Abstract

Insoluble fiber (IF) recovered from the enzyme-assisted aqueous extraction process (EAEP) of soybeans is a fraction rich in carbohydrates and proteins. It can be used to enhance ethanol production in an integrated corn-soy biorefinery, which combines EAEP with traditional corn-based ethanol processing. The present study evaluated IF as a substrate for ethanol production. The effects of treatment of IF (soaking in aqueous ammonia (SAA), liquid hot water (LHW), and enzymatic hydrolysis), primarily simultaneous saccharification and co-fermentation (SSCF), as well as scaling up (250 mL to 60 L) on ethanol production from IF alone or a corn and IF slurry were investigated. Enzymatic hydrolysis (pectinase, cellulase, and xylanase, each added at 5% soy solids during simultaneous saccharification and fermentation/SSCF) was the best treatment to maximize ethanol production from IF. Ethanol yield almost doubled when SSCF of IF was performed with Saccharomyces cerevisiae and Escherichia coli KO11. Addition of IF in dry-grind corn fermentation increased the ethanol production rate (~31%), but low ethanol tolerance of E. coli KO11 was a limiting factor for employing SSCF in combination corn and IF fermentation. Nonlinear Monod modeling accurately predicted the effect of ethanol concentration on E. coli KO11 growth kinetics by Hanes-Woolf linearization. Collectively, the results from this study suggest a potential of IF as a substrate, alone or in dry-grind corn fermentation, where it enhances the ethanol production rate. IF can be incorporated in the current bioethanol industry with no added capital investment, except enzymes.

1. Introduction

Enzyme-assisted aqueous extraction process (EAEP) is an environmentally friendly alternative to chemical (organic solvent such as hexane) or mechanical extraction of oil from soybeans [1,2,3]. In comparison to conventional oil extraction methods, EAEP provides sustainable, safe, and low-cost extraction of oil from soybeans, with simultaneous production of valuable co-products. In EAEP, soybeans are first mechanically treated to remove hulls, conditioned to set moisture, and extruded to increase surface area. Then, the mixture of soybean extrudes and water is subjected to protease treatment, and the cream and co-products are separated by decanting followed by demulsification with the same protease to recover oil [2]. EAEP of soybeans results in ~97% of oil recovery, in addition to the production of large amounts of skim (protein-rich liquid fraction) and insoluble fiber (IF; carbohydrate-rich solid fraction). For EAEP of soybeans to be economically viable, the proper use of skim and IF must be found. Dry-grind corn fermentation could be a suitable option.

Over 15.8 billion gallons of bioethanol were produced in the U.S. in 2017, of which 1.4 billion gallons were exported to more than 60 countries [4,5]. In addition, 37.4 million tons of Distillers Dried Grains with Solubles DDGS was produced, of which 11 million tons were exported to 54 countries. Integrating EAEP and dry-grind corn fermentation processes by the addition of EAEP co-products, soy skim and IF, in corn fermentation may enhance ethanol production and produce animal feed with enhanced nutrient profile [6]. Adding IF to corn fermentation may, however, bring some difficulties, due to its unique carbohydrate profile. The difference in the carbohydrate profiling of corn (~70% starch) and IF (mainly structural carbohydrates) could create challenges for ethanol production when IF is added to corn fermentation. It has been revealed in previous studies that soy IF recovered from EAEP can be readily saccharified, owing to the preprocessing of soybeans prior to the EAEP. Consequently, it has been discovered to be a potential lignocellulosic feedstock for ethanol production [7,8,9]. The addition of a mixture of soy skim and IF in dry-grind corn fermentation has been shown to significantly increase ethanol production rate (~3%) and ethanol yield (~20%) [6].

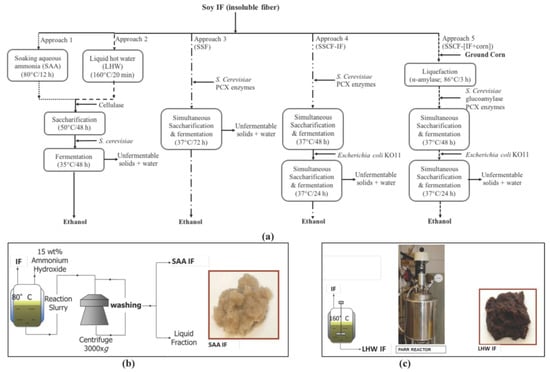

Various methods are being developed for the efficient production of ethanol from cellulosic biomass [10,11,12,13,14,15,16]. Three processes are widely tested: separate hydrolysis followed by fermentation, simultaneous saccharification and fermentation (SSF), and simultaneous saccharification and co-fermentation (SSCF). In this study, the following approaches for treatment, saccharification, and fermentation of IF for ethanol production were applied: (1) separate treatment of IF, followed by saccharification with cellulase, and fermentation with S. cerevisiae; (2) SSF of IF, with a cocktail of fiber-hydrolyzing enzymes PCX (Pectinase, Cellulase and Xylanase), and S. cerevisiae; and (3) SSCF of IF or mixture of IF and corn with PCX enzymes, and S. cerevisiae fermentation followed by E. coli KO11 fermentation (Figure 1).

Figure 1.

Schematic flow diagram of (a) different insoluble fiber (IF) treatment and fermentation methods for ethanol production, (b) soaking aqueous ammonia (SAA), and (c) liquid hot water (LHW) treatment methods for IF.

IF mainly constitutes cellulosic material—consequently, the breakdown of cellulose and hemicellulose to monomeric sugars (hexoses or pentoses) will enhance ethanol production [17]. Different physical, chemical, and biological treatment methods have been studied for cellulosic biomass [7,8,9,17,18,19,20,21,22,23,24]. Karki et al. [8] evaluated high-power ultrasound, ammonium hydroxide, sodium hydroxide, and sulfuric acid for the treatment of soy IF, and reported sodium hydroxide treatment with ammonium hydroxide as the most efficient method. In this study, the effect of treating IF by soaking in aqueous ammonia (SAA), liquid hot water, or SSF with PCX enzymes (added at SSF step) was investigated.

The specific objectives were to determine the effect of different treatment methods (soaking in aqueous ammonia (SAA), liquid hot water (LHW), and enzymatic hydrolysis) on ethanol production from IF-only fermentation with S. cerevisiae. Then, the effect of simultaneous saccharification and co-fermentation (SSCF) of IF alone, as well as corn and IF slurry with S. cerevisiae, followed by E. coli KO11 on ethanol production, was evaluated. Scaling up was performed to demonstrate, at a larger scale, the concept of producing ethanol from IF, and Monod-type nonlinear modeling was applied to predict the effect of ethanol concentration on E. coli KO11 kinetics in an integrated corn-soy fermentation.

2. Materials and Methods

2.1. Materials

Soy IF was obtained as a co-product of EAEP of soybeans, performed in the pilot plant of the Center for Crops Utilization Research, Iowa State University (Ames, IA, USA), according to de Moura et al. (2011). The composition of the IF was 14.4% solids, which contained 2.5% (db) oil, 11.5% (db) protein, 4.0% (db) ash, and 82% (db) carbohydrates. The IF samples were stored at −14 °C until used. Yellow dent the corn harvested in 2013 was from Honeyville (West Chester, OH, USA). The composition of corn was 89.9% (db) solids, which contained 5.1% (db) oil, 8.6% (db) protein, 1.1% (db) ash, and 74.6% (db) carbohydrates. The corn was ground using a Fitz Mill (Model DAS 06, Fitzpatrick Co., Elmhurst, IL, USA) according to Sekhon et al. [6]. The particle retention (%) on U.S.-standard sieve numbers 16, 20, 30, 40, 50, 70, and the pan after grinding was 17.8%, 17.3%, 17.6%, 12.9%, 11.2%, 9.2%, 7.7%, and 0.03%, respectively. The particles per gram were 119,335 and surface area (cm2/g) was 116. The ground corn was stored at 4 °C, and IF at −21 °C until further processing.

Soy fiber-hydrolyzing enzymes cellulase (powder; activity 75,000 CU/g; optimum pH 4–6, temperature 30–70 °C), xylanase (powder; activity 75,000 XU/g; optimum pH 4–6, temperature 40–65 °C), and pectinase (liquid; activity 3500 ENDO-PG/g; optimum pH 2–5, temperature 40–65 °C) were donated by Bio-Cat (Troy, VA, USA). Peptone N-Z Soy BL 7 enzymatic hydrolysate, d-glucose, chloramphenicol, and antibacterial lactrol were obtained from Sigma (St. Louis, MO, USA), BactoTM tryptone (pancreatic digest of casein) and BactoTM yeast extract (extract from autolyzed yeast cells) from Becton, Dickison, and Company (Sparks, MD, USA), sodium chloride (crystalline) from Fisher Scientific (Fair Lawn, NJ, USA), and Escherichia coli KO11 (ATCC® 55124™) was obtained from ATCC (Manassas, VA, USA). Corn liquefaction and saccharification enzymes, α-amylase (liquid), glucoamylase (liquid) (Spirizyme Excel XHS, Novozyme, Franklinton, NC, USA), and antibacterial chlorine dioxide (commercial grade) were obtained from Lincolnway Energy LLC (Ames, IA, USA). Dry yeast (Saccharomyces cerevisiae; Ethanol Red) was obtained from Fermentis, a division of Lesaffre Yeast Corp. (Headland, AL, USA). Ammonium sulfate, ammonium hydroxide and n-hexane were obtained from Fisher Scientific (Fair Lawn, NJ, USA).

2.2. Compositional Analyses

2.2.1. Proximate Analyses

Total solids (%) were determined by oven-drying samples at 110 °C overnight; oil content (%) was determined by the Mojonnier acid hydrolysis method (AOAC method 922.06), protein content (%) by the Dumas nitrogen combustion method with a nitrogen conversion factor of 6.25 (Vario MAXCN Elementar Analysensysteme GmbH, Hanau, Germany), and ash content (%) by carbonization in muffle furnace at 550 °C (AOAC 923.03). Total carbohydrate content (%) was calculated by subtracting oil, protein, and ash contents from 100%. All analyses were performed in duplicate.

2.2.2. Carbohydrate Composition and Lignin Content

The samples were analyzed according to NREL CAT (National Renewable Energy Laboratory-Chemical Analysis and Testing) Standard Procedure NREL/TP-510-42618 to estimate structural carbohydrate composition and lignin contents (acid soluble and acid insoluble). Analysis was performed in duplicate.

2.3. Insoluble Fiber Treatment

2.3.1. Effect of the Treatment Method on Ethanol Production in Insoluble Fiber Fermentation

Three treatment methods were evaluated for maximizing ethanol production in IF fermentation: soaking in aqueous ammonia (SAA) (Approach 1; Figure 1a,b), liquid hot water (LHW) (Approach 2; Figure 1a,c), and enzymatic hydrolysis using a cocktail of PCX enzymes (pectinase, xylanase, and cellulase; Approach 3; Figure 1a). Details of each treatment method are listed in Figure 1.

Soaking in Aqueous Ammonia Treatment

SAA treatment was performed by soaking 30 g (db) IF with 15% (wt.) aqueous ammonia at a solid-to-liquid ratio of 1:10 (w/w, db) in a 1 L screw-capped Pyrex laboratory bottle. The bottle was placed in a preheated oven (80 °C for 12 h), with constant mixing using a magnetic stir bar. After 12 h, the treated slurry was centrifuged at 3000× g for 15 min; the recovered solids were washed with distilled water until a neutral pH was achieved (6–15 washing cycles). The washed solids were weighed and stored in sealed plastic cups at 4 °C. The pretreated IF was then saccharified with cellulase (50 °C) for 48 h, followed by fermentation with S. cerevisiae (35 °C) for 48 h.

Liquid Hot Water Treatment

LHW treatment was conducted in a 1 L PARR reactor (4522M PARR Instrument Company, Moline, IL, USA). IF (1 kg, 14.4% solids) was added to the stainless-steel reactor, and the reactor was then heated to 160 °C at 0.68 MPa for 20 min. At the end of heating, the reactor was cooled to room temperature with running water. The pretreated slurry was then treated with cellulase (50 °C) for 48 h, followed by fermentation with S. cerevisiae (35 °C) for 48 h.

Enzymatic Hydrolysis

A cocktail of PCX (pectinase, cellulase, and xylanase) enzymes was added at the SSF of IF. A slurry of IF (2% glucan loading) was prepared as described in Section 2.3.2. PCX was added at 5, 10, 15, or 20% of soy solids. A PCX concentration of 5% was used for SSF with S. cerevisiae (Approach 3; Figure 1a). The effect of all four PCX concentrations on SSCF of IF with S. cerevisiae (37 °C for 48 h) followed by E. coli KO11 (37 °C for 48 h) was evaluated (Approach 4; Figure 1a). Each treatment was performed in duplicate, and ethanol concentration (g/L) and carbohydrate composition (g/L) were determined.

2.3.2. Simultaneous Saccharification and Co-Fermentation of Insoluble Fiber

SSCF of IF was performed according to Sekhon et al. [6]. The method is summarized in Figure 1a (Approach 4) and described below.

Yeast-Extract Peptone Media

Yeast-extract peptone (YP) media was prepared by dissolving 1 g yeast extract and 2 g peptone in 100 mL deionized (DI) water. Dry yeast (0.16 g) was allowed to soak in the YP media for 10 min before adding to 10 mL aliquots of IF slurry.

Escherichia coli KO11 Inoculum

KO11 inoculum was prepared by aseptically transferring one stock vial (1 mL) of E. coli KO11 into LB (Luria-Bertani) broth (prepared by mixing 0.50 g tryptone, 0.25 g yeast extract, 0.50 g sodium chloride, and 1.00 g glucose in 0.05 L deionized (DI) water, autoclaved at 121 °C for 15 min) and 1 mL of chloramphenicol (40 mg/L). The flask was incubated overnight (15–16 h) in a shaker incubator (Lab-line Orbit Shaker Bath model 3540) at 37 °C at 150 rpm. After incubation, the cell culture was aseptically transferred to a sterilized centrifuge tube and centrifuged at 9000× g for 10 min. The supernatant was aseptically discarded, and the pellet was re-suspended in 10 mL of sterile saline solution and centrifuged again to remove ethanol and unused glucose. The supernatant was again discarded, and the pellet was re-suspended in 10 mL of fresh LB broth (with no glucose). The re-suspended E. coli KO11 in LB broth (in 10 mL aliquots) was used as an inoculum for the saccharification and fermentation of IF and for the integrated corn-soy fermentation process.

Simultaneous Saccharification and Co-Fermentation with S. cerevisiae and E. coli KO11

SSCF of IF was performed in a 4 L, double-jacketed, round-bottom bioreactor. The slurry (3000 g as-is) was prepared by adding IF (2% glucan loading), 0.05 M citrate buffer (699.9 mL), pectinase, cellulase, and xylanase (PCX; each enzyme was added at 5% of soy solids), YP media (200 mL), S. cerevisiae (3.2 g), Lactrol (0.16 g), and water (233.7 mL). Simultaneous saccharification and fermentation (pH 4.5) was carried out at 37 °C for 48 h at 150 rpm. After 48 h, the pH of the fermentation broth was adjusted to 7.0 with sodium hydroxide and then inoculated with 10 mL of E. coli KO11. The slurry was fermented at 37 °C for 24 h at 150 rpm. At the end of a 72 h saccharification and fermentation period, the slurry was separated by centrifuging at 3000× g. Fermented IF had 14.3% solids, which contained 6.5% (db) oil, 16.5% (db) protein, 6% (db) ash, and 71% (db) carbohydrates. Ethanol concentration in liquid part was determined by the HPLC method, described in the HPLC analysis section.

2.4. Scale-Up

Saccharification and fermentation of IF was scaled up from laboratory scale (0.9 kg; 150 mL) to intermediate scale (6 kg; 10 L), and pilot plant scale (35 kg; 60 L). At the laboratory scale, saccharification and fermentation was performed in a Tornado IS6 Overhead Stirring System (Radleys Discovery Technologies, Shire Hill, Saffron Walden, UK), equipped with an anchored stirring shaft and six 250 mL round-bottom flasks. At the intermediate scale, saccharification was performed in a 20 L bioreactor vessel (17.5 in × 2 in; internal diameter 10 in). The 34.6-in stirrer shaft consisted of a flake cup, a 5-in agitator, and a 7.5-in high-viscosity agitator with an 8-in diameter. The flake cup was 15.5 in from top to shaft, the 5-in agitator was located 10.5 in from the flake cup, and the high viscosity agitator was placed 1.6-in below the 5-in agitator. The pilot scale bioreactor vessel consisted of a bottom-drive agitator with two Rushton impellers (5-in diameter, 6-in width, and 12-in from the bottom) and one marine impeller (8-in diameter down-flow; 2-in from bottom). The interior vessel diameter was 12.4-in, and contained one 1-in wide baffle. The effect of the scale-up of the SAA treatment method (from lab scale at 150 mL to pilot scale at 10 L) on ethanol production was also evaluated. Treatment conditions are listed in Figure 1.

2.5. Integrated Corn-Soy Fermentation

SSCF of the corn-soy slurry (Approach 5; Figure 1a) was performed according to Sekhon et al. [6]. Briefly, IF was mixed with coarsely ground corn and DI water in 250 mL flasks of the Tornado IS6 Overhead Stirring System. The ratio of corn to IF and water to solids were set at 1:0.16 (on db) and 2.5:1 (by weight), respectively. The amount of corn was kept constant in all fermentations. α-Amylase (0.167 mL) was added when the temperature of the slurry reached 85 °C. After 3 h, the flasks were cooled to 30 °C in an ice bath, and the pH of the cooled slurry was adjusted to 4.5 with 3 M sulfuric acid. Chlorine dioxide (0.028 mL; antimicrobial), ammonium sulfate (0.077 mL of 0.2 g/g solution; nitrogen source), glucoamylase (0.167 mL), soy fiber-hydrolyzing enzymes PCX (each added at 5% of soy solids), and dry yeast (0.167 g, S. cerevisiae) were then added. After 48 h of fermentation, the pH was adjusted to 7 with sodium hydroxide, and the fermentation slurry was inoculated with 10 mL of E. coli KO11 inoculum. The slurry was then fermented at 37 °C for another 24 h (a total of 72 h). At the end of the fermentation period, a 3 mL aliquot of slurry was pipetted into a microfuge tube, heated in a water bath at 75 °C for 10 min, cooled in an ice bath for 10 min, and centrifuged at 9000× g. The supernatant was transferred to an HPLC vial and analyzed for ethanol concentration (g/L) by HPLC.

In all fermentation setups, the vents of the flasks/bioreactor vessels were not sealed, to facilitate carbon dioxide release. At the beginning of the fermentation, the headspace in the flask/bioreactor was not modified, but as the fermentation progressed headspace was taken up by carbon dioxide. This imitated the industrial-scale fermentation process.

2.5.1. Post-Fermentation Processing

Ethanol from whole beer (fermented slurry) was distilled out at 85 °C for 15 min under a vacuum using a rotary evaporator (Buchi Rotavapor R-124, Flawil, Switzerland; Figure 1). After ethanol was removed, DI water was added to make up the weight of whole stillage to equal that of whole beer. Whole stillage was decanted using a MWCF (multi-wash centrifugal filtration) laboratory decanting device, according to Wang et al. [25]. Briefly, the MWCF device comprised of (1) a 400 mL wide-mouth centrifuge bottle, (2) a filtration pouch (100 × 90 mm with pore size 250 × 280 µm; Ombre rainbow sheer fabric material, made of 60% nylon and 40% polyester (Spring Creative Products Group, Rock Hill, SC, USA), and (3) a plastic cup with the bottom section perforated with 1 mm diameter holes and a cap. The filtration pouch was put in the plastic cup, which was fixed in the centrifuge bottle. Whole stillage was poured into the filtration pouch, and the pouch secured with a wire tie. The MWDF device was secured with a cap and centrifuged at 3000× g at ambient temperature (25 °C) for 2 min (Avanti J-20 XPI, Beckman Coulter, Fullerton, CA, USA). During centrifugation, the liquid and fine solid particles in the whole stillage passed to the bottom of the centrifuge bottle. This fraction was called thin stillage, and dewatered solids were called wet cake. After one centrifugal filtration, the wet cake was re-dispersed in the top clear liquid of the thin stillage by inverting the MWDF device and mixing for 1 min. This process (centrifugation and mixing) was repeated a total of four times before final centrifugation, to produce similar decanting results as that of the industry. The residual solids in the pouch were called wet cake, and the supernatant containing fine solids was called thin stillage. Wet cake and thin stillage were quantified for solid content, oil content, and solids and oil partition in thin stillage. Solids and oil partition were calculated based on the whole stillage, from which thin stillage and wet cake were produced.

2.5.2. Oil Recovery

The oil in the whole stillage can be characterized as free oil, which can be recovered by centrifugation; trapped or extractable oil, which cannot be recovered by centrifugation but extracted by hexane; and bound oil, which cannot be recovered at all [25,26,27,28]. Oil partition in thin stillage was based on oil content (determined by acid hydrolysis method) in the whole stillage, and free oil and extractable recovery were based on oil content in thin stillage.

Oil recovery from thin stillage was determined by hexane extraction, according to a procedure modified from Wang et al. [25]. Duplicate samples (30 g) of whole beer, whole stillage, or thin stillage were centrifuged at 3000× g for 10 min, and the top oil layer washed four times with 2 mL hexane. Hexane was then evaporated from the extract by an air stream, and the free oil yield determined gravimetrically. The leftover mixture in the centrifuge tube was extracted twice with 7 mL of hexane, by mixing vigorously for 10 s, centrifuging and collecting the extract, and evaporating the solvent by an air stream. The extractable oil yield was then determined gravimetrically.

In the fermentations for oil recovery, only pectinase and cellulase were used.

2.6. Effect of Ethanol and Sugar Concentration on the Growth of E. coli KO11

LB broth (10 mL) was prepared with different sugar types (glucose or xylose), different sugar concentrations (50 or 150 g/L), and different ethanol concentrations (0, 20, 50, or 100 g/L) in Erlenmeyer flasks. The broths were sterilized by autoclaving at 121 °C/60 min. E. coli KO11 inoculum (1 mL) was prepared (as described in Section 2.3.2.) and added to each flask. Flasks were covered with aluminum foil and allowed to incubate (with agitation) at 37 °C for 24 h in a Shaker incubator (Lab-line Orbit Shaker Bath model 3540). The change in absorbance (DU 640 Spectrophotometer, Beckman Coulter, Brea, CA, USA) of the broths was measured at 550 nm at 1 h intervals for 8 h, and then measured at 22 h and 24 h. Absorbance of broths inoculated with E. coli KO11 at the start of fermentation was ~0.6–0.7. Control samples were incubated along with fermentation broth to account for turbidity caused by factors other than E. coli KO11 growth; these included LB broth only (no additional sugars), LB broth with glucose or xylose only (with no E. coli KO11 inoculum), and LB broth with sugars and ethanol (but no inoculum). Flasks containing LB broth were agitated at 37 °C before adding the inoculum. Sugar and ethanol concentrations in broths were measured by HPLC analysis before the start of fermentation (0 h) and at the end of fermentation (24 h).

2.7. Prediction of E. coli KO11 Kinetics Using Monod Nonlinear Modeling

Mechanistically, since E. coli KO11 growth follows Monod kinetics, a plot of broth absorbance containing E. coli KO11 cells against time can be expressed as:

where, Abs = absorbance at 550 nm, Vmax = maximum initial velocity, Km = Michaelis constant, and t = time (h). Equation (1) was linearized using Hanes-Woolf, and Vmax and Km were estimated by plotting experimental data Abs/t versus t (Equation (2)):

The straight line was fitted to the points with slope 1/Vmax and y-intercept Km/Vmax. The two parameters Vmax and Km were then calculated: Vmax = 1/slope and Km = y-intercept x Vmax. The Vmax and Km values were then used to predict E. coli KO11 growth kinetics at any time (t) using Equation (1).

2.8. HPLC Analysis

Samples were analyzed for carbohydrates using HPLC (Varian Inc., Victoria, Australia) equipped with an auto sampler, an isocratic pump, a refractive index detector, and an Aminex HPX-87P carbohydrate column (Bio-Rad Laboratories, Hercules, CA, USA) set at 85 °C. The sample injection volume was 20 µL, and elution was conducted using 18 m × NANO pure water at a flow rate of 0.6 mL/min. The glucose peaks were quantified using a six-point external standard curve.

Ethanol was quantified using the same HPLC, with an Aminex HPX-87H organic acid column (Bio-Rad Laboratories, Hercules, CA, USA) at 65 °C. The sample injection volume was 20 µL, and 0.005 M sulfuric acid at 0.6 mL/min flow rate was used for the mobile phase.

2.9. Statistical Analysis

The data were analyzed using analysis of variance (ANOVA) in SAS (SAS Inc., Cary, NC, USA, version 9.3). The means were compared using a t-test and post-hoc Duncan’s test at p = 0.05 level of significance.

3. Results and Discussion

3.1. Treatment of Insoluble Fiber

Among the three treatment methods (SAA, LHW, and enzymatic hydrolysis), maximum ethanol production (12 g/L versus 2.3 g/L for control) was obtained when the PCX enzymes were used (Table 1). Although SAA increased glucan content (from 27 to 46% db) in the treated IF, the increase in ethanol production was not statistically different from the control. In addition, the solid content was significantly reduced (from 14.4 to 5.1% db) in SAA-treated samples. This could be because IF was washed repeatedly to neutralize pH and remove chemicals. The washing step also resulted in increased usage of water.

Table 1.

Composition of pretreated IF subjected to simultaneous saccharification and fermentation (SSF) with S. cerevisiae.

Mechanical treatment of soybeans (cracking using a corrugated roller mill, flaking using smooth roller mill to 0.25 mm thickness, and extruding at 100 °C) before EAEP ruptured the soybean cell walls, composed of cellulose, hemicellulose, pectin, and lignin [2]. The addition of PCX enzymes in SSF enabled further breakdown of pectin and hemicellulose to release cellulose, xylose, and arabinose. The activity of pectinase, cellulase, or xylanase on cellulosic soybean fraction has been studied [29]. The study reported significant degradation of cellulose after complete extraction of protein, pectin, and hemicellulose from the fiber. Although cellulase contains endo- and exo-cellulase and β-glucosidase activities for complete hydrolysis of cellulose, the cellulose’s activity is restricted by the other polysaccharides and lignin. Therefore, another enzyme (pectinase) is required to break down the cell wall matrix [30]. Another study has reported that 85% of the monomers released after the treatment of defatted soybean water extractable fractions with polysaccharide-degrading enzymes (Bio-Feed Plus, SP-249, Energex, and Driselase) were galactose and arabinose, with limited amounts of glucose, mannose, and xylose [31]. Furthermore, polysaccharide (fiber)-hydrolyzing enzymes have a viscosity-reducing effect on the fermenting slurry, hence allowing higher glucan loading. These results indicate that enzymatic hydrolysis, when PCX enzymes were added during SSF with S. cerevisiae, is the most efficient method for increasing ethanol yield from IF.

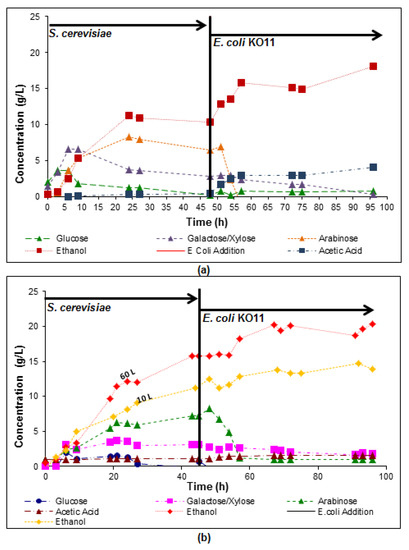

The effect of PCX enzymes (at 5, 10, 15, and 20% of soy solids; Figure 2) was further investigated. The addition of 5% PCX significantly increased the ethanol yield from ~2 g/L to 12 g/L (Table 1) compared to when PCX enzymes were not added. Increasing PCX enzyme concentration from 5 to 20% did not have a significant effect on ethanol production (Figure 2; before vertical red line). Therefore, 5% concentration of each PCX enzyme was used in all future fermentations. Adding E. coli KO11 after 48 h fermentation with S. cerevisiae fermentation further increased ethanol production (~12 g/L to up to 25 g/L; Figure 2). It can be seen from Figure 2 that the increase in ethanol concentration after the addition of E. coli KO11 was due to the conversion of arabinose and xylose to ethanol, because concentration of these sugars significantly decreased after the addition of E. coli KO11 (Figure 2). This confirms E. coli’s ability to convert both hexoses and pentoses (arabinan and xylan) into ethanol, compared to S. cerevisiae, which can only utilize hexoses (glucan and galactan).

Figure 2.

Effect of PCX (pectinase, cellulase, and xylanase) concentrations (a) 5%, (b) 10%, (c) 15%, and (d) 20% of soy solids on the carbohydrate profile and ethanol production during S. cerevisiae fermentation of IF. Error bars show standard deviations. Vertical red line indicates when E. coli KO11was added.

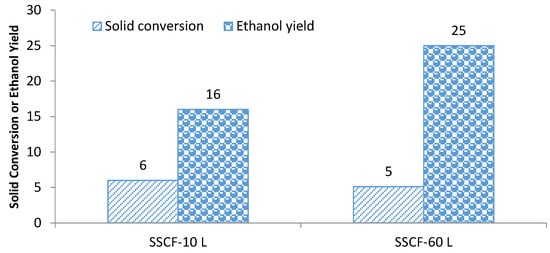

3.2. Scale-Up of the Simultaneous Saccharification and Co-Fermentation of Insoluble Fiber

The scale-up of SAA treatment from laboratory scale (150 mL) to intermediate scale (10 L) significantly decreased the ethanol concentration of 0.20 g/g of dry biomass from the 150 mL scale to 0.12 g/g of dry biomass for the 10 L scale (Figure 3). Safety issues with the handling of concentrated acid and challenges in washing the fiber after SAA treatment, as well as the disposal of used water makes its scale-up challenging. On the other hand, scale-up of the enzymatic treatment is a viable option, with no washing step and a significant increase in ethanol yield from 250 mL to 10 L, up to 60 L when PCX enzymes were added to the SSF step (Figure 4). However, scale-up to 60 L was observed to result in a higher ethanol yield compared to the scale-up to 10 L. Furthermore, SSCF of S. cerevisiae followed by E. coli KO11 showed a significant increase in ethanol concentration. The ethanol yield with E. coli fermentation increased from 10 to 18 g/L on the lab scale, and from 15 to 20 g/L on the pilot scale (Figure 3). Further, utilization of sugars during fermentation resulted in a 5% increase in the protein content of the residual IF (RIF) under all conditions (Table 2). This increase will be beneficial for IF co-product use in animal feed.

Figure 3.

Evolution of the carbohydrate profile and ethanol concentration during (a) lab-scale (150 mL), and (b) pilot-scale (60 L) simultaneous saccharification and co-fermentation (SSCF) of IF with a 5% enzyme cocktail (for 10 L, only ethanol concentration is shown in (b)).

Figure 4.

Solid conversion (%) and ethanol yield (kg/100 kg dry solids) from 10 L and 60 L enzymatic treatment and co-fermentation of IF with S. cerevisiae and E. coli KO11. Solid conversion = final dry biomass, kg × 100/initial biomass, kg as is.

Table 2.

Composition of starting material and residual materials after enzymatic treatment and co-fermentation with S. cerevisiae and E. coli KO11.

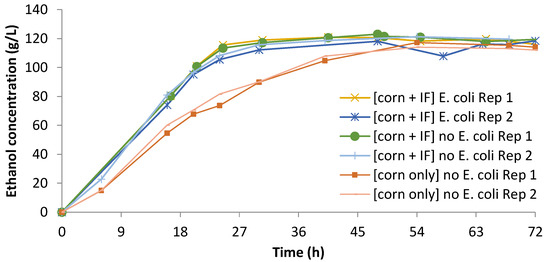

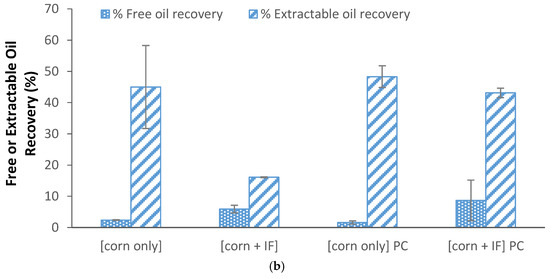

3.3. Integrated Corn-Soy Fermentation

Integrated corn-IF fermentation resulted in ~31% increase in ethanol production rate and a 5% increase in ethanol yield compared to corn-only fermentation. E. coli KO11 fermentation did not significantly increase ethanol yield compared to S. cerevisiae fermentation alone (Figure 5). E. coli KO11 can ferment both hexoses and pentoses, and hence can enhance ethanol production [16] Though results with IF-only fermentation showed the benefit of adding E. coli KO11 to ethanol production, in corn-soy integrated slurry, higher ethanol concentration was not favorable for E. coli KO11 growth. Therefore, the conversion of pentoses to ethanol in the integrated corn-IF slurry was not observed, as evident from higher xylan and arabinan concentrations in the whole beers (Table 2). To further understand the impact of ethanol on E. coli growth, additional investigations were performed.

Figure 5.

Ethanol production (g/L) from corn alone and corn-IF slurries with and without the addition of E. coli KO11 after 48 h of fermentation with S. cerevisiae. IF: insoluble fiber.

3.4. Effect of Ethanol and Sugar Concentration on E. coli KO11

The effect of ethanol and sugar concentrations on E. coli KO11 growth in LB broth was investigated by measuring absorbance values (at 550 nm) over a period of 24 h. The absorbance of LB broth inoculated with E. coli KO11 at the start of fermentation was ~0.6–0.7.

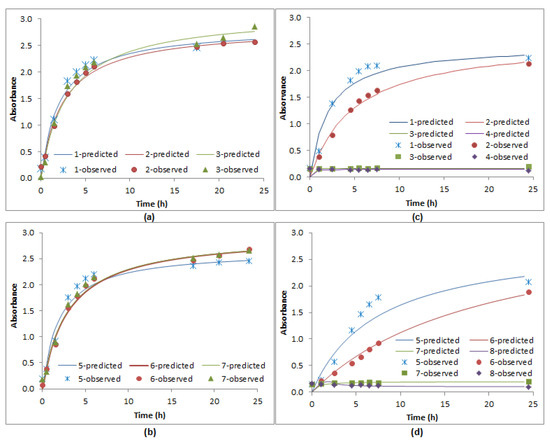

As ethanol concentration was gradually increased in the LB broth from 10 to 20 g/L, no negative effect on E. coli KO11 growth was noticed, as indicated by the absorbance values (marked scatter in Figure 6a,b). However, when the ethanol concentration in the LB broth was increased further, from 20 to 50 g/L, or 100 g/L, no change in initial absorbance value was observed (Figure 6c,d). This indicates that E. coli failed to grow in ethanol concentrations ≥50 g/L. An increase in xylose (pentose) concentration in the LB broth (from 50 to 150 g/L) had no effect on the ethanol yield (scatter plot in Figure 6c,d). These results indicate that the ethanol resistance of E. coli KO11 is independent of the type of fermentable sugar (glucose, a hexose or xylose, a pentose), and its concentration. This was in agreement with findings of previous study [32].

Figure 6.

Effect of sugar types, (a) glucose or (b) xylose; sugar concentration, (c) xylose-50 g/L or (d) xylose-150 g/L; and ethanol concentration on E. coli KO11 growth, as measured by absorbance values (550 nm). Lines 1 to 3 and 5 to 7 in (a) and (b) are 0, 10, and 20 g/L ethanol concentrations in Luria-Bertani (LB) broths. Lines 1 to 4 and 5 to 8 in (c) and (d) are 0, 20, 50, and 100-g/L ethanol concentrations in LB broths. Sugar and ethanol concentrations, and regression parameters are presented in Table 3 and Table 4, respectively.

Table 3.

Change in xylose and ethanol concentration in LB broth containing 50 or 150 g/L of xylose during E. coli KO11 fermentation.

Table 4.

Monod nonlinear parameters, as predicted by Hanes-Woolf linearization.

To test the LB broth for the production of interfering compounds during fermentation, aliquots (1.5 mL) of the fermentation broth were taken at the start and end of fermentation and analyzed in HPLC. No interfering compounds were observed. HPLC results also revealed the depletion of xylose content in fermentation broths containing 0 or 20 g/L ethanol. However, broths with higher ethanol concentrations (50 or 100 g/L) showed no xylose consumption after fermentation. These results validate E. coli KO11’s intolerance to higher ethanol concentrations. Intolerance of E. coli KO11 to higher ethanol concentration could be a limiting factor in its use in enhancing ethanol production by utilizing pentoses (xylose and arabinose) in corn-soy fermentation. Therefore, to effectively utilize pentoses in corn-soy fermentation, either E. coli KO11 should be added in a step before yeast fermentation, when ethanol concentration in the slurry is low (<50 g/L), or after distillation when ethanol has been removed from the whole beer [33]. A more robust strain of E. coli KO11 can also be used that can withstand higher ethanol concentrations [32,34].

3.5. Prediction of E. coli KO11 Kinetics

E. coli KO11 growth in LB broths (at lower ethanol concentrations, 0–20 mg/mL) followed Monod kinetics. To determine the kinetics parameters, the data was linearized by Hanes-Woolf. The parameters Vmax and Km, with corresponding R2 values, are listed in Table 4. Vmax values were equivalent for the two sugar sources (glucose or xylose), but were higher for fermentation broths containing lower concentrations of ethanol, and smaller for broths containing higher concentrations of ethanol. Lower Vmax values indicate a slower reaction rate or slower growth of E. coli KO11 depicted by lower absorbance values. This was also true for Km values. Vmax and Km values were successfully used to accurately predict the effect of ethanol concentration on E. coli KO11 kinetics (smooth lined scatter in Figure 6). As shown, higher concentrations of ethanol (>50 g/L) had a negative effect on the growth of E. coli KO11. It can be concluded that E. coli KO11 growth prediction was possible using Monod nonlinear behavior and Hanes-Woolf linearization. One disadvantage of using the Hanes-Woolf plot is that ordinate and abscissa are not independent variables—both are dependent on fermentation time. However, the Lineweaver-Burk plot and Eadie-Hofstee diagram were not able to predict E. coli KO11 growth kinetics as accurately as the Hanes-Woolf plot (data not shown).

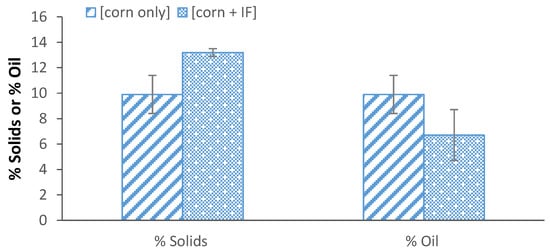

3.6. Effect of Insoluble Fiber on Oil Recovery from Integrated Corn-Soy Fermenation

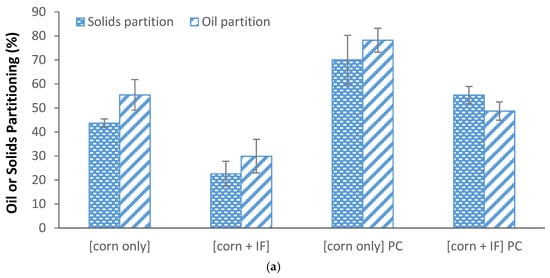

When IF was added to corn fermentation, a significant increase in solid content and a decrease in oil content in the whole stillage was observed (Figure 7). IF has lower oil content than corn; this contributed to decreased oil content in the corn-IF whole stillage. In the thin stillage, the addition of IF resulted in a significant decrease in solids partition compared to the corn-only slurry (Figure 8a). This could be because IF absorbs water and acts as a gel-like barrier to filtration. The decrease in solids partition in thin stillage, after the addition of IF in corn fermentation, could be beneficial in reducing the fouling rate and energy requirement for concentration of thin stillage to thick stillage. However, the addition of IF to corn fermentation resulted in a decrease in oil partition, ~43% in corn-only thin stillage to ~22% in corn-IF thin stillage, in thin stillage. The decrease in oil partition in thin stillage may not be desirable economically. Although free oil recovery (%) from the (corn-only) thin stillage was lower than the recovery from the corn-IF thin stillage, extractable oil recovery (%) from corn-only thin stillage was significantly greater than from the corn-IF stillage (Figure 8b). Free oil represents oil recovered by centrifugation, a method widely used for oil recovery in the industry. Hence, higher free oil recovery is desired. IF may aid in increasing free oil recovery by breaking the protein-oil emulsion in the corn slurry.

Figure 7.

Effect of the addition of IF in corn fermentation on % solids and % oil contents in the whole stillage. Error bars indicate standard deviation between at least duplicate runs.

Figure 8.

Effect of addition of IF and enzymes (pectinase and cellulase, PC) in corn fermentation on (a) solids and oil partition in thin stillage, and (b) %free and % extractable oil recovery from thin stillage. Error bars indicate standard deviation between at least duplicate runs.

3.7. Effect of Enzymes on Solids Partition and Oil Recovery

The effect of enzyme hydrolysis on oil recovery was determined. The addition of the enzymes pectinase and cellulase in the SSCF of corn-only or corn-IF showed a significant increase in solids partition and oil partition in the thin stillages. The increase in solids partition in corn-only stillages was ~60%, and in corn-IF stillages it was ~145%. The increase in oil partition in corn-only was ~41% and in corn-IF was ~62%. Though enzymes helped in relocating oil from wet cake to thin stillage through the breakdown of fiber and freeing oil trapped in solid matrix, the enzymes also allowed the movement of solid particles to thin stillage, hence increasing its solid content. It should be noted that enzyme hydrolysis also resulted in a higher free oil recovery (%) from corn-IF thin stillage compared to control runs. The increase in free oil recovery (%) from corn-IF thin stillage was ~47%. Furthermore, the extractable oil recovery (%) from corn-only and corn-IF thin stillages was significantly greater compared to control runs. The increase in extractable oil recovery (%) from corn-only thin stillage was ~7%, and from corn-IF thin stillage was ~167%. Previous studies have reported enhanced oil recovery from corn thin stillage after treatment with enzymes [35,36,37,38,39,40,41]

These results suggest that IF positively impacts solid partitioning and free oil recovery from corn fermentation. Further addition of pectinase and cellulase aids in oil partition, free oil recovery, and extractable oil recovery by the breakdown of fiber, hence releasing recoverable oil.

4. Conclusions

It was demonstrated that the co-product of EAEP of soybeans, insoluble fiber (IF), is a prospective substrate for bioethanol production. Breakdown of insoluble fiber by enzymes (pectinase, cellulose, and xylanase) is the best method, compared to chemical (SAA) and heat treatment (LHW). If IF is used alone as a substrate, SSCF with S. cerevisiae and E. coli KO11 can further increase ethanol yield. The growth yield of E. coli KO11 in a fermentation medium is affected by high ethanol concentration (>20 mg/mL) in said fermentation medium. This was predicted using Monod by Hanes-Woolf linearization. IF can be used alone or added to dry-grind corn fermentation, where it enhances the ethanol production rate, reduces solids partition, and increases free oil recovery from thin stillage. The incorporation of IF into dry-grind corn fermentation, without the need of new equipment, has the potential of an integrated corn-soy biorefinery. An integrated corn-soy biorefinery offers the advantage of being a sustainable and zero waste system with high ethanol production rates, and having better quality feed compared to traditional methods of soybean oil extraction and corn fermentation.

Author Contributions

Jasreen Sekhon and Devin Maurer designed and conducted experiments, and collected and analyzed data. Stephanie Jung mentored insoluble fiber treatment experiments, Kurt Rosentrater mentored prediction of E. coli kinetics experiments, Tong Wang mentored oil recovery experiments. Jasreen Sekhon wrote the manuscript; all authors contributed equally in editing the manuscript.

Funding

This research was funded by USDA National Institute of Food and Agriculture.

Acknowledgments

This research was funded by USDA NIFA. We thank Iowa State University for access to facilities and equipment. We also gratefully acknowledge the assistance of Shannon Box, Bishnu Karki, and Linxing Yao.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, Y.; Zhang, Y.; Wang, M.; Jiang, L.; Sui, X. Simplex-centroid mixture design applied to the aqueous enzymatic extraction of fatty acid-balanced oil from mixed seeds. J. Am. Oil Chem. Soc. 2013, 90, 349–357. [Google Scholar] [CrossRef]

- De Moura, J.M.L.N.; Maurer, D.; Jung, S.; Johnson, L.A. Pilot-plant proof-of-concept for integrated, countercurrent, two-stage, enzyme-assisted aqueous extraction of soybeans. J. Am. Oil Chem. Soc. 2011, 88, 1649–1658. [Google Scholar] [CrossRef]

- Jung, S.; Maurer, D.; Johnson, L. Factors affecting emulsion stability and quality of oil recovered from enzyme-assisted aqueous extraction of soybeans. Bioresour. Technol. 2009, 100, 5340–5347. [Google Scholar] [CrossRef] [PubMed]

- USDA/ERS. Fuel Ethanol Supply and Disappearance Calendar Year. 2018. Available online: https://www.ers.usda.gov/data-products/us-bioenergy-statistics/us-bioenergy-statistics/ (accessed on 1 May 2018).

- RFA. U.S. Ethanol Exports and Imports. 2018. Available online: http://www.ethanolrfa.org/wp-content/uploads/2018/02/2017-U.S.-Ethanol-Trade-Statistics-Summary_CORRECTED2.pdf (accessed on 27 April 2018).

- Sekhon, J.K.; Jung, S.; Wang, T.; Rosentrater, K.A.; Johnson, L.A. Effect of co-products of enzyme-assisted aqueous extraction of soybeans on ethanol production in dry-grind corn fermentation. Bioresour. Technol. 2015, 192, 451–460. [Google Scholar] [CrossRef] [PubMed]

- Karki, B.; Maurer, D.; Box, S.; Kim, T.H.; Jung, S. Ethanol production from soybean fiber, a co-product of aqueous oil extraction, using a soaking in aqueous ammonia treatment. J. Am. Oil Chem. Soc. 2012, 89, 1345–1353. [Google Scholar]

- Karki, B.; Maurer, D.; Jung, S. Efficiency of treatments for optimal enzymatic saccharification of soybean fiber. Bioresour. Technol. 2011, 102, 6522–6528. [Google Scholar] [CrossRef] [PubMed]

- Karki, B.; Maurer, D.; Kim, T.H.; Jung, S. Comparison and optimization of enzymatic saccharification of soybean fibers recovered from aqueous extractions. Bioresour. Technol. 2011, 102, 1228–1233. [Google Scholar] [CrossRef] [PubMed]

- Ojeda, K.; Sanchez, E.; El-Halwagi, M.; Kafarov, V. Energy analysis and process integration of bioethanol production from acid pre-treated biomass: Comparison of SHF, SSF and SSCF pathways. Chem. Eng. J. 2011, 176, 195–201. [Google Scholar] [CrossRef]

- Cardona, C.A.; Sanchez, O.J. Fuel ethanol production: Process design trends and integration opportunities. Bioresour. Technol. 2007, 98, 2415–2457. [Google Scholar] [CrossRef] [PubMed]

- Ballesteros, I.; Negro, M.J.; Oliva, J.M.; Cabañas, A.; Manzanares, P.; Ballesteros, M. Ethanol production from steam-explosion pretreated wheat straw. In Twenty-Seventh Symposium on Biotechnology for Fuels and Chemicals; Humana Press: New York, NY, USA, 2006; pp. 496–508. [Google Scholar]

- Teixeira, L.C.; Linden, J.C.; Schroeder, H.A. Optimizing peracetic acid treatment conditions for improved simultaneous saccharification and co-fermentation (SSCF) of sugar cane bagasse to ethanol fuel. Renew. Energy 1999, 16, 1070–1073. [Google Scholar] [CrossRef]

- Bokinsky, G.; Peralta-Yahya, P.P.; George, A.; Holmes, B.M.; Steen, E.J.; Dietrich, J.; Lee, T.S.; Tullman-Ercek, D.; Voigt, C.A.; Simmons, B.A.; et al. Synthesis of three advanced biofuels from ionic liquid-pretreated switchgrass using engineered Escherichia coli. Proc. Natl. Acad. Sci. USA 2011, 108, 19949–19954. [Google Scholar] [CrossRef] [PubMed]

- Geddes, C.C.; Mullinnix, M.T.; Nieves, I.U.; Peterson, J.J.; Hoffman, R.W.; York, S.W.; Yomano, L.P.; Miller, E.N.; Shanmugam, K.T.; Ingram, L.O. Simplified process for ethanol production from sugarcane bagasse using hydrolysate-resistant Escherichia coli strain MM160. Bioresour. Technol. 2011, 102, 2702–2711. [Google Scholar] [CrossRef] [PubMed]

- Lau, M.W.; Gunawan, C.; Balan, V.; Dale, B.E. Comparing the fermentation performance of Escherichia coli KO11, Saccharomyces cerevisiae 424A (LNH-ST) and Zymomonas mobilis AX101 for cellulosic ethanol production. Biotechnol. Biofuels 2010, 3, 11. [Google Scholar] [CrossRef] [PubMed]

- Hendriks, A.T.W.M.; Zeeman, G. Treatments to enhance the digestibility of lignocellulosic biomass. Bioresour. Technol. 2009, 100, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Ortiz, I.; Quintero, R. Recent advancements in treatment technologies of biomass to produce bioenergy. In Bioenergy Research: Advances and Application; Gupta, V.K., Kubicek, C.P., Saddler, J., Xu, F., Tuohy, M.G., Eds.; Elsevier: Oxford, UK, 2014; pp. 57–69. [Google Scholar]

- Yoo, J.; Alavi, S.; Vadlani, P.; Behnke, K.C. Soybean hulls pretreated using thermo-mechanical extrusion-hydrolysis efficiency, fermentation inhibitors, and ethanol yield. Appl. Biochem. Biotechnol. 2012, 166, 576–589. [Google Scholar] [CrossRef] [PubMed]

- Tomas-Pejo, E.; Alvira, P.; Ballesteros, M.; Negro, M.J. Treatment technologies for lignocellulose to bioethanol conversion. In Biofuels: Alternative Feedstocks and Conversion Processes; Pandey, A., Larroche, C., Ricke, S., Dussap, C.G., Gnansounou, E., Eds.; Academic Press: St. Louis, MO, USA, 2011; pp. 149–174. [Google Scholar]

- Wan, C.; Zhou, Y.; Li, Y. Liquid hot water and alkaline treatment of soybean straw for improving cellulose digestibility. Bioresour. Technol. 2011, 102, 6254–6259. [Google Scholar] [CrossRef] [PubMed]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of promising technologies for treatment of lignocellulosic biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef] [PubMed]

- Wyman, C.E.; Dale, B.E.; Elander, R.T.; Holtzapple, M.; Ladisch, M.R.; Lee, Y. Comparative sugar recovery data from laboratory scale application of leading treatment technologies to corn stover. Bioresour. Technol. 2005, 96, 2026–2032. [Google Scholar] [CrossRef] [PubMed]

- Wyman, C.E.; Dale, B.E.; Elander, R.T.; Holtzapple, M.; Ladisch, M.R.; Lee, Y.Y. Coordinated development of leading biomass treatment technologies. Bioresour. Technol. 2005, 96, 1959–1966. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, T.; Johnson, L.A. Effect of low-shear extrusion on corn fermentation and oil partition. J. Agric. Food Chem. 2009, 57, 2302–2307. [Google Scholar] [CrossRef] [PubMed]

- Majoni, S.; Wang, T. Characterization of oil precipitate and oil extracted from condensed corn distillers solubles. J. Am. Oil Chem. Soc. 2010, 87, 205–213. [Google Scholar] [CrossRef]

- Majoni, S.; Wang, T.; Johnson, L.A. Enzyme treatments to enhance oil recovery from condensed corn distillers solubles. J. Am. Oil Chem. Soc. 2011, 88, 523–532. [Google Scholar] [CrossRef]

- Wang, H.; Wang, T.; Johnson, L.A.; Pometto, A.L., III. Effect of the corn breaking method on oil distribution between stillage phases of dry-grind corn ethanol production. J. Agric. Food Chem. 2008, 56, 9975–9980. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Ouhida, I.; Pérez, J.F.; Gasa, J. Soybean (Glycine max) cell wall composition and availability to feed enzymes. J. Agric. Food Chem. 2002, 50, 1933–1938. [Google Scholar] [CrossRef] [PubMed]

- Beldman, G.; Rombouts, F.; Voragen, A.; Pilnik, W. Application of cellulase and pectinase from fungal origin for the liquefaction and saccharification of biomass. Enzym. Microb. Technol. 1984, 6, 503–507. [Google Scholar] [CrossRef]

- Marsman, G.J.P.; Gruppen, H.; Mul, A.J.; Voragen, A.G.J. In vitro accessibility of untreated, toasted, and extruded soybean meals for proteases and carbohydrases. J. Agric. Food Chem. 1997, 45, 4088–4095. [Google Scholar] [CrossRef]

- Yomano, L.P.; York, S.W.; Ingram, L.O. Isolation and characterization of ethanol-tolerant mutants of Escherichia coli KO11 for fuel ethanol production. J. Ind. Microbiol. Biotechnol. 1998, 20, 132–138. [Google Scholar] [CrossRef] [PubMed]

- Taylor, F.; Marquez, M.A.; Johnston, D.B.; Goldberg, N.M.; Hicks, K.B. Continuous high-solids corn liquefaction and fermentation with stripping of ethanol. Bioresour. Technol. 2010, 101, 4403–4408. [Google Scholar] [CrossRef] [PubMed]

- Jin, M.; Balan, V.; Gunawan, C.; Dale, B.E. Quantitatively understanding reduced xylose fermentation performance in AFEX TM treated corn stover hydrolysate using Saccharomyces cerevisiae 424A (LNH-ST) and Escherichia coli KO11. Bioresour. Technol. 2012, 111, 294–300. [Google Scholar] [CrossRef] [PubMed]

- Majoni, S.; Wang, T.; Johnson, L.A. Physical and chemical processes to enhance oil recovery from condensed corn distillers solubles. J. Am. Oil Chem. Soc. 2011, 88, 425–434. [Google Scholar] [CrossRef]

- Johnston, D.; Hicks, K.B.; Moreau, R.A.; Shetty, J.K. Methods for Obtaining Oil from Maize Using Acid Protease and Cell-Wall Polysaccharide-Degrading Enzymes. U.S. Patent Application No. 20,140,134,684, 15 May 2014. [Google Scholar]

- Luangthongkam, P.; Fang, L.; Noomhorm, A.; Lamsal, B. Addition of cellulolytic enzymes and phytase for improving ethanol fermentation performance and oil recovery in corn dry grind process. Ind. Crop. Prod. 2015, 77, 803–808. [Google Scholar] [CrossRef][Green Version]

- Fang, L.; Wang, T.; Lamsal, B. Use of surfactant and enzymes in dry-grind corn ethanol fermentation improves yield of ethanol and distillers corn oil. Ind. Crop. Prod. 2018, 111, 329–335. [Google Scholar] [CrossRef]

- Jung, S.; de Moura, J.M.L.N.; Campbell, K.A.; Johnson, L.A. Enzyme-assisted aqueous extraction of oilseeds. In Enhancing Extraction Processes in the Food Industry; Lebovka, N., Vorobiev, E., Chemat, F., Eds.; CRC Press: Boca Raton, FL, USA, 2011; pp. 477–518. [Google Scholar]

- Bon, E.P.; Ferrara, M.A. Bioethanol Production via Enzymatic Hydrolysis of Cellulosic biomass. In Proceedings of the FAO the Role of Agricultural Biotechnologies for Production of Bioenergy in Developing Countries, Rome, Italy, 12 October 2007. [Google Scholar]

- Talebnia, F.; Karakashev, D.; Angelidaki, I. Production of bioethanol from wheat straw: An overview on treatment, hydrolysis and fermentation. Bioresour. Technol. 2010, 101, 4744–4753. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).