Abstract

China has numerous closed coal mines with abundant residual resources. The combined effect of multiple factors has driven research on gas resources in the goafs of these mines. Elucidating the characteristics of goaf gas reservoir space is crucial for analyzing gas distribution and extraction. Therefore, investigating gas reservoir space characteristics under coal seam group conditions is vital. This study uses the Xinzhuangzi closed coal mine as a case study and presents methods for calculating goaf space under both individual coal seam and coal seam group conditions. The volumes of the caving, fissure, and floor failure zones are determined. The results reveal that 14 coal seams have been mined at the Xinzhuangzi coal mine, with a total mined area of 4583.04 × 104 m2 across all seams. Under individual coal seam assumptions, the caving, fissure, and floor failure zones have volumes of 455.98 × 106, 1648.40 × 106, and 614.65 × 106 m3, respectively, with a total goaf volume of 2719.03 × 106 m3. Under coal seam group conditions, the caving, fissure, and floor failure zones have volumes of 438.22 × 106, 871.24 × 106, and 154.90 × 106 m3, respectively, with a total goaf volume of 1464.36 × 106 m3. The caving, fissure, floor failure zones and total volumes under coal seam group conditions are 96.11%, 52.85%, 25.20%, and 53.86% of the corresponding volumes calculated under individual coal seam assumptions. This indicates that the coal seam group goaf volumes are neither a simply the sum nor a proportional reduction in the individual coal seam goaf volumes. This study provides a concise approach for investigating goaf gas reservoir space under coal seam group conditions.

1. Introduction

The number of closed or abandoned coal mines in China has steadily increased each year. By the end of 2021, about 5700 coal mines had been shut down or abandoned [1]. Estimates further indicate that the number of abandoned coal mines in China will reach 15,000 by 2030 [2,3]. These closed or abandoned mines still contain ~420 × 108 t of coal, nearly 5000 × 108 m3 of unconventional natural gas, and other valuable resources [4,5]. Owing to factors such as the recoverable value of residual resources, gas explosion risks, environmental pressures from methane-related greenhouse gas emissions [6,7], and national dual-carbon targets [8], research on resource recovery from abandoned coal mines has received increasing attention. International studies on the utilization of residual gas resources from closed coal mines began earlier and provide valuable reference cases. For example, in the UK, gas-extraction projects have been implemented in 30 of 300 closed underground coal mines [9]. Durucan [10] used numerical simulations to evaluate methane recovery from abandoned mines in the Saar Coalfield, Germany, and predicted future methane production based on the model results. Karacan [11] investigated abandoned coal mines in Pennsylvania, USA. The study identified two key uncertainties affecting the economic utilization of methane: the total methane available in the gas emission zone of the abandoned mine and the recoverable fraction of this methane.

For unmined coal seams, gas resources are contained within the coal, known as in situ gas resources [12,13], and research has mainly focused on their thickness and distribution. In mined coal seams, some residual gas remains in the goaf, known as goaf gas resources [13,14]. Therefore, studies in these areas have focused on the volume and distribution of the goaf. In closed coal mines mined for decades, many coal seams have been extracted, making goaf gas a key research focus. Reservoir characteristics are crucial for underground energy extraction, and therefore research on reservoir spaces is very extensive, such as coal reservoirs for coalbed methane [15], reservoirs of deep-water turbidite [16], and depleted gas reservoirs [17]. Goaf gas reservoir space is a special type of reservoir space. The goaf gas reservoir space reflects the volume and spatial arrangement of its components, including the size and distribution of voids. This gas reservoir space is crucial for investigating gas migration and extraction in closed coal mines and estimating free gas resources based on void volume and methane concentration [6]. While gas reservoir space under individual coal seam conditions is well-studied [18,19], most coal mines, including Xinzhuangzi, operate with coal seam groups. Here, interactions between adjacent goafs create a more complex system [20,21], a scenario that remains less explored. Although some studies have examined gas reservoir space under coal seam group conditions [22], research remains limited in scope, methodology, and findings. Therefore, investigating the characteristics of the goaf gas reservoir space under coal seam group conditions is crucial.

The Xinzhuangzi coal mine, with 14 of its 16 mineable coal seams mined, exhibits typical coal seam group mining characteristics [23]. After 70 years of operation, the coal mine was closed at the end of 2017, thereby terminating a production capacity of 400 × 104 t/a. Therefore, the Xinzhuangzi closed coal mine was selected as a case study to investigate the characteristics of the goaf gas reservoir space under coal seam group conditions.

2. Geological Background

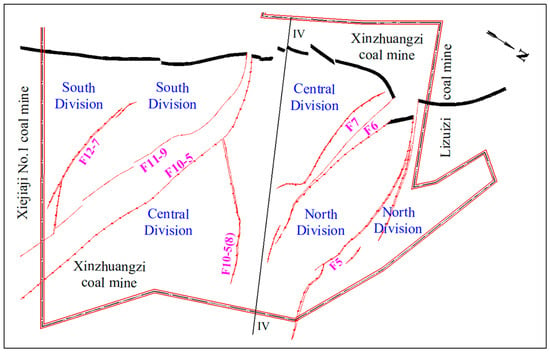

The Xinzhuangzi coal mine is a closed mine located in Bagongshan District, Huainan City, Anhui Province, China. This mine is bounded to the south by Xiejiaji No. 1 coal mine and to the north by the Lizuizi coal mine. The western boundary of the mine is defined by the westernmost line of the weathering and oxidation zone of all coal seams. The eastern boundary corresponds to the easternmost line of the −1000 m elevation horizontal projection of all coal seams [23]. The mine spans about 5.40 km strike length and 3.75 km dip width (total 17.7861 km2; Figure 1).

Figure 1.

Boundaries and structural divisions of the Xinzhuangzi coal mine.

The coal-bearing strata of the Xinzhuangzi coal mine include the Carboniferous Taiyuan Formation and the Permian Shanxi, Lower Shihezi, and Upper Shihezi Formations. The Carboniferous Taiyuan Formation has a total thickness of ~120 m and contains 7–10 coal seams. These seams are thin, highly unstable, and sulfur-rich, making them unmineable and unsuitable for exploration. The Shanxi, Lower Shihezi, and Upper Shihezi Formations have a total thickness of 820.69 m and contain over 40 coal seams with an average thickness of 41.52 m and a coal-bearing coefficient of 5.06% (Table 1). The Permian strata are divided from bottom to top into five coal-bearing members (A, B, C, D and E) and seven coal-bearing sections (No. 1, No. 2, No. 3, No. 4, No. 5, No. 6 and No. 7). The coal seams in members D and E are thin, unstable, and of low grade. Consequently, these seams were not mined at the Xinzhuangzi coal mine.

Table 1.

Characteristics of the Permian coal-bearing strata.

The Xinzhuangzi coal mine contains 16 mineable coal seams distributed across the No. 1 to No. 4 coal-bearing sections of the Permian. From top to bottom, the coal seams are labeled C14, C13, B11b, B11a, B10, B9, B8, B7b, B7a, B7a-, B6, B5b, B5a, B4, A3, and A1, with an average total thickness of 32.47 m (Table 2). The key mineable coal seams are C13, B11b, B8, B7a, B6, B4, A3, and A1.

Table 2.

Major characteristics of the 16 mineable coal seams.

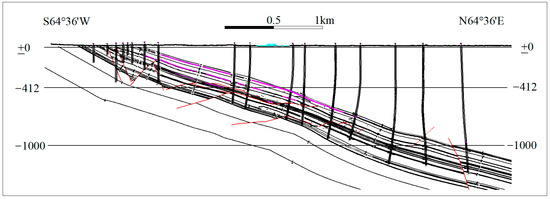

The coal mine exhibits a monocline structure (Figure 2), with well-developed faults and locally developed small folds. The strata strike is N40°W, the dip is toward NE, and dip angle varies significantly from 8° to 55° but mostly between 25° and 28°. Two fault groups, F6–F7 and F10-5–F11-9, control the overall structure of the coal mine. The coal mine is divided into three structural divisions based on these fault groups: the North Division (north of F6–F7), the Central Division (between F6–F7 and F10-5–F11-9), and the South Division (south of F10-5–F11-9). The coal seam extends from shallow to deep with significant depth variation. The mine is further subdivided into seven mining levels: −47 (Level 1), −112 (Level 2), −262 (Level 3), −412 (Level 4), −612 (Level 5), −812 (Level 6), and −1000 m (Level 7).

Figure 2.

Geological profile along the No. IV exploration line.

3. Characterization Methods for the Goaf Gas Reservoir Space

3.1. Individual Coal Seam Conditions

The goaf gas reservoir space created by coal mining under individual coal seam conditions includes the caving and fissure zones in the overlying strata and the floor failure zone in the underlying strata. This concept is widely accepted by researchers [19,20,24].

First, the horizontal area of the goafs is determined. The coal seam floor contour maps of the 16 mineable coal seams [23] reveal the positions of the working faces, mining events, and residual coal resource distributions for each seam. From these maps, the horizontal distribution of goaf areas for each coal seam in the different structural divisions can be determined. Here, AND, ACD, and ASD represent the goaf areas of a coal seam in the North, Central, and South Divisions, respectively.

Second, the vertical distribution of the goafs is determined. Reference [23] summarizes long-term resource exploration, coal production, and scientific research in the coal mine. This reference provides data on the heights of the caving and fissure zones and the depth of the floor failure zone for eight key mined coal seams. For the other six mined coal seams without these data, using empirical formulas for calculation is a concise and effective method [25,26], and among many empirical formulas, the empirical formulas in national regulations and standards are widely used [27,28], so these values are calculated using national regulations [29] and standards [30] (Equations (1)–(3)). Equations (1)–(3) correspond to medium-hardness overlying strata of this coal mine, and without loss of generality, the Equations omit the uncertainty range (±root mean square error).

where HM denotes the height of the caving zone (m), HL represents the height of the fissure zone (m), HD indicates the depth of the floor failure zone (m), ∑m signifies the total thickness of the mined coal seam (m), and L denotes the inclined length of the working face (m).

HD = 0.303L0.8

Third, the volume of the goafs is calculated. The data (AND, ACD, ASD, HM, HL, and HD) are used to compute the volumes of the caving, fissure, and floor failure zones for each coal seam in the North, Central, and South Divisions (VM+ND, VM+CD, VM+SD; VL+ND, VL+CD, VL+SD; VD+ND, VD+CD, VD+SD) (Equations (4)–(6)).

where VM+ND, VM+CD, and VM+SD represent the volumes of the caving zones in the North, Central, and South Divisions, respectively (×106 m3). VL+ND, VL+CD, and VL+SD denote the volumes of the fissure zone in the North, Central, and South Divisions, respectively (×106 m3). VD+ND, VD+CD, and VD+SD represent the volumes of the floor failure zones in the North, Central, and South Divisions, respectively (×106 m3). Other parameters are described above.

VM+ND = AND × HM; VM+CD = ACD × HM; VM+SD = ASD × HM

VL+ND = AND × HL; VL+CD = ACD × HL; VL+SD = ASD × HL

VD+ND = AND × HD; VD+CD = ACD × HD; VD+SD = ASD × HD

Finally, the volume of the goafs is calculated. The volumes of each coal seam in the caving, fissure, and floor failure zones (∑VM, ∑VL, ∑VD) are determined using Equation (7). The total volumes in each structural division (∑VND, ∑VCD, ∑VSD) are calculated using Equation (8), and the overall goaf volume (∑V) is determined using Equation (9).

∑VM =VM+ND + VM+CD + VM+SD; ∑VL = VL+ND + VL+CD + VL+SD; ∑VD = VD+ND + VD+CD + VD+SD

∑VND = VM+ND + VL+ND + VD+ND; ∑VCD = VM+CD + VL+CD + VD+CD; ∑VSD = VM+SD + VL+SD + VD+SD

∑V = ∑VM + ∑VL + ∑VD

Here, ∑VM, ∑VL, and ∑VD denote the total volumes of the caving, fissure, and floor failure zones, respectively (×106 m3). ∑VND, ∑VCD, and ∑VSD represent the total volumes in the North, Central, and South Divisions, respectively (×106 m3). ∑V indicates the total volume of the goaf (×106 m3). Other parameters are described above.

3.2. Coal Seam Group Conditions

The Xinzhuangzi coal mine operates under coal seam group conditions, with 14 mined coal seams. The goafs of the upper and lower coal seams often intersect. The caving, fissure, and floor failure zones of a coal seam may overlap with those of adjacent coal seams. Therefore, the goaf gas reservoir space under coal seam group conditions cannot be calculated as a simple sum. Instead, the reservoir space must be analyzed based on the specific characteristics of these interactions.

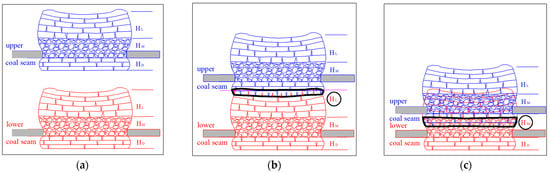

When the floor failure zone of the upper coal seam does not intersect the caving or fissure zones of the lower seam, the gas reservoir spaces of both seams can be calculated independently (Figure 3a). Under coal seam group conditions, coal mining is usually carried out from top to bottom, that is, the upper coal seam is mined first, the strata movement of upper coal seam occurs first, while the lower coal seam is mined later, the strata movement of lower coal seam occurs later. And then, the floor failure zone of the upper coal seam and the fissure zone of the lower coal seam are both characterized by fissure development. So, when the floor failure zone of the upper coal seam intersects the fissure zone of the lower coal seam, the overlapping volume is assigned to the fissure zone of the lower coal seam and not counted twice (Figure 3b). The caving zone, with larger and more fissures, and also with strong connectivity, is completely different from floor failure zone and fissure zone. So, similarly, when the floor failure zone of the upper coal seam intersects the caving zone of the lower coal seam, the overlapping volume is assigned to the caving zone of the lower seam and not counted twice (Figure 3c). Analogously with above, if the overlap involves a caving zone, the overlapping volume is assigned to the caving zone. If the caving zones of both coal seams are involved, the overlapping volume is assigned to the caving zone of the lower coal seam. If no caving zone is involved, the overlapping volume is assigned to the fissure zone of the lower coal seam.

Figure 3.

Characterization methods for the goaf gas reservoir space under coal seam group conditions. (a) the floor failure zone of the upper coal seam does not intersect the caving or fissure zones of the lower seam. (b) the floor failure zone of the upper coal seam intersects the fissure zone of the lower coal seam. (c) the floor failure zone of the upper coal seam intersects the caving zone of the lower coal seam.

According to the above rules for handling overlaps between upper and lower coal seam goafs, the goaf volume can be calculated using Equations (4)–(9).

4. Goaf Gas Reservoir Space Results

4.1. Goaf Volumes Under Individual Coal Seam Conditions

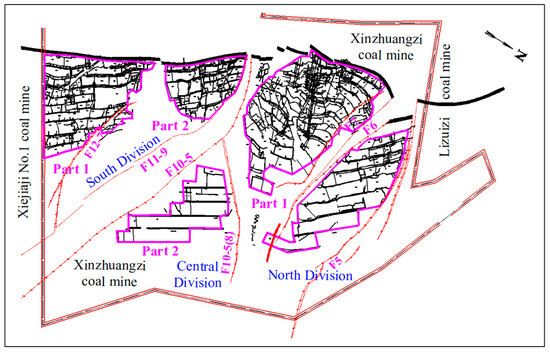

First, the horizontal distribution of the B11b goaf is analyzed. B11b, a key mined coal seam at the Xinzhuangzi coal mine, is used to illustrate the horizontal distribution of the goaf under individual coal seam conditions (Figure 4). In the South Division, Part 1 covers 115.59 × 104 m2, and Part 2 covers 54.28 × 104 m2, yielding a total ASD of 169.87 × 104 m2. In the Central Division, Part 1 covers 173.64 × 104 m2, and Part 2 covers 65.25 × 104 m2, resulting in a total ACD of 238.89 × 104 m2. The North Division (AND) covers 106.37 × 104 m2. Therefore, the total goaf area of B11b is 515.13 × 104 m2.

Figure 4.

Horizontal distribution of the B11b goaf.

Second, the horizontal distribution of all mined coal seams is determined using the same method as for B11b, with goaf areas calculated for each seam in each structural division (Table 3).

Table 3.

Goaf areas in each structural division.

Among the 16 mineable coal seams, B5a and B5b have not been mined. The total goaf area of the remaining 14 coal seams is 4583.04 × 104 m2. Regarding the coal seams, C13, B8, B11b, B11a, B7a, A1, and B6 have relatively large mined areas, accounting for 12.49%, 11.37%, 11.24%, 9.27%, 8.82%, 8.41%, and 8.20% of the total, respectively. These seven coal seams represent 69.80% of the mined area. In contrast, B4, B10, B7b, A3, B7-, C14, and B9b have smaller mined areas, accounting for the remaining 30.20%. Regarding structural divisions, the South, Central, and North Divisions have goaf areas of 2401.10 × 104, 1283.08 × 104, and 898.96 × 104 m2, respectively, corresponding to 52.39%, 28.00%, and 19.61% of the total goaf area.

Table 4 presents the vertical goaf distribution for each coal seam, including the caving zone height (HM), fissure zone height (HL), and floor failure depth (HD). In this table, the coal seam thickness represents the average thickness within the mined area, rather than the overall average thickness for the entire mine. The HM and HL values for eight coal seams—C13, B11b, B8, B7a, B6, B4, A3, and A1—are obtained from the reference [23]. The HM and HL values for the other six coal seams—C14, B11a, B10, B9, B7b, and B7a—are calculated using Equations (1) and (2). The HD value is calculated using Equation (3). According to this equation, a longer inclined length of the working face (L) results in a greater depth of the floor failure zone (HD). The working faces were relatively small before 2004, but with the advancement of mining technology, the working faces became larger after 2004. Owing to variations in the sizes and the inclined lengths of working faces at different stages of the mine production history, HD varies. Therefore, two HD values in Table 4 reflect these differences, L1 and L2 represent the average inclined length of the working face before and after 2004, while HD1 and HD2 represent the depth of the floor failure zone corresponding to the inclined length L1 and L2.

Table 4.

HM, HL, and HD for each mined coal seam.

Finally, the calculated goaf volumes for each coal seam and each structural division under individual coal seam assumptions are presented in Table 5 and Table 6.

Table 5.

Statistics of goaf volumes under individual coal seam conditions.

Table 6.

Goaf volumes by structural division under individual coal seam conditions.

4.2. Goaf Volumes Under Coal Seam Group Conditions

Under coal seam group conditions, 14 coal seams have been mined. Thus, the goafs of upper and lower coal seams may overlap both horizontally and vertically. Owing to the significant thickness of the coal-bearing strata and the large number of mined coal seams, the goaf volume is analyzed in sections. The 14 mined seams are assigned to Sections No. 1–4 of the coal-bearing strata (Table 1). Section No. 1 includes two mined coal seams (A3 and A1). Because the vertical distance between A3 and A1 is 7.70 m and the height of the A1 caving zone is 9.27 m, A3 falls within the A1 caving zone. Therefore, the overlapping portion of the A1 and A3 goafs is assigned to the A1 caving zone, rather than the A3 floor failure zone. Section No. 2 of the coal-bearing strata includes seven mined coal seams (B9, B8, B7b, B7a, B7a-, B6, and B4). The vertical distance between B4 and A3 is 59.60 m; thus, the overlapping portion of the B4 floor failure zone and the A3 fissure zone is assigned to the A3 fissure zone, rather than the B4 floor failure zone. Similarly, as the distance between B6 and B4 is 36.10 m, the B6 floor failure zone falls within the B4 fissure zone. Accordingly, the overlapping fraction of B6 is attributed to the B4 fissure zone. For B9, B8, B7b, B7a, B7a-, and B6, the distances between adjacent seams are 8.50, 4.30, 3.10, 1.07, and 12.37 m, respectively. Consequently, the upper coal seams fall within the caving zones of the lower seams. Additionally, B9, B7b, and B7a- have significantly smaller mined areas than their adjacent seams. Thus, the overlapping portions of these coal seams are assigned to the caving zones of the lower coal seams. Section No. 3 of the coal-bearing strata includes three mined coal seams (B11b, B11a, and B10). The distance between B10 and B9 is 32.50 m. Consequently, the overlapping portion of the B10 floor failure zone with the B9 and B8 fissure zones is assigned to the fissure zones of B9 and B8, rather than the B10 floor failure zone. The distances between B11b, B11a, and B10 are 2.10 and 29.50 m, respectively. Thus, the upper coal seams fall within the caving zones of the lower coal seams, and the overlapping fractions are assigned to the caving zone of the lower coal seams. Section No. 4 of the coal-bearing strata includes two mined coal seams (C14 and C13). The distance between C13 and B11b is 63.10 m. Consequently, the overlapping portion of the C13 floor failure zone and B11b fissure zone is assigned to the B11b fissure zone. However, the remaining portion of the C13 floor failure zone remains unchanged. The distance between C14 and C13 is 18.00 m, and C14 has a significantly smaller mined area than C13. Therefore, the overlapping portion of the C14 floor failure zone and C13 fissure zone is assigned to the C13 caving zone. The remaining portion of the C14 floor failure zone remains unchanged.

Based on the above, the results about goaf volumes of four sections are shown in Table 7, and the total goaf volumes are summarized in Table 8.

Table 7.

Goaf volumes of four sections under coal seam group conditions.

Table 8.

Statistics of goaf volumes under coal seam group conditions.

5. Discussion

Regarding the scope of goaf gas reservoir space: According to the theory of strata movement caused by coal mining, goaf gas reservoir space forms as the overlying strata fracture after a coal seam is mined. This fracturing creates three zones: the caving zone, the fissure zone, and the bending zone. The combined height of the caving and fissure zones, known as the height of the “two zones”, is a key factor in preventing roof water disasters and designing waterproof coal–rock pillars; however, the bending zone usually does not conduct water due to the continuity and integrity of the rock layers. Additionally, the underlying strata are disrupted after coal seam mining and form a floor failure zone, which is crucial for preventing floor water inrush and floor grouting reinforcement. The gas reservoir space represents the volume available for gas storage and transport. After coal seam mining, the caving, fissure, and floor failure zones contribute to the gas reservoir space and are not limited to the caving and fissure zones or the height of the “two zones”. The floor failure zone exhibits water conductivity, indicating its capacity to store and transport gas. Under coal seam group mining, the floor failure zone of the upper coal seam often overlaps with the caving or fissure zones of the lower coal seam, making the gas reservoir space more complex. This highlights the need to include the floor failure zone in research and consider the interactions between the floor failure zone of the upper coal seam and the caving and fissure zones of the lower coal seam.

Regarding the data on goaf gas reservoir space: Various methods can be used to determine HM, HL, and HD, and the accuracy of these data is crucial for reliable analysis of the gas reservoir space. In Table 4, many values are derived from years of mining operations at the coal mine, making them specific and reflective of actual production conditions. Additionally, some data are supplemented by calculations based on national regulations and standards in coal industry, ensuring broad applicability and adaptability. Overall, combining these two approaches balances ease of data acquisition with the scientific reliability of the parameters. Other methods, such as numerical simulation [31], physical modeling, microseismic monitoring [32], and drilling detection, can provide further detailed insights into the characteristics of the caving, fissure, and floor failure zones. The combination and cross-validation of various methods are helpful to accurately characterize the goaf gas reservoir space. However, these methods are also subject to some technical and economic limitations [33]. Future research will strive to combine numerical simulation, physical modeling, or drilling detection and other methods to obtain more reliable parameters (HM, HL, and HD), thereby serving the resource evaluation of favorable blocks and the design of development plans.

Regarding the goaf gas reservoir space under coal seam group conditions: The caving, fissure, floor failure zones and total volumes under coal seam group conditions are 96.11%, 52.85%, 25.20%, and 53.86% of the corresponding volumes calculated under individual coal seam assumptions (Table 9). This indicates that the coal seam group goaf volumes are neither a simply the sum nor a proportional reduction in the individual seam volumes. Therefore, developing accurate methods for calculating goaf volume under coal seam group conditions is crucial. This study provides a preliminary reference, and future research should aim to establish more scientific, practical, and concise approaches.

Table 9.

Comparison of goaf volumes under two different conditions.

Regarding the application of goaf gas reservoir space: The void volume of the goaf can be estimated based on the goaf volume (Table 8), combined with the coefficient of void volume. The determination of void volume coefficient is also very important because it has a significant impact on the estimation of void volume of the goaf, and the void volume coefficient often varies in different cases [34,35,36]. The coefficients of 0.3 for the caving zone and 0.2 for the fissure zone are used in the research of Panji No.1 Coal Mine in Huainan Coalfield [22]. Xinzhuangzi Coal Mine is also in Huainan Coalfield, and similar to Panji No. 1 Coal Mine in gas geology. So, for the time being, with a coefficient of 0.3 for the caving zone and 0.2 for the fissure and floor failure zones, the total void volume is calculated as 336.694 × 106 m3 (Table 10); Certainly, more precise and targeted coefficients of void volume need to be further studied in the future. The calculated void volume provides a basis for estimating free gas resources. The methane concentration of goaf is 35% [37], thus the estimated free gas resources are 336.694 × 106 m3 × 0.35 = 117.8429 ×106 m3. The void volume is not only a key parameter for investigating gas migration and extraction in goafs but also is a vital focus in multiple research fields. With ongoing research on coal mine underground reservoirs [35,36], CO2 storage in coal mines [38,39], and underground space resources [40,41], the void volume can serve as a reference and provide a basis for cross-verification.

Table 10.

Calculation of void volume in goaf.

6. Conclusions

(1) A calculation method for goaf space under coal seam group conditions has been established, providing a concise approach for investigating goaf gas reservoir space.

(2) Fourteen coal seams have been mined at the Xinzhuangzi coal mine, with a total mined area of 4583.04 × 104 m2 across all seams.

(3) For the 14 mined coal seams at the Xinzhuangzi coal mine under coal seam group conditions, the caving, fissure, and floor failure zones have volumes of 438.22 × 106, 871.24 × 106, and 154.90 × 106 m3, respectively. The total goaf volume is 1464.36 ×106 m3.

(4) The caving, fissure, floor failure zones and total volumes under coal seam group conditions are 96.11%, 52.85%, 25.20%, and 53.86% of the corresponding volumes calculated under individual coal seam assumptions. This indicates that the coal seam group goaf volumes are neither a simply the sum nor a proportional reduction in the individual coal seam goaf volumes.

Author Contributions

Conceptualization, Z.Z. and J.Z.; methodology, Z.Z. and J.Z.; software, Z.Z. and A.L.; validation, Z.Z., J.Z., A.L. and M.C.; formal analysis, Z.Z.; investigation, Z.Z., J.Z., A.L. and M.C.; resources, Z.Z.; data curation, Z.Z., A.L. and M.C.; writing—original draft preparation, Z.Z., J.Z., A.L. and M.C.; writing—review and editing, Z.Z.; visualization, Z.Z. and J.Z.; supervision, Z.Z.; project administration, Z.Z.; funding acquisition, Z.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (Grant No. U23A20601).

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liang, Y.P.; Li, Z.Y.; Zhu, S.C.; Chen, Q.; Wang, X.; Qin, C.Z. Research status and reduction strategies of methane emissions from closed/abandoned coal mines. J. China Coal Soc. 2023, 48, 1645–1660. [Google Scholar] [CrossRef]

- Yuan, L. Strategic Research on Coal Mine Safety and Resource Development of Abandoned Mines in China; Science Press: Beijing, China, 2020; pp. 147–218. [Google Scholar]

- Liu, Q.J.; Wang, J.J.; Yang, K.; Di, S.J.; Dong, Z.Y. Research on the model of accurate exploitation and utilization of underground space resources in closed/abandoned mines. Coal Geol. Explor. 2021, 49, 71–78. [Google Scholar] [CrossRef]

- Yuan, L.; Yang, K. Further discussion on the scientific problems and countermeasures in the utilization of abandoned mines. J. China Coal Soc. 2021, 46, 16–24. [Google Scholar] [CrossRef]

- Xie, H.P.; Gao, M.Z.; Gao, F.; Zhang, R.; Ju, Y.; Xu, H.; Wang, Y.W. Strategic conceptualization and key technology for the transformation and upgrading of shut-down coal mines. J. China Coal Soc. 2017, 42, 1355–1365. [Google Scholar] [CrossRef]

- Liu, W.G.; Zhang, K.S.; Han, J.Y.; Sang, F.Y.; Huang, L. Technology and prospect analysis of AMM development and utilization. China Coalbed Methane 2016, 13, 3–6. [Google Scholar]

- Wang, Y.R.; Huang, L. The review of regulations and policies on utilization of abandoned mine methane in developed countries. China Coalbed Methane 2020, 17, 45–47. [Google Scholar]

- Liu, F.; Guo, L.F.; Zhao, L.Z. Research on coal safety range and green low-carbon technology path under the dual-carbon background. J. China Coal Soc. 2022, 47, 1–15. [Google Scholar] [CrossRef]

- Sang, F.Y.; Liu, W.G.; Han, J.Y.; Wang, Y.R. Enlightenment of China on successful experiences of abandoned mine methane development in Britain. China Coalbed Methane 2019, 16, 3–5. [Google Scholar]

- Durucan, S.; Shi, J.Q.; Korre, A. Numerical modeling and prediction of abandoned mine methane recovery: Field application at the Saar coalfield, Germany. Geol. Belg. 2006, 7, 207–213. [Google Scholar]

- Karacan, C.Ö.; Warwick, P.D. Assessment of coal mine methane (CMM) and abandoned mine methane (AMM) resource potential of longwall mine panels: Example from Northern Appalachian Basin, USA. Int. J. Coal Geol. 2019, 208, 37–53. [Google Scholar] [CrossRef]

- Sang, S.X.; Han, S.J.; Zhou, X.Z.; Liu, S.Q.; Wang, Y.J. Deep coalbed methane resource and its exploration and development prospect in East China. Pet. Reserv. Eval. Dev. 2023, 13, 403–415. [Google Scholar] [CrossRef]

- Zhao, Z.G.; Chen, M.; Zhang, J.J. Research on in-situ gas resources characteristics of Xiajiaji No. 1 closed coal mine in Huainan mining area. J. Jiamusi Univ. Nat. Sci. 2025, 43, 82–85. [Google Scholar] [CrossRef]

- Zhang, Z.J. Potential and utilization directions of coalbed methane resources in the closed coal mines of Xishan mining area. Shanxi Coking Coal Sci. Technol. 2022, 46, 4–8+15. [Google Scholar]

- Cao, L.; Lv, M.; Li, C.; Sun, Q.; Wu, M.; Xu, C.; Dou, J. Effects of crosslinking agents and reservoir conditions on the propagation of fractures in coal reservoirs during hydraulic fracturing. Reserv. Sci. 2025, 1, 36–51. [Google Scholar] [CrossRef]

- Li, M.; Liu, J.; Xia, Y. Risk prediction of gas hydrate formation in the wellbore and subsea gathering system of deep-water turbidite reservoirs: Case analysis from the South China Sea. Reserv. Sci. 2025, 1, 52–72. [Google Scholar] [CrossRef]

- Wu, J.; Ansari, U. From CO2 sequestration to hydrogen storage: Further utilization of depleted gas reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Meng, Z.P.; Shi, X.C.; Liu, S.S.; Tian, Y.D.; Li, C. Evaluation model of CBM resources in abandoned coal mine and its application. J. China Coal Soc. 2016, 41, 537–544. [Google Scholar] [CrossRef]

- Yang, Z.B.; Wang, J.C.; Yang, Y.Q.; Qin, Y.; Li, G.F.; Dong, Z.Y.; Meng, X.H. Spatial division of abandoned mine methane reservoir: Taking 12501 working face of Tunlan coal mine as an example. Coal Sci. Technol. 2023, 51, 243–255. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, Q.Z.; Liu, W.G.; Yu, Z.J.; Liu, C.C.; Shi, M.J.; Zhou, X.G.; Han, J.Y.; Guo, Q.S. Geological characteristics of gas occurrence and technical countermeasures of Wulan abandoned coal mine. J. Henan Polytech. Univ. Nat. Sci. 2022, 41, 10–17. [Google Scholar] [CrossRef]

- Wang, Y.; Xiang, J.; Qin, Y.; Chen, S.B.; Zhu, Y.M.; Huang, M.L.; Shi, Y. Characteristics and drainage modes of coalbed methane resources in closed coal mines in Yangquan and Jincheng mining areas. Coal Sci. Technol. 2024, 52, 165–179. [Google Scholar] [CrossRef]

- Tao, X.F.; Shi, B.M.; Yue, J.W.; Liang, Y.H.; Zhong, Z.; Zhang, H.Q.; Mei, W.Q.; Xue, Y.L.; Peng, J.; Zhang, C.C. Characteristics and applications of gas resources in abandoned coal seam groups within mining areas. Coal Sci. Technol. 2025, 53, 161–173. [Google Scholar] [CrossRef]

- Anhui Provincial Bureau of Coal Geology Third Team. Geological Report on the Closed Xinzhuangzi Coal Mine in Huainan City of Anhui Province; Huainan Mining (Group) Co., Ltd.: Huainan, China, 2017. [Google Scholar]

- Han, B.S.; Zhang, X.M.; Zhang, Q. Theoretical study on calculation limits of CBM resource of abandoned coal mine. Coal Geol. Explor. 2004, 32, 29–31. [Google Scholar]

- Chen, G.H. Study on development height of overlying rock two zones in fully mechanized caving mining of inclined longwall working face. Coal Technol. 2022, 41, 41–45. [Google Scholar] [CrossRef]

- Xing, M.L. Causes and discussion of fault water inrush after regional treatment in coal seam floor. Saf. Coal Mines 2023, 54, 204–211. [Google Scholar] [CrossRef]

- Hao, G.; Yu, D.H.; Xu, Y.; Wang, L.; Liu, H. Numerical simulation and field test of height of caving zone and fracture zone in Heshan coal mine. Saf. Coal Mines 2023, 54, 174–179. [Google Scholar] [CrossRef]

- Yin, S.X.; Xu, W.; Yin, H.C.; Cao, M. Study on risk assessment method of water inrush from thick floor aquifuge in deep mining. Coal Sci. Technol. 2020, 48, 83–89. [Google Scholar] [CrossRef]

- National Coal Industry Administration. Regulations for the Coal Pillars Setting of and Coal Mining Under Buildings, Water Bodies, Railways, and Main Wells and Tunnels; China Coal Industry Publishing House: Beijing, China, 2000. [Google Scholar]

- State Administration of Work Safety; State Administration of Coal Mine Safety; National Energy Administration; National Railway Administration. Standards for the Coal Pillars Setting of and Coal Mining Under Buildings, Water Bodies, Railways, and Main Wells and Tunnels; China Coal Industry Publishing House: Beijing, China, 2017. [Google Scholar]

- Fan, J.P.; Zhang, J.; Su, Y.Y.; Hu, C.Y.; Zhang, H.S.; Wang, Q.S.; Wang, Y.F. Study on mechanism of structurally induced floor water inrush under mining-induced stress and monitoring and prevention based on micro-seismic monitoring techniques. Coal Technol. 2025, 44, 171–177. [Google Scholar] [CrossRef]

- Han, Y.C.; Li, L.C.; Yu, G.F.; Dang, B.Q.; He, S.F.; Mou, W.Q.; Zhang, Y.S. Application of microseismic monitoring technology in regional management of coal floor grouting. Coal Technol. 2025, 44, 143–148. [Google Scholar] [CrossRef]

- Li, Q.; Qin, Y.J.; Gao, Z.N. Research on the height prediction of “two zones” of overburden based on BP neural network. Coal Sci. Technol. 2021, 49, 53–59. [Google Scholar] [CrossRef]

- Li, Q.F.; Song, S.Y. Feasibility analysis of water storage at goaf areas of Changcun coal mine. Coal 2024, 33, 90–94. [Google Scholar] [CrossRef]

- Gu, D.Z. Theory framework and technological system of coal mine underground reservoir. J. China Coal Soc. 2015, 40, 239–246. [Google Scholar] [CrossRef]

- Pang, Y.H.; Li, P.; Zhou, B.J. Underground reservoir construction technical feasibility analysis in 8.0 m large mining height working face. Coal Eng. 2018, 50, 6–9. [Google Scholar]

- Anhui Provincial Bureau of Coal Geology First Team. Geological Report on Xinzhuangzi Coal Mine of Huainan Mining (Group) Co., Ltd.; Huainan Mining (Group) Co., Ltd.: Huainan, China, 2010. [Google Scholar]

- Wang, S.M.; Shen, Y.Y.; Sun, Q.; Liu, L.; Shi, Q.M.; Zhu, M.B.; Zhang, B.; Cui, S.D. Underground CO2 storage and technical problems in coal mining area under the “dual carbon” target. J. China Coal Soc. 2022, 47, 45–60. [Google Scholar] [CrossRef]

- Li, S.G.; Zhang, J.F.; Lin, H.F.; Bao, R.Y.; Ding, Y.; Bai, Y.; Zhou, Y.X.; Zhu, B. Research on the characteristics of CO2-water interface and the law of dissolution and mass transfer under the condition of carbon sequestration in goaf. J. China Coal Soc. 2024, 49, 513−527. [Google Scholar] [CrossRef]

- Liu, F.Y.; Chen, W.Y.; Yang, K.; Duan, M.K.; Liu, Q.J.; Yang, L.Y. Investigation and comprehensive utilization of resources in closed coal mines in Anhui Province, China. Coal Geol. Explor. 2024, 52, 1–11. [Google Scholar] [CrossRef]

- Yang, K.; Wei, J.L.; Fu, Q.; Lv, X. Potential of underground space energy storage and carbon reduction benefits of closed/abandoned mines in Anhui Province. Coal Sci. Technol. 2025, 53, 45–55. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.