1. Introduction

The chemical industry is facing diverse challenges to conduct a profitable production of chemicals along the value of chain. Those challenges are mainly driven by increasing uncertainties affecting the economics and technology of production processes. Uncertainties arise in economic boundary conditions and increasing needs for product variety and overall demand volatilities on the one hand. On the other hand, increasing uncertainties arise in supply and costs of raw material and energy. The latter are caused by the objective to decarbonize raw material and energy supply.

In addition, future markets and customers become less predictable. New investments in production capacities for the extension of existing products or the exploitation of new markets with product innovations are increasingly risky. This economic trend is intensified by an increasing global competition.

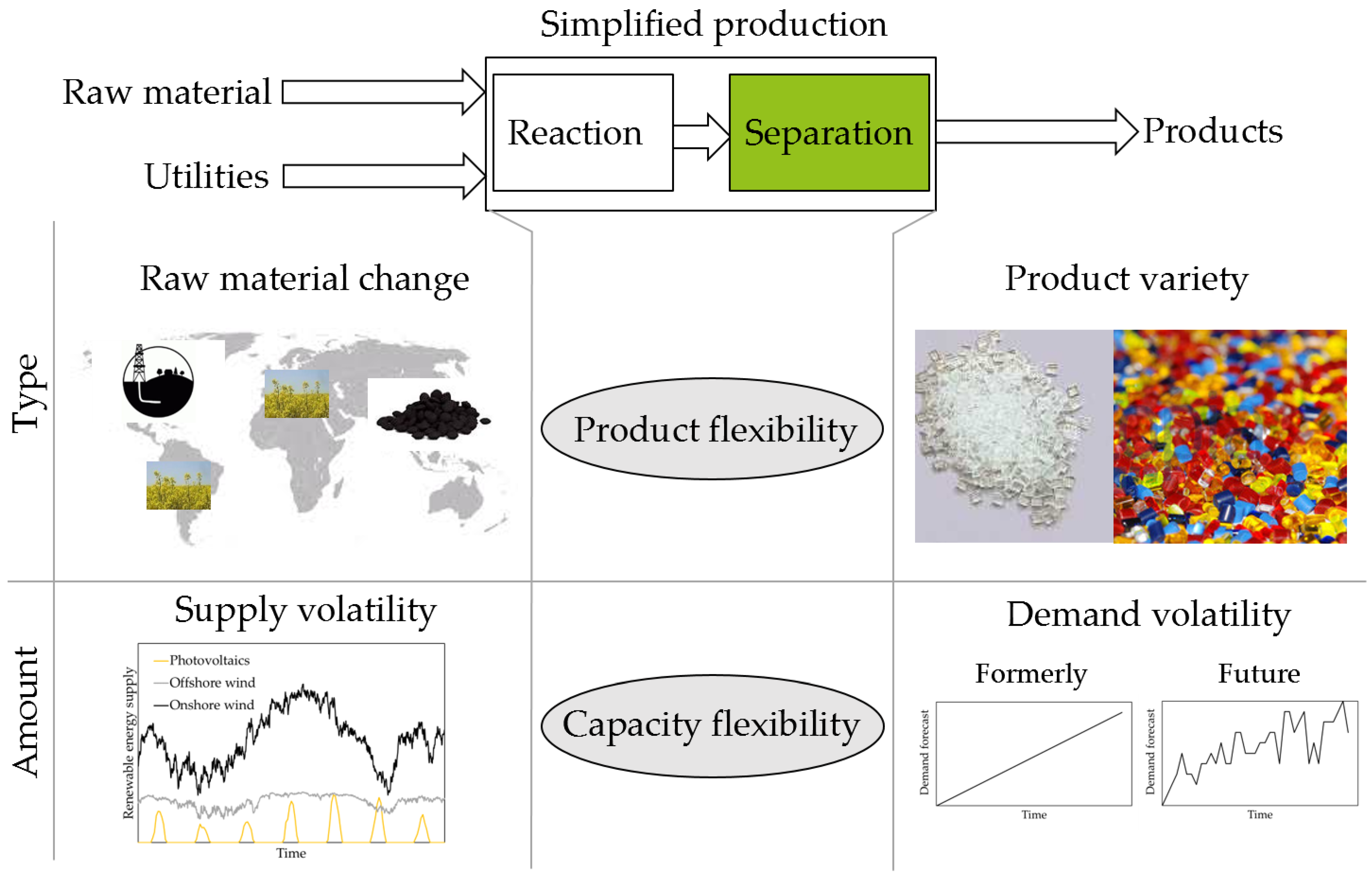

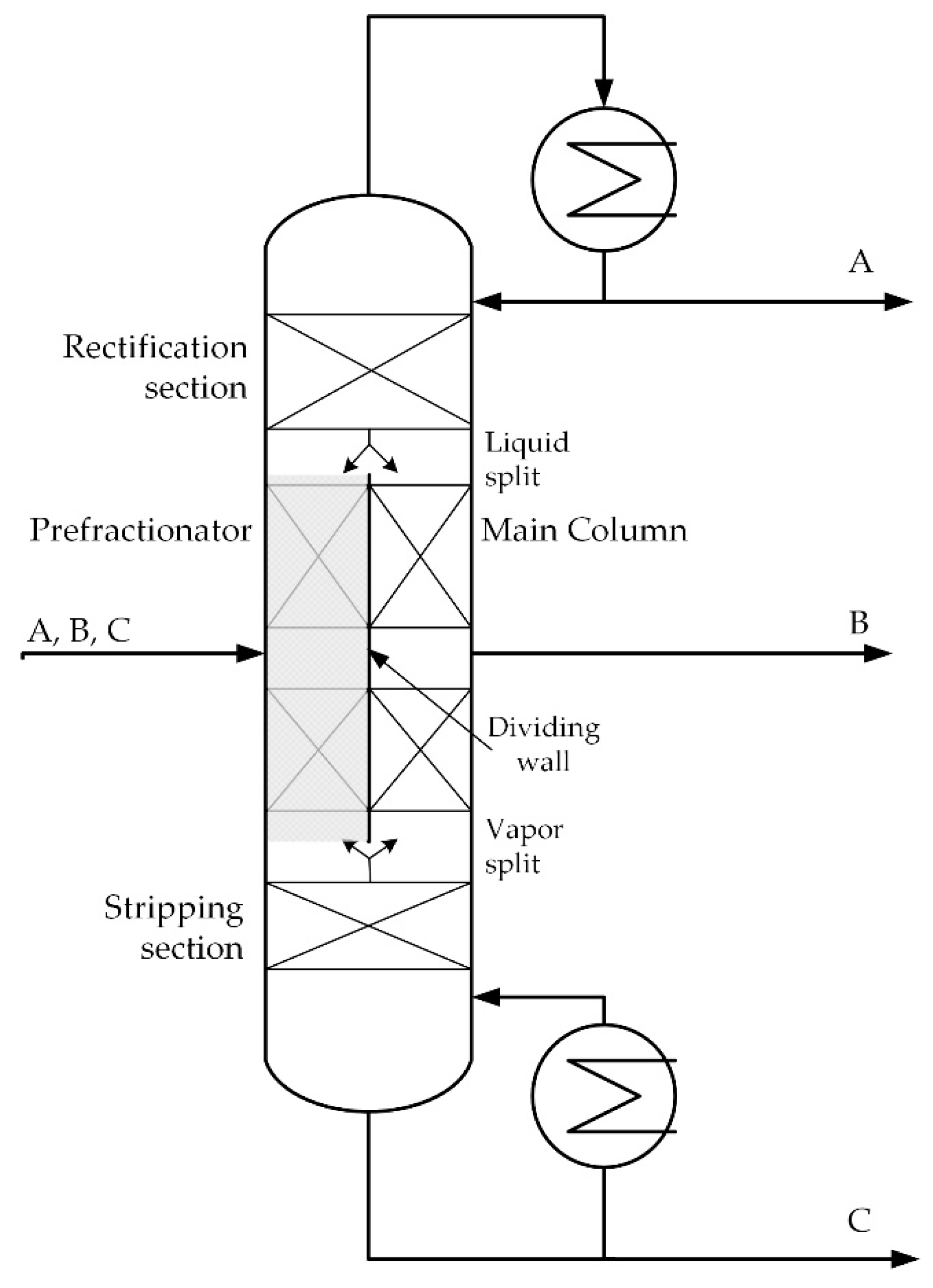

Figure 1 summarizes the uncertainties discussed further within this article.

On the demand side, there are three trends and challenges especially for the production of fine and specialty chemicals. First, for increasingly customized solutions, an increasing product differentiation and variety occurs [

1,

2]. In the past decade, supplier markets developed into buyer markets [

3]. The second trend is the shortening of product life cycles especially within specialty products [

2,

4]. Product life cycles have been halved within the last 40 years [

5]. Consequently, the lifetime of product specific plants decreases as well. A third aspect is the increasing market volatility and insecurity of demand, known as market dynamics [

2,

4]. Shortening life cycles create more volatility because long maturity phases are shortened. Thus, processes and equipment are needed to adopt to these changes, which are associated with increasing need in product and capacity flexibility.

Regarding the supply side, efforts are made to decarbonize the value chain by producing organic base chemicals from bio-based raw materials. Two strategies to transform the chemical industry into a bio-based industry are possible: use of bio-based hydrocarbons as platform chemicals or the use of functionalized bio-based building blocks as raw material for other chemicals [

6,

7]. Both strategies enable a transformation of the feedstock for the chemical industry. Anyway, the efficiency of the chemical routes needed within the transformation is low and thus processes that are more effective have to be developed [

8,

9]. Whereas many production routes are feasible in laboratory scale obstacles have to be overcome regarding the scale-up of the processes. Most important are the development of better catalysts and shorter time-to-market periods [

10].

Modular plant technology, which is based on novel apparatus concepts, can be a solution to overcome this obstacle. Additionally, some other aspects support the approach to process bio-based feedstock by flexible technologies. Most important is the reduction of transportation efforts if biomass is pre-processed close to the origin by means of small-scale plants [

11,

12]. Varying regional yields and amounts of biomass (e.g., [

13]) are other drivers for flexible process equipment. A large variability of feed quantity can also be associated with changing regional conditions for harvesting, which highly affects the efficiency of processes. This is especially the case for the separation tasks involved in the processing of bio-based raw material [

14].

Power-to-X processes give another possible field of application for flexible or modular process equipment. Those processes are based on the conversion of electricity coming from renewable sources into hydrogen by water electrolysis. Subsequently, the hydrogen is converted into hydrocarbons (e.g., methane, methanol of Fischer Tropsch Fuels) together with CO

2 or into ammonia together with nitrogen [

15]. Various research is published on the techno-economic and ecologic impact of those process chains (e.g., [

16,

17,

18,

19,

20]). In all studies, it is assumed that the electrolysis is able to follow the dynamics of energy supply from renewable sources, mostly solar and wind power, whereas the produced hydrogen then needs to be stored to allow for a steady state operation of the subsequent more complex chemical plant. To minimize storage costs and to utilize the electrolysis more efficiently it can be suitable to enhance the flexibility of the chemical plant. Therefore, novel apparatus concepts have to be developed to enable higher flexibilities in Power-to-X processes.

The presented work is supposed to give an insight in possible technical solutions regarding modular and flexible apparatus concepts. The focus regarding technical solutions is on modular plants on the one hand and apparatus concepts for the unit operations absorption and distillation on the other hand. Solutions for chemical reaction engineering are not discussed in detail as there are reviews already available [

21,

22,

23,

24,

25,

26] indicating that for reaction engineering solutions they are already available. Therefore, the article is organized as follows:

Section 2 gives more detailed structuring of needed flexibilities. The concept of transformable plants is introduced in

Section 3. In

Section 4, examples for suitable apparatus concepts are given in order of their physical scale, starting from small-scale solutions and ending with industrial-scale examples.

2. Classification of Boundary Conditions and Flexibility Types

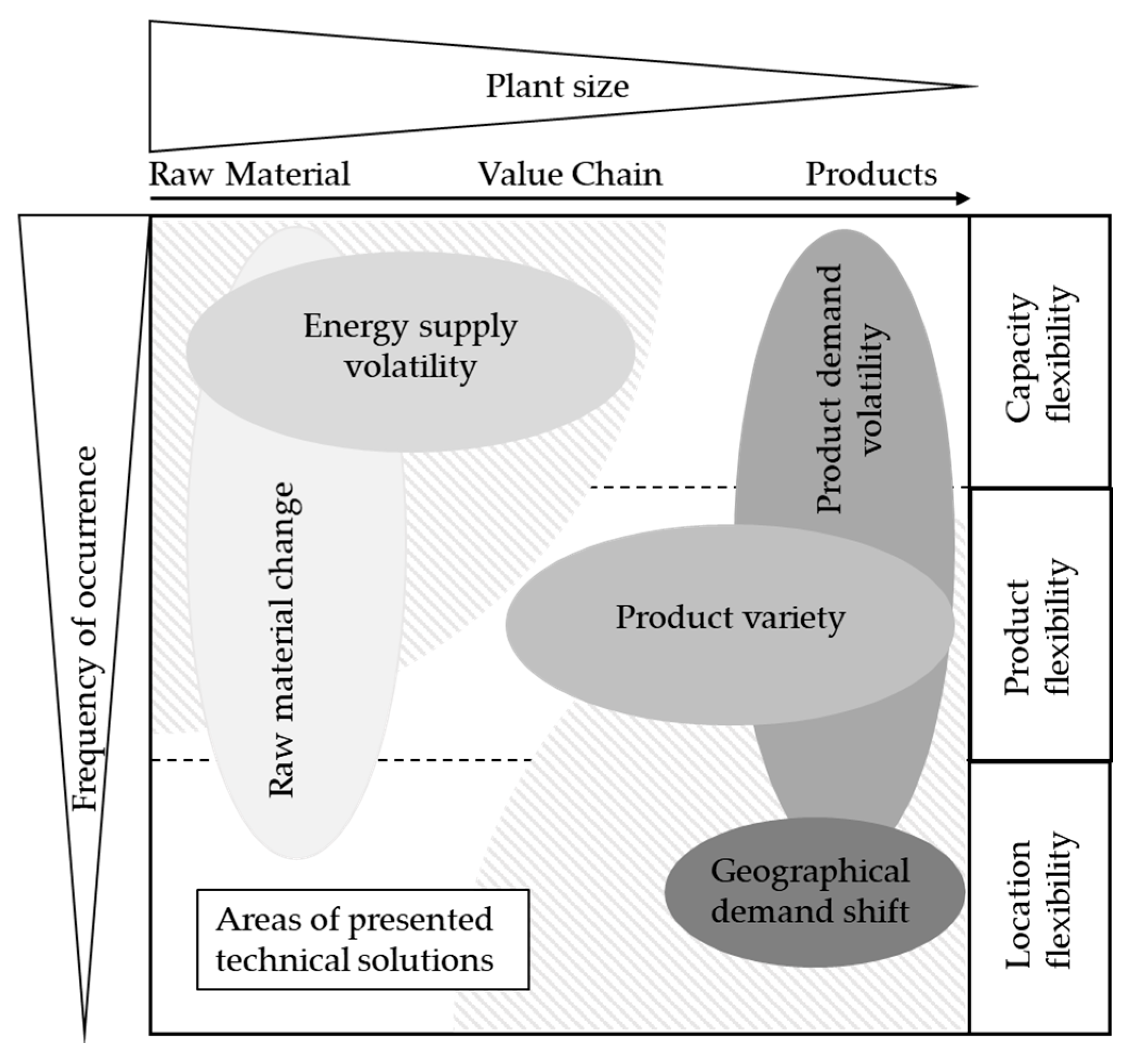

Before going into detail regarding the description of possible technical solutions, a brief classification of the introduced boundary condition with respect to the type of flexibility, the possible frequency of occurrence, and the relevant position along the value chain, which is associated with the usual plant size, is given (see

Figure 2).

The derived types of flexibility regarding capacity, product, and location can be assigned to different frequencies of occurrence. Needs for capacity flexibility are caused by uncertainties in amount of raw material and energy as well as by volatile product demand. These boundary conditions are likely to change most frequently from a relative point of view. For example, in an electricity system with high shares of wind and solar power, large gradients in electricity availability can occur within seconds or minutes. Even with high storage capacities, differences in availability occur within days or weeks. On the other hand, a need for product flexibility is induced by changing raw material qualities, especially for bio-based production routes, and more importantly by increasing product variety. The raw material quantities can change due to seasonal changes during the harvest in one year but are assumed to change less frequently than the energy supply in a renewable energy system. Both boundary conditions are changing less rapidly and often as those presented to induce capacity flexibility. Needs for a change in production location are assumed to happen even less frequently and can be assigned, for example, to global market changes.

Furthermore, these boundary conditions can be classified with respect to their relevance along the value chain. Uncertainties in amount and type of raw material are only relevant for energy intensive processes at the beginning of the value chain usually performed in large-scale continuous plants. Due to increasing product variety, processes with high customer proximity are generally performed in smaller plants (e.g., batch-wise operated multi-purpose plants). The same is the fact for increasing product demand volatilities. Today’s production concepts in the process industry cannot handle the resource and market dynamics, as described above, properly. Conventional plants are mostly dedicated and multi-purpose plants are not efficient enough.

Nonetheless, for some of the mentioned challenges there are solutions on hand or under research [

27,

28,

29]. These solutions deal with market volatilities by sequential investments that have to be carried out with multiproduct continuous production which efficiently serve the supply chain and lower investment risks [

30,

31,

32,

33] in smart factories [

34]. Plant flexibility is a key issue in this context [

35,

36,

37]. The impact of these potential small-scale production solutions on investment costs has to be low in order to overcome economies of scale [

38,

39,

40,

41,

42]. At the same time, so far unsolved questions concerning planning methodologies [

43,

44,

45], information technologies [

44], safety aspects [

46], and business models [

47] have to be further developed.

The approach of a transformable plant being based on modular small-scale production units can help to increase all relevant types of flexibility discussed (capacity flexibility, product flexibility, and location flexibility). However, a successful operation of a modular plant is depending on suitable apparatuses. But the named flexibility types are not only challenging small-scale production sites but also large-scale plants as indicated in

Figure 2. Therefore, within this article, a differentiation between small-scale, technical-scale, and large-scale is carried out representing the above mentioned evaluation of plant size along the value chain.

3. Transformable Production Concepts

Transformable, modular production as a new production paradigm is striving for flexibility, rapid re-configurability, and standardization. In recent years, prototypes of such manufacturing equipment have been built and proven to be technically feasible (for example F

3-Factory project). These prototypes are smaller production units (e.g., in standard ISO-containers), which are modular and scalable in order to produce the desired quantity of product adjusted to the current demand. Due to their smaller size compared to conventional systems, investment risks decrease and the production can follow market dynamics in time and space with a rapid reconfiguration of the inherent modular units of such systems as apparatuses [

48]. At the same time, development and planning times as well as efforts are drastically reduced because tedious scale-ups for large-scale plants are no longer necessary due to smaller equipment sizes and standardization. Times to market for new products, as an answer to rapid changes in market demands, can be halved [

49].

Flexibility regarding capacity is reached by scalability and compatibility in addition to modularity. Scaling by numbering-up or numbering-down offers the chance to produce the current demanded product quantities without over-dimensioning the initial production plant. Thus, capital costs decrease in spite of working against economies of scale. Modules already applied and no longer required, as a result of market decrease, can be re-used for other purposes if sufficiently standardized.

Flexibility regarding different products is given by universality and compatibility in addition to modularity. Thus, a quick and effortless reconfiguration of the production system offers the possibility to produce the product, which has the highest contribution margins momentarily. Especially in the multi-purpose environment for specialties, this goes along with a change from discontinuous batch processes to autonomous continuous processes coming along with modular, small-scale production. Thereby, the economic production of very small lot sizes with an easy reconfiguration of the modular production system is introduced. This contributes to the realization of the lean-manufacturing paradigm in the process industry. In this way, a higher number of product variations can be produced in the same time.

Anyway, a change from one product to a new one, even if it is chemically related, is associated with a high effort regarding the apparatuses and their instrumentation. A change in product mostly comes with a change of the reactor configuration at least a change of the catalyst becomes necessary. The same is true for the design parameters of downstream processing units. Separations columns might be equipped with more or less stages or equipped with other packings or tray configurations. Lastly, it has to be addressed that there might be a change in operation conditions leading to new challenges or configurations regarding process and utility integration. Altogether, this leads to the fact that process design methods for product flexibility have to be developed in further research steps to cope with those obstacles.

Flexibility regarding location is reached by mobility and compatibility in addition to modularity. This flexibility type is generally desirable as demand shifts can be tracked regionally. Due to the new possibilities of decentralized production close to the customer, reactions to amount or other variations can take place just in time with shorter response and delivery times, resulting in higher service levels [

50].

A production plant that possesses high flexibility in location is able to carry out the production in direct proximity to the customer. Thus, transportation and storage costs and efforts for the products are reduced, which is especially beneficial if the product is classified hazardous. The same benefits apply on the raw material side if the production is placed towards raw material locations. In the best case, production can be placed at locations where raw material and final product production come together. In this case, transportation efforts are reduced to a minimum.

In research and industry, several designs are present; however, they do not combine all of the enablers. Thus, innovative designs vary in their degree of transformability and target different purposes. A morphology for defining and describing each transformable design in process industry and determining its degree of transformability as well as a potential analysis model for this has been developed by Wörsdörfer et al. [

51,

52].

In order to meet the challenges which have been described in the introduction, there is a need for flexibility and transformability on both levels of the production system: the plant and its apparatuses. Therefore, the transformable production concepts introduced contain flexible apparatus concepts, in which components of these apparatuses are set up modular as well to increase flexibility.

4. Flexible Apparatus Concepts

As shown in the previous section the approach of transformable, flexible, and modular production processes can be one possible solution to enhance flexibility in chemical industry. Additionally, this approach is more beneficial for processes with high customer proximity and thus comparably low throughputs (e.g., production of fine and specialty chemicals). Nonetheless, a successful implementation is based on the availability of suitable apparatus concepts. This is also valid for large-scale processes being at the beginning of the value chain. In this case, modular plants have disadvantages due to the economies of scales. Thus, for large-scale processes other measures are necessary to enhance the flexibility of the overall process. These measures can also be realized on apparatus level as discussed further in this section.

However, operation ranges of conventional apparatuses for chemical conversion and thermal separation do often limit the flexibility [

53]. This limitation of operation range becomes even more important with unit operations having complex hydrodynamic interactions at the interface between gas and liquid phase. Important unit operations characterized thereby are absorption and distillation. Nonetheless, it is necessary to mention that the problem definition is equivalent for apparatuses for chemical conversion involving free interfaces. Due to the high complexity in the design and operation of those reactors (e.g., bubble columns or trickle bed reactors), they are excluded here. Consequently, in the following parts of this article, we are focusing on the development of concepts to meet above mentioned arising challenges (see

Section 2) for absorption and distillation processes. This is enhancing flexibility regarding the range of feedstock as well as product and capacity flexibility for a wide range of plant sizes and throughput, respectively.

Compared to

Figure 2, the presented technical solutions regarding named unit operations are discussed in the opposite direction from the value chain indicated there. Thus, starting with solutions suitable for plants with small size and high customer proximity and ending with solutions for large-scale plants having a high energy and raw material demand. First, in

Section 4.1 concepts for small-scale applications are presented. Those concepts are mostly based on micro-structured devices being able to produce only small amounts of products and are predominately inspired by modular equipment developed for micro-reaction technology. In

Section 4.2, concepts for technical-scale are presented which are inspired by already existing modular equipment like plate heat exchangers. In addition, in

Section 4.3 and

Section 4.4 possibilities to transform existing strategies to conventional large-scale equipment are discussed. Those strategies include the implementation of transformability for the design of distillation columns for multi-purpose applications and the segmentation of large-scale columns to enhance capacity flexibility.

4.1. Flexibility by Modular, Small-Scale Apparatus Concepts with Examples from Absorption and Distillation

Examples for lab concepts, which represent mostly solutions on micro- and milli-scale for large-scale problems are well-known, especially for chemical reaction technology. For example, Löb et al. [

54] describe a micro bubble column in which a segmentation of the gas–liquid flow enables the performance of a multiphase reaction in micro-structured channels. Vankayala et al. [

55] present a falling film reactor that is scalable from lab to pilot scale by a duplication of the falling film principle therefore allowing mass transfer at a free phase boundary. Roberge et al. [

56] give an example for scalability and present a reactor that is expandable in reaction volume according to throughput. Those micro reactors do have in common that a scaling regarding production volume is performed by numbering-up single channels or units to enhance production rates.

Kockmann [

57] describes the principle of fully scalable, micro-structured tubular or channel reactors to close the gap in production rates between lab-on-chip devices and conventional equipment (batch reactors, PFR’s (Plug Flow Reactor) or CSTR’s (Continuously Stirred Tank Reactor)). Anyway, it did not take into account that not all reactors are suitable for all types of reactions. In addition to this, Roberge et al. [

58,

59] show the economic benefits of the implementation of those concepts in the production of fine chemicals and pharmaceuticals. Other examples for micro-reaction engineering can be found in several reviews [

21,

22,

23,

24,

25,

26]. Subsequently, some of the concepts presented in this section for absorption and distillation are adopted from concepts for micro-reaction engineering.

From literature it can be concluded that micro-separation technologies are not evolved in the same manner than micro-reaction technologies [

59,

60,

61]. Nevertheless, there are some experimental examples to facilitate absorption and distillation processes within micro-structured devices.

The experimental studies on micro-structured apparatuses for absorption are classified in devices containing membranes or microchannels. Those two types of devices differ in the structure of the phase boundary between gas and liquid. In membrane contactors, a defined fixed phase boundary is installed between gas and liquid flow, while both phases are in free contact when microchannels are used.

Constantiou et al. [

62] present a metal mesh micro-structured absorption apparatus, which can be classified as membrane contactor. The advantage of membrane contactors is the defined mesh between the two phases for stabilization of the gas–liquid interface. The experiments show high absorption rates of CO

2 in NaOH. Due to the small geometries of the device, liquid flow rates were in the range of 1.5 to 2.5 mL/min.

Another type of micro absorption device are microchannel devices. Yue et al. [

63] give insights about hydrodynamics and mass transfer characteristics in a microchannel system with concurrent gas–liquid flow. The experiments were mostly performed in the slug flow or slug–annular flow regime. Apart from pressure drop the authors also measured mass transfer coefficients, which are identified to be at least one order of magnitude higher than in conventional gas–liquid mass transfer devices.

In addition to solely micro-structured channels to perform absorption, the devices can further be classified with respect to the applied measures for temperature control. Apart from using an external heat exchanger for temperature control, it is also possible to integrate temperature control within the apparatus. This operation mode is called heat pump system and is realized by a hot and a cold side within the apparatus. Due to the different temperature levels on both sides of the device, gas and liquid flow is facilitated. One example for this principle is given by TeGrotenhuis et al. [

64]. The micro apparatus presented is operated according to the wick principle and is originally designed for heat transfer applications. Inside the apparatus is the wick with a diameter of 0.1–0.5 mm in which the liquid phase flows. Below the wick there is a channel for the gas phase. The mass transfer takes place along the wick. Since the micro apparatus was originally used for heat transfer, there is another separate channel for heat supply or removal below the active separation channels. Ammonia and water is used as the material system to investigate mass transfer efficiency. Scale-up experiments with up to 18 channels were carried out. The heat pump principle is also taken up by Drost et al. [

65] who designed a micro contactor in which diffusion is enhanced by a temperature gradient.

Similar principles also apply to micro distillation technologies: heat-pipe type, falling film technologies, membrane contactor, conventional microchannels, or rotating spiral microchannels. Soek et al. [

66] published first research on a micro distillation technology in 1985. The developed zero-gravity distillation apparatus is designed as a horizontal heat-pipe type distillation device. Another example for heat-pipe type of micro distillation system is published by Sundberg et al. [

67] in which the countercurrent flow of gas and liquid is supported with capillary forces. Tonkovich et al. [

68] developed a miniature distillation column with a gravity and capillary separation principle that is designed as a falling film device. This micro column is based on a modular structure and numbering-up to six micro distillation assemblies is examined. Alternatively, micro distillation can be performed by using an additional membrane for phase separation and to provide a high specific area for mass and energy transfer between the phases. Devices based on this principle were developed by Adiche et al. [

69], Zhang et al. [

70], or Ziogas et al. [

71], whereas the latter is only developed for analytical and preparative applications only. In contrast to membrane assisted micro distillation, Lam et al. [

72] and Hartmann et al. [

73] examined distillation within horizontal microchannels. Different in separation principles and structure MacInnes et al. [

74] carried out studies on rotating spiral microchannel distillation. The separation principle is fundamentally different and uses centrifugal and Coriolis forces to maintain segregation of the phases depending on rotation rate and pressure.

Despite the large variety of the separation principle, all studies show the technical feasibility of absorption and distillation in micro-structured devices. Nevertheless, it is also important to realize sufficient throughputs for the implementation in chemical or pharmaceutical production. To get further insights on possible production rates, Dercks [

75] performed studies on the volumetric efficiency as a function of flow-rate for conventional technology, in this case a conventional packed column and micro-structured distillation devices. Increasing flow-rates were made possible by different channel heights of the micro-structured device. The results indicate that with increasing flow-rates, which might be necessary for higher production rates, the volumetric efficiency decreases dramatically and is, for equivalent flow-rates, close to the efficiency of a conventional packed column. This means that for an efficient operation with high flow-rates the number of parallel channels needs to be very high. With this need, some important disadvantages are associated. One consequence is a high specific material demand for construction and subsequently high costs per volume. Another aspect associated with numbering-up in multiphase separation devices are high requirements regarding an equal distribution of the gas and liquid phase to enable unique operation of all micro devices/channels to maintain high efficiencies of the overall apparatus.

Those drawbacks regarding the implementation of micro-structured devices on a technical-scale do not match with the vision of transformable production concepts described in

Section 3, even if numbering-up and numbering-down give possibilities for capacity flexibility. A lack of economic feasibility and achievable throughput for higher production rates leads to the fact that micro-scale separation devices are not implemented in modular arrangements so far [

60,

76,

77]. Additionally, as all presented concepts are lab devices without standardized interfaces which are also mandatory in a transformable and reconfigurable plant. This is why in the following section a modular absorption column for the implementation on technical-scale in transformable plants is presented.

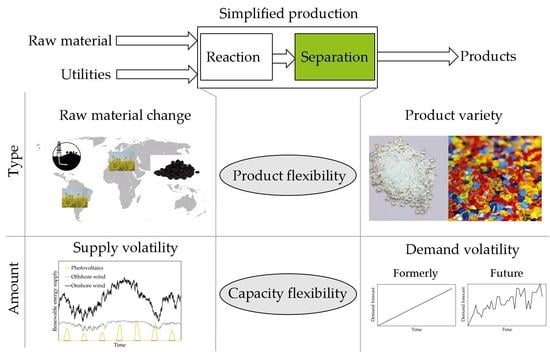

4.2. Flexibility by Modularization on Technical-Scale Shown within Absorption

Examples of concepts enabling high flexibility in technical-scale based on modularization are plate heat exchangers or the filter press, which represent established technologies [

78,

79,

80,

81,

82,

83]. Due to their easy scale-up and standardized interfaces those apparatuses can be described as highly modular. Their rectangular geometries include planar areas for the necessary interfaces between the modules. By connecting multiple modules, the capacity (parallel connection) or performance (serial connection) of the overall module system is increased.

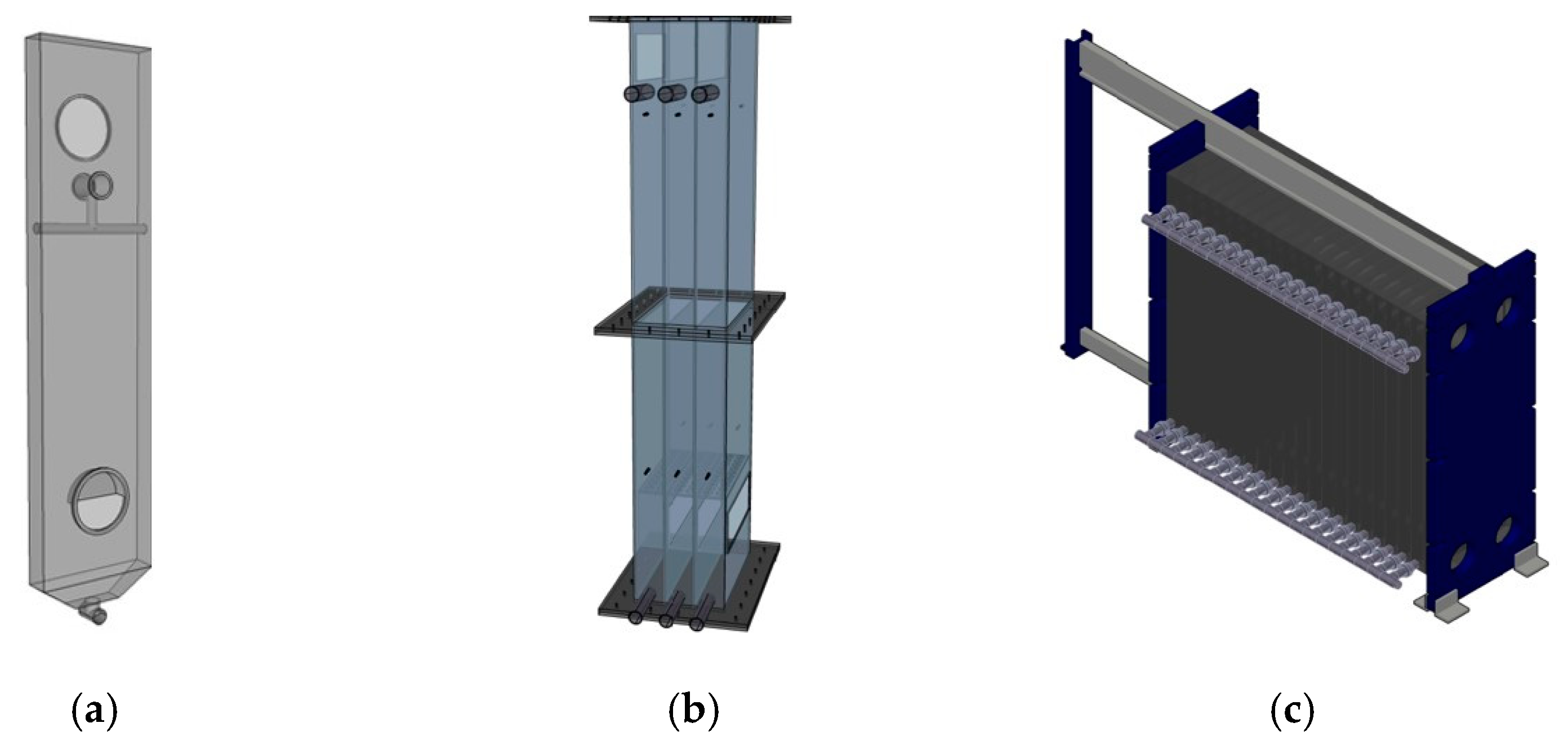

Müller et al. [

84] adopted those characteristics to develop a modular absorption column on the technical-scale in which more realistic flow-rates are possible than in presented micro devices. The overall concept is shown in

Figure 3 and it is important to notice that the initial scale of the module differs from the micro-scale concepts presented in

Section 4.1. One module has a width of 500 mm, a depth of 100 mm, and a height of 2000 mm. The concept shown in

Figure 3 allows an easy scale-up by numbering-up of the developed single module due to its inherent modular set-up [

85]. Experimental investigations on the characteristics have been carried out in terms of hydrodynamics and mass transfer efficiency with random and structured packings (Pall Ring 25 M/Raschig™ Super Pak 250) for the single module (

Figure 3a) and three modules operated parallel (

Figure 3b). A comparison between the module’s and conventional absorption columns performance showed the feasibility of this new concept [

84]. The vision of a fully modular construction of the overall absorption unit in a rack which is constructed for applications in filter presses or plate heat exchangers today is shown in

Figure 3c.

As stated above, the main advantage of modular apparatuses is the possibility of an easy scale-up by numbering-up of single units or modules. In this case, a parallel connection of modules leads to an enhancement of capacity or throughput, respectively. In contrast, a serial connection leads to an enhancement of mass transfer efficiency because the number of separation stages is increased. This is especially necessary, if the possible height of the single module is limited due to specific boundary conditions but a high number of separation stages is needed. Nonetheless, it has to be stated that a serial connection of the presented modules is associated with higher efforts for the interconnection. Those efforts include constructional aspects as well as higher needs for pumping to transport the fluid from the bottom of one module to the top of the next one. A placement of the modules on top of each other is related with a loss in movability as flexibility option for the whole concept.

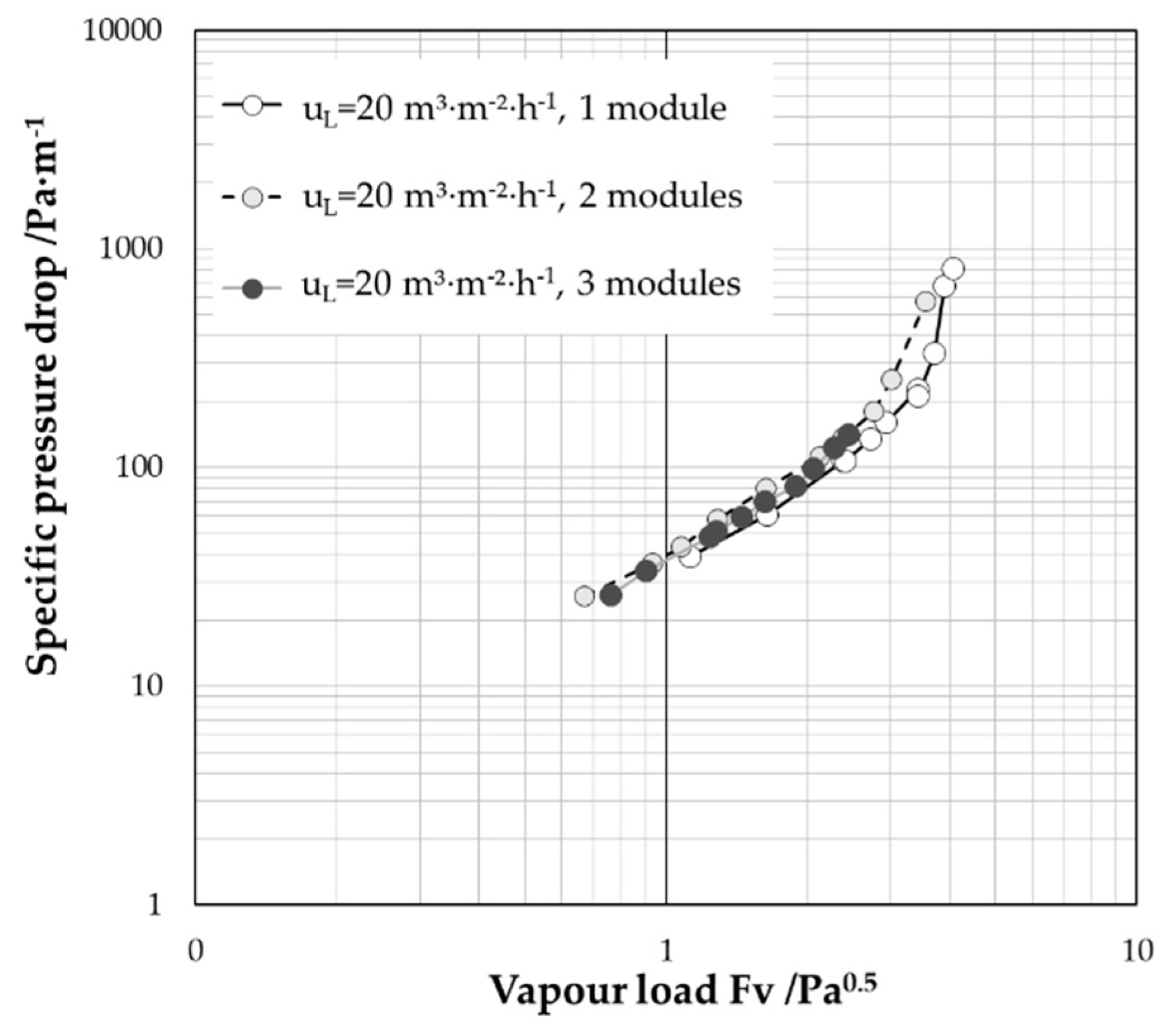

Anyhow, experimental studies with a parallel connection of the absorption module were performed to support the stated advantages in scale-up by numbering-up. Therefore, one, two, and three modules were operated in parallel and again hydrodynamics and mass transfer efficiency was evaluated.

Figure 4 shows the specific average pressure loss for a liquid load of 20° m

3·m

−2·h

−1 as a function of vapor load for the operation of one, two and three modules. This result indicates that by numbering-up of the modules a capacity expansion with identical hydrodynamic behavior of all operated modules is possible. More information regarding the experimental set-up and mass transfer efficiency can be found in [

87].

In summary, the modular, rectangular absorption column represents a promising approach for the implementation of a flexible multiphase unit into a transformable production system concerning capacity and mass transfer performance. An adaption of these parameters is realized by numbering-up. The challenge coming along with numbering-up modular devices in technical-scale is an equal feed flow and, subsequently, a unique phase distribution in every single module. Additionally, it is necessary to proof the principle for distillation processes, which are at least as important in chemical industry.

4.3. Product Flexibility of Distillation Columns for Multi-Purpose Applications

One important aspect of transformable plants is the paradigm of re-configurability [

3]. This is also important in the context of multi-purpose plants for the production of fine and specialty chemicals. Therefore, Staak et al. [

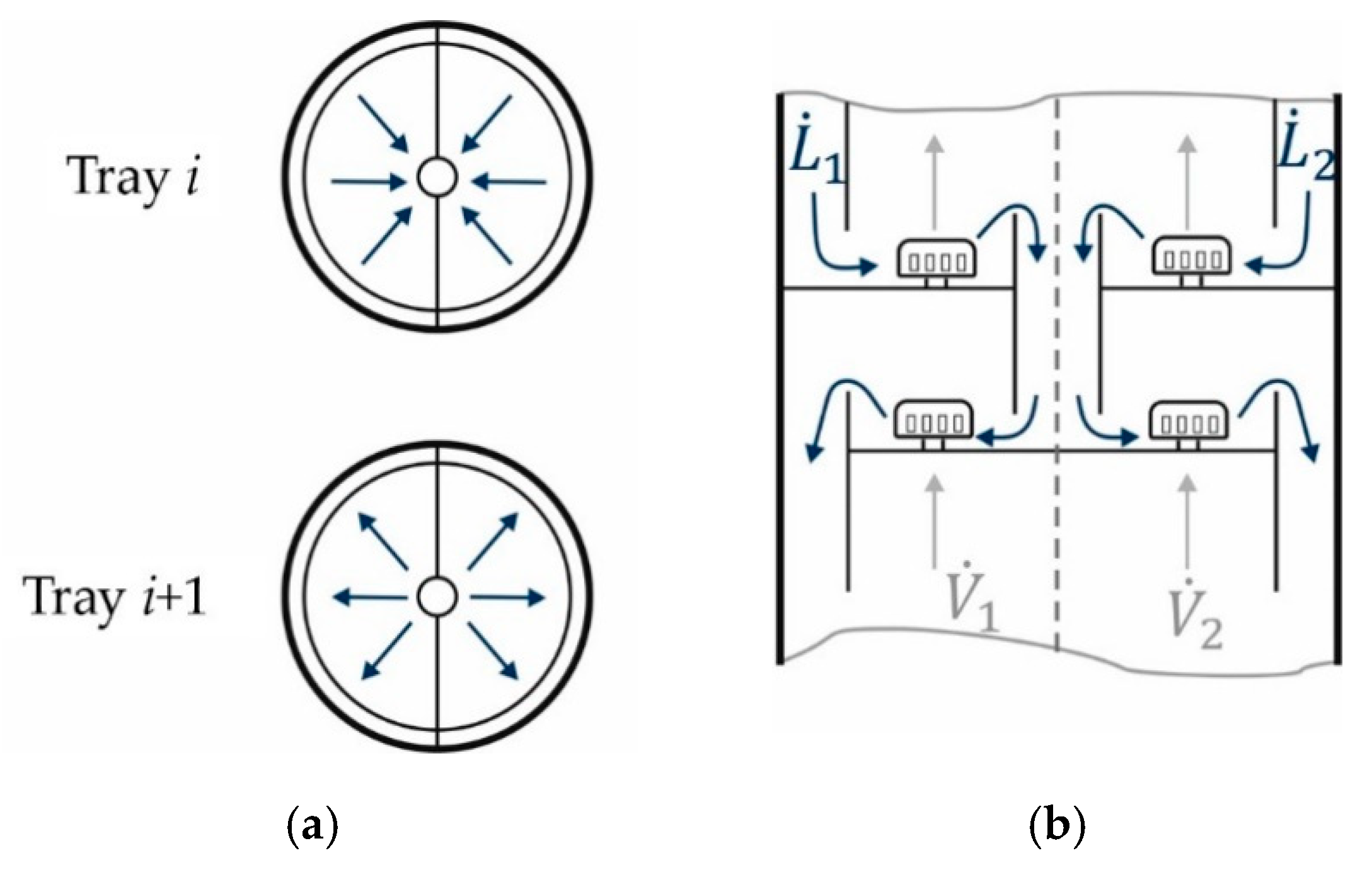

88] suggest the use of dividing wall columns (DWC) in a multi-purpose chemical plant to achieve fast an easy adoption to new production needs.

DWCs in principle enable the separation of multicomponent mixtures comprising three or more components with just one reboiler and condenser by installing one or more vertical walls within the column shell [

89]. Other more complex configurations are also possible. An overview regarding various configurations are available in [

89,

90].

Figure 5 gives a schematic representation of a divided-wall column for the separation of a three-component mixture.

The design approach of a DWC results in a more energy efficient separation of multicomponent mixtures with a reduction of energy costs of roughly 30% compared to direct or indirect coupled columns [

91]. Simultaneously, this column configuration leads to lower capital costs in the same order of magnitude as energy costs. More than 95% of installed DWCs are used for the separation of three-component mixtures. Other applications are azeotropic distillation, reactive distillation, or extractive distillation [

91]. A main disadvantage of DWCs is the complex design having more degrees of freedom than conventional columns. Moreover, an optimization is more complex in comparison to a direct coupled design where process variables can be optimized separately [

92]. The design of DWCs can lead to a high number of stages resulting in a high apparatus limiting the installation at specific sites [

90].

Regardless of these limitations, Staak et al. [

88] suggest the installation of DWCs in multi-purpose chemical plants with the aim to adopt to changing separation tasks. Therefore, some fundamental changes in the design of DWCs are proposed. Those changes include the utilization of a robust construction material to enhance resistance to corrosion by changing component mixtures. Furthermore, a manually operable liquid distributor should be installed in the column to enable flexible split fractions of the liquid above the dividing wall. This is necessary to adopt to changing operating parameter and e.g., purity specifications associated with a new separation task performed within the multi-purpose chemical plant. Finally, it is mandatory to change the position of the feed stage and the side draw over the height of the column to separate different multicomponent mixtures in one column consecutively [

88]. In addition to these requirements, it can also be important to adjust the placement of the dividing wall within the column. Nonetheless, this task is linked with a comparatively high effort than before mentioned requirements. Nonetheless, all those adjustments in the design and operation of a DWC make it possible to operate one column in a multi-purpose chemical plant, which was demonstrated by Staak et al. [

88]. They showed the operation of one column in for the production of three different products in a multi-purpose chemical plant within two years.

In connection with the discussion in

Section 2 follows that those redesigned and adoptable DWCs enhance the flexibility regarding the processing of various mixtures in one apparatus. For separation equipment, this can be interpreted as a way to enhance product flexibility in production scale. Anyway, this concept still has drawbacks regarding location flexibility and capacity flexibility. This is mostly due to a conventional, non-modular design of this apparatus, which limits its easy and flexible movability towards other production sites. The conventional design of distillation columns also limits the capacity flexibility with respect to hydrodynamic operating limits. Subsequently, this example shows a potential way to enable product flexibility in separation devices but a combination with other research approaches (e.g., demonstrated in

Section 4.2) is necessary to fully adapt to the presented changing boundary conditions in chemical production.

4.4. Capacity Flexibility of Distillation Columns by Segmentation of the Apparatus

The operation range and therefore the flexibility of conventional large-scale columns is limited by minimum and maximum gas and liquid loads, respectively. Those limits depend on design and operation parameter as well as the choice of column internals to enhance interfacial areas for heat and mass transfer. Kister [

93] gives a comprehensive description of the hydrodynamic limitations for tray columns and packed columns, respectively. With respect to throughput, those hydrodynamic limitations lead to low possible variations even if a bubble cap trays are used. Bubble cap trays have a comparably broad operation range [

94]. Therefore, with changing boundary conditions for the overall production process the design of distillation columns needs to be reconsidered. An enhancement of capacity flexibility can be achieved by a reduction of liquid holdup enabling lower gas and liquid loads as well as a safe operation of the column. An adaption of the apparatus with respect to throughput is conventionally performed by changing the diameter of the column with respect to internal gas and liquid volume flows. This can lead to very small diameters if the volume flows to be processed become very small.

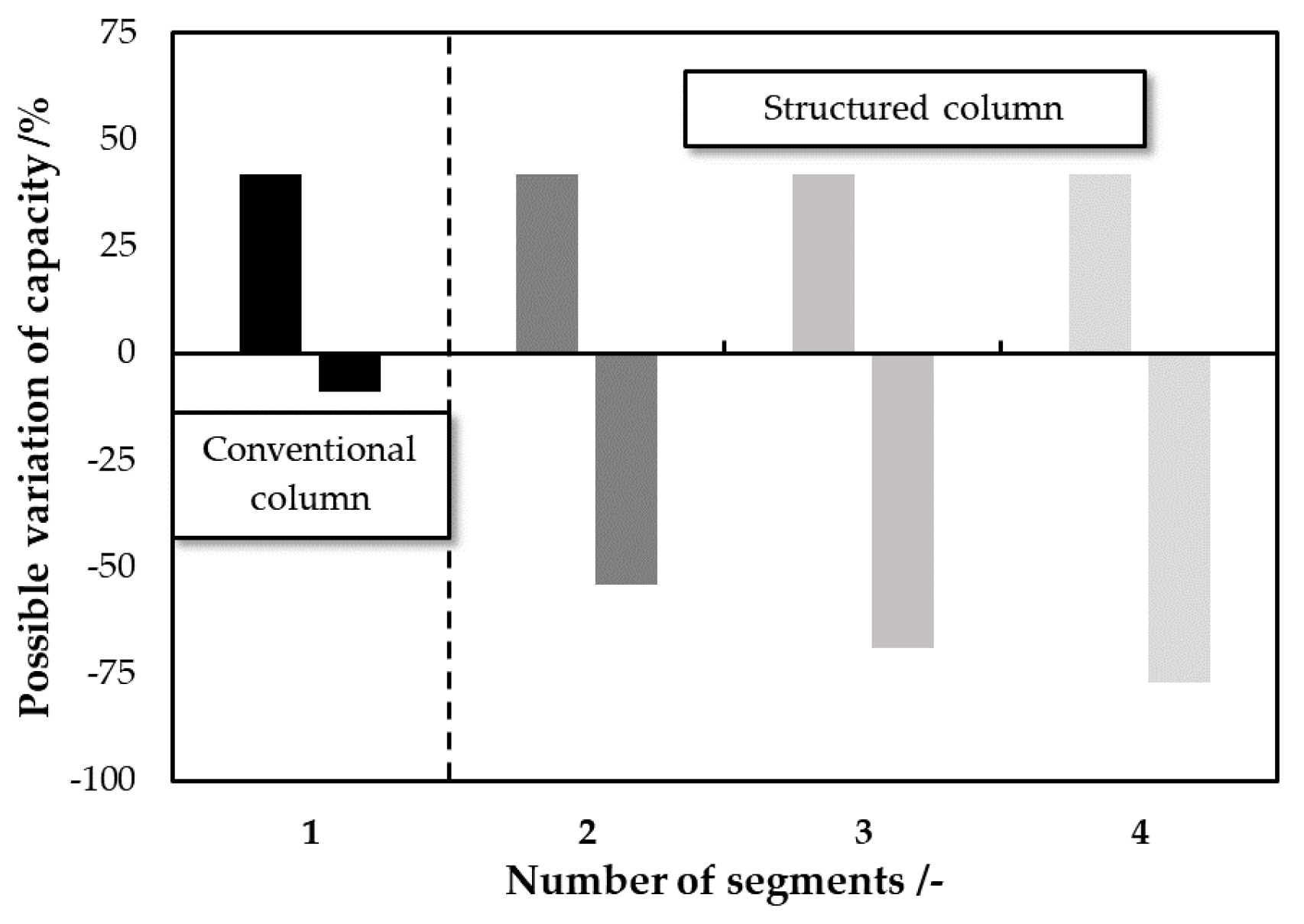

An alternative way to adopt to changing throughput and; therefore, to enhance capacity flexibility in a large-scale column is the internal segmentation of the apparatus. This is made possible by adopting and expanding the idea of a dividing wall within the column shell. The concept is illustrated in

Figure 6. Using one or more vertical partition walls along the total height of the column enables a segmentation of the apparatus leading to a minimum of two independently operable segments.

Figure 6 shows the concepts for two consecutive trays as a top (left) and side view (right). The grey dotted line indicates the partition wall along the total height of the column. In this case two segments are built-up within the column, leading to two separate liquid flows (

and

) and two vapor flows (

and

). In this example the liquid flows alternating from the exterior area of the tray to the center (tray

i), and from the center to the exterior area of the tray (tray

I + 1). These altering flow directions are known from radial flow trays.

This kind of segmentation has two major advantages. First, in comparison with, for example, a tangential flow direction of the liquid, the radial flow direction leads to a more uniform distribution of the liquid phase on the tray. This results in a more uniform residence time distribution [

96] and; therefore, acceptable separation efficiencies. Second, this approach allows the easy design of equiareal segments. Thus, each segment has comparable design parameters resulting in comparable operating limits.

Using a defined separation problem, the potential of this approach is evaluated with the help of steady state simulations using equilibrium stages in Aspen Plus

® [

87,

95]. The separation problem is defined by a feed of 10,000 kg·h

−1 containing 50 mole-% chlorobenzene and 50 mole-% ethylbenzene. For all scenarios, bubble cap trays are used as internals. The number of theoretical stages is set to 30 and the column is operated with a reflux ratio of 11.4 and a distillate to feed ratio of 0.5. This results in a column diameter of 3 m and an overall pressure drop of 0.21 bar. With this design and operating parameters, operation takes place at 66% of the liquid load for flooding, which is within the range of 50%–90% of the maximum liquid load. Without violating the operating limits, a variation in throughput is possible in the range between 91% and 142% around the design point.

To evaluate the above presented concept, a conventional column is divided into two, three, and four equiareal segments. In order to make comparison consistent the total active bubbling area is hold constant independent from the number of segments. Moreover, the operating parameters (e.g., feed quantity and composition, reflux ratio) and some design parameters (e.g., number of stages, feed stage) are constant as well. All other parameters are recalculated for each scenario. Due to performing rigorous simulation in Aspen Plus

® it is not possible to account for non-circular columns. Anyway, in each scenario examined a comparison is most reasonable at constant reflux ratio and constant total active bubbling area.

Figure 7 shows the variation of throughput within the optimal operation range for different number of segments in comparison to the conventional column.

With the assumption of constant active bubbling area, the upper bound of throughput variation is constant for all scenarios. The reason is that for maximum throughput within the possible operating range all segments are in use and the overall apparatus is subject to the same hydrodynamic limits as the conventional column without segmentation. In contrast, the lower bound of throughput variation is affected by the segmentation of the apparatus.

As it can be seen from

Figure 7, the higher the number of segments the higher the possible variation of throughput within the optimal operation range. The reason is that each segment can be operated in a steady state mode having characteristic upper and lower bounds in throughput variation. For each segment the minimum and maximum gas limits this variation and liquid loads for the specific design parameters of the bubble cap trays. For the considered scenarios, the load range of the continuous distillation can be enhanced from 51% (conventional column) to 119% (column with four segments). For all operating points within that load range, an optimal separation of the binary mixture can be expected at constant operation parameters.

Theoretically, the number of segments is unlimited making even smaller minimum throughputs possible. Nevertheless, from a constructional point of view this seems not expedient. The effort for construction and design gets even higher the higher the number of the segments is. Additionally, with even smaller active bubbling areas per segment, the use of bubble cap trays as internals is becoming harder to realize. This is due to the many design and operation parameters, which have to meet specific ranges to ensure optimal separation. Higher costs due to higher effort of design, construction and control can also be expected and have to be considered by choosing the maximum number of segments.

Concluding from the shown example, it is possible to enhance capacity flexibility in large-scale columns by an internal segmentation of gas and liquid flow in combination with an appropriate design of the internals. This approach is also subject of various patents from the last century [

87]. Nevertheless, the theoretical potential has to be proven experimentally. This means, not exclusively, the determination of operating ranges in a segmented column but also concerns questions related to suitable start-up procedures of single segments, the transfer of liquid from one segment to the other, or the study of fluid dynamics on the radial flow tray.

5. Conclusions

Production in the chemical industry is facing new challenges regarding uncertainties in the supply and costs of raw material and energy, as well as increasing needs for product variety and overall demand volatility. This results in new requirements regarding the flexibility of production processes to meet these challenges in terms of capacity, products, and location. Transformable, modular production as a new production paradigm and as an answer to these challenges is striving for flexibility, rapid re-configurability, and standardization. In recent years, prototypes of such manufacturing equipment have been built and proven technical feasibility.

Additionally, a successful operation of a modular plant is depending on suitable apparatuses. These apparatuses have to be able to meet above classified requirements meaning, inter alia, they have to be scalable regarding throughput while showing constant high performance. Within this article, a differentiation between the possible technical solutions for the unit operations absorption and distillation on small-scale, technical-scale, and large-scale is carried out. Already existing modular units illustrate that the concepts of flexible apparatus concepts can be divided into two different areas. On one hand, there are lab concepts, which represent mostly small-scale solutions for large-scale problems, and result in apparatuses having a superior performance but that are limited in throughput. On the other hand, there are established modular concepts, mostly in the technical- or industrial-scale, that can be transferred to separation tasks like absorption as well. This results in concepts that are easily scalable but also have a significant high throughput and performance for rapid integration in chemical production. In addition, there are solutions to enable product and capacity flexibility in large-scale applications. Those concepts are not categorized as modular concepts but they address some of the same enablers as for transformable plants.

Not always are all enablers of transformability and all dimensions of flexibility necessary. Depending on the requirements, only capacity, only product, or only location flexibility, or a combination of them, is necessary. The scale is also dependent on the requirements of application. In some cases, small-scale (e.g., micro-or milli process engineering), in other cases medium technical-scale (e.g., modular absorption), and in some large-scale (e.g., segmentation of conventional apparatuses) is needed.

Regardless of the defined scope of application, this overview on available solutions shows that there is further need to develop and analyze apparatuses that enable a flexible operation of chemical processes on various scales. This is not only valid for the presented unit operations and not limited to separation technology.