Abstract

In this paper influence of the excess Ca and Cu cations on the critical temperature (Tc) and critical transport current density (Jc) of high-temperature superconducting ceramics of the compositions (HTSC) Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy synthesized by the glass-ceramic method has been studied. The synthesis of superconducting ceramics was carried out on the basis of the glass phase, obtained by ultra-fast quenching of the melt. Melting of the mixture of starting components was carried out without the use of a crucible under the influence of IR radiant heating. Analysis of the elemental composition of the samples of the initial precursors showed a significant deviation from stoichiometry in oxygen (increase), as well as a decrease in calcium content. The synthesis of HTSC ceramics was carried out at a temperature of 849–850 °C for 96 h with intermediate grinding every 24 h. Studies of the phase composition of ceramic samples by X-ray diffraction have shown that HTSC ceramics consist only of a superconducting high-temperature phase Bi-2223. Studies of current-carrying characteristics by the four-point probe method according to the criterion of 1 µV/cm2 have shown that high-temperature superconducting ceramics of the compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy have an increased density of critical transport current of 9.12 A/cm2, 7.62 A/cm2 and 7.26 A/cm2, respectively. At the same time, it was found that with a decrease in the content of Ca and Cu cations in HTSC ceramics, an increase in the critical current density is observed.

1. Introduction

Among high-temperature superconducting systems, bismuth superconducting compounds (Bi,Pb)2Sr2CaCu2O8 (Bi-2212) and (Bi,Pb)2Sr2Ca2Cu3O10 are widely used in practice. They are used in such fields as energy, electronics, etc. They are used to create motors and electric generators [1], power cables [2,3,4], current limiters for short circuits [5,6,7] and many others. It is known that the main parameters of superconductors are critical temperature (Tc), critical current (Jc) and critical magnetic field (Hc). From a practical point of view, the most important parameter of these three is the critical current. The magnitude of the critical current in ceramic superconductors can be significantly increased using methods that could increase densities and textures. A method is also used to increase the critical current by creating effective pinning centers to anchor the vortex magnetic flux. A more effective way to increase the density and texture in ceramic superconductors is using glass-ceramic technology, according to which the production of ceramics is associated with the use of precursors from the glass phase [8,9,10,11,12,13,14]. The use of this technology provides advantages such as reducing phase segregation, improving the uniformity of the distribution of components and increasing their mutual solubility, reducing the synthesis time due to the metastable state of the glass phase, flexibility in molding a complex-shaped product, obtaining dense and textured ceramics, which can directly affect the increase in the current-carrying characteristics of superconducting ceramics. Among the superconducting materials for the use of the glass-ceramic method for the synthesis of HTSC ceramics, only bismuth-containing superconductors can be acceptable. The bismuth superconducting system is the only representative among superconductors that can be obtained in a glassy state during ultrafast quenching of the melt. This method was first developed on the basis of a superconducting bismuth system in the 1990s and was used by many researchers. However, they could not evaluate its advantages over the solid-phase method, due to lack of full investigation of the processes during crystallization from the amorphous state of the phase with a high content of Tc 2223. Based on the analysis of the results of numerous studies, it can be argued that the process of obtaining the initial precursors is an important step of using the method of synthesis of superconducting ceramics from the glass phase. Traditionally, the melting of the initial charge is carried out in a crucible of corundum or platinum. At the same time, there are some difficulties associated with obtaining a phase with a high Tc (2223) due to a violation of the stoichiometry of the composition (especially for oxygen). In [15,16], a mixture of Bi2Sr2Ca2Cu3−xErxO10+δ(x = 0.5 and 1.0) was melted in an alumina crucible at 1050 °C and 1250 °C for 30 min to 3 h and the melt was poured onto a cold copper plate and quickly pressed with another cold plate to obtain a glass phase. To obtain the HTSC phases, the samples were annealed for 240 h in oxygen, which is associated with oxygen deficiency. In [16,17], a mixture of Bi2Sr2CaCu2Oxand Bi2Sr2Ca2Cu3Ox was melted in a platinum crucible at a temperature from 1000 °C to 1300 °C, while a significant violation of stoichiometry in terms of oxygen content, as well as calcium (9.7% and 25%, respectively) was found. According to Wong-Ng et al. [17,18] to increase the content of the phase with high Tc (2223), excessive amounts of calcium and copper are necessary. Chen and his colleagues [18,19,20,21,22] suggested that the optimal composition should be stoichiometric in Ca and Cu content, but with a small excess of Pb.

The generalized results of the work on glass-ceramic technology were considered in details in the work of Abe [22,23]. Data on the significant loss of oxygen in amorphous precursors during the production of melt in crucibles are also given. According to [23,24], a significant loss of oxygen occurs during melting of the initial samples in the crucible, so that the ratio of Cu+/(Cu1++ Cu2+) cations can reach a value of 0.7–0.8. Similar results with the reduction of Cu2+ copper cations to Cu+ when obtaining a melt in the crucible were observed in [24,25,26,27].

Based on the analysis of numerous studies, it can be concluded that during melting there is a significant violation of the stoichiometric composition, especially in oxygen (oxygen deficiency). In the future, oxygen deficiency may negatively affect the completeness of the formation of the superconducting phase 2223, which is associated with the complexity of oxygen diffusions into the dense structure of precursors. Accordingly, in the future they can affect the kinetics and dynamics, the completeness of the formation of the high-temperature phase 2223, as well as the properties and parameters of the target material.

As for other components, analysis of the works also shows that violation of stoichiometry occurs not only in oxygen, but also among the cationic composition. The Bi-Pb-Sr-Ca-Cu-O system also contains highly volatile cations. Melting a mixture of components at a temperature of 1150–1300 °C for 1 h (average holding time in a molten state) is enough to disrupt significantly the stoichiometry of the cationic composition (especially for Ca). These disturbances can also negatively affect the completeness of the formation of the high-temperature 2223 phase. In addition, they can also affect the critical parameters of superconducting ceramics.

On the other hand, as literature data shows [17,18], to increase the completeness of the formation of the superconducting phase 2223 in HTSC ceramics, an excess content of Ca and Cu components is necessary.

All these results from researchers show that in order to synthesize superconducting ceramics with an increased content of the 2223 phase with high critical parameters (especially the critical current), it is necessary to use a method that does not lead to a significant violation of the stoichiometry of the composition, but increases the density and texture of ceramics.

In this regard, in this work we used glass-ceramic technology based on the glass phase to obtain HTSC ceramics with an excess content of Ca and Cu with a high critical current and to ensure complete formation of the superconducting phase with high Tc (2223).

The purpose of this work is to obtain HTSC ceramics with high critical currents and with an increased content of the high-temperature Bi-2223 phase based on the compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy by using a glass phase, which is obtained under the influence of IR radiation using the glass-ceramic method.

2. Materials and Methods

Bi2O3, PbO, PbO2, SrCO3, CaO, CuO reagents of high purity with a content of the main component of at least 99.99% were used for the synthesis of HTSC ceramics.

Glass–ceramic technology based on glass phase was used for the synthesis of high–temperature superconducting ceramics in the Bi(Pb)–Sr–Ca-Cu-O system. As the results of the work on the synthesis of HTSC ceramics from glass phase show, the melting of the initial mixture in crucibles leads to a significant violation of the stoichiometry of the composition of precursors, especially oxygen, which leads to its deficit. In this regard, we developed and applied a method for producing HTSC ceramics using glass-ceramic technology, eliminating oxygen deficiency, significantly reducing the synthesis time and contributing to the completeness of the formation of the superconducting phase 2223 without using a crucible.

To obtain the initial precursors, IR radiation was used as a heating source. In order to ensure uniform heating, the method of melting samples was applied without using crucible, in which platinum wire was used as a support for the starting materials. This can ensure uniform exposure of the IR radiant flux to the surface of the melted original sample. The sample is located in the middle of the chamber, where IR heating sources are located on four sides. The chamber of the device has a through vertical hole to create a thermal convection flow of atmospheric air (possibly in the flow of oxygen or ozone). The lower hole was also provided for the melt runoff. The melting of the initial materials occurred in no equilibrium, strongly temperature-gradient conditions, since the initially prepared samples are loaded into the chamber (on a platinum stand) when the device is in melting mode. Melting of the initial sample begins from the surface under the influence of IR heating (the thickness of the melt is several dozen microns), which creates a strong temperature gradient condition. The quenching device consists of two oppositely rotating drums or a spray steel disc rotating at a speed of 3000 rpm. The quenching of the melt occurs by the flow of the melt from the surface of the molten sample to the quenching device.

The phase compositions of the initial precursors and superconducting samples were studied on Bruker D8ADVANCEECO X-ray diffractometers (Germany, Karisruhe city), XPertPRO (The Netherlands). Microstructural and elemental analyses of samples were carried out on scanning electron microscopes JEOL-6490LA (Japan, Tokio) with an energy dispersive analyzer system “OXFORD Instruments Analytikal Limited” (UK) and JSM-6390LV (Japan, Tokio) with an integrated energy dispersive X-ray analyzer (EDS). Studies of critical parameters of superconducting samples were carried out by a four-point probe method using a closed Cryo Industry REF-1808-ACS cryocamera cooled by helium gas, a Lake Shore Model 340 temperature meter and a microvoltmeter (Kuala Lumpur, Malaysia). The density of the critical transport current (Jc) was determined by the criterion of 1 µV/cm.

3. Results and Discussion

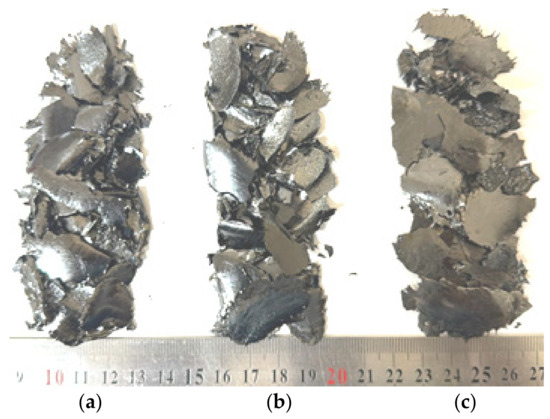

To study the completeness of the formation of phase 2223, depending on the composition, we prepared samples of stoichiometric composition with an excess content of calcium and copper Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy. For compaction, the initial mixtures were pressed into the form of cylinders weighing about 25–30 g and annealed at a temperature of 800 °C for 0.5 h in a muffle furnace. The preparation of precursors was carried out according to the above-mentioned method by a non-melting method under the influence of an IR radiant flux by ultrafast quenching of the melt. The quenching rate of the melt was about 105 degrees/s. At the same time, the hardened initial precursors were plates (Figure 1). The maximum thickness of the plates reached 350 microns.

Figure 1.

The initial precursors obtained by ultrafast quenching of the melt. (a) Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, (b) Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy, (c) Bi1.6Pb0.4Sr2Ca3Cu4Oy.

The plates had the appearance of a glassy state, because it was possible to distinguish characteristic for glass visually by gloss. The results of measuring the phase composition of the precursors of the plates by X-ray diffraction confirmed the glassy appearance of the precursors.

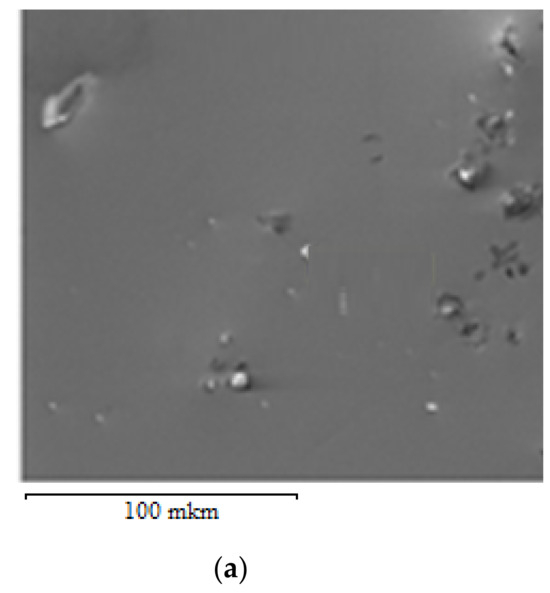

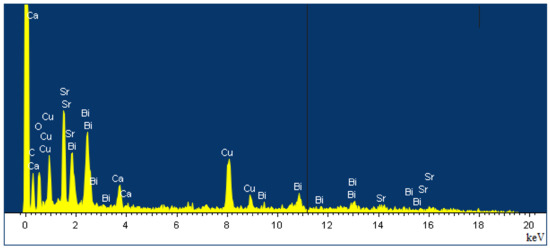

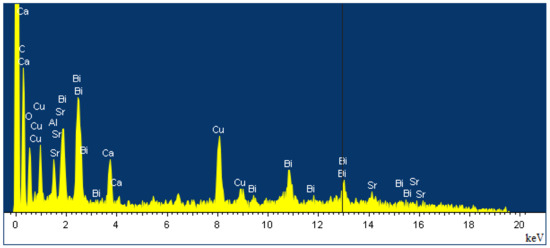

According to the elemental composition of precursors, there is a violation of the stoichiometric ratio of atoms. The results of the elemental composition of the plates are shown in Figure 2, Figure 3 and Figure 4 and in Table 1.

Figure 2.

SEM picture (a) and Energy-dispersive X-ray spectrum of the elemental composition (b) of an amorphous plate Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy.

Figure 3.

Energy-dispersive X-ray spectrum of the elemental composition of an amorphous plateBi1.6Pb0.4Sr2Ca2.25Cu3.25Oy.

Figure 4.

Energy-dispersive X-ray spectrum of the elemental composition of an amorphous plate Bi1.6Pb0.4Sr2Ca3Cu4Oy.

Table 1.

Average values of the elemental composition of amorphous precursors (weight %).

Analysis of the elemental composition of amorphous precursors of the compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy, Bi1.6Pb0.4Sr2Ca3Cu4Oy was taken from the surface of the plate from several points and the average weight percentages of atoms are presented in Table 1. Since there is no noticeable difference in the SEM picture of amorphous plates, therefore, further in Figure 3 and Figure 4, only energy-dispersive X-ray spectra from the surface of the precursors of plates of Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy compositions are presented.

Results of the study on the elemental composition of the precursor plates shows that there are no significant changes in the content of Bi, Pb, Sr and Cu cations. As for Ca, its content turned out to be less relative to the stoichiometric composition, which is consistent with the data [16,17]. According to the results of the study, a significant change is also observed in the oxygen content. Its content is significantly higher than the stoichiometric composition, which is especially important when synthesizing HTSC using glass-ceramic technology. During the formation of a superconducting phase for synthesis of HTSC from amorphous precursors with oxygen deficiency with heat treatment, the diffusion of oxygen into the dense structure of the precursor becomes difficult, which requires a significant increase in heat treatment time (up to 200–400 h) and multiple intermediate grinding of samples. Violation of oxygen stoichiometry with oxygen deficiency can lead to decrease in the thermal stability of phase 2223 [27,28]. And the excess oxygen stabilizes the crystal lattice of Bi(Pb) 2223. Also, according to [29], the excess oxygen leads to an increase in the concentration of holes in the Cu-O planes due to the removal of electrons from copper. And tunneling of pairs of holes in Cu-O planes has a positive effect on superconducting parameters. Increase of the critical temperature leads to increase in the concentration of holes [29,30,31], and possibly growth of the critical current, which is associated with the concentration of charge carriers. As for Ca, its deficiency does not significantly affect the formation of phase 2223. The position of calcium in the crystal structure can be replaced by other cations. According to the authors of [31,32,33,34], in superconducting bismuth compounds Bi2Sr2CaCu2O8+δ (2212) and (Bi,Pb)2Sr2Ca2Cu3Oy (2223), cation substitution occurs in a wide range of homogeneity, which is compensated by other cations for Ca vacancies. In addition, according to [34,35], alkaline earth cations can replace each other in the positions of calcium and strontium.

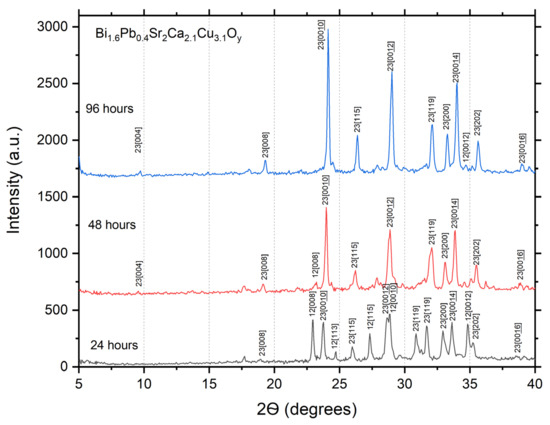

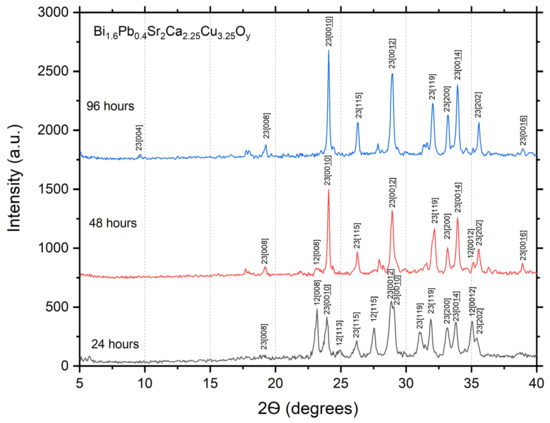

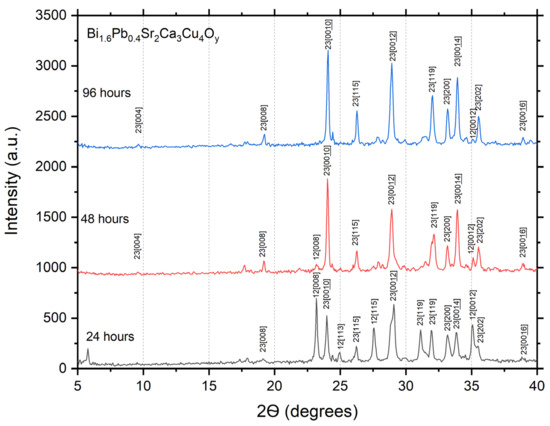

Further synthesis of ceramics and the formation of the superconducting phase 2223 was carried out according to the following scheme: pre-annealing recrystallization of glassy plates at a temperature of 750 °C in a muffle furnace for 0.5–1 h—dry grinding in a planetary mill—pressing into tablets with a diameter of 15 mm and a thickness of 2–2.5 mm under uniaxial pressure of 7000 kgf /cm2—thermal annealing at a temperature of 840 °C for 24 h—grinding, pressing, thermal annealing at a temperature of 850 °C for 72 h (grinding and pressing samples every 24 h). The completeness of the formation of the high-temperature phase Bi-2223 samples of HTSC ceramics of the compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy studied using X-ray diffraction method. Results of the study are shown in Figure 5, Figure 6 and Figure 7.

Figure 5.

Diffractograms of Bi-2223 superconducting phase formation of composition Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy at 850 °C based on glass phase.

Figure 6.

Diffractograms of Bi-2223 superconducting phase formation of composition Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy at 850 °C based on glass phase.

Figure 7.

Diffractograms of Bi-2223 superconducting phase formation of composition Bi1.6Pb0.4Sr2Ca3Cu4Oy at 850 °C based on glass phase.

A preliminary qualitative assessment of the presence of superconductivity in ceramic samples after final heat treatment was carried out by testing for the Meissner effect at a temperature of 77 K (levitation effect) and measuring the ohmic resistance at room temperature. All samples synthesized by us exhibit pronounced Meissner effects at a temperature of 77 K. Many years of experience show that with a poor Meissner effect and high ohmic resistance, the low-temperature superconducting phase 2212 was always present in the samples.

Analysis of the results of X-ray examination of the phase composition of HTSC samples showed that in all samples, at a heat treatment time of 96 h at a temperature of 950 °C, only X-ray peaks related to the high-temperature phase 2223 are present on diffractograms. It confirms the monophasicity of superconducting ceramics. Even with prolonged heat treatment (150–400 h), a low-temperature phase 2212 is always present. There are no noticeable differences in the texture of the samples. Permanent gratings for samples of superconducting ceramics are: for the composition Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy a = 0.5440 nm, b = 0.5029 nm, c = 3.6861 nm, for Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy a = 0.5439 nm, b = 0.5053 nm, c = 3.6935 nm, for Bi1.6Pb0.4Sr2Ca3Cu4Oy a = 0.5443 nm, b = 0.5050 nm, c = 3.6935 nm. There is no noticeable difference in the magnitude of the lattice constant.

The rate of formationof phase 2223 in samples of the composition Bi1.6Pb0.4Sr2Ca3Cu4Oy is relatively slightly higher than in other superconducting ceramics (judging by the ratio of peak intensities of [008] 2212 and [0010] 2223). In all samples after 24 h of heat treatment at a temperature of 850 °C, the content of the high-temperature phase 2223 is greater than the low-temperature 2212. And after 48 h of heat treatment, the content of phase 2212 remains less than 5%, and only traces of the low-temperature phase 2212 are observed in the diffractograms of the sample composition Bi1.6Pb0.4Sr2Ca3Cu4Oy. The monophasicity of the samples and the high rate of formation of the high-temperature phase 2223 using glass-ceramic technology with IR heating applying method without crucible are apparently related to the method of obtaining the initial amorphous precursors. The monophasicity and rate of the phase 2223 can be influenced by factors such as excess oxygen (promotes the oxidation of cations with variable valence Bi, Pb, especially Cu), metastability of the initial precursors (increases interphase reactions) and minimal change in the cation composition relative to stoichiometric (especially for Ca). It is also important to note the peculiarities of the influence of the anisotropic effect of IR radiant flux. The anisotropic effect of the radiant flux creates a nonequilibrium condition for the melting of the mixture of initial components, which can contribute to the formation of various defects in the structure of amorphous precursors.

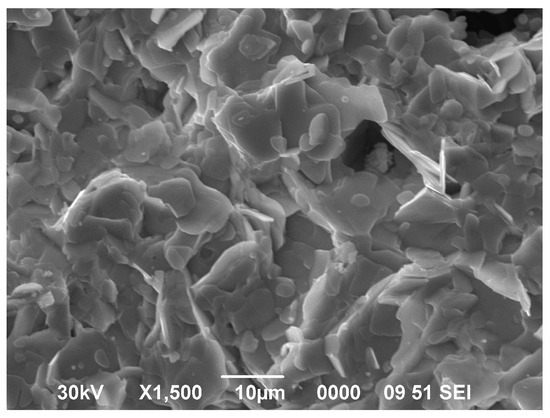

The electron microscopic measurementresults of the surface of superconducting ceramicssamples, show that the crystallites are densely packed (Figure 8).

Figure 8.

Microstructure of ceramics synthesized from glass phase.

Density of HTSC ceramics samples of compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy are 5.23 g/cm3, 5.26 g/cm3 and 5.34 g/cm3 respectively. The crystallites are plate-shaped. The maximum size of the plates reaches 25–30 microns. According to the morphology of the crystallites and X-ray data (Figure 2, Figure 3 and Figure 4), no noticeable texture is observed.

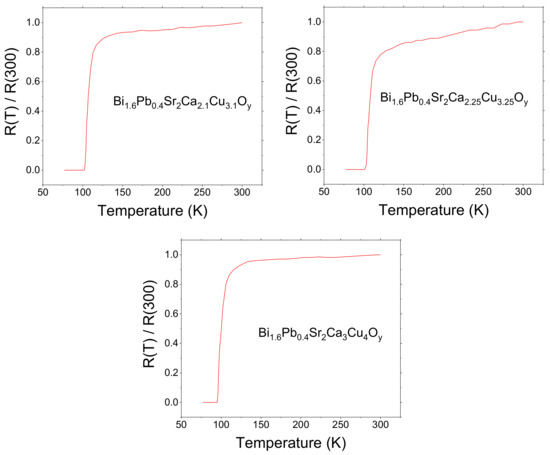

The critical temperature of ceramic samples was determined by measuring the temperature dependence of the resistance using a four-point probe method in the temperature range from room temperature (300 K) to the boiling point of liquid nitrogen (77 K) (Figure 9).

Figure 9.

Curves of temperature dependence of resistance of samples of HTSC compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy, synthesized based on glass phase.

According to the curve of the temperature dependence of the resistance of samples of superconducting ceramics, the transition temperatures to the superconducting state were determined, which corresponded to Tsn—115–120 K, and the critical temperatures were in the range of 98–103 K, depending on the composition (for composition Bi0.6Pb0.4Sr2Ca3Cu4Oy Tc,Zero = 98K, for Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy Tc,Zero = 103 K). A decrease in the critical temperature with an increase in the Ca and Cu content is associated, according to our assumptions, with the localization of excess cations on the surface of crystallites in the grain boundaries. During the formation of the HTSP structure of phase 2223, excess Ca and Cu cations can be displaced to the surface of the crystallites, which can affect the critical temperature.

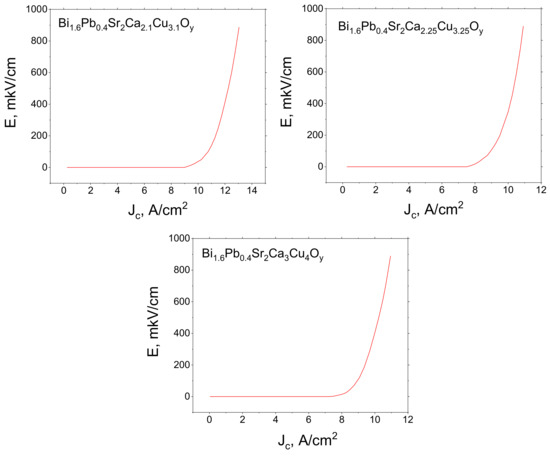

To determine the density of the critical transport current (Jc), a four-point probe method with a criterion of 1 µV/cm was used. The measurements were carried out at a temperature of 77 K in zero magnetic fields, the results of which are shown in Figure 10.

Figure 10.

Dependence curves of the critical transport currentdensity of samples of HTSC compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy, synthesized based on glass phase.

The results of the study of the current-carrying characteristics of HTSC samples at 77 K show that in superconducting ceramics of the compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy, the critical transport current densities are 9.12 A/cm2, 7.62 A/cm2 and 7.27 A/cm2, respectively, which is significantly higher comparing with superconducting ceramics prepared using other methods (co-deposition, sol-gel, solid-phase method) [35,36,37]. Such a large difference in the magnitude of the critical current is due to the method of obtaining (glass-ceramic method), the formation of texture during the synthesis of HTSC ceramics from glass phase, which can also lead to an improvement in intergrain bonds. (It is also possible that an excess of Ca and Cu could partially contribute to the critical current, forming non-superconducting oxide compounds in the form of particles (or clusters) of nanoscale size on the surface of crystalline grains). They could be located in the intergrain boundaries in the form of pinning centers (as effective pinning centers for fixing vortex magnetic flows) formed by displacing superconducting crystallites to the surface during the formation of a high-temperature superconducting structure 2223.

4. Conclusions

It has been established that the crucible-free method for obtaining glassy precursors under the influence of IR heating allows enrichment with oxygen and helps to minimize the violation of the stoichiometric composition of cations. The synthesis of HTSC ceramics based on glassy precursors makes it possible to obtain superconducting ceramics from a pure (without impurities) high-temperature phase 2223 based on the compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy and Bi1.6Pb0.4Sr2Ca3Cu4Oy and with significantly higher densities of critical transport currents 9.12 A/cm2, 7.62·A/cm2 and 7.27·A/cm2, respectively, than when using the traditional solid-phase method, the co-precipitation method, etc. A decrease in the value of the critical current with an increase in the content of Ca and Cu in HTSC ceramics. Apparently, this is due to the displacement of these cations during the formation of the 2223 phase onto the surface of the crystallites into grain boundaries. Also, when using this method, the technological process of obtaining HTSC ceramics is significantly reduced (3–4 times), stability and reliability are increased, which can be proposed for practical use.

It is determined that a significant increase in the critical transport current density of the Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy, and Bi1.6Pb0.4Sr2Ca3Cu4Oy compositions is associated with an improvement in density and texture as a result of the use of a glass-ceramic method of synthesis of superconducting ceramics. It is also assumed that the increase in the critical current may additionally be influenced by the effect associated with the displacement of excess Ca and Cu cations during the formation of the 2223 phase on the surface of crystallites, which are localized at inter grain boundaries. Perhaps they can serve as effective pinning centers.

When using this method, the technological process for producing HTSC Bi-2223 is significantly reduced by 3–4 times, the stability and reliability of the yield of the target compound is increased. This method can be proposed for practical use for the manufacturing long-length and volumetric, high-temperature superconducting parts in energy, electronics and other fields.

Author Contributions

D.U. Writing an article, setting tasks, analyzing results, A.N. (Adolf Nogai). X-ray studies of the phase composition of HTS ceramics, decoding and analysis of the results, A.U. Working out of technological modes and obtaining initial amorphous precursors, K.Z. Synthesis of HTS ceramics compositions Bi1.6Pb0.4Sr2Ca2.1Cu3.1Oy, Bi1.6Pb0.4Sr2Ca2.25Cu3.25Oy, E.N. Investigation of critical parameters of HTS ceramics (critical temperature and density of critical transport current)., P.D. Study of the microstructure and elemental composition of samples of HTS ceramics, A.Z. Synthesis of HTSP ceramics of the composition Bi1.6Pb0.4Sr2Ca3Cu4Oy, A.N. (Artur Nogai) Graphical processing of results and preparation of materials for the article. All authors have read and agreed to the published version of the manuscript.

Funding

The work was supported by a grant from the Committee of Science of Ministry of Science and Higher Education of the Republic of Kazakhstan AP09260251.

Conflicts of Interest

The authors declare that there is no conflict of interest regarding the publication of this article.

References

- Hull, J.R.; Strasik, M. Concepts for using trapped-flux bulk high-temperature superconductors motors and generators. Supercond. Sci. Technol. 2010, 23, 124005. [Google Scholar] [CrossRef]

- Hajiri, G.; Berger, K.; Trillaud, F.; Lévêque, J.; Caron, H. Impact of Superconducting Cables on a DC Railway Network. Energies 2023, 16, 776. [Google Scholar] [CrossRef]

- Hamabe, M.; Sugino, M.; Watanabe, H.; Kawahara, T.; Yamaguchi, S.; Ishiguro, Y.; Kawamura, K. Critical current and its magnetic field effect measurement of HTSC tapes forming DC superconducting cable. IEEE Trans. Appl. Supercond. 2011, 21, 1038–1041. [Google Scholar] [CrossRef]

- Bulinski, A.; Densley, J. High voltage insulation for power cables utilizing high temperature superconductivity. IEEE Electr. Insul. Mag. 1999, 15, 14–22. [Google Scholar] [CrossRef]

- Kozak, J. Forces and Stresses in the Windings of a Superconducting Fault Current Limiter. Energies 2022, 15, 6519. [Google Scholar] [CrossRef]

- Choi, Y.; Song, S.; Kim, J.; Choi, Y.S.; Ko, T.K. Thermal and Electrical Characteristics of Hollow Former with Fault Current Limiting Function for Superconducting Power Cable. IEEE Trans. Power Deliv. 2022, 37, 1100–1108. [Google Scholar] [CrossRef]

- Lim, S.H. Study on current limiting characteristics of SFCL with two trigger current levels. Phys. C Supercond. Appl. 2010, 470, 1631–1635. [Google Scholar] [CrossRef]

- Gazda, M.; Winiarski, A. XPS and XRD studies of early stages of crystallisation process in (Bi-Pb)4Sr3Ca3C4Ox glass-ceramics. Physica C 2005, 432, 35–42. [Google Scholar] [CrossRef]

- Koralaya, H.; Cavdar, S.; Arslan, A.; Ozturk, O.; TolgaTasci, A.; Tugluoglu, N. Experimental and theoretical approaches for magnetic, superconducting and structural characterization of Bi1.75Pb0.25Sr2Ca2Cu32212xSnxO10+y glass ceramics. Cryogenics 2017, 88, 17–21. [Google Scholar] [CrossRef]

- Gavdar, S.; Koralay, H.; Altındal, S. Effect of vanadium substitution on the dielectric properties of glass ceramic Bi-2212 superconductor. J. Low Temp. Phys. 2011, 164, 102–114. [Google Scholar]

- Koralay, H.; Hicyilmaz, O.; Cavdar, S.; Asikuzun, E.; Tasci, A.T.; Ozturk, O. Effect of Zn content on microstructure and mechanical performance in Bi1.8Sr2Ca2Cu3.2−xZnxO10+δ glass ceramic. J. Mater. Sci. Mater. Electron. 2014, 25, 3116–3126. [Google Scholar] [CrossRef]

- Gulamova, D.D.; Uskenbaev, D.E. Effect of substrate composition and crystal structure on the BSCCO texture with the 2223 composition obtained under the action of solar radiation. Appl. Sol. Energy (Engl. Transl. Geliotekhnika) 2006, 42, 40–42. [Google Scholar]

- Fruth, V.; Tanase, G.; Atkinson, I.; Pandele, C.J.; Aldica, G.; Zaharescu, M. Synthesis and characterization of glass-ceramic superconductors in (Pb,B)-doped Bi-Sr-Ca-Cu-O system. Rev. Roum. Chim. 2014, 59, 375–383. [Google Scholar]

- Gazda, M.; Klimczuk, T. Magnetic Field Influence on the Superconducting Transition in Granular (BiPb)-Sr-Ca-Cu-O Superconductors. Acta Phys. Pol. A 2010, 118, 373–374. [Google Scholar] [CrossRef]

- Aksan, M.A.; Yakinci, M.E. Synthesis and characterization of Er-substituted Bi-2223 H-Tc glass–ceramic superconductors. J. Alloys Compd. 2004, 385, 33–43. [Google Scholar] [CrossRef]

- Nilsson, A.; Gruner, W.; Acker, J.; Wetzig, K. Glass–ceramic route of BSCCO superconductors—Fabrication of amorphous precursor. Physica C 2007, 460, 1331–1332. [Google Scholar] [CrossRef]

- Nilsson, A.; Gruner, W.; Acker, J.; Wetzig, K. Critical aspects on preparation of Bi-2223 glassy precursor by melt-process. J. Non-Cryst. Solids 2008, 354, 839–847. [Google Scholar] [CrossRef]

- Chen, Y.L.; Stevens, R. 2223 phase formation in Bi(Pb)-Sr-Ca-Cu-O: I, The role of chemical compositions. Am. Ceram. Soc. 1992, 75, 1142–1149. [Google Scholar] [CrossRef]

- Wong-Ng, W.C.K.; Chiang, S.W.; Freiman, L.P.; Cook, M.D. Mill, Phase formation of high Tc superconducting phases in the Bi-Pb-Sr-Ca-Cu oxides. Ceram. Bull. 1992, 8, 1261. [Google Scholar]

- Chen, Y.L.; Stevens, R. 2223 phase formation in Bi(Pb)-Sr-Ca-Cu-O: II, The role of temperature-reaction mechanisms. J. Am. Ceram. Soc. 1992, 75, 1150–1159. [Google Scholar] [CrossRef]

- Chen, Y.L.; Stevens, R. 2223 Phase Formation in Bi(Pb)-Sr-Ca-Cu-O: III, The Role of Atmosphere. J. Am. Ceram. Soc. 1992, 75, 1160–1166. [Google Scholar] [CrossRef]

- Abe, Y. (Ed.) Superconducting Glass–Ceramics in Bi–Sr–Ca–Cu–O: Fabrication and its Application; World Scientific Publishing Co. Pte. Ltd.: Singapore, 1997; ISBN 981-02-3204-7. [Google Scholar]

- Lee, W.-H. Effect of Copper Ions (Cu(I), Cu(II)) on the Properties of Bi-Sr-Ca-Cu-O Glasses and Superconducting Glass-Ceramics. In Superconducting Glass-Ceramics in BiSrCaCuO; Abe, Y., Ed.; World Scientific: Singapore, 1997; pp. 79–94. [Google Scholar]

- Komatsu, T.; Sato, R.; Kuken, Y.; Matusita, K. Kinetics of Nonisothermal Crystallization of BiSrCaCuO Glasses with Different Copper Valence States. J. Am. Ceram. Soc. 1993, 76, 2795–2800. [Google Scholar] [CrossRef]

- Chatterjee, S.; Bhattacharya, S.; Chaudhuria, B.K. Structural and Transport Properties of (Bi,Pb)4Sr3Ca3Cu42212mFemOx (m = 0 − 0.06) glasses: Precursors for high Tc superconductors. J. Chem. Phys. 1998, 108, 2954–2961. [Google Scholar] [CrossRef]

- Aruchamy, A.; Kim, S.; Birnie, D.; Uhlmann, D. Glass microstructure and initial crystallization of Pb0.32Bi1.68Sr1.75Ca2Cu3O. J. Non-Cryst. Solids 1993, 160, 60–67. [Google Scholar] [CrossRef]

- Yin, S.; Kao, H.-C.; Wang, C. Kinetic study of the peritectic transition of a Bi-2223 superconductor. Phys. C Supercond. 1994, 235, 323–324. [Google Scholar] [CrossRef]

- Karppinen, M.; Lee, S.; Lee, J.M.; Poulsen, J.; Nomura, T.; Tajima, S.; Chen, J.M.; Liu, R.S.; Yamauchi, H. Hole doping in Pb-free and Pb-substituted (Bi,Pb)2Sr2Ca2Cu3O10+δsuperconductors. Phys. Rev. B 2003, 68, 054502. [Google Scholar] [CrossRef]

- Takita, K.; Akinaga, H.; Katoh, H.; Masuda, K. Relation between Superconducting Tc and Hole Concentration: Hall Effect Measurement and Chemical Analysis in Charge-Doped and Oxygen-Doped System Nd1+xBa2−xCu3O7−δ. Jpn. J. Appl. Phys. 1988, 27, L1676. [Google Scholar] [CrossRef]

- Govind, A.; Tripathi, R. Superconducting properties of bilayer cuprates: Role of CuO chains. Phys. C Supercond. 2000, 334, 215–228. [Google Scholar] [CrossRef]

- Hong, B.; Mason, T.O. Solid Solution Ranges of the n = 2 and n = 3 Superkonducting Phases in Bi2(SrxCa12212x)n+1CunOy and the Effect on Tc. J. Am. Ceram. Soc. 1991, 74, 1045–1052. [Google Scholar] [CrossRef]

- Majewski, P.; Su, H.L.; Hettich, B. The High-Tc Superconducting Solid Solution Bi2+x(Sr,Ca)3Cu2O8+b (2212Phase)-Chemical Composition and Superconducting Properties. Adv. Mater. 1992, 4, 508–511. [Google Scholar] [CrossRef]

- Nomura, S.; Yamashita, T.; Yoshino, H.; Ando, K. Cation Deficienci in Bi2(Sr,Ca)3Cu2O8+b. J. Am.Ceram. Soc. 1991, 74, 2711–2714. [Google Scholar] [CrossRef]

- Ikuta, H.; Kushimoto, T.; Enomoto, H.; Namuto, S. X-Ray Photoemission Spectroscopy Study on Bi2Sr2−xCa1+xCu2O8+b. Phase Transit. 1993, 42, 1–5. [Google Scholar] [CrossRef]

- Jannah, A.N.; Abdullah, H. Critical Current Density, Jc Improvement of BSCCO Superconductor Tapes with Nano Co3O4 Addition. IOP Conf. Ser. Mater. Sci. Eng. 2018, 395, 012007. [Google Scholar] [CrossRef]

- Agail, A.; Abd-Shukor, R. Transport current density of (Bi1.6Pb0.4)Sr2Ca2Cu3O10 superconductor added with different nano-sized ZnO. Appl. Phys. A 2013, 112, 501–506. [Google Scholar] [CrossRef]

- Azman, N.J.; Huda Abdullah, H.; Abd-Shukor, R. Transport Critical Current Density of (Bi1.6Pb0.4)Sr2Ca2Cu3O10 Ceramic Superconductor with Different Nanosized Co3O4 Addition. Adv. Condens. Matter Phys. 2014, 2014, 498747. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).