Multi-Objective Parameter Optimization Dynamic Model of Grinding Processes for Promoting Low-Carbon and Low-Cost Production

Abstract

:1. Introduction

2. Establishment of a Multi-Objective Optimization Model for the Grinding Process

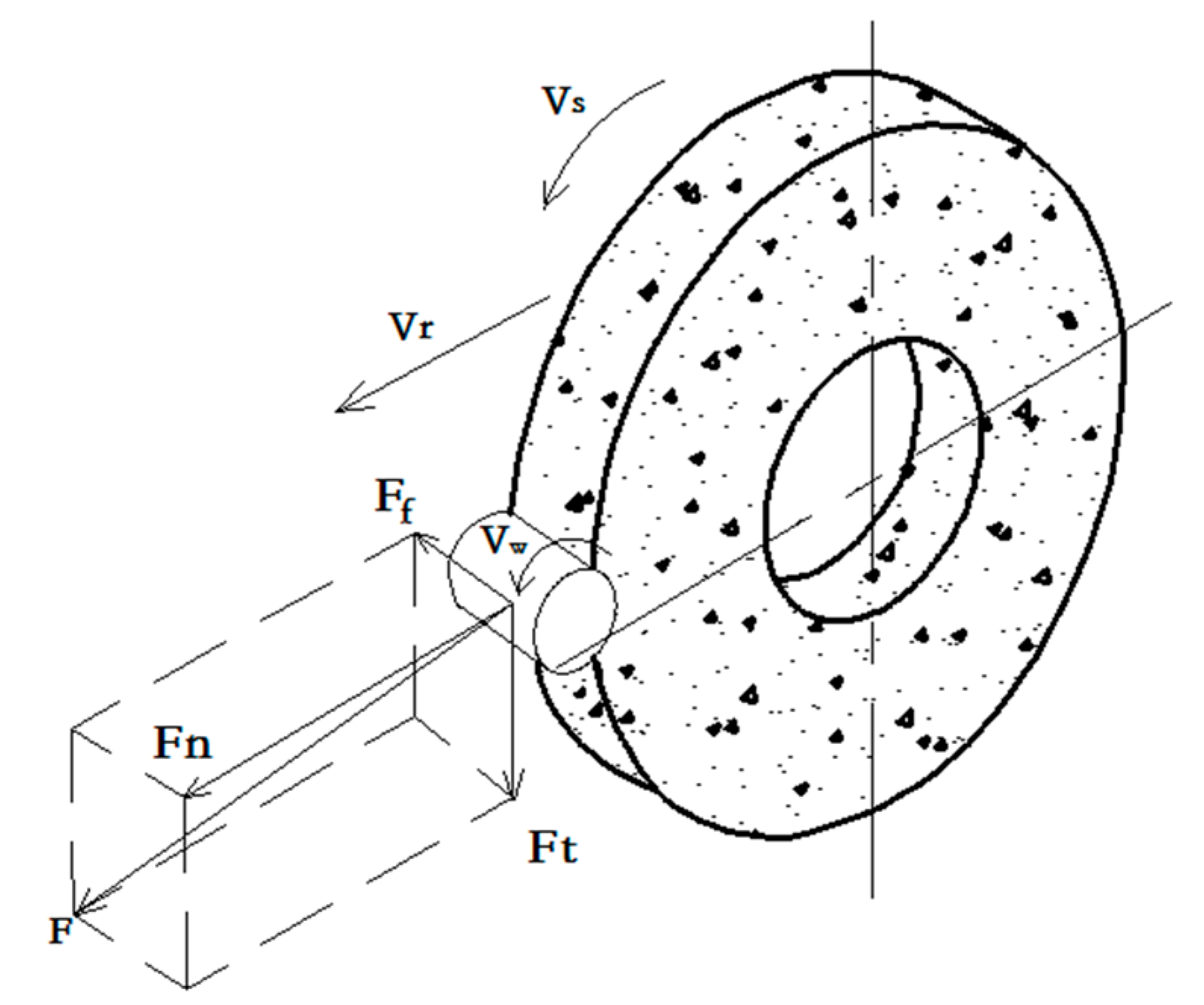

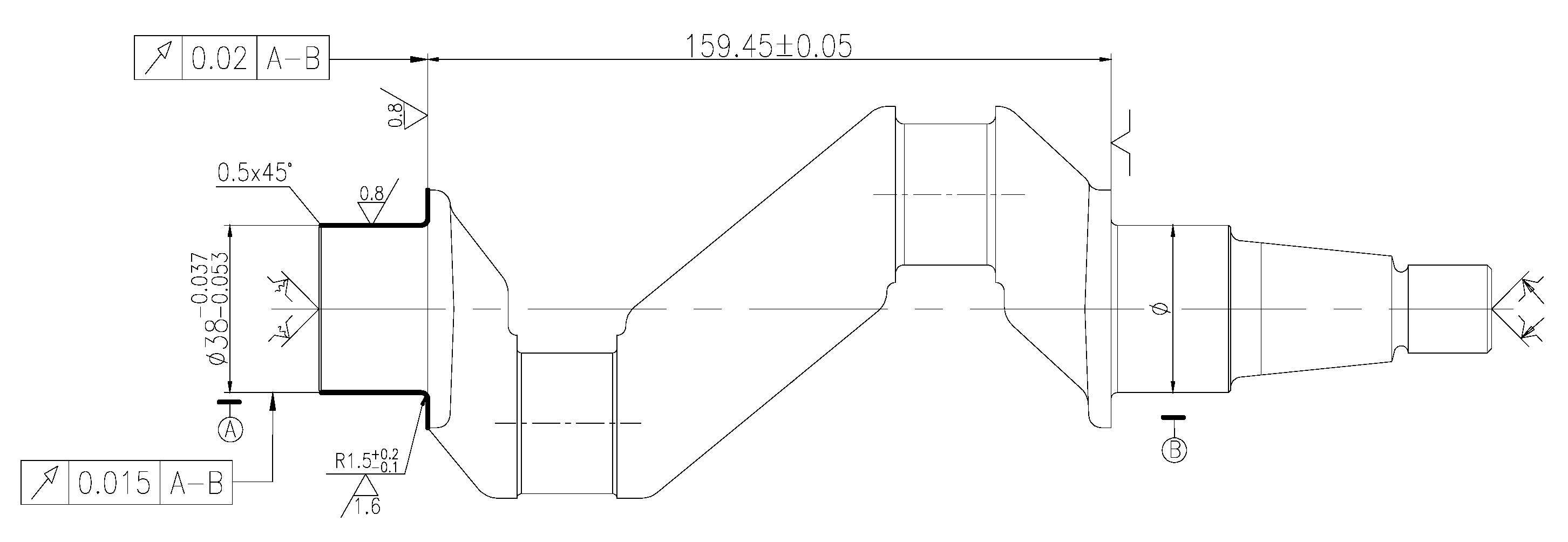

2.1. Optimization Variable

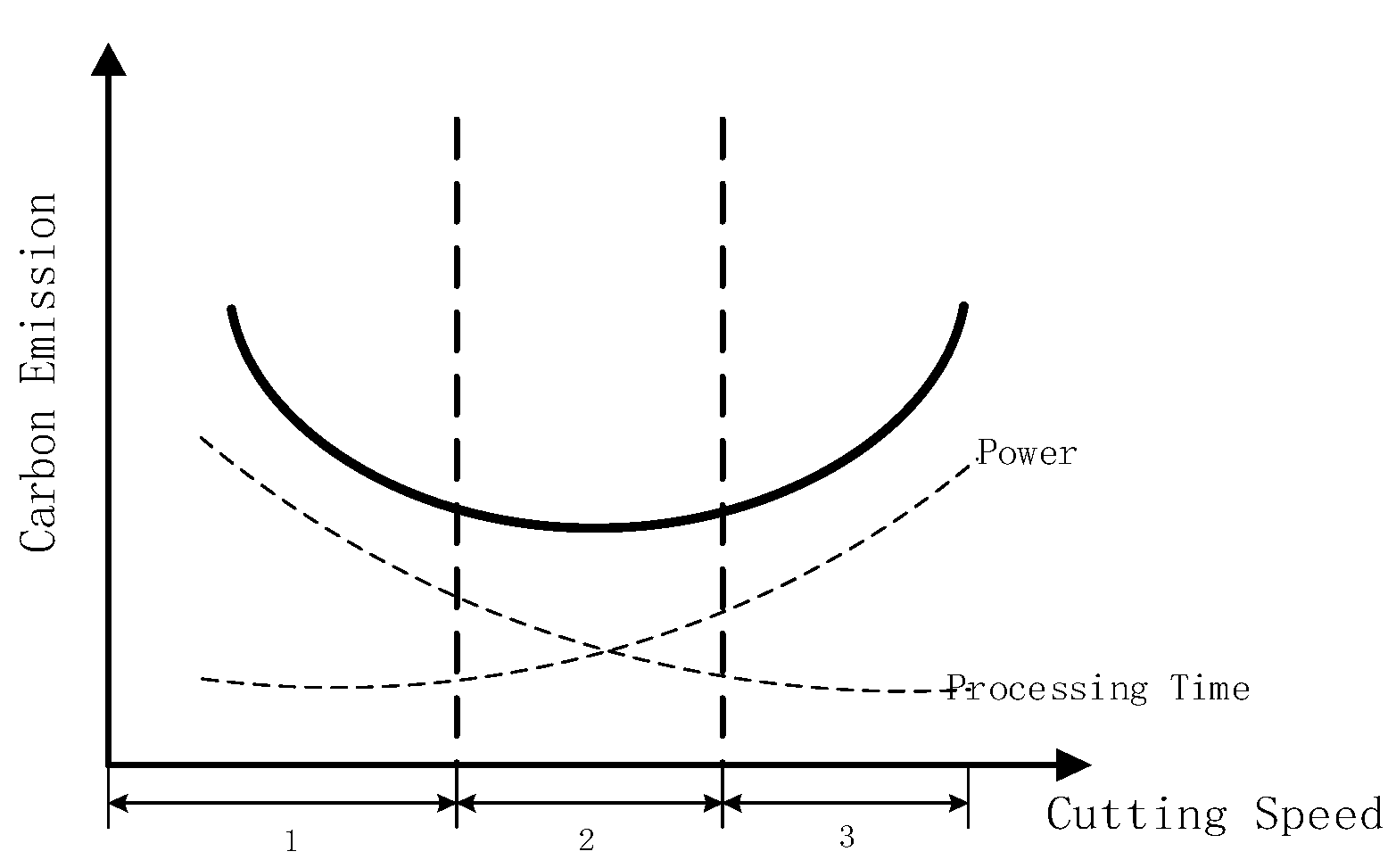

2.2. Carbon Emission Model in the Grinding Process

2.3. Cost Model in the Grinding Process

2.4. Constraint and Optimization Model

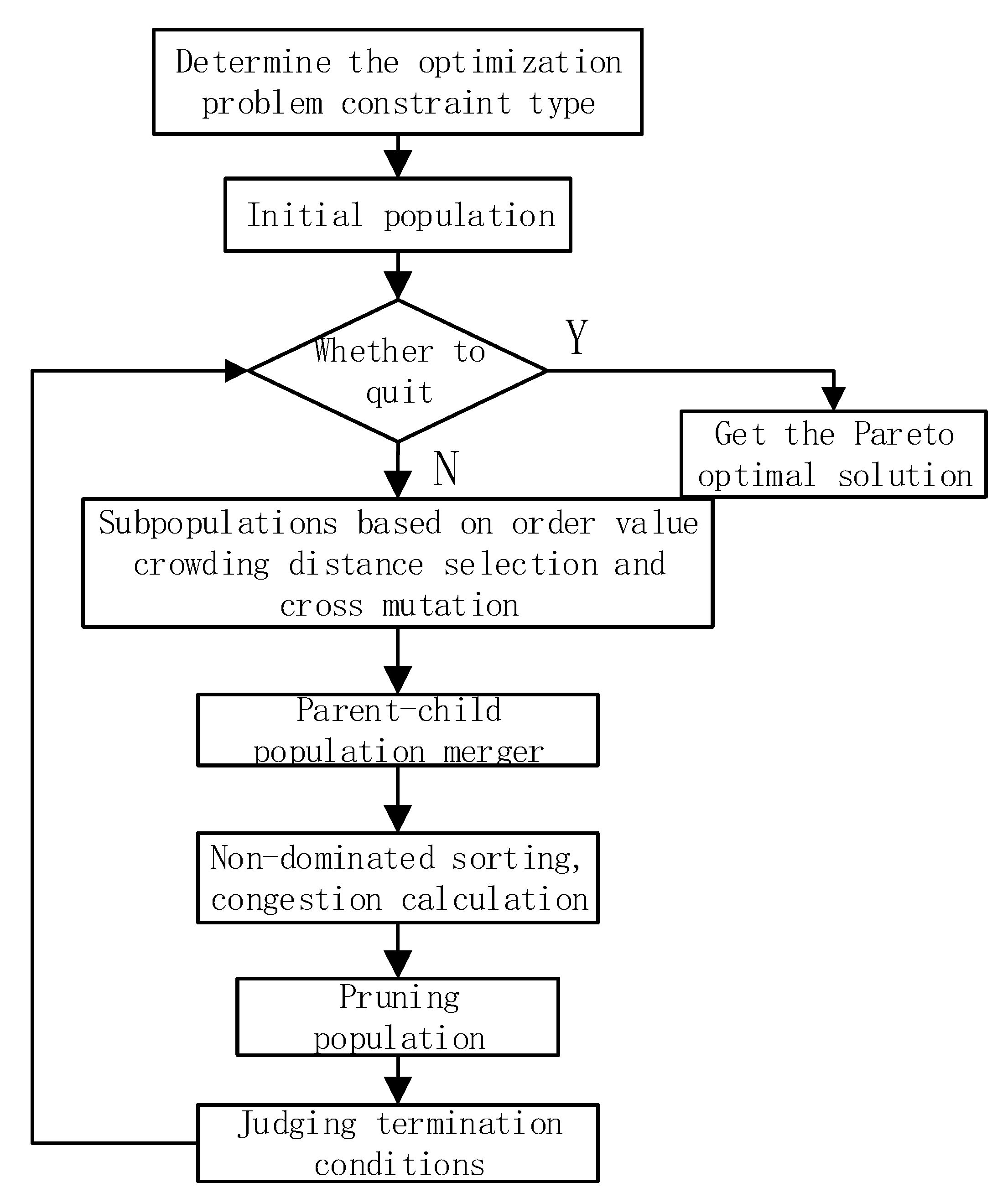

3. Parameter Optimization Based on Improved NSGA-II Algorithm

3.1. Improved NSGA-II Algorithm

3.2. Optimization Target Solving

3.3. Fuzzy Matter Element-Based Decision-Making

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Priarone, P.C. Quality-conscious optimization of energy consumption in a grinding process applying sustainability indicators. Int. J. Adv. Manuf. Technol. 2016, 86, 2107–2117. [Google Scholar]

- Arriandiaga, A.; Portillo, E.; Sánchez, J. A new approach for dynamic modelling of energy consumption in the grinding process using recurrent neural networks. J. Neural Comput. Appl. 2016, 27, 1577–1592. [Google Scholar]

- Salonitis, K. Energy efficiency assessment of grinding strategy. Int. J. Energy Sect. Manag. 2015, 9, 20–37. [Google Scholar] [CrossRef]

- Jiang, P.; Li, G.L.; Liu, P.X.; Jiang, L.; Li, X.Z. Energy consumption model and energy efficiency evaluation for CNC continuous generating grinding machine tools. Int. J. Sustain. Eng. 2017, 10, 226–232. [Google Scholar] [CrossRef]

- Lv, J.; Peng, T.; Tang, R. Energy Modeling and a Method for Reducing Energy Loss Due to Cutting Load During Machining Operations. J. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 699–710. [Google Scholar] [CrossRef]

- Calleja, A.; Bo, P.; González, H.; Bartoň, M.; de López Lacalle, L.N. Highly-accurate 5-axis flank CNC machining with conical tools. Int. J. Adv. Manuf. Technol. 2018, 97, 1605–1615. [Google Scholar]

- Draganescu, F.; Gheorghe, M.; Doicin, C. Models of Machine Tool Efficiency and Specific Consumed Energy. J. Mater. Process. Technol. 2003, 141, 9–15. [Google Scholar] [CrossRef]

- Aramcharoen, A.; Mativenga, P.T. Critical factors in energy demand modelling for CNC milling and impact of toolpath strategy. J. Clean. Prod. 2014, 78, 63–74. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical energy requirements for manufacturing processes. In 13th CIRP International Conference on Life Cycle Engineering; CIRP International Leuven: Leuven, Belgium, 2006. [Google Scholar]

- Liu, F.; Wang, Q.; Liu, G. Content Architecture and Future Trends of Energy Efficiency Research on Machining Systems. J. Mech. Eng. 2013, 49, 87. [Google Scholar] [CrossRef]

- Shin, S.J.; Woo, J.; Rachuri, S. Energy efficiency of milling machining: Component modeling and online optimization of cutting parameters. J. Clean. Prod. 2017, 161, 12–29. [Google Scholar] [CrossRef]

- Liu, F.; Liu, P.J.; Li, C.B.; Tuo, J.B.; Cai, W. The Statue and Difficult Problems of Research on Energy Efficiency of Manufacturing Systems. J. Mech. Eng. 2017, 53, 1–11. [Google Scholar] [CrossRef]

- Park, C.-W.; Kwon, K.-S.; Kim, W.-B.; Min, B.-K.; Park, S.-J.; Sung, I.-H.; Yoon, Y.-S.; Lee, K.-S.; Lee, J.-H.; Seok, J. Energy consumption reduction technology in manufacturing—A selective review of policies, standards, and research. Int. J. Precis. Eng. Manuf. 2009, 10, 151–173. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farné, S. Barriers drivers and decision making process for indus-trial energy efficiency: A broad study among manufacturing small and medium-sized enterprises. J. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Abdelaziz, E.A.; Saidur, R.; Mekhilef, S. A review on energy saving strategies in industrial sector. J. Renew. Sustain. Energy Rev. 2011, 15, 150–168. [Google Scholar] [CrossRef]

- Dietmair, A.; Alexander, V. A Generic Energy Consumption Model for Decision Making and Energy Efficiency Optimisation in Manufacturing. Int. J. Sustain. Eng. 2009, 2, 123–133. [Google Scholar] [CrossRef]

- Cai, W.; Liu, C.; Zhang, C.; Ma, M.; Rao, W.; Li, W.; He, K.; Gao, M. Developing the ecological compensation criterion of industrial solid waste based on emergy for sustainable development. J. Energy 2018, 157, 940–948. [Google Scholar] [CrossRef]

- Cai, W.; Liu, F.; Zhou, X.; Xie, J. Fine energy consumption allowance of workpieces in the mechanical manufacturing industry. J. Energy 2016, 114, 623–633. [Google Scholar] [CrossRef]

- Greinacher, S.; Lanza, G. Optimisation of lean and green strategy deployment in manufacturing systems. J. Appl. Mech. Mater. 2015, 794, 748–785. [Google Scholar] [CrossRef]

- Cai, W.; Liu, C.; Lai, K.-H.; Li, L.; Cunha, J.; Hu, L. Energy performance certification in mechanical manufacturing industry: A review and analysis. J. Energy Convers. Manag. 2019, 186, 415–432. [Google Scholar] [CrossRef]

- Ma, F.; Zhang, H.; Hon, K.; Gong, Q.S. An optimization approach of selective laser sintering considering energy consumption and material cost. J. Clean. Prod. 2018, 199, 529–537. [Google Scholar] [CrossRef]

- Jiang, Z.; Ding, Z.; Liu, Y.; Wang, Y.; Hu, X.; Yang, Y. A data-driven based decomposition–integration method for remanufacturing cost prediction of end-of-life products. Robot. J. Comput. Integr. Manuf. 2020, 61, 101838. [Google Scholar] [CrossRef]

- Lin, W.; Yu, D.; Wang, S.; Zhang, C.; Zhang, S.; Tian, H.; Luo, M.; Liu, S. Multi-objective teaching–learning-based optimization algorithm for reducing carbon emissions and operation time in turning operations. J. Eng. Optim. 2015, 47, 994–1007. [Google Scholar] [CrossRef]

- Wei, Y.; Hua, Z.; Zhi-gang, J.; Hon, K.K.B. A new multi-source and dynamic energy modeling method for machine tools. Int. J. Adv. Manuf. Technol. 2018, 95, 4485–4495. [Google Scholar] [CrossRef]

- Bustillo, A.; Urbikain, G.; Perez, J.M.; Pereira, O.M.; Lopez de Lacalle, L.N. Smart optimization of a friction-drilling process based on boosting ensembles. J. Manuf. Syst. 2018, 48, 108–121. [Google Scholar] [CrossRef]

- Shen, N.Y.; Wang, W.D.; Li, J.; Cao, Y.L.; Wang, Y. Modelling and Analysis of Grinding Energy Consumption in Non-circular Grinding Process. J. Mech. Eng. 2017, 53, 208–216. [Google Scholar] [CrossRef]

- Li, H.N.; Yu, T.B.; Wang, Z.X.; Zhu, L.D.; Wang, W.S. Detailed modeling of cutting forces in grinding process considering variable stages of grain-workpiece micro interactions. Int. J. Mech. Sci. 2016, 126, 319–339. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Li, C.H.; Ji, H.J. Analysis of grinding mechanics and improved predictive force model based on material-removal and plastic-stacking mechanisms. Int. J. Mach. Tools Manuf. 2017, 122, 67–83. [Google Scholar] [CrossRef]

- Liu, P.J.; Junbo, T.; Liu, F.; Li, C.B.; Zhang, X.C. A Novel Method for Energy Efficiency Evaluation to Support Efficient Machine Tool Selection. J. Clean. Prod. 2018, 191, 57–66. [Google Scholar] [CrossRef]

- Paetzold, J.; Kolouch, M.; Wittstock, V.; Putz, M. Methodology for process-independent energetic assessment of machine tools. J. Procedia Manuf. 2017, 8, 254–261. [Google Scholar] [CrossRef]

- Jiang, Z.; Ding, Z.; Zhang, H.; Cai, W.; Liu, Y. Data-driven ecological performance evaluation for remanufacturing process. J. Energy Convers. Manag. 2019, 198, 111844. [Google Scholar] [CrossRef]

- Ding, Z.; Jiang, Z.; Zhang, H.; Cai, W.; Liu, Y. An integrated decision-making method for selecting machine tool guideways considering remanufacturability. Int. J. Comput. Integr. Manuf. 2018, 1–12. [Google Scholar] [CrossRef]

- Schudeleit, T.; Züst, S.; Wegener, K. Methods for evaluation of energy efficiency of machine tools. J. Energy 2015, 93, 1964–1970. [Google Scholar] [CrossRef]

- Ma, F.; Zhang, H.; Gong, Q.S.; Hong, K.K.B. A Novel Energy Evaluation Approach of Machining Processes Based on Data Analysis. J. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 1–15. [Google Scholar] [CrossRef]

- Cai, W.; Lai, K.; Liu, C.; Wei, F.F.; Ma, M.D.; Jia, S.; Jiang, Z.G.; Lv, L. Promoting sustainability of manufacturing industry through the lean energy-saving and emission-reduction strategy. J. Sci. Total Environ. 2019, 665, 23–32. [Google Scholar] [CrossRef]

- Jia, S.; Yuan, Q.; Cai, W.; Li, M.; Li, Z. Energy modeling method of machine-operator system for sustainable machining. J. Energy Convers. Manag. 2018, 172, 265–276. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, S.; Wan, J.; Liu, G. Green Product Assessment Method Based on Fuzzy-Matter Element. J. China Mech. Eng. 2007, 18, 166–170. [Google Scholar]

- Wang, Y.; Zhang, H.; Zhang, Z.; Wang, J. Development of an Evaluating Method for Carbon Emissions of Manufacturing Process Plans. J. Discret. Dyn. Nat. Soc. 2015, 2015. [Google Scholar] [CrossRef]

- Zhang, L.; Ma, J.; Fu, Y.G. Carbon Emission Analysis for Product Assembly Process. J. Mech. Eng. 2016, 52, 151–160. [Google Scholar] [CrossRef]

- Li, C.; Cui, L.; Liu, F.; Li, L. Multi-objective NC Machining Parameters Optimization Model for High Efficiency and Low Carbon. J. Mech. Eng. 2013, 49, 87–96. [Google Scholar] [CrossRef]

- Zhuang, S.X. Grinding Technology; Mechanical Industry Press: Beijing, China, 2007; pp. 53–55. [Google Scholar]

| Parameters | Numerical Value |

|---|---|

| Wheel speed (r/min) | 1500–3000 |

| Head frame speed (r/min) | 50–500 |

| Grinding wheel feed rate (mm/min) | 0.05–5000 |

| Wheel size (outer diameter × width × inner diameter; mm) | Ø 500 × 80 × Ø 203 |

| Motor power (kW) | 7.5 |

| Surface roughness (μm) | Ra 0.08 |

| No. | Grinding Variable | Coding | Measured Value of Tangential Grinding Force | ||||||

|---|---|---|---|---|---|---|---|---|---|

| ap/mm | vs/m·min−1 | vw/m·min−1 | b0 | b1 | b2 | b3 | Ft/N | lnFt | |

| 1 | 0.005 | 2.5 | 12 | +1 | −1 | +1 | −1 | 48 | y1 = 3.87 |

| 2 | 0.005 | 1.0 | 48 | +1 | −1 | −1 | +1 | 77 | y2 = 4.34 |

| 3 | 0.020 | 1.0 | 12 | +1 | +1 | −1 | −1 | 87 | y3 = 4.46 |

| 4 | 0.020 | 2.5 | 48 | +1 | +1 | +1 | +1 | 449 | y4 = 6.11 |

| Parameters | Numerical Value |

|---|---|

| 1.526 kW | |

| 2.772 kW | |

| 0.322 kW | |

| 1200 s | |

| 600 s | |

| 120 s | |

| 5 μm | |

| L | 150 mm |

| Q | 30 pieces |

| N | 120 pieces |

| G | 21 |

| vs | vr | vw | W | C | |

|---|---|---|---|---|---|

| 1 | 24.994 | 1.602 × 10−4 | 13.057 | 0.023 | 1.055 |

| 2 | 23.998 | 1.637 × 10−4 | 14.339 | 0.027 | 0.808 |

| 3 | 25.000 | 1.602 × 10−4 | 13.003 | 0.023 | 1.069 |

| ... | ... | ... | ... | ... | ... |

| 21 | 24.235 | 1.609 × 10−4 | 14.028 | 0.025 | 0.825 |

| ... | ... | ... | ... | ... | ... |

| 30 | 24.975 | 1.611 × 10−4 | 13.012 | 0.023 | 1.060 |

| vs | vr | vw | W | C | |

|---|---|---|---|---|---|

| Low cost | 23.99770954 | 0.000163744 | 14.3388749 | 0.026951585 | 0.808222327 |

| Low carbon and low cost | 24.23538375 | 0.000160926 | 14.02766146 | 0.025212982 | 0.824788898 |

| Low carbon | 24.99970889 | 0.000160212 | 13.00277846 | 0.022746323 | 1.068775876 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, M.; Sun, Y.; Gong, Q.; Tian, S.; Wu, Y. Multi-Objective Parameter Optimization Dynamic Model of Grinding Processes for Promoting Low-Carbon and Low-Cost Production. Processes 2020, 8, 3. https://doi.org/10.3390/pr8010003

Hu M, Sun Y, Gong Q, Tian S, Wu Y. Multi-Objective Parameter Optimization Dynamic Model of Grinding Processes for Promoting Low-Carbon and Low-Cost Production. Processes. 2020; 8(1):3. https://doi.org/10.3390/pr8010003

Chicago/Turabian StyleHu, Mingmao, Yu Sun, Qingshan Gong, Shengyang Tian, and Yuemin Wu. 2020. "Multi-Objective Parameter Optimization Dynamic Model of Grinding Processes for Promoting Low-Carbon and Low-Cost Production" Processes 8, no. 1: 3. https://doi.org/10.3390/pr8010003

APA StyleHu, M., Sun, Y., Gong, Q., Tian, S., & Wu, Y. (2020). Multi-Objective Parameter Optimization Dynamic Model of Grinding Processes for Promoting Low-Carbon and Low-Cost Production. Processes, 8(1), 3. https://doi.org/10.3390/pr8010003