Abstract

Automation equipment with different functions from different manufacturers is common in lithium ion battery manufacturing workshops, which is manifested as heterogeneous data distributed at different network levels at the information level. The interconnection between a workshop system and equipment is the basis for realizing manufacturing informatization and intelligence, and is a core problem of intelligent manufacturing workshop integration. The key to solve this problem is to establish a standardized and consistent information model. Aiming at the problem of information interconnection, this paper established an information model of the intelligent manufacturing workshop of lithium ion batteries based on the analysis of the architecture, functional categories, and information interaction of the intelligent manufacturing workshop. Then, by clarifying the attribute set, component set, and the information objects contained in each information model, the hierarchical architecture of the information model was constructed. Then, the rules that map the information model in to the OLE for Process Control Unified Architecture (OPC UA) address space is established. The approach for implementing data storage and interaction of the information model based on the OPC UA server/client are also discussed. Finally, taking the soft-pack battery manufacturing workshop as an example, the information model is applied to realize the interconnection and interoperability of production management data, material management data, equipment management data, and quality management data among various levels of the workshop, which verifies the feasibility of the proposed information model.

1. Introduction

After the Second Industrial Revolution, society developed rapidly. The extensive use of traditional fossil energy combustion not only brought serious environmental pollution, but also caused a great energy crisis. The use of new energy sources such as solar energy, wind energy, and hydrogen energy can effectively alleviate this problem, and has received strong support from various countries [1]. Although these energy sources are abundant in reserves and can be recycled cleanly, there are still problems in their large-scale application, such as energy conversion, transportation, and storage. Therefore, new energy storage technologies have received extensive attention, at the same time, the efficient and safe energy storage devices are playing the significant roles in the new energy sources [2]. Lithium ion batteries are favored for their advantages of high-energy density, high-power density, long service life, convenient carrying, and low cost, and have been widely used in the fields of power grid energy and storage [3], automobile and aviation [4], health care [5], consumer electronic products [6], and wearable intelligent products [7]. In recent years, the lithium ion battery industry is developing towards intelligent manufacturing [8]. Under the background of the “new normal” of industrial economic development, the intelligent level of the domestic lithium ion battery industry has a good foundation, but it still faces the current situation of heterogeneous control systems and differences in communication protocols in the workshop equipment layer. In the process of implementing an intelligent manufacturing workshop, a large number of protocol conversion modules need to be added in the equipment layer. As a result, the cost of integration and upgrading of intelligent manufacturing workshops has soared, the real-time and reliability of information have decreased, and information reuse and sharing are difficult, which has seriously hindered the upgrading of lithium ion battery manufacturing workshops to digitalization, networking, and intelligence [9,10]. There is an urgent need to solve information interconnection between all levels of lithium ion battery workshops and promote the development of intelligent lithium battery manufacturing.

Information integration and interconnection of intelligent manufacturing workshops are important guarantees and foundations for eliminating isolated islands of information and realizing digitalization and networking of workshops, and the key to this is to establish a standard information model [11]. The essence of an intelligent manufacturing workshop is to realize workshop information integration, interconnection, and consistent transmission of information/data. Its core includes three levels [12]: (a) Define the meaning of physical objects in the manufacturing process, and clarify the types and meanings of materials, equipment, environment, etc. in the physical objects; (b) Network construction based on data interconnection includes network construction among various levels and unification of data format and communication protocol in equipment layer; (c) Establishment of an information model of intelligent manufacturing workshop, including workshop architecture, functional architecture, hierarchical architecture, etc., to realize standardization of an information model.

In order to solve the data interconnection between various levels of the workshop, relevant institutions at home and abroad launched research on intelligent manufacturing information models, mainly including UML (Unified Modeling Language, UML), CIM-OSA (Computer Integrated Manufacturing-Openness System Architecture, CIM-OSA), and OPC UA (OLE for Process Control Unified Architecture) [13]. The UML model describes software views from different angles such as functional model, object model, and dynamic model, providing reference basis for software developers. However, this model is mostly used in software development, and it is difficult to completely describe the hierarchy of enterprises, resulting in insufficient definition among various levels of workshops. CIM-OSA is an open architecture, which proposes four views of function, information, organization, and resources. However, due to the imperfect content of the model framework, it has not been popularized in the field of industrial applications. OPC UA, as a new generation of communication specification launched by OPC Foundation, received extensive research in industrial process communication and information modeling [14].

In order to solve the problem of information integration and communication in digital workshops, those in academia conducted extensive research. Document [15] discussed the information modeling and standardization of a digital workshop; combed the ways and methods of standardization; compared the modeling methods of CIM-OSA, UML, and OPC UA; pointed out the advantages and scalability of OPC UA; and defined the development direction of information model standardization. Document [16] used OPC UA to model the information of knitting equipment, which was oriented to the equipment and control layer and solves the problem of equipment monitoring. However, it failed to consider the production process and did not reflect the function of an intelligent manufacturing workshop. Document [17] proposed an information interaction method based on OPC UA to realize information interaction at all levels of a machine tool workshop, but it failed to model the information of the intelligent manufacturing workshop, resulting in the data of the intelligent manufacturing workshop not being described in a unified format. Document [18] modelled the data between OPC UA protocol application and client and server, which solved the underlying data collection and production process monitoring, but did not realize the real information interconnection at all system levels, making it lack guidance in the process of popularization and application.

To sum up, the key to solve the above problems was to organize and sort out the workshop data by adopting a unified information model for intelligent manufacturing of lithium ion batteries, to define a unified description format to support the analysis of the information model, and to adopt a standardized integration scheme to provide a unified information interaction mode. At present, although there are some pieces of research and applications on workshop information models at home and abroad, most of them are the real-time collection of production factors and equipment for equipment and control layer, and are committed to solving the data collection and production process monitoring at the bottom layer. However, they did not systematically consider the production process, and could not realize the interconnection of information between various levels of the workshop, thus could not reflect the function of the intelligent manufacturing workshop. The existing lithium ion battery intelligent manufacturing system is still embodied in the form of stand-alone software version, lacking a unified information model, thus affecting the flexibility and scalability of the intelligent manufacturing system. There is still a gap in the research of the information model of intelligent manufacturing workshops in the field of lithium ion battery manufacturing. It is urgent to establish a set information model architecture of a lithium ion battery intelligent manufacturing workshop with a clear structure and flexible expansion, so as to solve the information interaction and integration in the lithium ion battery manufacturing process and realize the barrier-free circulation and sharing of information in the workshop.

In this paper, the establishment and application of an information model for an intelligent manufacturing workshop of lithium ion batteries are studied. Firstly, based on the core function category, organizational structure, and information interaction of an intelligent manufacturing workshop, this paper proposes a set of information model architectures suitable for an intelligent manufacturing workshop of lithium ion batteries, defines various attributes and attribute objects of the information model, and establishes the hierarchical architecture of the information model, which enables all data in the workshop to be described based on a standard protocol, a unified format, and the same language, thus realizing barrier-free circulation and sharing of data in the workshop. Secondly, through the combination of the OPC UA protocol, the instantiation and implementation method of the information model are discussed, and the application of the information model is verified based on OPC UA protocol and field application scenarios. Finally, a set of intelligent manufacturing information systems is developed and the information interaction mode of equipment layer, workshop layer, and enterprise layer in the intelligent manufacturing workshop is established based on the information model of OPC UA protocol, which realizes the information interconnection and interoperation among all levels in an intelligent manufacturing workshop for lithium ion batteries.

2. Architecture and Functions of an Intelligent Manufacturing Workshop

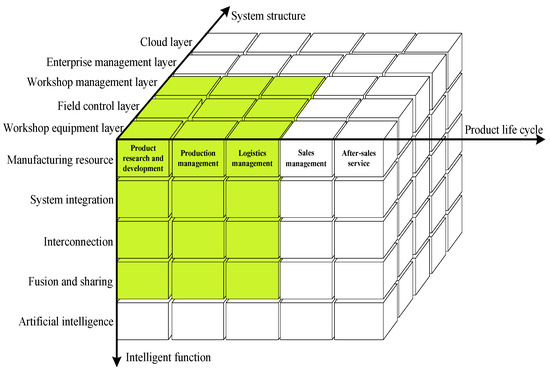

The intelligent manufacturing system architecture mainly describes the research and development, production, characteristics, and other contents involved in the workshop from three dimensions of system structure, product life cycle, and intelligent function, providing reference for the industry to build an intelligent manufacturing architecture and framework [19]. Referring to the National Intelligent Manufacturing Standard System Construction Guidelines (2015 Edition) [20], the system structure dimension of the intelligent workshop includes workshop equipment layer, on-site control layer, and workshop management layer. Product life cycle dimensions include product research and development, production management, and logistics management. The dimensions of intelligent functions include manufacturing resources, system integration, interconnection, integration, and sharing. The architecture of the intelligent manufacturing system and the scope of the intelligent workshop coverage are shown in Figure 1.

Figure 1.

Intelligent manufacturing system architecture and scope of intelligent workshop coverage.

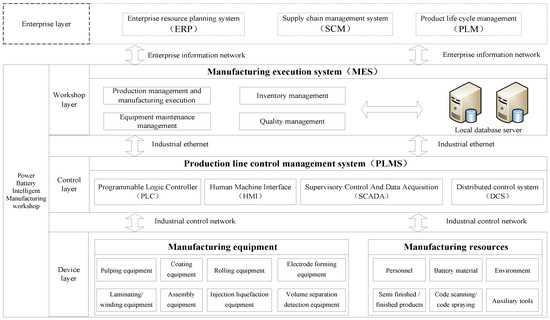

According to the organizational structure and coverage of the intelligent workshop, and in combination with the living conditions and requirements of lithium ion batteries, the lithium ion battery intelligent manufacturing workshop includes a workshop equipment layer, on-site control layer, and workshop management layer, as well as the functions and businesses covered by each level. The organizational structure is shown in Figure 2 below. The equipment layer is mainly composed of production equipment and production resources, of which the production equipment includes battery manufacturing equipment, and the production resources include materials, personnel, work in process, finished products, auxiliary tools, etc. The control layer is mainly composed of an equipment control system, workshop HMI, data acquisition and monitoring system (SCADA), and distributed control system (DCS). This layer includes computer software, network data communication link, and user interface, which can realize the functions of real-time data acquisition, equipment layer supervision and management, abnormal data alarm, etc. The workshop layer is mainly composed of a manufacturing execution system (MES) and database server, which mainly realizes the functions of workshop production organization management, material management, equipment management, and quality management, and focuses on solving the production management problems of the workshop. In addition, the upper layer of the intelligent manufacturing workshop is the enterprise layer and the cloud platform layer. The enterprise layer is mainly composed of an enterprise resource planning (ERP) system, supply chain management (SCM) system, product life-cycle management (PLM), and other systems, which realize the interaction of order business with the MES system in the workshop layer, providing some resource data required to produce, schedule, and monitor the operation status of the entire intelligent manufacturing workshop.

Figure 2.

Organization structure schematic diagram of lithium ion battery intelligent manufacturing workshop.

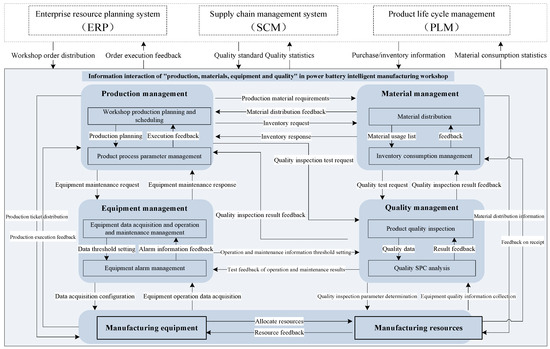

Regarding “Industrial Automation Systems and Integration-Functional Architecture of Manufacturing Execution System” [21], the core functions of an intelligent manufacturing workshop include four functional modules: production management, material management, equipment management, and quality management. According to the requirements of lithium battery production and manufacturing, the main information flow of each functional module and each other is shown in Figure 3.

Figure 3.

Information interaction of main functions in lithium ion battery intelligent manufacturing workshop.

According to the requirements of organizational structure, functional modules, and information interaction between functional modules of the lithium battery intelligent manufacturing workshop, it is necessary to model and describe the equipment, functions, and data or documents generated in the process in the lithium ion battery manufacturing workshop to form an information model of the intelligent manufacturing workshop. Due to the complex process, huge data information, inconsistent manufacturing processes, and diversified product specifications in the lithium battery production workshop [22], the following basic requirements should be met when modeling information regarding the lithium battery intelligent manufacturing workshop.

- Integrity. The information model of an intelligent manufacturing workshop should include three system levels of workshop equipment, on-site control, and workshop management, so as to cover the dimensions of product life cycle and intelligent functions, express rich information to the maximum extent, and embody the value of intelligent manufacturing.

- Scalability. The main functions and information interaction in the intelligent manufacturing workshop will change with time, so the information model must be open, and each functional module and each level directly need to provide scalable interfaces to facilitate upgrading and transformation.

- Consistency. The intelligent manufacturing information workshop model has consistent information descriptions for all kinds of information in the workshop, so it is necessary to choose the same description method and use standardized terms to express it in the modeling process.

- Flexibility. Due to the different nature and scale of lithium battery manufacturing workshops, as well as the differences in software, hardware, and coverage functions, there are differences in the architecture composition of information models, and the information models should have object-oriented methods for modeling.

3. Information Model of Intelligent Manufacturing Workshop for Lithium Ion Batteries

Information model is a method used to define the representation of information. When constructing the information model of an intelligent manufacturing workshop, the contents of three dimensions should be defined: (a) Determining the objects to be defined and the data contained in the objects; (b) How to build a hierarchical structure to organize these objects and data; (c) Clarify the role of information model in the whole intelligent manufacturing workshop. Through the establishment of the information model and the definition of various elements and hierarchical structures in the information model, all the information in the workshop can be described based on a standard protocol, in a unified format and in the same language, thus realizing barrier-free communication and sharing of information in the workshop.

3.1. Hierarchical Architecture of Information Model for a Lithium Ion Battery Intelligent Manufacturing Workshop

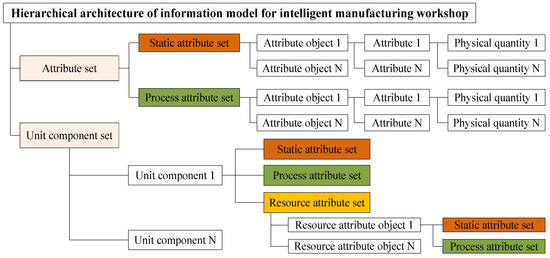

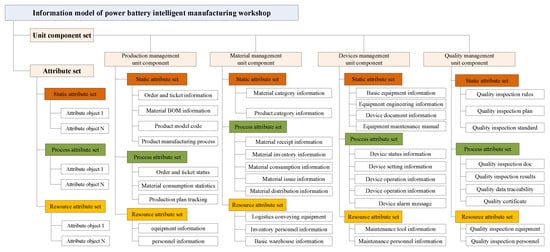

As shown in Figure 3, the intelligent manufacturing workshop is mainly composed of functional modules (production management, material management, equipment management, quality management module) and production resources (personnel, manufacturing equipment, manufacturing resources, materials, semi-finished products, finished products, etc.) to realize various functions. In the process of information modeling, the above parts are defined as components, functional modules are defined as unit components, and production resources are defined as resource components, in which unit components contain resource components, and the set of all information data contained in unit components is called a unit component set. In addition to the unit component set, various data and documents involved in the intelligent manufacturing workshop are defined as attributes, and the set of all information data contained in the attributes is called an attribute set. According to the form of information data, attribute sets can be divided into static attribute sets and process attribute sets [23]. Static attribute sets represent information data sets that will not change or change slowly, such as material codes, order and ticket numbers, equipment identification and model numbers, etc.; the process attribute set represents the information data set that will change with time, such as equipment process/operation data, logistics status information, product processing status and quality information, etc. Therefore, the information model of a lithium ion battery intelligent manufacturing workshop includes attribute set and unit component set. Its attribute set, component set, and the attribute objects it contains form the hierarchical structure of the information model, as shown in Figure 4.

Figure 4.

Hierarchical architecture of intelligent manufacturing workshop information model.

As shown in Figure 4, the information model of the intelligent manufacturing workshop is divided into levels, and the elements of the information model are explained as follows from small to large:

Physical quantity: The basic element that makes up the attribute and is the basic unit of the attribute. It consists of static physical quantities and process physical quantities, of which: Static physical quantities include name, manufacturer, model, etc.; Process physical quantities include parameters of equipment moving parts, such as speed, tension, accuracy, temperature, etc.

Attribute: Used to describe the properties and characteristics of attribute objects, and each attribute consists of multiple physical quantities. Attribute object is an entity in intelligent manufacturing workshop, including real or abstract entities, which can be digitally defined and described through attributes, such as equipment components, inventory documents of materials, process formula of a certain product, etc.

Attribute object: It is an information body in the workshop field, which is used to describe real or abstract entities that can be conceptualized as a whole. Examples of attribute objects include workshop orders, maintenance statistics of certain equipment, and processing routes of certain products. The attribute set completes its digital definition and digital description through its attributes.

Attribute set: A set of all attribute objects. According to the static and dynamic characteristics of data, it is divided into a static attribute set and dynamic attribute set. Static attribute sets represent information data that will not change or number slowly after definition. In workshops, they are mainly represented by asset representation, order or work order data, etc. The process attribute set represents the data generated, disappeared, or changed in real time along with the production process, generally including equipment status data, parts production process record data, etc.

Unit component set: It represents the set of all information involved in workshop functions. Unit components nest static attribute sets, process attribute sets, and resource attribute sets of corresponding auxiliary resources (materials, personnel, products, etc.). Among them, the resource attribute set represents the production factors that realize each function in the unit component set, and is generally composed of personnel, equipment, semi-finished products, finished products, etc.

3.2. Establishment of Information Model for an Intelligent Manufacturing Workshop for Lithium Ion Batteries

According to the organizational structure, information interaction, and hierarchical structure of an information model for a lithium ion battery intelligent manufacturing workshop, this paper proposes an information model for a lithium ion battery intelligent manufacturing workshop, as shown in Figure 5. The information model consists of attribute sets and unit components, of which: The attribute set includes static attribute set and process attribute set; The unit component set covers four unit components of production management, material management, quality management, and maintenance management in the intelligent manufacturing workshop. Each unit includes a static attribute set, process attribute set, and resource component set.

Figure 5.

Schematic diagram of information model of lithium ion battery intelligent manufacturing workshop.

The static attribute set in the information model provides static basic data support for the operation of the intelligent manufacturing workshop. The process attribute set summarizes the execution status of the order/work order of the intelligent manufacturing workshop and the statistical information of each unit component information model for real-time feedback to the enterprise layer. The unit component set includes the production management, material management, equipment maintenance, and quality management unit information sub-models of the intelligent manufacturing workshop, which are used to realize business interaction and data transmission in the battery manufacturing process. The attribute objects and descriptions of the information model are shown in Table 1, Table 2, Table 3, Table 4 and Table 5.

Table 1.

Attribute objects and function descriptions contained by static attribute set and process attribute set of lithium ion battery intelligent manufacturing workshop.

Table 2.

Attribute objects and function descriptions contained by production operation unit components.

Table 3.

Attribute objects and function descriptions contained by material management unit components.

Table 4.

Attribute objects and function descriptions contained by equipment management unit components.

Table 5.

Attribute objects and function descriptions contained by quality management unit components.

4. Information Interaction Architecture Based on OPC UA

In the previous chapter, an information model for the intelligent manufacturing workshop of lithium ion batteries was constructed. In the modeling and software development of the actual intelligent manufacturing workshop, the data collection between the equipment should be realized, and the data of the manufacturing equipment and manufacturing resources should be transmitted to the information model in real time by standard protocols, thus realizing the information interaction between different levels of the intelligent manufacturing workshop. This paper provides an information model interaction architecture and implementation method based on OPC UA protocol.

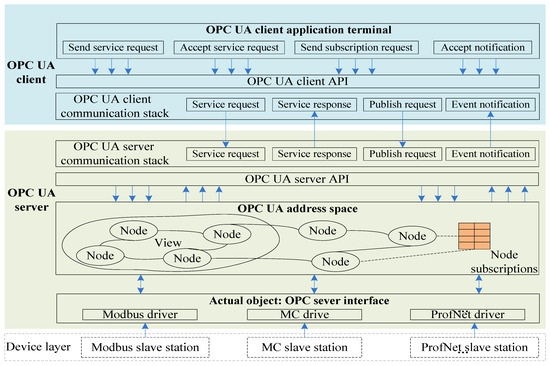

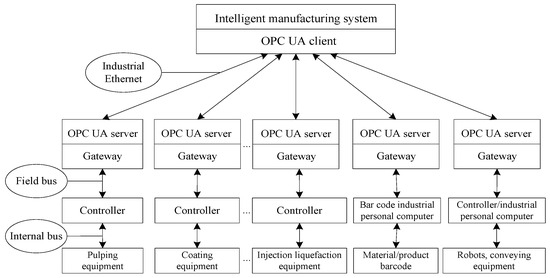

OPC UA is a new standard created by OPC Foundation, called OPC Unified Architecture (OPC UA). It defines a set of common data description and syntax expression methods; that is, each heterogeneous control system can use OPC UA specification to describe its own information, and then through OPC server/client mode, the third-party system can obtain the data of a heterogeneous control system [24]. OPC UA uses address space and adds object semantic recognition function to support information models and provide rich information hierarchy architecture, which can realize interoperability of information models. In addition to the information model, OPC UA provides a platform-independent interoperability standard for data and information transmission between factory workshops and enterprises, which can meet the unified architecture for communication between industrial equipment PLC, HMI, or industrial personal computers and upper intelligent systems [25,26]. In this paper, aiming at multi-protocol access of lithium battery manufacturing equipment, the corresponding relationship with equipment data information address is established through data configuration and mapping, and different protocols are uniformly converted into OPC UA standards by using OPC UA conversion layer, and the collected data are uploaded to OPC UA clients of intelligent systems in real time through OPC UA servers. The communication modes of the OPC server and the OPC client are shown in Figure 6.

Figure 6.

OPC UA server/client architecture.

- Field device layer: It mainly includes lithium ion battery manufacturing equipment or manufacturing resources, and its control system involves communication protocols such as Modbus RTU, Modbus TCP, Mitsubishi MC and CC-Link, Siemens Profinet, etc.

- OPC UA server: Build a space node with the device layer in the OPC UA server, establish a communication channel with the device, and set the connection channel mode, including the IP address, port number, sampling period, address label, etc. of the device control system. Through the configuration software of OPC UA server, various heterogeneous communication protocols in device layer are mapped into the address space of OPC UA server and uploaded to OPC UA client with OPC UA standard communication protocol.

- OPC UA client: The client is deployed in the upper management system and is responsible for listening and reading the model nodes and address space in the OPC UA server to upload real-time data from the equipment layer to the client. The upper management system can read the data of OPC UA client, and will use C language, VB language, C# language, Python language, and other software development to form application management terminal software.

- OPC UA communication stack: It can realize information communication between OPC UA server/client, including message coding and analysis, message transmission, and other functions.

- OPC UA address space: It defines the node set in the OPC UA server and is used to represent the actual physical objects, object definitions, and mutual reference relationships between objects. OPC UA clients can search the node set in the address space by using development software.

- OPC UA client/server API: It is used to separate the interface between client/server application code and communication stack, and realize the functions of managing session and message processing.

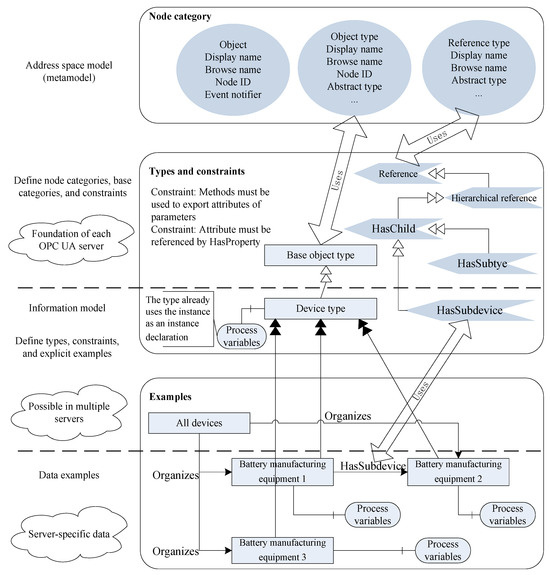

The basic component unit of OPC UA address space is nodes, which form the meta-model of address space and are used to represent real physical objects, the definition of objects, and the reference relationship between objects [27]. The nodes organize the address space into an interrelated network structure with hierarchical structure and mutual reference relationship [28]. The relationship between address space model, information model, and data is shown in Figure 7.

Figure 7.

OPC UA address space model, information model, and data example.

OPC UA address space is made of nodes and references between nodes, and clients can browse the way reference type nodes to obtain the current reference semantics. Table 6 summarizes the reference types, relationships, and descriptions between OPC UA elements.

Table 6.

Reference type relationships between elements.

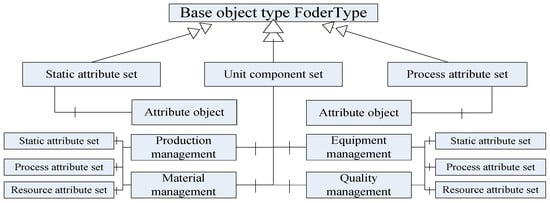

The OPC UA address space model is a specification that describes the syntax and semantics of the information model. In the process of mapping information model objects to OPC UA address space, it is necessary to realize the mapping of information model attribute data and hierarchical structure. Combined with the analysis of Figure 7, the information model of intelligent manufacturing workshop for lithium ion batteries is instantiated, and HasSubtype reference type is used to represent the relationship between the unit component set, static attribute set, and procedure attribute set of the information model with FolderType basic object in OPC UA address space; and HasComponent reference type is used to represent the relationship between the information model and unit component, unit component and attribute set, attribute set and attribute object [29]. The mapping method of the information model to the address space is shown in Figure 8.

Figure 8.

Mapping method of lithium ion battery intelligent manufacturing workshop information model and OPC UA address space.

5. Information Model Verification Based on OPC UA

The architecture based on OPC UA server/client is adopted to verify the feasibility of the information model of a lithium ion battery intelligent manufacturing workshop. Then, the gateway based on OPC UA standard is selected as the server side, and the independent bus or specific interface is adopted to the lower device control system, and the information model is mapped into the OPC UA address space through the software on the OPC UA server side. The standard OPC UA communication protocol is adopted for the upper intelligent manufacturing workshop information system, and the data of the information model in the address space of the OPC UA server can be searched and traversed through the software of the OPC UA client. The schema connection of the OPC UA server/client is shown in Figure 9.

Figure 9.

Architecture of OPC UA server/client in lithium ion battery intelligent manufacturing workshop.

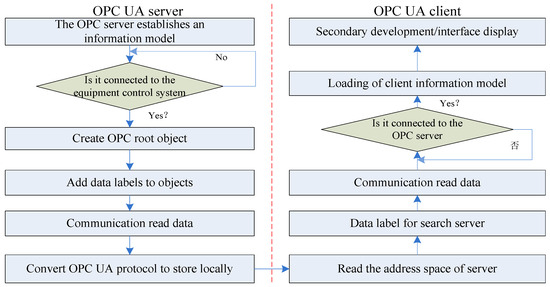

According to the OPC UA server/client architecture, the OPC UA server uses the configuration software generated by the secondary development of the OPC UA SDK software development kit to complete the mapping of the information model to the OPC UA server address space. OPC UA client uses UA Expert 1.4. 1 software to load the information model of a lithium ion battery intelligent manufacturing workshop. The specific process is as follows: (1) The OPC UA server establishes a driving channel with the information model of the lithium ion battery intelligent manufacturing workshop; maps the attribute set, component set, and various elements of the information model to the OPC UA address control node; and sets the IP address and port number connecting the physical objects; (2) Judging whether that drive channel and the device lay slave station are connected successfully; (3) Creating an OPC UA root object group in that OPC UA server; (4) Adding data labels; (5) Reading the data and converting to the OPC UA protocol; (6) Using OPC UA client to search and read the address space of OPC UA server to obtain data of information model; (7) Loading and browsing of OPC UA client information model; (8) The development of an intelligent information system based on the data obtained by OPC UA client. The information model validation process for OPC UA is shown in Figure 10.

Figure 10.

Information model validation process based on OPC UA.

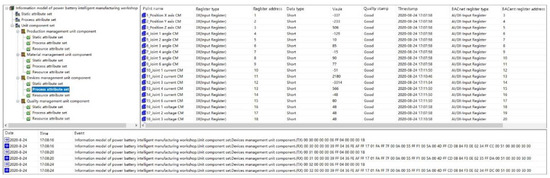

Taking the process attribute set of the device management unit component-robot Modbus TCP communication protocol as an example and the data information to be collected is shown in Table 7. In addition, it also needs to load the robot’s information model into the server’s address space through OPC UA server configuration software, including creating Modbus TCP root object, data label information, IP address, port number of the control system, etc., as shown in Figure 11. Then through the OPC UA client software to search the server address space information model data, complete the OPC UA server/client information model verification.

Table 7.

Information table of collected robot data (Part).

Figure 11.

Partially results test of information model mapping to OPC UA server.

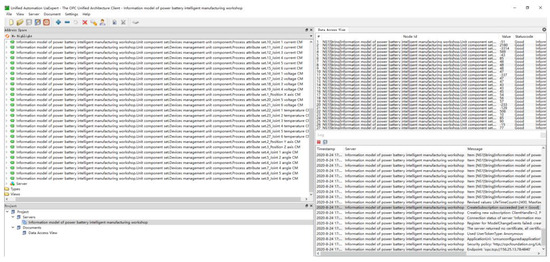

After the OPC UA client accesses the information model of the server, it can traverse all NodeId nodes to load the information model of the lithium ion battery intelligent manufacturing workshop to obtain the contents of the information model. The test results are shown in Figure 12.

Figure 12.

Data results of the OPC UA client search server information model.

Verification tests show that the information model designed can realize the mapping of OPC UA server address space. Combined with OPC UA server/client architecture, the client can obtain all the contents of the information model, which verifies the feasibility of the information model based on OPC UA.

6. Application Case of an Information Model in an Intelligent Manufacturing Workshop for Lithium Ion Batteries

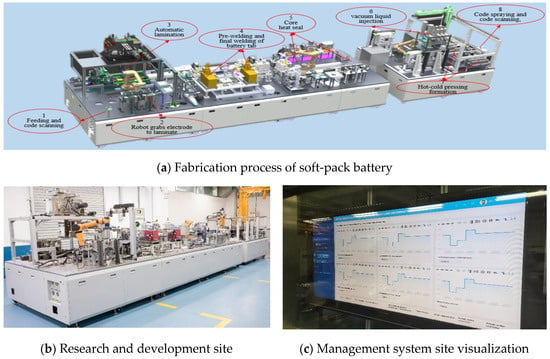

Taking the site of the intelligent soft envelope line test line developed by us as an example, the site application test was carried out on the information model for the lithium ion battery intelligent manufacturing workshop. The site environment is shown in Figure 13. The soft-pack single battery consists of four modules: a lamination unit, a welding unit, a packaging unit, and a liquid injection unit. Its main production process is as follows: (a) The positive and negative electrodes enter the transition cabin and enter the lamination module under the glove box environment to scan the code; (b) The robot grabs the positive and negative electrodes to the laminate table; (c) The laminate unit automatically laminates; (d) The transplanting mechanism transfers the battery core to the welding unit to carry out pre-welding and final welding of the pole lugs; (e) Transferring the welded battery core to the packaging unit through the logistics conveying line for heat sealing of the aluminum-plastic film; (f) The packaged battery cell is transferred to the liquid injection unit through the transition cabin for vacuum liquid injection and stationary; (g) The battery cell after liquid injection is transferred to the liquid injection unit through the transition chamber for hot and cold pressing; (h) After the cut battery cell is scanned into the warehouse, it is ready for charging and discharging test, thus the soft pack single battery is prepared.

Figure 13.

Schematic diagram of production process and site of soft-pack battery.

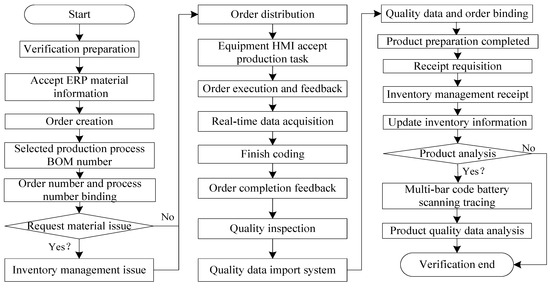

In practical application, it usually takes the manufacturing process of soft-pack batteries as an example, and takes the import of material information, order creation, binding of orders, and production processes, scheduling of materials in and out of the warehouse, order issuance, feedback of order execution progress, statistics of equipment operation status, binding of quality inspection and data, and product warehousing as the test processes. The specific test flow chart is shown in Figure 14. The data of OPC UA client is read through the background database of the intelligent system, and the application verification of production management, material management, equipment management, and quality management information models is completed.

Figure 14.

Field application test flow chart.

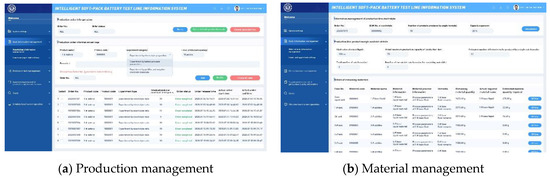

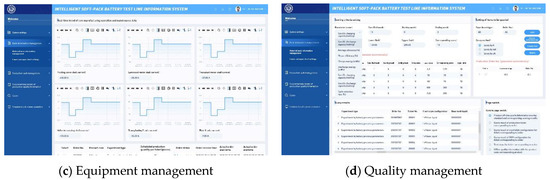

According to the practical requirements of the production of the demonstration line of the soft-pack battery, on the basis of completing the information model of the OPC UA server read by the OPC UA client, the “Intelligent Soft-pack Battery Test Information System” is designed and developed by using C # as the development language, Microsoft SQL Server 2008 as the database system, and Visual Studio 2010 as the development tool. The intelligent information system is guided by the main functions of the lithium ion battery intelligent manufacturing workshop, covering the functional fields of production management, material management, equipment management, quality management, and reading the material data, equipment manufacturing process data, electrolyte ratio, and other data of the OPC UA client. After the intelligent information system creates the order, it is sent to the HMI interface of the equipment layer to realize the task distribution and execution tracking of production management, and the information interaction and integration of material data, equipment data, and quality data. Some interfaces of its four main functions are shown in Figure 15.

Figure 15.

Display of some software interfaces of an intelligent information system.

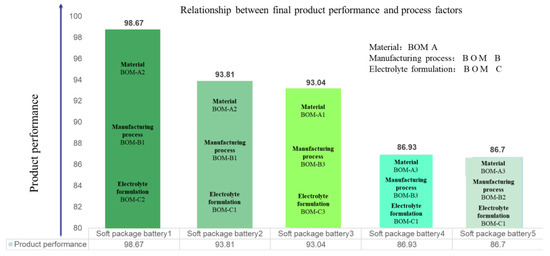

The evaluation standard for the performance of a soft-pack single battery is based on the comprehensive consideration of the charging and discharging capacity in the first week, the charging and discharging capacity in the second week, the charging and discharging capacity in the 100 weeks detected after the battery is offline, and what the customer scores the finished product (0–100 points). Taking material data A, specific parameters BOM-A1, BOM-A2, BOM-A3, equipment manufacturing process data B, specific parameters BOM-B1, BOM-B2, BOM-B3, electrolyte formula data C, specific formula BOM-C1, BOM-C2, BOM-C3 as examples, we can scan the quick response code to query the finished batteries through the quality analysis and tracing module of the intelligent system, and form BOM information of process parameters (materials, manufacturing process, electrolyte formula) of multiple battery batches. Based on the optimization of the product quality judgment data of the quality management module, the order and work order data of the production management module, the material data of the material management module, the manufacturing process of the equipment management module, and the electrolyte ratio data can be matched to realize the functional business exchange of the lithium battery intelligent manufacturing workshop. See Table 8, Table 9, Table 10, Table 11 and Table 12 for the product quality evaluation table and the matching relationship between the product quality and each functional module.

Table 8.

Product quality evaluation table.

Table 9.

Order and BOM information corresponding to products.

Table 10.

Correspondence between battery quality and material information.

Table 11.

Correspondence between battery quality and equipment manufacturing process.

Table 12.

Correspondence between battery quality and electrolyte proportion parameters.

Through the output results of the intelligent information system, the information interaction relationship between each functional module in the lithium battery manufacturing process can be analyzed. In addition, aiming at the best performance of the final product, the optimal matching relationship of material data BOM-A2, equipment manufacturing process data BOM-B1, and electrolyte ratio data BOM-C2 is screened out, as shown in Figure 16, which can provide scientific researchers with conditions for product research, development, trial production and shorten the research and development cycle of new products.

Figure 16.

Relationship between product performance and process factors.

According to the field application test results and through the data mapping method, the intelligent system can realize the static data writing and real-time process data collection of the production management, material management, equipment management, and quality management function modules in the soft-pack battery manufacturing process. In addition, by combining the OPC UA address space information model, this paper verifies the feasibility of the proposed information model and realizes the information interaction among equipment layer, workshop layer, and enterprise layer. Contrary from the original “Lithium Battery Intelligent Manufacturing Workshop Management System”, all the information data in the background of the system developed in this paper came from OPC UA address space information model and are organized according to the information model architecture and hierarchical structure proposed in this paper. Through field application tests, the integrity of the proposed information model was verified, and the organization and management of all information could be realized. Compared with the relational database, the information model can fully realize the functions equivalent to the relational database. However, its standardized and hierarchical architecture facilitates the integration of new equipment, expansion of workshops, and information interaction with enterprises. In the later period, the functions of the intelligent manufacturing workshop and the elements contained in the functions can be further expanded on the basis of the established information model and hierarchical architecture technology, so as to promote the upgrading of the lithium ion battery intelligent workshop to the direction of digitalization, networking, and intelligence.

7. Conclusions

By analyzing the organizational structure, functional modules, and information flow of the lithium ion battery intelligent manufacturing workshop, the requirements and modeling methods of its information model are defined. In this paper, the four functional modules of production management, material management, equipment management, and quality management of a lithium ion battery intelligent manufacturing workshop are modeled. In addition, the information model architecture scheme according to attribute set, unit component set, attribute object, attribute, and physical quantity is proposed, and the hierarchical and modular information model system is constructed. Through the OPC UA server and client, this paper completes the mapping of the information model in the OPC UA address space, and describes all the data in the workshop based on a unified standard protocol and the same data structure, which solves the problem of “information isolated island” commonly existing in manufacturing workshops in the lithium battery industry, so that the data in the lithium battery manufacturing process can be freely circulated and shared among various levels of the intelligent workshop.

The information model proposed in this paper was instantiated and verified on the spot in the intelligent soft-pack test line of the Institute of Industrial Technology, Guangzhou & Chinese Academy of Sciences, and a set of intelligent manufacturing information system was developed. Based on the information model of OPC UA protocol, the information interaction mode of equipment layer, workshop layer, and enterprise layer in an intelligent manufacturing workshop is established, and the information interconnection of each level in intelligent manufacturing workshop is realized, and the practicability of the information model is proved.

The information model defined in this paper has the advantages of strong applicability, feasibility, and operability, and has important reference significance for guiding the information model modeling and information integration construction of a lithium ion power battery intelligent manufacturing workshop, which can be flexibly applied to other lithium ion battery manufacturing fields, solve the problem of data interconnection between various levels of intelligent workshops, and promote the development of the lithium ion battery industry towards informatization and intelligence.

Author Contributions

Conceptualization, Y.H. (Youjun Han); methodology, Y.H. (Yueming Hu); software, Y.W.; validation, Y.H. (Youjun Han); formal analysis, Y.H. (Yueming Hu); resources, X.H.; software, Y.W.; data curation, G.J. and C.G.; writing—original draft preparation, Y.H. (Youjun Han); writing—review and editing, Y.H. (Youjun Han) and Y.H. (Yueming Hu); project administration, C.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science and Technology Planning Project (No.2018YFB0104100, No. 2019YFA0705100).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sun, Y.-K.; Myung, S.-T.; Park, B.-C.; Prakash, J.; Belharouak, I.; Amine, K. High-energy cathode material for long-life and safe lithium batteries. Nat. Mater. 2009, 8, 320–324. [Google Scholar] [CrossRef] [PubMed]

- Blomgren, G.E. The Development and Future of Lithium Ion Batteries. J. Electrochem. Soc. 2016, 164, A5019–A5025. [Google Scholar] [CrossRef]

- Ning, X.; Phadke, S.; Chung, B.; Yin, H.; Burke, P.; Sadoway, D.R. Self-healing Li–Bi liquid metal battery for grid-scale energy storage. J. Power Sources 2015, 275, 370–376. [Google Scholar] [CrossRef]

- Swornowski, P.J. Destruction mechanism of the internal structure in Lithium-ion batteries used in aviation industry. Energy 2017, 122, 779–786. [Google Scholar] [CrossRef]

- Moslemi, N.; Gohari, S.; Mozafari, F.; Zardian, M.G.; Burvill, C.; Yahya, M.Y.; Ayob, A. A novel smart assistive knee brace incorporated with shape memory alloy wire actuator. J. Intell. Mater. Syst. Struct. 2020, 31, 1543–1556. [Google Scholar] [CrossRef]

- McAllister, J.A.; Farrell, A.E. Electricity consumption by battery-powered consumer electronics: A household-level survey. Energy 2007, 32, 1177–1184. [Google Scholar] [CrossRef]

- Poon, C.C.; Liu, Q.; Gao, H.; Lin, W.-H.; Zhang, Y.-T. Wearable Intelligent Systems for E-Health. J. Comput. Sci. Eng. 2011, 5, 246–256. [Google Scholar] [CrossRef]

- Turetskyy, A.; Thiede, S.; Thomitzek, M.; Von Drachenfels, N.; Pape, T.; Herrmann, C. Toward Data-Driven Applications in Lithium-Ion Battery Cell Manufacturing. Energy Technol. 2020, 8, 1900136. [Google Scholar] [CrossRef]

- Schnell, J.; Reinhart, G. Quality Management for Battery Production: A Quality Gate Concept. Proc. CIRP 2016, 57, 568–573. [Google Scholar] [CrossRef]

- Wood, D.L.; Li, J.; Daniel, C. Prospects for reducing the processing cost of lithium ion batteries. J. Power Sources 2015, 275, 234–242. [Google Scholar] [CrossRef]

- Cerdas, F.; Thiede, S.; Juraschek, M.; Turetskyy, A.; Herrmann, C. Shop-floor Life Cycle Assessment. Proc. CIRP 2017, 61, 393–398. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Jawahir, I.; Balaji, A.; Rouch, K.; Baker, J. Towards integration of hybrid models for optimized machining performance in intelligent manufacturing systems. J. Mater. Process. Technol. 2003, 139, 488–498. [Google Scholar] [CrossRef]

- Lam, A.N.; Haugen, O. Implementing OPC-UA services for Industrial Cyber-Physical Systems in Service-Oriented Architecture. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society; Institute of Electrical and Electronics Engineers (IEEE), Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 5486–5492. [Google Scholar]

- Sudarsan, R.; Fenves, S.; Sriram, R.; Wang, F. A product information modeling framework for product lifecycle management. Comput. Des. 2005, 37, 1399–1411. [Google Scholar] [CrossRef]

- Chen, Y.; Xiao, F.; Yu, L.; Cui, P. Design of Multi-Line Elastic Belt Conveying Control System for Knitting Machine Based on I2C Protocol. IEEE Access 2020, 8, 51803–51809. [Google Scholar] [CrossRef]

- Mourtzis, D.; Milas, N.; Athinaios, N. Towards Machine Shop 4.0: A General Machine Model for CNC machine-tools through OPC-UA. Proc. CIRP 2018, 78, 301–306. [Google Scholar] [CrossRef]

- Nikiel, P.P.; Farnham, B.; Filimonov, V.; Schlenker, S. Generic OPC UA Server Framework. J. Phys. Conf. Ser. 2015, 664, 082039. [Google Scholar] [CrossRef]

- Adnan, M.; Lu, Y.; Jones, A.; Cheng, F.-T.; Yeung, H. A New Architectural Approach to Monitoring and Controlling AM Processes. Appl. Sci. 2020, 10, 6616. [Google Scholar] [CrossRef]

- Xin, G.B.; Tian, S.H. Guidelines for the Construction of national Intelligent Manufacturing Standard System; Publishing House of Electronic Industry: Beijing, China, 2016; pp. 183–189. [Google Scholar]

- Vogel-Heuser, B.; Schütz, D.; Frank, T.; Legat, C. Model-driven engineering of Manufacturing Automation Software Projects—A SysML-based approach. Mechatronics 2014, 24, 883–897. [Google Scholar] [CrossRef]

- Kenney, B.; Darcovich, K.; MacNeil, D.; Davidson, I.J. Modelling the impact of variations in electrode manufacturing on lithium-ion battery modules. J. Power Sources 2012, 213, 391–401. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Shao, Z.; Wang, M. Research on the Information Model of Digital Machining Workshop for Machine Tools and Its Applications. J. Mech. Eng. 2019, 5, 9. [Google Scholar]

- Picault, S.; Huang, Y.; Sicard, V.; Beaudeau, F.; Ezanno, P. A Multi-Level Multi-Agent Simulation. Paams 2017 2017, 2, 209–221. [Google Scholar] [CrossRef]

- Wu, K.; Li, Y.; Chen, L.; Wang, Z. Research of Integrity and Authentication in OPC UA Communication Using Whirlpool Hash Function. Appl. Sci. 2015, 5, 446–458. [Google Scholar] [CrossRef]

- Gruner, S.; Pfrommer, J.; Palm, F. RESTful Industrial Communication with OPC UA. IEEE Trans. Ind. Inform. 2016, 12, 1832–1841. [Google Scholar] [CrossRef]

- Cavalieri, S.; Salafia, M.G. Insights into Mapping Solutions Based on OPC UA Information Model Applied to the Industry 4.0 Asset Administration Shell. Computers 2020, 9, 28. [Google Scholar] [CrossRef]

- Lu, H.; Zhifeng, Y. Research on key technology of the address space for OPC UA Server. In Proceedings of the 2010 2nd International Conference on Advanced Computer Control, Institute of Electrical and Electronics Engineers (IEEE), Shenyang, China, 27–28 March 2010; Volume 3, pp. 278–281. [Google Scholar]

- Bell, A.; Halbgewachs, C.; Kentischer, T.J.; Schmidt, W.; Von Der Lühe, O.; Sigwarth, M.; Fischer, A. DKIST visible tunable filter control software: Connecting the DKIST framework to OPC UA. SPIE Astron. Telesc. Instrum. 2014, 9152, 91521D. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).