A Comparison of Ansys Fluent and MFiX in Performing CFD-DEM Simulations of a Spouted Bed

Abstract

:1. Introduction

2. Materials and Methods

2.1. Governing Equations

2.1.1. Pressure Gradient Force

2.1.2. Drag Force

2.1.3. Magnus Lift Force

2.1.4. Contact Forces

2.2. Simulation Procedure

2.2.1. Simulated Geometry and Data

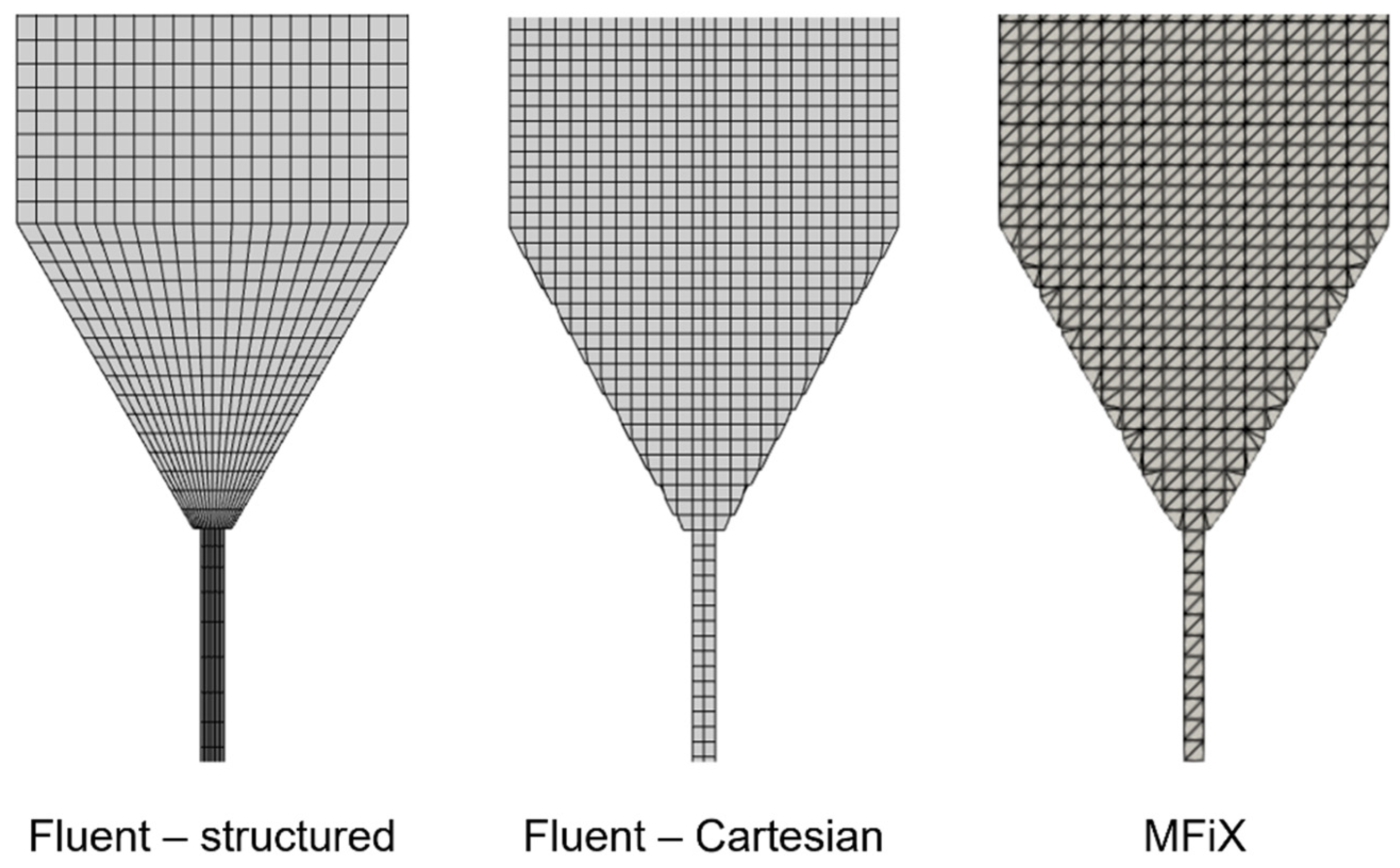

2.2.2. Mesh

2.2.3. Simulation Setup

2.2.4. Particle Data Averaging

2.2.5. Result Extraction and Post Processing

3. Results and Discussion

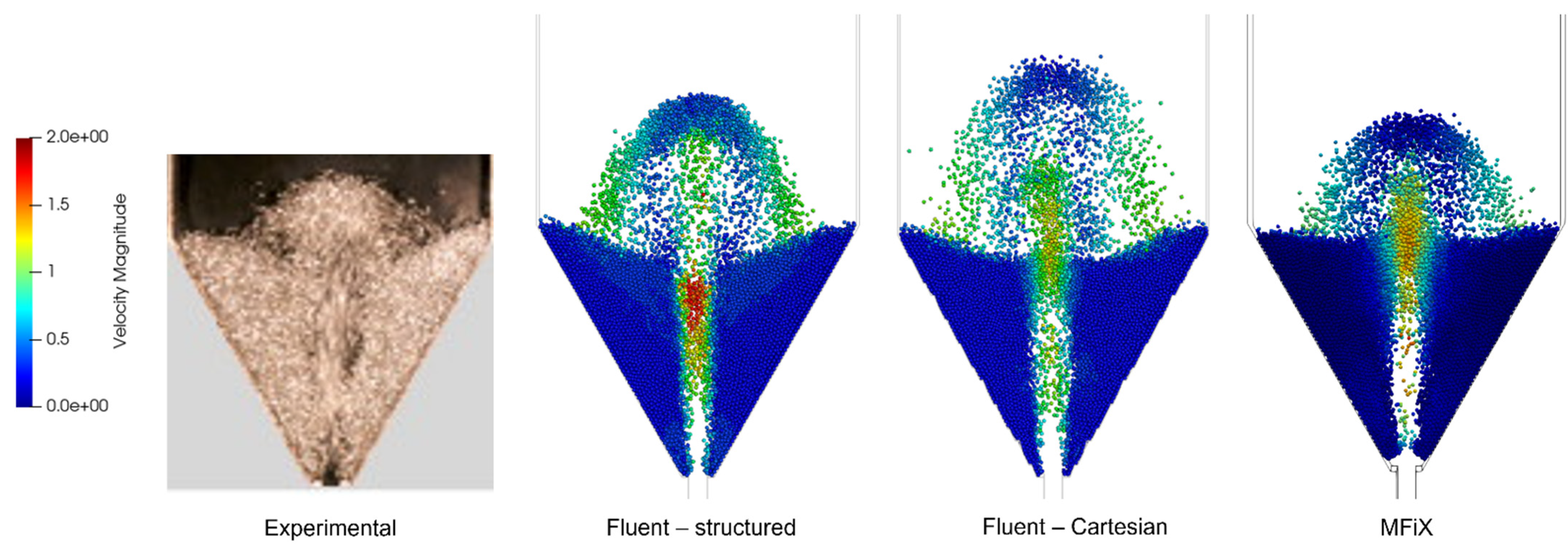

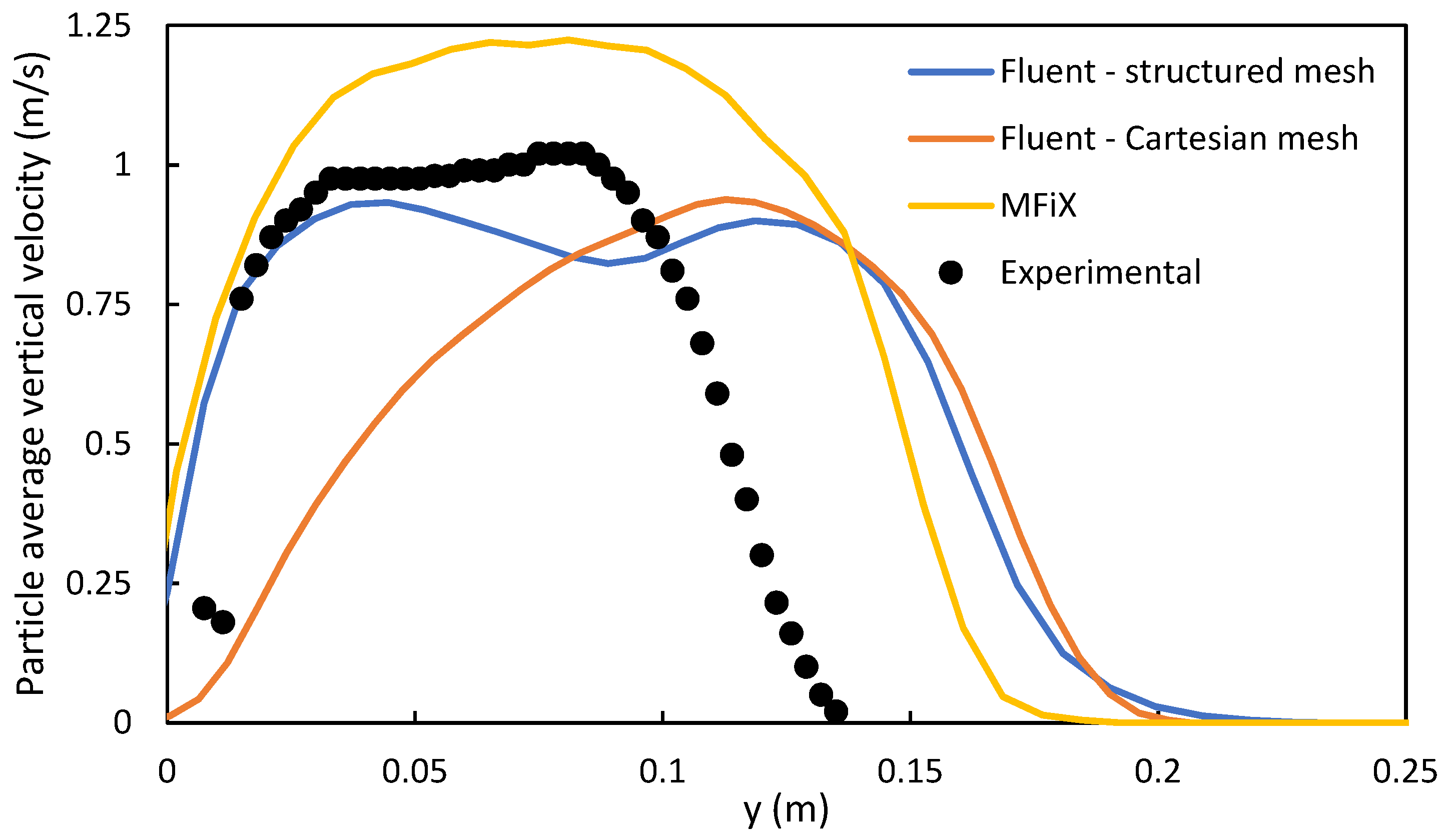

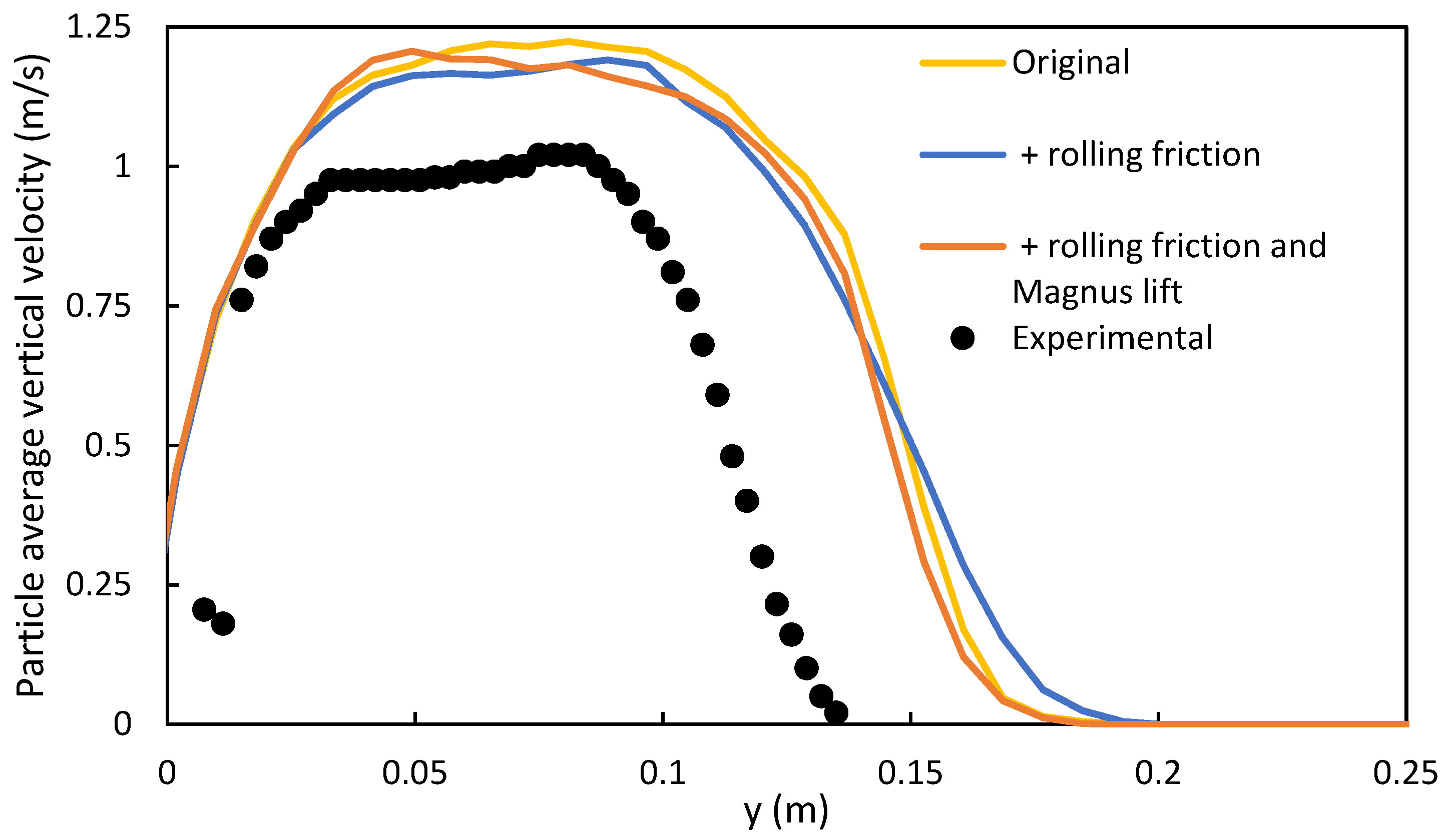

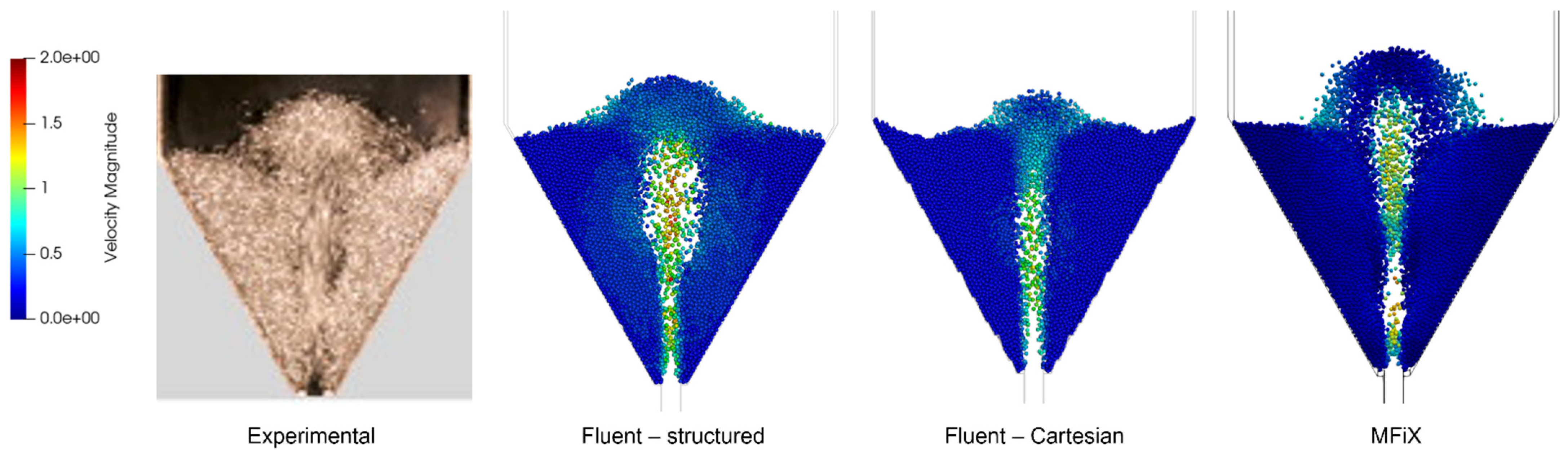

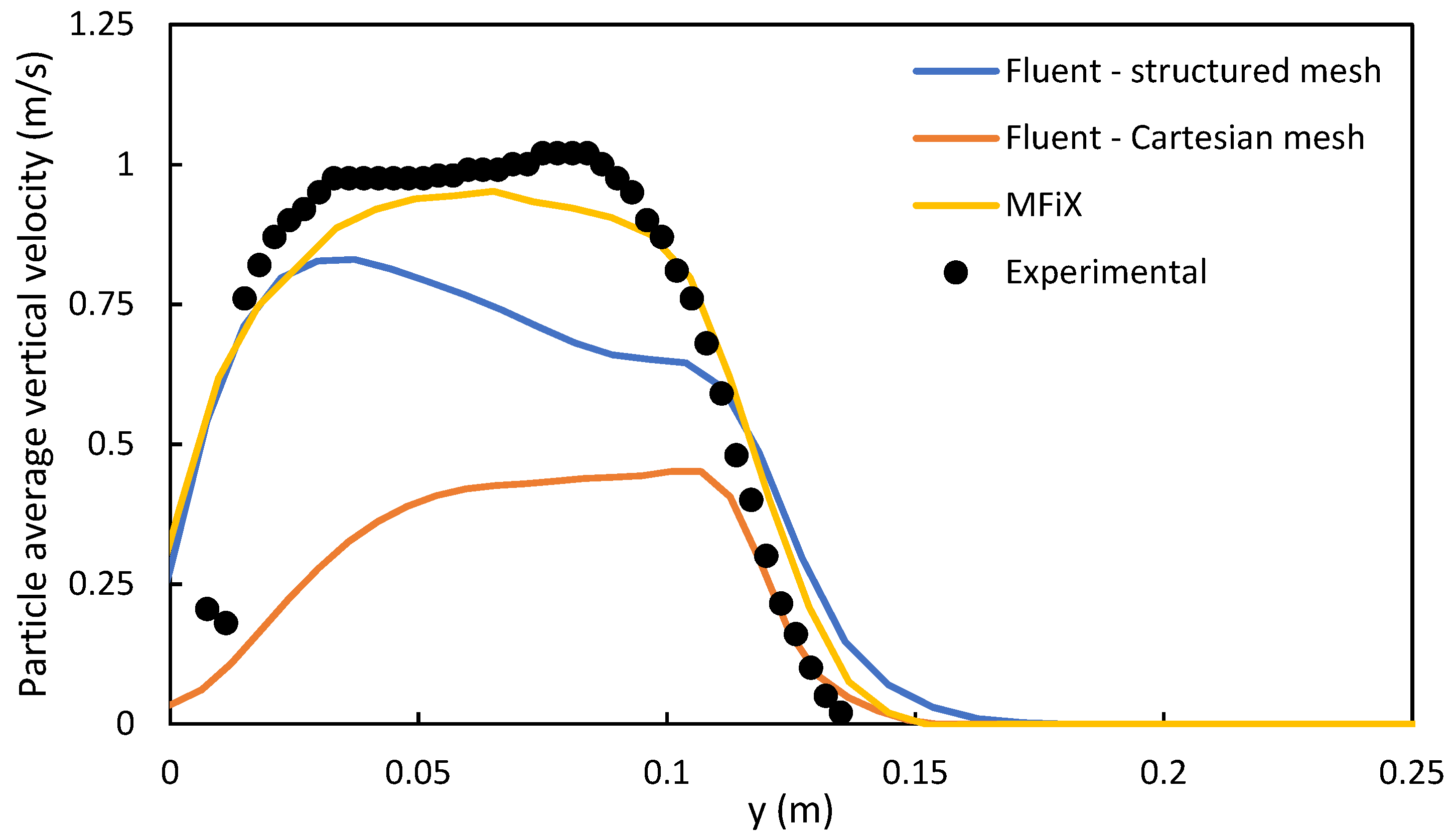

3.1. Comparison of Results

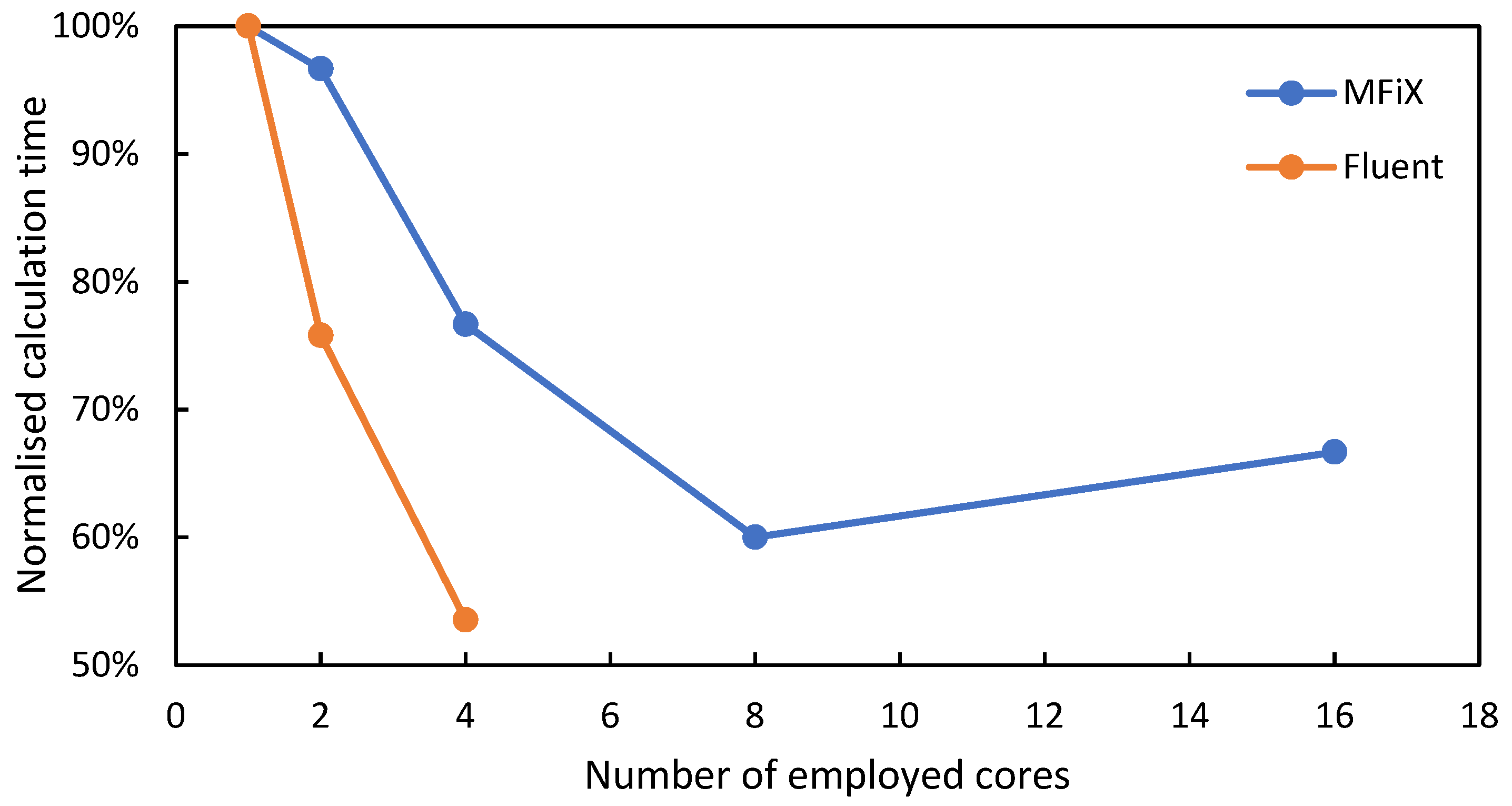

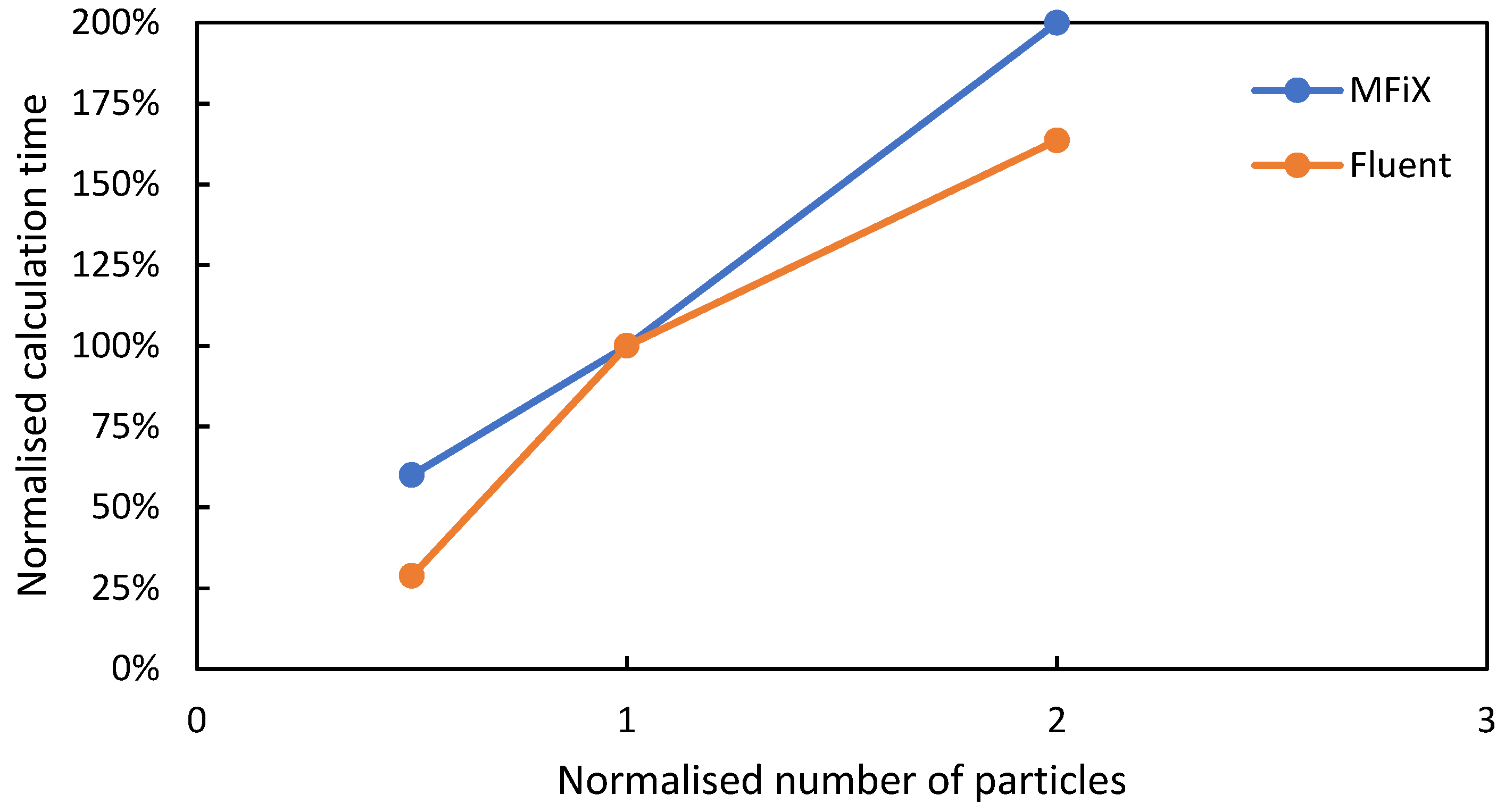

3.2. Comparison of Calculation Time

3.3. Summary of Advantages and Disadvantages

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kennedy, D. What Don’t We Know? Science 2005, 309, 75. [Google Scholar] [CrossRef] [Green Version]

- Van der Hoef, M.A.; Ye, M.; van Sint Annaland, M.; Andrews, A.T.; Sundaresan, S.; Kuipers, J.A.M. Multiscale Modeling of Gas-Fluidized Beds; Elsevier: Amsterdam, The Netherlands, 2006; Volume 31, ISBN 0120085313. [Google Scholar]

- Ngo, S.I.; Lim, Y.-I. Multiscale Eulerian CFD of Chemical Processes: A Review. ChemEngineering 2020, 4, 23. [Google Scholar] [CrossRef] [Green Version]

- Kieckhefen, P.; Pietsch, S.; Dosta, M.; Heinrich, S. Possibilities and Limits of Computational Fluid Dynamics–Discrete Element Method Simulations in Process Engineering: A Review of Recent Advancements and Future Trends. Annu. Rev. Chem. Biomol. Eng. 2020, 11, 397–422. [Google Scholar] [CrossRef] [Green Version]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Tsuji, Y.; Tanaka, T.; Ishida, T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 1992, 71, 239–250. [Google Scholar] [CrossRef]

- Moliner, C.; Marchelli, F.; Spanachi, N.; Martinez-Felipe, A.; Bosio, B.; Arato, E. CFD simulation of a spouted bed: Comparison between the Discrete Element Method (DEM) and the Two Fluid Model (TFM). Chem. Eng. J. 2019, 377, 120466. [Google Scholar] [CrossRef] [Green Version]

- Ostermeier, P.; DeYoung, S.; Vandersickel, A.; Gleis, S.; Spliethoff, H. Comprehensive investigation and comparison of TFM, DenseDPM and CFD-DEM for dense fluidized beds. Chem. Eng. Sci. 2019, 196, 291–309. [Google Scholar] [CrossRef]

- Lungu, M.; Siame, J.; Mukosha, L. Comparison of CFD-DEM and TFM approaches for the simulation of the small scale challenge problem 1. Powder Technol. 2021, 378, 85–103. [Google Scholar] [CrossRef]

- Liu, D.; Bu, C.; Chen, X. Development and test of CFD–DEM model for complex geometry: A coupling algorithm for Fluent and DEM. Comput. Chem. Eng. 2013, 58, 260–268. [Google Scholar] [CrossRef]

- Marchelli, F.; Hou, Q.; Bosio, B.; Arato, E.; Yu, A. Comparison of different drag models in CFD-DEM simulations of spouted beds. Powder Technol. 2020, 360, 1253–1270. [Google Scholar] [CrossRef]

- Li, J.; Campbell, G.M.; Mujumdar, A.S. Discrete Modeling and Suggested Measurement of Heat Transfer in Gas–Solids Flows. Dry. Technol. 2003, 21, 979–994. [Google Scholar] [CrossRef]

- Albano, A.; le Guillou, E.; Danzé, A.; Moulitsas, I.; Sahputra, I.H.; Rahmat, A.; Duque-Daza, C.A.; Shang, X.; Ching Ng, K.; Ariane, M.; et al. How to Modify LAMMPS: From the Prospective of a Particle Method Researcher. ChemEngineering 2021, 5, 30. [Google Scholar] [CrossRef]

- Zhao, X.-L.L.; Li, S.-Q.Q.; Liu, G.-Q.Q.; Yao, Q.; Marshall, J.-S.S. DEM simulation of the particle dynamics in two-dimensional spouted beds. Powder Technol. 2008, 184, 205–213. [Google Scholar] [CrossRef]

- Geldart, D. Types of gas fluidization. Powder Technol. 1973, 7, 285–292. [Google Scholar] [CrossRef]

- Moliner, C.; Marchelli, F.; Bosio, B.; Arato, E. Modelling of spouted and spout-fluid beds: Key for their successful scale up. Energies 2017, 10, 1729. [Google Scholar] [CrossRef] [Green Version]

- Herzog, N.; Schreiber, M.; Egbers, C.; Krautz, H.J. A comparative study of different CFD-codes for numerical simulation of gas–solid fluidized bed hydrodynamics. Comput. Chem. Eng. 2012, 39, 41–46. [Google Scholar] [CrossRef]

- Venier, C.M.; Urrutia, A.R.; Capossio, J.P.; Baeyens, J.; Mazza, G. Comparing ANSYS Fluent ® and OpenFOAM ® simulations of Geldart A, B and D bubbling fluidized bed hydrodynamics. Int. J. Numer. Methods Heat Fluid Flow 2019, 30, 93–118. [Google Scholar] [CrossRef]

- Marchelli, F.; Moliner, C.; Curti, M.; Bosio, B.; Arato, E. CFD-DEM simulations of a continuous square-based spouted bed and evaluation of the solids residence time distribution. Powder Technol. 2020, 366, 840–858. [Google Scholar] [CrossRef]

- Garg, R.; Galvin, J.; Li, T.; Pannala, S. Open-source MFIX-DEM software for gas-solids flows: Part I-Verification studies. Powder Technol. 2012, 220, 122–137. [Google Scholar] [CrossRef]

- ANSYS ANSYS Fluent User Guide; ANSYS: Canonsburg, PA, USA, 2019.

- ANSYS ANSYS Fluent Theory Guide; ANSYS: Canonsburg, PA, USA, 2019.

- Syamlal, M.; Rogers, W.; O‘Brien, T.J. MFIX Documentation Theory Guide; Department of Energy: Oak Ridge, TN, USA, 1993; Volume 1004.

- Chu, K.W.; Kuang, S.B.; Zhou, Z.Y.; Yu, A.B. Model A vs. Model B in the modelling of particle-fluid flow. Powder Technol. 2018, 329, 47–54. [Google Scholar] [CrossRef]

- Marchelli, F.; Di Felice, R. A Discrete Element Method Study of Solids Stress in Cylindrical Columns Using MFiX. Processes 2020, 9, 60. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Weaver, D.S.; Mišković, S. A Study of RANS Turbulence Models in Fully Turbulent Jets: A Perspective for CFD-DEM Simulations. Fluids 2021, 6, 271. [Google Scholar] [CrossRef]

- Gidaspow, D. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Descriptions; Academic Press: Cambridge, MA, USA, 1994. [Google Scholar]

- Di Felice, R. The voidage function for fluid-particle interaction systems. Int. J. Multiph. Flow 1994, 20, 153–159. [Google Scholar] [CrossRef]

- Ergun, S. Fluid flow through packed columns. Chem. Eng. Prog. 1952, 48, 89–94. [Google Scholar]

- Wen, C.Y.; Yu, Y.H. Mechanics of Fluidization. Chem. Eng. Prog. Symp. Ser. 1966, 162, 100–111. [Google Scholar]

- Rong, L.W.; Dong, K.J.; Yu, A.B. Lattice-Boltzmann simulation of fluid flow through packed beds of uniform spheres: Effect of porosity. Chem. Eng. Sci. 2013, 99, 44–58. [Google Scholar] [CrossRef]

- Marchelli, F.; Moliner, C.; Bosio, B.; Arato, E. A CFD-DEM sensitivity analysis: The case of a pseudo-2D spouted bed. Powder Technol. 2019, 353, 409–425. [Google Scholar] [CrossRef]

- Liu, R.-J.; Xiao, R.; Ye, M.; Liu, Z. Analysis of particle rotation in fluidized bed by use of discrete particle model. Adv. Powder Technol. 2018, 29, 1655–1663. [Google Scholar] [CrossRef]

- Rubinow, S.I.; Keller, J.B. The transverse force on a spinning sphere moving in a viscous fluid. J. Fluid Mech. 1961, 11, 447. [Google Scholar] [CrossRef]

- Marchelli, F.; Di Felice, R. On the influence of contact models on friction forces in discrete element method simulations. Chem. Eng. Trans. 2021, 86, 811–816. [Google Scholar]

- Ai, J.; Chen, J.F.; Rotter, J.M.; Ooi, J.Y. Assessment of rolling resistance models in discrete element simulations. Powder Technol. 2011, 206, 269–282. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Wright, B.D.; Yang, R.Y.; Xu, B.H.; Yu, A.B. Rolling friction in the dynamic simulation of sandpile formation. Phys. A Stat. Mech. Its Appl. 1999, 269, 536–553. [Google Scholar] [CrossRef]

- Boyce, C.M.; Holland, D.J.; Scott, S.A.; Dennis, J.S. Limitations on Fluid Grid Sizing for Using Volume-Averaged Fluid Equations in Discrete Element Models of Fluidized Beds. Ind. Eng. Chem. Res. 2015, 54, 10684–10697. [Google Scholar] [CrossRef]

- Hamidouche, Z.; Dufresne, Y.; Pierson, J.-L.; Brahem, R.; Lartigue, G.; Moureau, V. DEM/CFD Simulations of a Pseudo-2D Fluidized Bed: Comparison with Experiments. Fluids 2019, 4, 51. [Google Scholar] [CrossRef] [Green Version]

- Berger, M. Cut Cells: Meshes and Solvers. In Handbook of Numerical Analysis; Elsevier: Amsterdam, The Netherlands, 2017; Volume 18, pp. 1–22. [Google Scholar]

- Chu, K.W.; Chen, J.; Wang, B.; Yu, A.B.; Vince, A.; Barnett, G.D.; Barnett, P.J. Understand solids loading effects in a dense medium cyclone: Effect of particle size by a CFD-DEM method. Powder Technol. 2017, 320, 594–609. [Google Scholar] [CrossRef]

- Di Renzo, A.; Napolitano, E.; Di Maio, F. Coarse-Grain DEM Modelling in Fluidized Bed Simulation: A Review. Processes 2021, 9, 279. [Google Scholar] [CrossRef]

- Gopalakrishnan, P.; Tafti, D. Development of parallel DEM for the open source code MFIX. Powder Technol. 2013, 235, 33–41. [Google Scholar] [CrossRef]

- Liu, H.; Tafti, D.K.; Li, T. Hybrid parallelism in MFIX CFD-DEM using OpenMP. Powder Technol. 2014, 259, 22–29. [Google Scholar] [CrossRef]

| Variable | Value |

|---|---|

| Inlet width | 0.9 cm |

| Bottom width | 1.5 cm |

| Column width | 15.2 cm |

| Column depth | 1.5 cm |

| Base angle | 60° |

| Height of the inclined part | 11.9 cm |

| Total height | 60 cm |

| Variable | Value |

|---|---|

| Spring constant | 1000 N/m |

| Restitution coefficient | 0.9 |

| Friction coefficient | 0.3 |

| Rolling friction coefficient | 0.03 |

| Air density | 1.225 kg/m3 |

| Air dynamic viscosity | 1.7894·10−5 Pa·s |

| Particle density | 2380 kg/m3 |

| Particle diameter | 2.033 mm |

| Total number of particles | 15,990 |

| Ansys Fluent | MFiX | |

|---|---|---|

| Cost | Commercial program, a free student licence with limitations is available. | Open-source program, entirely free. |

| GUI | Both programs are equipped with a user-friendly GUI. | |

| Geometry and mesh | Ansys programs provide numerous options to generate geometry and mesh. | The geometry can be created in MFiX or imported, but only Cartesian cut-cell meshes can be employed. This may be a limiting factor for some geometries. |

| CFD-DEM methodology | Available for spherical particles, including coarse-graining. It is also possible to include lift forces, rolling friction torque and other forces. | Available for spherical particles, including coarse-graining. Lift forces and rolling friction torque are not included in the standard version of the code. |

| Code visibility | The code is not accessible by the user. | The code is completely transparent to the user. |

| Personalisation | User-defined functions (written in C) allow some level of personalisation, but some variables (such as contact forces) cannot be modified. | The code (written in Fortran) is entirely editable by the user. |

| Results visualisation and analysis | Numerous and flexible options are available. However, some variables (such as the drag force) cannot be accessed. | The standard options are more limited, but anything can be accessed by editing the code. Paraview is often needed to analyse and visualise the results. |

| CPU cost | For the present application, it is about 17.5 times larger than with MFiX. However, it seems to be less sensitive to increases in the number of particles. | For the present application, it is about 17.5 times smaller than with Fluent. However, it seems to be more sensitive to increases of the number of particles. |

| Parallelisation | With the same number of cores, the relative speed-up is larger than with MFiX. The student licence does not allow more than 4 cores. | With the same number of cores, the relative speed-up is smaller than with Fluent. |

| Available material | The user and theory guide are very detailed, and the interface is clear, but the material related to the CFD-DEM methodology is scarce. | Several tutorials on the CFD-DEM methodology are available, but learning how to modify the code can require some effort. |

| Other applications | The program has many options and can be employed for a variety of applications in different fields. | The program is specifically aimed at situations involving granular materials. It allows employing other related methodologies (TFM, MP-PIC, DEM). |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marchelli, F.; Di Felice, R. A Comparison of Ansys Fluent and MFiX in Performing CFD-DEM Simulations of a Spouted Bed. Fluids 2021, 6, 382. https://doi.org/10.3390/fluids6110382

Marchelli F, Di Felice R. A Comparison of Ansys Fluent and MFiX in Performing CFD-DEM Simulations of a Spouted Bed. Fluids. 2021; 6(11):382. https://doi.org/10.3390/fluids6110382

Chicago/Turabian StyleMarchelli, Filippo, and Renzo Di Felice. 2021. "A Comparison of Ansys Fluent and MFiX in Performing CFD-DEM Simulations of a Spouted Bed" Fluids 6, no. 11: 382. https://doi.org/10.3390/fluids6110382

APA StyleMarchelli, F., & Di Felice, R. (2021). A Comparison of Ansys Fluent and MFiX in Performing CFD-DEM Simulations of a Spouted Bed. Fluids, 6(11), 382. https://doi.org/10.3390/fluids6110382