Abstract

Plastics make up a significant proportion of the stream of the European Waste of Electric and Electronic Equipment (WEEE), yet the use of recycled plastic materials is very low in new manufactured products. A description of the WEEE waste stream in Europe is given, with a focus on the plastic materials commonly found in WEEE that include four principal polymers: polypropylene (PP), polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS) and polystyrene (PS). Furthermore, the legislative aspects related to WEEE and plastics recycling in Europe are complex, and numerous norms have been dictated by the European Commission. These norms are crucial to the sector of polymer recycling and production in Europe. Moreover, an overview of the entire treatment chain is presented. More specifically, each step of a typical recycling chain is introduced, with a focus on the sorting of plastics and the separation of polymers. Lastly, the influence of contaminants in the plastic fraction is discussed, both in terms of polymer particles and unwanted additives. By showing the impact of the purity rate on the mechanical properties of recycled plastics, the consequences of inadequate end-of-life treatment for WEEE-plastics is highlighted, hence linking the quality of recycled plastics to the separation step and the re-compounding of recycled granulates.

1. Introduction and Context

Electric and electronic equipment (EEE) have started to become more and more complex. Indeed, their components often incorporate critical materials and are assembled in a very intricate way. It is estimated that more than 75% of the elements of the periodic table are used in EEEs [1].

As economic motivation seems to be insufficient to develop large scale recycling circuits [2,3], legislation plays a major role in the development of the WEEE recycling industry in Europe [4]. Even though norms and targets vary depending on the country, the EU still gives a broad direction to be followed by the member states [5]. These guidelines set goals for recycling as well as constraints on usable substances. Indeed, the European Commission has set recycling objectives for the member states to attain: between 55% and 80%, depending on the waste category [6].

In the last two decades, the production of plastics worldwide has more than doubled: from 200 Mt in 2002 to more than 400 Mt in 2022 [7], but because of the complexity of the waste of electric and electronic equipment (WEEE), and the presence of rare and precious materials, plastics are often put aside while other more economically viable materials, such as non-ferrous and precious metals, are recycled. As a result, in Europe, new EEEs only integrate 3% of recycled plastics [7,8].

In an attempt to explain this low re-integration rate, this review will address mechanical recycling in the European Union, and will be centred on plastics from WEEE (WEEE-p).

Chemical recycling is developing at a fast pace, but will not be discussed in this review. Chemical recycling, as opposed to mechanical recycling, is a term used to gather all techniques that depolymerise the macromolecules composing a monomer, effectively “breaking” the chemical bonds. Ma et al., (2016) [9] wrote a review on the theme of the chemical recycling of plastics from WEEE containing flame retardants, and Ragaert et al., (2017) [10] extensively developed chemical recycling (for all polymers). Their conclusions highlight the potential of chemical treatment for plastics recycling, and its development could be the key to tackling the hazardous substance concerns and increasing material purity. However, chemical recycling is not yet ready to be used industrially for several main polymer types comprising the WEEE stream [11,12]. For instance, in the case of pyrolysis, PVC, PET and PU should be removed beforehand from the waste stream. For catalytic depolymerisation through hydrocracking, the suitable polymer types are hierarchised as follows: PIP > PS > PET > PP ≈ PBD > LDPE > HDPE, and PVC is not suitable [11].

Section 2 will present methods for the characterisation of the WEEE-p stream. The ways to obtain the share of plastic per equipment as well as their nature will be presented and discussed here. Printed circuit boards (PCBs) are still part of the waste stream of WEEE, but their recovery is not linked to polymers recycling since they are not composed of the same materials. They will be mentioned in Section 4, but the overall scope of the review will be focused on plastics.

This review also aims to present the organisational and legal aspects of WEEE-p circularity to researchers who initially sought insight into the material and technical aspects of the problem. To this end, Section 3 will be dedicated to the organisation of the European recycling chains of WEEE, to the terms used to legally define WEEE, and to the norms that one must follow to use recycled plastics in an industrial context.

Section 4 will introduce the different techniques currently used in the industry to mechanically sort plastics from the waste stream, and from each other. We will give details on the target polymers for each of them and expose their limitations.

The case of informal recycling will not be developed in this review, as the literature on that matter often refers to the output material as “undocumented”. Moreover, different considerations about health and environment must be taken into account when studying informal recycling [13]. Indeed, the plastic fraction may contain hazardous substances, and the loss of material during the end-of-life stage of an EEE is a major issue, as they may release said hazardous substances into the environment [14,15,16]. The issue of contaminants within the waste stream and in recycled plastics will be developed in Section 5.

2. Assessment of the WEEE-Plastic Stream

The separation between WEEE and municipal waste began around 1990 [17]. As some technologies become obsolete (CRT monitors for instance) new technologies make their appearance on the market, and a few years later, in WEEE streams. Reports currently show that small electrical vehicles such as bikes, scooters and hoverboards are starting to appear as a new end-of-life WEEE equipment type [18].

The analysis of the overall WEEE stream and its evolution has been studied and recently summed up in a review [19]. An exhaustive and exact description of the flow is not possible as a significant part of WEEE does not end up in the monitored end-of-life flows: for instance, only 17.1% of screens are recycled within the official scheme, and the rest are considered undocumented. As a result, more and more attention is given to complementary flows and the exact whereabouts of missing WEEEs [20].

As for the overall WEEE stream, the exact composition of the WEEE-plastic (WEEE-p) stream is hard to assess. First, we will review studies from academic, peer-reviewed papers before considering private company reports available in free access.

2.1. Peer-Reviewed Published Results

Even though reliable data on informal recycling are difficult to obtain, estimations of the proportion of waste collected in formal and informal recycling are available. Table 1 shows an estimate for two different waste streams. In this case, it would seem that a significant number of the waste screens goes through informal recycling, but it looks like plastics are not generally the main focus of this type of recycling [21,22,23].

Table 1.

Collection rates in formal and informal schemes for WEEE-screens [21,22] and WEEE-p [23].

In the case of recycling within official schemes, several methods have historically been used to assess the composition of the WEEE waste stream.

Martinho et al. (2012) studied the composition of WEEE-p by equipment [24]. A first analysis underlines the significant variation of the proportion of plastics from one piece of equipment to another. For instance, around 50 wt% of the mass of small WEEE are plastics while large cooling appliances only include around 10 wt% of plastics. This is of interest as the share of small WEEE is increasing within the WEEE stream [24].

A breakdown of the composition of the WEEE-p by type of equipment is also provided. The main polymer types significantly vary depending on the equipment. Cooling appliances, CRT and televisions for instance mainly include polystyrene (PS)/high impact polystyrene (HIPS), 76% and 51%, while other studied equipment use a high amount of ABS (CRT monitors, printing equipment, CPUs, and small WEEEs). Other common polymer types are PP, PC and PC/ABS blends.

Stenvall et al., (2013) also studied the output of a sorting plant and recorded the composition and contamination level of the obtained plastics [25]. They found high proportion of styrenics as PS and HIPS account for 42 wt% and ABS for 38 wt% while PP represents 10 wt%. They also reported considerable deviation of 21.4%, 16.5% and 60.7% (respectively), underlining the important variation even in a single batch [25].

Other authors have focused on the sub-category of flat-panel display (FPD) screens. Table 2 (left) shows the materials flows (in weight) obtained after the dismantling of a flat panel display (FPD) screen [21]; but, studies also exist on the overall waste stream of WEEE, presented in Table 3 (right) [23].

Table 2.

(a) Composition of an FPD screen; (b) Distribution of plastic types in WEEE [21,23].

Another, more currently used approach consists of the manual disassembling and identification of the plastics, allowing for the precise characterisation of a specific piece of equipment’s composition. The only disadvantage of this method is that the batch sizes, age and origin of the studied waste are different, leading to difficult direct comparison. Some authors go even as far as to give a breakdown by components, like Tan et al. (2022) [26] in the case of washing machines.

Some authors [27,28,29,30], sometimes solely focus on a specific type of equipment [31,32,33,34,35]. These studies confirm the results of previously discussed work and allow for a deeper understanding of the breakdown of the plastic stream.

Alassali et al. (2020) [27] describe a work on end-of-life products from the small WEEE category. The authors tried to identify the age of the equipment collected in Hamburg, Germany in 2019. Even though for most of them (54%) the age of the equipment could not be found, the remaining items were identified as follow: 6.6% after 2011, 28% between 2002 and 2011, 7.6% between 1995 and 2001 and the remaining 3.8% were older than 1995. This indicates that, even though variations can be observed, the most common lifespan is from 10 to 15 years.

The disassembly and analysis (through Fourier Transform IR, FTIR, see Section 4) of keyboard parts revealed that ABS, HIPS and PS are the three main polymer types used in these pieces of equipment [29].

Various dismantled WEEE components have been studied with the same method (FTIR) and it was revealed that styrenic polymers (ABS, PS, HIPS), along with PA, PC and PET have been found in these piece of equipment (the exact proportions are not specified) [30].

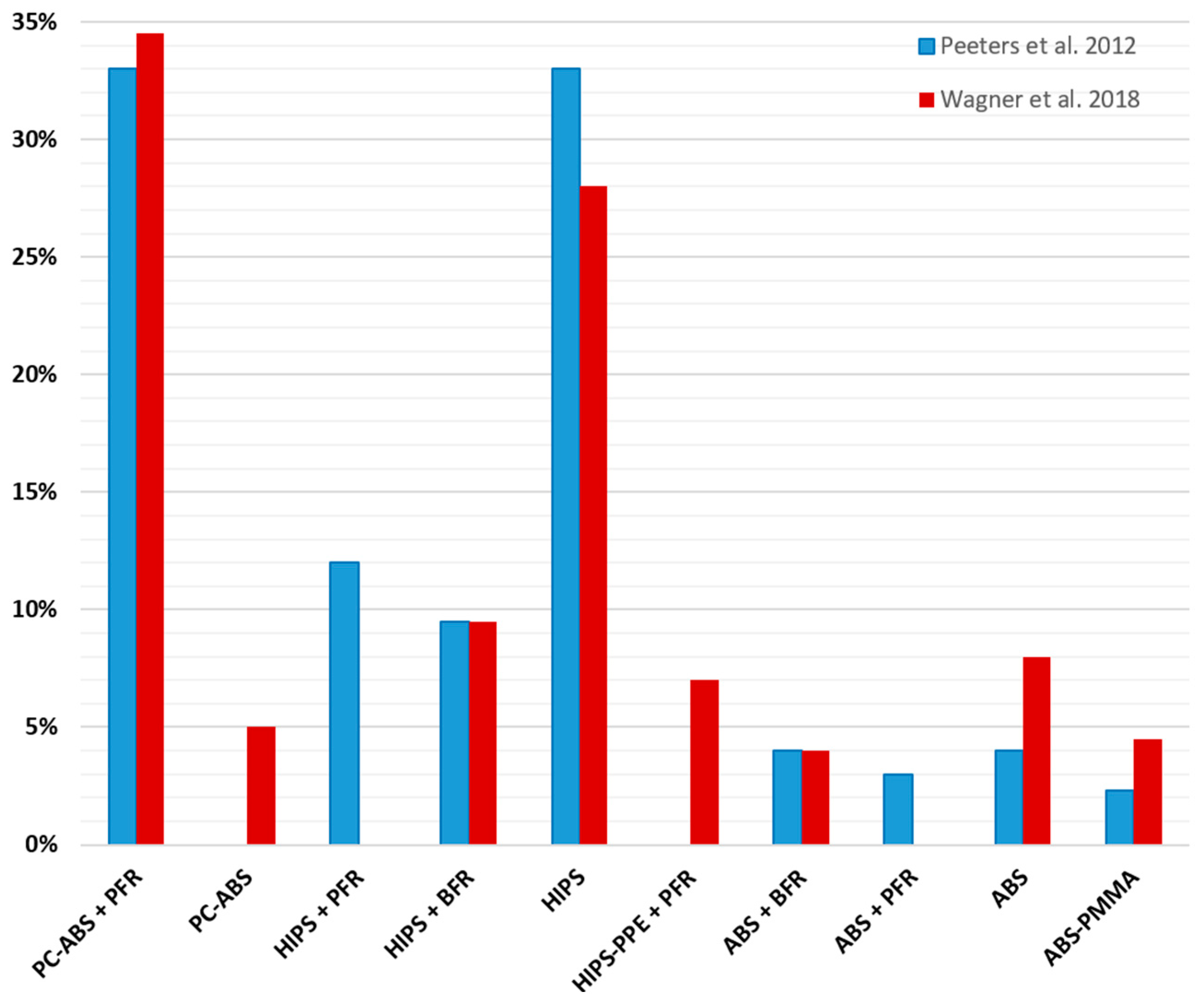

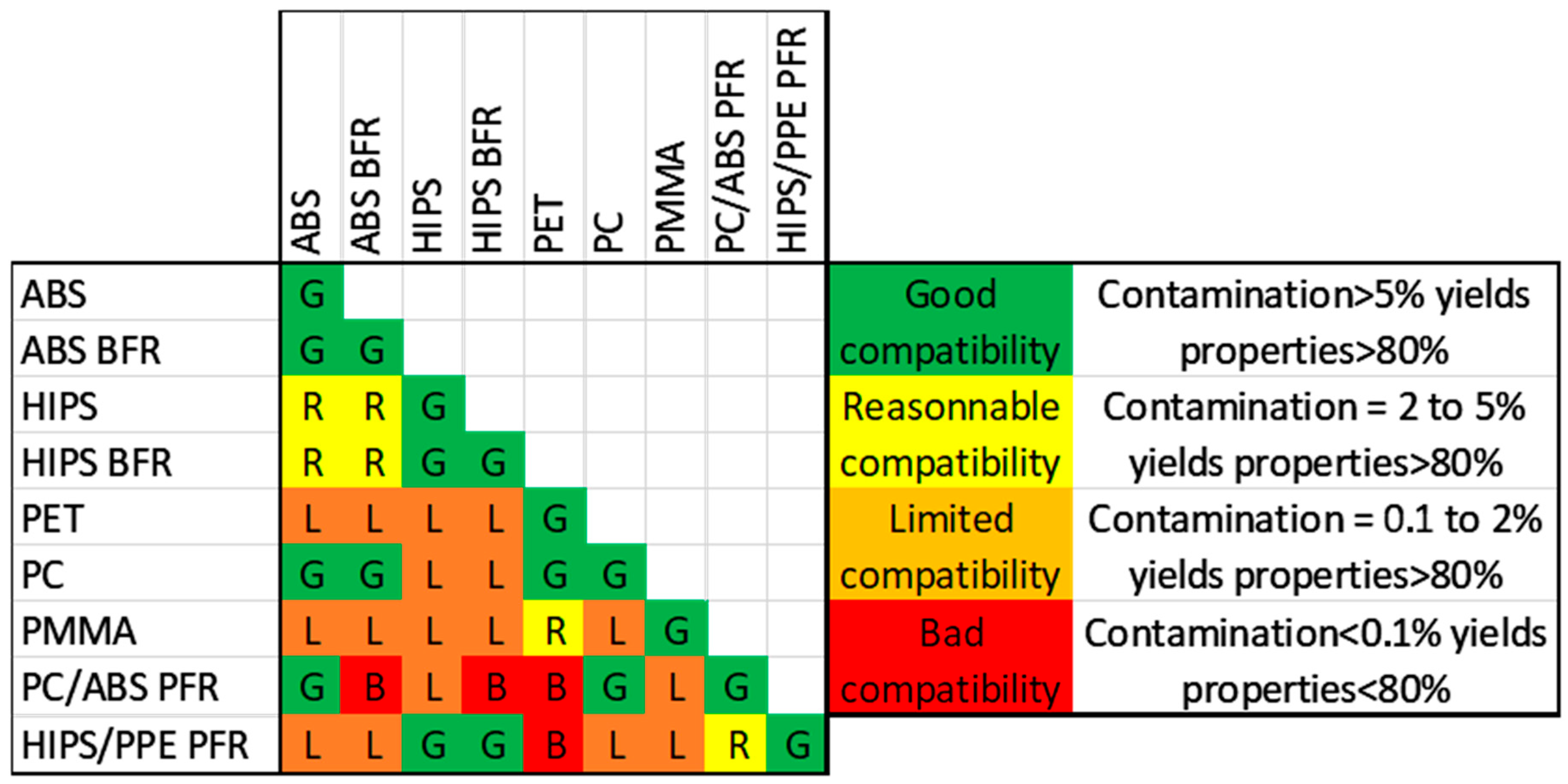

We mentioned in a previous paragraph that comparison between studies was difficult because of differences between the studied waste streams. Peeters et al. (2012) [33] and Wagner et al. (2018) [34] both investigated back covers of flat screens TVs within the same research group, with a 4-year time gap. This allowed for an interesting comparison of the evolution of end-of-life polymers. The study from 2012 was conducted on 100 objects and the study from 2018 was conducted on 2500 objects. The results for each study are reported in Figure 1.

Figure 1.

Distribution of polymer types in LCD screens back cover. Adapted from (Peeters et al., 2012; Wagner et al., 2018) [33,34].

HIPS and PC-ABS blends are very commonly used. Between both studies, we can note the apparition of HIPS/PPE and the recoil of HIPS at the expense of other polymers and blends. Moreover, HIPS with Phosphorus Flame Retardants (PFRs) disappeared and there is a small increase in plastics with no detected flame retardants (mainly PC/ABS, ABS/PMMA and ABS).

An other study based on different waste sub-categories was carried out [36], the results are given in Table 3 below.

Table 3.

Repartition of the main polymer types in sub-groups of equipment within the WEEE stream [36].

Table 3.

Repartition of the main polymer types in sub-groups of equipment within the WEEE stream [36].

| Equipment Type | Composition (Polymers) |

|---|---|

| ICT equipment | ABS (80%), PC/ABS (13%), HIPS, POM |

| Televisions | PS (63%), PC/ABS (32%) |

| Printers/faxes | ABS (80%), PC/ABS (13%), HIPS, POM |

| Toys | ABS (70%), HIPS (10%), PA (5%) |

| Computers | ABS (50%), PC/ABS (35%), HIPS (15%) |

| Monitors | PC/ABS (90%), ABS (5%), HIPS (5%) |

| Dishwashers | PS (8%), ABS (7%) |

| Small household appliances | PA (19%), ABS/SAN (17%), PC (10%), PBT |

| Temperature exchange equipment (cold) | PS (31%), ABS (26%) |

The most interesting part of this study is that overall, after the aggregation of data, the main types of polymers seem to be ABS (22%), PC/ABS (11%), PS/HIPS (10%), PP (9%) and PC (4%).

2.2. Independent Studies

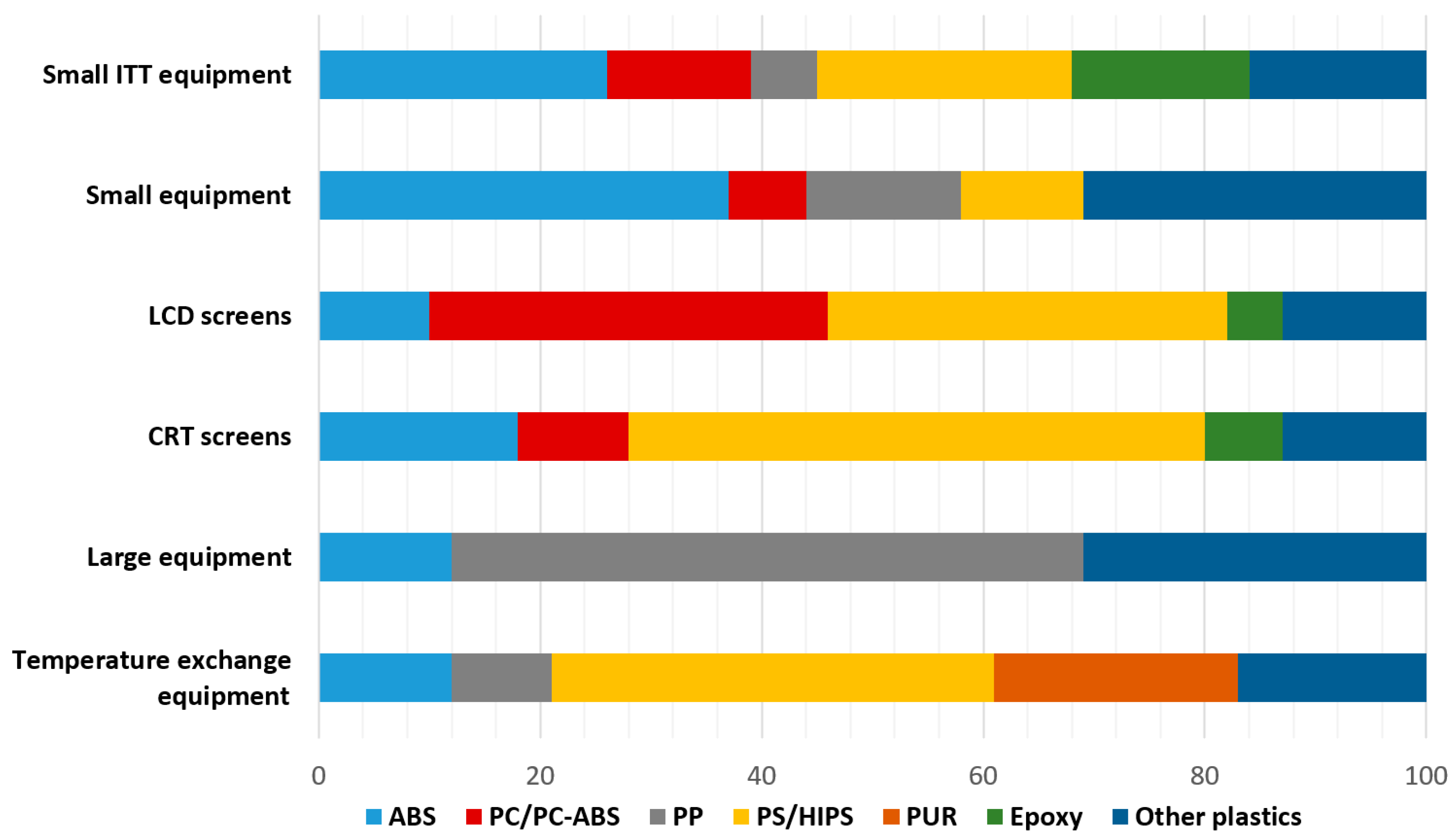

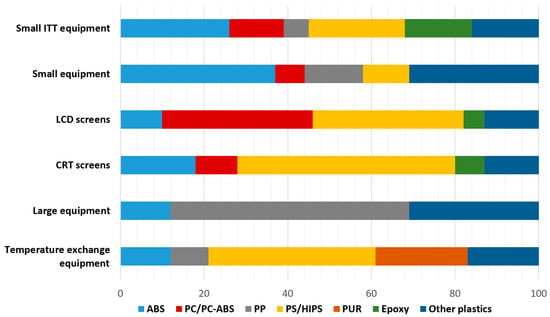

The most precise estimations of WEEE-p stream known by the authors are given in two private reports. First, a report on the impact of brominated flame retardants on WEEE-p recycling was published by the organisation Sofies in 2020, in a joint effort with ecosystem, a French WEEE producer’s responsibility organisation (PRO) [23]. This report offers a breakdown over six categories of WEEE, represented in Figure 2.

Figure 2.

Distribution of polymer types by WEEE category, adapted from Haarman et al. (2020) [23].

The percentage value under the equipment category name represents the weight fraction of plastic commonly found in such equipment. Within each bar, the share of each plastic is illustrated with colours. The data for Figure 2 was aggregated from more than 800 data points coming both from published data and field data from WEEE recycling plants. Though we do not have access to the exact calculation method to assemble them into a unique graphic, it is a very thorough investigation.

Moreover, a second independent report was published in 2020 by the PRO ecosystem to discuss the viability of chemical recycling as a route for WEEE (Parenty et al., 2020) [37] (details about European PROs can be found in Section 3). Here, a breakdown of the WEEE-p fraction and composition for five different categories of WEEE is given. These data comes from industrial recycling plants, ensuring a significative amount of WEEE for each category. The results mostly rejoin the ones given by the report published by Haarman et al. (2020) [23], but we must state that a direct comparison of the studies would be misleading, since the categories taken into account are not the same.

As we can see both in the peer reviewed literature and private reports, it is very challenging to give an exact breakdown of the plastic stream composition in WEEE. The proportion varies with legislation changes and the appearance of new equipment and disappearance of others. From one country to another, the proportion of equipment types varies, making in even more challenging to give a worldwide value that might end up giving a slanted viewpoint.

To sum up, even though exact values are hard to obtain, the main polymer types and their approximate share can be clearly identified. The Sofies report proposes a majority of PP (20%) closely followed by ABS and HIPS/PS (19% and 18% respectively). These three major polymers are followed by PC and PC/ABS blends of around 7% and finally accounting for around 0–2% of the flow each, PUR, PA, PMMA, and many others. These are very rough estimates and do not represent the exact reality of any recycling plants Other sources tend to consider the ABS and (HI)PS stream to be higher at around 30%. ABS is used for its impact toughness and is mainly found in IT equipment and screens, sometimes in a blend with PC. HIPS and PS are popular for all equipment except large household appliances. Finally, PP is found almost exclusively in large household appliances and equipment that heat up (i.e., kettle, irons, etc.). Out of these main polymer types, ABS and HIPS contain BFR more often than PP which leads to more balanced final outputs of recycled plastics more balanced between ABS, HIPS/PS and PP as evidenced by (Liu et al., 2022) in China [31]. Similar trends can be expected in Europe, where recycling is organised according to legislation mainly implemented by the EU.

3. Organisational and Legal Aspects of WEEE Recycling in Europe

3.1. Perimeter of the Recycling Chain

First of all, a definition of “waste” must be provided: it is defined by the Directive 2008/98/EC [38] as “any substance or object which the holder discards, intends to discard, or is required to discard”.

Therefore, in the case of an EEE, this definition divides its life cycle into two parts:

- The manufacturing and use phases

- The end-of-life phase, where the EEE becomes WEEE

Furthermore, directive 2002/96/EC [6] establishes a legal framework for waste treatment in Europe, by adopting the concept of extended producer responsibility (EPR), stating that the manufacturer of the EEE is responsible for it until the end-of-life treatment of the product. According to this directive, the status of waste is therefore reversible, given that the waste undergoes a process or series of processes which aim to recover its value.

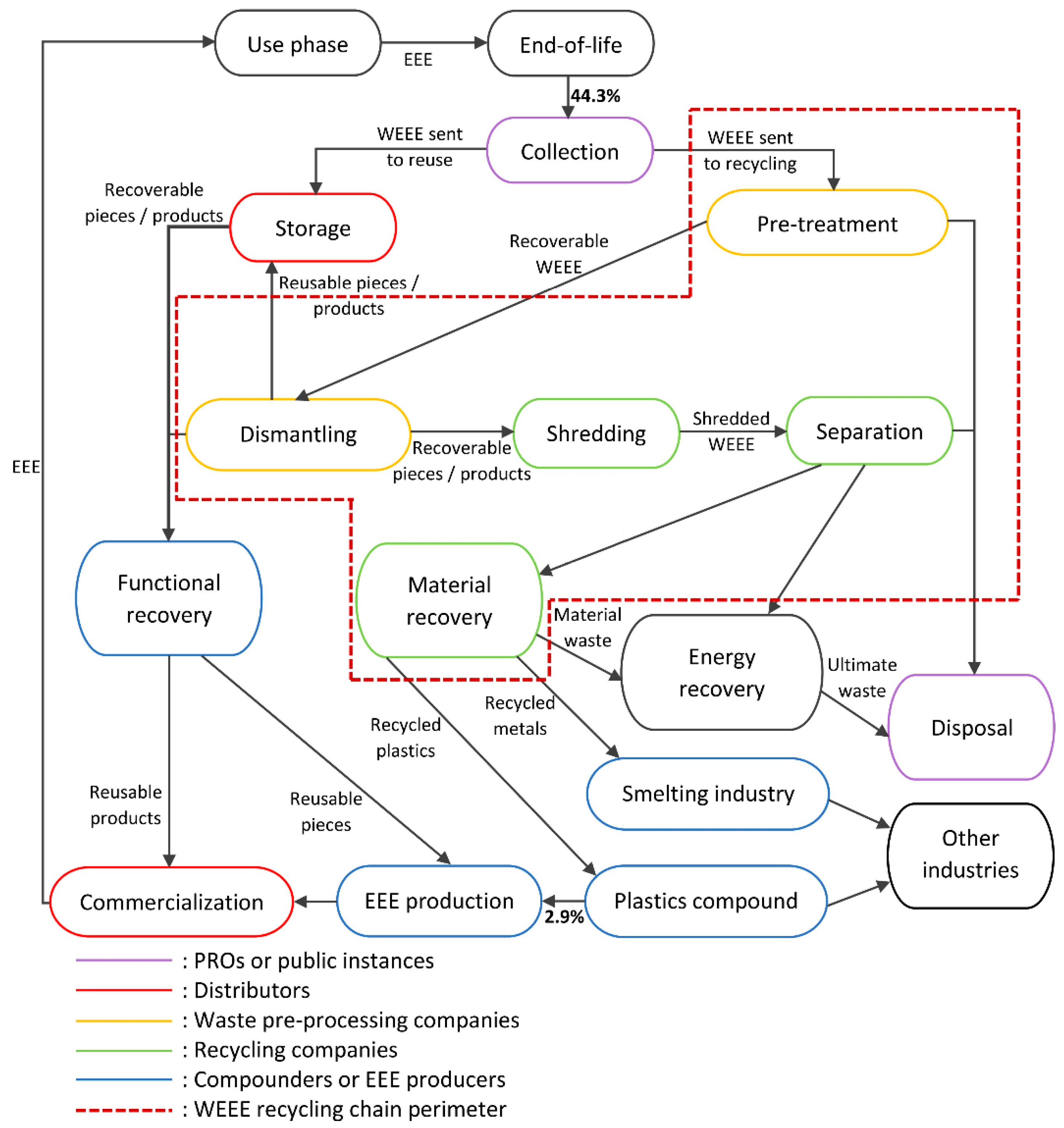

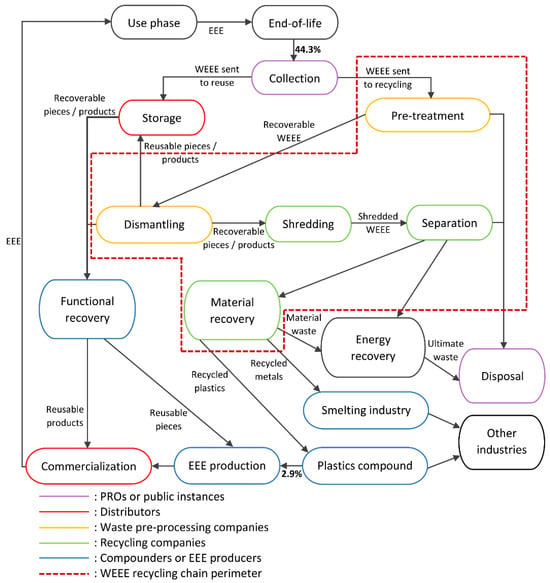

Figure 3 shows a summary of the different steps of the end of life (EoL) of an EEE, along with the material inputs and outputs of each step, and when the data are available, the associated proportion.

Figure 3.

Illustration of the life cycle of an EEE. Data from ADEME [39] and Plastics Europe [7].

The recycling chain includes all stakeholders of the waste treatment field, among which are the following [6,40]:

- The waste preparation organisms (their identity can change depending on the country), who are in charge of the gathering and pre-sorting of the waste.

- The recycling companies, which oversee the shredding and sorting of the waste, the regeneration of materials, and the compounding, to create recycled plastics materials (RPM).

- The compounders, who create plastic granules with the previously mentioned RPM. This step consists of mixing the regenerated materials with additional substances in order to give specific properties to a recycled plastic. The compounder and recycling company are often the same entity.

- The producer’s responsibility organisations (PROs):, whose functioning depends on the specific laws on each country, but generally speaking, they work alongside the governments and take responsibility for the collection of waste, and the coordination of all other stakeholders involved in the waste treatment chain, as well as overseeing the treatment of WEEE. Note that PROs are also called compliance schemes.

3.2. The End-of-Life Options for Waste Treatment

Even though the process of recycling is the focus of this review, the other end-of-life treatment options for WEEE are discussed here. It is important to keep in mind that recycling is not the most environmentally efficient method for waste treatment.

The different treatment options can be classified into four categories:

- functional recovery: total or partial

- material recovery

- energy recovery

- disposal: incineration without energy recovery, or landfill

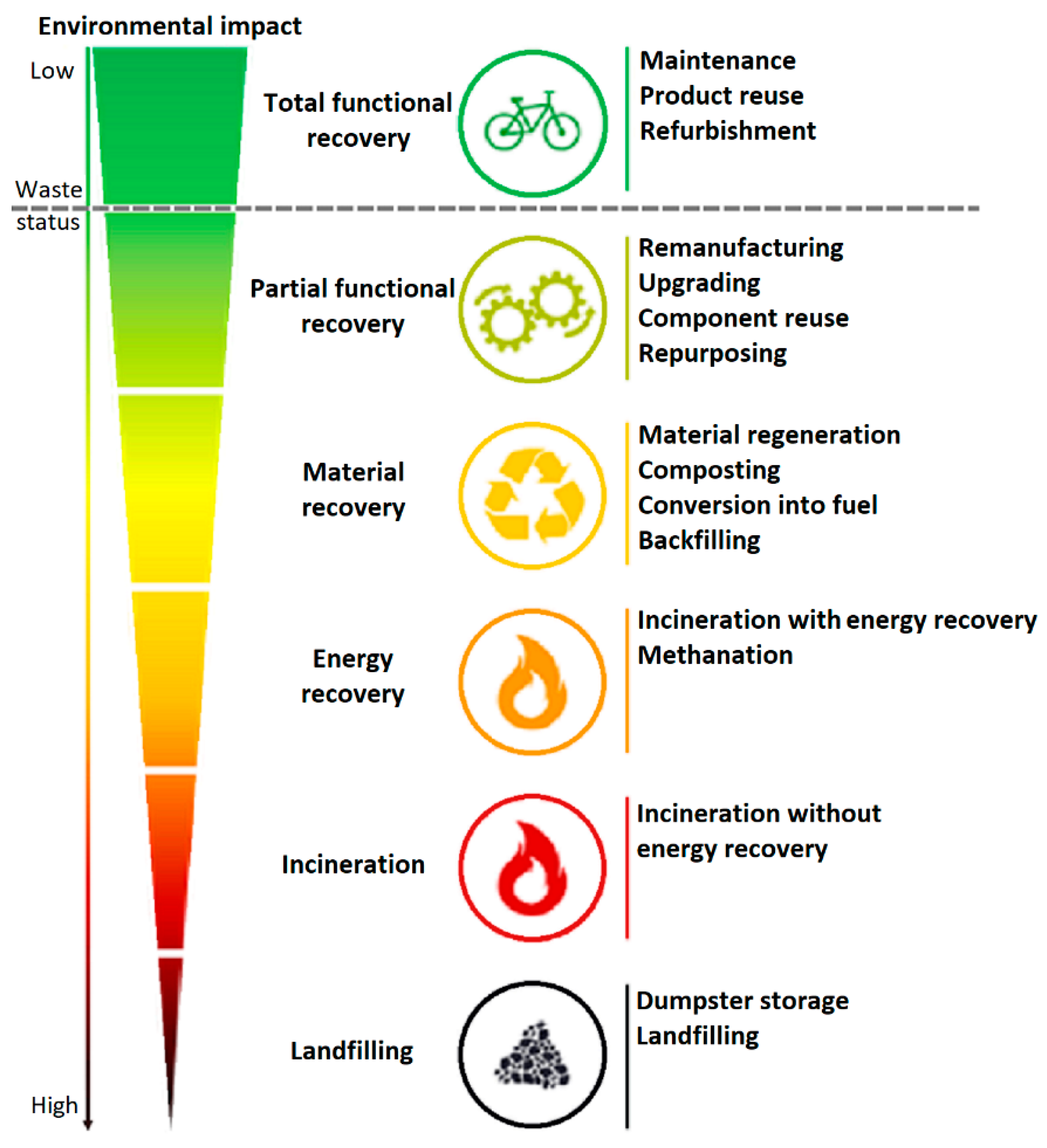

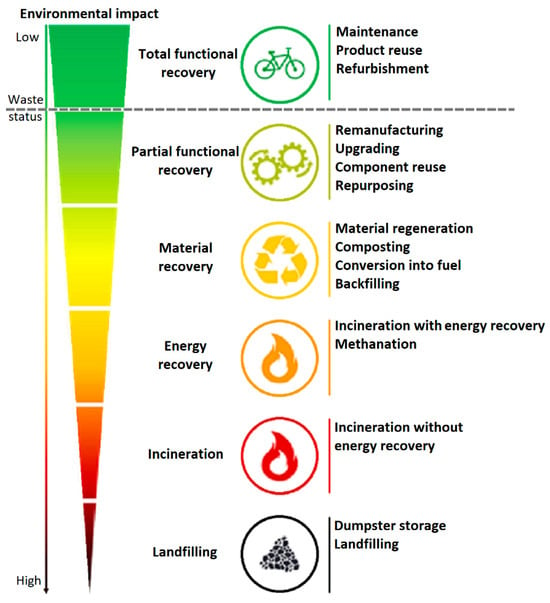

Directive 2008/98/EC also gives the hierarchy of waste treatment methods, in terms of environmental impact, as illustrated by Figure 4.

Figure 4.

Environmental impact hierarchy of the different end-of-life treatment options, adapted from [41].

Details about the different waste treatment processes are given in this section.

3.2.1. Total and Partial Functional Recovery

The total functional recovery of waste can be sub-divided into three processes: maintenance, product reuse and refurbishment [38,42]. In those cases, the product is not considered to be waste yet. Hence, these three processes are not considered waste recovery options.

Maintenance is a way to extend the lifespan of a product by pre-emptively checking its structural and functional integrity. It is considered to be the best way to prevent environmental impact [41].

Reuse is defined as “any operation by which products or components that are not waste are used again for the same purpose for which they were conceived”. It avoids the production of a substance or product from primary resources. Preparation for reuse can include performing maintenance, cleaning and repairing so that the equipment can be reused as is.

Refurbishment is meant to restore the original state of the component or product. The goal here is to repair the components or product and make them «as good as new» by using brand new parts.

Partial recovery of waste is composed of three waste recovery processes.

For remanufacturing, the goal is the same as refurbishment, but on a larger scale: the product must be rebuilt to satisfy the specifications it had when it first left the factory. In other words, the remanufactured product must have the same functionalities as a brand new one, but the final product is a combination of reused parts, refurbished parts, and new parts.

The repurposing of products is reserved for devices that cannot be used for their original purpose anymore but could still be used for less demanding purposes. For instance, car batteries that have lost too much capacity can still be gathered and used for energy storage.

Even though recycling is the core of this review, we still want to exert caution: as shown in Figure 3, recycling is not the least environmentally impactful option for WEEE treatment. Indeed, partial or total functional recovery are more efficient, yet some authors have exposed the lack of action towards the latter. For instance, Zacho et al., (2018) [43] observe that the incentives towards recycling eclipse the potential for the reuse of WEEE.

3.2.2. Material Recovery

Material recovery includes four options: material regeneration, composting, conversion into fuel and backfilling. The two first two options comprise what is usually called recycling, which refers to any operation by which waste materials are reprocessed into products, materials, or substances. Composting is not usually used for WEEE-p, hence it will not be discussed in this paper [44].

In the case of WEEE, material regeneration is the combination of several operations that aim at extracting all pollutants or unwanted substances contained in the waste, in order to retrieve valuable materials from the waste stream such as metals, rare earth elements, and plastics [21,45]. These operations include pre-treatment, sorting and compounding, which will be thoroughly discussed in Section 4.

Conversion into fuel and backfilling are not considered to be recycling techniques, but they are still within the scope of material recovery.

Non-hazardous waste can be converted into fuel and used to power other industrial processes, thus avoiding the use of oil, coke, or gas. Although this process seems to enter the energy recovery scope, it is in fact considered to be material recovery, as the recovered fuel is indeed a material output. The case of solid recovered fuels is specifically covered by the ISO 21640 [46] norm series. Moreover, the norm EN 45555 [44] explicitly excludes it from the scope of recycling.

The backfilling of quarries is usually carried out with large volumes of waste from building demolition, soil levelling residue, or infrastructure construction waste, but solid residue from WEEE-p such as talc can be recovered for the backfilling of excavated sites in some cases [47]. In any case, the waste has to undergo a sorting process to ensure the exclusion of any hazardous materials. To further illustrate this treatment option, Kaliyavaradhan et al. (2022) [48] wrote a review on the use of WEEE-p in cement and concrete composites.

3.2.3. Energy Recovery and Elimination

In the case of energy recovery, non-hazardous waste is directly used as fuel for other industrial applications. This is still one of the most widespread end-of-life treatment methods across Europe. When waste cannot be recovered, either because it is too technically difficult, not economically profitable, or because it contains hazardous contaminants, it must be eliminated. Two main methods are currently used.

Firstly, the waste can be incinerated without energy recovery, which eliminates the waste and all its constitutive elements. The second method is landfilling, which is still widely used in the European Union, even though some countries have implemented restrictions, or even banned it.

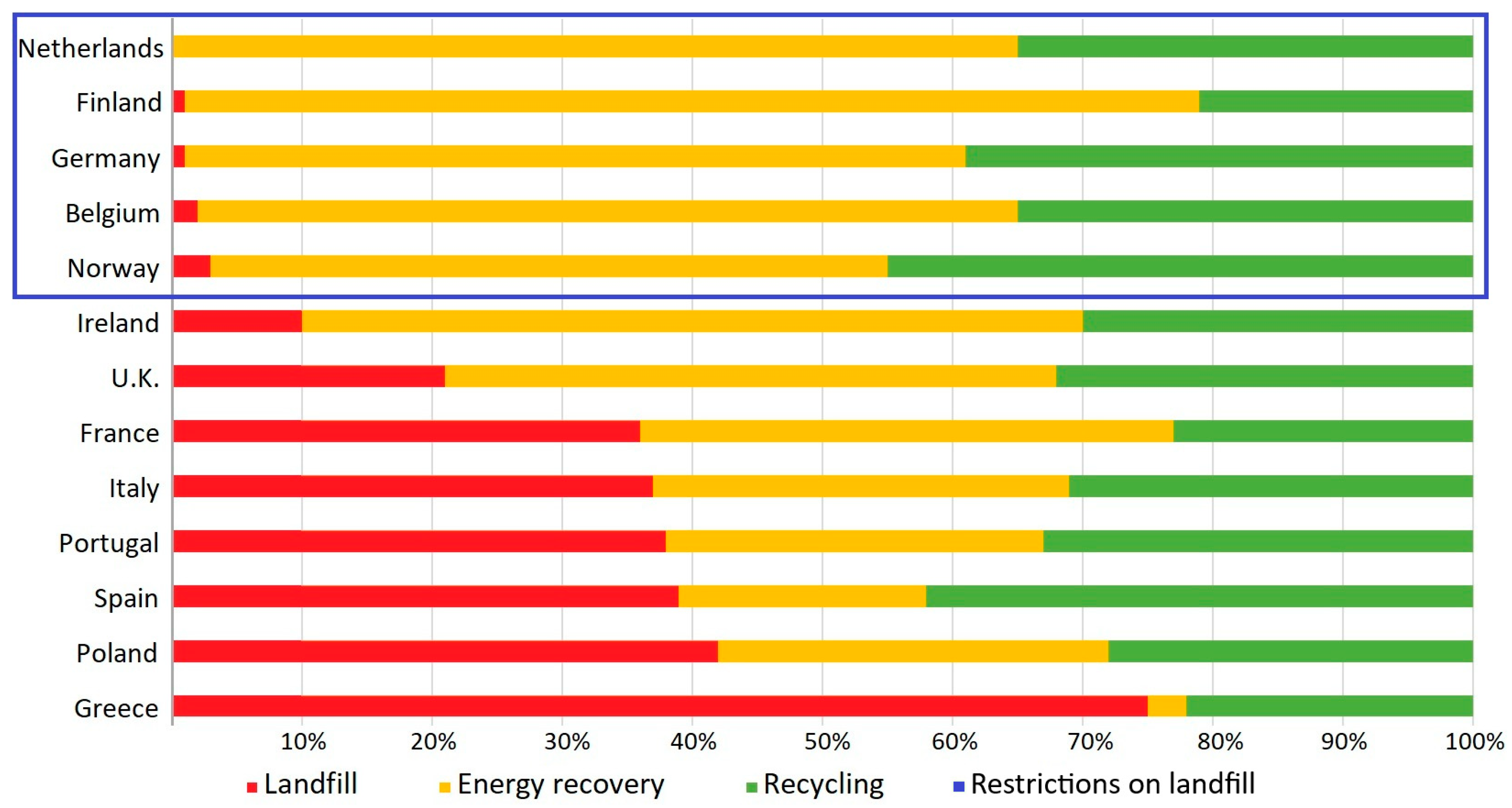

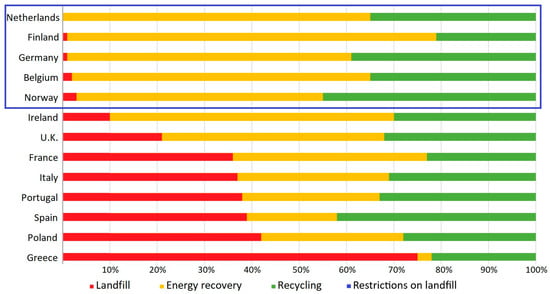

The following graph (Figure 5) illustrates the use, across Europe, of each main end-of-life treatment method: recycling, energy recovery and landfilling, for overall post-consumer plastic waste (not only WEEE-p). The blue rectangle highlights countries that have implemented restriction on landfilling [7].

Figure 5.

Distribution of EoL treatment in the EU methods for specific polymers.

The same steady increase in incineration can be found in other regions of the world. For instance, the impact of the incineration of PS and ABS is thoroughly discussed by Chu et al. (2022) [49] and reveals an increase in the use of incineration as a treatment method throughout the years as a preferred solution compared to landfilling.

3.3. Legal Aspects

This section aims to provide legal elements related to WEEE and recycled plastics in Europe. When reviewing the literature, numerous mentions of the REACH and RoHS directives can be found, however some norms and standards widely used in the industry for the characterisation of plastics at an industrial level are often overlooked or disregarded. They will be introduced in this section.

3.3.1. Defining WEEE

The first directive on WEEE, the 2002|96|EC directive, entered into force in 2003, it defines the concept of WEEE and integrates the aspect of extended producer responsibility (EPR) to the end-of-life chain [6]. The European EPR model has been extensively analysed by Favot et al., (2022) [4]: the authors compared the current economic motivation with the existing organisational and institutional aspects. The results for WEEE indicate that the recycling of these pieces of equipment could benefit from the settlement of new compliance schemes.

Different methodologies have historically been used to classify WEEE. There are currently seven legal categories in Europe, as defined by the 2012|19|EU regulation, updated in 2018 [50]:

- Category 1: Heating and cooling appliances

- Category 2: Screens and equipment with screens

- Category 3: Lighting equipment

- Category 4: Large appliances

- Category 5: Small appliances

- Category 6: Small IT and telecom equipment

- Category 7: Photovoltaic panels

However, these categories do not accurately represent how waste is treated in the different European countries. Indeed, the European directive on WEEE sets a classification for the different types of WEEE, but in reality, each country is entitled to choosing how to respect the directive (Sander et al., 2007) [51]. For instance, in France or in the UK, the legal WEEE categories follow the recommendations of the EU directive, but the collected WEEE is classified using different categories, as shown in Table 4.

Table 4.

Classification for the collection of WEEE in France and the United Kingdom [39,51,52].

It is very interesting to note that although all waste categories are classified as WEEE, their fates can differ completely. Table 5 below shows the fates of different WEEE categories in Europe.

Table 5.

Repartition of the treatment options for different types of equipment in Europe [22,23].

This table highlights why data from different countries can be difficult to compare, as numbers are often gathered for different categories, meaning direct comparison can be misleading.

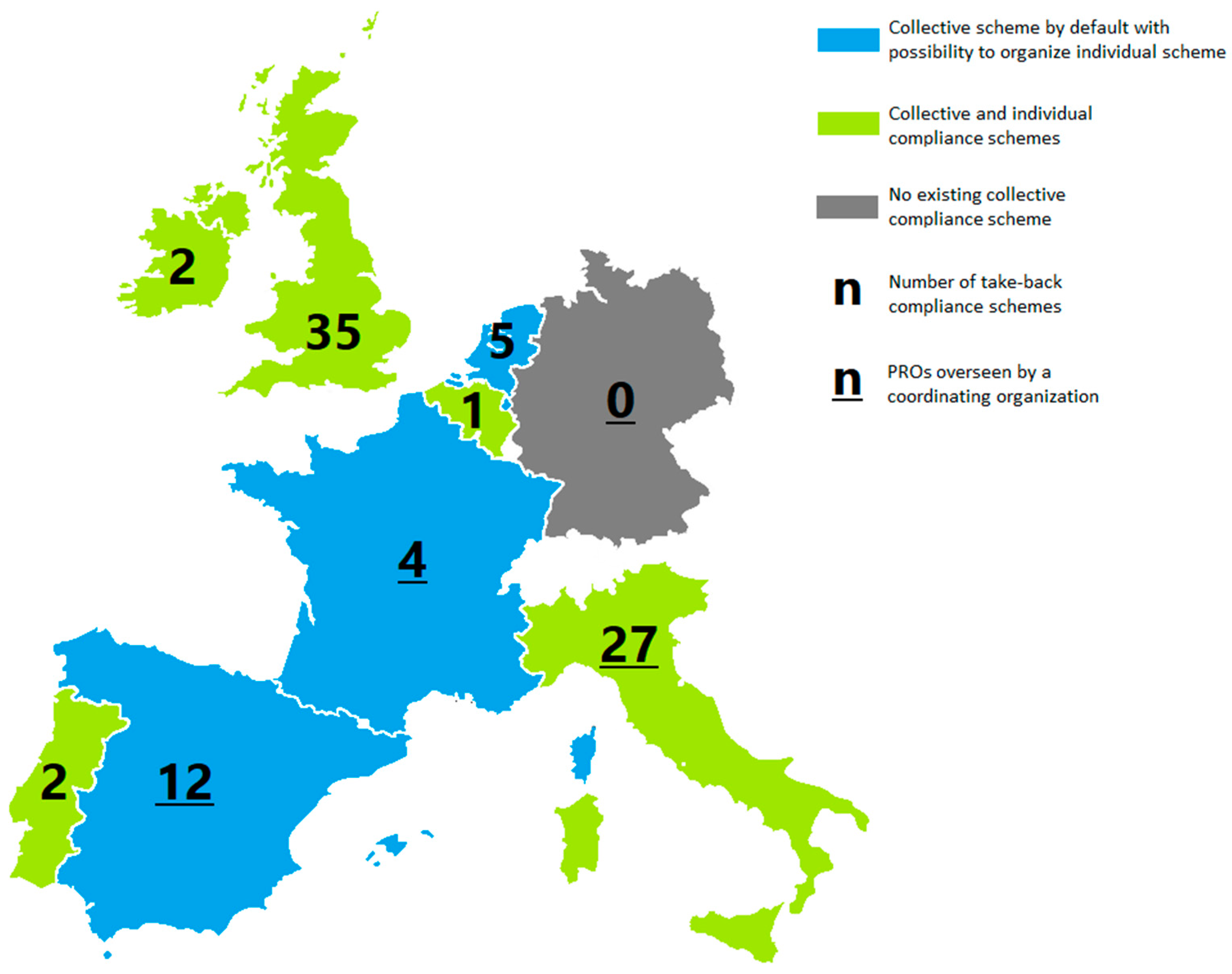

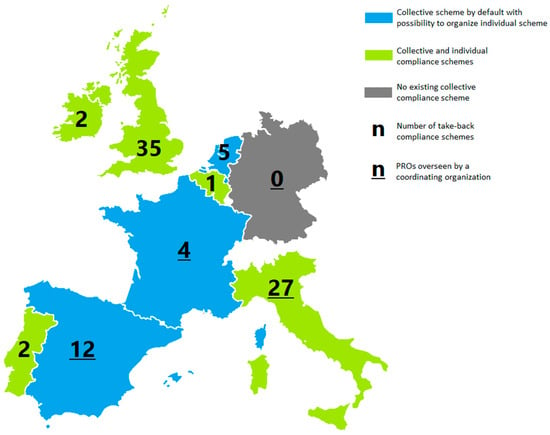

The WEEE directive of the European Union defines a framework for the collection and treatment of WEEE, based on the notion of EPR [5]. To do so, PROs, also called compliance schemes, take care of the producers’ responsibility of the waste. The financing of these schemes is ensured by the EEE producers. Some countries have implemented the addition of a small fee to the price of EEEs, called an eco-contribution, but once again, the financing and functioning of these compliance schemes vary from one country to another. Moreover, the non-existence of a government-approved organisation can hinder the efficiency of data collection. Therefore, information on the waste stream can be more difficult to find in some countries. Figure 6 illustrates these differences for some countries of Western Europe.

Figure 6.

Organisation of the PROs in Western Europe, adapted from [40].

Germany is a very special case. The German Stiftung EAR is not legally a PRO, based on the definition of the European Commission.

In Germany, WEEE collection is a system based on competitivity. EEE producers are charged by the Stiftung EAR with providing and collecting municipal WEEE bins. The market share of each producer indirectly determines the number of bins they will be charged with collecting [5]. It is the case of an individual producer’s responsibility, as opposed to the extended producer responsibility [53].

In many countries, photovoltaic panels are treated by specific entities, making it difficult to generalise the results on WEEE and WEEE-p recycling to this category of waste. This subject will thus not be discussed in this review, but some authors have compiled recent advancements in the recycling of photovoltaic panels, such as Deng et al. (2022) [54].

3.3.2. The REACH Directive on Hazardous Substances and Restrictions

The REACH (registration, evaluation, authorisation and restriction of chemicals) directive was created for chemicals used in put on market products [55]. It is linked to the production and sale of plastics in Europe, as many of the existing polymers used in the market include substances that are covered by this norm. The three main aspects of REACH will be discussed: registration, authorisation and restriction.

- 1.

- Registration

Anyone who produces or imports a substance, by itself, or used in a mixture, in a quantity over one ton per year must register and report it to the ECHA (European Chemicals Agency).

All producers (or importers) of a polymer have to register the monomer substances, and by extension, any substance that has not been registered beforehand by a stakeholder higher up in the supply chain, if the following conditions are met:

- The polymer is composed of at least 2% w/w of the said substance or any chemically related substance.

- The total quantity of produced substance is higher than one ton per year.

- 2.

- Authorisation

The following substances have to be authorised before use:

- Carcinogenic substances

- Mutagenic substances

- Reprotoxic substances

- Persistent, bio-accumulative, and toxic substances

- Very persistent and very bio-accumulative substances

- Substances that contain endocrine disruptors, and more generally, any substance that does not meet the previous two criteria, but for which there is scientific evidence of serious effects on human health or on the environment.

For the substances that meet at least one of these criteria, the European Commission or member states themselves can propose a list of candidate substances for a potential inclusion in the list of authorised substances.

- 3.

- Restriction

If a substance, alone, in a mixture or in a product, appears on the list of restricted substances it cannot be used, produced or placed on the market unless it respects the conditions of the said restriction. Moreover, an authorisation cannot be delivered for a substance if it goes against the restrictions of the list.

If the European Commission considers that the manufacturing, the use or the putting on market of a substance alone, in a mixture or in a product, creates an unmanageable risk for human health or the environment, it asks the European Chemicals Agency to write a file composed of the following:

- A proposition including the identity of the substance and the proposed restrictions for its production, use and putting on the market.

- Information on the hazardous nature of the substance and on the potential risks described based on a risk analysis and presented as a chemical safety report.

- Data on the alternative substances.

- Justifications for the restriction towards the member States.

When a risk for human health or environmental toxicity is detected during the production, use or putting on the market of a substance, alone, in a mixture or in a product, the list of restricted substances is updated by implementing new restrictions or by amending the ones already in place.

3.3.3. RoHS and Other Norms and Standards for WEEE-p Recycling

In addition to the REACH directive, the European Commission issued another list of substances specifically designed for EEE, established by the RoHS (Restriction of Hazardous Substances) directive. On this list are very specific substances that are prohibited in electric and electronic equipment: brominated flame retardants often found in plastics, heavy metals such as mercury, cadmium and lead, and hexavalent chromium Cr(IV) [56].

As mentioned before, the European parliament is one of the main actors of the WEEE legislation, but there are other entities, such as the European Committee for Standardization, which dictates the standards. These standards are identical in the 34 member countries of this committee. The European legislation dictates the objectives to be reached, and the standards usually indicate the method to apply in order to reach these objectives [57]. The main goal of these standards is to increase the resilience of society towards climate change, and they can be sorted in different categories.

Some norms are directly relevant to plastics recycling:

The series of norms ISO 15270 provide general guidelines for plastics recycling. They aim at harmonising data collection and analysis methods of micro-plastics of all types (tires, plastic granules, synthetic fibres). The ISO 15270 series are very general, but there are other more specific standards that define a maximal acceptable quantity of certain substances and a testing method for sorted plastics pre- and post-recycling. These standards help in assessing the quantity of recycled plastics on the market, by giving the detail of the methods to measure collected and sorted plastics, along with input and output data from recycling companies [58].

The norm ISO EN 15343 is also commonly used as a communication tool between the recycling companies and the producers, as it specifies the adequate procedures to ensure a good traceability of the recycled plastics [59].

For PROs, demands in terms of traceability are also evolving. In addition to ISO EN 15343, less recent actions like the Bâle convention sets specifications in terms of proportion of contaminants for the exportation of polymers [60].

The norm ISO EN 15347 provides information about the characterisation methods for plastic waste. The communication between the producer and the user of a batch of recycled plastics is centred on this norm, as it specifies which properties the producer is required to provide, and which properties are useful but can remain optional [61].

4. Waste Treatment, from WEEE to Recycled Plastics

This section proposes a synthesis of pre-treatment, sorting, and separation techniques that are commonly used in Europe [62], by presenting their goals, limitations, and potential innovations.

4.1. Pre-Treatment

The complexity of electronic products is what makes the pre-treatment step necessary. Indeed, in order to ensure a good material quality for recycled plastics, it is essential to remove all non-plastic impurities from the waste stream, such as metallic parts, organic residue, glass and rare earths. Furthermore, within the plastic waste stream, some of them can contain restricted substances, such as the brominated flame retardants of heavy metals regulated by the RoHS directive mentioned earlier. To address this, the goal of waste pre-treatment is to roughly separate plastics from other materials.

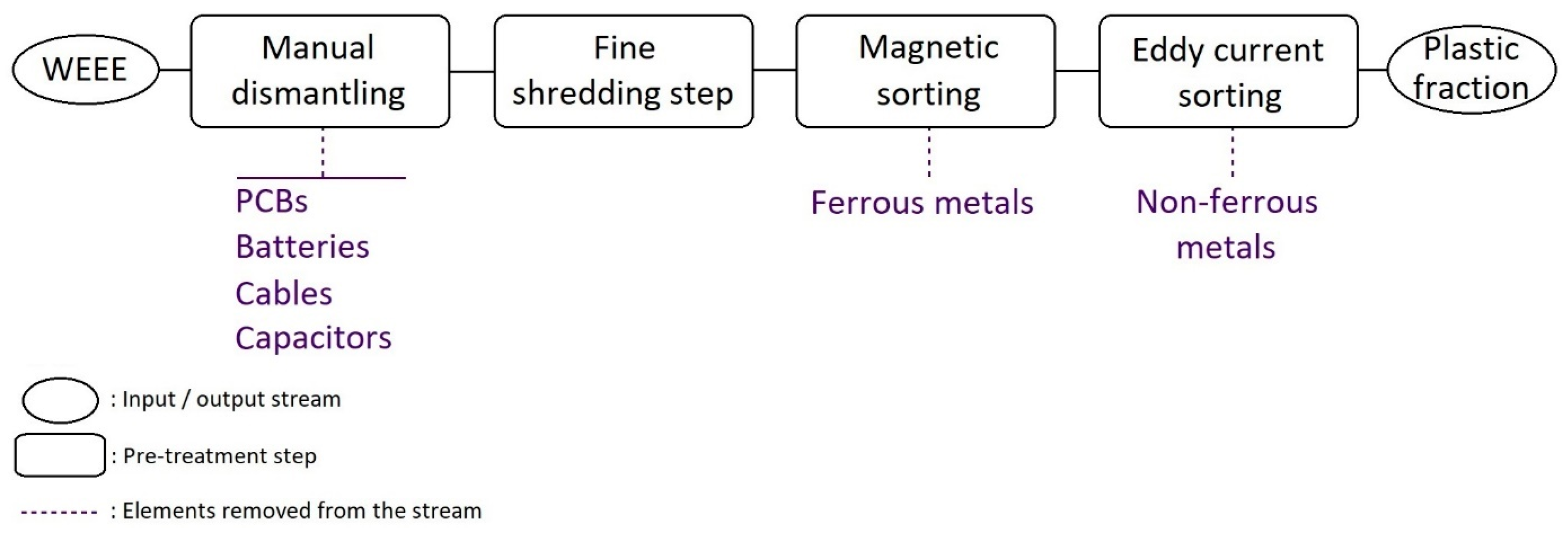

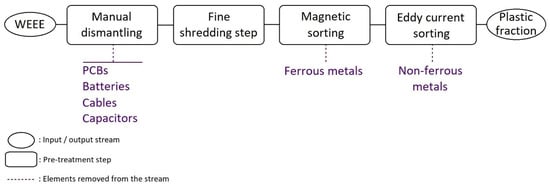

Manual dismantling takes place first and acts as a pre-sorting step. It is mainly used to remove contaminant parts of the WEEE, such as cables, printed circuit boards (PCB), batteries, and capacitors. Moreover, some parts such as cathodic ray tubes from TV monitors, and refrigerant fluid from cooling appliances can contaminate the waste stream, that is why this step is sometimes also called decontamination.

The recycling of lithium-ion batteries was presented by Windisch-Kern et al., (2022), who point out the need for a dedicated recycling chain, especially in terms of pre-treatment and metallurgic regeneration [63].

PCBs are treated separately (Soomro et al., 2022) [64], and even though they only contain about 35% of metals in mass, Horta et al. (2020) [22] note that these metals are the only recycled material in PCBs, the rest is sent to energy recovery. To support this claim, a comparison between the composition of PCBs from different equipment has been developed by Konaté et al., (2022) [65], as well as recycling recommendations such as particle size after shredding, however the recommendations show that the authors drove their focused solely on the metal fraction of the PCB. Sorting techniques applicable to waste PCBs have been discussed by Lu et al., (2022) [66], they show the potential health and recycling benefits of a combination of traditional sorting techniques with intelligent sorting systems for PCBs.

Shredding, also called “size reduction”, is a crucial step, as it allows for the waste to be fractioned into smaller sized particles, and thus, enabling it to undergo automated separation methods. In the field of WEEE, Maisel et al. (2020) [28] noted that mechanical shredding is the most widespread method, and listed several shredding devices used in the industry. The output fraction size will be different depending on the method used, and it will have an impact on the separation techniques that follow. We will explicitly define the link between particle size and separation techniques in the next section.

The sorting step comes after shredding in order to remove non-plastics from the waste stream. The non-ferrous metals are removed from the stream using eddy currents sorting, and the ferrous materials are removed using magnetic sorting. As a result, the output of the pre-treatment phase is a mix of plastic flakes that need to be further separated.

The following figure (Figure 7) illustrates the commonly used steps for WEEE pre-treatment:

Figure 7.

Pre-treatment chain of WEEE [40].

Maisel et al. (2020) also include an additional shredding step before the first separation technique [28].

Indeed, pre-treatment may be different from one waste preparator to another, however, most authors agree that obtaining a mix of polymers flakes marks the end of the pre-treatment phase. The next phase will be to separate the different polymer types from each other, so that they can be treated individually.

In Europe, the important part of the waste is treated with this type of formal recycling chains, which is the main scope of this review, but some authors have also compiled data on informal recycling. Arain et al. (2022) [13] present informal e-waste recycling in Thailand and its benefits on the economy and the resources, along with the need for the better regulation of the dismantling of products containing hazardous substances. From a more social point of view, McMahon et al. (2021) [67] have put into perspective the benefits of non-compliant recycling chains in Ireland, in terms of efficiency, costs and employment.

4.2. Separation Techniques

In the previous section, we discussed material sorting. The word “sorting” here refers to the removal of one or several elements from the waste stream. To avoid any confusion, we propose that the processes aiming at sorting polymers from each other be called “separation” [40].

Hence, the “sorting” of plastics refers to the removal of the non-plastic materials from the waste stream, whereas plastic “separation” aims to classify the polymers found in the plastic fraction.

There are numerous polymer separation techniques currently used in the industry of mechanical recycling. These techniques include a lot of parameters, such as the nature of the process (e.g., dry techniques, fluid-based techniques, optical techniques), the input fraction size and of course the polymers they can separate.

In the following sections we are going to give an overview of the most widespread separation techniques, along with the ongoing research or possible improvements for each of them.

4.2.1. Fluid-Based Techniques

Techniques based on the separation of polymers by density, or density-based separation, are the most used techniques for the recycling of WEEE [68].

- Flotation separation

This type of technique has existed for a long time, but improvements have been made over the years to increase its yield. Flotation separation, or the float-sink test, as a simple and effective way to separate light fractions from heavy fractions. It is a commonly used non-destructive technique with a high technology readiness level (TRL).

The process is simple: the waste enters one side of a large tank of water, often treated with an anti-capillarity detergent. The heavier particles sink, whereas the lighter ones reach the other side of the tank. Wang et al. (2019) [69] also point out that the density of the solution can be altered by using different elements, such as sodium or chlorine, therefore changing the density limit for the separation of polymers. Stenvall et al. (2013) [25] indicate that calcium carbonate (CaCO3) can also be used for this density adjustment.

Ragaert et al. (2017) [10] describe the industrial use of this technique with the example of a Belgian recycling company (Eco-OH). In this case, this technique is used in combination with others. First, the waste batches are prepared by drum washing and friction washing, then they are shredded into fractions ranging from 1 to 12 mm, and friction-washed again. These pre-processed fractions are then separated with a float-sink test. Note that as this technique is fluid-based, it allows for the fractions to be washed. This first separation allows for the efficient separation of the polymers into two categories.

First, the “sink fraction” undergoes a sorting step with eddy currents to remove all remaining metals.

Second, the “float fraction” is dried up, and is further separated with an air table (defined further in Section 4), which allows for the separation of light and heavy fraction, among the float fractions.

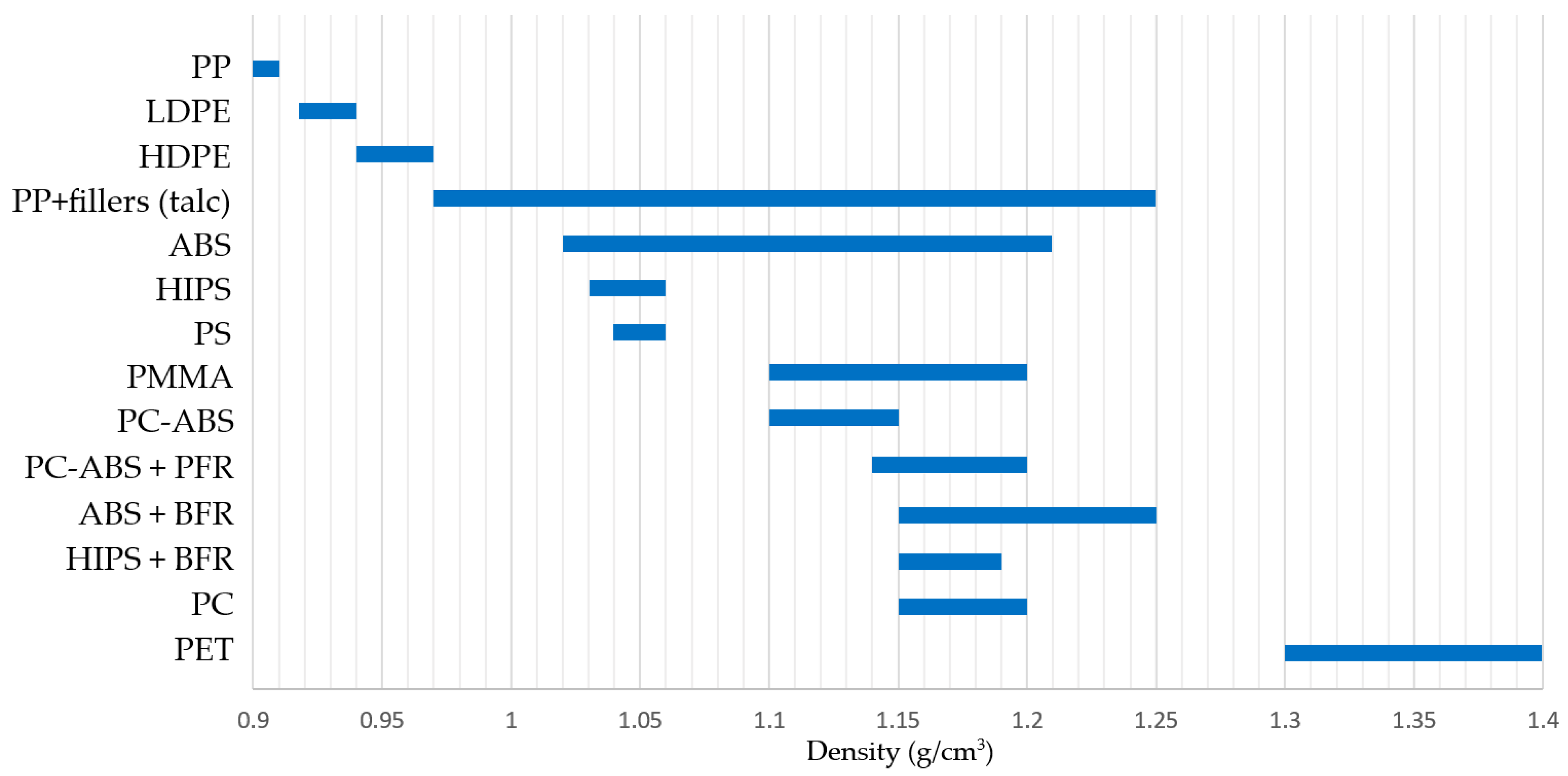

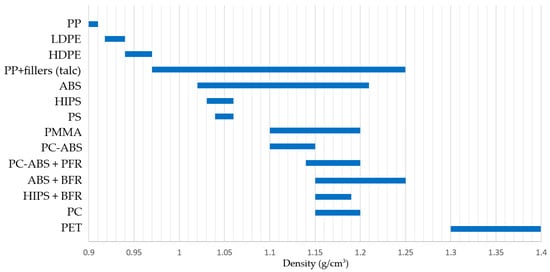

However, plastics have a wide range of densities, depending on the type of polymer, or on the additives for instance. This technique is thus not very efficient when it comes to separating plastics that have similar densities. Figure 8 illustrates the density of several polymer types found in e-waste.

Figure 8.

Density range of typical WEEE plastics [40,70].

For WEEE, Bill et al. (2022) [70] indicate that brominated plastics, or plastics that contain fillers such as talc, are often heavier than their non-filled counterparts, and are therefore eliminated after a float-sink test.

This is a very important point, as the elimination of brominated flame retardants (BFRs), considered hazardous contaminants, is essential to the recycling process of WEEE-plastics [71]. Other techniques used for the detection of BFRs will be discussed in this section, but it is important to note that densiometric sorting is often used as one of the first steps within the separation process, hence eliminating hazardous materials right away.

Regarding waste pre-treatment requirements, and more specifically for shredding, Maisel et al. (2020) [28] highlight the fact that this technique works best on particles ranging from 10 to 20 mm.

Arena and Ardolino, (2022) [47] point out that the combination of this technique with optical separation (defined further in Section 4) allows for the recycling of ABS, HIPS, PC, PP and PVC.

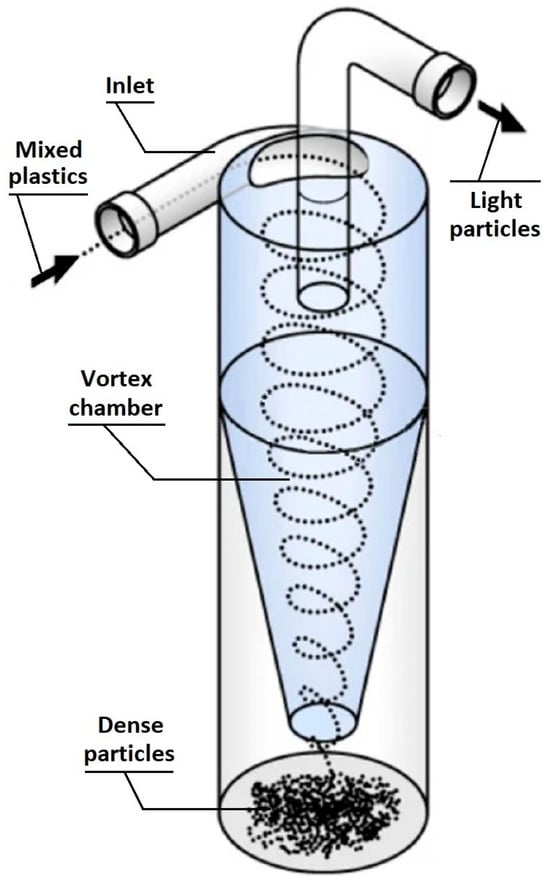

- Hydrocyclone separation

Hydrocyclone separation is a variation of the flotation separation technique that uses specific equipment. Wang et al. (2019) [72] highlight the hydrocyclone technique as being one of the most widespread fluid-based techniques to separate plastics.

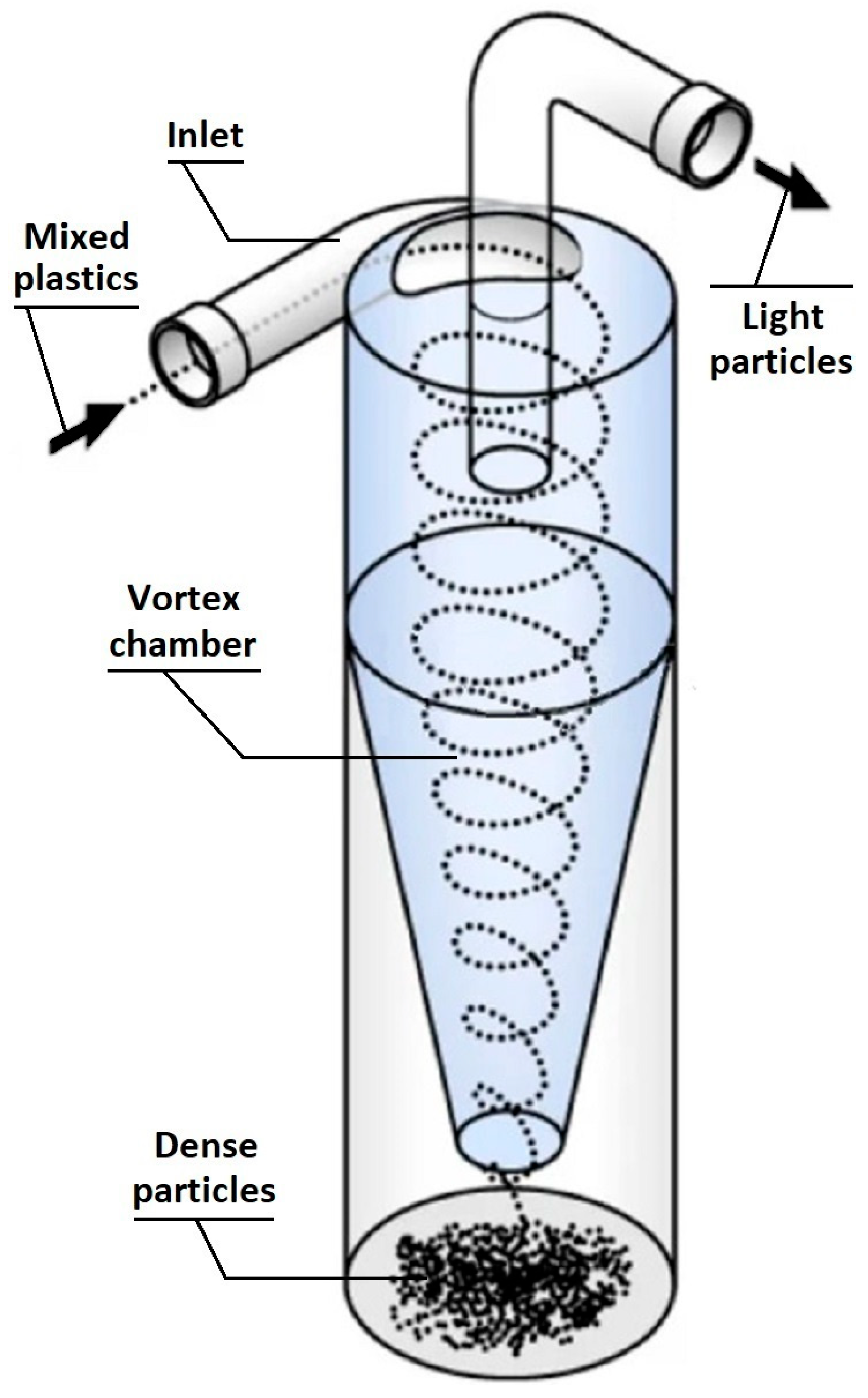

The waste is mixed with water, enters the device at the inlet and forms a vortex. Then, due to the shape of the device, they are drawn to the top by centrifugal force, while heavier materials move towards the bottom of the cyclone, as illustrated in Figure 9.

Figure 9.

Layout of a hydrocyclone separation device.

This process can be repeated to refine the purity of the material. And a purity of 99% can be attained after repeating the process several times. However, although the separation capacity is better than with the float-sink test, hydro-cyclone separation still relies on density properties to sort plastics, thus presenting the same issue when it comes to separating plastics within same density range.

Maisel et al., (2020) [28] indicate that the treated fraction size should be between 1 and 8 mm. This technique allows for the separation of PVC, PET, PE, PP, HDPE and LDPE.

Optimisations of the design of hydrocyclone devices have been developed by Fu et al., (2022) [73]. The authors highlight the influence of the cone angle on the separation of light and heavy plastics (in this case, PET and PVC).

- Selective flotation

As opposed to the float-sink test, selective flotation does not rely on density to separate plastics. Grigorescu et al., (2019) [30] describe this technique as a non-destructive test that uses the difference in wettability between materials. Froth flotation involves three phases: the solids to be separated, an aqueous medium, and air bubbles. Several factors can influence the wettability of materials, the most important of which are particle size and shape, surface chemistry, and froth stability [74].

The mix of plastics is plunged in water, and surface-reactive surfactants are used to create air bubbles at the surface of the aqueous medium. The hydrophobic particles aredragged towards the surface of the liquid, whereas the others will sink at different speeds. The advantage of this method is that additional surfactants can be used to enhance the hydrophobicity of target materials [74].

This method allows for the separation of plastics even if they have similar densities. This technique is highly efficient and is a good way to circumvent the problem of plastics with the same density range.

Chemical wetting agents can be used to better separate the materials, and frothing agents can be added to the water to optimize the efficiency of this technique [75]. The addition of a polymeric aluminium chloride solution seems to increase the sorting efficiency for PET, ABS and PS (Wang et al., 2022) [76].

Wang et al. (2019) [69] indicate that, in the case of a mix of two polymers, an organic macromolecule (calcium for example) can be added to the water in order to specifically modify the wettability of one of the polymers, making it hydrophilic. However, it is still in development for the field of recycled plastics, and it requires a homogeneous input stream, which means pre-treatment to isolate the plastic fraction is mandatory.

According to Maisel et al. (2020) [28], there are no limitations on the fraction size, as it will work on all particles bigger than 0.1 mm. This technique is can separate heavy polymers such as PS, PVC, PET, PC, and POM. Thanh Truc and Lee (2016) [77] give a detailed example of the selective separation of ABS and PVC using this technique.

4.2.2. Dry Techniques

- Air table separation

Density-based tests using water were discussed in the previous section, but separation processes relying on density can also use air as a medium. The air shaking table is a vibrating porous, and inclined metallic surface, with a continuous air stream placed underneath. The air flow pushes the lighter particles down the slope, while the heavier particles remain at the top of the device. The physical phenomenon is described as early as 2005 [78] and is still in use today [62].

This process is very easy to put in place and allows for a good pre-separation of polymers that have different densities. In some cases, this technique is also used to separate non-ferrous metals from the plastic fraction. However as seen in the last section, density-based separation must be completed with an additional separation step of a different type.

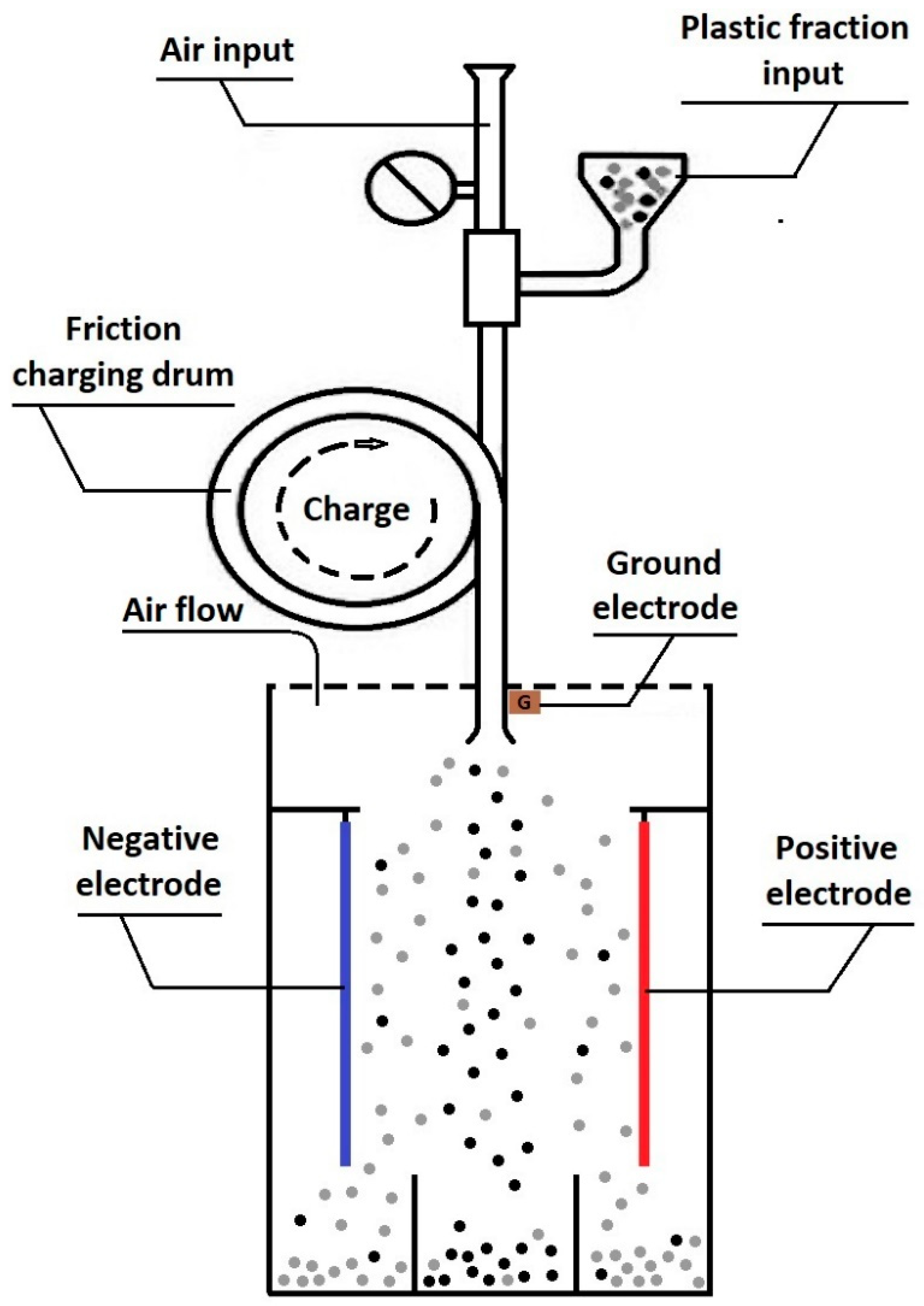

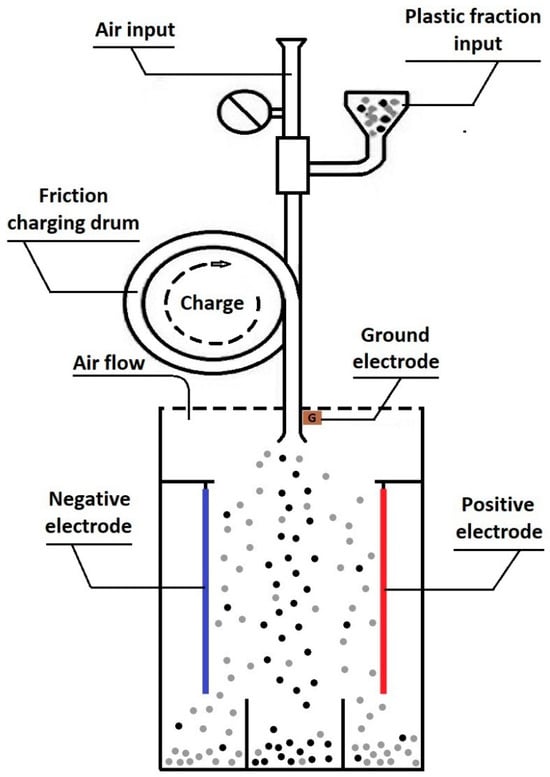

- Electrostatic separation

This technique uses the difference in electric conductivity between plastics. The polymers are charged negatively or positively, using the principle of triboelectricity. The charged plastic particles then pass through an electric field, thus being deflected towards the electrode of opposite charge.

Figure 10 shows an example of the application of this technique. In this case, the particles are charged by passing through a metallic drum, where the particles knock together and knock with the metal casing, charging them in the process. The charged particles then enter a chamber bordered with electrodes, which will attract the particles depending on their charge. The different polymers will end up in different trays, ensuring that they can be individually treated afterwards.

Figure 10.

Illustration of the electrostatic separation process.

This technique is efficient in separating a mix of plastics, ideally not more than two different types, given that they can potentially be charged by friction. It must also be noted that additives and fillers can modify the triboelectric properties of some types of polymers. Moreover, as this technique uses the difference in electric charge between plastic particles, the latter must be dried beforehand. Moreover, electrostatic separation works better on a mix of particles with homogeneous sizes and clean surfaces.

A case of materials that have similar electric charges can occur. For instance, when considering a PP and PE plastic mix, the waste should receive an additional pre-treatment step to increase the difference in electric potential (e.g., bombarding it with electrons).

The plastic particles should ideally not be smaller than 1 mm [28]. This technique allows for the separation of numerous polymer pairs. From the most negatively charged to the most positively charged, the following polymers can be separated using electrostatic separation: PVC, PET, PP, PE, PS, PA, PC and PMMA. In the case of WEEE, it is used to deal with ABS + PS, PP + PS, or PC + PS.

We can note that a case study was carried out [79], where waste from IT equipment was used as a test for electrostatic separation. The equipment was composed of two components, one mainly composed of HIPS and the other one mainly composed of a PC-ABS blend. The study compared the efficiency of the separation technique with different mixtures (90% of the HIPS shredded component, 10% of the PC-ABS shredded component, and vice-versa), and found that both components could be sorted, with a respective purity rate of 90% and 99%.

4.2.3. Optical Techniques

In addition to the literature presented in this section, Kroell et al., (2022) [80] have conducted a bibliometric review on this theme. Optical separation, also called sensor-based separation [80], includes techniques that rely on spectrometry to separate different materials. For further precisions on the functioning of the techniques, the authors recommend a handbook that has recently been written (Chen et al., 2024) about separation techniques, and in which a chapter is dedicated to optical ones [81].

- Infrared spectroscopy

Techniques using this technology can use infrared wavelengths from the entire spectrum, which can be separated into two parts, called near infrared (MIR) that cover wavenumbers from 400 to 4000 cm−1 and mid infrared (NIR) that includes wavenumbers from 4000 to 14,000 cm−1.

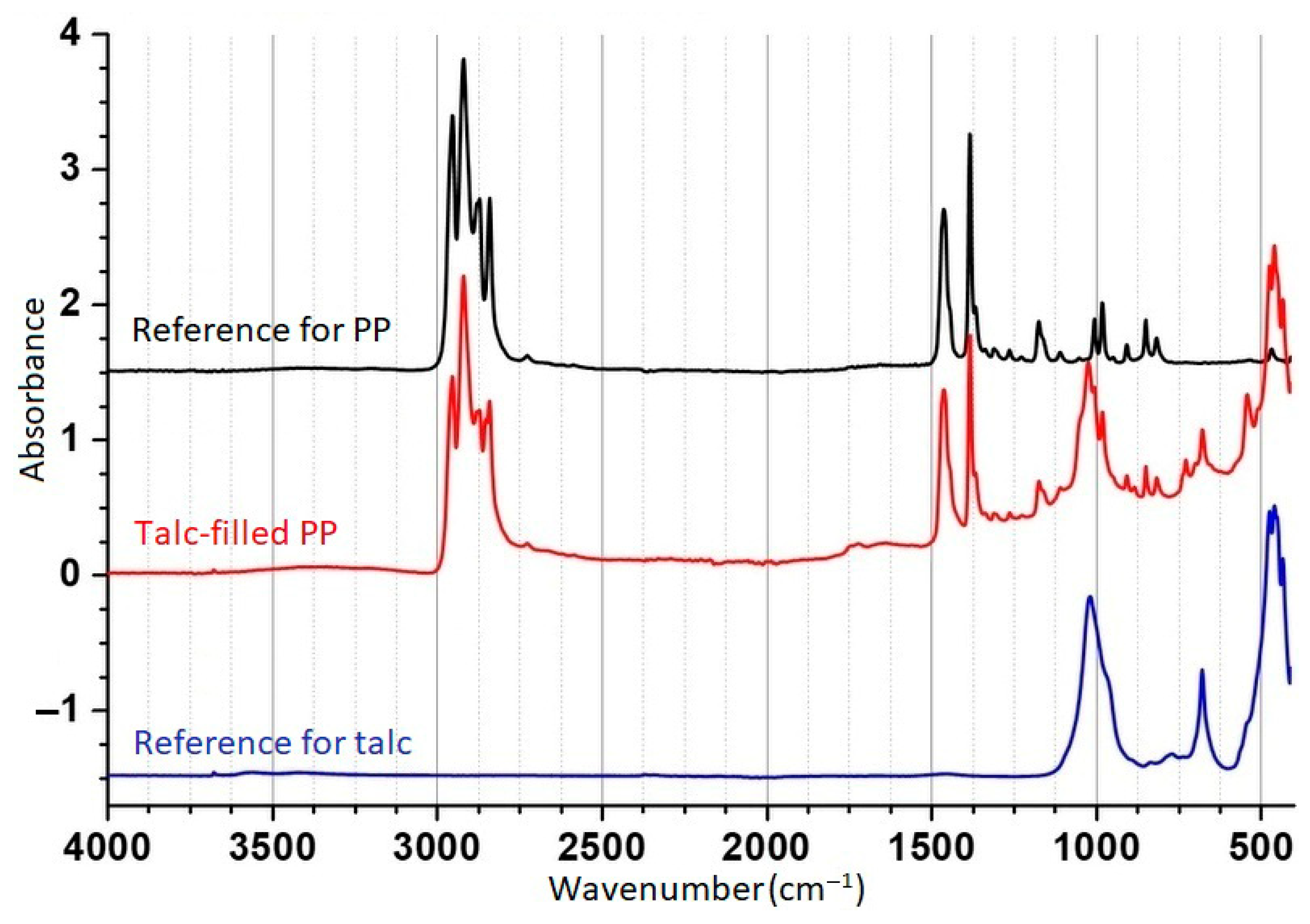

Fourier transform infrared (FTIR) is an effective method to detect plastics, due to its cheap cost and its high TRL. It is mainly used to analyse a polymer sample in order to confirm its composition [10,26].

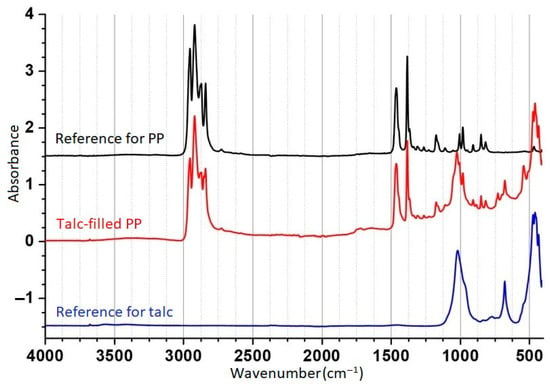

To use this technique, the sample to be analysed is lit with halogen lamps, and will reflect a portion of the light towards a sensor. This information is then sent to a spectrometer which will translate the intensity of the reflection into different wavelengths. An infrared spectrum can then be drawn, on which each polymer has its own signature rays. Figure 11 illustrates the spectrum analysis process: we can observe that the spectrum for talc-filled PP seems to be the “sum” of the individual spectra of PP and talc.

Figure 11.

Comparison of FTIR-MIR spectra for PP and PP + talc (Adapted from Wagner et al., 2020) [82].

However, this method also has some limitations. First of all, it is impossible to use on black plastics, as they do not reflect light [15,27].

Secondly, in the case of a multi-layer plastic composed of more than one polymer, this method will only be able to detect the polymer composing the top layer, as it is the only one which will reflect light towards the sensor. Of course, this problem not only arises for multi-layer plastic, but by extension to anything that covers the polymer to be analysed, such as labels, plastic wrapping, paint, or glue.

Lastly, even though this method can recognise halogen molecules (bromine for instance), it must be paired with another technique to sort BFRs, because its detection level (5000 ppm) is superior to the highest limit authorised by the RoHS directive (1000 ppm).

Maisel et al. (2020) [28] indicate that the ideal particle size should not be less than 10 mm and propose a maximum size of 150 mm.

This technique is extremely precise when well used and is capable of detecting a mix of multiple polymers (not limited to two as seen previously for triboelectricity or density separation for example), and can be used on all polymers commonly found in WEEE, such as PP, ABS, PS, PVC, and PE.

Research on the use of mid-infrared has been in progress for years, as it allows for the detection of fillers containing brominated flame retardants even on dark polymers, and sufficient progress has been made for it to be used in an industrial context [83,84,85].

- Visible light separation

The principle is close to that of infrared detection, but this time, the sensors are designed to detect and analyse wavelengths within the visible light spectrum. This method is adapted to the treatment of a single-polymer stream by colour, PET for instance. The primary use of this method is to act like a pre-separation step, which is why it is often used in combination with other optical techniques. It can also be used to separate two types of plastics in a single stream by comparing their reflective properties. It can for instance sort HDPE from PET and PVC from PET. New research by Vogelgesang et al. (2025) on the subject of separation using RGB cameras has shown that the use of deep learning could reduce the mean relative sorting error to just 5% [86].

However, the issue of the non-detection of dark plastics remains. Maisel et al. (2020) [28] also suggests that the optimal particle size should be more than a centimetre, with a minimal size of between 1 and 10 mm, and a maximum of between 30 and 150 mm. Also, to accurately detect the colour of the plastic particles, they must be washed beforehand.

As Han et al. (2022) [87] point out that research is still ongoing on this method in order to have a more accurate definition and representation of the colour, combining the detection of colour, saturation and luminance values. In addition to the analysis of colour, Tan et al. (2022) [26] found that visible light detection can be paired with shape recognition methods, in order to sort the different parts of a product.

- X-ray detection

Two different techniques exist: X-ray fluorescence and X-ray transmission (respectively XRF and XRT) [81].

In the case of XRF, a cathode ray tube emits X-rays on the plastic particles. Its constitutive atoms will then become excited and will radiate light. This secondary radiation is then analysed with a spectrometer. A spectrum is then obtained containing information on the atomic constitution of the particles to analyse, along with the concentration of each element (Wagner et al., 2020) [82].

The main advantage of XRF is the detection of brominated flame retardants. More specifically, this technique can detect bromine, but is unable to differentiate the different types of brominated flame retardants. Recent research on this technique on the separation of polymers from flat panel display screens shows, at an industrial level, its efficiency in the separation of hazardous substances such as bromine and antimony [88]. However, it was found that in an industrial context, handheld XRF devices have an optimal analysis time of 10 s, placing them on the slow side of detection techniques [88].

Furthermore, Maisel et al. (2020) [28] found that the minimal particle size should be between 2 and 15 mm, with a maximum of from 60 to 120 mm. The particles also have to be perfectly cleaned beforehand.

The principle of XRT is similar: the particles to be analysed are lit with X-rays, and the resulting image is a black and white picture with different intensities and shades depending on the atomic mass of each element. This transmitted image is treated with a computer and compared with references to determine the composition of the sample. This technique is mainly used to detect heavy atoms, such as metals and halogens [81].

The main advantage of this technique is its automation potential. Indeed, it is a fast technique compared to XRF, and is often used in the pre-sorting of WEEE-p because of its ability to be used on a conveyor belt [10,36].

- Laser induced breakdown spectroscopy (LIBS)

LIBS spectroscopy is another optical separation technique used in WEEE-plastics separation [88]. The technique works via the excitation of a sample with a laser. Utilizing emission spectroscopy, the concentration and properties of a material are determined, which allows for the easy categorisation of the material [36].

A case study of LIBS-Raman has been conducted on a mix of PP, PC, PLA, PMMA, and nylon. Raman spectroscopy refers to the analysis of specific emission rays that differs for all materials. However, additives in WEEE-plastics seem to be an additional challenge for this technique alone, hence the combination of techniques in order to correctly identify the polymer types.

More specifically, three spectral regions have been investigated (UV, visible light, and NIR) to determine which one gives the best results for material classification. In the end, NIR was selected to be the main characterisation spectre. It is also very interesting to note that this technique is extremely fast, with an exposure time ranging from 10 ms to 30 ms [89].

4.3. Summary

To sum up, it is important to use a combination of sorting and separation techniques to ensure a high purity of the output materials, a low error rate, and the possibility to treat high volumes.

The density-based techniques allow for an indirect separation of brominated flame retardants, as plastics containing it are often heavier than the other ones. However, it means that the sink fraction is often automatically eliminated, even if it includes plastics that do not contain BFRs. For that reason, X-ray detection, while costly, is considered more efficient as it has a lower error rate.

Density separation is cost-effective and can treat high volumes of waste and, while they are sufficient in some cases, they cannot separate each type of plastics, as some of them have the same density range. That is why further separation steps, for example selective flotation or optical separation are required.

Even though XRF can recognise plastic types, it is not its primary use, as it cannot treat high volumes. That is why it is mainly used to test the presence of BFRs.

Table 6 summarises the efficiency of the separation and separation techniques previously discussed, according to their advantages and limitations.

Table 6.

Summary of sorting and separation techniques.

However, sorting and separation are not the last steps before a usable recycled polymer. Indeed, the sorted polymers need to be compounded (additives need to be added), heated, filtrated and eventually regranulated.

This means that the purity of the polymer after the separation step is crucial for the quality of the regranulated recycled polymer.

In the next section, we are going to discuss the impact of the potential contamination of the recycled polymers.

5. The Issue of Contaminants in WEEE-Plastics

Degradation is a term that is often used interchangeably with the ageing of the polymers. However, degradation covers a broader range of phenomena, with ageing being only one of them. All the issues causing the degradation of the polymer proper-ties will be discussed, starting with ageing followed by the two main types of contamination found in WEEE-p.

The word “contaminant” covers a broad range of materials and products such as ageing substances, fillers, polymeric contaminants, or additives (intentional or unintentional).

“Additive” designates chemical compounds added to tamper with the polymer’s properties (e.g., FR, antioxidants, unmoulding agents, plasticisers, etc.).

The subject of contaminants and additives in WEEE-p seems important, as they seem to cause issues during reprocessing. We are going to discuss their impact in this section.

We tackled the subject of flame retardants in the previous section. We will now assume that flame retardants have been extracted from the waste stream, and that optical testing has revealed that the plastic fraction is flame-retardants-free and is ready to be compounded and re-granulated.

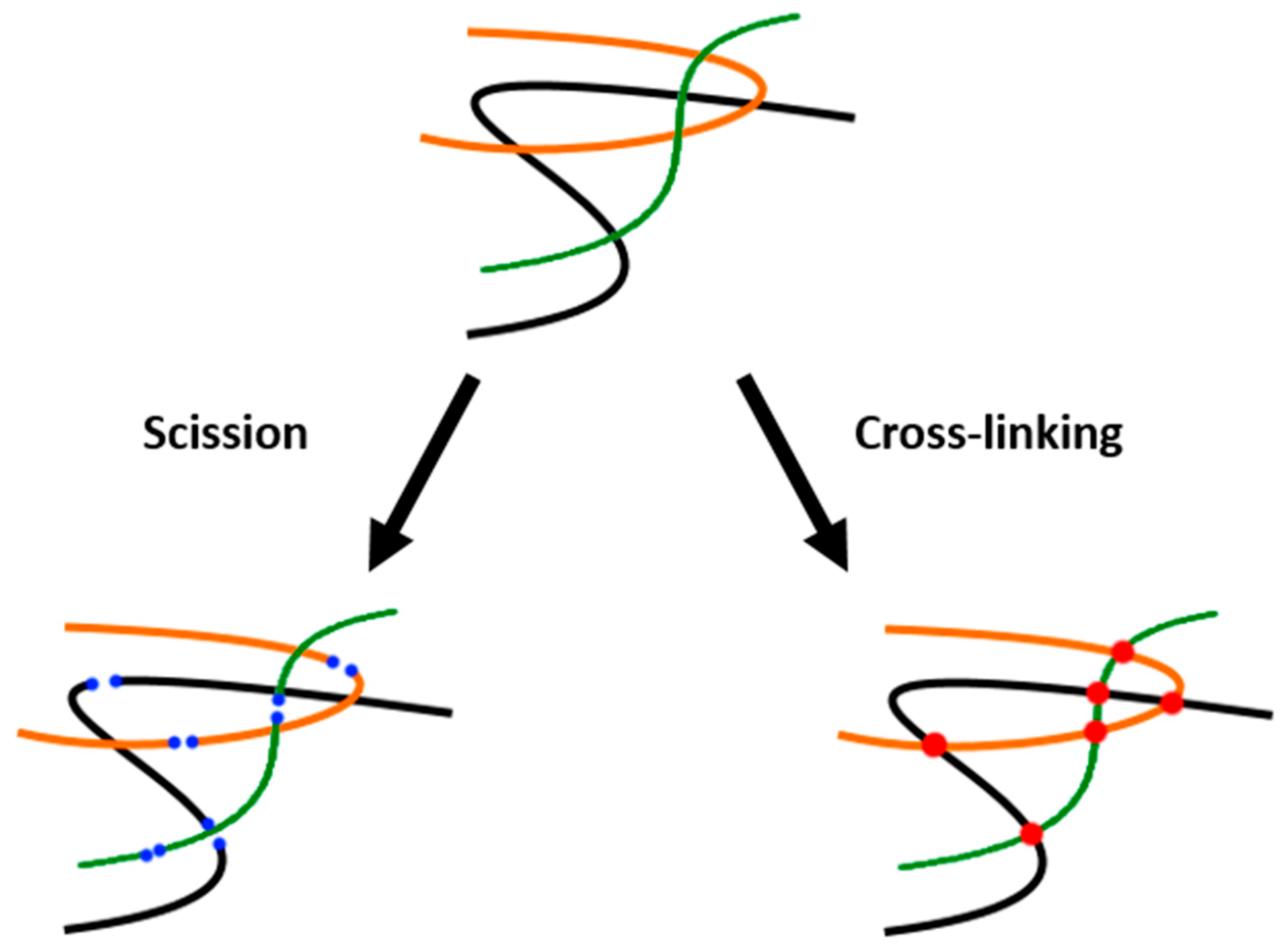

5.1. Ageing

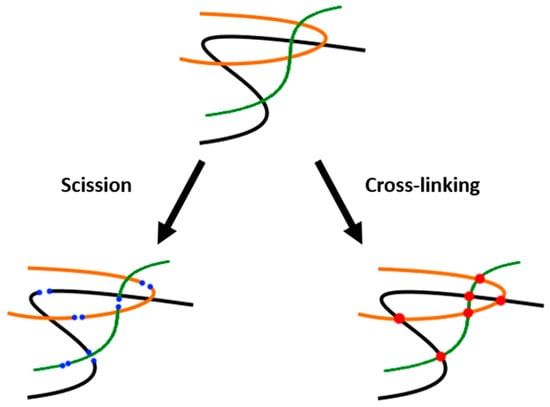

During their lifetime, plastic parts undergo a range of chemical and physical changes referred to as ageing [90]. The chemical changes are of interest here as the physical changes will disappear when the WEEE-p undergoes reprocessing. During chemical ageing, the macromolecules composing the polymer will be cut or cross-linked. This means the initially long and linear polymer chains will become shorter or branch out to neighbouring ones respectively as illustrated in Figure 12. These chemical changes within the molecules are triggered by various outside influences. First and foremost are oxidation and hydrolysis, which are triggered as oxygen and water diffuse into the polymer and react with it. Many other activating factors may initiate or increase such reactions, for instance heat, or UV radiation.

Figure 12.

Schematic illustration of chain scission and cross-linking during chemical ageing.

The colours represent different polymer chains within the material, the blue dots represent a polymer that is “split” on the microscopic level, due to ageing scission mechanisms, the red dots represent «fused» strands.

These chemical ageing mechanisms irreversibly alter the chemical structure of polymers, which impacts their macroscopic properties. Such changes include increased brittleness [91], poor processability [92,93], and aesthetic degradation, as many polymers undergo yellowing during chemical ageing [84].

The subject of polymer ageing is vast and will not be addressed in details here, as each polymer ages at a variable rate, depending on the nature of the polymer, the additives such as antioxidants that were added to delay the ageing, or even the environment in which the plastic part was used (i.e., indoors or outdoors).

These phenomena being complex and diverse, yet widespread, force recyclers to address them. In the literature, three main approaches are pursued: First, some authors proposed to dispose of the “overaged” plastics during the separation phase. Indeed, such chemical modifications can sometimes be tracked by spectroscopy. This implies that the optical separation step may allow for the exclusion of the “overaged” fraction, therefore indirectly allowing for a better quality of recycled plastics [84]. However, the main risk is to detect chemical ageing on the surface of used parts and to consider the whole part as overaged, leading to more eliminated polymers. Indeed, oxidation only appears at the surface of the parts (typically the first 100 µm). The volume of the degraded polymer is therefore small compared to the total volume. Reprocessing can lead to an overall lightly degraded part.

As mentioned in the introduction, chemical recycling aims to depolymerise the macromolecules [94]. In those cases, polymer chains shortened by ageing will undergo the same process and yield the same results as virgin or “full” length polymers.

Finally, some authors explore the possibility of using additives referred to as “chain extenders” [95]. Such additives aim to repair chains that have been shortened during ageing by adding new elements at the end of the chains or even stitching chains back together.

5.2. Fillers

Fillers usually refer to foreign solids intentionally included into the polymer matrix to improve its properties. Common fillers may typically be glass or carbon fibres from composites or talc added in PP. Powders like talc or carbon black may also be referred to as additives in some cases making their classification challenging. In the case of recycling, filler contaminants refer to these aforementioned “intentional fillers” that were added on purpose but also to any foreign contaminants remaining, such as small metallic particles or small paper pieces [71]. Such contaminants that were not removed during separation can be removed during the compounding by using a filter at the end of the extruder, right before the die, where the strands are extruded and pelletised. Therefore, the size of filler particles in recycled WEEE-p range from 0 to 30 µm in their smallest dimension [96].

The “intentional fillers” are generally harmless and can remain within the matrix as they were properly treated to be well integrated. However, they may yield unexpected properties compared to those of a “pure material”. On the other hand, unintentional fillers are responsible for dramatic drops in mechanical properties. Several authors report these issues for different foreign inclusions [96,97]. Unwanted contaminants usually act as defects that initiate cracks when the matrix is strained. These cracks are caused by the incompatibility between the foreign body and the matrix leading to poor adhesion at the interface. In the case of very hard or conductive materials like metal parts, they may damage the processing equipment or compromise the insulating properties of plastic [97].

These sorting errors may be compensated by more restrictive separation at a higher cost for the recycler. Labels may be more thoroughly washed away and metal parts may be removed by finer shredding which leads to lower throughput [71]. Qin et al. (2021) even suggest running a metal separation step after compounding [97]. As all pellets have the same size and density it allows for the strict condition of separation that enables the removal of very small metallic particles.

5.3. Contamination by Other Plastics

“Polymeric contaminants” designate small amounts of foreign polymer within another specific polymer. This can come from a sorting error, as a macroscopic polymer flake may be directed to the wrong batch, or from the limitations of the separation process. Indeed, paint, labels, surface treatment or dust may not be detectable [97].

There are very few publicly available data on the actual levels of contamination of recycled plastics by other plastics. Moreover, this value will vary from one separation technology to another, making it difficult to obtain an absolute value. However, an evaluation of output material purity for each process is available in the literature used in Section 3.

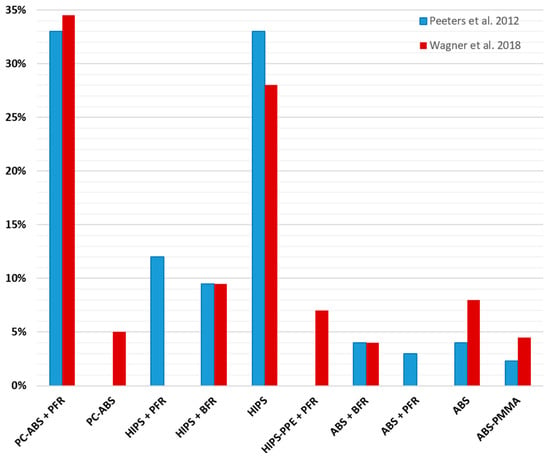

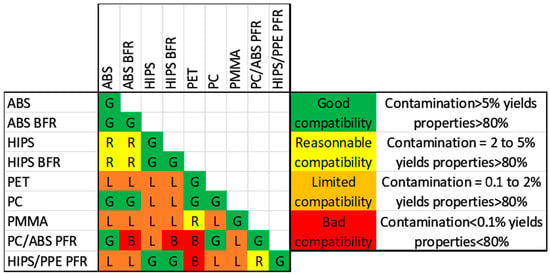

Polymeric contaminants may cause the deterioration of the expected properties in many ways. Aesthetics, colour or mechanical properties can be hindered by even a small concentration of contaminants [98,99], as most polymeric materials are incompatible with one another. When an incompatible contaminant is added to an object, it will act as a defect in the same way an unintended filler would, and can cause brittleness in manufactured products. A “Miscibility or recycling compatibility” table for some plastics found within WEEE can be found in the figure below (Figure 13). “Recycling compatibility” designates how well a couple of plastics mechanically behaves when blended. Bad compatibility causes a decrease in mechanical properties of more than 20% with 0.1% of contaminants. Sadly, PP is not considered in this study even though it represents a significative share of the WEEE-p stream.

Figure 13.

Miscibility or recycling compatibility of common plastics in WEEE [32].

Sometimes, two polymers may be compatible. In that case, the resulting blend tends to acquire the average properties (sometimes superior) of the two plastics. This is of use because the polymer is not rendered fragile by the contaminants. As the presence of contaminants seem to be economically and technically unavoidable, and the compatibilization of blend is well studied, different compatibilization strategies for recycling are explored in the literature [10,100]. These different degrees of compatibility are well illustrated by the study of Perrin et al. (2016) [101], where different samples of recycled HIPS from computer housings were prepared with various amounts of added PS, ABS or PP. Mechanical properties were monitored by impact strength and tensile tests. They concluded that up to 8 wt% of PS is acceptable and cause little deterioration of properties. For ABS, 4 wt% is tolerated and, finally, PP contaminants must be kept below 1 wt% to avoid large deterioration.

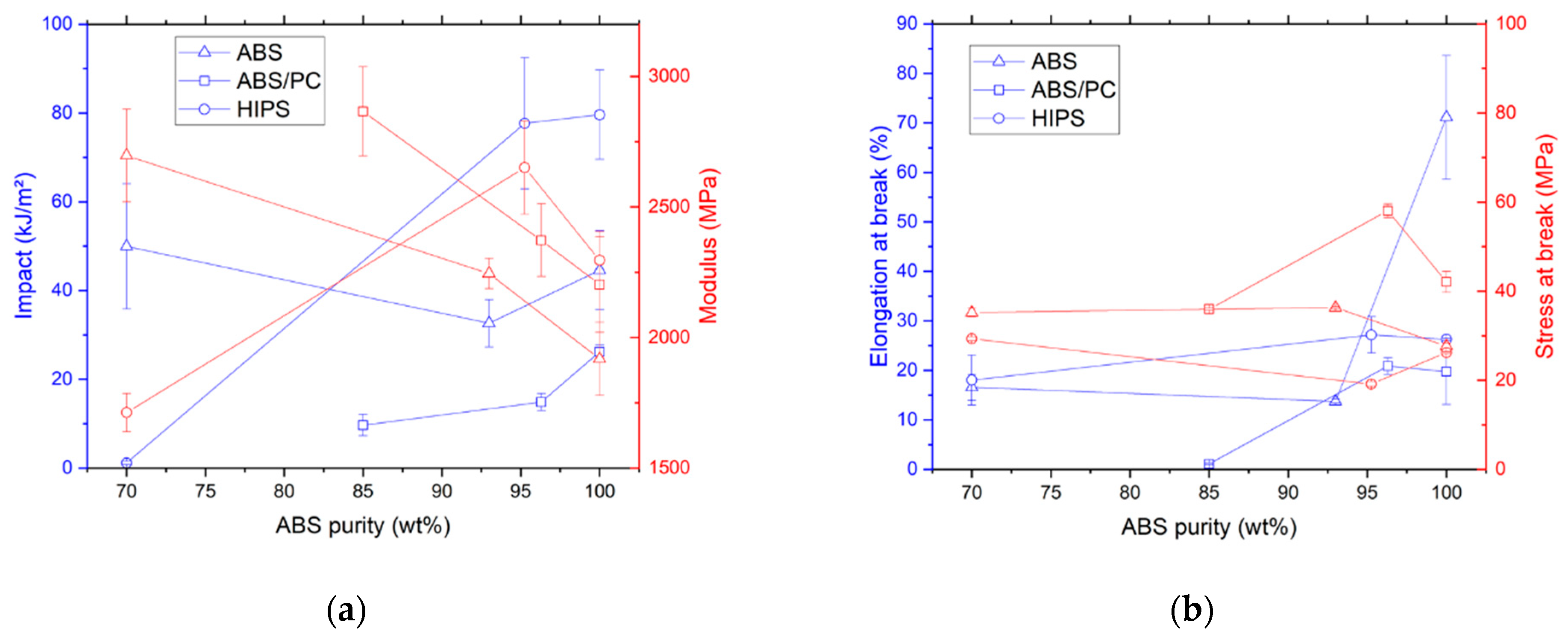

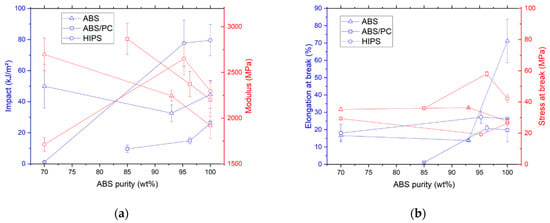

Beigbeder et al. [98] propose an estimation of the effect of these contaminants, but as virgin materials are being taken as a reference, ageing effects must also be included. In this article, two NIR separation machines are compared in terms of efficiency of separation on different waste polymer samples. The sorted sample are then injected into test specimens for mechanical property assessment. Figure 14 sums up their results in terms of the evolution of mechanical properties as a function of purity of the sorted sample.

Figure 14.

(a) Evolution of the impact strength and tension modulus of a sorted sample according to the purity rate; (b) Evolution of the elongation at break and stress at break of a sorted sample according to the purity rate [98].

Considering impact strength, higher purity leads to a higher increase in toughness especially for HIPS. A notable exception is the value for ABS at a 70% purity rate. It can probably be explained by the fact that this specific sample contains high amounts of HIPS, which has a higher impact strength than ABS (180% of the value of ABS), thus, this blend will present a similar impact strength to ABS. This is a good example of the previously mentioned phenomenon, where polymeric contaminants are partially compatible and lead to average values between those of the individual polymers.

Another value highly affected by contaminants is the elongation at break. As previously mentioned, contaminants can act as initiation sites for cracks that may propagate through the whole sample. For every sample, we can notice that elongation at break increases with purity. It is interesting to note that the values for high purity in recycled ABS/PC and HIPS are close to those of pure virgin materials, indicating that a low amount of contaminants might be tolerated in some cases. This tolerance will always depend on both on the type of introduced contaminants, and on the original polymer, as shown by the fact that 93% purity ABS has an elongation at break five times lower than that of virgin ABS.

These results shed light on the complexity of the topic of polymer contaminants, and on the difficulty of predicting the behaviour of contaminated polymers. Hence, the sorting and separation step discussed in Section 4 is crucial to ensure the quality of recycled polymers.

6. Conclusions

The EU has been promoting circularity since 2002 and regularly set more ambitious objectives. Even though the recovery rate of WEEE is increasing, there is still a lack of incentives towards the re-integration of recycled plastics in new equipment. It is important to note that the legal aspects discussed in this review and the data regarding the WEEE deposit are based on Europe; the reported results reported might be applicable to other regions of the world, but one should exert caution doing so. For WEEE that are sent to recycling, we can observe high disparities in the results of their treatment. Electric and electronic equipment are indeed diverse, and the composition of two equipment from different categories can be totally different, in terms of polymer composition, but also regarding potential contaminants. A definitive characterisation of the plastic fraction in each category of waste seems difficult to attain, but the main polymer types per equipment can be identified, with the major polymer types being ABS and PS/HIPS, followed by PP and PC. Other polymers only constitute a small part of the waste stream, and as such, are rarely sought after, and hence, are rarely recycled. Thus, a thorough characterisation of the waste stream seems necessary, especially within the recycling chain where the separation step is the central process to recover the economic and material value of plastics

Consequently, current recycling technologies are focused on the treatment of the major plastic flows, and other polymers that are present in lesser quantities are often disregarded. This is an issue for the plastic fraction of WEEE, as it is composed of numerous polymer types, requiring several separation steps to retrieve the different plastics.The efficient separation of polymers is essential in the recycling process of WEEE-plastics. However, the low selectivity of the most cost-effective separation techniques allows for the separation of the main polymer types, and the removal of most hazardous substances, but hinders the retrieval of minor plastic flows. Innovation in the field of separation techniques, and the development of new ones seems to be crucial, as an efficient separation process will limit the material loss, and allow for a satisfactory purity rate for plastics, thus facilitating their recycling and their use in new manufactured products.

Indeed, the presence of polymeric contaminants and fillers in recycled plastics negatively impacts their mechanical properties and damages the structural integrity of extruded plastics. The development of innovative solutions for material regeneration seems necessary in the near future, as the separation of plastics can only go so far as to retrieve the majority of polymeric and particular contaminants from the plastic fraction. As the polymers age, it becomes more and more difficult to re-extrude them into usable parts, pushing the research towards new ways of regenerating these materials. Thus, policy makers and industrial decision makers might find it relevant to reflect on the overuse of additives on the adequate insertion of polymers into the recycling chains.

Author Contributions

Conceptualisation, N.N., X.M.-D., N.P., C.C., S.P., B.F., M.G. and C.S.; Methodology, N.N. and X.M.-D.; Validation, N.P., C.C., S.P., B.F., M.G. and C.S.; Investigation, N.N. and X.M.-D.; Data curation, N.N. and X.M.-D.; Writing—original draft preparation, N.N.; Writing—review and editing, N.N. and N.P.; Visualisation, N.N. and N.P.; Supervision, N.P. and B.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded with a doctorate thesis (affectation 20 3178 071 CL71) by the non-profit public French PRO ecosystem, through the Chaire Mines Urbaines, Scientific Chair for Research and Formation.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR): Geneva, Switzerland, 2020; p. 120. Available online: https://collections.unu.edu/eserv/UNU:7737/GEM_2020_def_july1.pdf (accessed on 28 September 2022).

- Harscoet, E.; Dadou-Willmann, C. Analyse de La Chaîne de Valeur du Recyclage des Plastiques en France; ADEME, Deloitte: Angers, France, 2022. [Google Scholar]

- Garcia-Gutierrez, P.; Amadei, A.M.; Klenert, D.; Nessi, S.; Tonini, D.; Tosches, D.; Ardente, F.; Saveyn, H. Environmental and Economic Assessment of Plastic Waste Recycling; JRC: Canton, MA, USA, 2023. [Google Scholar]

- Favot, M.; Grassetti, L.; Massarutto, A.; Veit, R. Regulation and competition in the extended producer responsibility models: Results in the WEEE sector in Europe. Waste Manag. 2022, 145, 60–71. [Google Scholar] [CrossRef]

- Andersen, T. A comparative study of national variations of the European WEEE directive: Manufacturer’s view. Environ. Sci. Pollut. Res. 2021, 29, 19920–19939. [Google Scholar] [CrossRef]

- European Parliament. ‘2002/96/EC’, Official Journal L 037, 13/02/2003 p. 0024-0039. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX%3A32002L0096 (accessed on 29 November 2022).