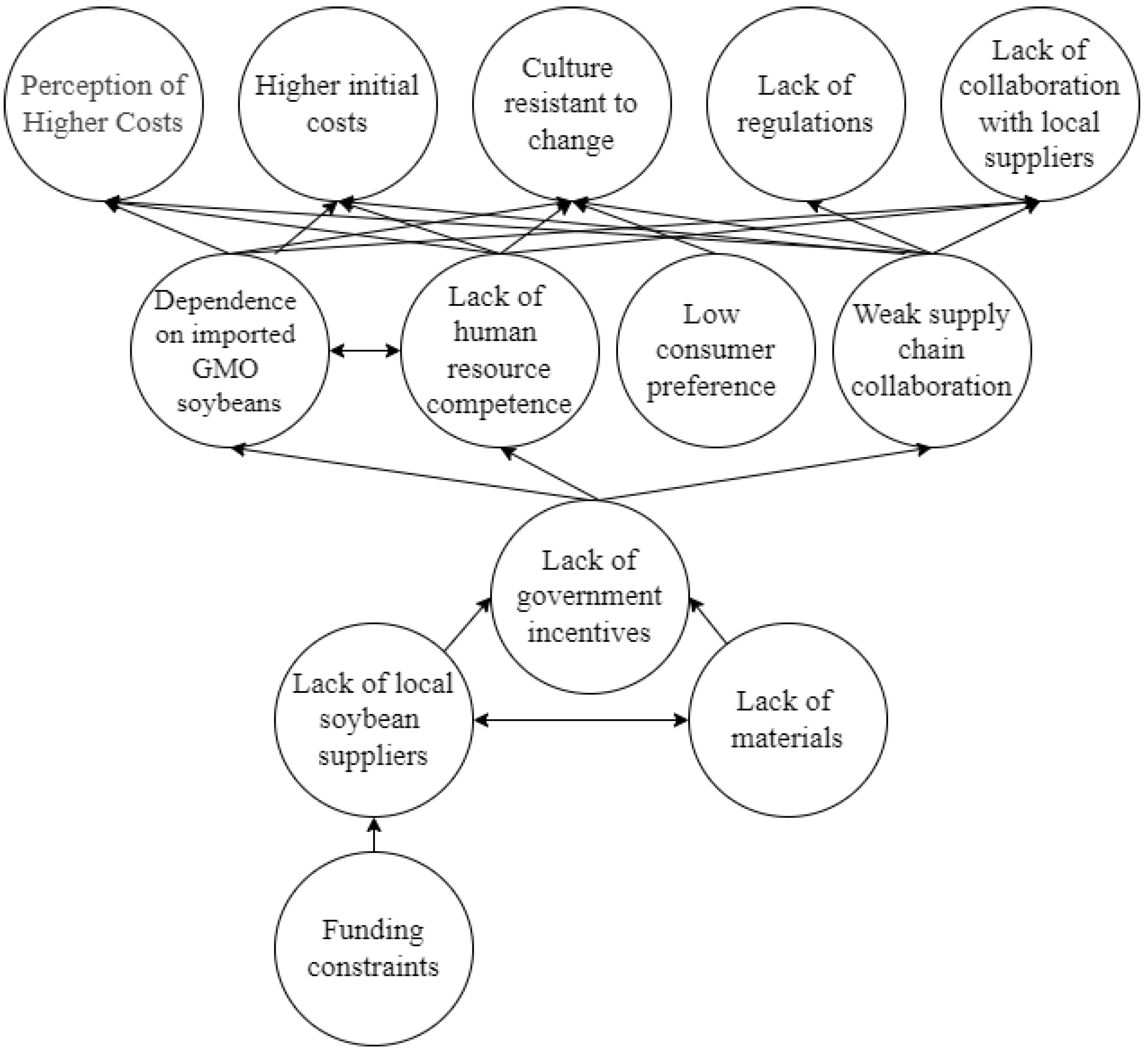

4.1. Identification of Key Barriers Through SP Performance Indicators

The identification of barriers to sustainable procurement in Indonesian food SMEs was conducted through a multi-stage, systematic process to ensure comprehensiveness and validity. The process commenced with an extensive literature review of peer-reviewed journals, conference proceedings, and reports on sustainable procurement, with a specific focus on SMEs and developing economies. This initial stage generated a comprehensive longlist of 23 potential barriers. To contextualize these findings and ensure their relevance to the Indonesian food manufacturing sector, semi-structured interviews and on-site observations were conducted with a group of SME owners and managers within a traditional industrial cluster. This qualitative phase confirmed the practical relevance of many literature-derived barriers and identified context-specific challenges, such as the critical dependence on imported GMO soybeans.

The consolidated list of barriers was then subjected to a validation and refinement process by our expert panel (described in

Section 3.3). Through a structured discussion and ranking exercise, the experts assessed the relevance and prevalence of each barrier. The final selection of 13 key barriers was determined by expert consensus, focusing on those deemed most critical and frequently encountered in the Indonesian SME context. This multi-method approach, triangulating literature, practitioner input, and expert validation, ensures the list is both academically grounded and contextually robust. The final 13 barriers, their operational definitions, and their supporting evidence from both literature and our empirical study are presented in

Table 3.

Key barriers were identified by further examining the performance indicators of sustainable procurement (SP) (

Table 3), which are categorized into three dimensions: economic, social, and environmental. The initial identification of barriers to implementing sustainable procurement among small and medium-sized enterprises (SMEs) within a traditional food-manufacturing industrial cluster in Indonesia was conducted through in-depth interviews with SME owners, on-site observations of production activities, and an extensive literature review on sustainable procurement practices. From this process, 23 initial barriers were formulated and subsequently validated by experts, consisting of practitioners and academics, resulting in 13 agreed-upon key barriers. These findings were further reinforced using the Analytic Hierarchy Process (AHP), which revealed the priority of barriers based on their weighted criteria. The analysis showed that the economic dimension dominates (63.38%), followed by the social (21.05%) and environmental (15.57%) dimensions.

4.4. Level Partitioning

Based on the FRM, level partitioning was performed iteratively using reachability sets (RS), antecedent sets (AS), and their intersections (IS). Variables with RS identical to IS were eliminated at each iteration until the final hierarchical structure was obtained.

Table 6,

Table 7,

Table 8,

Table 9 and

Table 10 present the iterative results, while

Table 11 summarizes the final level partitions.

Table 6.

Level Partitions (iteration 1).

Table 6.

Level Partitions (iteration 1).

| Code | RS | AS | IS | Level |

|---|

| EK1 | 1, 12, 13 | 1, 2, 5, 10, 13 | 1, 13 | |

| EK2 | 1, 2, 4 | 2, 10, 13 | 2 | |

| EK3 | 3 | 3, 10, 13 | 3 | 1 |

| EK4 | 4 | 2, 4, 5, 10, 13 | 4 | 1 |

| EK5 | 1, 4, 5, 6, 7, 9, 12, 13 | 5 | 5 | |

| SO6 | 6, 12 | 5, 6 | 6 | |

| SO7 | 7 | 5, 7, 10, 13 | 7 | 1 |

| SO8 | 8, 12 | 8 | 8 | |

| SO9 | 9, 11 | 5, 9, 10, 13 | 9 | |

| LN10 | 1, 2, 3, 4, 7, 9, 10, 12, 13 | 10, 13 | 10, 13 | |

| LN11 | 11 | 9, 11 | 11 | 1 |

| LN12 | 12 | 1, 5, 6, 8, 10, 12, 13 | 12 | 1 |

| LN13 | 1, 2, 3, 4, 7, 9, 10, 12, 13 | 1, 5, 10, 13 | 1, 10, 13 | |

In the first stage of constructing level partitions, five variables were eliminated: EK3, EK4, SO7, LN11, and LN12.

Table 7.

Level Partitions (iteration 2).

Table 7.

Level Partitions (iteration 2).

| Code | RS | AS | IS | Level |

|---|

| EK1 | 1, 13 | 1, 2, 5, 10, 13 | 1, 13 | 2 |

| EK2 | 1, 2 | 2, 10, 13 | 2 | |

| EK5 | 1, 5, 6, 9, 13 | 5 | 5 | |

| SO6 | 6 | 5, 6 | 6 | 2 |

| SO8 | 8 | 8 | 8 | 2 |

| SO9 | 9 | 5, 9, 10, 13 | 9 | 2 |

| LN10 | 1, 2, 9, 10, 13 | 10, 13 | 10, 13 | |

| LN13 | 1, 2, 9, 10, 13 | 1, 5, 10, 13 | 1, 10, 13 | |

At the second iteration level of partitions, the variables EK1, SO6, SO8, and SO9 were excluded from the subsequent iteration process.

Table 8.

Level Partitions (iteration 3).

Table 8.

Level Partitions (iteration 3).

| Code | RS | AS | IS | Level |

|---|

| EK2 | 2 | 2, 10, 13 | 2 | 3 |

| EK5 | 5, 13 | 5 | 5 | |

| LN10 | 2, 10, 13 | 10, 13 | 10, 13 | |

| LN13 | 2, 10, 13 | 5, 10, 13 | 10, 13 | |

At the third iteration partition level, the variable EK2 was excluded from the subsequent iteration process.

Table 9.

Level Partitions (iteration 4).

Table 9.

Level Partitions (iteration 4).

| Code | RS | AS | IS | Level |

|---|

| EK5 | 5, 13 | 5 | 5 | |

| LN10 | 2, 10, 13 | 10, 13 | 10, 13 | 4 |

| LN13 | 2, 10, 13 | 5, 10, 13 | 10, 13 | 4 |

At the fourth iteration level of the partition process, variables LN10 and LN13 were excluded from subsequent iterations.

Table 10.

Level Partitions (iteration 5).

Table 10.

Level Partitions (iteration 5).

The level partitioning process reached its final stage in the fifth iteration, eliminating variable EK5 as the last element. The overall results of all iterations are presented in

Table 11, which represents the Final Level Partitions that clearly map the hierarchical relationships among all analyzed variables.

Table 11.

Final Level Partitions.

Table 11.

Final Level Partitions.

| Code | Dependence | Level |

|---|

| EK3 | Highly Dependent | 1 |

| EK4 | ![Logistics 09 00175 i001 Logistics 09 00175 i001]() | 1 |

| SO7 | 1 |

| LN11 | 1 |

| LN12 | 1 |

| EK1 | 2 |

| SO6 | 2 |

| SO8 | 2 |

| SO9 | 2 |

| EK2 | 3 |

| LN10 | 4 |

| LN13 | 4 |

| EK5 | Highly Independent | 5 |

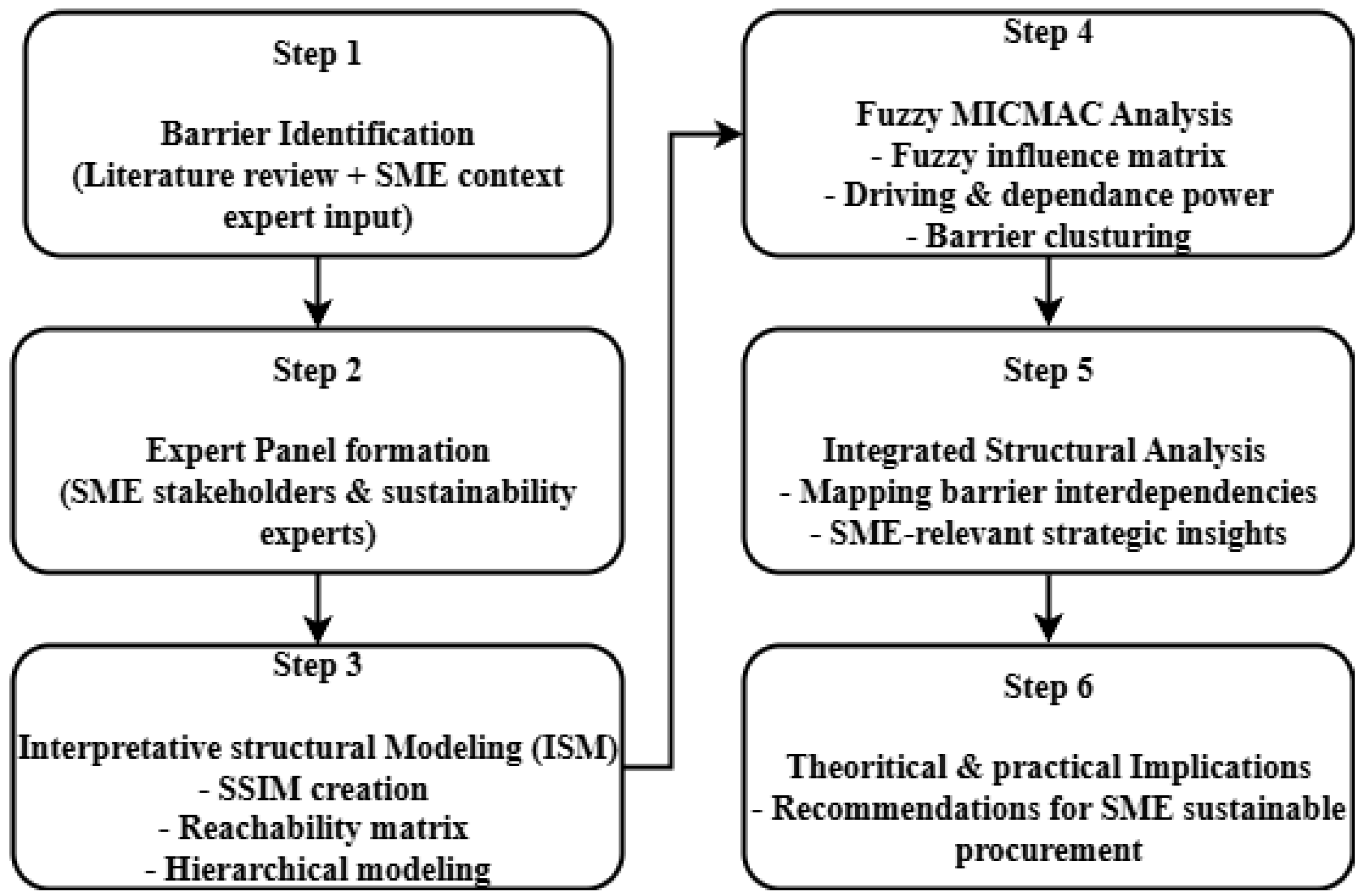

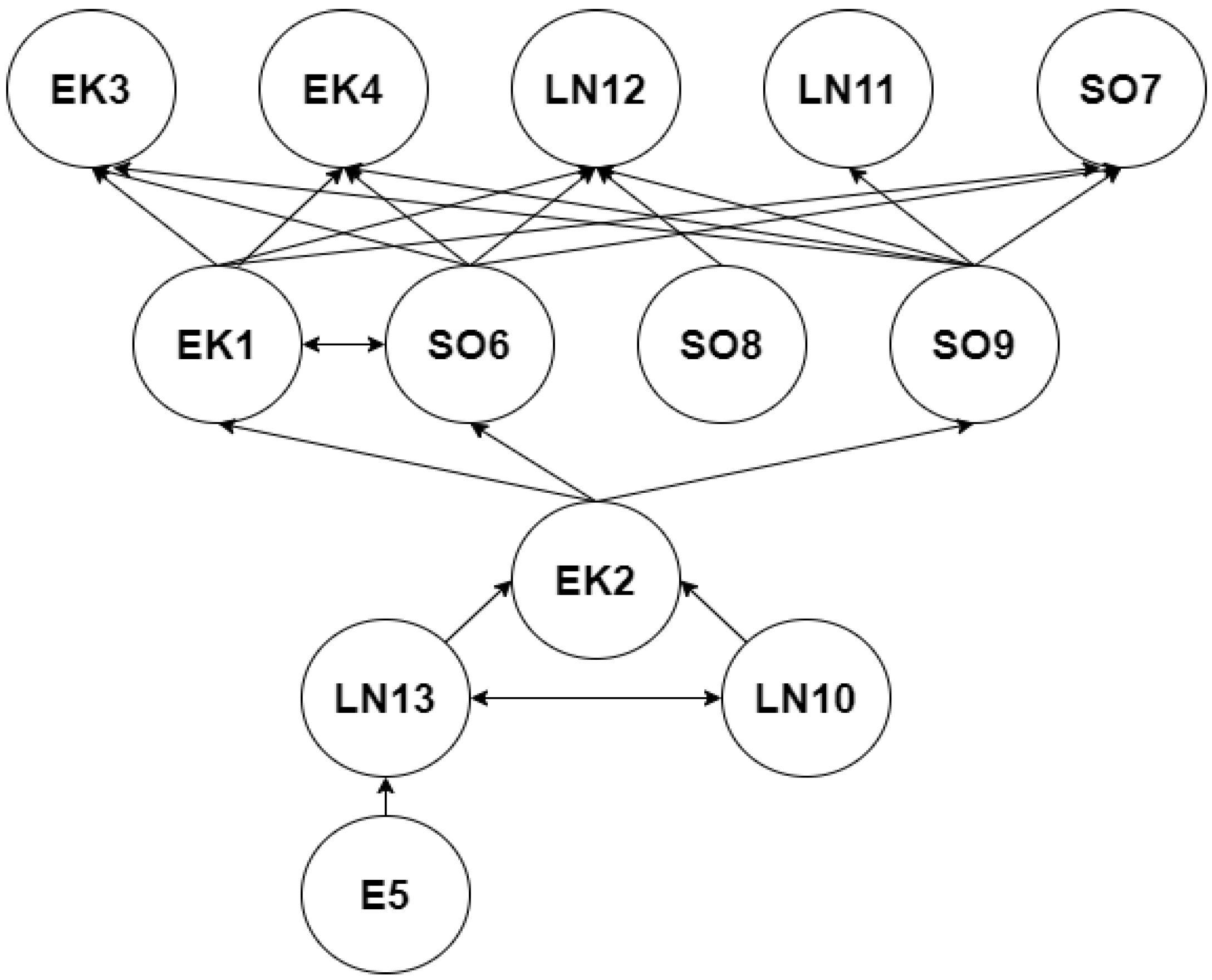

The final hierarchy categorizes barriers into five levels, ranging from Level I (highly dependent. The level partitioning process yielded a definitive seven-level hierarchical structure, visually represented in

Figure 2 and

Figure 3. This hierarchy is pivotal for understanding the relational dynamics between barriers. At the foundational Level I, E5 (Funding Limitations) was identified as the sole root or independent barrier. This positioning signifies its critical role as a fundamental driver of the system, exerting significant influence on other barriers while being largely unaffected by them. Conversely, occupying the highest level (Level VII) are the most dependent barriers: E3 (Unfamiliarity with Green Logistics), E4 (Resistance to Change), S7 (Lack of Strategic Partnerships), L11 (Inadequate Infrastructure), and L12 (Unsupportive Government Policies). These represent the ultimate outcomes or symptoms within the model, being highly influenced by barriers at lower levels but generating minimal influence themselves. The intermediate levels (II through VI) contain linkage barriers that act as critical transmission channels, propagating the effects of the root cause upward toward the dependent outcomes. This clear structural mapping underscores that effective intervention strategies must prioritize the root barrier, E5, to create meaningful change throughout the entire system

4.5. Development of the ISM Model

The ISM structural model was developed from the FRM and represented as a directed graph (digraph). Each barrier is depicted as a node, with arrows representing direct influences. To simplify the model, transitive links were removed.

Figure 2 presents a directed graph that reveals a complex system where barriers in one dimension actively cause barriers in another. The structure identifies key “driver” barriers, which align perfectly with the “Highly Dependent” Level 1 codes in the accompanying table. Specifically, Perception of Higher Costs and Higher initial costs (EK3 & EK4), both Level 1 barriers, form a potent economic cluster that reinforces each other and suppresses social demand (Low consumer preference). Similarly, the other Level 1 barriers, Lack of collaboration with local suppliers (SO7), Culture resistant to change (LN12), and Lack of regulations (LN11), act as profound root causes within the graph. This hierarchy of influence is visually confirmed in

Figure 3, which lists these same issues as the primary, foundational barriers at the top of its structure. Conversely, the graph highlights critical “outcome” barriers, with Lack of local soybean suppliers (LN13) emerging as a central bottleneck. According to the table, LN13 is a Level 4 barrier (Highly Independent), confirming its role as a resultant problem. It is not a standalone issue but the culmination of multiple influences from more dependent barriers, such as Dependence on imported GMO soybeans (EK1, Level 2) and the Level 1 barrier, Weak collaboration with local suppliers (SO7).

This interconnected model, where Level 1 driver barriers cause Level 4 outcome barriers, aligns with and refines prior research. The potency of the Level 1 economic perceptions as primary drivers confirms findings that financial constraints and cost premiums are the most significant and foundational hurdles [

51]. Furthermore, the position of the other Level 1 barriers from

Figure 3, particularly Culture resistant to change, as a key influencer of Lack of human resource competence, substantiates claims that organizational culture is a more foundational issue than a lack of skills [

52]. The convergence of multiple influences on the Level 4 barrier Lack of local soybean suppliers, provides a specific case study of resource dependence theory. It demonstrates that this critical bottleneck, also positioned as a culminating barrier in

Figure 3, is the ultimate effect of a network of preceding, more dependent economic and social failures [

53]. This synthesis shows that while

Figure 2 illustrates the causal “how” of influence, the dependence level table and the hierarchy in

Figure 3 categorize the “why,” collectively identifying which barriers are the fundamental levers for systemic intervention.

4.6. Construction of the Fuzzy Direct Reachability Matrix (FDRM)

The FDRM was constructed from the Binary Direct Relationship Matrix (BDRM), derived from the IRM but excluding transitivity rules. Experts then assigned influence levels using fuzzy scales: 0.0 = no influence, 0.1 = very low, 0.3 = low, 0.5 = moderate, 0.7 = high, 0.9 = very high, 1.0 = absolute.

Table 12 presents the Fuzzy Direct Reachability Matrix (FDRM), which refines the Binary Direct Relationship Matrix (BDRM) by incorporating expert judgments on the degree of influence between barriers using fuzzy scales. The results highlight that “funding limitations” (EK5) exert strong influence on several barriers, including EK1 (import dependency, 0.9), SO6 (limited human resources, 0.7), SO9 (weak supply chain collaboration, 0.5), LN12 (cultural resistance, 0.7), and LN13 (limited local non-GMO supply, 0.9), underscoring its role as a primary driver. Similarly, LN10 (availability of eco-friendly raw materials) also shows strong bidirectional relationships, particularly with EK1 (0.9), EK2 (0.7), and LN13 (0.9), suggesting that raw material availability is both a consequence and a reinforcing factor of systemic barriers. In contrast, some variables, such as EK3 (perception of high costs), EK4 (large initial costs), and LN11 (inadequate regulations), demonstrate weak or no direct influence, placing them in more dependent roles. These findings support earlier studies emphasizing that financial constraints and resource scarcity act as dominant structural barriers in sustainable procurement systems [

54].

4.8. Construction of the Driving Power–Dependence Diagram

Based on the driving power and dependence power values calculated in the Final Fuzzy MICMAC-Stabilized Matrix, the barriers can be classified into four main clusters: Autonomous Indicators (Cluster I), Dependent Indicators (Cluster II), Linkage Indicators (Cluster III), and Independent Indicators (Cluster IV).

The Driving–Dependence Diagram categorizes barriers into four clusters based on their driving power and dependence. The interpretation of each cluster is as follows:

Cluster I (Autonomous).

This cluster comprises barriers EK3 (perception of high costs), SO6 (limited human resource competence), and SO8 (low consumer preference), all of which exhibit low driving power and dependence, indicating minimal direct influence on the broader sustainable procurement system. Although these barriers do not play a dominant structural role, they represent underlying behavioral and perceptual challenges that can indirectly slow sustainability adoption among SMEs. The perception of high costs often serves as a psychological and cognitive barrier, deterring small business owners from investing in green initiatives despite potential long-term benefits [

29]. Similarly, the limited competence of human resources constrains firms’ ability to implement and manage sustainability programs effectively, aligning with findings by Purgał-Popiela [

56], who emphasized that skill and knowledge gaps impede operational sustainability in smaller enterprises. Low consumer preference for sustainable products further reinforces this stagnation, as weak market demand discourages firms from transitioning toward eco-friendly procurement practices [

57]. Addressing these autonomous barriers requires strategic interventions focused on awareness campaigns, targeted training programs, and consumer education initiatives to foster a supportive cultural and market environment that can complement broader systemic reforms.

Cluster II (Dependent).

This cluster comprises EK4 (large initial costs), SO7 (weak local supplier collaboration), SO9 (weak supply chain collaboration), LN11 (inadequate regulations), and LN12 (cultural resistance). These barriers are primarily dependent in nature, meaning they arise as consequences of other systemic challenges rather than serving as root causes within the sustainable procurement framework. High initial costs are often linked to SMEs’ limited access to external financing and credit facilities, which constrain their ability to invest in sustainable technologies and raw materials [

58]. Similarly, weak collaboration with local suppliers and broader supply chain partners reflects the fragmented and informal structure of SME networks in developing contexts, emphasizing the need to strengthen trust-based relationships and cooperative procurement mechanisms [

59]. Furthermore, inadequate regulatory support and cultural resistance act as institutional and behavioral barriers that reinforce this dependency pattern. Studies by Gibral et al. [

60] emphasize that without consistent government regulations, awareness programs, and social incentives, firms are less motivated to adopt sustainable practices. Therefore, overcoming these dependent barriers requires a combination of financial facilitation, network-building initiatives, and policy reforms that address both structural and cultural dimensions of sustainable procurement.

Cluster III (Linkage).

This cluster comprises barriers with both high driving power and high dependence, making them unstable and highly interconnected within the sustainable procurement system. It includes EK1 (dependence on imported GMO soybeans, representing 60% of total imports and priced 37% cheaper), EK2 (minimal government incentives), LN10 (availability of eco-friendly raw materials covering less than 30% of domestic demand), and LN13 (limited local non-GMO soybean suppliers). These barriers create a self-reinforcing feedback loop in which minor disruptions can trigger cascading effects throughout the supply chain. For example, the inability of SMEs to transition toward sustainable raw materials is driven not only by the scarcity of eco-friendly inputs but also by the absence of adequate policy and financial incentives to stimulate local production. According to Meliany et al. [

61], domestic soybean production reached only 851,286 tons, fulfilling just 29% of national demand compared to an annual import dependency of 2.08 million tons, highlighting the structural imbalance in supply. Such findings align with Göçer et al. [

62], who emphasized that sustainability barriers often interact dynamically, amplifying systemic risks rather than acting independently. Similarly, Abbas et al. [

63] noted that linkage barriers are inherently volatile due to their dual influence and dependence, requiring integrated interventions across policy, supply chain, and market levels. Therefore, addressing these linkage barriers demands a coordinated multi-stakeholder strategy that simultaneously enhances local raw material availability, introduces targeted government incentives, and strengthens supplier collaboration to stabilize the sustainable procurement ecosystem in SMEs.

Cluster IV (Independent/Driving).

This cluster contains a single barrier, EK5 (funding limitations), which emerges as the root cause with the strongest driving power. The financial gap between sustainable and conventional procurement options is substantial: locally sourced or eco-friendly materials are often significantly more expensive than imported or non-sustainable alternatives, while environmentally responsible packaging options can cost several times more than conventional plastic. Such economic disparities create a heavy burden on SMEs that typically operate with limited capital and cash flow [

64]. Without accessible financing mechanisms, such as green credit schemes, fiscal incentives, or collaborative investment programs, SMEs struggle to absorb additional costs or achieve economies of scale necessary for sustainable transformation [

65]. Consequently, funding limitations remain the most critical structural barrier to the widespread adoption of sustainable procurement practices, reinforcing previous findings that financial constraints often overshadow environmental and social priorities in SME operations [

23].

4.9. Summary of Fuzzy MICMAC Clusters

The Fuzzy MICMAC analysis provides a critical classification of the barriers, moving beyond a simple list to reveal their strategic roles within the system based on driving and dependence power. The 13 barriers are categorized into four distinct clusters, as will be visualized in the subsequent driving-dependence diagram (

Figure 4). Cluster I (Autonomous Barriers: EK3, SO6, SO8) encompasses barriers with weak driving and dependence power, indicating their relative isolation from the core system dynamics. These barriers, which include the perception of high costs, limited human resource competence, and low consumer preference, represent persistent background challenges. However, their autonomous nature does not render them insignificant; as noted by Purwandani & Michaud [

29], such perceptual and awareness gaps can create a latent resistance that indirectly stifles sustainability initiatives by shaping managerial attitudes and consumer behaviour. Cluster II (Dependent Barriers: EK4, SO7, SO9, LN11, LN12) is characterized by high dependence but low driving power, identifying them as outcomes of the system’s deeper issues. Barriers in this cluster, such as large initial costs, weak supplier collaboration, and inadequate regulations, are often the most visible symptoms but are not root causes. Their dependent nature aligns with findings that these challenges frequently arise from a lack of external support and internal capacity, where SMEs, due to their limited financial and structural resources, become highly susceptible to external pressures and institutional voids [

25,

66]. The most volatile and interconnected group is Cluster III (Linkage Barriers: EK1, EK2, LN10, LN13), which exhibits both high driving and high dependence. These barriers, including dependence on imported raw materials, minimal government incentives, and limited availability of eco-friendly inputs, form a self-reinforcing feedback loop. This cluster embodies the systemic linkage problems described in prior research, where variables are unstable and a change in one can create cascading effects throughout the entire system, making them critical leverage points for intervention [

32,

63]. Finally, Cluster IV (Independent/Driver Barriers: EK5) is comprised solely of “funding limitations,” which possesses the highest driving power and the lowest dependence. This positions it as the most critical, independent barrier, the foundational root cause of the system. This finding robustly confirms a central theme in SME sustainability literature: that financial constraints are the paramount, overriding obstacle that dictates the feasibility of all other sustainable procurement efforts, often overshadowing environmental and social considerations in decision-making [

3,

23]. This cluster-based typology thus provides a strategic map, distinguishing between superficial symptoms, unstable linkage variables, and the fundamental financial driver that must be addressed to enable a transition to sustainable procurement in SMEs.

4.11. Analysis of Key Barriers in the Implementation of Sustainable Procurement in SMEs

The analysis reveals that financial constraints are not merely one barrier among many but the central, driving force inhibiting sustainable procurement in SMEs. This is starkly illustrated by the classification of “funding limitations” (EK5) as the sole independent barrier in Cluster IV, possessing the highest influence over the entire system. The significant cost disparity between local, sustainable raw materials and cheaper imported alternatives, coupled with the prohibitive expense of eco-friendly packaging, creates a fundamental economic disincentive. This finding strongly aligns with prior research, such as Gonçalves et al. [

3], who identified cost as the most significant hurdle for SMEs, and Nasyiah et al. [

23], who argued that financial constraints often overshadow environmental and social considerations in procurement decisions. The data confirms that without resolving this core financial viability issue, through innovative financing models or cost-mitigation strategies, other efforts to promote sustainable practices are likely to be ineffective, as SMEs simply lack the capital to invest.

Furthermore, the study identifies a critical “linkage” cluster (Cluster III) of interconnected systemic barriers, including high import dependency, lack of government incentives, and scarce sustainable raw materials. These barriers form a vicious cycle that reinforces the financial core problem. For instance, the lack of government incentives (EK2) exacerbates the cost issue, while limited local non-GMO soybean supply (LN13) forces SMEs to rely on the cheaper import market, thereby undermining the business case for sustainable sourcing. This interdependence echoes the work of Narayanan et al. [

67], who found that barriers in sustainable supply chains are rarely isolated and often create cascading effects. Similarly, studies in developing economies, like those by Shaikh et al. [

50], highlight how weak institutional support and underdeveloped local markets create a uniquely challenging environment for SME sustainable procurement, making a piecemeal approach insufficient. Therefore, tackling these linkage barriers requires a coordinated, multi-stakeholder strategy that simultaneously addresses policy, market structure, and supply chain development to break the cycle.

4.12. Analysis of Key Barriers Using Interpretive Structural Modeling (ISM)

The application of the ISM methodology provides a critical hierarchical perspective, revealing that the barriers to sustainable procurement are not a flat list but a structured system with a clear power dynamic. The model’s most significant revelation is the identification of “funding limitations” (EK5) as the sole independent variable in Level IV, positioning it as the most powerful driver or root cause within the system. This structural finding is consistent with the foundational principles of ISM, which posit that factors at the lowest level of the hierarchy have the highest driving power [

68]. In practice, this means that the high cost of sustainable raw materials and packaging is not just a standalone issue; it exerts fundamental pressure on the entire system. This corroborates prior ISM studies in supply chain contexts, such as the work of Gonçalves et al. [

3], which also identified financial constraints as a key independent barrier in sustainable supply chain management, suggesting its foundational role is a common theme across different industrial contexts.

Delving deeper into the hierarchy, the ISM model elucidates the critical role of the “linkage” barriers in Cluster III (e.g., EK1, EK2, LN10, LN13). These barriers are characterized by high both driving and dependence power, making them unstable and critical leverage points. The model visually demonstrates how a barrier like “minimal government incentives” (EK2) is both influenced by the root funding problem and, in turn, directly influences the “availability of eco-friendly raw materials” (LN10) and reinforces “dependence on imports” (EK1). This interconnectedness creates a self-reinforcing feedback loop that is difficult to break. As noted by Mannan et al. [

68], linkage variables in an ISM hierarchy are often the most complex to manage because any action on them can have unpredictable ripple effects. Our findings thus extend the research of Hussain et al. [

69], who identified similar governmental and market barriers, by using ISM to map their precise position and dynamic role within the causal web, highlighting that interventions here require a systemic rather than a siloed approach.

4.13. Analysis of Key Barriers Using Fuzzy MICMAC

The Fuzzy MICMAC analysis provides a nuanced understanding of the influence and dependence relationships between barriers, moving beyond the binary linkages of traditional ISM to account for the real-world ambiguity in these connections. The classification of barriers into four distinct quadrants validates and refines the structural model. The most critical finding is the positioning of “funding limitations” (EK5) alone in the independent quadrant (Quadrant IV), confirming it possesses the highest driving power with very low dependence. This means that while EK5 exerts a strong influence on other barriers, it is largely unaffected by changes within the system itself. This finding aligns with the fuzzy-based supply chain studies of Khan and Haleem [

70], who emphasized that financial barriers often emerge as autonomous “drivers” in complex systems, requiring targeted external intervention rather than expecting them to be resolved through internal system changes.

Furthermore, the Fuzzy MICMAC plot powerfully identifies the cluster of unstable “linkage” barriers (EK1, EK2, LN10, LN13) in Quadrant I, characterized by high both driving and dependence power. This quadrant is often described as the “volatile zone,” where variables are both key influencers and highly sensitive to changes in other variables [

32]. For instance, the high dependence of “limited local non-GMO supply” (LN13) on factors like government incentives (EK2) and the high cost of local materials (driven by EK5) creates a feedback loop of dependency. This fuzzy clustering provides empirical weight to the qualitative insights of prior research, such as that of Abbas et al. [

63], who noted that sustainable sourcing challenges are often a result of intertwined external pressures. The Fuzzy MICMAC analysis thus quantifies this volatility, suggesting that policies aimed at these linkage barriers, such as subsidizing local sustainable soybean cultivation, could have a high-leverage, multiplicative effect by simultaneously stabilizing multiple critical nodes in the barrier network.

4.14. Sustainability Procurement as a Managerial Strategy

The findings of this study highlight sustainable procurement not merely as a compliance measure but as a core managerial strategy that directly influences SME competitiveness and long-term viability. By addressing the root barrier of financial constraints and strategically engaging with linkage barriers such as dependence on imports and lack of government incentives, SMEs can create more resilient supply chains. Prior research suggests that integrating sustainability into procurement decisions enhances operational efficiency, reduces risks, and fosters stronger relationships with stakeholders [

71]. However, unlike Walker and Preuss [

51], who argue that cost is only one among several competing sustainability barriers, our results demonstrate that in emerging economies financial constraints function as the

primary structural driver, shaping downstream institutional and operational challenges. This contrasts with studies in developed contexts where institutional support mitigates cost pressures, suggesting that SMEs in Indonesia face a more rigid financial–institutional dependency than previously reported. In resource-constrained environments, procurement managers who align sustainability objectives with cost-reduction and risk-mitigation strategies are more likely to secure buy-in from both top management and supply chain partners.

Moreover, adopting sustainability-oriented procurement practices positions SMEs to leverage institutional support and market opportunities. For example, government incentives, eco-certifications, and consumer demand for environmentally friendly products can provide SMEs with competitive differentiation when managers proactively integrate sustainability into procurement frameworks [

72]. This finding is consistent with Nasyiah et al. [

23], who emphasize the role of leadership in mobilizing sustainability capabilities; however, our results extend their conclusions by showing that such leadership effectiveness is contingent on resolving financial and institutional barriers first. Similarly, while Shaikh et al. [

43] highlight sustainability as a pathway to competitive advantage, the current study adds that competitive gains materialize only when SMEs overcome systemic funding limitations, an insight less emphasized in prior models. Compared with Gonçalves et al. [

3], who treat financial and institutional barriers individually, this study demonstrates their interdependence through a hierarchical ISM–MICMAC structure, offering a more integrated understanding of how procurement choices cascade across the system. This strategic orientation not only addresses external pressures but also creates internal value through innovation, enhanced reputation, and improved supplier collaboration. As this study indicates, managerial focus on overcoming funding limitations and fostering systemic interventions across linkage barriers transforms procurement from a transactional activity into a strategic tool for building sustainable advantage.

4.15. Theoretical Contribution and Sustainable Procurement Integration

This study makes a significant theoretical contribution by advancing the understanding of sustainable procurement barriers as a structured and interdependent system, rather than as isolated challenges. Using Interpretive Structural Modeling (ISM) and Fuzzy MICMAC, the research identifies financial constraints as the root driver with the highest influence, confirming earlier studies that cost remains the most significant hurdle for SMEs [

51]. However, it extends prior work by mapping the causal relationships between barriers and showing how systemic issues, such as weak institutional incentives, limited local raw material supply, and high import dependency, operate as linkage variables within a self-reinforcing cycle [

73]. This hierarchical approach enriches sustainability theory by demonstrating how certain barriers, while dependent, create cascading effects that amplify the core financial challenge, underscoring the value of systemic analysis in procurement research. From a practical perspective, the findings highlight that integrating sustainability into procurement cannot rely solely on operational adjustments or firm-level initiatives but must be embedded in broader financial, policy, and supply chain frameworks. As emphasized by Nasyiah et al. [

23], SMEs in developing economies face intensified constraints due to weak institutional support, and this study reinforces the need for coordinated public–private collaboration to enable cost mitigation, incentivize sustainable sourcing, and strengthen local supply bases. In line with systemic perspectives in sustainable supply chain research [

32,

74], the results suggest that sustainable procurement integration must balance financial viability, institutional incentives, and resource availability through multi-stakeholder strategies, thereby ensuring that SMEs can overcome structural constraints and achieve long-term sustainability.

This study’s primary theoretical advancement lies in its methodological approach to barrier analysis. While previous studies have effectively used surveys and regression [

27,

43] to identify which barriers are significant, these methods treat barriers as independent variables, potentially missing the systemic picture. For instance, Shaikh et al. [

43] identify cost and institutional pressures as important constraints but analyze them in isolation, without mapping how these constraints interact or cascade through the procurement system. In contrast, our integrated ISM-Fuzzy MICMAC approach reveals the structure of the problem. For example, we show that ‘cultural resistance’ (LN12) is not a standalone issue but a dependent barrier (Cluster II), influenced by more fundamental drivers like funding. This finding differs from earlier studies such as Walker and Preuss [

51], which treat cultural and behavioral barriers as relatively autonomous; our results demonstrate that these barriers gain importance only after upstream financial and institutional challenges remain unresolved. Similarly, while Gonçalves et al. [

3] highlight several sustainability barriers, they do not investigate their hierarchical relationships, leaving the underlying causal structure unexamined. This hierarchical result challenges studies that might place equal emphasis on all barriers and provides a evidence-based framework for prioritizing interventions, thereby addressing a key gap in the sustainable procurement literature for SMEs identified in

Table 1.