Novel Morphology for NiWMo Carbides Obtained by Mechanical Alloying and Quenching

Abstract

1. Introduction

2. Materials and Methods

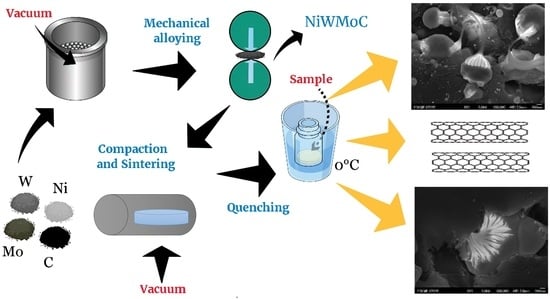

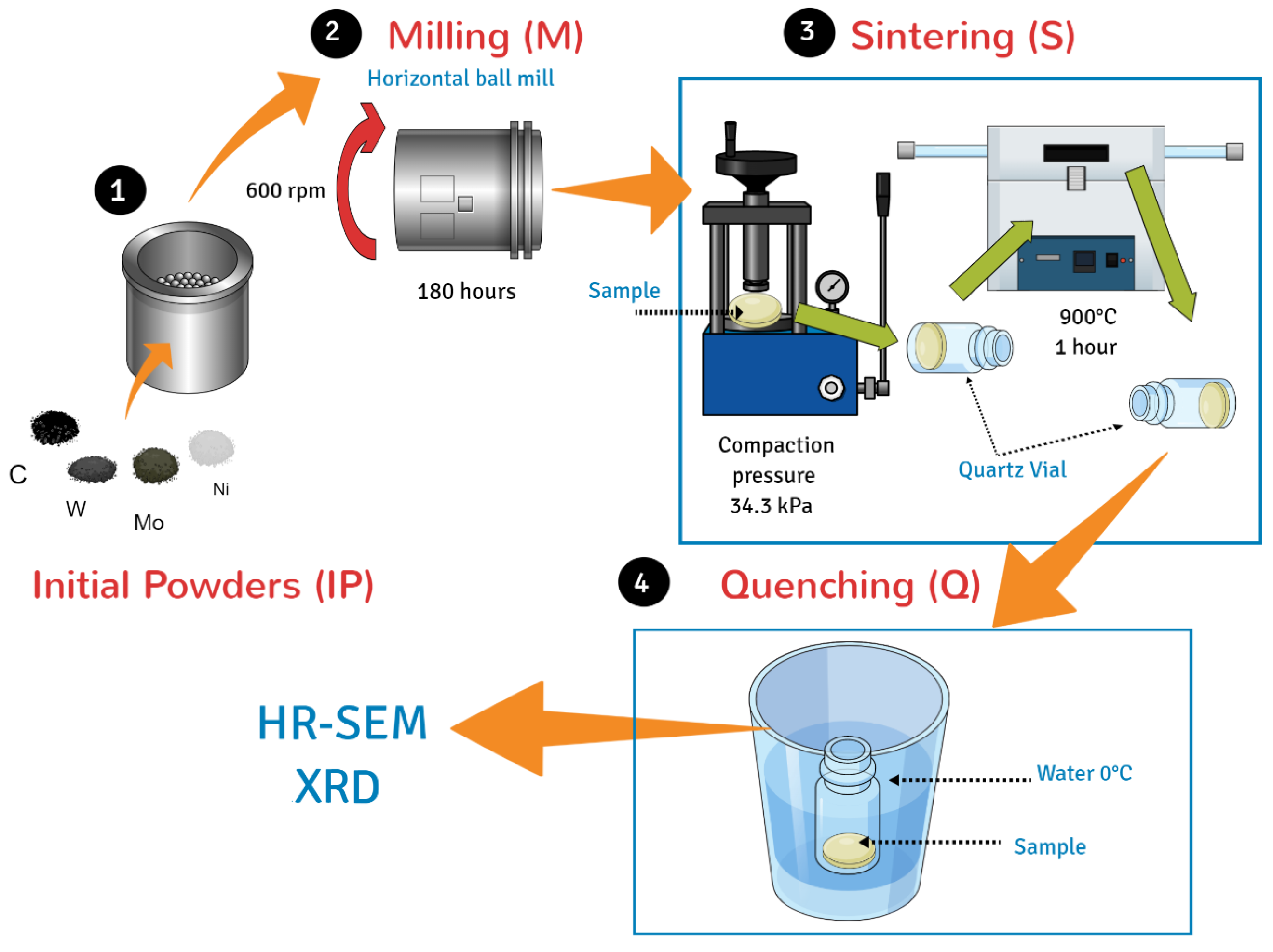

2.1. Synthesis

2.2. Characterization

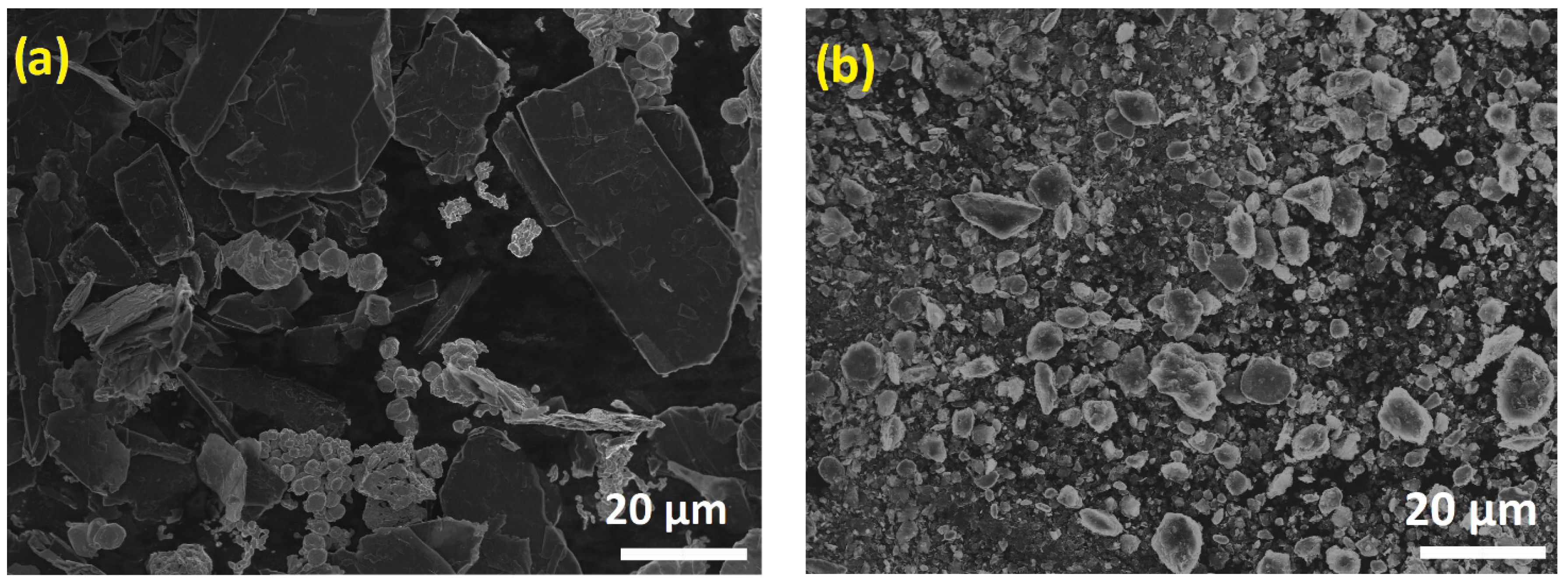

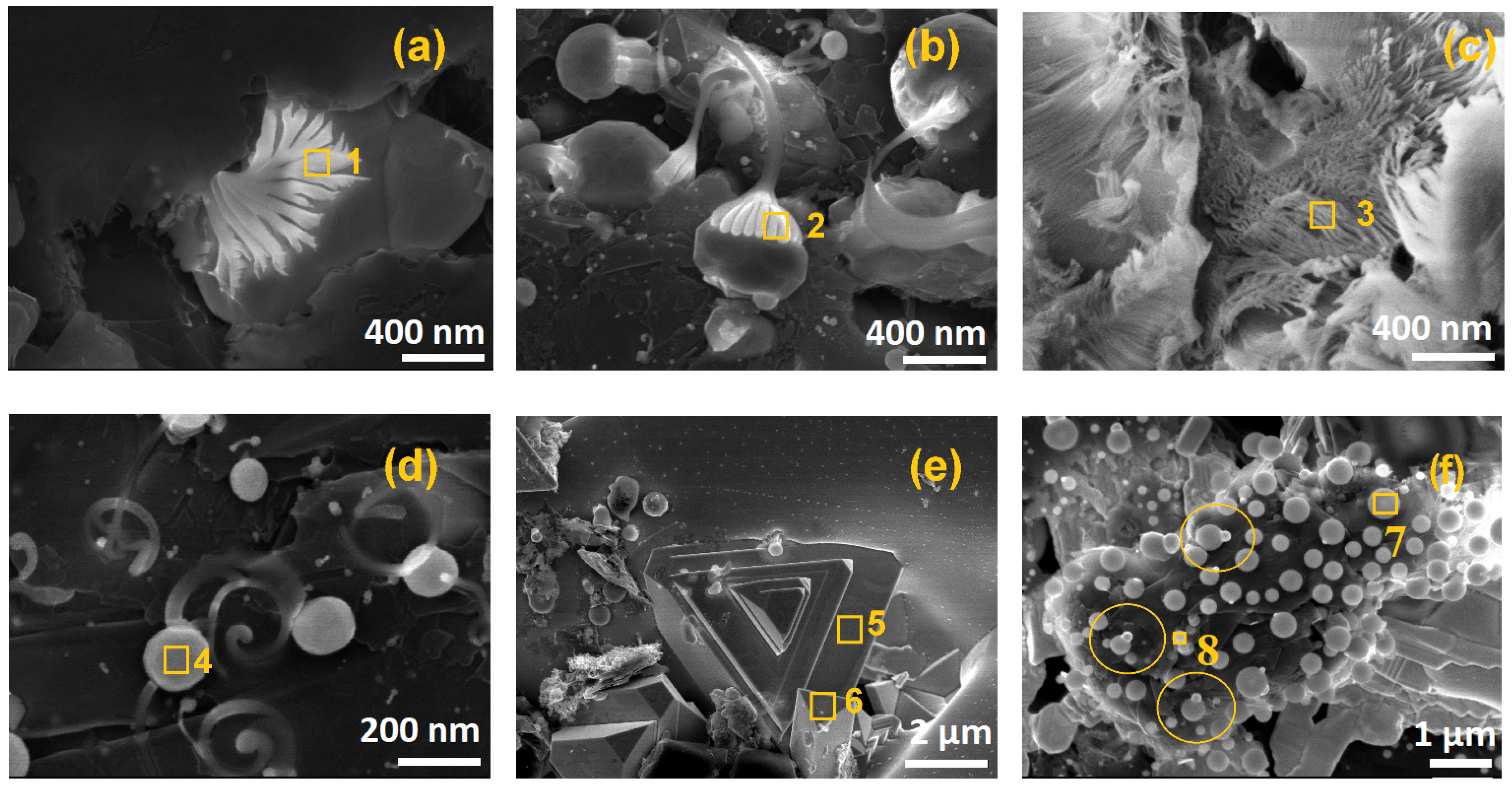

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kostorz, G. Phase Transformations in Materials; Wiley-VCH: Weinheim, Germany, 2001; Chapter 6; ISBN 3527302565. [Google Scholar]

- Vvedensky, D.D. Transformations of Materials; IOP Publishing: Bristol, UK, 2019; ISBN 1643276212. [Google Scholar]

- Jurgen Buschow, K.H.; Cahn, R.W. Encyclopedia of Materials: Science and Technology; Elsevier Publishing: Amsterdam, The Netherlands, 2001; ISBN 978-0-08-043152-9. [Google Scholar]

- Reedijk, J.; Poeppelmeier, K. Comprehensive Inorganic Chemistry II, 2nd ed.; Elsevier Publishing: Amsterdam, The Netherlands, 2013; ISBN 978-0-08-096529-1. [Google Scholar]

- Rudraraju, S.; Van der Ven, A.; Garikipati, K.T. Mechanochemical spinodal decomposition: A phenomenological theory of phase transformations in multi-component crystalline solids. NPJ Comput. Mater. 2016, 2, 16012. [Google Scholar] [CrossRef]

- Sun, L.; Vasina, R.N.; Islamov, A.K.; Bobrikova, I.A.; Sumnikova, S.V.; Balagurov, A.M.; Guo, W.; Cheng, W.C.; Golovin, I.S. Spinodal decomposition in ternary Mn-Cu-Cr alloy and its influence on martensitic transition temperatures. J. Alloys Comp. 2021, 884, 161082. [Google Scholar] [CrossRef]

- Zhou, X.; Kamachali, R.D.; Boyce, B.L.; Clark, B.G.; Raabe, D.; Thompson, G.B. Spinodal Decomposition in Nanocrystalline Alloys. Acta Mater. 2021, 221, 117054. [Google Scholar] [CrossRef]

- Chen, W.; Yu, G.; Li, K.; Wang, Y.; Zhang, J.; Sun, J. Plastic instability in Ti–6Cr–5Mo–5V–4Al metastable β-Ti alloy containing the β-spinodal decomposition structures. Mater. Sci. Eng. A 2021, 811, 141052. [Google Scholar] [CrossRef]

- Velázquez, D.; Chaparro, M.A.E.; Böhnel, H.N.; Romero, R.; Lanzini, F. Spinodal decomposition, chemical and magnetic ordering in Cu–Al–Mn shape memory alloys. Mater. Chem. Phys. 2020, 246, 122793. [Google Scholar] [CrossRef]

- Schultz, A.H.; Stubican, V.S. Modulated structures in the system TiO2-SnO2. Philos. Mag. 1968, 18, 155. [Google Scholar] [CrossRef]

- Xiao, Y.; Hwanga, J.; Sun, Y. Transition metal carbide-based materials: Synthesis and applications in electrochemical energy storage. J. Mater. Chem. 2016, 4, 10379–10393. [Google Scholar] [CrossRef]

- Shahzad, F.; Iqbal, A.; Kim, H.; Koo, C.M. 2D Transition Metal Carbides (MXenes): Applications as an Electrically Conducting Material. Adv. Mater. 2020, 32, 2002159. [Google Scholar] [CrossRef]

- Li, Z.; Wu, Y. 2D Early Transition Metal Carbides (MXenes) for Catalysis. Nano micro-Small. Adv. Mater. 2019, 15, 1804736. [Google Scholar]

- Vasilevich, A.V.; Baklanova, O.N.; Lavrenov, A.V. Molybdenum Carbides: Synthesis and Application in Catalysis. Solid Fuel Chem. 2020, 54, 354–361. [Google Scholar] [CrossRef]

- Plata, F.J.C.; Olvera, J.N.R.; Febles, V.G.; Barriga, L.G.D. Thermodynamic analysis and microstructural evolution of the W-Mo-Ni-C system produced by mechanical alloying. Phys. B Phys. Cond. Matt. 2022, 644, 414126. [Google Scholar] [CrossRef]

- Pierson, H.O. Properties, Characteristics, Processing and Applications (Materials Science and Process Technology; William Andrew Publishing: Norwich, NY, USA, 1996; ISBN 978-0815513926. [Google Scholar]

- Patel, P.; Kim, I.S.; Kumta, P.N. Nanocomposites of silicon/titanium carbide synthesized using high-energy mechanical milling for use as anodes in lithium-ion batteries. Mater. Sci. Eng. B 2005, 116, 347–352. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Progress in Materials Science. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Díaz-Barriga Arceo, L.; Rendón-Vázquez, L.; Orozco, E.; Garibay-Febles, V.; Palacios Gonzalez, E.; Leyte Guerrero, F. Nanotubes Obtained from Mono and Bimetallic Carbides Produced by Mechanical Alloying. Mater. Sci. Forum. 2007, 539–543, 2731–2736. [Google Scholar] [CrossRef]

- Padmanaban, D.B.; Mohan, L.; Giri, P.; Bera, P.; An an, C.; Barshilia, H.C. Effect of Molybdenum Content on Mechanical and Tribological Properties of Diamond-Like Carbon Coatings over Titanium β-21S Alloy. J. Carbon. Res. 2021, 7, 1. [Google Scholar] [CrossRef]

- Czaplicka, N.; Rogala, A.; Wysocka, I. Metal (Mo, W, Ti) Carbide Catalysts: Synthesis and Application as Alternative Catalysts for Dry Reforming of Hydrocarbons—A Review. Int. J. Mol. Sci. 2021, 22, 12337. [Google Scholar] [CrossRef]

- Bao, X.; Wang, T.; Yang, Y. Recent progress in bimetallic carbide-based electrocatalysts for water splitting. Mater. Chem. Front. 2024. [Google Scholar] [CrossRef]

- Balbino, N.A.N.; Correa, E.O.; Huanca, D.R.; Flávio Amaury de Freitas Matos and Livio de Carvalho Valeriano. Comparative Study of Corrosion Behaviors of WC-NiMo and WC-Co Cemented Carbides. Materials 2023, 16, 4480. [Google Scholar] [CrossRef]

- JOlvera, e.N.R.; Gutiérrez, J.; Serrano, J.A.R.; Ovando, M.; Febles, V.G.; Arceo, L.D.B. Use of unsupported, mechanically alloyed NiWMoC nanocatalyst to reduce the viscosity of aquathermolysis reaction of heavy oil. Catal. Commun. 2014, 43, 131–135. [Google Scholar] [CrossRef]

- Cullity, B.D.; Stock, S.R. Elements of X-ray Diffraction; Prentice Hall: Englewood Cliffs, NJ, USA, 2001; ISBN 0201610914. [Google Scholar]

- Martinez Ruiz, M.; Rivera Olvera, J.N.; Morales Davila, R.; González Reyes, L.; Garibay Febles, V.; Garcia Martinez, J.; Diaz Barriga Arceo, L.G. Synthesis and Characterization of Mechanically Alloyed, Nanostructured Cubic MoW Carbide. Appl. Sci. 2020, 10, 9114. [Google Scholar] [CrossRef]

- Olvera, J.N.R.; Paredes, G.G.; Serrano, A.R.; López, E.R.; Franco, E.M.; Meza, P.T.; Arceo, L.D.B. Synthesis and characterization of a MoWC-WC-NiC nanocomposite via mechanical alloying and sintering. Powder Technol. 2015, 271, 292–300. [Google Scholar] [CrossRef]

- Akbarpour, M.R. Effects of mechanical milling time on densification, microstructural characteristics and hardness of Cu–SiC nanocomposites prepared by conventional sintering process. Mater. Chem. Phys. 2021, 261, 124205. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E.; Sherif, M.Y. Phase Transformations in Metals and Alloys; CRC Press: Boca Raton, FL, USA; Taylor and Francis Group LLC: New York, NY, USA, 2009; Chapter 5; pp. 302–309. ISBN 9781420062106. [Google Scholar]

- Carter, C.B. Solid-State Phase Transformations and Reactions. In Ceramic Materials; Springer: New York, NY, USA, 2007; ISBN 978-0-387-46271-4_25. [Google Scholar]

- Illescas, C.R.E. Analysis of Phase Separation in Aged Alloys by the Phase Field Method. Master’s Thesis, National Polytechnic Institute of Mexico, Mexico City, Mexico, 2018; p. 112, Figure C. Available online: https://tesis.ipn.mx/handle/123456789/25979 (accessed on 3 January 2024).

- C-Ni Phase Diagram. Available online: https://www.crct.polymtl.ca/fact/phase_diagram.php?file=C-Ni.jpg&dir=SGTE2014 (accessed on 3 January 2024).

- Corletto, A.; Shapter, J.G. Nanoscale Patterning of Carbon Nanotubes: Techniques, Applications, and Future. Adv. Sci. 2021, 8, 2001778. [Google Scholar] [CrossRef] [PubMed]

- Egerton, R.F. Physical Principles of Electron Microscopy: An Introduction to TEM, SEM, and AEM; Springer Publishing: Berlin/Heidelberg, Germany, 2016; ISBN 978-3319398761. [Google Scholar]

- Zhang, L.; Peng, Y.; Zhang, L.; Lei, X.; Yao, W.; Wang, N. Temperature and initial composition dependence of pattern formation and dynamic behavior in phase separation under deep-quenched conditions. RSC Adv. 2019, 9, 10670–10678. [Google Scholar] [CrossRef]

- Mo-Ni Phase Diagram. Available online: http://www.factsage.cn/fact/phase_diagram.php?file=Mo-Ni.jpg&dir=SGTE (accessed on 3 January 2024).

- Mitcheson, P.D.; Miao, P.; Stark, B.H.; Yeatman, E.M.; Holmes, A.S.; Green, T.C. MEMS electrostatic micropower generator for low frequency operation Green. Sens. Actuators A 2004, 115, 523–529. [Google Scholar] [CrossRef]

| Phases (M—Milled and Q—Quenched) | Crystalline Structure | Lattice Parameter (nm) | Phase Percentage % | ICDD Card * |

|---|---|---|---|---|

| Cubic | a = 0.3148 | 70.28 | Ref. [26] | |

| Hexagonal | a = 0.2464, c = 0.6736 | 20.26 | 120212 | |

| Cubic | a = 0.3523 | 8.96 | 040850 | |

| Cubic | a = 0.3539 | 0.50 | 140020 | |

| Hexagonal | a = 0.2900, c = 0.2831 | 23.44 | 654539 | |

| - | - | 16.04 | Unknown | |

| Orthorhombic | a = 0.5064, b = 0.4224, c = 0.4448 | 12.44 | 652587 | |

| Orthorhombic | a = 0.9128, b = 0.9134, c = 0.8835 | 1.16 | 481745 | |

| Cubic | a = 0.3523 | 0.32 | 040850 | |

| Hexagonal | a = 0.3012, c = 0.4735 | 8.00 | 350787 | |

| Tetragonal | a = 0.5730, c = 0.3553 | 7.46 | 652673 | |

| Hexagonal | a = 0.2464, c = 0.6736 | 31.14 | 120212 |

| SEM–EDS * (Figure 4) | C (at.%) | Mo (at.%) | Ni( at.%) | W (at.%) | O (at.%) | Fe (at.%) |

|---|---|---|---|---|---|---|

| Spot 1 | 2.67 ± 0.04 | 22.98 ± 0.41 | 73.34 ± 0.84 | 0.98 ± 0.09 | 0.23 ± 0.01 | - |

| Spot 2 | 12.18 ± 0.13 | 66.48± 0.54 | 15.99± 1.02 | 5.22 ± 0.01 | 0.13 ± 0.04 | - |

| Spot 3 | 97.42 ± 0.75 | 0.95 ± 0.01 | 0.32 ± 0.02 | 0.44 ± 0.01 | 0.87 ± 0.03 | - |

| Spot 4 | 1.26 ± 0.03 | 65.78 ± 1.64 | 14.05 ± 0.67 | 18.91 ± 0.86 | - | - |

| Spot 5 | 93.80 ± 2.01 | - | 0.99 ± 0.01 | 4.35 ± 0.22 | 0.35 ± 0.02 | 0.51 ± 0.04 |

| Spot 6 | 78.15 ± 1.78 | 4.10 ± 0.52 | - | 17.58 ± 0.75 | 0.17 ± 0.02 | - |

| Spot 7 | 72.56 ± 1.57 | 0.18 ± 0.03 | - | 27.26 ± 0.75 | - | - |

| Spot 8 | 1.04 ± 0.01 | 34.3 ± 0.43 | 64.52 ± 0.74 | - | - | 0.14 ± 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rivera Olvera, J.N.; Hernández Maya, L.; Diaz Barriga Arceo, L.G. Novel Morphology for NiWMo Carbides Obtained by Mechanical Alloying and Quenching. C 2024, 10, 11. https://doi.org/10.3390/c10010011

Rivera Olvera JN, Hernández Maya L, Diaz Barriga Arceo LG. Novel Morphology for NiWMo Carbides Obtained by Mechanical Alloying and Quenching. C. 2024; 10(1):11. https://doi.org/10.3390/c10010011

Chicago/Turabian StyleRivera Olvera, Jesús Noé, Luis Hernández Maya, and Lucia Graciela Diaz Barriga Arceo. 2024. "Novel Morphology for NiWMo Carbides Obtained by Mechanical Alloying and Quenching" C 10, no. 1: 11. https://doi.org/10.3390/c10010011

APA StyleRivera Olvera, J. N., Hernández Maya, L., & Diaz Barriga Arceo, L. G. (2024). Novel Morphology for NiWMo Carbides Obtained by Mechanical Alloying and Quenching. C, 10(1), 11. https://doi.org/10.3390/c10010011