Simulation for the Performance and Economic Evaluation of Conventional Activated Sludge Process Replacing by Sequencing Batch Reactor Technology in a Petroleum Refinery Wastewater Treatment Plant

Abstract

1. Introduction

2. Materials and Methods

2.1. Case Study and Influent Wastewater

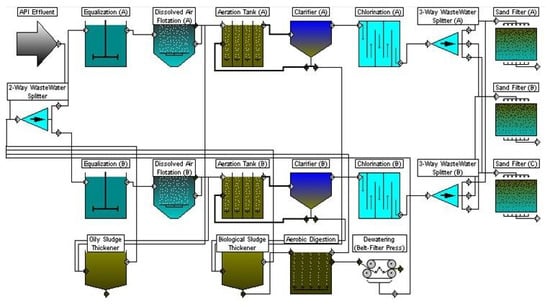

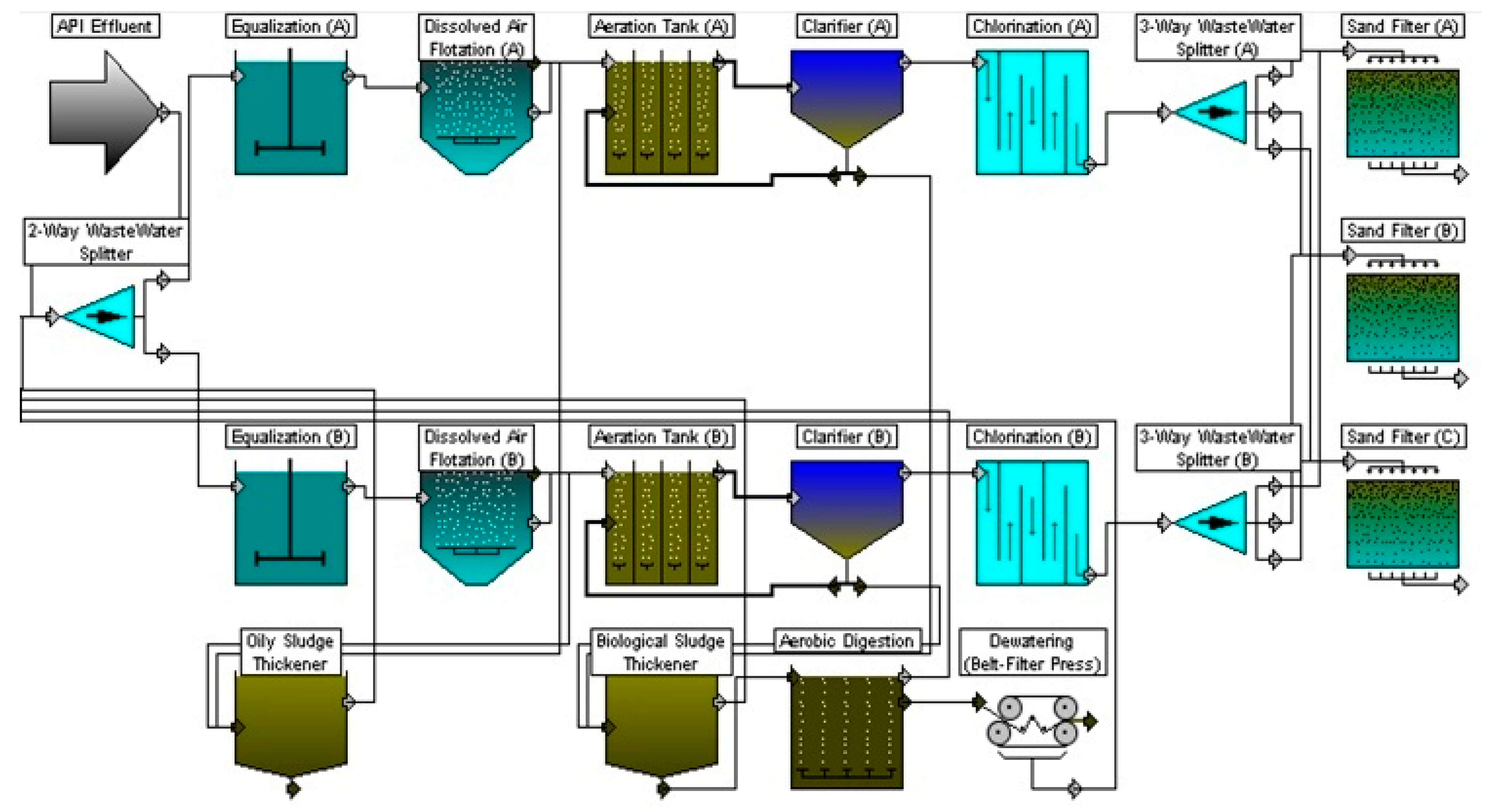

2.2. PRWWTP Containing CAS Process

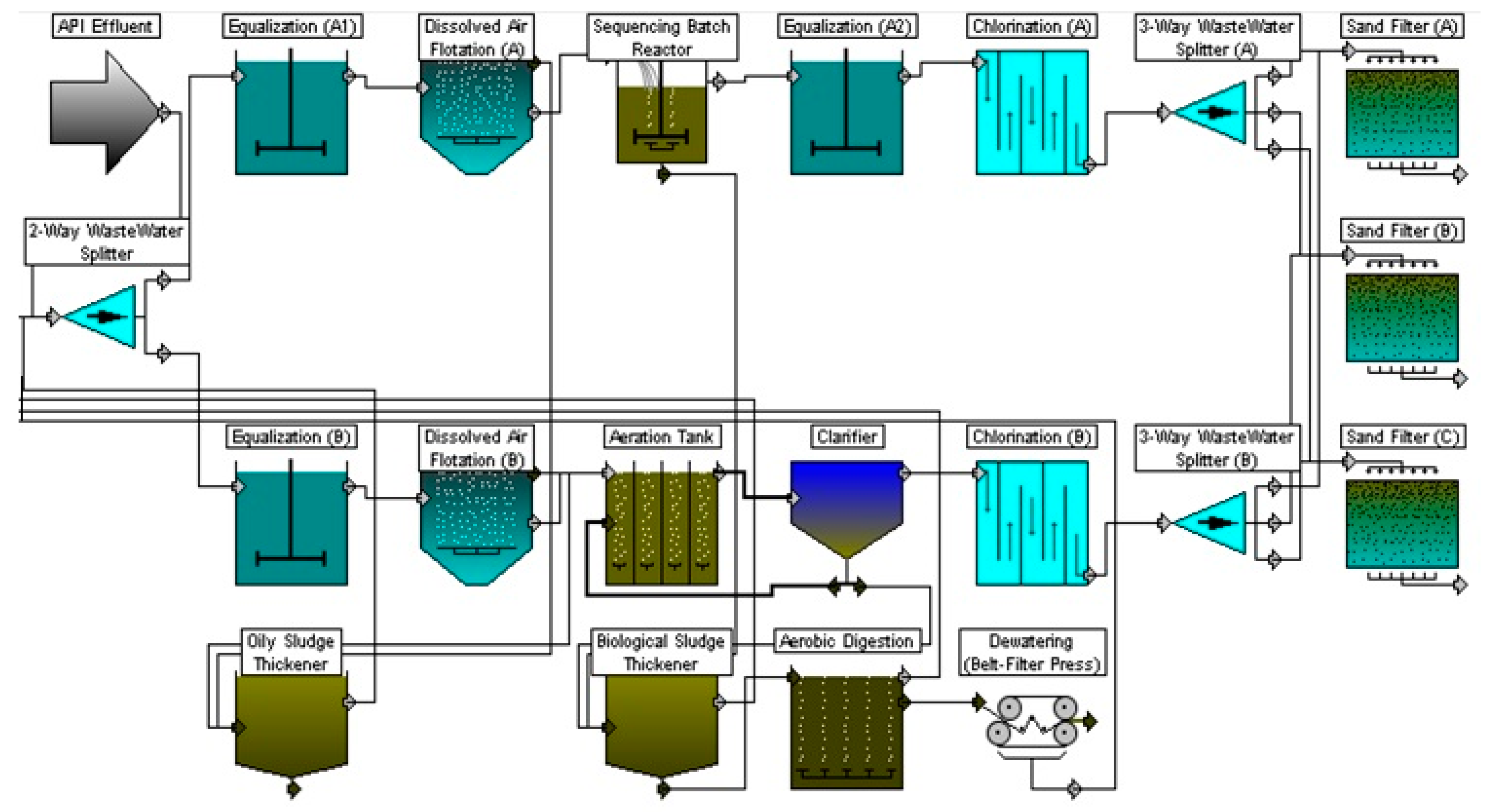

2.3. PRWWTP Containing SBR Process

2.4. Simulation Methods

- (i)

- Introduction of two additional growth processes, one for the autotrophic organisms and one for the heterotrophic organisms;

- (ii)

- Use of the temperature-dependent kinetic parameters by Arrhenius equation [26].

- (iii)

- Introduction of aerobic denitrification in the model according to the Münch modification [40].

3. Results and Discussion

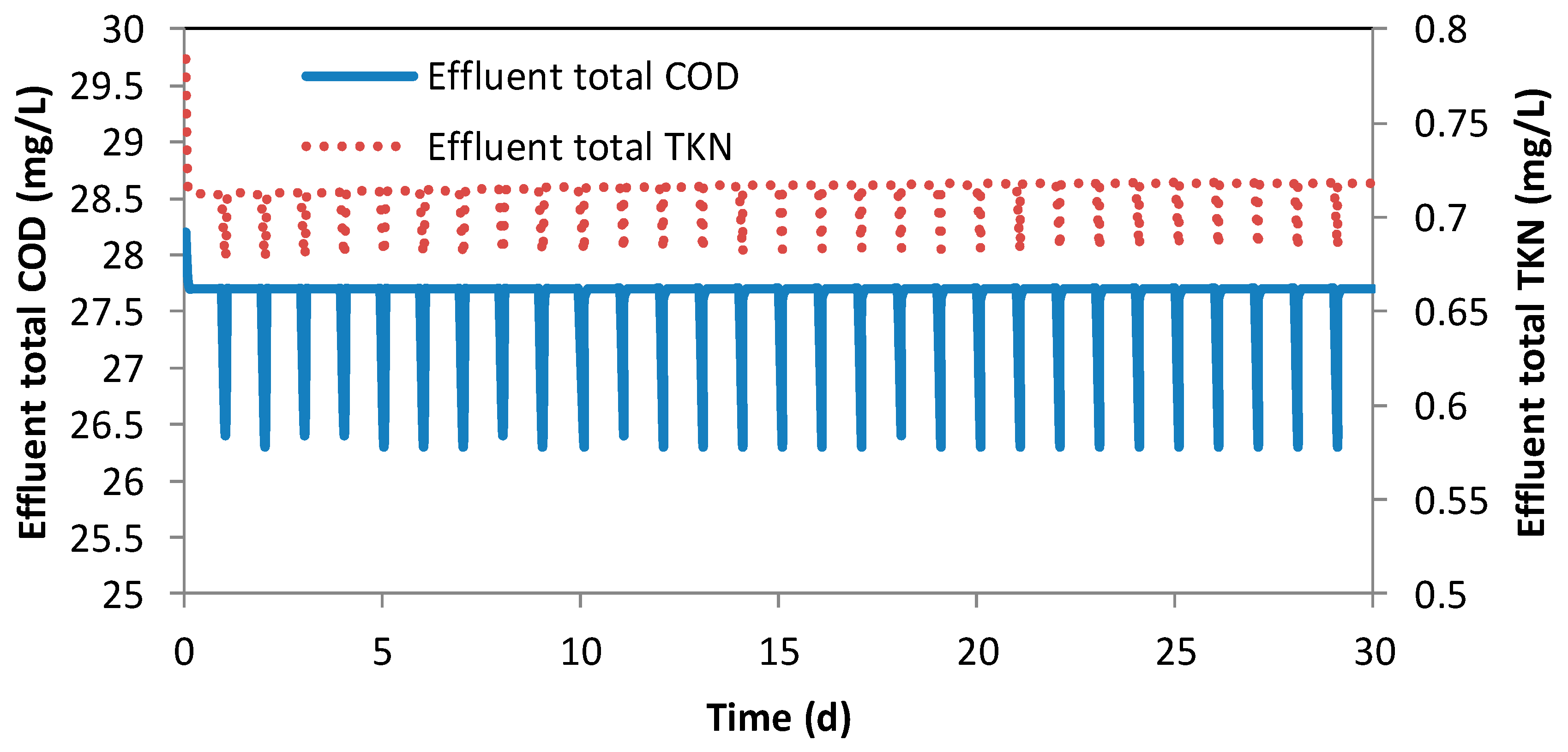

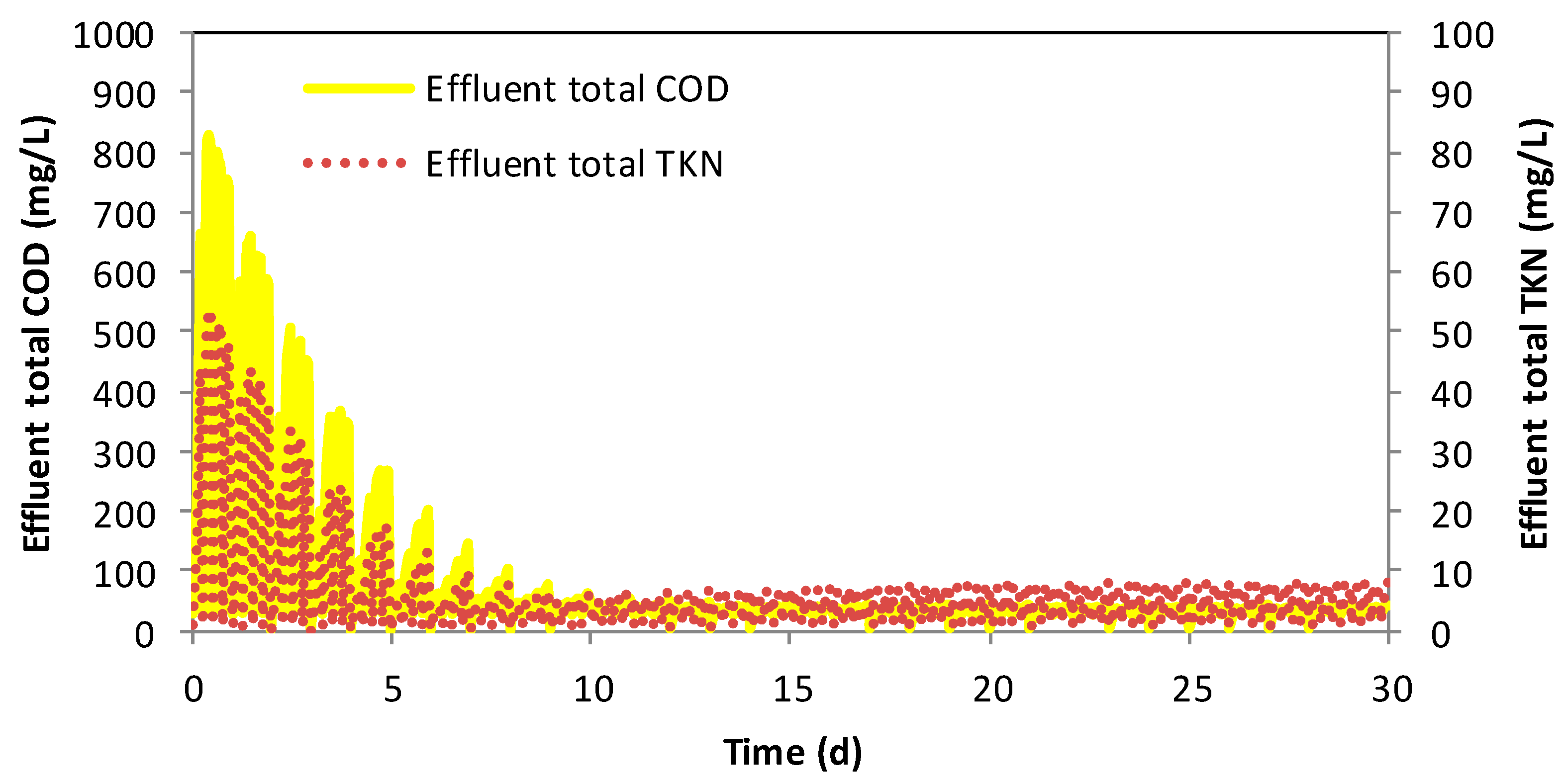

3.1. Performance Comparison of the PRWWTPs Containing CAS + CAS and SBR + CAS Processes

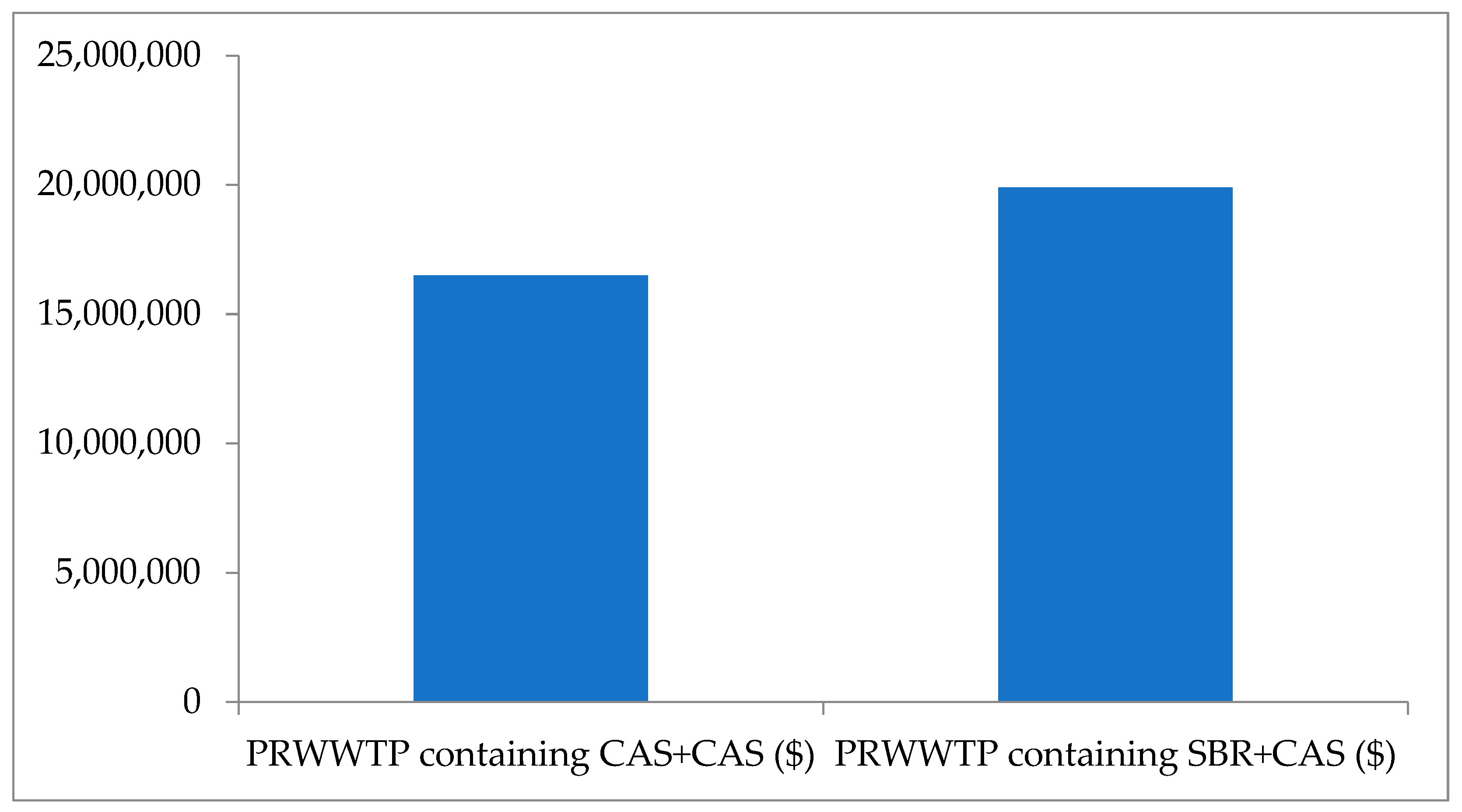

3.2. Economic Comparison of the PRWWTPs Containing CAS + CAS and SBR + CAS Processes

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Jafarinejad, S. Control and treatment of sulfur compounds specially sulfur oxides (SOx) emissions from the petroleum industry: A review. Chem. Int. 2016, 2, 242–253. [Google Scholar]

- Jafarinejad, S. Odours emission and control in the petroleum refinery: A review. Curr. Sci. Perspect. 2016, 2, 78–82. [Google Scholar]

- Jafarinejad, S. Petroleum Waste Treatment and Pollution Control, 1st ed.; Elsevier/Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Jafarinejad, S. Recent developments in the application of sequencing batch reactor (SBR) technology for the petroleum industry wastewater treatment. Chem. Int. 2017, 3, 241–250. [Google Scholar]

- Jafarinejad, S. Activated sludge combined with powdered activated carbon (PACT process) for the petroleum industry wastewater treatment: A review. Chem. Int. 2017, 3, 268–277. [Google Scholar]

- Beychock, M.R. Aqueous Wastes from Petroleum and Petrochemical Plants; John Wiley & Sons: London, UK, 1967. [Google Scholar]

- Santos, B.; Crespo, J.G.; Santos, M.A.; Velizarov, S. Oil refinery hazardous effluents minimization by membrane filtration: An on-site pilot plant study. J. Environ. Manag. 2016, 181, 762–769. [Google Scholar] [CrossRef]

- Tyagi, R.D.; Tran, F.T.; Chowdhury, A.K.M.M. Biodegradation of petroleum refinery wastewater in a modified rotating biological contactor with polyurethane foam attached to the disks. Water Res. 1993, 27, 91–99. [Google Scholar] [CrossRef]

- Ghorbanian, M.; Moussavi, G.; Farzadkia, M. Investigating the performance of an up-flow anoxic fixed-bed bioreactor and a sequencing anoxic batch reactor for the biodegradation of hydrocarbons in petroleum-contaminated saline water. Int. Biodeterior. Biodegrad. 2014, 90, 106–114. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (US EPA). Profile of the Petroleum Refining Industry; EPA Office of Compliance Sector Notebook Project; EPA/310-R-95-013; Office of Compliance, Office of Enforcement and Compliance Assurance; U.S. Environmental Protection Agency: Washington, DC, USA, September 1995.

- Benyahia, F.; Abdulkarim, M.; Embaby, A.; Rao, M. Refinery wastewater treatment: A true technological challenge. In Proceedings of the Seventh Annual U.A.E. University Research Conference, Al Ain, UAE, 22–24 April 2006. [Google Scholar]

- IPIECA. Petroleum Refining Water/Wastewater Use and Management; IPIECA Operations Best Practice Series; IPIECA: London, UK, 2010. [Google Scholar]

- European Commission; Joint Research Center. Best Available Techniques (BAT) Reference Document for the Refining of Mineral Oil and Gas, Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); Joint Research Center, Institute for Prospective Technological Studies Sustainable Production and Consumption Unit European IPPC Bureau R: Brussels, Belgium, 2013. [Google Scholar]

- Goldblatt, M.E.; Gucciardi, J.M.; Huban, C.M.; Vasconcellos, S.R.; Liao, W.P. New Polyelectrolyte Emulsion Breaker Improves Oily Wastewater Cleanup at Lower Usage Rates; Technical Paper, GE Water and Power, Water & Process Technologies; General Electric Company: Boston, MA, USA, 2014; pp. 1–6. [Google Scholar]

- Environmental Protection Agency (EPA). Waste Water Treatment Manuals, Primary, Secondary and Tertiary Treatment; Environmental Protection Agency: Wexford, UK, 1997.

- Isha, S.; Malakahmad, A.; Isa, M.H. Refinery wastewater biological treatment: A short review. J. Sci. Ind. Res. 2012, 71, 251–256. [Google Scholar]

- Pajoumshariati, S.R.; Bonakdarpour, B.; Zare, N.; Ashtiani, F.Z. The effect of hydraulic retention time on the performance and fouling characteristics of membrane sequencing batch reactors used for the treatment of synthetic petroleum refinery wastewater. Bioresour. Technol. 2011, 102, 7692–7699. [Google Scholar]

- Mohan, S.V.; Prakasham, R.S.; Satyavathi, B.; Annapurna, J.; Ramakrishna, S.V. Biotreatability studies of pharmaceutical wastewaters using an anaerobic suspended film contact reactor. Water Sci. Technol. 2001, 43, 271–276. [Google Scholar] [CrossRef]

- Mohan, S.V.; Sharma, P.N. Pharmaceutical wastewater and treatment technologies. Pharma Bio World 2002, 11, 93–100. [Google Scholar]

- Mohan, S.V.; Rao, N.C.; Prasad, K.K.; Madhavi, B.T.V.; Sharma, P.N. Treatment of complex chemical wastewater in a sequencing batch reactor (SBR) with an aerobic suspended growth configuration. Process. Biochem. 2005, 40, 1501–1508. [Google Scholar] [CrossRef]

- Wang, L.K.; Hung, Y.T.; Lo, H.H.; Yapijakis, C. Waste Treatment in the Process Industries; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2006. [Google Scholar]

- Hudson, N.; Doyle, J.; Lant, P.; Roach, N.; de Bruyn, B.; Staib, C. Sequencing batch reactor technology: The key to a BP refinery (Bulwer Island) upgraded environmental protection system—A low cost lagoon based retrofit. Water Sci. Technol. 2001, 43, 339–346. [Google Scholar] [CrossRef]

- Mohr, K.S.; Veenstra, J.N.; Sanders, D.A. Refinery wastewater management using multiple angle oil-water separators. In Proceedings of the International Petroleum Environment Conference, Albuquerque, NM, USA, 20 October 1998. [Google Scholar]

- Jafarinejad, S. Cost estimation and economical evaluation of three configurations of activated sludge process for a wastewater treatment plant (WWTP) using simulation. Appl. Water Sci. 2017, 7, 2513–2521. [Google Scholar] [CrossRef]

- Korniluk, M.; Montusiewicz, A.; Piotrowicz., A.; Lagod, G. Simulation of wastewater treatment systems with membrane separation. Proc. ECOpole 2008, 2, 41–45. [Google Scholar]

- Hydromantis Inc. GPS-X Technical Reference; Hydromantis Inc.: Hamilton, ON, Canada, 2011. [Google Scholar]

- Nasr, M.S.; Moustafa, M.A.E.; Seif, H.A.E.; El Kobrosy, G. Modelling and simulation of German BIOGEST/EL-AGAMY wastewater treatment plants-Egypt using GPS-X simulator. Alex. Eng. J. 2011, 50, 351–357. [Google Scholar] [CrossRef]

- Abdel-Kader, A.M.; Aljefry, M.H.; Eladawy, S.M. Studying the effects of alum, Lime and ferric chloride on the treatment efficiency of rotating biological contactors plant. In Proceedings of the 13th International Conference on Environmental Science and Technology, Athens, Greece, 5–7 September 2013. [Google Scholar]

- Lester, J.N.; Soares, A.; San Martin, D.; Harper, P.; Jefferson, B.; Brigg, J.; Wood, E.; Cartmell, E. A novel approach to the anaerobic treatment of municipal wastewater in temperate climates through primary sludge fortification. Environ. Technol. 2009, 30, 985–994. [Google Scholar] [CrossRef] [PubMed]

- Beck, C.; Prades, G.; Sadowski, A.G. Activated sludge wastewater treatment plants optimisation to face pollution overloads during grape harvest periods. Water Sci. Technol. 2005, 51, 81–88. [Google Scholar] [CrossRef][Green Version]

- Mannina, G.; Viviani, G. Hybrid moving bed biofilm reactors: An effective solution for upgrading a large wastewater treatment plant. Water Sci. Technol. 2009, 60, 1103–1116. [Google Scholar] [CrossRef]

- El Monayeri, O.D. Comparative study to assess the performance of an integrated treatment system using ANN vs. GPS-X. Int. J. Appl. Eng. Res. 2016, 11, 5604–5609. [Google Scholar]

- Mikosz, J. Determination of permissible industrial pollution load at a municipal wastewater treatment plant. Int. J. Environ. Sci. Technol. 2015, 12, 827–836. [Google Scholar] [CrossRef]

- Pereira, S.F. Modeling of a Wastewater Treatment Plant Using GPS-X. Master’s Thesis, Faculdade de Ciências e Tecnologia, Departamento de Química, Universidade Nova de Lisboa, Lisbon, Portugal, 2014. [Google Scholar]

- Metcalf & Eddy. Wastewater Engineering, Treatment, Disposal and Reuse; Mc Graw—Hill Book Company: New York, NY, USA, 1991. [Google Scholar]

- United States Environmental Protection Agency (US EPA). Wastewater, Technology Fact Sheet: Sequencing Batch Reactors; U.S. Environmental Protection Agency, Office of Water: Washington, DC, USA, 1999; EPA 932-F-99-073.

- Dohare, D.; Meshram, R. Biological treatment of edible oil refinery wastewater using activated sludge process and sequencing batch reactors—A Review. Int. J. Eng. Sci. Res. Technol. 2014, 3, 251–260. [Google Scholar]

- Mahvi, A.H. Sequencing batch reactor: A promising technology in wastewater treatement. Iran. J. Environ. Health Sci. Eng. 2008, 5, 79–90. [Google Scholar]

- United States Environmental Protection Agency (US EPA). Wastewater, Technology Fact Sheet: Package Plants; U.S. Environmental Protection Agency, Office of Water: Washington, DC, USA, 2000; EPA 832-F-00-016.

- Münch, E.V.; Lant, P.; Keller, J. Simultaneous Nitrification and Denitrification in Bench-scale Sequencing Batch Reactors. Water Res. 1996, 30, 277–284. [Google Scholar] [CrossRef]

- World Bank Group. Environmental, Health, and Safety Guidelines Petroleum Refining. pp. 1–35. Available online: http://www.ifc.org/wps/wcm/connect/df09eb23-f252-4d08-ac86-db1972c781a7/2016-EHS+Guidelines+for+Petroleum+Refining+FINAL.pdf?MOD=AJPERES (accessed on 17 November 2016).

- Koyuncu, I. Effect of operating conditions on the separation of ammonium and nitrate ions with nanofiltration and reverse osmosis membranes. J. Environ. Sci. Health Part A 2002, 37, 1347–1359. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Mean influent flow (m3/d) | 3120 |

| Total COD (mg/L) | 550 |

| Soluble COD (mg/L) | 300 |

| Total BOD (mg/L) | 270 |

| Soluble BOD (mg/L) | 80 |

| Total suspended solids (TSS) (mg/L) | 231.5 |

| Volatile solids (%) | 75 |

| Average summer temperature (°C) | 38 |

| Average winter temperature (°C) | 10 |

| Total TKN (mgN/L) | 40 |

| Soluble TKN (mgN/L) | 28 |

| Ammonia (mgN/L) | 15 |

| Total phosphorus (mgP/L) | 8 |

| pH | 7.6 |

| Cations (mg/L) | 160 |

| Anions (mg/L) | 160 |

| Settleable solids (mL/L) | 10 |

| Oil and grease (mg/L) | 150 |

| Non-degradable fraction of VSS (%) | 40 |

| Parameter | Value |

|---|---|

| Process design | Carbon removal plus nitrification |

| Maximum volume | 1170 m3 |

| Tank width | 17 m |

| Tank depth | 4.05 m |

| Aeration method | Diffused air |

| Total air flow into aeration tank | 31,464 m3/d |

| Bubble size | Fine bubble |

| Alpha factor for oxygen transfer in wastewater | 0.5 |

| Beta factor for oxygen saturation in wastewater | 0.95 |

| Standard oxygen transfer efficiency | 30% |

| Maximum heterotrophic specific growth rate | 3.2 1/d |

| Heterotrophic decay rate | 0.62 1/d |

| Maximum autotrophic specific growth rate | 0.9 1/d |

| Autotrophic decay rate | 0.17 1/d |

| Biomass yield | 0.5 |

| Mixed liquor suspended solids (MLSS) | 1500 |

| Safety factor for calculated SRT | 1.5 |

| Parameter | Value |

|---|---|

| Filter bed depth | 1.2 m |

| Surface area | 15 m2 |

| Loading rate | 8 m3/(m2·h) |

| Approach velocity | 0.15 cm/s |

| Sixty percent finer size | 0.75 mm |

| Specific weight of sand | 2649.5 kg/m3 |

| Porosity of bed | 0.4 |

| Expanded depth | 1.52 m |

| Number of trough | 50 |

| Width of trough | 0.304 m |

| Underdrain depth | 0.304 m |

| Head loss in underdrain | 0.304 m |

| Operating depth of water above sand | 0.91 m |

| Height of trough from underdrain | 1.98 m |

| Backwash time | 10 min |

| Freeboard | 1.2 m |

| Number of layers | 1 |

| Coefficient of permeability in the layer | 5 |

| Porosity of layer | 0.4 |

| Particle diameter in the layer | 0.0007 m |

| Shape factor | 8.5 |

| Specific gravity of particles in the layer | 2.65 |

| Parameter | Value |

|---|---|

| Process design | Carbon removal plus nitrification |

| Surface area | 290 m2 |

| Maximum water level | 4.05 m |

| Feed point from bottom | 2 m |

| Number of mixers per SBR | 2 |

| Aeration method | Diffused air |

| Total air flow into aeration tank | 31,464 m3/d |

| Bubble size | Fine bubble |

| Alpha factor for oxygen transfer in wastewater | 0.5 |

| Beta factor for oxygen saturation in wastewater | 0.95 |

| Standard oxygen transfer efficiency | 30% |

| Maximum heterotrophic specific growth rate | 3.2 1/d |

| Heterotrophic decay rate | 0.62 1/d |

| Maximum autotrophic specific growth rate | 0.9 1/d |

| Autotrophic decay rate | 0.17 1/d |

| Biomass yield | 0.5 |

| Safety factor for calculated SRT | 1.5 |

| Mixing (and fill) time | 0.5 h |

| Aeration (and fill) time | 1.5 h |

| Aeration time (only) | 2 h |

| Settling time | 1.4 |

| Decant time | 0.5 |

| De-sludge time | 0.1 h |

| Process | Model |

|---|---|

| Equalization Tanks | Noreact |

| Coagulant addition | Chemeq |

| DAF | Simple1d |

| Aeration tanks or CAS process | Mantis |

| SBR process | Mantis |

| Secondary clarifiers | Simple1d |

| Chlorination | Empiric |

| Sand filters | Simple1d |

| Oily sludge thickener | Empiric |

| Biological sludge thickener | Empiric |

| Aerobic digestion | Mantisdig |

| Dewatering or belt-filter press | Press |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jafarinejad, S. Simulation for the Performance and Economic Evaluation of Conventional Activated Sludge Process Replacing by Sequencing Batch Reactor Technology in a Petroleum Refinery Wastewater Treatment Plant. ChemEngineering 2019, 3, 45. https://doi.org/10.3390/chemengineering3020045

Jafarinejad S. Simulation for the Performance and Economic Evaluation of Conventional Activated Sludge Process Replacing by Sequencing Batch Reactor Technology in a Petroleum Refinery Wastewater Treatment Plant. ChemEngineering. 2019; 3(2):45. https://doi.org/10.3390/chemengineering3020045

Chicago/Turabian StyleJafarinejad, Shahryar. 2019. "Simulation for the Performance and Economic Evaluation of Conventional Activated Sludge Process Replacing by Sequencing Batch Reactor Technology in a Petroleum Refinery Wastewater Treatment Plant" ChemEngineering 3, no. 2: 45. https://doi.org/10.3390/chemengineering3020045

APA StyleJafarinejad, S. (2019). Simulation for the Performance and Economic Evaluation of Conventional Activated Sludge Process Replacing by Sequencing Batch Reactor Technology in a Petroleum Refinery Wastewater Treatment Plant. ChemEngineering, 3(2), 45. https://doi.org/10.3390/chemengineering3020045