Abstract

This study aimed to manufacture kefir from camel milk using an extensive production system with different amounts of kefir grains, as well as to highlight their nutritional, sensorial, and technological characteristics. During processing, the pasteurization of camel milk, the addition of three doses of kefir grains (2%, 5%, and 10%), and incubation for 18 h were carried out. The microbiological and nutritional properties of the camel milk, kefir grains, and resulting kefirs were assessed. The sensory evaluation and technological processes involved in the production of the selected kefir were then carried out. The results showed that the chemical composition of the camel milk was as follows: fat: 41.7 ± 3.18 g/L; protein content: 37.82 ± 0.66 g/L; ash: 8.92 ± 0.61 g/L; dry matter: 114.21 ± 0.11 g/L; and lactose: 41.3 ± 0.21 g/L. Kefir grains were acidic and moist and contained low fat content (0.02 ± 0.01). The total aerobic flora in camel milk was FAMT 4.77 × 104 CFU/mL. The bacterial load of lactic acid bacteria in the camel kefir prepared with 10% kefir grains was 5.1 ± 0.6 log10 CFU/mL, while the yeast and mold load was 4.24 ± 0.83 log10 CFU/mL. The amount of kefir grains present had a significant effect (p < 0.05) on pH, acidity, and viscosity and improved the protein content, resulting in higher nutritional quality. According to a sensory evaluation, the ranking test showed that the best camel kefir can be produced by the addition of 2% kefir grains. It was the most appreciated by 73% of the tasters based on its physicochemical, microbiological, and sensory characteristics. All obtained camel kefirs were able to fulfill the Codex Alimentarius requirements, ensuring their safety and quality, with overall improvements in taste, texture, and acceptability. A phenotypic and morphological study of lactic acid bacteria isolated from the selected kefir (CK 2%, 18H) showed that these bacteria are Gram+, citrate+, catalase−, shell−, and rod-shaped. All the strains isolated showed good lipolytic and proteolytic activity, with areas of proteolysis between 8 and 15 mm. These strains were also revealed to have antibacterial activity and good acidifying and texturizing effects.

1. Introduction

Camels are pseudoruminant mammals that are highly adapted to desert breeding systems [1]. In Tunisia, camel farming is conventionally extensive, a method perfectly suited to the biology of the species, and is concentrated in the southern areas of the country. Camel milk is a vital part of the daily diet of desert dwellers [2]. In pastoral areas, the camel is able to graze on a great variety of plants, including halophyte grasses, bushes, and trees, leading to lower pressure on the floristic biodiversity of the arid lands [3]. Camels are able to provide highly nutritious milk via the exploitation of the limited grazing space in difficult regions, unlike other herbivorous ruminants [4]. Indeed, camel milk is famous for its benefits due to its nutritional quality and medicinal properties [5]. It could soon become a new superfood due to its high nutritional value, easy digestibility, and low fat content [6]. It is mainly consumed raw, pasteurized, or fermented to extend its shelf life. Kefir, a traditional fermented milk product believed to have come from the Caucasus region, is one of these fermented products. It is produced by the fermentation of milk from various animals (goats and cows). Its organoleptic parameters include an acidic taste and a yeasty aroma [7]. The beverage is produced by fermenting milk with kefir grains (KGs), which are a kind of white to yellow, gelatinous starter culture. The grains vary in size (varying from 0.3 to 3.5 cm in diameter) and are composed of a microbial symbiotic mixture of lactic acid bacteria (108 CFU/g), yeast (106–107 CFU/g), and acetic acid bacteria (105 CFU/g) that stick to a polysaccharide matrix [8]. After successive fermentations, kefir grains can break up to generate new grains [9]. Kefir is the product that remains after removing the kefir grains [7].

Codex Stan 243-2003 [10] recommends that milk kefir have at least 2.8% protein, below 10% fat, and at least 0.6% lactic acid. Even though this product has therapeutic value [11], the use of camel milk for the preparation of kefir remains limited. The processing of camel milk is commonly perceived as challenging, and the quality of the end products is often deemed inferior compared to their counterparts derived from cow milk [12,13]. In recent years, there has been an increasing interest in the commercial use of kefir, since it can be marketed as a natural, safe, and inexpensive food that is easily produced at home. In Tunisia, knowledge of this beverage, its benefits, and the kefir manufacturing process is not very widespread. This drink differs from other fermented dairy products because it is not the result of the metabolic activity of a single or a few microbial species [14]. The composition of the grains and the production process influence the properties of the kefir product. In fact, the characteristics of kefir depend on the ratio of kefir grains to milk [15]. There is a lack of detailed characterization of camel milk kefir produced with varying kefir grain concentrations, particularly regarding its physicochemical, microbiological, and sensory properties. This study aimed to determine some of the physicochemical, microbiological, and sensory characteristics of camel kefir using various grain amounts. Finally, the isolation of lactic acid bacteria from the selected kefir and the analysis of their technological properties will undoubtedly add value to the products.

2. Materials and Methods

2.1. Camel Milk and Kefir Grains (KGs)

The camel milk used in this study was a mixture from the total milking of 10 healthy, multiparous, and mid-lactating dairy camels (Camelus dromedarius) raised in an extensive Saharan breeding system. The samples were produced on a native camel farm in southeastern Tunisia (Medenin; Halg Gemel, Gabes; Zarat, Tataouine; Kerchawa). Kefir grains (KGs) exhibit a notable physical resemblance to cauliflower, featuring a distinctive shape and measuring approximately 1–3 cm in length. They typically possess an off-white or cream color. The KGs used in this study were collected from private consumers and stored at 4 °C until use.

2.2. Manufacture of Camel Milk Kefir

In accordance with [16], 2%, 5%, and 10% kefir grains (w/v) were added to pasteurized camel milk (heated to 63 °C for 30 min) [17]. The mixture was then incubated for 18 h at 25 °C. After fermentation, the kefir grains were separated from the fermented milk through filtration and could be used to initiate further fermentation with milk. This experiment was repeated five times.

2.3. Physicochemical Characteristics (Milk, Kefir, and KGs)

The pH values of the various samples of raw milk, kefir, and kefir grains were determined using a pH meter (Jenway 3510 type pH meter, Cole-Parme, Vernon Hills, IL, USA). The titratable acidity was determined in triplicate according to [18].

The viscosity (cP) of milk and kefir was measured using a Brookfield-type viscosimeter (model DV-E, AMETEK Brookfield, Middleborough, MA, USA) with an accuracy of ±1%. The rotational speed was set to 100 rpm. The dry matter (DM) of milk, kefir, and KGs, expressed in g/L, was determined by drying samples at 105 °C for 24 h until a constant weight was achieved using an oven (Binder, Bohemia, NY, USA). The ash content was determined by incinerating milk, kefir, and KGs for 4 h at 550 °C in an electric muffle furnace [18].

The fat content of milk and kefir was measured using the Gerber method with the Neusal method [19]. The fat content of KGs was determined using the Soxhlet method after boiling the samples with HCl to obtain bound lipid fractions [20].

The fat content was calculated according to the following formula:

with m0 = mass of sample in grams; m1 = mass of empty extraction flask; and m2 = mass of extraction flask after drying.

Fat (g/L) = (m2 − m1) × 100/m0

The protein content of milk and kefir was measured using the Bradford method [21]. The lactose content of milk and kefir was determined by HPLC using a mixture of Carrez I (0.5 mol/L aqueous potassium ferrocyanide), Carrez II (0.5 mol/L aqueous zinc acetate), and acetonitrile [22].

2.4. Microbiological Analysis of Camel Milk and Kefir Grains (KGs)

The microbiological analysis used is in accordance with [18]. Yeast and mold (YM) loads were enumerated in Sabouraud Chloramphenicol medium (Pronadisa Micro and Molecular Biology) and incubated for 4 to 5 days at 25 °C. An aliquot (0.1 mL) of the dilution was evenly spread on the agar surface using a sterile spreader.

The lactic acid bacteria (LAB) were cultured in MRS (Man, ROGOSA, Sharpe Agar) [23] (37 °C for 24–48 h).

The bacterial CFU was determined by selecting colonies that grew from 25 to 250 colonies in a Petri dish as follows:

Colony/gram (CFU/mL) = the number of colonies × (1/dilution factor)

2.5. Sensory Analysis

The sensory characteristics of the kefir sample were assessed using the hedonic test [24] with the participation of 100 untrained tasters (male and female, aged 21 to 55 years). Samples of camel kefir, coded with three random numbers and varying in inoculation doses, were randomly assigned in 30 mL portions. These were then presented in 50 mL glasses for evaluation. The tasters were given drinking water between every two samples. The considered attributes are the salinity, viscosity, odor, acidity, and color of the drinks, scored using the nine-point hedonic scale [25]. The sensory score was coded from 1 to 9, with the following definitions: dislike extremely, dislike very much, dislike moderately, dislike slightly, neither like nor dislike, like slightly, like moderately, like very much, and like extremely. Finally, according to a ranking test, the tasters indicated the most acceptable camel kefir. The data from the sensory evaluation were subjected to One-Way ANOVA using SPSS (Version 20).

2.6. Isolation of Lactic Acid Bacteria (LAB) from Selected Kefir

Strain isolation from camel kefir (CK, 2%, 18H) was performed by preparing serial dilutions of the samples. A 0.1 mL sample of the dilution was spread on de Man, Rogosa, and Sharpe (MRS) agar. The LAB isolates were incubated (37 °C for 48 h). The isolates were identified by morphological characteristics on selective media, and the biochemical tests used were the Gram reaction, catalase test, citrate test, and Sherman Milk Culture test. Only Gram-positive bacteria with catalase-negative responses were found. Citrate utilization in the presence of carbohydrates was studied on Simmons citrate medium (Fluka Biochemica). The presence of blue coloration indicated a positive reaction. The growth of strains in NaCl (4, 6.5%) at different temperatures (10–45 °C) and at two different pH values (4.2, 9.6) was determined. During the test, representative colonies were stored in glycerol culture at −20 °C and kept to investigate their technological aspects and antibacterial activities. Cultures were also kept on an MRS agar slant at 4 °C and streaked every 4 weeks [26].

The test of Sherman Milk Culture indicates the ability of bacteria to grow in the presence of methylene blue, which is blue in a highly oxidizing medium and colorless in a reduced medium. Each culture to be tested was inoculated into skimmed milk with 0.1% and 0.3% methylene blue. After incubation for 24 to 48 h at 37 °C, observations of methylene blue reduction and milk coagulation were noted. Lactococci reduce methylene blue with coagulation; however, thermophilic streptococci are sensitive to this dye [27].

2.7. Technological Aspects of Selected Kefir

- Acidifying activity

The acidifying activity of the strains was measured according to the method described by [28]. This evaluation involved monitoring the pH changes in the cultures over time while simultaneously determining total acidity through titration with sodium hydroxide at regular intervals (0, 2, 4, 6, and 24 h). Precultures were prepared using pasteurized camel milk and strains obtained from MRS medium agar plates. These precultures were used to inoculate 100 mL of pasteurized camel milk in a 250 mL Erlenmeyer flask, which was incubated at 37 °C for 24 h.

- Proteolytic activity

To determine the proteolytic activity of LAB, MRS agar supplemented with 10% skim milk was poured, solidified, and then dried. Sterile Whatman paper discs were deposited on the surface of the agar. Each disc received a volume of 20 µL of a young culture. After incubation at 37 °C for 24 h, proteolysis was indicated by clear zones around the discs [29].

- Lipolytic activity

To determine the lipolytic activity, the strains were inoculated on agar spots in Tween-80 (1, 3, 5%) [30]. Incubation was carried out at 25 °C for 72 h. Strains with an opaque area due to the formation of esters with calcium-liberated fatty acids were considered positive [31].

- Exopolysaccharide production

The cultures were streaked on modified MRS (m-MRS; glucose replaced with 100 g/L sucrose) [32], incubated at the optimal growth temperature for 24 h, and then tested for slime formation using the inoculated loop method [33]. Formed colonies were dragged up using a metal loop, and the strains were considered positive slime producers if the length of the slime was above 1.5 mm [34].

2.8. Antimicrobial Activity Tests

The antibacterial activity of camel kefir strains was determined using the agar well method in MH agar against pathogenic strains [35]. The pathogenic strains used were Pseudomonas, Escherichia coli, Micrococcus, Klebsiella pneumoniae, Staphylococcus, and Streptococcus sp. These bacterial strains are widely utilized in antibacterial studies, as they encompass both Gram-positive and Gram-negative bacteria, including opportunistic and pathogenic species. Additionally, their clinical significance lies in their frequent association with human infections.

All test bacteria were cultured in Mueller–Hinton broth (MHB; Difco) and incubated at 37 °C for 24 h. Twenty microliters of each kefir strain was directly dropped onto the surface of the MHA. The Petri dishes were incubated for 24 h at 37 °C, and the inhibition zone was observed. The presence of a clear zone at the site of strain inoculation was considered total inhibition. All activity tests were performed in triplicate.

2.9. Statistical Analysis

The study was designed with a randomized complete design (RCD) with three levels of kefir grains (2%; 5%; 10%) with five replications. The statistical analysis was carried out by the SPSS software (20). The chemical composition, sensory quality, and biological activities of each strain were assessed by analysis of variance (ANOVA; variation in the dose) using the Duncan test (p < 0.05).

3. Results and Discussion

3.1. Characterization of Camel Milk and KGs

The physicochemical and microbiological composition of camel milk and kefir grains are given in Table 1.

Table 1.

Physicochemical and microbiological characteristics (mean ± Standard Deviation) of camel milk and kefir grains.

The pH and acidity of camel milk (6.77 ± 0.11 and 17.36 ± 0.34, respectively) were found to be similar to the values reported by Fguiri [36]. The acidity level is influenced by microbial flora that produces lactic acid during milking at room temperature [37] and high vitamin C content [38]. The concentrations of fat, proteins, and lactose in camel milk were also consistent with previous studies [39,40,41]. Various factors, such as geographical location, feeding conditions, lactation stage, age, health, environment, milking practices, and weather conditions, can significantly affect the composition of camel milk [42].

The lactic acid bacteria load in camel milk from the extensive system was 3.55 ± 0.22 log10 CFU/mL, while the load of yeasts and molds was 3.75 ± 0.36 log10 CFU/mL. According to [43], the highest bacterial load in camel milk was observed in the extensive system (1.43 ± 0.87 log10 CFU/mL for LAB and 6.36 ± 2.44 log10 CFU/mL for MY), possibly influenced by environmental factors, milking conditions, and transport time from milking to laboratory analysis. Other studies have also suggested that the breeding system can impact the quality of cow’s milk [44].

The KGs were yellowish-white in color with an acidic pH, with [45] reporting similar pH values (3.5 and 4.0). The fat content of kefir grains is very low, ranging from 0.02 to 0.01 g/kg. These results align with those reported by [46], which showed a fat content of 0.06% to 2% of the grain weight. The microbial load of KGs in YM was 6.63 ± 0.19 log10 CFU/g, equivalent to 4.3 ± 2.3 × 106 CFU/g, and in LAB, it ranged from 8.48 ± 0.15 log10 CFU/g, equal to 3 ± 1.2 × 108 CFU/g. The grains consisted of a symbiotic microbial mixture of lactic acid bacteria (108 CFU/g) and yeast (106–107 CFU/g) [47]. These grains contain lactic acid bacteria (LAB) and various yeasts combined with casein and complex sugars in a polysaccharide matrix [16].

3.2. The Effect of the KG Dose on the Composition of Kefir

The dose of kefir grains (KGs) was a crucial key factor influencing the physicochemical and microbiological composition of kefir. In this study, various KG doses were analyzed to determine their impact on essential quality parameters, such as acidity, pH, microbial count, and overall composition. The composition of kefir produced with three different KG doses is presented in Table 2.

Table 2.

The effect of dose on the quality of camel kefir (mean ± Standard Deviation).

The dose of KGs had a significant effect on physical parameters. Acidity and viscosity increased proportionally to the kefir grain dose. Conversely, the pH of kefir exhibited a relationship with the amount of grains used as inoculum. These findings align with previous research [48], which showed a pH decrease in cow milk kefir after 24 h of incubation. This pH reduction is primarily attributed to the production of organic acids, ethanol, CO2, and other volatile compounds [49]. The viscosity of kefir increased with higher doses of grains, as it led to a higher concentration of lactic acid bacteria (LAB) and yeasts, accelerating protein coagulation. This resulted in a thicker milk matrix. Some LAB strains also produced exopolysaccharides (EPSs) like kefiran, which further increased viscosity, improved stability, strengthened the gel network, and enhanced texture [50].

No significant differences were observed in the fat, DM, ash, or lactose content of kefir when varying the dose of KGs. The chemical composition of cow kefir consists mainly of water (90%), followed by sugars (6%), fats (3.5%), proteins (3%), and ash (0.7%) [51]. The fermentation process converts lactose into lactic acid, resulting in a decrease in pH and a thicker consistency. Camel kefir may be a suitable option for individuals with lactose intolerance [52].

The use of different doses of KGs did not show any significant effect on the bacterial load (LAB and YM). According to a study by [48], kefir from a cow contains 108 CFU/mL of lactic acid bacteria, 106 CFU/mL of yeast, and 106 CFU/mL of acetic acid bacteria. The symbiotic interaction between LAB and yeasts plays a critical role in kefir’s unique composition, influencing both texture and flavor [53]. However, excessive yeast activity may lead to excessive CO2 and alcohol production, potentially affecting the sensory characteristics of kefir [54].

All camel kefirs from the extensive system match the description of typical kefir in the Codex Alimentarius. They contain at least 2.8% protein (from 2.2 to 3.11 ± 5.4%), 0.6% lactic acid (from 0.89 to 1.12%), and less than 10% fat (~4%). The total number of microorganisms in the final product must be at least 107 (CFU)/mL (5.32 log10 CFU/mL) and the number of yeasts at least 104 CFU/mL (4.53 log10 CFU/mL) [52]. Maintaining an optimal microbial load is essential for sensory quality. Controlled fermentation improves texture, flavor, and aroma, while excessive microbial growth deteriorates sensory properties and reduces shelf life. A balanced microbial load improves product stability, enhances sensory appeal, and ensures safety [55].

3.3. Sensory Evaluation of Camel Kefirs (CKs)

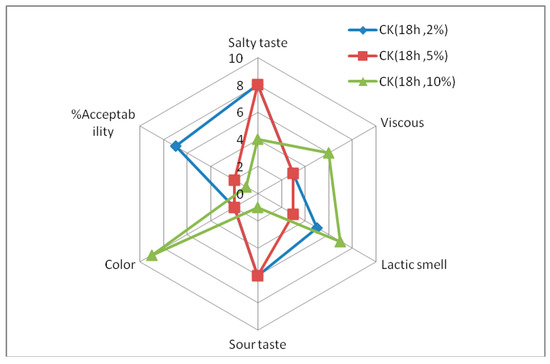

CK (2%, 18 h) was the most acidic with a pH of 6.3, showing pronounced acidity, attributed to lactic acid production during fermentation (18 h). Camel kefir (10%, 18 h) exhibited increased viscosity and a strong lactic odor, indicative of lactic acid bacteria presence in kefir grains [56]. The evaluated CK (2%, 18 h) scored above 2.5 for all attributes. Camel kefir with 2% and 5% CK (5%, 18 h) had a saltier taste (8.08 ± 2.51), with CK (5%, 18 h) exhibiting the weakest color. The kefirs scored above 3 for salinity, influenced by a diet of halophytic plants rich in salts [57].

The results of the classification test revealed that camel kefir (2%, 18 h) was preferred by 73% of testers. Organoleptic analysis indicated that CK (2%, 18 h) received higher scores for all evaluated attributes, demonstrating overall great acceptance (Figure 1). Sensory evaluation revealed that CK (2%, 18 h) scored higher in taste, texture, and appearance, indicating the highest level of acceptability.

Figure 1.

Sensory evaluation of camel kefir. CK (2%, 18 h), CK (5%, 18 h), and CK (10%, 18 h): camel kefir with 18 h of incubation and 2, 5, and 10% KGs.

In a study by [58], it was concluded that camel kefir (2%, 18 h) was the most preferred by tasters when assessing the sensory quality of camel kefir from a semi-intensive system.

3.4. Physiological and Biochemical Tests

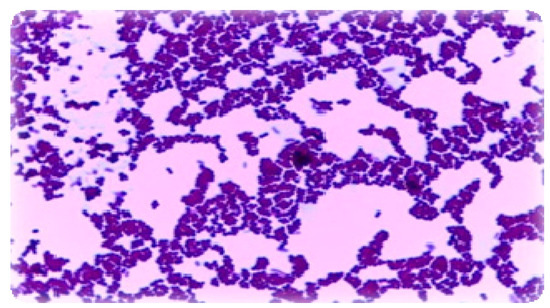

The strains were identified through physiological and biochemical tests; the results are presented in Table 3. Out of thirty-eight lactic acid bacteria strains isolated and purified from camel kefir, eighteen were selected. These strains are Gram-positive, unable to produce catalase, and exhibit various morphologies. They appear purple under the microscope due to their peptidoglycan-rich cell walls [59].

Table 3.

Physiological and morphological profiles of bacterial strains isolated from selected camel kefir.

After performing Gram staining (Figure 2), the bacteria were observed by a microscope at a magnification of 100×. All bacteria were Gram-positive, indicated by their purple color, and exhibited various forms, such as cocci and coccobacilli (spherical). Following the catalase test, no bubbles were produced, indicating that all the bacteria were catalase-negative. The lack of catalase activity is a characteristic of lactic acid bacteria, although some species may acquire this activity.

Figure 2.

Microscopic observation of lactic acid bacteria with magnification (G: 10X100).

Table 4 presents the various tests employed to identify and characterize microbial strains based on their physiological and biochemical properties. This included strain codes and growth conditions, such as temperature tolerance, pH range, and NaCl tolerance.

Table 4.

Physiological and biochemical characterization of isolated strains.

By using physiological and biochemical tests, the isolated strains were classified into two groups: mesophilic and thermophilic strains (Table 4). Mesophilic strains can thrive at moderate temperatures, typically between 20 and 45 °C, while thermophilic strains show optimal growth at higher temperatures, usually above 45 °C. This classification offers valuable information on the adaptability of the strains and their potential uses in various environmental conditions.

All isolated strains were capable of growing in MRS broth at temperatures of 10 °C, 39 °C, and 45 °C (Table 4), indicating their thermophilic nature. The ability to thrive at different temperatures suggests that the strains are well adapted to warmer environments, a common trait of thermophilic microorganisms.

Furthermore, all the strains exhibited growth at pH 4.2 and pH 9.6, as well as in hypersaline media with 4%, 6%, and 9% NaCl. These findings confirm the robustness of the isolated strains and their ability to survive in challenging conditions, such as extreme pH and high salinity.

All results of the NaCl growth test were positive, indicating that the strains exhibited high salinity tolerance. This is significant, as it suggests that the isolates may belong to the genus Enterococcus, known for its ability to grow at 45 °C and tolerate salinity levels up to 6.5% and a pH of 9.6, consistent with the findings of this study. In contrast, lactococci do not thrive under such extreme conditions, providing additional support for the identification of the isolates as Enterococcus species [60].

Growth and Activity of Isolated Strains in Sherman’s Milk

Table 5 presents the results of methylene blue reduction and milk coagulation tests for each isolated strain grown in Sherman’s milk. The observations were recorded for cultures supplemented with methylene blue at concentrations of 0.1% and 0.3%.

Table 5.

Cultivation of lactic acid strains in Sherman’s milk.

During incubation, some tested isolates caused significant coagulation of Sherman’s milk, regardless of the methylene blue concentration. However, no reduction of methylene blue was observed for the others, as indicated by the lack of discoloration in the medium. This suggests a negative reaction in terms of methylene blue reduction for these tested strains.

The lactic acid bacteria strains (SK1 to SK10) isolated from camel kefir showed their ability to grow in and acidify Sherman’s milk, resulting in coagulation at both 0.1% and 0.3% methylene blue concentrations.

The lactic acid bacteria strains SK11 to SK18 did not induce coagulation of Sherman’s milk or show any capacity to reduce methylene blue at either tested concentration. The absence of coagulation suggests that these strains either lack sufficient acidifying activity or do not grow effectively in this medium. These strains also failed to reduce methylene blue significantly, indicating that their population density in the medium was not high enough to trigger a visible color change. Due to their inability to produce visible technological changes, strains SK11 to SK18 were not subjected to further technological evaluations. Consequently, they were excluded from subsequent phases of this study, as they do not exhibit the essential functional properties required for further analysis.

3.5. Technological Activities of Lactic Acid Strains Isolated from Selected Kefir

The evaluation of the technological properties of lactic acid bacteria (LAB) strains isolated from kefir made with camel milk (KC, 2%, 18 h) was essential for selecting appropriate starter cultures for the standardized production of dairy products. This assessment encompassed various factors that impacted the fermentation process and the quality of the final product. The key technological properties typically assessed included the acidification rate, proteolytic and lipolytic activity, and gas production.

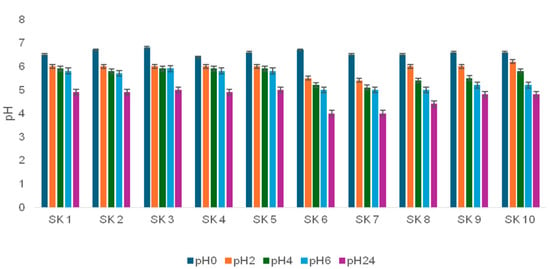

3.5.1. Acidifying Activity

The acidifying activity of LAB strains was studied to control both pH and acidity levels during fermentation. The strains were evaluated based on their acid production capacity to determine the most suitable starter culture. Figure 3 illustrates the acidifying activity of the strains, as indicated by the pH decrease. The results depicted in Figure 3 show that the pH decreased from 6.7 to 5.55 within the first two hours of incubation. After 24 h of incubation, the pH values ranged between 4.03 and 5.02. According to a previous study, strains are classified as fast, medium, or slow acidifiers based on the pH reaching 0.4 U in 3, 3 to 5, and >5 h, respectively [34]. In our study, all isolated strains exhibited varying levels of acidifying activity. Strains SK6 and SK7 showed the highest acidifying activity, with pH values of 3.7 and 3.6, respectively, after 24 h of fermentation. These strains were classified as acidifying and selected for further testing. Fast-acidifying strains like this are ideal candidates in the dairy fermentation processes as starters.

Figure 3.

Evaluation of the pH of isolated bacteria. SK1 → SK10: lactic strains isolated from camel kefir.

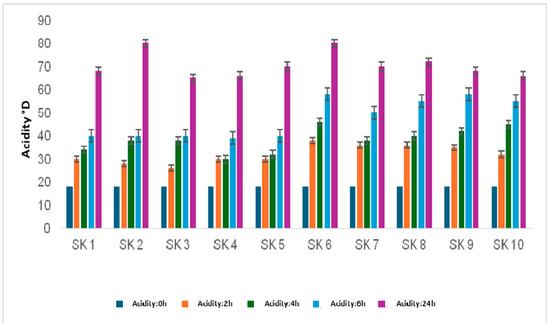

Differences in pH reduction between genera, between species, and sometimes between strains of the same species have been mentioned by many authors, including Luquet [61]. Acidity increased during fermentation, and there was variability in the acidification rate between the different strains used (Figure 4). After 24 h of incubation, the results obtained allowed all the strains studied to be classified into the categories of lactic acid bacteria with acidity between 64.8 °D and 81.9 °D.

Figure 4.

Changes in acidity over time in kefirs inoculated with different strains. SK1 → SK10: lactic strains isolated from camel kefir.

The results show that all isolated bacterial strains can lower pH and increase acidity, but the degree of acidification varies. This aligns with Lu-quet’s [61] findings, highlighting differences not only between bacterial genera but also among species and even within individual strains. While all strains contributed to acid production, some induced a more significant pH decrease, indicating variations in their ability to ferment sugars and produce organic acids like lactic acid and acetic acid. These variations may be due to genetic factors, enzyme activity, and adaptability to different substrates [62].

Some strains grow faster and can acidify the medium more quickly, while others have a greater affinity for some sugars, affecting their acid production. These differences suggest the possibility of selecting particular bacterial strains for specific uses, such as in fermented dairy products and probiotics. A better grasp of strain-specific acidification can lead to improved fermentation conditions and higher product quality.

3.5.2. Proteolytic Activity

The results of proteolytic activity are summarized in Table 6. All strains produced clear zones around the discs, with diameters ranging from 8 to 15 mm, indicating that all strains exhibit proteolytic activity. According to Veuillemard (1986) [29], a strain is considered proteolytic if it produces a lysis zone with a diameter between 5 and 15 mm. These findings confirm the proteolytic nature of lactic acid bacteria. Previous research has shown that lactic acid bacteria lack the ability to synthesize certain amino acids but possess a complex bacterial proteolytic system that enables them to thrive in protein-rich environments with low free amino acids, such as milk [63]. In conclusion, all strains studied demonstrated proteolytic activity, supporting their adaptation to environments abundant in proteins and deficient in free amino acids.

Table 6.

Technological activities of lactic acid strains isolated from selected kefir.

3.5.3. Lipolytic Activity

The lipolytic activity of lactic acid bacteria strains was analyzed, and the results are presented in Table 6. It was found that a substrate concentration of 3% Tween 80 provided optimal conditions for lipolytic activity in all tested strains.

Different genera of lactic acid bacteria exhibited varying levels of lipolytic activity, with lactococci and enterococci exhibiting significant activity when 1% olive oil was used as a substrate [64]. This indicates that these bacteria have strong lipase or esterase activity, allowing them to effectively break down lipids.

The lipolytic potential of these bacteria likely influences the flavor and texture development of fermented dairy products, as lipid hydrolysis leads to the release of free fatty acids, which impact sensory properties [65].

3.5.4. Texturizing Activity

The results of the production of exopolysaccharides by lactic isolates are illustrated in Table 6. All strains studied were capable of growing on a hypersucrose medium and forming sticky colonies, indicating the production of exopolysaccharides (EPSs). The production of EPSs by lactic acid bacteria is a beneficial phenomenon for many industrial food processes [66]. The ability of lactic acid bacteria to produce EPSs is important for enhancing texture, preventing syneresis, and increasing viscosity in finished products [67]. Factors influencing EPS production include the strain, growth rate, temperature, culture medium, acidification rate, pH, and oxygen levels in the culture medium [68]. Lactic acid bacteria synthesize exocellular polysaccharides (sugar polymers) during growth, which are used to improve the texture and viscosity of products like kefir [69].

3.5.5. Gasogenic Activity

The gasogenic activity test yielded positive results for all tested strains, except for KS1 and KS2 (Table 6). KS1 and KS2 exclusively metabolized lactose into lactic acid without producing CO2, indicating their classification as strictly homofermentative lactic acid bacteria. In contrast, the remaining eight strains (KS3 to KS10) produced both lactic acid and CO2. The presence of CO2, observed as gas bubbles in the Durham tube, is a characteristic trait of heterofermentative bacteria. This test effectively distinguished between homofermentative and heterofermentative strains based on their ability to generate CO2 from glucose. This differentiation was crucial, as gas production served as a metabolic indicator for the identification and classification of lactic acid bacteria, which are essential for their technological applications in fermentation processes [70].

Through the evaluation of bacteria, we identified LAB strains that not only facilitated the fermentation process but also contributed to the desired characteristics of camel kefir (2%, 18H).

3.6. Antibacterial Properties of Lactic Acid Bacteria Isolated from Camel’s Kefir

This test aimed to assess the sensitivity of six pathogenic strains against 10 lactic acid bacteria strains isolated from camel milk kefir (2%, 18 h) (Table 7). All lactic acid strains showed strong antibacterial activity against pathogens, including Pseudomonas, Escherichia coli, Micrococcus, Klebsiella pneumoniae, Staphylococcus, and Streptococcus. Among them, camel kefir strain 4 (KS4) showed the most significant antibacterial activity, while strain KS2 showed lower activity compared to the others. According to a study by [71], the antibacterial properties of lactic acid bacteria are attributed to the production of various antibacterial metabolites, such as bacteriocins, hydrogen peroxide, organic acids, and diacetyl.

Table 7.

Antibacterial activity of the 10 strains of lactic acid bacteria against 6 pathogenic strains.

Research has shown that kefir exhibits antibacterial properties. Antimicrobial peptides and bioactive molecules, such as lysozymes, act as the first line of defense against pathogen colonization [72]. Both bacteria and yeasts isolated from kefir have demonstrated antimicrobial activity against enteropathogenic bacteria and spoilage fungi in both in vivo and in vitro studies. Additionally, kefir’s microbiota and associated compounds have exhibited promising antimicrobial effects [73].

4. Conclusions

In recent decades, the popularity of kefir has been increasing, with numerous nutritional benefits attributed to this fermented beverage. However, in Tunisia, fermented camel milk, known as camel kefir, is not widely recognized. This study aimed to produce and characterize camel kefirs with varying levels of kefir grains. The results of the research indicated a significant impact of the kefir grain dosage on the quality of the camel beverage. Furthermore, the quality of the camel kefirs produced met safety standards set by regulations. Among the different formulations tested, camel kefir with 2% kefir grains and fermented for 18 h aligned with Codex Alimentarius requirements and was preferred by the taste testers.

The technological aspects of ten strains of lactic acid bacteria isolated from camel kefir showed promising potential, including acidification, proteolysis, lipolysis, thickening, gas production, and antibacterial activities. These findings suggest that lactic acid bacteria from camel kefir have favorable technological characteristics. Encouraging the consumption and commercialization of camel milk kefir could be beneficial. Further research is needed to assess the shelf life of this dairy product.

Author Contributions

Conceptualization, S.A., A.S. and T.K.; methodology, S.A., A.S., M.D., I.F. and T.K.; software, S.A. and N.A.; validation, S.A. and A.S.; formal analysis, S.A.; resources, M.D., I.F. and M.H.; writing—original draft, S.A.; writing—review and editing, S.A., A.S., I.F., NA., M.H. and T.K.; visualization, M.H.; supervision, A.S., I.F. and T.K.; project administration, T.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| MRS | de Man, Rogosa, and Sharpe |

| LAB | Lactic acid bacteria |

| GK | Kefir grain |

| DM | Dry matter |

| YM | Yeast and molds |

| CK (2%, 18 h) | Camel kefir with 2% kefir grains and 18 h incubation time |

| CK (5%, 18 h) | Camel kefir with 5% kefir grains and 18 h incubation time |

| CK (10%, 18 h) | Camel kefir with 10% kefir grains and 18 h incubation time |

| SK1–SK10 | Lactic strains isolated from selected camel kefir. |

References

- Mohammed, A.A.; Almuyidi, A.; Almarri, H.; Alkhalifah, H.; Alhmad, A.; Alali, H.; AlHuwaish, O.; AlKhawaher, M. Unique Characteristics of Camel Body Systems: Adaptation to Harsh Conditions, Productive and Reproductive Performances: A Review. Indian. J. Anim. Res. 2025, 1–10. [Google Scholar] [CrossRef]

- Aroua, M. L’élevage Camelin en Tunisie Élevage et Lait de Chamelle; Editions Universitaires Européennes: Saarbrücken, Germany, 2021. [Google Scholar]

- Subbulakshmi, V.; Sheetal, K.R.; Noor Mohamed, M.B.; Renjith, P.S.; Kala, S. Arid Agroforestry for Thar Desert. In Natural Resource Management in the Thar Desert Region of Rajasthan; Springer International Publishing: Cham, Switzerland, 2023; pp. 155–192. [Google Scholar]

- Boudjnah, H.S. Aptitude à la Transformation du Lait de Chamelle en Produit Dérives: Effet des Enzymes Coagulantes Extraites de Caillettes de Dromadaires. Ph.D. Thesis, Universite Mouloud Mameri, Tizi-Ouzou, Algérie, 2012; pp. 40–60. [Google Scholar]

- Sboui, A.; Atig, C.; Khabir, A.; Hammadi, M.; Khorchani, T. Camel milk used as an adjuvant therapy to treat type 2 diabetic patients: Effects on blood glucose, HbA1c, cholesterol, and TG levels. J. Chem. 2022, 2022, 5860162. [Google Scholar] [CrossRef]

- Abdelazez, A.; Abd-elmotaal, H.; Abady, G. Exploring the potential of camel milk as a functional food: Physicochemical characteristics, bioactive components, innovative therapeutic applications, and development opportunities analysis. Food Mater. Res. 2024, 4, e031. [Google Scholar] [CrossRef]

- Soutelino, M.E.M.; da Silva Rocha, R.; Mársico, E.T.; Esmerino, E.A.; de Oliveira Silva, A.C. Innovative approaches to kefir production, challenges, and current remarks. Curr. Opin. Food Sci. 2025, 61, 101252. [Google Scholar] [CrossRef]

- La Torre, C.; Caputo, P.; Fazio, A. Effect of Milk and Water Kefir Grains on the Nutritional Profile and Antioxidant Capacity of Fermented Almond Milk. Molecules 2025, 30, 698. [Google Scholar] [CrossRef]

- Mujahid, M.; Wakeel, M.; Ali, A.M.; Saeed, S.; Nawaz, A.S.; Hafeez, K. Food fermentation: Traditional practices and modern applications in food industry. Int. J. Food Ferment. Technol. 2024, 14, 239–273. [Google Scholar] [CrossRef]

- Codex Alimentarius International Food Standards 2003. Codex Standard for Fermented Milks (Codex Stan CXS 243-2003). Available online: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/es/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B243-2003%252FCXS_243e.pdf (accessed on 22 December 2024).

- Dahiya, D.; Nigam, P.S. Therapeutic and Dietary Support for Gastrointestinal Tract Using Kefir as a Nutraceutical Beverage: Dairy-Milk-Based or Plant-Sourced Kefir Probiotic Products for Vegan and Lactose-Intolerant Populations. Fermentation 2023, 9, 388. [Google Scholar] [CrossRef]

- Arain, M.A.; Salma, H.M.; Ali, M.; Khaskheli, G.B.; Barham, G.S.; Marghazani, I.B.; Ahmed, S. A review on camel milk composition, techno-functional properties and processing constraints. Food Sci. Anim. Resour. 2023, 44, 739. [Google Scholar] [CrossRef]

- Seifu, E. Camel milk products: Innovations, limitations and opportunities. FPPN 2023, 5, 1–20. [Google Scholar] [CrossRef]

- Farnworth, E.R.; Mainville, I. Kefir—A Fermented Milk Product. In Handbook of Fermented Functional Foods, 2nd ed.; Farnworth, E.R., Ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2008; pp. 89–127. [Google Scholar]

- Agustina, L.T.; Setyawardani, T.; Astuti, T.Y. Penggunaan starter biji kefir dengan konsentrasi yang berbeda pada susu sapi terhadap pH dan kadar asam laktat (The use of different concentration of kefir grainsion cow’s milk and its effect on pH and lactic acid level). JIPT 2013, 1, 254–259. [Google Scholar]

- Otles, S.; Cagindi, O. Kefir: A Probiotic Dairy-Composition, Nutritional and Therapeutic Aspects. Pak. J. Nutr. 2003, 2, 54–59. [Google Scholar]

- Deak, T. Food safety management: Chapter 17. In Thermal Treatment; Elsevier Inc.: Amsterdam, The Netherlands, 2013. [Google Scholar]

- AFNOR. Contrôle de la Qualité des Produits Alimentaires; Lait et produits laitiers, Afnor: Paris, France, 1993. [Google Scholar]

- Wangoh, J.; Farah, Z.; Puhan, Z. Composition of milk from three camel (Camelus dromedarius) breeds in Kenya during lactation. Milchwissenschaft 1998, 53, 136–139. [Google Scholar]

- International Standard ISO 1443; Meat and Milk Products-Determination of Total Fat Content. International Standard ISO: Geneva, Switzerland, 2010.

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Sharma, R.; Rajput, Y.S.; Poonam Dogra, G.; Tomar, S.K. Estimation of sugars in milk by HPLC and its application in detection of adulteration of milk with soy milk. Int. J. Dairy Technol. 2009, 62, 514–519. [Google Scholar] [CrossRef]

- De Man, J.C.; Rogosa, M.; Sharpe, M.E. A medium for the cultivation of lactobacilli. J. Appl. Microbiol. 1960, 23, 130–135. [Google Scholar] [CrossRef]

- Jrad, Z.; Oussaief, O.; Bouhemda, T.; Khorchani, T.; EL Hatmi, H. Potential effects of ultrafiltration process and date powder on textural, sensory, bacterial viability, antioxidant properties and phenolic profile of dromedary Greek yogurt. IJFST 2019, 54, 854–861. [Google Scholar] [CrossRef]

- Abdo, E.M.; Mansour, H.M.; Darwish, A.M.G.; El-Sohaimy, S.A.; Gomaa, M.A.; Shaltout, O.E.; Allam, M.G. Beetroot Stalk Extract as a Functional Colorant for Stirred Yogurt Beverages: Effect on Nutritional Value and Stability during Storage. Fermentation 2023, 9, 878. [Google Scholar] [CrossRef]

- Zarour, K.; Benmechernene, Z.; Hadadji, M.; Moussa-Boudjemaa, B.; Henni, D.J.; Kihal, M. Bioprospecting of Leuconostoc mesenteroides strains isolated from Algerian raw camel and goat milk for technological properties useful as adjunct starters. Afr. J. Microbiol. Res. 2012, 6, 3192–3201. [Google Scholar]

- Maghnia, D.A. Etude de Potentiel Technologique des Bactéries Lactiques Isolées des Aliments Fermentés Traditionnels Algériens. Ph.D. Thesis, Université d’Oran, Oran, Algeria, 2011. [Google Scholar]

- Meng, Z.; Zhang, L.; Xin, L.; Lin, K.; Yi, H.; Han, X. Technological characterization of Lactobacillus in semi hard artisanal goat cheeses from different Mediterranean areas for potential use as nonstarter lactic acid bacteria. JDS 2018, 101, 2887–2896. [Google Scholar]

- Vuillemard, J.C. Microbiologie des aliments. Evolution de l’activité protéolytique des bactéries lactiques. Tech. Doc. Lavoisier Paris 1986, 3, 1–65. [Google Scholar]

- Smibert, R.M.; Krieg, N.R. General characterization. In Manual of Methods for General Bacteriology; Gerhardt, P., Ed.; American Society for Microbiology: Washington, DC, USA, 1981; pp. 409–443. [Google Scholar]

- Smith, J.L.; Haas, M.J. Lipolytic microorganisms. In Compendium of Methods for the Microbiological Examination of Foods; APHA Press: Washington, DC, USA, 1992; pp. 183–191. [Google Scholar]

- Van Geel-Schutten, G.H.; Faber, E.J.; Smit, E.; Bonting, K.; Smith, M.R.; TenBrink, B.; Kamerling, J.P.; Vliegenthart, J.F.; Dijkhuizen, G.L. Biochemical and structural characterization of the Glucan and Fructan Exopolysaccharides synthesized by the Lactobacillus reuteriwild-type strain and by mutant strain. Appl. Environ. Microbiol. 1999, 65, 3008–3014. [Google Scholar] [CrossRef] [PubMed]

- Knoshaug, E.P.; Ahlgrent, J.A.; Trempy, J.E. Growth associated exopolysaccharide expression in Lactococcus lactis subspecies cremoris Ropy352. JDS 2000, 83, 633–640. [Google Scholar] [CrossRef] [PubMed]

- Ayad, E.H.E.; Nashat, S.; El-Sadek, N.; El-Soda, M. Selection of wild lactic acid bacteria isolated from traditional Egyptian dairy prod-ucts according to production and technological criteria. Food Microbiol. 2004, 21, 715–725. [Google Scholar] [CrossRef]

- Jrad, Z.; El Hatmi, H.; Fguiri, I.; Arroum, S.; Assadi, M.; Khorchani, T. Antibacterial activity of Lactic acid bacteria isolated from Tunisian camel milk. Afr. J. Microbiol. Res. 2013, 7, 1002–1008. [Google Scholar]

- Fguiri, I.; Manel, Z.; Sboui, A.; Ayeb, N.; Atigui, M.; Arroum, S.; Hammadi, M.; Khorchani, T. Microbiological quality and biochemical characteristics of lactic acid bacteria from camel milk as affected by the production system and stage of lactation. In Milk Protein: New Research Approaches; IntechOpen: London, UK, 2022; Volume 13. [Google Scholar]

- Fouzia, R.; Noureddine, S.; Mebrouk, K. Evaluation of the factors affecting the variation of the physicochemical composition of Algerian camel’s raw milk during different seasons. Adv. Environ. Biol. 2013, 7, 4879–4884. [Google Scholar]

- Ismaili, M.A.; Saidi, B.; Zahar, M.; Hamama, A.; Ezzaier, R. Composition and microbial quality of raw camel milk produced in Morocco. J. Saudi Soc. Agric. Sci. 2019, 18, 17–21. [Google Scholar] [CrossRef]

- Arroum, S.; Zamouli, K.; Gaddour, A.; Fguiri, I.; Ayeb, N.; Khorhani, T. Etude comparative des caractéristiques physicochimiques et microbiologiques du lait camelin en fonction du mode d’élevage. J. New Sci. 2015, 4, 4648. [Google Scholar]

- Hazebrouck, S. Laits de chèvre, d’ânesse et de chamelle: Une alternative en cas d’allergie au lait de vache ? Innov. Agron. 2016, 52, 73–84. [Google Scholar]

- Chethouna, F.; Boudjenah, S.H.; Beldi, N.; Siboukeur, O. Comparative Study of the Physico-Chemical and Microbiological Characteristics of Raw and Pasteurized Camel Milk. Emir. J. Food Agric. 2022, 34, 10. [Google Scholar] [CrossRef]

- Chamekh, L.; Calvo, M.; Khorchani, T.; Castro-Gómez, P.; Hammadi, M.; Fontecha, J.; Yahyaoui, M.H. Impact of management system and lactation stage on fatty acid composition of camel milk. J. Food Compos. Anal. 2020, 87, 103–418. [Google Scholar] [CrossRef]

- Fguiri, I.; Ziadi, M.; Sboui, A.; Ayeb, N.; Atigui, M.; Arroum, S.; Khorchani, T. Effect of the production system and stage of lactation on the microbiological and biochemical characteristics of camel milk. J. Camelid Sci. 2018, 11, 57–63. [Google Scholar]

- Sraïri, M.T.; Alaoui, H.I.; Hamama, A. Relations entre pratiques d’élevage et qualité globale du lait de vache en étables suburbaines au Maroc. Rev. Med. Vet. 2005, 156, 155–162. [Google Scholar]

- Garrote, G.L.; Abraham, A.G.; De Antoni, G.L. Chemical and microbiological characterisation of kefir grains. Res. J. Dairy Sci. 2001, 68, 639–652. [Google Scholar] [CrossRef]

- Jelen, P.; Fuquay, J.; Fox, P.; McSweeney, P. Encyclopedia of Dairy Sciences; Academic Press: Oxford, UK, 2003. [Google Scholar]

- Chen, Z.; Shi, J.; Yang, X.; Nan, B.; Liu, Y.; Wang, Z. Chemical and physical characteristics and antioxidant activities of the exopolysaccharide produced by Tibetan kefir grains during milk fermentation. Int. Dairy J. 2015, 43, 15–21. [Google Scholar] [CrossRef]

- Suriasih, K.; Sucipta, I.N.; Putri, W.C.W.; Wirawan, I.P.S. Chemical Characteristics And Microbiological Kefir Beverages from Bali Cattle During Storage. IJSTR 2020, 9, 135–138. [Google Scholar]

- Irigoyen, A.; Arana, I.; Castiella, M.; Torre, P.; Ibanez, F.C. Microbiological, physicochemical, and sensory characteristics of kefir during storage. Food Chem. 2005, 90, 613–620. [Google Scholar] [CrossRef]

- Dedhia, N.; Marathe, S.J.; Singhal, R.S. Food polysaccharides: A review on emerging microbial sources, bioactivities, nanoformulations and safety considerations. Carbohydr. Polym. 2022, 287, 119–355. [Google Scholar] [CrossRef]

- Sarkar, S. Biotechnological innovations in kefir production: A review. Br. Food J. 2008, 110, 283–295. [Google Scholar] [CrossRef]

- Ferreira, C. Quefir como alimento funcional. In Alimentos Funcionais–Componentes Bioativos e Efeitos Fisiológicos [NMB Costa and CO Rosa, Editors]; Editora Rubio LTDA: Rio de Janeiro, Brazil, 2010; Volume 1, pp. 111–122. [Google Scholar]

- Cheng, T.; Zhang, T.; Zhang, P.; He, X.; Sadiq, F.A.; Li, J.; Gao, J. The complex world of kefir: Structural insights and symbiotic relationships. CRFSFS 2024, 23, e13364. [Google Scholar] [CrossRef]

- Farag, M.A.; Jomaa, S.A.; Abd El-Wahed, A.; El-Seedi, H.R. The many faces of kefir fermented dairy products: Quality characteristics, flavour chemistry, nutritional value, health benefits, and safety. Nutrients 2020, 12, 346. [Google Scholar] [CrossRef]

- Schmidt, K.A. Dairy: Ice cream. In Food Processing: Principles and Applications; Wiley-Blackwell: Hoboken, NJ, USA, 2004; pp. 287–296. [Google Scholar]

- Hu, Y.; Zhang, L.; Wen, R.; Chen, Q.; Kong, B. Role of lactic acid bacteria in flavor development in traditional Chinese fermented foods: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 2741–2755. [Google Scholar] [CrossRef] [PubMed]

- Arroum, S.; Sboui, A.; Fguiri, I.; Ayeb, N.; Hammadi, M.; Khorchani, T. Qualité du kéfir camelin issu du système d’élevage extensif en Tunisie. Rev. Marocaine Des Sci. Agron. Et Vétérinaires 2023, 11, 269–277. [Google Scholar]

- Arroum, S.; Sboui, A.; Atigui, M.; Fguiri, I.; Dbara, M.; Ayeb, N.; Khorchani, T. Camel’s Kefir Milk: Optimisation of Processing Conditions. JCPR 2023, 30, 221–227. [Google Scholar] [CrossRef]

- Larpen, J.P. Mémento Technique de Microbiologie, 3rd ed.; Technique et Documentation: Lavoisier, Paris, France, 1997; p. 910. [Google Scholar]

- Axelsson, L. Lactic acid bacteria: Classification and physiology. In Lactic Acid Bacteria: Microbiology and Functional Aspects, 2nd ed.; Revised and Expanded; Salminen, S., von Wright, A., Eds.; Marcel Dekker: New York, NY, USA, 1998; pp. 1–72. [Google Scholar]

- Luquet, F.M.; Corrieu, G. Bactéries Lactiques et Probiotiques; Technique et Documentation: Lavoisier, Paris, France, 2005. [Google Scholar]

- Guan, Y.; Cui, Y.; Qu, X.; Li, B.; Zhang, L. Post-acidification of fermented milk and its molecular regulatory mechanism. Int. J. Food Microbiol. 2024, 426, 110920. [Google Scholar] [CrossRef]

- Shirai, K.; Guerrero, I.; Huerta, S.; Saucedo, G.; Castillo, A.; Gonzalez, R.O.; Hall, G.M. Effect of initial glucose concentration and inoculation level of lactic acid bacteria in shrimp waste ensilation. Enzyme Microb. Technol. 2001, 28, 446–452. [Google Scholar] [CrossRef]

- Karam, N.E.; Dellali, A.; Zadi-Karam, H. Activité lipolytique chez les bactéries lactiques. Rencontres Autour Des Rech. Sur Les Rumin. 2012, 19, 415. [Google Scholar]

- Akın, N.; Aydemir, S.; Koçak, C.; Yıldız, M.A. Changes of free fatty acid contents and sensory properties of white pickled cheese during ripening. Food Chem. 2003, 80, 77–83. [Google Scholar] [CrossRef]

- Walling, É.; Gindreau, E.; Lonvaud-Funel, A. La biosynthèse d’exopolysaccharide par des souches de Pediococcus damnosus isolées du vin: Mise au point d’outils moléculaires de détection. Le Lait 2001, 81, 289–300. [Google Scholar] [CrossRef][Green Version]

- Cerning, J. Exocellular polysaccharides produced by lactic acid bacteria. FEMS Microbiol. Rev. 1990, 7, 113–130. [Google Scholar] [CrossRef]

- Latreche, B.; Kharroub, K. Caractérisation des Bactéries Lactiques Isolées du Beurre cru, Evaluation de Leurs Aptitudes Technologiques et Leur Utilisation Dans la Fabrication de la Crème Sure. 2016. Available online: https://theses-algerie.com/2437191150150627/memoire-de-magister/universite-freres-mentouri---constantine-1/caract%C3%A9risation-des-bact%C3%A9ries-lactiques-isol%C3%A9es-du-beurre-cru-%C3%A9valuation-de-leurs-aptitudes-technologiques-et-leur-utilisation-dans-la-fabrication-de-la-cr%C3%A8me-sure (accessed on 24 December 2024).

- Dupont, I.; Roy, D.; Lapointe, G. Comparison of exopolysaccharide production by strains of Lactobacillus rhamnosus and Lactobacillus paracasei grown in chemically defined medium and milk. J. Ind. Microbiol. Biotechnol. 2000, 24, 251–255. [Google Scholar]

- Badis, A.; Laouabdia-Sellami, N.; Guetarni, D.; Kihal, M.; Ouzrout, R. Caractérisation phénotypique des bactéries lactiques isolées à partir de lait cru de chèvre de deux populations caprines locales «Arabia et Kabyle». Sci. Technol. C Biotechnol. 2005, 23, 30–37. [Google Scholar]

- Aslam, S.; Qazi, J.I. Isolation of acidophilic lactic acid bacteria antagonistic to microbial contaminants. Pak. J. Zool. 2010, 42, 567–573. [Google Scholar]

- Liévin-Le Moal, V.; Servin, A.L. The front line of enteric host defense against unwelcome intrusion of harmful microorganisms: Mucins, antimicrobial peptides, and microbiota. Clin. Microbiol. Rev. 2006, 19, 315–337. [Google Scholar] [CrossRef] [PubMed]

- González-Orozco, B.D.; García-Cano, I.; Jiménez-Flores, R.; Alvárez, V.B. Invited review: Milk kefir microbiota—Direct and indirect antimicrobial effects. J. Dairy Sci. 2022, 105, 3703–3715. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).