Ultra-Compact Reflective Waveguide Mode Converter Based on Slanted-Surface and Subwavelength Metamaterials

Abstract

1. Introduction

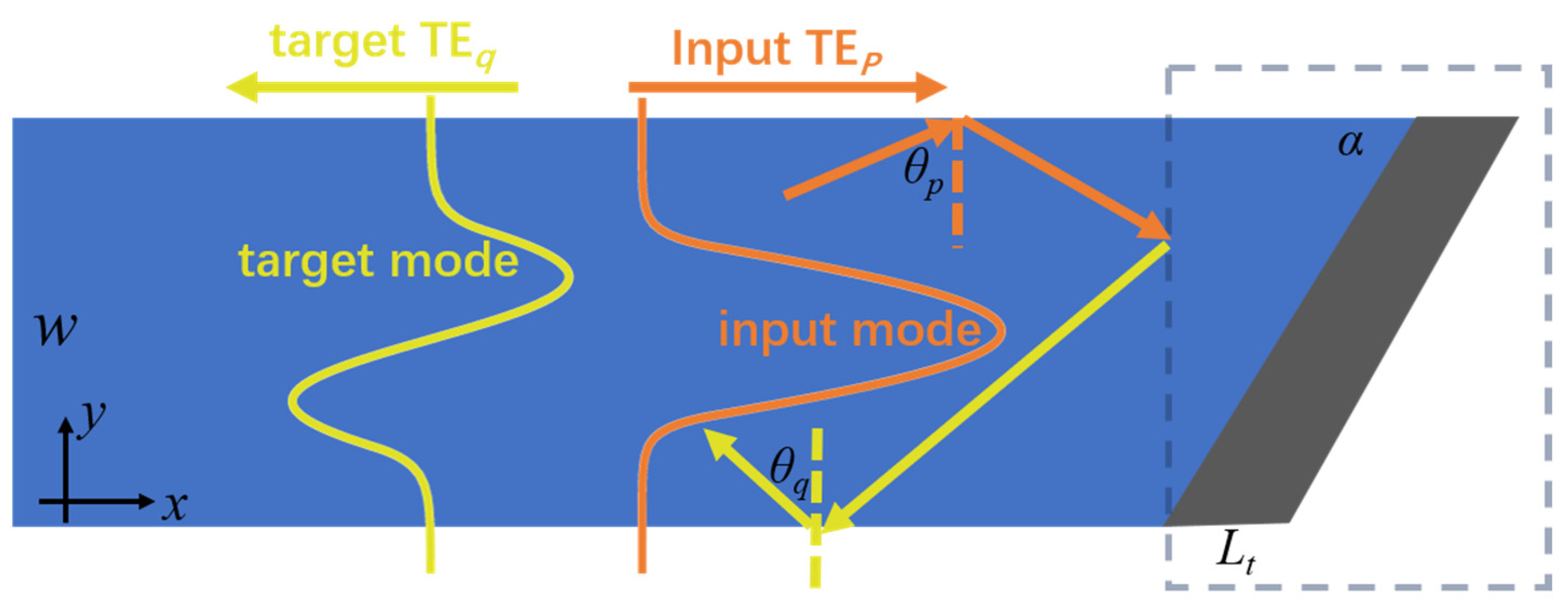

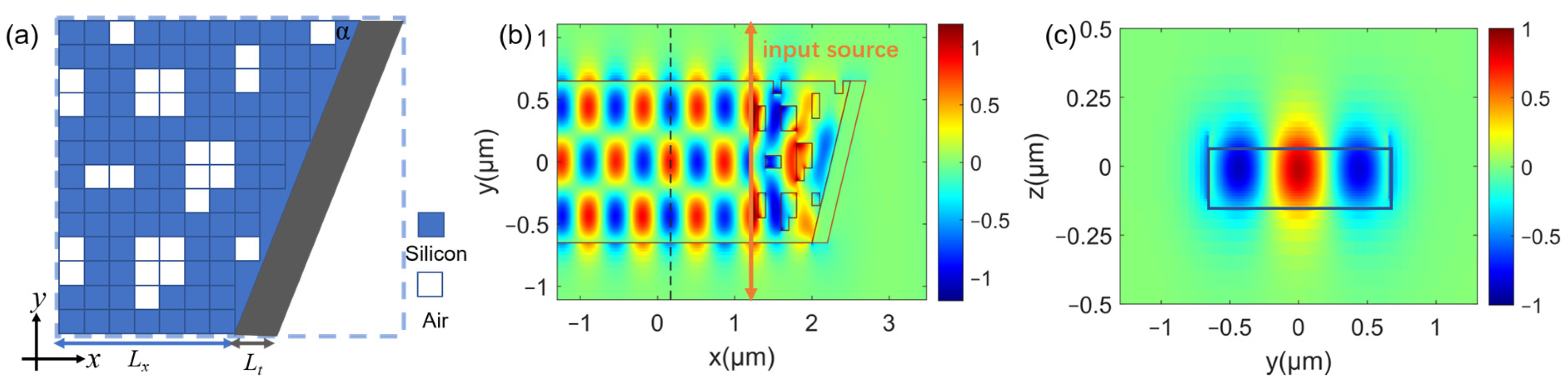

2. Design Principle of the RMC

3. Optimized Design and Performance Analysis of RMC

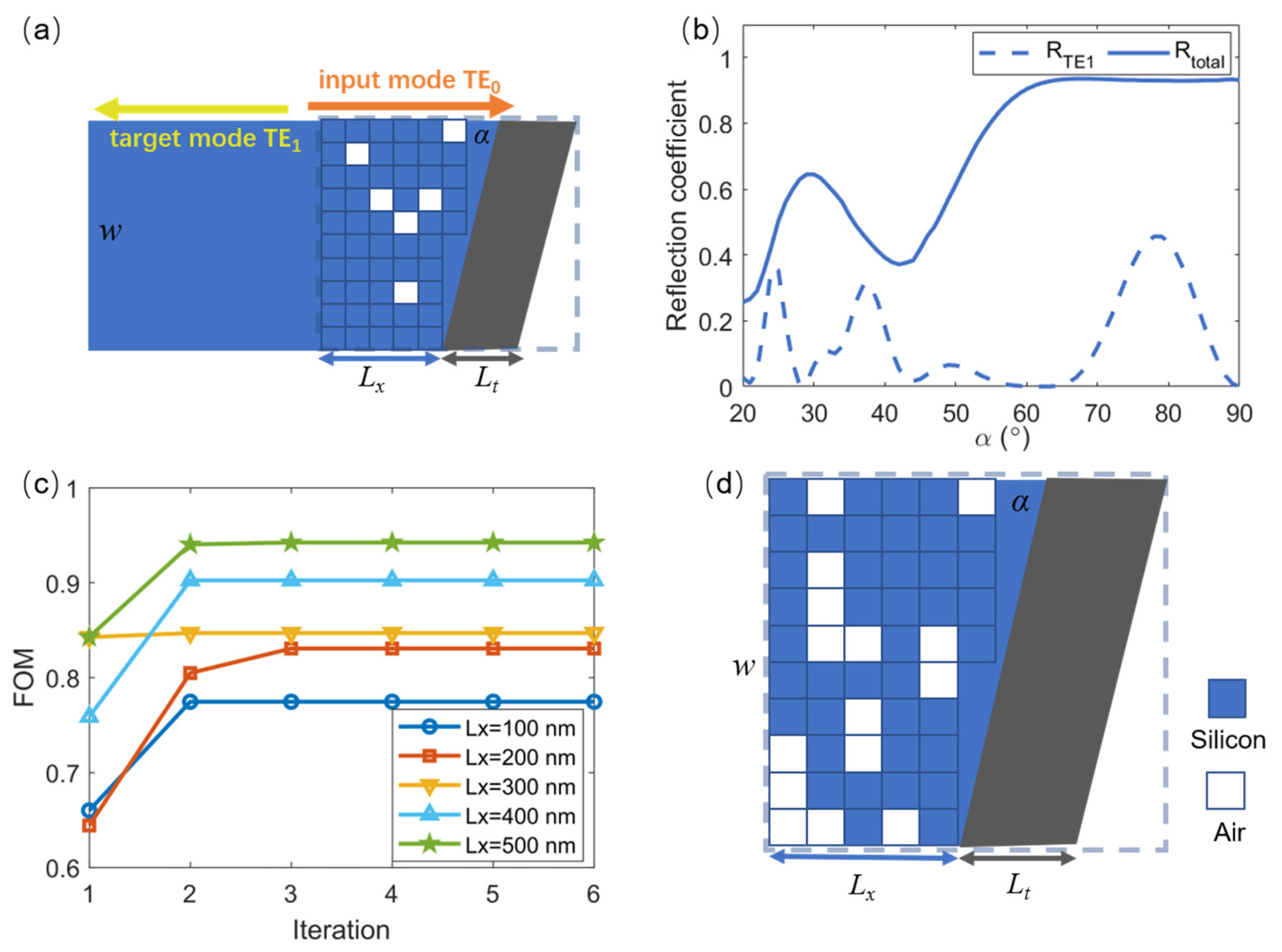

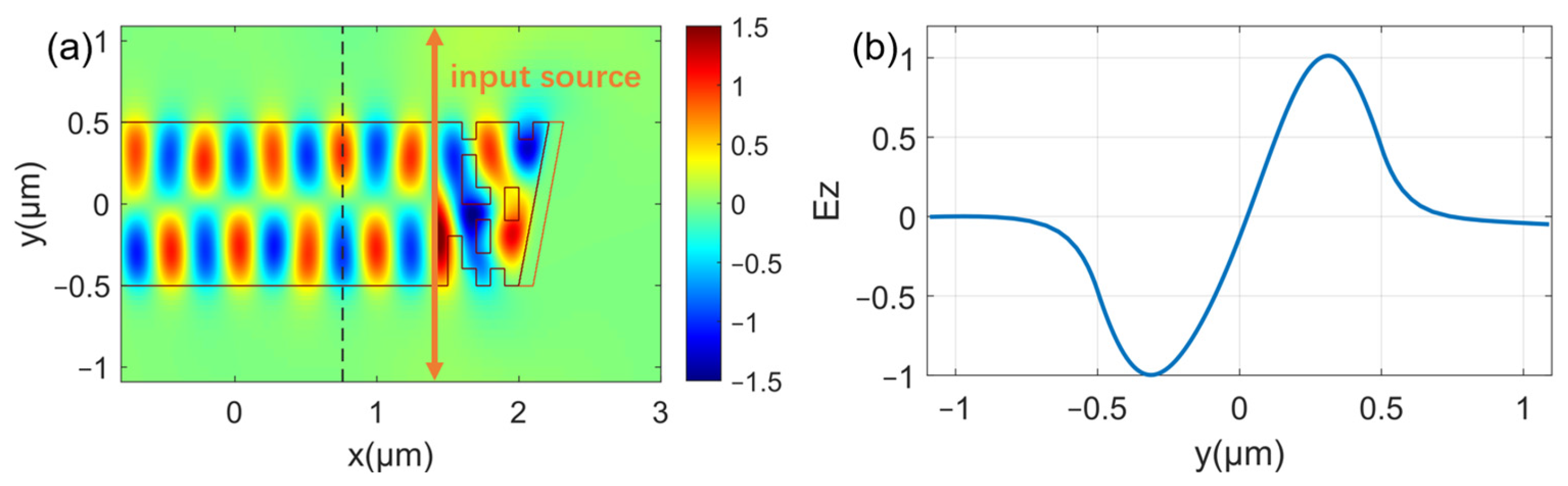

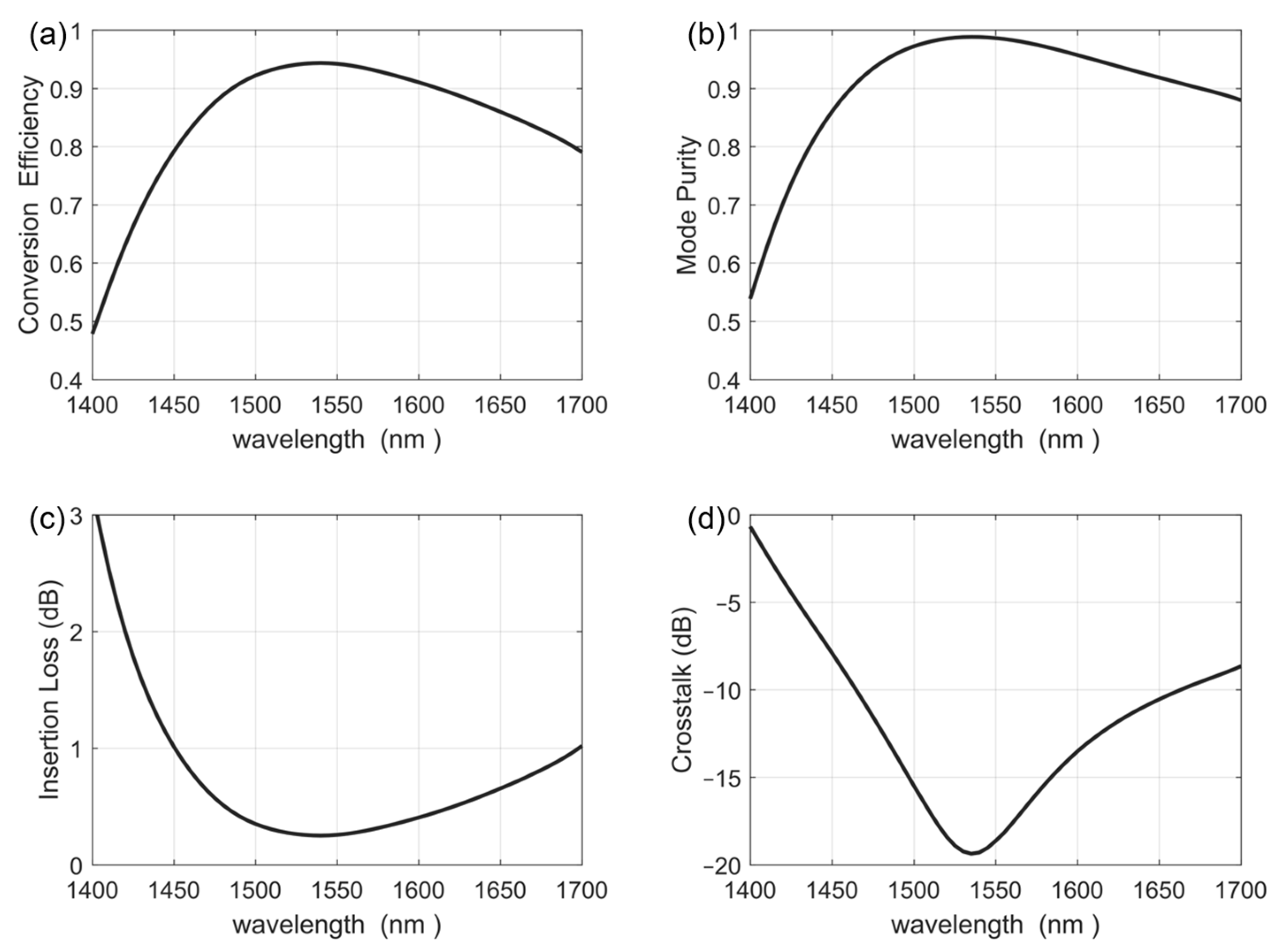

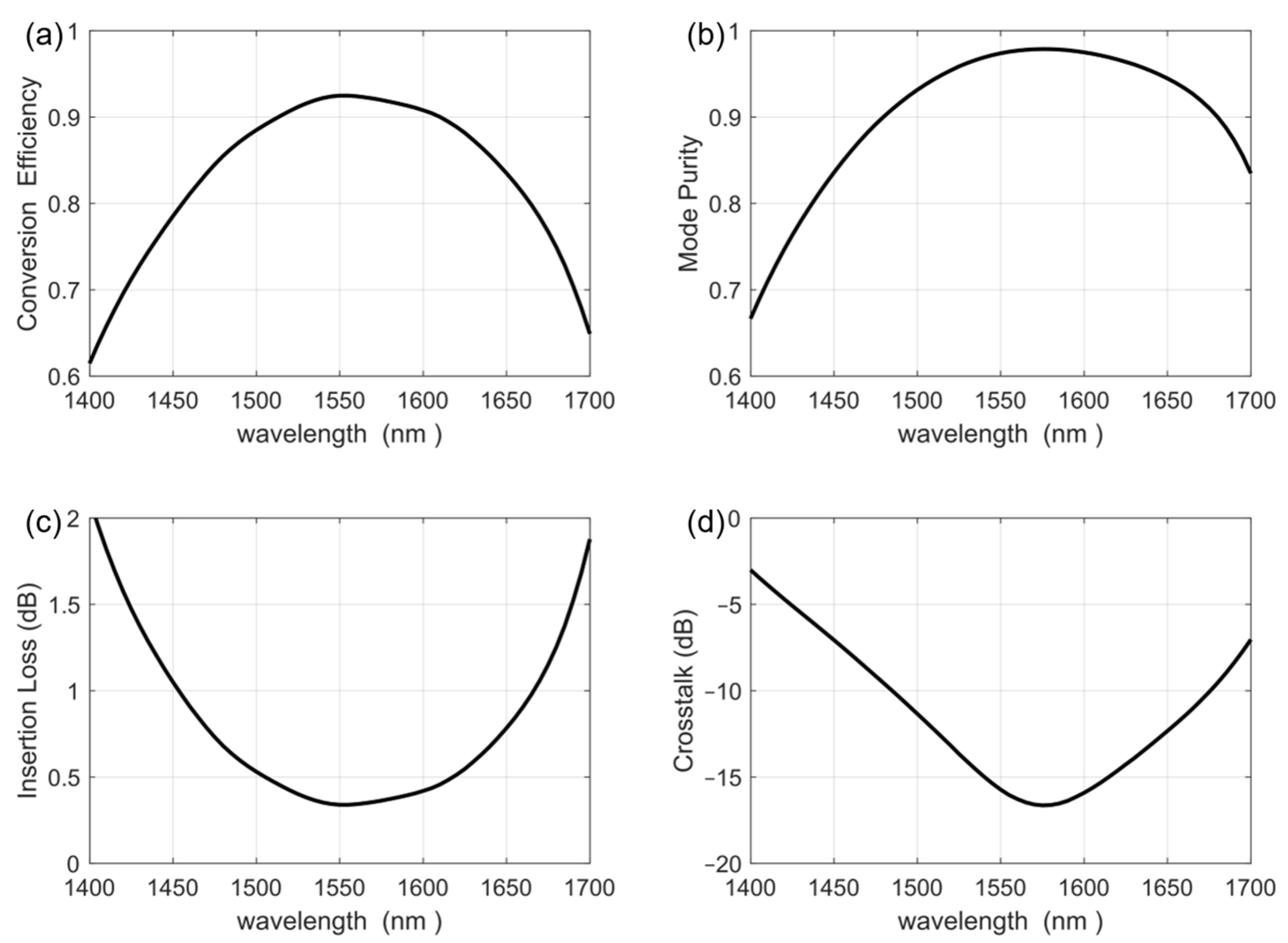

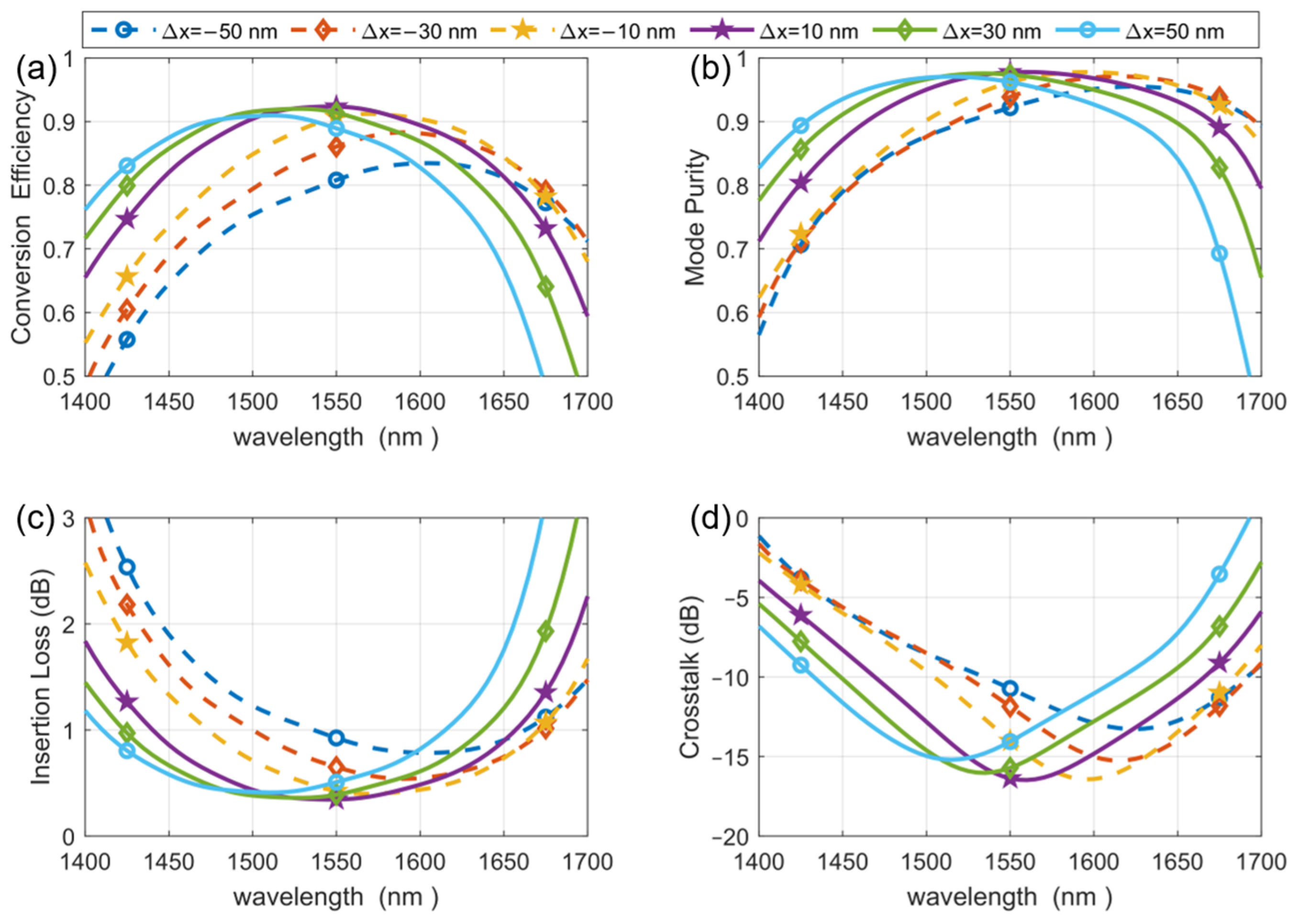

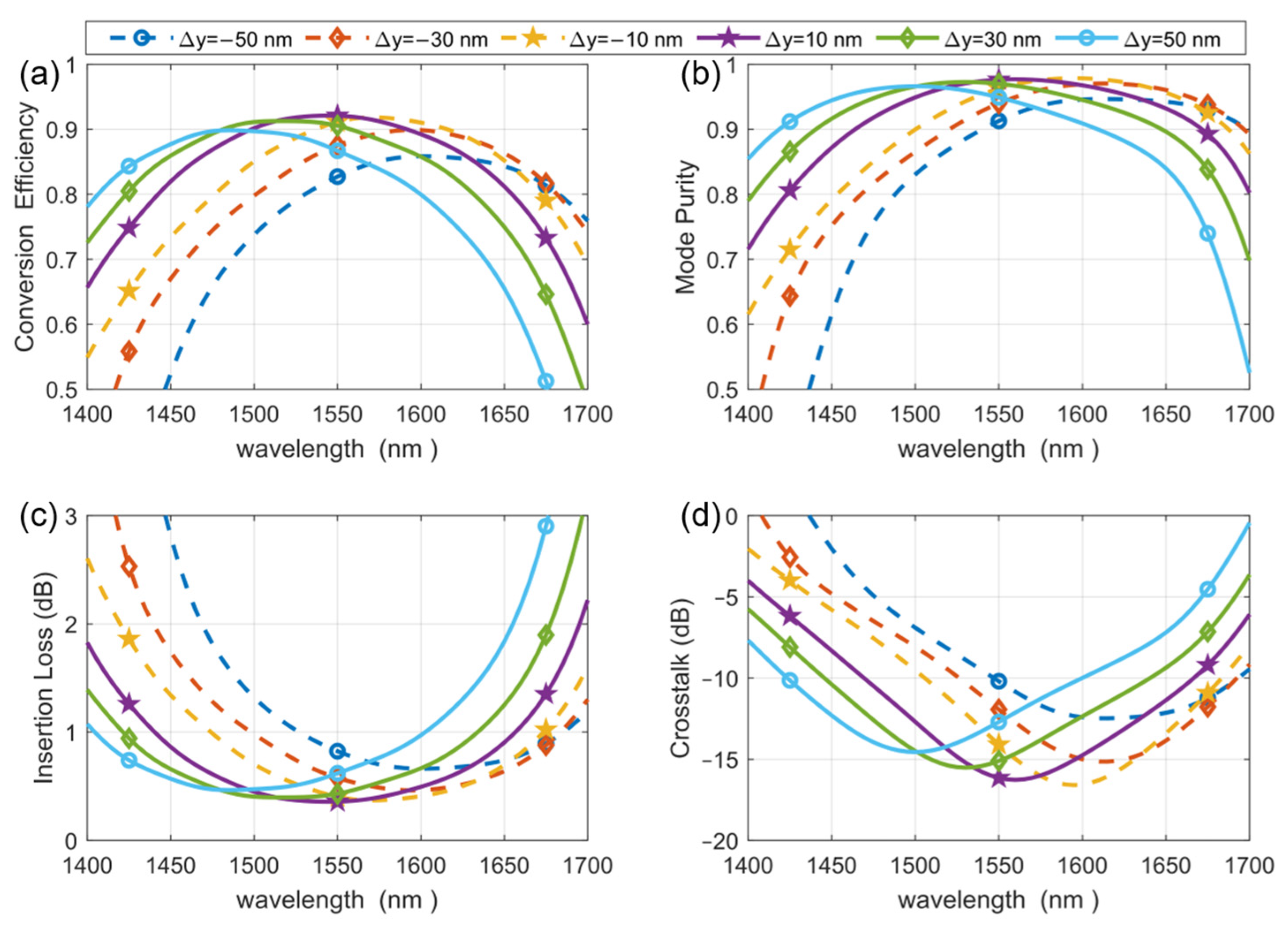

3.1. Optimization Design of RMC for 2D Waveguide

3.2. Optimization Design of RMC for 3D Waveguide

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khonina, S.N.; Kazanskiy, N.L.; Butt, M.A.; Karpeev, S.V. Optical multiplexing techniques and their marriage for on-chip and optical fiber communication: A review. Opto-Electron. Adv. 2022, 5, 210127. [Google Scholar] [CrossRef]

- Cheng, Q.; Bahadori, M.; Glick, M.; Rumley, S.; Bergman, K. Recent advances in optical technologies for data centers: A review. Optica 2018, 5, 1354–1370. [Google Scholar] [CrossRef]

- Shen, Y.; Meng, X.; Cheng, Q.; Rumley, S.; Abrams, N.; Gazman, A.; Manzhosov, E.; Glick, M.S.; Bergman, K. Silicon Photonics for Extreme Scale Systems. J. Light. Technol. 2019, 37, 245–259. [Google Scholar] [CrossRef]

- Urbonas, D.; Mahrt, R.F.; Stöferle, T. Low-loss optical waveguides made with a high-loss material. Light Sci. Appl. 2021, 10, 15. [Google Scholar] [CrossRef]

- Fang, Y.; Sun, M. Nanoplasmonic waveguides: Towards applications in integrated nanophotonic circuits. Light Sci. Appl. 2015, 4, e294. [Google Scholar] [CrossRef]

- Kazemi, F. Slow light structure implementation to improve Fano response of optical waveguide as a refractive index sensing. Optik 2023, 288, 171189. [Google Scholar] [CrossRef]

- Dutta, H.S.; Goyal, A.K.; Srivastava, V.; Pal, S. Coupling light in photonic crystal waveguides: A review. Photon Nanostruct. Fundam. Appl. 2016, 20, 41–58. [Google Scholar] [CrossRef]

- Maleki, M.J.; Soroosh, M. A novel proposal for performance improvement in two-dimensional photonic crystal-based 2-to-4 decoders. Laser Phys. 2020, 30, 076203. [Google Scholar] [CrossRef]

- Luo, L.-W.; Ophir, N.; Chen, C.P.; Gabrielli, L.H.; Poitras, C.B.; Bergmen, K.; Lipson, M. WDM-compatible mode-division multiplexing on a silicon chip. Nat. Commun. 2014, 5, 3069. [Google Scholar] [CrossRef]

- Yu, Y.; Sun, C.; Zhang, X. Silicon chip-scale space-division multiplexing: From devices to system. Sci. China Inf. Sci. 2018, 61, 080403. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, M.; Shi, Y.; Dai, D. Four-Channel CWDM (de)Multiplexers Using Cascaded Multimode Waveguide Gratings. IEEE Photon Technol. Lett. 2020, 32, 192–195. [Google Scholar] [CrossRef]

- Pan, P.; An, J.; Wang, Y.; Zhang, J.; Wang, L.; Qi, Y.; Han, Q.; Hu, X. Compact 4-channel AWGs for CWDM and LAN WDM in data center monolithic applications. Opt. Laser Technol. 2015, 75, 177–181. [Google Scholar] [CrossRef]

- Wang, J.; He, S.; Dai, D. On-chip silicon 8-channel hybrid (de)multiplexer enabling simultaneous mode- and polarization-division-multiplexing. Laser Photon Rev. 2014, 8, L18–L22. [Google Scholar] [CrossRef]

- Du, J.; Shen, W.; Liu, J.; Chen, Y.; Chen, X.; He, Z. Mode division multiplexing: From photonic integration to optical fiber transmission [Invited]. Chin. Opt. Lett. 2021, 19, 091301. [Google Scholar] [CrossRef]

- Su, Y.; He, Y.; Chen, H.; Li, X.; Li, G. Perspective on mode-division multiplexing. Appl. Phys. Lett. 2021, 118, 200502. [Google Scholar] [CrossRef]

- Xu, H.; Dai, D.; Shi, Y. Silicon Integrated Nanophotonic Devices for On-Chip Multi-Mode Interconnects. Appl. Sci. 2020, 10, 6365. [Google Scholar] [CrossRef]

- Ding, Y.; Xu, J.; Da Ros, F.; Huang, B.; Ou, H.; Peucheret, C. On-chip two-mode division multiplexing using tapered directional coupler-based mode multiplexer and demultiplexer. Opt. Express 2013, 21, 10376–10382. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Wu, Y.; Jin, W.; Chiang, K.S. Mode Multiplexer with Cascaded Vertical Asymmetric Waveguide Directional Couplers. J. Light. Technol. 2018, 36, 2903–2911. [Google Scholar] [CrossRef]

- Sun, C.; Yu, Y.; Chen, G.; Zhang, X. Integrated switchable mode exchange for reconfigurable mode-multiplexing optical networks. Opt. Lett. 2016, 41, 3257–3260. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, R.; Peng, Y.; Yi, X.; Chen, H.; Dai, D. High-performance silicon polarization switch based on a Mach–Zehnder interferometer integrated with polarization-dependent mode converters. Nanophotonics 2022, 11, 2293–2301. [Google Scholar] [CrossRef]

- Chen, D.; Xiao, X.; Wang, L.; Yu, Y.; Liu, W.; Yang, Q. Low-loss and fabrication tolerant silicon mode-order converters based on novel compact tapers. Opt. Express 2015, 23, 11152–11159. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, Y.; He, Y.; Zhu, Q.; Sun, L.; Su, Y. Compact Silicon Waveguide Mode Converter Employing Dielectric Metasurface Structure. Adv. Opt. Mater. 2018, 7, 1801191. [Google Scholar] [CrossRef]

- Xiang, J.; Tao, Z.; Li, X.; Zhao, Y.; He, Y.; Guo, X.; Su, Y. Metamaterial-enabled arbitrary on-chip spatial mode manipulation. Light Sci. Appl. 2022, 11, 168. [Google Scholar] [CrossRef] [PubMed]

- Ohana, D.; Levy, U. Mode conversion based on dielectric metamaterial in silicon. Opt. Express 2014, 22, 27617–27631. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Xu, Y.; Dong, Y.; Zhang, B.; Ni, Y. Efficient silicon-based higher-order mode converters based on subwavelength grating slots. J. Opt. Soc. Am. B 2021, 38, 2908–2914. [Google Scholar] [CrossRef]

- Li, Z.; Kim, M.-H.; Wang, C.; Han, Z.; Shrestha, S.; Overvig, A.C.; Lu, M.; Stein, A.; Agarwal, A.M.; Lončar, M.; et al. Controlling propagation and coupling of waveguide modes using phase-gradient metasurfaces. Nat. Nanotechnol. 2017, 12, 675–683. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Wang, Y.; Gao, X.; Gao, D.; Dong, J.; Huang, D.; Li, F.; Wai, P.A.; Zhang, X. Dielectric Metasurfaces Enabled Ultradensely Integrated Multidimensional Optical System. Laser Photon Rev. 2022, 16, 2100521. [Google Scholar] [CrossRef]

- Yao, C.; Wang, Y.; Zhang, J.; Zhang, X.; Zhao, C.; Wang, B.; Singh, S.C.; Guo, C. Dielectric Nanoaperture Metasurfaces in Silicon Waveguides for Efficient and Broadband Mode Conversion with an Ultrasmall Footprint. Adv. Opt. Mater. 2020, 8, 2000529. [Google Scholar] [CrossRef]

- Dou, T.; Yue, S.; Wang, R.; Hou, Y.; Shi, H.; Zhang, Z.; Liu, Y.; Xue, M.; Zhang, Z. Ultra-compact and ultra-broadband arbitrary-order silicon photonic multi-mode converter designed by an intelligent algorithm. Opt. Express 2023, 31, 9481–9495. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, Y.; He, Y.; Wang, H.; Su, Y. Subwavelength structured silicon waveguides and photonic devices. Nanophotonics 2020, 9, 1321–1340. [Google Scholar] [CrossRef]

- Lu, M.; Deng, C.; Sun, Y.; Wang, D.; Huang, L.; Liu, P.; Lin, D.; Cheng, W.; Hu, G.; Lin, T.; et al. Compact and broadband silicon mode-order converter using bricked subwavelength gratings. Opt. Express 2022, 30, 24655–24666. [Google Scholar] [CrossRef] [PubMed]

- Luque-González, J.M.; Ortega-Moñux, A.; Halir, R.; Schmid, J.H.; Cheben, P.; Molina-Fernández, Í.; Wangüemert-Pérez, J.G. Bricked Subwavelength Gratings: A Tailorable On-Chip Metamaterial Topology. Laser Photon Rev. 2021, 15, 2000478. [Google Scholar] [CrossRef]

- Guo, J.; Ye, C.; Liu, C.; Zhang, M.; Li, C.; Li, J.; Shi, Y.; Dai, D. Ultra-Compact and Ultra-Broadband Guided-Mode Exchangers on Silicon. Laser Photon Rev. 2020, 14, 2000058. [Google Scholar] [CrossRef]

- Yu, N.; Genevet, P.; Kats, M.A.; Aieta, F.; Tetienne, J.-P.; Capasso, F.; Gaburro, Z. Light Propagation with Phase Discontinuities: Generalized Laws of Reflection and Refraction. Science 2011, 334, 333–337. [Google Scholar] [CrossRef] [PubMed]

- Abu-Elmaaty, B.E.; Shalaby, H.M.H. Highly efficient silicon mode converter and polarization rotator using a silicon-based hybrid plasmonic waveguide. J. Opt. Soc. Am. B 2023, 40, 2789–2795. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, L.; Hu, X.; Dong, Y.; Zhang, B.; Ni, Y. Scalable silicon-based mode-order converters assisted by tapered metal strip layer. Opt. Laser Technol. 2022, 151, 108028. [Google Scholar] [CrossRef]

- Chen, H.; Jia, H.; Yang, J.; Tian, Y.; Wang, T. Ultra-compact switchable mode converter based on silicon and optical phase change material hybrid metastructure. Opt. Commun. 2020, 473, 125889. [Google Scholar] [CrossRef]

- Fei, Y.; Xu, Y.; Dong, Y.; Zhang, B.; Ni, Y. Nonvolatile phase change material based multifunctional silicon waveguide mode converters. Opt. Laser Technol. 2024, 168, 110006. [Google Scholar] [CrossRef]

- Mao, S.; Cheng, L.; Zhao, C.; Khan, F.N.; Li, Q.; Fu, H.Y. Inverse Design for Silicon Photonics: From Iterative Optimization Algorithms to Deep Neural Networks. Appl. Sci. 2021, 11, 3822. [Google Scholar] [CrossRef]

- Jia, H.; Zhou, T.; Fu, X.; Ding, J.; Yang, L. Inverse-Design and Demonstration of Ultracompact Silicon Meta-Structure Mode Exchange Device. ACS Photon 2018, 5, 1833–1838. [Google Scholar] [CrossRef]

- Shen, B.; Wang, P.; Polson, R.; Menon, R. An integrated-nanophotonics polarization beamsplitter with 2.4 × 2.4 μm2 footprint. Nat. Photon 2015, 9, 378–382. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, R.; Shi, B.; Jia, Q.; Li, H.; Li, X.; Sun, F.; Cao, Y.; Ding, W. Ultra-compact mode converter based on longitudinal refractive index modulation. Opt. Commun. 2024, 554, 130197. [Google Scholar] [CrossRef]

- Guo, Z.; Xiao, J.; Wu, S.; Lai, Y.; Cheng, S. Compact, Scalable and Flexible Multi-Mode-Converting Model Employing Subwavelength Gratings. J. Light. Technol. 2024, 1–14. [Google Scholar] [CrossRef]

| Structure | Footprints | CE | IL (dB) | CT (dB) | BW (nm) | Function |

|---|---|---|---|---|---|---|

| Reference [28] | 1 × 2.42 µm2 | 90% | 0.46 | NO | 230 (MP > 90%) | TE0–TE1 |

| Reference [31] | 2.1 × 9.39 µm2 2.67 × 11.27 µm2 | NO NO | <1 <1 | <−15 <−15 | 128 (IL < 1 & CT < −15) 126 (IL < 1 & CT < −15) | TE0–TE1 TE0–TE2 |

| Reference [36] | 1 × 2.5 µm2 | 93% | 1.7 | −14 | 230 (CE > 90%) | TE0–TE1 |

| Reference [33] | 1.3 × 2.7 µm2 1.9 × 2.7 µm2 | 95.8% 95.4% | 0.19 0.21 | −19 −32 | 407 (IL < 0.65 & CT < −10) 340 (IL < 0.85 & CT < −10) | TE0–TE1 TE0–TE2 |

| Reference [43] | 2.21 × 13.38 µm2 | NO | 0.37 | −21.2 | 100 (IL < 0.65 & CT < −13) | TE0–TE1 |

| TE0–TE2 | ||||||

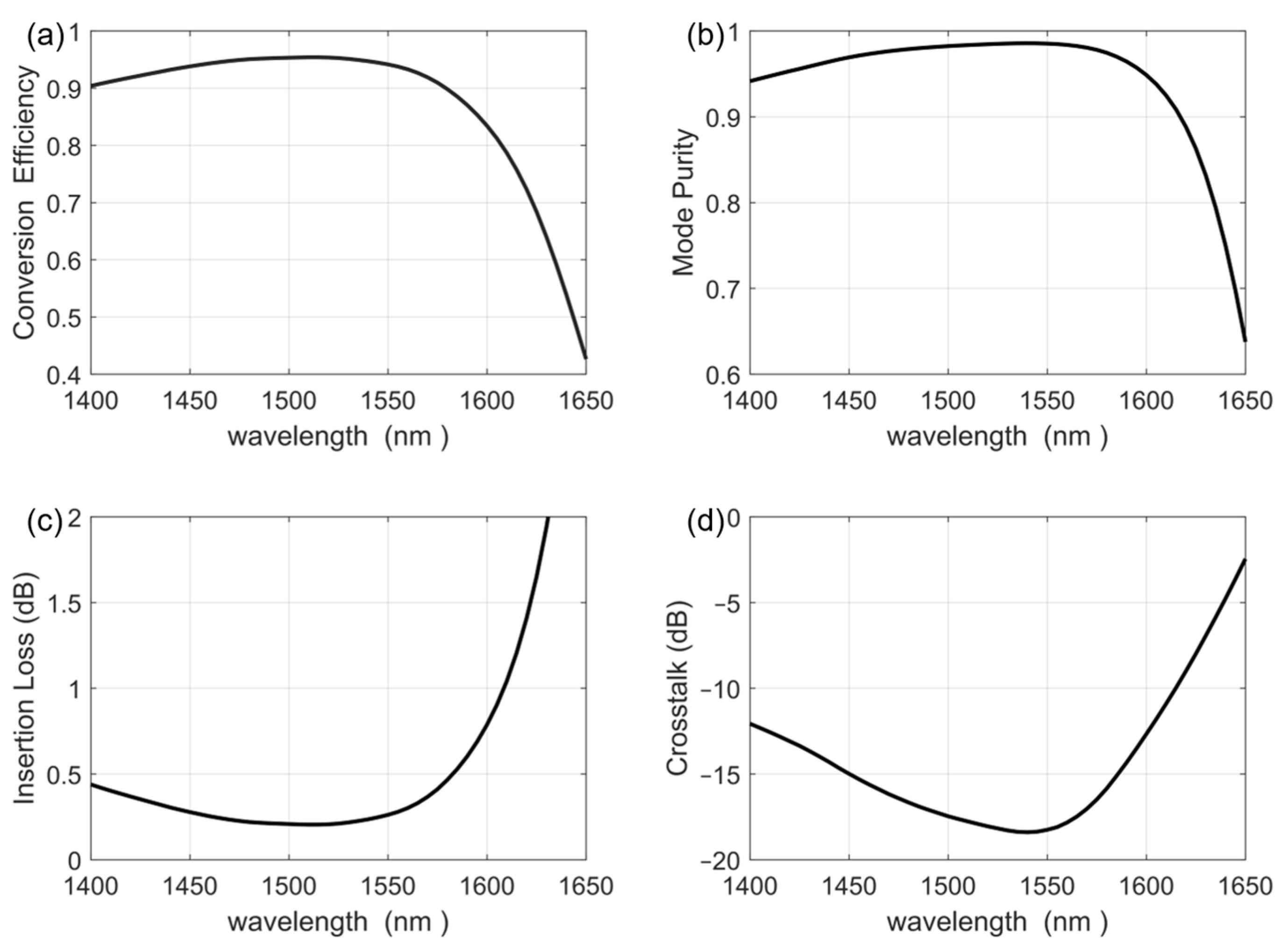

| This work | 1 × 1.14 µm2 | 92.5% | 0.34 | −16 | 180 (IL < 1 & CT < −10) | TE0–TE1 |

| 1.3 × 1.4 µm2 | 94.1% | 0.26 | −18 | 205 (IL < 1 & CT < −10) | TE0–TE2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Feng, R.; Shi, B.; Li, X.; Gao, Y.; Gao, W.; Jia, Q.; Sun, F.; Cao, Y.; Ding, W. Ultra-Compact Reflective Waveguide Mode Converter Based on Slanted-Surface and Subwavelength Metamaterials. Photonics 2024, 11, 838. https://doi.org/10.3390/photonics11090838

Zhang Y, Feng R, Shi B, Li X, Gao Y, Gao W, Jia Q, Sun F, Cao Y, Ding W. Ultra-Compact Reflective Waveguide Mode Converter Based on Slanted-Surface and Subwavelength Metamaterials. Photonics. 2024; 11(9):838. https://doi.org/10.3390/photonics11090838

Chicago/Turabian StyleZhang, Yanxia, Rui Feng, Bojian Shi, Xiaoxin Li, Yanyu Gao, Wenya Gao, Qi Jia, Fangkui Sun, Yongyin Cao, and Weiqiang Ding. 2024. "Ultra-Compact Reflective Waveguide Mode Converter Based on Slanted-Surface and Subwavelength Metamaterials" Photonics 11, no. 9: 838. https://doi.org/10.3390/photonics11090838

APA StyleZhang, Y., Feng, R., Shi, B., Li, X., Gao, Y., Gao, W., Jia, Q., Sun, F., Cao, Y., & Ding, W. (2024). Ultra-Compact Reflective Waveguide Mode Converter Based on Slanted-Surface and Subwavelength Metamaterials. Photonics, 11(9), 838. https://doi.org/10.3390/photonics11090838