity and a low wetting angle, resulting in a lower surface energy and suggesting its classification as a non-polar liquid. All the samples modified with waste particles exhibited an increased total surface free energy in comparison to neat bioPET. The addition of waste particles decreased the wetting angle and led to the lower adhesion of the particles to the structure, as confirmed by bending strength tests (Table 4).

Table 4.

Contact angle and total surface free energy (the Owens–Wendt method).

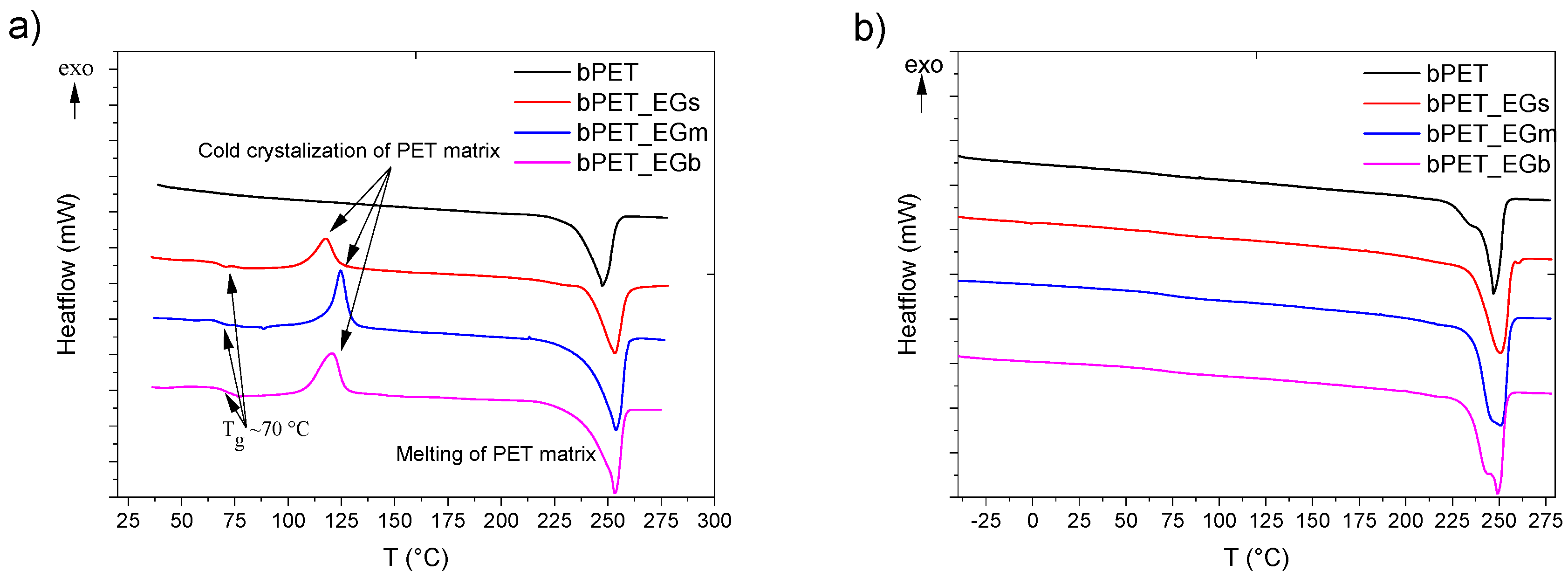

2.3. DSC Analysis of Developed Composites

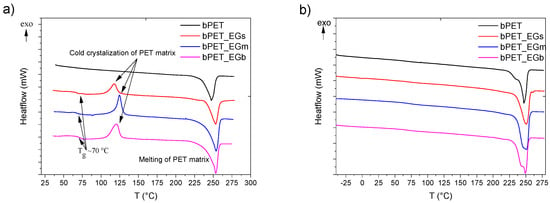

The influence of EG on the bPET polymer matrix behaviour was assessed by looking at the thermal properties of the composites. Differential Scanning Calorimetry (DSC) was conducted through a series of heating and cooling cycles: initial heating, cooling, and then a second round of both. The DSC curves from the first and second heating cycles are shown in Figure 7. The glass transition temperature (Tg) of the bPET matrix, observed as a step change in heat flow around 70 °C, was unaffected by the addition of EG fillers. However, EG particles had a notable impact on the crystallization behaviour of the bPET polymer. They inhibited the crystallization of PET, leaving the matrix in an amorphous state below Tg. During the gradual heating process of the bPET composites, the increased mobility of the polymer chains facilitated cold crystallization, indicated by an exothermic peak between 100 °C and 130 °C. Additionally, a melting peak of the bPET polymer matrix was observed at around 240 °C. In the second heating cycle, only the Tg step transition and melting endothermic peak were visible. Moreover, the presence of EG particles affected the overall crystallinity of the bPET matrix, which may, in turn, have influenced the mechanical properties of the composites.

Figure 7.

DSC graphs of composite samples: (a) first heating cycle and (b) second heating cycle.

3. Materials and Methods

3.1. Materials

BioPET, under the trade name NP002, was purchased from SK Chemicals (Seongnam-si, Republic of Korea). The polymer is a polyethylene terephthalate enriched with glycol (PETG) and 15% of it comprises bio-components derived from plants. A compatibilizer, Scona TPPL 5112P, in the amount of 3 wt.%., was used to produce samples.

Chicken eggshells came from waste containers from a number of restaurants in Kraków (Poland). Fresh waster was used to wash the collected EG to eliminate various impurities, such as the thin membrane. For surface treatment, EG particles were soaked separately in 10 wt.% NaOH solution for 45 min at room temperature and stirred carefully. Sodium hydroxide treatment strengthens the matrix-reinforcement interfacial bond, thus improving the mechanical quality of the material. Next, different particle fractions were separated using a sieve. They were rinsed with distilled water and dried at 110 °C in an oven until weight stabilization. In the next stage, they were boiled for 30 min. The dried shells were then ground in a disc mill (FRITSCH, PULVERSIETTE 13, Idar-Oberstein, Germany). Subsequently, the particle size was analyzed using a vibration shaker (FRITSCH, analysette 3) and four fractions were separated: 1. particles larger than 3 mm—these particles were rejected; 2. particles between 1.60 and 3 mm—large particles; 3. particles between 1.60 and 1 mm—medium particles; 4. particles between 1 mm and 200 μm—small particles.

3.2. Testing Methods

An Anton–Paar PSA 1190LD laser was used as a particle size analyzer. The wet method-based test involved distilled water as a dispersant. An average of four individual measurements per material was calculated using the particle analysis software Kalliope Professional version 2.1.

An optical microscope VHX 5000 by Keyence (Osaka, Japan) was used to analyze images of organic waste particles at 50×, 100×, and 200× magnifications. A morphological analysis of composites was carried out using a scanning electron microscope (SEM) JEOL JSM-5510LV (Tokyo, Japan) at 10 kV. Before SEM observations, a thin gold layer was added to samples under vacuum conditions using an auto-vacuum coater made by Cressington (Watford, UK) to prevent electrical charge accumulation.

A 10 kN testing machine AGS-X by Shimadzu (Kyoto, Japan) was employed for static tensile tests and low-cycle dynamic tests. In line with PN-EN ISO 527-1 [19], the tensile strength test was conducted at a cross-head speed of 10 mm/min. In the dynamic test, deformation was loaded cyclically in the range 400–1200 N at speed of 5 mm/min. A universal testing machine, MTS Criterion 43 (Eden Prairie, MI, USA), equipped with a piece of dedicated software, MTS TestSuites 1.0, was used to determine flexural properties following the PN-EN ISO 178 [20] norm at a cross-head speed of 10 mm/min. A Charpy impact strength test was carried out with a Zwick/Roell testing machine (Ulm, Germany) at an impact energy of 5 J for unnotched samples obeying the PN-EN ISO 179-1 norm [21].

Contact angle and interfacial free energy were determined on the composite surface by means of a See System goniometer produced by Advex Instruments (Brno, Czech Republic) using water and diiodomethane.

A Mettler Toledo DSC 823e was used for differential scanning calorimetry (DSC). The tested samples weighed about 7 mg; aluminium crucibles with pins were used for the test. The sample was heated from 30 °C to 280 °C (10 °C/min), cooled from 180 °C to −50 °C (10 °C/min), and heated back to 280 °C (10 °C/min). The second heating was used to calculate the glass transition temperature.

4. Conclusions

Composites based on a biopolymer matrix and a waste filler in the form of eggshells were successfully obtained. The addition of waste particles reduced the wetting angle and increased the total surface energy of the biocomposites in comparison to the reference material. The waste additive resulted in lower adhesion of the waste particles to the polymer matrix, as confirmed by mechanical tests. The filler’s particle size had an impact on the mechanical strength of the biocomposites. The smallest fraction of eggshells was found to be the most advantageous modifier of the polymer matrix.

Author Contributions

Conceptualization, S.K. and K.R.-Ż.; methodology, S.K. and K.R.-Ż.; formal analysis, S.K.; investigation, S.K. and K.R.-Ż.; data curation, S.K. and K.R.-Ż. writing—original draft preparation, M.K.; writing—review and editing, M.K. and S.K.; supervision, M.K. and S.K.; project administration, S.K.; funding acquisition, S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Center for Research and Development (NCBiR), grant number mERA.NET3/2021/79/EcoMat/2022, “Durable bio-based polymer composites reinforced with natural waste fillers with antibacterial properties”.

Data Availability Statement

All data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- O’Halloran, A. The Normative Role of the Circular Plastics Alliance in the EU’s Transition towards a European Circular Economy for Plastics. In Circular Economy and Sustainability; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Owuamanam, S.; Cree, D. Progress of bio-calcium carbonate waste eggshell and seashell fillers in polymer composites: A review. J. Compos. Sci. 2020, 4, 70. [Google Scholar] [CrossRef]

- Hassen, A.A.; Dizbay-Onat, M.; Bansal, D.; Bayush, T.; Vaidya, U. Utilization of chicken Eggshell Waste as a Bio-Filler for thermoplastic Polymers: Thermal and Mechanical characterization of Polypropylene Filled With naturally derived CaCO3. Polym. Polym. Compos. 2015, 23, 653–662. [Google Scholar] [CrossRef]

- Farm, Y.Y.; Mohammad Sappa, A.A.A.; Mustafa, Z.; Muzammil, W.K.; Ismail, M.A.; Amaludin, N.A.; Kiring, A. Mechanical properties of eggshells powder reinforced recycled high-density polyethylene. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1217, 012003. [Google Scholar] [CrossRef]

- Sunardi, S.; Ariawan, D.; Surojo, E.; Prabowo, A.R.; Akbar, H.I.; Cao, B.; Carvalho, H. Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material. J. Mech. Behav. Mater. 2023, 32, 20220269. [Google Scholar] [CrossRef]

- Jasim, S.H.; Alhassan, W.A.R.; Almalki, Z.T. Egg Shell Powder Reinforced Polypropylene (PP)Composite: Effect of Mechanical and Heat Capacity. Al Qadisiyah J. Pure Sci. 2020, 25, 16–27. [Google Scholar] [CrossRef]

- Chandrappa, D.R.K.; Kamath, M.S.S. The Egg shell as a filler in composite materials—A review. J. Mech. Energy Eng. 2021, 4, 335–340. [Google Scholar] [CrossRef]

- Obianuju, O.H. Mechanical Properties, Morphology and Elemental Composition of Composites Produced from Thermoplastic Polymers Filled with Egg Shell. Int. Res. J. Pure Appl. Chem. 2021, 22, 59–78. [Google Scholar] [CrossRef]

- Iloabachie, I.C.C.; Ajina, O.T.; Chime, A.C. Effect of Egg Shell Composition on the Flexural and Hardness Properties of Epoxy Resin/Egg Shell Particles Composite. J. Eng. Res. Rep. 2021, 20, 1–7. [Google Scholar] [CrossRef]

- Ajao, K.; Shuaib-Babata, Y.L.; Adegboola, J.O.; Ambali, I.O.; Obanise, T.E. Characterization and Evaluation of Mahogany (Khaya ivorensis) Dust-Egg Shell-Epoxy Composites. Acta Tech. Corviniensis-Bull. Eng. 2021, 14, 19–23. [Google Scholar]

- Skórczewska, K.; Lewandowski, K.; Szewczykowski, P.; Wilczewski, S.; Szulc, J.; Stopa, P.; Nowakowska, P. Waste Eggshells as a Natural Filler for the Poly(Vinyl Chloride) Composites. Polymers 2022, 14, 4372. [Google Scholar] [CrossRef] [PubMed]

- Vieira, K.P.; Reichert, A.A.; Cholant, G.M.; Marin, D.; Beatrice, C.A.G.; de Oliveira, A.D. Sustainable composites of eco-friendly polyethylene reinforced with eggshells and bio-calcium carbonate. Polimeros 2023, 33, e20230026. [Google Scholar] [CrossRef]

- Leszczyńska, M.; Ryszkowska, J.; Szczepkowski, L.; Kurańska, M.; Prociak, A.; Leszczyński, M.K.; Gloc, M.; Antos-Bielska, M.; Mizera, K. Cooperative effect of rapeseed oil-based polyol and egg shells on the structure and properties of rigid polyurethane foams. Polym. Test. 2020, 90, 106696. [Google Scholar] [CrossRef]

- Hanumantharaju, H.G.; Prashanth, K.P.; Ramu, B.; Venkatesh, N.; Chethan, G.R. 3D Printing of Biopolymer Composites Investigation on Effect of Egg Shell Particles on Polylactic Acid Matrix. Biointerface Res. Appl. Chem. 2023, 13, 251. [Google Scholar] [CrossRef]

- Homavand, A.; Cree, D.E.; Wilson, L.D. Polylactic Acid Composites Reinforced with Eggshell/CaCO3 Filler Particles: A Review. Waste 2024, 2, 169–185. [Google Scholar] [CrossRef]

- Jorda, M.; Montava-Jorda, S.; Balart, R.; Lascano, D.; Montanes, N.; Quiles-Carrillo, L. Functionalization of partially bio-based poly(ethylene terephthalate) by blending with fully bio-based poly(amide) 10, 10 and a glycidyl methacrylate-based compatibilizer. Polymers 2019, 11, 1331. [Google Scholar] [CrossRef] [PubMed]

- Rusin-Żurek, K.; Kuciel, S.; Kurańska, M. The effect of funcionalized ethylene-n-octene copolymer on mechanical properties of bioPET with organic waste fillers. Polimery 2023, 68, 330–336. [Google Scholar] [CrossRef]

- Cree, D.; Soleimani, M. Bio-Based White Eggshell as a Value-Added Filler in Poly(Lactic Acid) Composites. J. Compos. Sci. 2023, 7, 278. [Google Scholar] [CrossRef]

- ISO 527-1; Plastics—Determination of Tensile Properties. ISO: Geneva, Switzerland, 2019.

- ISO 178; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- ISO 179; Plastics—Determination of Charpy Impact Properties. ISO: Geneva, Switzerland, 2023.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).