Abstract

This study addresses the need for sustainable and energy-efficient agricultural practices by integrating turbine systems into greenhouse irrigation setups that utilize water from storage basins or ponds. The purpose is to harness excess pressure to generate electricity, enhancing overall system efficiency. This study involves designing a scalable turbine system that adapts to different greenhouse sizes and water pressure conditions. Key methods include a novel 3D design and implementation of a turbine outlet, using CAD modeling and high-precision 3D printing, and the experimental characterization of the system’s power–pressure relationship and pressure losses. Results demonstrate that a single Banki-type turbine generates nearly 12 W at a maximum pressure of 1.4 bar, 0.98 m3/h of flow, pressure 92% loss performance, and 32% efficiency. Scalability tests in the study case reveal that up to eight turbines can be installed in series without dropping below the critical pressure threshold, that is, above 0.6–0.7 bar, the minimum pressure expected for adequate irrigation, and the turbines collectively produce around 60 W, considering the pressure losses with respect to production. These findings confirm the system’s potential to enhance sustainability and energy efficiency in greenhouse operations. This study lays a foundation for future research to optimize 3D-printed components, integrate renewable energy sources, and conduct long-term performance studies, aiming to further improve the system’s applicability and performance in agricultural settings.

1. Introduction

The increasing demand for energy-efficient and sustainable agricultural practices has led to the exploration of innovative solutions in the management of greenhouse environments [1]. One such promising approach is the integration of turbine systems into irrigation setups within greenhouses, where the water source is derived from storage basins or ponds. This method capitalizes on the existing infrastructure to not only meet the irrigation requirements but also to generate electricity, thus enhancing the overall efficiency and sustainability of agricultural operations [2]. This method is of special interest in regions like Almería (Spain).

The agricultural model of Almería, a region in southeastern Spain, stands out for being a highly efficient model of intensive agriculture in terms of water and nutrient use as well as energy consumption [3]. Additionally, it is characterized by innovation, competitiveness, and the ability to adapt to demand [4]. Currently, the total area of greenhouse structures amounts to 32,827 hectares, with greenhouse production reaching 3,561,056 tons in Almería [5]. Energy consumption is very low, coming almost exclusively from the localized irrigation systems used and the energy demand of passive climate control systems, representing just over 1.50% of the total production cost [6].

Greenhouse crops are characterized by their drip irrigation systems, which provide slow and frequent application of water to the crops through emitters. These emitters are drainage devices present in the pressurized pipe network distributed over the crop surface. Drip irrigation systems offer several advantages, such as watering only the surface closest to the plant, thereby avoiding water loss, reducing weed growth, and not interfering with other cultivation tasks that can be carried out simultaneously [7]. The drip irrigation system comprises the system head, primarily the pumping equipment, which provides the necessary energy for the pressurized operation of the system. Typically, irrigation systems operate at a pressure between 100 and 200 kPa [8]. The irrigation distribution network within the greenhouse is usually divided into sectors ranging from 2000 to 10,000 m2. These sectors are divided into several manifold pipes, which in turn are divided into sets of lateral pipes that carry the emitters [9].

Traditionally, greenhouse irrigation systems rely on pumps to deliver water at the necessary pressure. These systems often incorporate pressure-reducing valves to lower the pressure to levels suitable for irrigation [10]. However, this approach results in the dissipation of energy that could otherwise be harnessed. In response to this inefficiency, this study proposes the use of turbines in series within the irrigation system [11]. This setup not only fulfills the irrigation needs but also converts the excess pressure into electric energy, providing a dual benefit [12,13]. Pressure-reducing valves have the advantage of being able to adjust the pressure to a certain value with a certain degree of precision, as is their purpose. However, the turbines are not initially designed for this purpose; therefore, the adjustment of said pressure reduction requires a more detailed analysis of how the turbines, and their implementation in series, affect the water pressure.

The concept of using water turbines in irrigation systems, considering their application within greenhouses, presents unique challenges and opportunities. The primary challenge lies in designing a system that can efficiently convert the varying pressure levels from storage basins into usable energy without compromising the irrigation process. To address this, this study focuses on developing a scalable turbine system that can adapt to different greenhouse sizes and water pressure conditions.

This research involves an analysis of the power–pressure relationship, pressure losses, and the overall energy generation potential of the proposed turbine system [14]. The scalability of the system is a critical aspect, as greenhouses vary significantly in size and water requirements. By characterizing the system’s performance under different conditions, the aim is to provide a comprehensive understanding of its feasibility and benefits.

The significance of this research is underscored by the increasing emphasis on sustainable agricultural practices. Greenhouses are integral to modern agriculture, providing controlled environments for crop production. However, they are also energy-intensive, particularly in regions where climate conditions necessitate extensive use of irrigation and climate control systems [15]. Integrating energy generation within the irrigation system not only reduces the operational costs [16,17] but also aligns with global efforts to enhance energy efficiency and sustainability in agriculture.

This study presents a detailed design of a turbine system integrated into a greenhouse irrigation setup. The system’s performance is evaluated through both theoretical analysis and practical experiments. The relationship between power generation and pressure levels is analyzed, taking into account the pressure losses incurred [18] due to the turbine integration, and calculating the potential energy generation for a specific case study. The findings provide valuable insights into the system’s viability and offer guidelines for its implementation in various greenhouse settings.

Previous studies have explored various methods to enhance the energy efficiency of irrigation systems. For instance, hydropower generation from irrigation channels has been investigated, demonstrating the potential for energy recovery in agricultural settings [19,20]. Additionally, the use of micro-hydro turbines in small-scale irrigation systems has shown promise in rural and off-grid applications [21]. Another innovative approach involves the application of fuzzy logic to determine the feasibility of turbine placement. This method employs a decision-making program that evaluates multiple criteria to optimize the integration of turbines within irrigation systems [22,23,24,25,26]. Moreover, research has been conducted on the specific deployment of micro-turbines in irrigation systems, highlighting their adaptability and efficiency in various agricultural environments [27,28,29]. Studies also delve into the placement of turbines in irrigation channels, examining the technical specifications and performance outcomes in different settings [30]. This research builds on these foundations but focuses specifically on the integration within greenhouse environments, which presents distinct technical and operational challenges. The unique conditions within greenhouses, such as controlled climates and limited space, necessitate tailored solutions to effectively incorporate energy recovery systems. Furthermore, general advancements in microgeneration technologies have been shown to significantly enhance energy efficiency and sustainability in various applications, providing a solid foundation for innovative solutions in greenhouse environments [31,32].

The adoption of turbine-based energy generation systems in greenhouse irrigation can significantly contribute to the sustainability goals of the agricultural sector [33]. By converting excess pressure into electricity, these systems reduce reliance on external energy sources and lower the overall carbon footprint of greenhouse operations. Moreover, the modular nature of the proposed system allows for its adaptation to various greenhouse sizes and configurations, enhancing its applicability across different agricultural contexts.

Therefore, the integration of turbine systems into greenhouse irrigation offers a promising avenue for improving the energy efficiency and sustainability of modern agriculture. This study aims to provide a comprehensive analysis of the design, scalability, and performance of such a system, contributing to the growing body of knowledge on sustainable agricultural technologies. Through detailed theoretical and experimental evaluations, this study seeks to demonstrate the feasibility and benefits of this innovative approach, paving the way for its broader adoption in the agricultural sector.

2. Materials and Methods

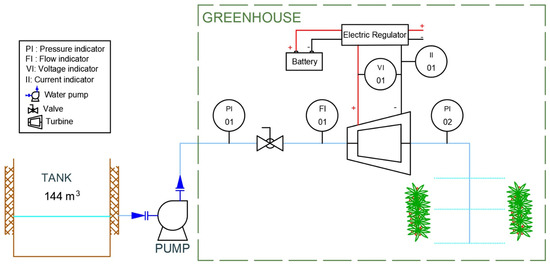

In this section, the components and functionality of the designed turbine system for integrating energy generation into the greenhouse irrigation setup are detailed. The schematic provided in Figure 1 illustrates the key elements and their interconnections within the system.

Figure 1.

System schematic.

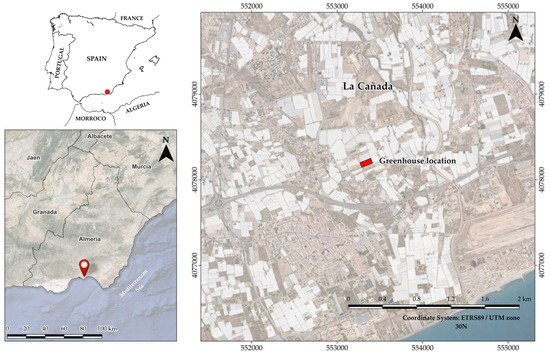

In Figure 2, the location where the installation would be placed is shown.

Figure 2.

Location of the greenhouse, La Cañada, Almería.

The components of the designed system are described below:

- Water Tank: A large, durable structure designed to hold 144 m3 of water, positioned at an elevation to facilitate gravity-fed flow to the pump. Acts as the primary water reservoir for the greenhouse irrigation system, ensuring a consistent supply for both irrigation and energy generation purposes.

- Water Pump: A high-capacity pump capable of handling the flow rate and pressure demands of the system, drawing water from the tank and delivering it to the turbines and irrigation network. Increases the water pressure to the required level for driving the turbines and ensuring adequate irrigation.

- Turbines: Designed to operate efficiently under the pressure and flow conditions of the irrigation system, connected sequentially to maximize energy generation while managing pressure drops effectively. Convert the hydraulic energy from the pressurized water into electric energy, placed in series to optimize energy extraction from the flowing water. Turbines are used in this system as a substitute for pressure-reducing valves, since the water requires pumping from the pond at a higher pressure than that subsequently required for irrigation.

- Pressure Indicators: Precision pressure sensors placed before and after the turbines to ensure accurate pressure readings, essential for optimizing the performance of the turbines and maintaining appropriate irrigation pressure. Measure the water pressure at various points within the system to monitor and control the operation.

- Flow Indicator: A flow meter installed upstream of the turbines to provide real-time data on water flow, helping to adjust the pump operation and turbine settings as needed. Measures the flow rate of water within the system to ensure that the turbines receive an adequate and consistent supply of water.

- Valve: A robust, adjustable valve that can be regulated to manage water pressure and flow, ensuring the optimal operation of the turbines and protecting the system from pressure spikes, in case of turbine malfunctioning. Controls the flow and pressure of water entering the turbine system, allowing for manual adjustments and maintenance. This also enables characterization of the system pressure.

- Electric Regulator: An electronic device that adjusts the voltage and current from the turbines, protecting the battery and other electric components from fluctuations in power generation. Regulates the electric output from the turbines to ensure a stable and usable power supply.

- Battery: A high-capacity battery designed to store the energy produced by the turbine system, providing a reliable power source for the greenhouse’s electric needs. Stores the electric energy generated by the turbines for later use.

- Voltage Indicators: Voltage sensors placed at strategic points within the electric circuit to monitor the performance of the turbines and the regulator. Measure the electric output of the turbine system, providing data on voltage levels.

- Current Indicators: Current sensors installed in the electric circuit to monitor the current flow from the turbines to the battery and other electric components. Measure the electric current in the system, ensuring that the flow of electricity is within safe and optimal operating limits.

- Irrigation Network: A network of pipes and emitters designed to deliver water efficiently to the plants within the greenhouse, operating at lower pressures to benefit from the pressure reduction provided by the turbines. Distributes water throughout the greenhouse, ensuring that all plants receive adequate moisture.

The water pump draws water from the storage tank and increases its pressure. This pressurized water is then directed through a valve and flow indicator before entering the turbines. As the water passes through the turbines, it drives the turbine blades, generating electric energy. Pressure indicators placed before and after the turbines monitor the pressure drop across the turbines, ensuring optimal operation and maintaining the necessary pressure for the irrigation network.

The generated electric energy is regulated by the electric regulator to provide a stable power output, which is then stored in the battery. The voltage indicators provide real-time data on the electric output, allowing for monitoring and adjustments as needed.

Finally, the water exits the turbines at a reduced pressure and is distributed throughout the greenhouse via the irrigation network, ensuring efficient water delivery to the plants.

This integrated approach not only meets the irrigation requirements of the greenhouse but also harnesses the otherwise wasted energy from pressure reduction, contributing to the sustainability and energy efficiency of the agricultural operation.

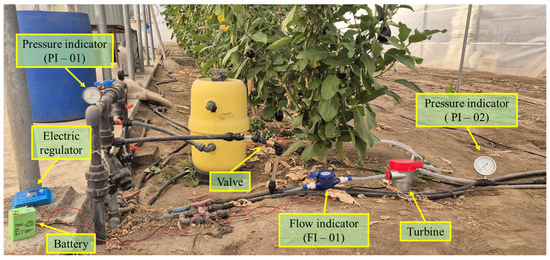

The schematic in Figure 1 outlines the key components and their interconnections within the system. Following the schematic design, the system has been installed as shown in Figure 3 and Figure 4. These figures provide a visual representation of the setup within the greenhouse environment and illustrate the practical application of the schematic design. As shown in Figure 3 and Figure 4, the system implementation is as follows.

Figure 3.

System implementation.

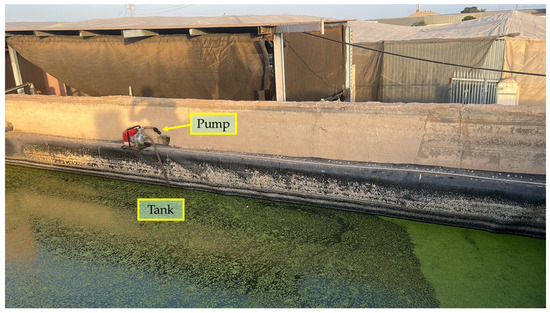

Figure 4.

System implementation. Pump and tank.

The water tank, depicted in Figure 4, is an open storage basin that serves as the primary water reservoir. This tank, positioned near the greenhouse, ensures a consistent supply of water for both irrigation and energy generation. The water pump, also visible in Figure 4, is installed adjacent to the tank. This pump draws water from the tank and increases its pressure to the required level. The pump is connected via pipelines to the rest of the system inside the greenhouse. The drive system of the pump consists of a two-stroke engine with a displacement of 52 cc, capable of developing a power of 1450 W. The pump offers a flow rate up to 12 m3/h with a power of 24 m of water column and a suction capacity of 7 m.

Inside the greenhouse, as shown in Figure 3, the water flows through a network that includes several key components:

- Turbine: The turbine is installed in the irrigation pipeline, converting the hydraulic energy from the pressurized water into electric energy. The turbine’s placement ensures optimal energy extraction while maintaining the necessary water pressure for irrigation.

- Pressure Indicators: These indicators are strategically placed before and after the turbine to monitor the pressure levels. Their location before and after the turbine provides critical data for assessing the pressure drop and ensuring efficient turbine operation.

- Flow Indicator: Positioned upstream of the turbine, the flow indicator measures the water flow rate entering the turbine. This real-time data assists in adjusting the pump operation and optimizing the turbine’s performance.

- Valve: Installed near the flow indicator, the valve regulates the water pressure and flow entering the turbine. This adjustable valve allows for manual adjustments and maintenance, ensuring the system operates within safe parameters.

- Electric Regulator and Battery: Located near the electric components, the electric regulator adjusts the voltage and current generated by the turbine, ensuring a stable power output. The battery, placed nearby, stores this energy for later use, providing a reliable power source for the greenhouse.

- Voltage Indicators and Current Indicators: These sensors are placed at strategic points in the electric circuit to monitor the performance of the turbine and the regulator. They provide essential data on voltage and current levels, ensuring the system operates within optimal electric parameters.

The irrigation network, visible in Figure 3, distributes water throughout the greenhouse. The network of pipes and emitters delivers water efficiently to the plants, benefiting from the pressure reduction provided by the turbine to ensure all plants receive adequate moisture.

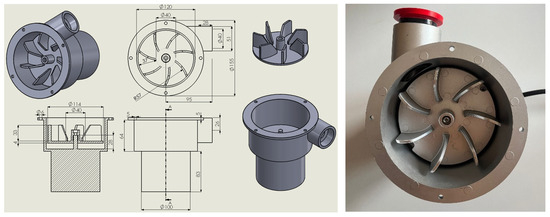

Figure 5 showcases the installed turbine, a Banki-type turbine featuring 7 blades. This turbine, with maximum dimensions of 16.8 × 15.1 × 9.8 cm3, operates at a maximum rotational speed of 1500 RPM. Constructed from durable plastic, the turbine weighs around 1000 g. The selected rotational speed (in RPM) corresponds to a range of working flow rates, showing that for the minimum flow rate of 0.25 m3/h, the rotational speed is approximately 211 RPM, and for the maximum flow rate of 0.98 m3/h, the rotational speed is approximately 827 RPM. The speed range between 200 and 800 RPM is a direct consequence of the inlet flow rate to the system, which varies according to operating conditions. The RPM will not normally be controlled or adjusted during operation; they are the natural result of the incoming flow rate. It should be noted that, although this is the maximum range, the speed is normally kept stable in each of the turbines within its section of the system. The reason why the RPM can drop to around 200 is that the last turbine placed, when placed in series, receives a significantly lower flow rate, which affects its rotation speed.

Figure 5.

Installed turbine with geometric design.

3. Results

3.1. 3D Design and Implementation of the Turbine Outlet

The turbine selected in this study, chosen for its wide availability, is an open outlet turbine with no fluid redirection. However, for the intended application within the greenhouse irrigation system, it was necessary to modify the turbine to include an outlet channel to be able to redirect the pressurized water of the irrigation system to the turbine. This modification allows the redirected irrigation water to be channeled appropriately to the plantation, ensuring efficient and targeted watering of the crops. To achieve this, a novel design of the turbine cover and outlet channel was created using 3D modeling.

The design of the hydraulic turbine cover included a coupling to redirect the drive water towards an irrigation pipe. This design was optimized to minimize turbulence and facilitate water flow, thereby improving the system’s efficiency. To enhance the fluid’s exit towards the irrigation pipes, an outlet nozzle was designed with a larger diameter than the turbine’s inlet. This feature aimed to facilitate water outflow, reducing the possibility of internal turbulence. A smooth and continuous flow is crucial for system efficiency and to prevent premature wear of the components.

Additionally, to avoid the formation of dead volumes within the turbine, the cover was designed so that the volume increases as it approaches the outlet nozzle, guiding the flow more efficiently and ensuring that no stagnant areas affect system performance.

The cover was manufactured using 3D printing technology with PLA material. PLA (polylactic acid) is a bioplastic that offers an appropriate combination of strength and durability, suitable for applications where exposure to high temperatures is not a critical factor. 3D printing allows the creation of complex geometries with high precision and significantly reduces production time and cost. The weight of the cover is 226 g, which adds to the 1000 g of the turbine.

To ensure a watertight seal between the casing and the turbine, a rubber gasket was incorporated. This gasket prevents possible water leaks, guaranteeing the system’s efficiency and reliability. The cover and the turbine casing were connected using M6 screws, along with their respective nuts and washers. This fastening method provides a robust and easy-to-maintain connection, allowing for easy disassembly for maintenance or inspection tasks.

The design process began with the initial conceptualization of the outlet channel and cover, ensuring it would fit the existing turbine model. Using CAD 25.0 software, the design was refined to create a precise 3D model. Key considerations included the dimensions, fitment, and structural integrity of the cover and channel. Before printing, the design was subjected to simulations to verify that it would handle the expected water pressure and flow without failure.

For the 3D printing process, a durable and water-resistant material was selected to ensure longevity and reliability under operational conditions. The cover and outlet channel were printed using a high-precision 3D printer. The printing process included multiple iterations to ensure the final product met the design specifications.

Once printed, the cover and outlet channel were carefully assembled and integrated with the existing turbine. This involved ensuring a secure fit and sealing any potential leakage points. The integrated turbine was then tested within the irrigation system to verify its performance, and adjustments were made as necessary to optimize the fit and functionality.

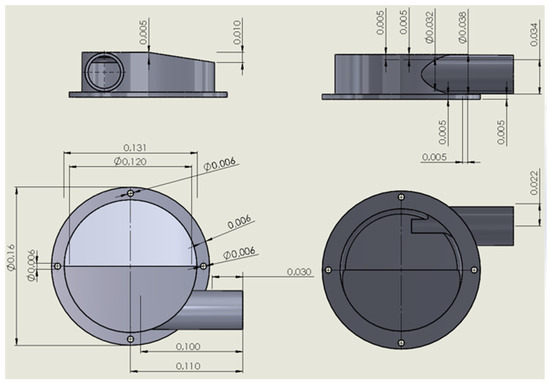

A detailed plan view of the 3D-printed component is shown in Figure 6. This schematic includes all critical dimensions and annotations, serving as a blueprint for the design and providing exact measurements and specifications needed for replication or further modification. It plays a crucial role in documenting the design process and ensuring consistency in manufacturing.

Figure 6.

Detailed plan view of the 3D-printed turbine cover and outlet channel.

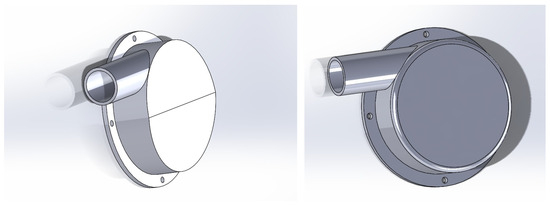

The final design of the 3D-printed turbine cover and outlet channel are shown in Figure 7. These images illustrate the completed component, highlighting the detailed design and its smooth integration with the existing turbine. Figure 7 displays the final 3D-printed cover and outlet channel from different angles, showcasing the design’s inclusion of a flange for secure attachment to the turbine body and a channel to direct the water flow effectively. The novel design and integration of the 3D-printed cover and outlet channel significantly enhanced the functionality of the turbine within the greenhouse irrigation system. This modification not only ensures efficient irrigation but also demonstrates the potential of using 3D printing technology for customized solutions in agricultural applications.

Figure 7.

Final 3D-printed turbine cover and outlet channel.

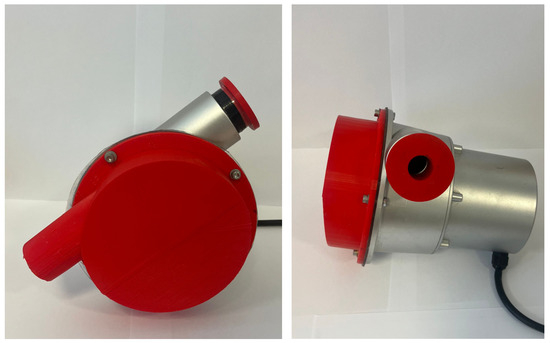

Figure 8 showcases the printed turbine cover and outlet channel after its integration into the greenhouse irrigation system. This image highlights the practical application of the 3D-printed component, demonstrating its secure fitment and functional role in redirecting the irrigation flow. The installation ensures that the modified turbine operates effectively within the system, maintaining optimal water pressure and directing the flow precisely to the designated areas. This figure provides a clear visual confirmation of the successful implementation and operational efficiency of the 3D-printed design within the realworld greenhouse environment.

Figure 8.

Printed turbine cover and outlet channel installed in the irrigation system.

3.2. Experimental Characterization of the Turbine System

The following section of the results focuses on the experimental characterization of the turbine system for the specific application within the greenhouse irrigation setup. Initially, a single turbine was characterized to understand its performance under different pressure conditions and electric loads.

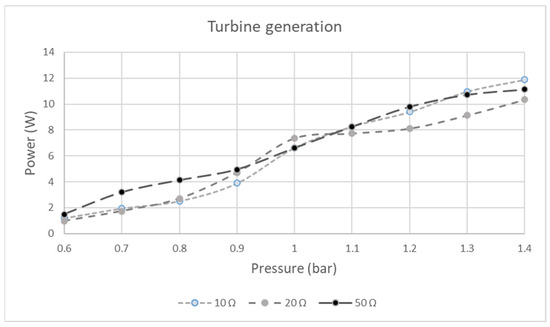

Figure 9 illustrates the relationship between pressure and power output for the turbine under various electric loads (10 Ω, 20 Ω, and 50 Ω). The graph demonstrates that, as the pressure increases, the power output also increases for all loads. Notably, the turbine achieves nearly 12 W of power at the maximum installation pressure of approximately 1.4 bar. This is the maximum pressure from the pump for this particular plantation. For higher pressures, progressively greater power results would be obtained.

Figure 9.

Power generation of a single turbine at various loads and pressures.

The experimental data begin at a pressure of around 0.6–0.8 bar, as pressures lower than this range are not considered practical for the operation of this irrigation system. At these lower pressures, the power output starts at about 1 W for a 10 Ω load, gradually increasing as the pressure rises. The power output for the 20 Ω and 50 Ω loads follows a similar trend but at different rates, reflecting the load-dependent efficiency of the turbine. The graph shows that higher resistive loads result in lower power outputs at the same pressure, indicating the sensitivity of power generation to the electric load connected to the turbine.

This detailed analysis of Figure 9 confirms that the turbine operates efficiently within the pressure range of the greenhouse irrigation system. The turbine can generate significant power even at the higher pressures typically found in the setup, ensuring that the energy recovery from the irrigation system is both feasible and beneficial for sustainable operation.

The efficiency is also obtained as the relation of the upstream water flow rate and its pressure at the inlet, with the electrical power at the outlet as shown in the following expression. The results provide an efficiency of around 30%, considering that the rotational speed does not reach the maximum that is possible for the turbine in its real implementation conditions.

where:

- ε: efficiency

- P: power (W)

- Q: flow (m3/s)

- p: pressure (N/m2)

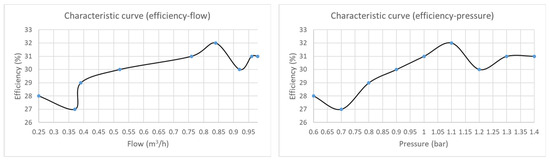

Figure 10 shows the characteristic curves that reflect the relationship of efficiency with respect to the flow rate and pressure ranges analyzed.

Figure 10.

Characteristic curves of efficiency with respect to flow rate and pressure under the conditions analyzed.

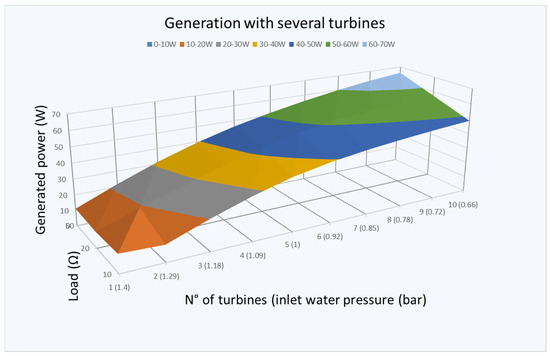

Following the initial characterization of a single turbine, the system was further analyzed to determine the performance when multiple turbines are installed in series. As expected, the installation of additional turbines results in increased power generation but also a progressive loss of pressure. It is crucial to ensure that the pressure does not drop below the minimum operational threshold of 0.8–0.6 bar. The purpose of adding several turbines is not only to obtain more power, but also to progressively reduce the pressure to the irrigation value, thus replacing the function that the reducing valve would perform.

In Figure 11, the graph represents the generated power at different electric loads and varying pressures, with each pressure value corresponding to the number of turbines installed in series. As the number of turbines increases, the pressure decreases, impacting the power generation capabilities of the system. Note that the legend in Figure 11 refers to the value of power generated in W. Likewise, on the axis of the number of turbines, the corresponding pressure in bar is indicated in parentheses, given that, as the number of turbines in series progressively increases, the total output pressure decreases.

Figure 11.

Power generation with multiple turbines in series under various loads and pressures.

The graph clearly shows that the system can accommodate up to approximately eight turbines. At the point of installing the ninth turbine, the input pressure for the subsequent turbine would fall below 0.7 bar, which is considered too low for efficient operation. At this stage, the system generates around 60 W of power, indicating a practical limit for turbine installation. Starting from the eighth turbine, the electrical production becomes very low, nearly negligible. This is because the turbine blades, when operating below 0.6–0.7 bar, fail to achieve continuous rotation. Additionally, reducing the irrigation pressure below this pressure can cause significant issues within the irrigation system. The inability of the turbines to maintain consistent rotation under these conditions not only diminishes energy output but also risks compromising the functionality and reliability. As shown in Figure 10, efficiency varies between 32% and 28% within the range of pressures we are working with. As more turbines are added, pressure losses occur, causing this efficiency to change. This characterization is carried out from the sensor system described previously, without the use of specific software.

The scalability of the system is evident from the results, showing that the number of turbines that can be installed in series depends significantly on the initial input pressure, the number of parallel lines, and the power rating of the turbines used. This analysis underscores the importance of balancing the number of turbines with the available pressure to optimize both irrigation and power generation within the greenhouse setup.

4. Discussion

The results obtained from the 3D design and implementation of the turbine outlet, as well as the experimental characterization of the turbine system, provide valuable insights into the feasibility and efficiency of integrating turbine-based energy generation into greenhouse irrigation systems. This discussion section interprets these findings in the context of the existing literature and the initial hypotheses, while also exploring the broader implications and potential future research directions.

The 3D design and successful implementation of the turbine outlet demonstrated the practical applicability of customizing standard components to meet specific operational needs. The modification allowed the open outlet turbine to function efficiently within the greenhouse irrigation system, ensuring targeted water delivery to the plants. This innovation aligns with previous studies that have highlighted the benefits of using 3D printing technology for creating bespoke components in agricultural systems. The ability to rapidly prototype and implement such modifications not only enhances system efficiency but also offers a cost-effective solution to adapting existing technologies for new applications.

The experimental characterization of the turbine system provided critical data on the power generation capabilities under varying pressure conditions and electric loads. The findings confirmed that the turbine operates effectively within the pressure range of the greenhouse irrigation system, achieving nearly 12 W of power at the maximum pressure of 1.4 bar. The data also highlighted the importance of maintaining sufficient pressure levels, with the operational range identified as between 0.6 and 1.4 bar, to ensure optimal performance, considering also that the outlet pressure of one turbine will be the inlet pressure of the next turbine when they are connected in series.

The analysis of multiple turbines installed in series further emphasized the scalability of the system. The results indicated that up to eight turbines could be installed without dropping below the critical pressure threshold, generating approximately 60 W of power. This finding supports the hypothesis that series installations can enhance energy recovery in irrigation systems. However, it also underscores the need for careful pressure management to prevent efficiency losses. The system’s scalability suggests that larger greenhouse operations, or those with higher initial pressures, could benefit significantly from this approach. Specifically, the findings indicate that the installation of 10 turbines would result in the generation of approximately 0.066 kWh of energy. This generated energy has the potential to be utilized in two primary ways: first, for self-consumption within the system, which would directly offset the energy demand from external sources; and second, by feeding the energy back into the grid, contributing to the overall efficiency and sustainability of the energy system. By adopting this approach, it is possible to quantitatively assess the energy dynamics of the system, specifically evaluating the balance between the energy that the turbines consume and the energy that they generate. This approach also provides a strong foundation for the further optimization and broader application of the energy-saving device, showcasing not only its feasibility but also its potential for scalable impact.

The broader implications of these findings are significant for sustainable agricultural practices. Integrating energy generation into greenhouse irrigation systems not only reduces operational costs but also contributes to energy efficiency and sustainability goals. This dual functionality of irrigation and power generation can help offset the energy demands of greenhouses, particularly in regions with high energy costs or limited access to reliable electricity.

Future research directions could focus on optimizing the design and materials used for the 3D-printed components to further enhance durability and performance. Additionally, exploring the integration of renewable energy sources, such as solar panels, with the turbine system could provide a more comprehensive solution to energy management in greenhouses. Investigating the long-term performance and maintenance requirements of the system in different climatic conditions would also provide valuable data to support widespread adoption.

This study thus demonstrates the practical and theoretical viability of using turbine-based energy generation in greenhouse irrigation systems. The successful implementation and experimental characterization provide a strong foundation for future advancements in this field, highlighting the potential for sustainable and efficient agricultural practices.

5. Conclusions

This study demonstrated the feasibility and benefits of integrating turbine-based generation within greenhouse irrigation systems, addressing the goals of enhancing energy efficiency and sustainability. While traditional irrigation systems use pressure-reducing valves to lower the high pressure from pumps drawing water from storage basins, this study proposed using turbines to reduce pressure while generating electricity, thus utilizing the otherwise wasted energy. By designing and implementing a 3D-printed turbine outlet cover, the study showcased the potential for customizing components to meet specific needs, ensuring efficient water delivery. Experimental results confirmed that a single turbine could generate nearly 12 W within the operational pressure range of 0.6 to 1.4 bar, and scalability tests showed that up to eight turbines could be installed in series, generating around 60 W without dropping below the critical pressure threshold. These findings advance the objective of converting excess pressure into electric energy, in turn reducing operational costs and supporting sustainability goals by lowering greenhouse carbon footprints. The study highlights the importance of balancing the number of turbines with available pressure to optimize both irrigation and power generation. Future research should focus on optimizing 3D-printed components, integrating other renewable energy sources, and conducting long-term performance studies in various climatic conditions, establishing a strong foundation for practical applications of turbine-based energy generation in greenhouse irrigation systems.

Author Contributions

Conceptualization, Á.M.R.-P. and J.J.C.-M.; methodology, J.J.C.-M.; software, Á.M.R.-P. and A.G.-C.; validation, A.G.-C., Á.M.R.-P. and C.A.R.; formal analysis, Á.M.R.-P.; investigation, J.J.C.-M.; resources, Á.M.R.-P.; data curation, A.G.-C. and Á.M.R.-P.; writing—original draft preparation, C.A.R.; writing—review and editing, J.J.C.-M.; visualization, Á.M.R.-P.; supervision, C.A.R.; project administration, J.J.C.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article. The tool files used for this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank Deryck J. Barker Fraser for the translation of the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, M.; Yan, T.; Wang, W.; Jia, X.; Wang, J.; Klemeš, J.J. Energy-saving design and control strategy towards modern sustainable greenhouse: A review. Renew. Sustain. Energy Rev. 2022, 164, 112602. [Google Scholar] [CrossRef]

- Nicotra, A.; Zema, D.A.; D’agostino, D.; Zimbone, S.M. Equivalent Small Hydro Power: A Simple Method to Evaluate Energy Production by Small Turbines in Collective Irrigation Systems. Water 2018, 10, 1390. [Google Scholar] [CrossRef]

- Aznar-Sánchez, J.A.; Velasco-Muñoz, J.F.; García-Arca, D.; López-Felices, B. Identification of Opportunities for Applying the Circular Economy to Intensive Agriculture in Almería (South-East Spain). Agronomy 2020, 10, 1499. [Google Scholar] [CrossRef]

- Mendoza-Fernández, A.J.; Peña-Fernández, A.; Molina, L.; Aguilera, P.A. The Role of Technology in Greenhouse Agriculture: Towards a Sustainable Intensification in Campo de Dalías (Almería, Spain). Agronomy 2021, 11, 101. [Google Scholar] [CrossRef]

- Cajamar. Análisis de la Campaña Hortofrutícola de Almería. Campaña 2021/2022. 2022. Available online: https://publicacionescajamar.es/series-tematicas/informes-coyuntura-analisis-de-campana/analisis-de-la-campana-hortofruticola-de-almeria-campana-2021-2022/ (accessed on 20 February 2024).

- Valera, D.; Belmonte, L.; Molina, F.; López, A. Los Invernaderos de Almería: Análisis de Sus Tecnología y Rentabilidad; Cajamar, Caja Rural: Almería, Spain, 2014; 504p. [Google Scholar]

- Jarwar, A.H.; Wang, X.; Long Wang, L.z.; Zhanshuai, L.; Zhaoyang, Q.; Mangi, N.; Pengjia, B.; Jinjin, W.; Ma, Q.; Shuli, F. Performance and Evaluation of Drip Irrigation System, and Its Future Advantages. J. Biol. Agric. Healthc. 2019, 9, 25–35. [Google Scholar] [CrossRef]

- Mistry, P.; Akil, M.; Suryanarayana, T.M.V.; Parekh, F.P. Evaluation of drip irrigation system for different operating pressures. Int. J. Adv. Eng. Res. Dev. 2017, 72, 2348–4470. [Google Scholar] [CrossRef]

- Pande, P.; Singh, A.; Ansari, S.; Vyas, S.; Dave, B. Design development and testing of a solar PV pump based drip system for orchards. Renew. Energy 2003, 28, 385–396. [Google Scholar] [CrossRef]

- Covelli, C.; Cimorelli, L.; Cozzolino, L.; Della Morte, R.; Pianese, D. Reduction in water losses in water distribution systems using pressure reduction valves. Water Sci. Technol. Water Supply 2016, 16, 1033–1045. [Google Scholar] [CrossRef]

- Pérez-Sánchez, M.; Sánchez-Romero, F.J.; Ramos, H.M.; López-Jiménez, P.A. Optimization Strategy for Improving the Energy Efficiency of Irrigation Systems by Micro Hydropower: Practical Application. Water 2017, 9, 799. [Google Scholar] [CrossRef]

- Bideris-Davos, A.A.; Vovos, P.N. Algorithm for Appropriate Design of Hydroelectric Turbines as Replacements for Pressure Reduction Valves in Water Distribution Systems. Water 2023, 15, 554. [Google Scholar] [CrossRef]

- Sinagra, M.; Aricò, C.; Tucciarelli, T.; Morreale, G. Experimental and numerical analysis of a backpressure Banki inline turbine for pressure regulation and energy production. Renew. Energy 2020, 149, 980–986. [Google Scholar] [CrossRef]

- Ko, Y. Development, Testing and Optimization of a Pico Hydro Turbine for Pressure Regulation and Energy Harvesting; Malaysian Palm Oil Council (MPOC); University of Toronto: Toronto, ON, Canada, 2020; Volume 21. [Google Scholar]

- Soussi, M.; Chaibi, M.T.; Buchholz, M.; Saghrouni, Z. Comprehensive Review on Climate Control and Cooling Systems in Greenhouses under Hot and Arid Conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- Powell, J.W.; Welsh, J.M.; Pannell, D.; Kingwell, R. Can applying renewable energy for Australian sugarcane irrigation reduce energy cost and environmental impacts? A case study approach. J. Clean. Prod. 2019, 240, 118177. [Google Scholar] [CrossRef]

- Reca, J.; Torrente, C.; López-Luque, R.; Martínez, J. Feasibility analysis of a standalone direct pumping photovoltaic system for irrigation in Mediterranean greenhouses. Renew. Energy 2016, 85, 1143–1154. [Google Scholar] [CrossRef]

- Fontana, N.; Giugni, M.; Portolano, D. Losses Reduction and Energy Production in Water-Distribution Networks. J. Water Resour. Plan. Manag. 2012, 138, 237–244. [Google Scholar] [CrossRef]

- Chacón, M.C.; Díaz, J.A.R.; Morillo, J.G.; McNabola, A. Estimating regional potential for micro-hydropower energy recovery in irrigation networks on a large geographical scale. Renew. Energy 2020, 155, 396–406. [Google Scholar] [CrossRef]

- Chacón, M.C.; Díaz, J.A.R.; Morillo, J.G.; McNabola, A. Hydropower energy recovery in irrigation networks: Validation of a methodology for flow prediction and pump as turbine selection. Renew. Energy 2020, 147, 1728–1738. [Google Scholar] [CrossRef]

- Rodríguez-Díaz, J.; Camacho-Poyato, E.; López-Luque, R.; Pérez-Urrestarazu, L. Benchmarking and multivariate data analysis techniques for improving the efficiency of irrigation districts: An application in spain. Agric. Syst. 2008, 96, 250–259. [Google Scholar] [CrossRef]

- Rodríguez-Pérez, M.; Rodríguez, C.A.; Márquez-Rodríguez, A.; Mancera, J.J.C. Viability Analysis of Tidal Turbine Installation Using Fuzzy Logic: Case Study and Design Considerations. Axioms 2023, 12, 778. [Google Scholar] [CrossRef]

- Pérez, M.R.; Rodríguez, C.A.; Rodríguez, L.O.; Mancera, J.J.C. Revitalizing the Canal de Castilla: A Community Approach to Sustainable Hydropower Assessed through Fuzzy Logic. Appl. Sci. 2024, 14, 1828. [Google Scholar] [CrossRef]

- Tarjuelo, J.M.; Rodriguez-Diaz, J.A.; Abadía, R.; Camacho, E.; Rocamora, C.; Moreno, M.A. Efficient water and energy use in irrigation modernization: Lessons from Spanish case studies. Agric. Water Manag. 2015, 162, 67–77. [Google Scholar] [CrossRef]

- Galán-Martín, Á.; Vaskan, P.; Antón, A.; Esteller, L.J.; Guillén-Gosálbez, G. Multi-objective optimization of rainfed and irrigated agricultural areas considering production and environmental criteria: A case study of wheat production in Spain. J. Clean. Prod. 2017, 140, 816–830. [Google Scholar] [CrossRef]

- Mitrovic, D.; Chacón, M.C.; García, A.M.; Morillo, J.G.; Diaz, J.A.R.; Ramos, H.M.; Adeyeye, K.; Carravetta, A.; McNabola, A. Multi-Country Scale Assessment of Available Energy Recovery Potential Using Micro-Hydropower in Drinking, Pressurised Irrigation and Wastewater Networks, Covering Part of the EU. Water 2021, 13, 899. [Google Scholar] [CrossRef]

- Rodríguez-Pérez, A.M.; Rodríguez-Gonzalez, C.A.; López, R.; Hernández-Torres, J.A.; Caparrós-Mancera, J.J. Water Microturbines for Sustainable Applications: Optimization Analysis and Experimental Validation. Water Resour. Manag. 2024, 38, 1011–1025. [Google Scholar] [CrossRef]

- Elbatran, A.; Yaakob, O.; Ahmed, Y.M.; Shabara, H. Operation, performance and economic analysis of low head micro-hydropower turbines for rural and remote areas: A review. Renew. Sustain. Energy Rev. 2015, 43, 40–50. [Google Scholar] [CrossRef]

- Date, A.; Akbarzadeh, A. Design and cost analysis of low head simple reaction hydro turbine for remote area power supply. Renew. Energy 2009, 34, 409–415. [Google Scholar] [CrossRef]

- Maraveas, C.; Karavas, C.-S.; Loukatos, D.; Bartzanas, T.; Arvanitis, K.G.; Symeonaki, E. Agricultural Greenhouses: Resource Management Technologies and Perspectives for Zero Greenhouse Gas Emissions. Agriculture 2023, 13, 1464. [Google Scholar] [CrossRef]

- Fitz-Rodríguez, E.; Kubota, C.; Giacomelli, G.A.; Tignor, M.E.; Wilson, S.B.; McMahon, M. Dynamic modeling and simulation of greenhouse environments under several scenarios: A web-based application. Comput. Electron. Agric. 2010, 70, 105–116. [Google Scholar] [CrossRef]

- El Hafdaoui, H.; Khallaayoun, A.; Ouazzani, K. Long-term low carbon strategy of Morocco: A review of future scenarios and energy measures. Results Eng. 2023, 2023, 101724. [Google Scholar] [CrossRef]

- Elbatran, A.H.A.; Yaakob, O.B.; Ahmed, Y.M. Experimental Investigation of a Hydraulic Turbine for Hydrokinetic Power Generation in Irrigation/Rainfall Channels. J. Mar. Sci. Appl. 2021, 20, 144–155. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).