Abstract

In order to address the challenges of soft coal texture, poor permeability, and wellbore instability in tectonic coal reservoirs, a new biodegradable fuzzy-ball drilling fluid combined with a bio-based surfactant and enzyme system was developed. The optimal formula was determined through single-factor experiments and orthogonal optimization: 6% KCl–2% trehalose composite base slurry + 4% carboxymethyl chitosan + 0.4% hydroxypropyl methylcellulose + 0.15% xanthan gum + 0.12% guar gum + 0.3% cocamidopropyl betaine + 0.15% lauryl alcohol + 0.2% triethanolamine, with the degrading agent consisting of 0.2% composite-modified amylase + 0.04% composite-modified cellulase. The performance evaluation results show that the drilling fluid has stable rheological properties in the temperature range of 40~60 °C (yield point-plastic viscosity ratio: 0.8~0.9) and low filtration loss (5.8~6.5 mL); it exhibits excellent inhibition on tectonic coal, the inhibition rate of linear expansion rate is 72.1%, and the 14-mesh rolling recovery rate is 82.5%; at 55 °C, the gel breaking rate reaches 96.9% after 1.5 h, the mud cake removal rate reaches 98.8%, and the permeability recovery rate reaches 84.8%. After applying this drilling fluid, the unconfined compressive strength of tectonic coal increases from 1.2 MPa to 2.8 MPa (an increase of 133.3%), and the triaxial compressive strength increases from 20.1 MPa to 38.5 MPa (an increase of 91.5%); the numerical simulation shows that the radial displacement around the wellbore decreases by 62.1% and the plastic zone area shrinks by 73.2%. This novel biodegradable fuzzy-ball drilling fluid has the characteristics of efficient wellbore stabilization, easy degradation, and low formation damage, providing effective technical support for the green development of coalbed methane in tectonic coal reservoirs.

1. Introduction

China possesses abundant coalbed methane (CBM) resources [1]. According to The China Coalbed Methane Resource Assessment (2022) [2], the national geological resources volume of CBM with a burial depth of less than 2000 m has exceeded 36 trillion m3, of which more than 60% comes from tectonic coal reservoirs, which are the core area of coalbed methane development [2,3,4,5,6,7].Tectonic coal, having undergone intense tectonic movements (such as compression and extension), exhibits marked structural degradation characterized by a loose texture, abundant microfractures, breached cleats, and increased clay mineral content (predominantly kaolinite). These alterations lead to wellbore instability issues during drilling, including wall collapse, spalling, and formation plugging.

Conventional drilling fluids possess a certain degree of wellbore stabilization capability; however, they suffer from inadequate fluid loss control (API fluid loss typically >10 mL), formation of dense filter cakes that are difficult to remove, and low permeability recovery ratios (mostly 50~65%), severely restricting coalbed methane (CBM) development efficiency. In contrast, the fuzzy-ball drilling fluid, featuring a unique “one-core, two-layer, three-membrane” microstructure, exhibits excellent self-adaptive plugging performance and low formation damage characteristics, and has been preliminarily applied in CBM drilling operations.

Zheng Lihui [7,8] first proposed the concept of fuzzy-ball drilling fluid, enabling precise plugging of lost circulation pathways across different scales. Subsequently, extensive research has been conducted by scholars both domestically and internationally on the optimization of fuzzy-ball drilling fluid formulations [9]. Li [10] optimized the fuzzy-ball drilling fluid formulation by employing a composite system of SDS and dodecanol, significantly enhancing plugging efficiency; however, the fluid exhibited poor degradability [11,12,13].Yue Qiansheng [14] developed a biodegradable polymeric drilling fluid using an oxidative gel-breaking system, achieving a permeability recovery ratio of 78% in field applications in the Qinshui Basin [15,16]; however, wellbore stability was insufficient. Existing fuzzy-ball drilling fluids are predominantly reliant on chemical surfactants, resulting in poor biocompatibility [17], and their degradation systems exhibit low hydrolytic selectivity toward polymeric components, leading to inefficient degradation and a narrow applicable temperature range [18].

Bio-based surfactants have emerged as a research hotspot in the drilling fluid field due to their environmental friendliness and high interfacial activity. Cai [19] formulated a drilling fluid using coconut-derived alkyl polyglucoside (APG), achieving a 30% improvement in inhibition performance; however, the fuzzy-ball structure exhibited poor stability. Regarding composite enzymatic degradation systems, Lyu [20] employed a combination of α-amylase and β-mannanase, achieving a gel-breaking efficiency of 90%; however, the process required high temperature (65 °C), making it unsuitable for medium-to-low temperature tectonic coal reservoirs [21,22,23].

Overall, it can be seen that the related research in China is still in its infancy, and there are few studies on the fuzzy-ball drilling fluid coordinated with a bio-based surfactant and composite enzyme system in the world. Major challenges must be solved in the formulation design and performance collaborative optimization [24,25]. Therefore, the development of a novel biodegradable fuzzy-ball drilling fluid with integrated capabilities of efficient wellbore stabilization, easy degradation, and low formation damage holds significant theoretical and engineering significance for addressing drilling challenges in tectonic coal reservoirs and promoting green coalbed methane exploitation [26,27,28,29,30,31].

2. Experimental Materials and Methods

2.1. Experimental Materials

The base slurry components included potassium chloride (KCl, analytical reagent), trehalose (analytical reagent), and deionized water.

In the fuzzy-ball fluid materials, the core-forming agent was cocamidopropyl betaine (CAPB, industrial grade), which had high surface activity and good biodegradability; the membrane-forming agents were lauryl alcohol (analytical reagent) and triethanolamine (analytical reagent); the layer-forming agents were carboxymethyl chitosan (CMCS, degree of deacetylation ≥ 90%) and hydroxypropyl methylcellulose (HPMC, viscosity 4000 mPa·s); the fuzz-generating agents were xanthan gum (XG, food grade) and guar gum (industrial grade); and the degradation agents were composite-modified amylase (enzyme activity 5 × 105 U/g) and composite-modified cellulase (enzyme activity 1 × 106 U/g), both of which were industrial grade.

The structural coal sample was taken from the coal seam of Zhangji Coal Mine in Huainan. After being crushed, it was sieved through a 0.075 mm sieve to prepare a reshaped tectonic coal sample (Figure 1). The sample had a uniaxial compressive strength of 1.2 MPa, an elastic modulus of 43 MPa, and a Poisson’s ratio of 0.37.

Figure 1.

Tectonic coal sample.

2.2. Experimental Instruments

Rheological property testing was conducted using a ZNN-D6 rotational viscometer with six speeds, which was manufactured by Qingdao Tongchun Petroleum Instrument Co., Ltd. (Qingdao, China). For filtration property testing, a Model ZNS mud filtration tester (produced by Qingdao Haitongda Special Instrument Co., Ltd. (Qingdao, China)) was adopted.

Inhibition testing required two pieces of equipment: a Model BGRL roller heating furnace (from Qingdao Zhongyou Keli Machinery Co., Ltd. (Qingdao, China)) and a rock swelling meter (supplied by Wuhan Yanhai Engineering Technology Co., Ltd. (Wuhan, China)). For degradation property testing, the instruments used included a Model NDJ-5S rotational viscometer (manufactured by Shanghai Jingtian Electronic Instrument Co., Ltd. (Shanghai, China)) and a low temperature constant temperature circulator (produced by Shanghai Yuming Instrument Co., Ltd. (Shanghai, China)).

Permeability testing relied on a multifunctional core displacement device (from Haian Petroleum Scientific Research Instrument Co., Ltd. (Nantong, China)), while mechanical property testing used a Model TKA-1UM automatic stress–strain loading system (made by Jinan Tianchen Testing Machine Manufacturing Co., Ltd. (Jinan, China)).

Additionally, a Model NB-1 mud balance (from Hebei Chuyang Test Instrument Co., Ltd. (Cangzhou, China)) was used for density testing, and a Model PHS-25 pH meter (produced by Shanghai Yidian Scientific Instrument Co., Ltd. (Shanghai, China)) was applied for pH testing.

2.3. Experimental Methods

2.3.1. Preparation of the Biodegradable Fuzzy-Ball Drilling Fluid

The experiment was designed to optimize the formulation using the single-factor variable method, with the aim of improving the structural stability and biodegradability of the fuzzy-ball system.

Base slurry preparation involved dissolving potassium chloride (KCl) and trehalose in deionized water at a specified ratio, followed by continuous stirring for 30 min. Finally, a 6% KCl–2% trehalose composite base slurry was prepared.

For fuzzy-ball material blending, CMCS and HPMC were first added sequentially to the base slurry and were subjected to high-speed stirring at 3000 rpm for 40 min. Subsequently, XG and guar gum were added, and stirring was continued for 20 min. Finally, CAPB, lauryl alcohol, and triethanolamine were added; the rotation speed was adjusted to 1000 rpm for low-speed stirring; and after 15 min of additional stirring, the fuzzy-ball drilling fluid base was formed.

The steps for degradation solution addition were as follows: composite-modified amylase and composite-modified cellulase were first mixed in different proportions and then dissolved in a small amount of deionized water. Immediately before use, this solution was added to the base slurry, and after 10 min of stirring, the preparation of the degradation solution was completed.

2.3.2. Basic Performance Tests

For rheological property testing, a ZNN-D6 rotational viscometer was used to measure readings at 600 r/min and 300 r/min (denoted as φ600 and φ300, respectively). Based on these readings, the apparent viscosity (AV = 0.5φ600), plastic viscosity (PV = φ600 − φ300), dynamic shear stress (YP = 0.5(φ300 − PV)), and ratio of dynamic shear stress to plastic viscosity (YP/PV) were calculated.

For filtration property testing, a ZNS mud filtration tester was employed to determine API filtration loss or HTHP filtration loss within 30 min under preset temperature and pressure conditions.

For density testing, an NB-1 mud balance was used, and the test was conducted in accordance with the GB/T 16783.1-2014 standard [32].

For pH testing, a PHS-25 pH meter was utilized to directly measure the pH of the drilling fluid.

2.3.3. Inhibition Performance Tests

For the linear expansion rate test, tectonic coal powder passing through a 100-mesh sieve was loaded into the sample cylinder of the swelling meter. After the coal powder was compacted, drilling fluid was added. The linear expansion rate within 16 h was measured at 60 °C, and the inhibition rate was calculated using the following formula:

Inhibition rate = [(expansion rate in water − expansion rate in drilling fluid)/expansion rate in water] × 100%

For the rolling recovery rate test, 50 g of tectonic coal particles passing through a 7–14 mesh (or 8–16 mesh) sieve was weighed, and 350 mL of drilling fluid was added. The mixture was hot-rolled at 60 °C for 16 h; afterward, the coal particles were sieved through a 14-mesh (or 16-mesh) sieve, dried, and weighed. The rolling recovery rates were then calculated using the following formulas:

R14 = (mass of 14-mesh screen residue/50) × 100%

R16 = (mass of 16-mesh screen residue/50) × 100%

2.3.4. Degradation Performance Tests

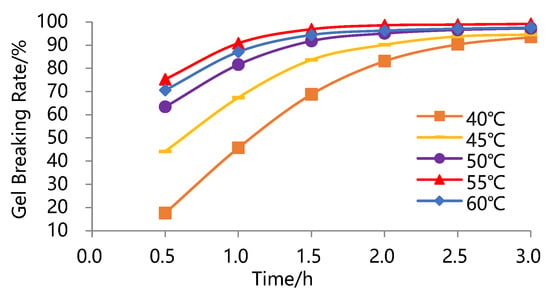

For the gel-breaking rate test, 200 mL of drilling fluid was taken, and the compound-degrading agent was added. The mixture was incubated at constant temperature under different conditions (40 °C, 45 °C, 50 °C, 55 °C, and 60 °C). The apparent viscosity (AV) was measured at different time intervals (0.5 h, 1 h, 1.5 h, 2 h, 2.5 h, and 3 h), and the gel-breaking rate was calculated using the following formula:

Gel-breaking rate = [(AV before degradation − AV after degradation)/AV before degradation] × 100%

For the mud cake degradation test, mud cakes were prepared using a Model ZNS mud filtration tester. The mud cakes were immersed in the degrading agent solution and were incubated at 55 °C for 1.5 h. The thickness and mass of the mud cakes before and after degradation were measured, and the mud cake removal rate was calculated using the following formula:

Mud cake removal rate = [(mass before degradation − mass after degradation)/mass before degradation] × 100%

For the permeability recovery rate test, a drilling fluid seepage simulation device was used. Tectonic coal cores were vacuum-saturated with drilling fluid; after plugging for 3 h, the degrading agent was added. Degradation was conducted at 55 °C for 3 h, after which seepage with clean water was performed. The permeability after stable seepage was measured, and the permeability recovery rate was calculated using the following formula:

Permeability recovery rate = (permeability after degradation/initial permeability) × 100%

2.3.5. Wellbore Stability Tests

For the unconfined compression test, tectonic coal samples were vacuum-saturated with drilling fluid and were cured at 60 °C for 24 h, after which the unconfined compression test was conducted. The loading rate was set to 0.1 mm/min, and parameters including compressive strength, elastic modulus, and Poisson’s ratio were measured.

For the triaxial compression test, tectonic coal samples were vacuum-saturated with drilling fluid and were cured at 60 °C for 24 h, followed by the triaxial compression test. The confining pressure was set to 6 MPa, the loading rate was set to 0.05 mm/min, and parameters such as compressive strength, cohesion, and internal friction angle were determined.

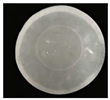

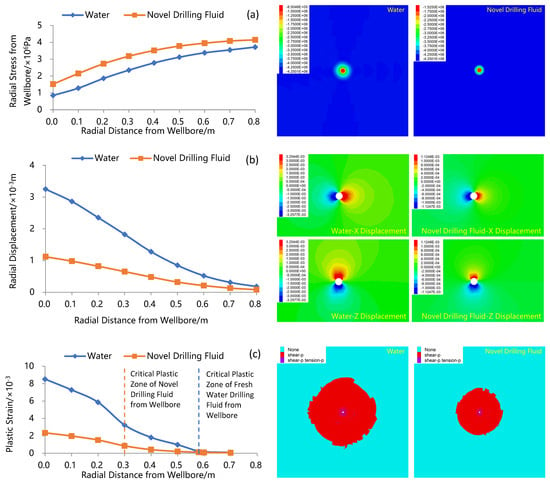

For numerical simulation, a 20 m × 20 m × 10 m tectonic coal horizontal well model (well diameter 0.22 m) was constructed, and simulation reliability was ensured through multidimensional design (Figure 2). The grid was divided nonuniformly; the stress concentration zone within 0–3 m around the well was refined using 0.1 m3 grid cells, while the far-field region from 3–10 m used 1 m3 grid cells. The total number of grid units was approximately 12,800, with the grid warpage kept below 5% and the aspect ratio kept below 8. The boundary conditions were set to match actual field conditions: horizontal displacement was fixed at both ends of the x- and y-axes, and vertical displacement was fixed at the bottom of the z-axis. The drilling fluid column pressure in the wellbore was set to 12 MPa (corresponding to a density of 0.92–0.95 g/cm3). Experimental data calibration was performed based on measured values, and the mechanical parameters of coal rock after drilling fluid treatment were input to simulate radial stress, tangential displacement, and plastic strain around the well.

Figure 2.

Grid structure display.

3. Results and Discussion

3.1. Formulation Optimization

3.1.1. Screening of Base Slurry

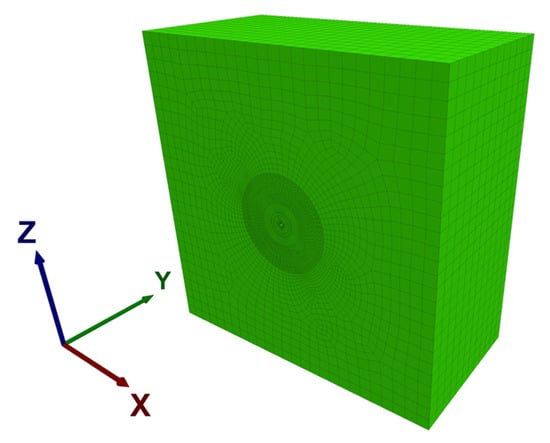

Based on KCl solution, trehalose (which has the effect of synergistically inhibiting clay hydration) was introduced. Single-factor experiments were conducted to investigate the effects of KCl and trehalose concentrations on the inhibition of tectonic coal, with the results shown in Figure 3. It can be seen from Figure 3a that as the KCl concentration increases, the linear expansion rate of tectonic coal first decreases rapidly and then increases slowly, but the increase range is small; the expansion rate reaches a minimum of 1.24% at a KCl concentration of 6%. Figure 3b shows that as the trehalose concentration increases, the linear expansion rate of tectonic coal first decreases continuously and then changes insignificantly; an inflection point occurs at a trehalose concentration of 2%, where the expansion rate drops to 0.83%. After comprehensive consideration, 6% KCl–2% trehalose is selected as the composite base slurry. At this point, the linear expansion rate is 0.72%, and the linear expansion rate inhibition rate reaches 72.1%. K+ and trehalose synergistically inhibit the hydration and expansion of clay minerals, reducing the dispersion of clay minerals.

Figure 3.

The effect of KCl and trehalose concentrations on the inhibition of tectonic coal: (a) the effect of KCl concentration on linear expansion rate and (b) the effect of trehalose concentration on linear expansion rate.

3.1.2. Orthogonal Optimization of Fuzzy-Ball Materials

An orthogonal experimental optimization design was established by combining key variable factors with fixed adjuvants. Five variable factors were selected: carboxymethyl chitosan (A), hydroxypropyl methylcellulose (B), xanthan gum (C), cocamidopropyl betaine (D), and lauryl alcohol (E); guar gum (0.12%) and triethanolamine (0.2%) were used as two fixed adjuvants.

Each variable factor was set with three levels, as shown in Table 1. Taking apparent viscosity (AV), plastic viscosity (PV), yield point (YP), API filtration loss (FL), and YP/PV ratio as evaluation indices, experiments were conducted using the L27(35) orthogonal array, with the results shown in Table 2.

Table 1.

Factors and levels of orthogonal experiment.

Table 2.

Orthogonal experiment results.

Based on the range analysis shown in Table 3, it can be seen that AV is crucial for the rheological properties and cuttings-carrying capacity of drilling fluid. Its range order is A (5.1) > C (4.2) > B (3.8) > D (2.3) > E (1.5). (A) is the most critical factor affecting apparent viscosity—the higher the concentration, the greater the AV—followed by (C), while (E) has the least impact.

Table 3.

Range analysis results.

YP is a critical parameter that determines the drilling fluid’s ability to suspend cuttings and maintain wellbore cleaning efficiency. The range analysis yields the following order of influence: A (3.5) > C (2.8) > B (2.4) > D (1.9) = E (1.9). (A) contributes the most to YP by forming a three-dimensional network structure through molecular entanglement, while (C) enhances YP through its cross-linking capability. (B) exhibits a weaker contribution due to its relatively low viscosity. (D) and (E) only slightly modify interfacial tension through surfactant action, resulting in minimal impact on yield point.

The yield point to plastic viscosity ratio is a key indicator of a drilling fluid’s shear-thinning behavior and cuttings transport efficiency. The range analysis yields the following order of influence: A (0.06) > C (0.05) > B (0.04) > D (0.03) = E (0.03). CMCS (A) contributes the most to YP, followed by (C), while (B), (D), and (E) exhibit similar and relatively minor effects on YP/PV, resulting in a weak and consistent influence on this ratio.

API fluid loss is a critical parameter for evaluating filter cake compactness and formation protection capability. The range analysis shows A (0.7) = B (0.7) > D (0.5) > C (0.3) > E (0.2). (A) and (B) play equally dominant and essential roles in reducing fluid loss by synergistically forming a dense, low-permeability filter cake. (D) moderately improves filter cake structure by reducing interfacial tension. (C) primarily enhances viscosity with limited impact on filtration control, while (E) has the least effect on fluid floss.

Based on the analysis and verification experiments, and considering practical field requirements, AV is 45~55 mPa·s, PV is 24~28 mPa·s, YP is 20~25 Pa, API fluid loss is minimized, and YP/PV ratio is 0.8~0.9. Therefore, the optimal formulation of the fuzzy-ball components is determined as follows: 4% CMCS, 0.4% HPMC, 0.15% XG, 0.12% guar gum, 0.3% CAPB, 0.15% lauryl alcohol, and 0.2% triethanolamine.

3.1.3. Optimization of Degrading Agent Compounding

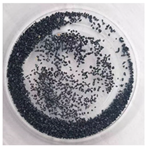

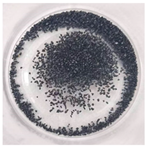

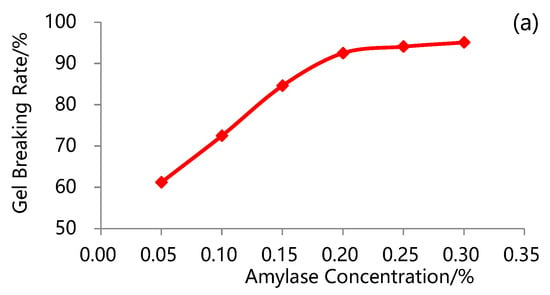

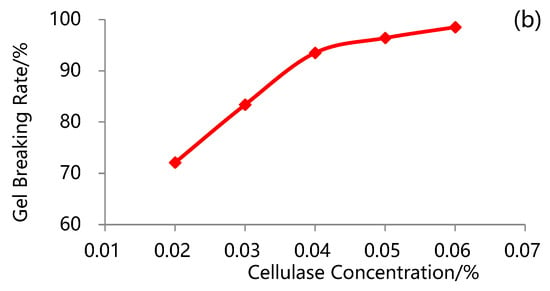

Aged at 55 °C for 1.5 h, the effects of different concentrations of composite-modified amylase and composite-modified cellulase on the gel-breaking rate were evaluated, with the results presented in Figure 4. As indicated in Figure 4a, with the increase in the concentration of composite-modified amylase, the gel-breaking rate first rises rapidly and then slows down, showing an inflection point at a concentration of 0.20%, where the gel-breaking rate reaches 92.5%. Figure 4b demonstrates that when the concentration of composite-modified cellulase increases from 0.02% to 0.06%, the gel-breaking rate increases from 72.1% to 98.5%; it also first rises rapidly and then slows down, with an inflection point at a concentration of 0.04%, where the gel-breaking rate hits 93.5%. Through comprehensive analysis, the optimal formulation of the degrading agents is determined as 0.2% composite-modified amylase + 0.04% composite-modified cellulase. Under the condition of 55 °C for 1.5 h, the gel-breaking rate achieves 96.9%. The comparison of samples before and after degradation is shown in Figure 5.

Figure 4.

Effect of degrading agent concentrations on gel-breaking rate: (a) effect of composite-modified amylase concentration on gel-breaking rate and (b) effect of composite-modified cellulase concentration on gel-breaking rate.

Figure 5.

Comparison of samples before and after degradation: (a) before (55 °C, 1.5 h) and (b) after (55 °C, 1.5 h).

3.2. Basic Performance Evaluation

3.2.1. Rheological Properties

The rheological parameters of the drilling fluid at different temperatures are presented in Table 4. Within the temperature range of 40 °C~60 °C, the apparent viscosity (AV) decreases from 52.5 mPa·s to 46.5 mPa·s, the plastic viscosity (PV) decreases from 28.7 mPa·s to 24.4 mPa·s, and the yield point (YP) decreases from 23.6 Pa to 20.9 Pa. The YP/PV ratio is maintained within the range of 0.8~0.9, which meets the requirements for drilling fluid rheological properties in tectonic coal drilling (YP/PV > 0.6, facilitating cuttings carrying and wellbore cleaning). At 60 °C, the drilling fluid still exhibits excellent shear-thinning behavior: it has low viscosity at high shear rate (600 r/min) and high viscosity at low shear rate (300 r/min), satisfying the demands of hydraulic rock breaking and cuttings suspension during the drilling process.

Table 4.

Rheological parameters of drilling fluid under different temperatures.

3.2.2. Filtration Properties

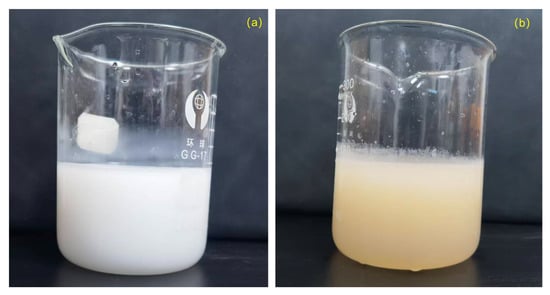

The variations of API filtration loss and high-temperature high-pressure (HTHP) filtration loss with time are presented in Figure 6. Under normal temperature and pressure (25 °C + 0.69 MPa), the API filtration loss stabilizes at 5.8 mL within 30 min; under medium temperature and normal pressure (60 °C + 0.69 MPa), the API filtration loss stabilizes at 6.5 mL within 30 min, which is much lower than that of conventional drilling fluids (API filtration loss usually > 10 mL). Under high temperature and high pressure (120 °C + 3.5 MPa), the HTHP filtration loss is 12.3 mL. CMCS and HPMC form a dense mud cake with a uniform pore structure, which effectively prevents the invasion of drilling fluid filtrate into the reservoir.

Figure 6.

Change of drilling fluid filtration loss with time.

3.2.3. Density and pH Value

The drilling fluid density ranges from 0.92 to 0.95 g/cm3, which belongs to low-density drilling fluid and can effectively reduce the collapse pressure of tectonic coal wellbore. The pH value is stable between 7.5 and 7.8, showing weakly alkaline property. This not only inhibits clay hydration but also ensures the activity of degrading enzymes (the optimal pH of enzymes is 7.0~8.0).

3.3. Inhibition Performance Evaluation

3.3.1. Linear Expansion Rate

The linear expansion rates of tectonic coal under the action of different drilling fluids are presented in Table 5. The 16 h expansion rate of the fresh water group reaches 2.58%, while the linear expansion rate of the novel drilling fluid is only 0.72%, with an inhibition rate of 72.1%. This outperforms the traditional SDS-type fuzzy-ball drilling fluid (with an inhibition rate of 52.5%) and APG-type fuzzy-ball drilling fluid (with an inhibition rate of 58.7%).

Table 5.

Linear swelling rate and inhibition rate of structured coal under the action of different drilling fluids.

3.3.2. Rolling Recovery Rate

The rolling recovery rates of different drilling fluids are presented in Table 6. The 14-mesh rolling recovery rate of the novel degradable fuzzy-ball drilling fluid reaches 82.5%, and the 16-mesh rolling recovery rate reaches 98.7%, which are significantly higher than those of fresh water. The novel degradable fuzzy-ball drilling fluid forms a protective film on the surface of tectonic coal particles, reducing friction between particles and collision-induced breakage, thereby improving the recovery rate.

Table 6.

Rolling recovery rate and improvement magnitude of different drilling fluids.

3.4. Degradation Performance Evaluation

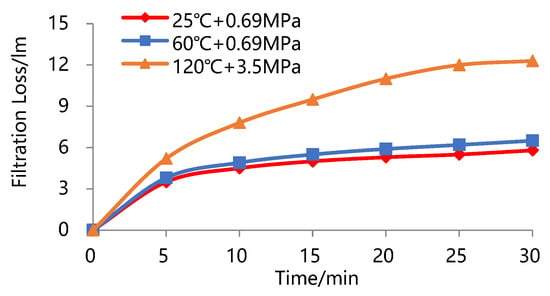

3.4.1. Gel-Breaking Rate

The variations of gel-breaking rate with time at different temperatures are presented in Figure 7. The gel-breaking efficiency is the highest at 55 °C: the gel-breaking rate reaches 90.8% at 1 h and 96.9% at 1.5 h. At 45 °C, the gel-breaking rate is 90.2% at 2 h; at 60 °C, the gel-breaking rate is 87.1% at 1 h. This indicates that the compound enzymatic system exhibits high degradability within a wide temperature range.

Figure 7.

Change of gel-breaking rate with time under different temperatures.

3.4.2. Mud Cake Degradation and Permeability Recovery

Changes in thickness and mass of mud cake before and after degradation are presented in Table 7. At 55 °C for 1.5 h, the mud cake thickness decreases from 1.21 mm to 0.03 mm, and its mass decreases from 0.983 g to 0.012 g, with a mass removal rate of 98.8%. After degradation, the mud cake has a loose structure and interconnected pores, facilitating fluid seepage. Permeability recovery experiments show that the original permeability of tectonic coal is 1.25 mD, which decreases to 0.18 mD after being plugged by drilling fluid, and recovers to 1.06 mD after degradation, with a permeability recovery rate of 84.8%.

Table 7.

Changes in physical parameters of mud cake before and after degradation.

3.5. Wellbore Stability Evaluation

3.5.1. Rock Mechanical Properties

The results of uniaxial and triaxial compression tests are presented in Table 8. After treatment with the novel degradable fuzzy-ball drilling fluid, the uniaxial compressive strength of tectonic coal increases from 1.2 MPa to 2.8 MPa, the elastic modulus increases from 43 MPa to 85 MPa, and Poisson’s ratio decreases from 0.37 to 0.26. Under a triaxial confining pressure of 6 MPa, the compressive strength increases from 20.1 MPa to 38.5 MPa, representing an increase of 91.5%; the cohesion increases from 0.37 MPa to 0.82 MPa, an increase of 121.6%; and the internal friction angle increases from 19.5° to 22.3°, an increase of 2.8°. This indicates that the drilling fluid enhances the mechanical strength of tectonic coal and reduces wellbore deformation through physical plugging and chemical inhibition.

Table 8.

Mechanical parameters of structured coal before and after the action of drilling fluid.

3.5.2. Numerical Simulation

The results of FLAC3D simulation are presented in Figure 8. From the perspective of radial stress, as the radial distance (with the radial distance at the wellbore set to 0) increases, the radial stress gradually increases, and the average radial stress of the novel drilling fluid is 0.686 MPa higher than that of the fresh water drilling fluid. From the perspective of radial displacement, as the radial distance increases, the radial displacement gradually decreases, and the average radial displacement of the novel drilling fluid is reduced by 62.1% compared with that of the fresh water drilling fluid. From the perspective of plastic strain, as the radial distance increases, the plastic strain gradually decreases, and within a radial distance of 0.58 m, the average plastic strain of the novel drilling fluid is 74.8% lower than that of the fresh water drilling fluid. After treatment with the novel drilling fluid, the stress plastic zone is reduced from 0.58 m (before treatment with fresh water drilling fluid) to 0.30 m. Calculated by radius, the plastic zone is reduced by 48.3%; calculated by area, it is reduced by 73.2%. This indicates that the novel degradable fuzzy-ball drilling fluid can significantly improve coal rock wellbore stability and enhance drilling safety.

Figure 8.

Numerical simulation results: (a) radial mean stress and distribution around the wellbore, (b) radial mean displacement and X and Z displacement distribution around the wellbore, and (c) mean plastic strain and critical plastic zone distribution around the wellbore.

4. Conclusions and Recommendations

4.1. Conclusions

(1) A novel degradable fuzzy-ball drilling fluid was developed, with the optimal formulation detailed as follows: 6% KCl–2% trehalose composite base slurry, 4% CMCS, 0.4% HPMC, 0.15% XG, 0.12% guar gum, 0.3% CAPB, 0.15% lauryl alcohol, and 0.2% triethanolamine. The degrading agent consists of 0.2% composite-modified amylase and 0.04% composite-modified cellulase.

(2) The novel drilling fluid exhibits excellent rheological properties, with values measured at 60 °C including an AV of 46.5 mPa·s, a PV of 24.4 mPa·s, a YP of 20.9 Pa, and a YP/PV ratio of 0.86. It also has low filtration properties, with an API filtration loss of 5.8 mL and an HTHP filtration loss of 12.3 mL; strong inhibition, shown by a linear expansion rate inhibition rate of 72.1%, a 14-mesh rolling recovery rate of 82.5%, and a 16-mesh rolling recovery rate reaching 98.7%; and efficient degradability, with test results at 55 °C for 1.5 h including a gel-breaking rate of 96.9%, a mud cake thickness reduction of 97.5%, a mud cake mass removal rate of 98.8%, and a permeability recovery rate reaching 84.8%.

(3) The novel degradable fuzzy-ball drilling fluid can significantly improve the wellbore stability of tectonic coal. After treatment with the novel drilling fluid, the uniaxial compressive strength of tectonic coal increases by 133.3%, the elastic modulus increases by 97.7%, and the triaxial compressive strength increases by 91.5%. The average wellbore surrounding radial stress increases by 0.686 MPa, the radial displacement decreases by 62.1%, and the plastic zone area shrinks by 73.2%, which effectively inhibits the collapse risk of tectonic coal wellbore.

4.2. Recommendations

(1) The current study has verified the macroscopic performance advantages of the novel degradable fuzzy-ball drilling fluid. In the future, microscopic methods such as molecular dynamics simulation, scanning electron microscopy (SEM), and energy dispersive spectroscopy (EDS) will be used to further explore the adsorption mechanism between the drilling fluid and coal-rock reservoirs, the hydrolysis mechanism of compound enzymes on polymers, and the dynamic plugging and degradation evolution law of the fuzzy-ball structure during drilling. This will provide more accurate theoretical support for formula optimization.

(2) Subsequent field tests will be carried out to verify the application effect of the drilling fluid in tectonic coal reservoir development. Meanwhile, combined with the geological differences of tectonic coal reservoirs in different regions, the drilling fluid formula will be adjusted to improve its field adaptability.

(3) In the future, the temperature application range of the drilling fluid can be further expanded. For medium-high-temperature (>60 °C) tectonic coal reservoirs, a high-temperature-resistant drilling fluid system will be developed, and the thermal stability of the degradation system will be optimized.

Author Contributions

Writing—review and editing, project administration, original draft preparation, validation, Y.C.; supervision, L.Z.; formal analysis, R.L.; literature research, Q.G.; investigation, J.Z.; validation, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

National Science and Technology Major Project “Co-production of Multiple Gases: Drilling and Completion Technology and Reservoir Protection” (Project No.: 2016ZX05066002). CNOOC Major Project “Marine Formation Damage Original Information Database and Auxiliary Design System” (Project No.: G2317A-0521T057).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors wish to appreciate the College of Petroleum Engineering, China University of Petroleum (Beijing).

Conflicts of Interest

Authors Yuanbo Chen and Yufei Zhang were employed by the company China Oilfield Services Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Sang, S.; Zhou, X.; Liu, S.; Wang, H.; Cao, L.; Liu, H.; Li, Z.; Zhu, S.; Liu, C.; Huang, H.; et al. Research advances in theory and technology of the stress release applied extraction of coalbed methane from tectonically deformed coals. J. China Coal Soc. 2020, 45, 2531–2543. [Google Scholar] [CrossRef]

- Strategic Research Center of Oil & Gas Resources, Ministry of Natural Resources. Evaluation and Development Strategy of CBM Resources in China; Geological Publishing House: Beijing, China, 2022; pp. 45–62.

- Yue, Q.; Li, G.; Li, D.; Shen, Y. Development and application of degradable polymer drilling fluid for coalbed methane horizontal well. J. China Coal Soc. 2015, 40, 425–429. [Google Scholar] [CrossRef]

- Xu, T.; Liu, X. Drilling Fluid Technology; Petroleum Industry Press: Beijing, China, 2019; pp. 189–205. [Google Scholar]

- Yang, X. Research Progress on Fluid Loss Additives for Water-Based Drilling Fluids. Drill. Fluid Complet. Fluid 2020, 37, 141–152. [Google Scholar]

- Sun, J.; Liu, Y.; Yang, Z. Research Progress on Environmental-Friendly Drilling Fluid Mud Cake Removal Technology. Acta Pet. Sin. 2022, 43, 865–878. [Google Scholar]

- Zhang, L.; Zhou, Y.; Jing, X. Evaluation Method and Control Technology of CBM Formation damage. Nat. Gas Ind. 2020, 40, 56–65. [Google Scholar]

- Zheng, L.; Cao, Y.; Han, Z. Novel low-density drilling fluid containing fuzzy ball structure. Acta Pet. Sin. 2010, 31, 490–493. [Google Scholar]

- Cai, J.; Gu, S.; Liu, H. Gel breaking affecting factors analysis on polymer bio-degradation. Adv. Mater. Res. 2012, 550–553, 1369–1373. [Google Scholar] [CrossRef]

- Zheng, L.; Kong, L.; Cao, Y.; Wang, H.; Han, Z.; He, X. Lost Circulation Prevention and Plugging Mechanism of Fuzzy-Ball Working Fluid. Chin. Sci. Bull. 2010, 55, 1522–1530. [Google Scholar] [CrossRef]

- Cui, J.B.; Zhang, J.H.; Zhu, Q.Z.; Chen, B.W. Practice of fuzzy-ball drilling fluid technology in Qinping CBM well 12-11-3H with six branch holes. Appl. Mech. Mater. 2013, 423–426, 649–652. [Google Scholar] [CrossRef]

- Zheng, L.H.; Wan, X.H.; Zhang, H.J.; Chi, L.J.; Peng, K.W. A novel multifunctional bionic fuzzy-ball drilling fluid. Adv. Mater. Res. 2011, 236–238, 608–615. [Google Scholar] [CrossRef]

- Zheng, L.H.; Kong, L.C.; Cao, Y.; Wang, H.Y.; Han, Z.X.; He, X.Q. The mechanism for fuzzy-ball working fluids for controlling & killing lost circulation. Chin. Sci. Bull. 2010, 55, 4074–4082. [Google Scholar] [CrossRef]

- Yue, Q.; Zou, L.; Jiang, G.; Tian, Z.; Hu, Y. Laboratory research on degradable drilling fluid for pinnate horizontal well based on coalbed methane. J. China Coal Soc. 2010, 35, 1692–1695. [Google Scholar] [CrossRef]

- Zhang, T. Study on Fuzzy-Ball Composite Plugging Drilling Fluid System. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2015. [Google Scholar]

- Wang, J.; Yang, C.; Mao, D.; Gou, F. Prediction of equivalent static density of water-based fuzzy ball drilling fluid by BP neural network method. Oil Drill. Prod. Technol. 2013, 35, 32–35. [Google Scholar] [CrossRef]

- Geng, X.; Su, Y.; Zheng, X.; Gao, B. Research and Application of Solids-Free Coalbed Protection Drilling Fluid. Oil Drill. Prod. Technol. 2017, 39, 455–459. [Google Scholar] [CrossRef]

- Liu, T. Vesicle Formation Process of Fuzzy-Ball Drilling Fluid. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2017. [Google Scholar]

- Chen, S.; Shi, Y.; Yang, X.; Xie, K.; Cai, J. Design and evaluation of a surfactant–mixed metal hydroxide-based drilling fluid for maintaining wellbore stability in coal measure strata. Energies 2019, 12, 1862. [Google Scholar] [CrossRef]

- Lyu, S.; Wang, S.; Chen, X.; Shah, S.M.; Li, R.; Xiao, Y.; Dong, Q.; Gu, Y. Experimental study of a degradable polymer drilling fluid system for coalbed methane well. J. Pet. Sci. Eng. 2019, 178, 678–690. [Google Scholar] [CrossRef]

- Huang, N.; Sun, J.-S.; Liu, J.-P.; Lv, K.-H.; Wang, Z.-L.; Deng, X.-F.; Dai, Z.-W.; Zhang, X.-F. Montmorillonite modified by composite modifier as a rheological regulator of drilling fluid suitable for ultra-low temperature conditions in Antarctica. Pet. Sci. 2024, 21, 4344–4357. [Google Scholar] [CrossRef]

- Zhong, H.; Li, S.; Li, D.; Jin, J.; Chen, C.; Mou, T.; Qiu, Z.; Huang, W. Carbon microspheres prepared from soluble starch hydrothermal carbonization for extending thermal stability of water-based drilling fluid. Int. J. Biol. Macromol. 2024, 282, 137391. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, J.; Wang, Z.; Liu, J.; Lv, K. Development and evaluation of a high temperature and high salinity resistant rheological enhancer for water-based drilling fluids. J. Phys. Conf. Ser. 2022, 2353, 012001. [Google Scholar] [CrossRef]

- Mikhienkova, E.I.; Lysakov, S.V.; Neverov, A.L.; Zhigarev, V.A.; Minakov, A.V.; Rudyak, V.Y. Experimental study on the influence of nanoparticles on oil-based drilling fluid properties. J. Pet. Sci. Eng. 2022, 208, 109452. [Google Scholar] [CrossRef]

- Leng, K.; Guan, B.; Liu, W.; Jiang, C.; Cong, S.; Xin, Y. Research progress of coalbed methane extraction. Energy Rep. 2024, 12, 5728–5746. [Google Scholar] [CrossRef]

- Zhong, R.; Mitchell, T.; Johnson, J.; Leonardi, C. Efficient implicit methods for wellbore shear failure analysis during drilling and production in coalbeds. Int. J. Rock Mech. Min. Sci. 2022, 155, 105129. [Google Scholar] [CrossRef]

- Xuan, D.; Wang, B.; Xu, J. A shared borehole approach for coal-bed methane drainage and ground stabilization with grouting. Int. J. Rock Mech. Min. Sci. 2016, 86, 235–244. [Google Scholar] [CrossRef]

- Li, C.; Sun, L.; Zhao, Z.; Zhang, J.; Li, Y.; Meng, Y.; Wang, L. A Method for Evaluating Coalbed Methane Reservoir Productivity Considering Drilling Fluid Damage. Energies 2024, 17, 1686. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, Z.; Wang, Q.; Chen, W.; Liu, T.; Zhou, T.; Li, S.; Xin, T.; Cao, J.; Xin, X. Preparation and Evaluation of a Novel Branched Polymer as Thickener for Calcium Chloride-Based Drilling and Completion Fluids. Molecules 2024, 29, 5542. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Yang, J.; Yu, L.; Song, B.; Du, W. Synthesis and Mechanism Study of an Environmental Additive Used in Water-Based Drilling Fluids from Bovine Bone Glue. Materials 2024, 17, 5547. [Google Scholar] [CrossRef]

- Misbah, B.; Sedaghat, A.; Balhasan, S.; Elgaddafi, R.; Malayer, M.A.; Malhas, R.N.; Omar, M.; Benomran, M. Enhancing thermal stability and filtration control for water-based drilling fluid using viscosifier polymers and potassium chloride additives. Geoenergy Sci. Eng. 2023, 230, 221235. [Google Scholar] [CrossRef]

- GB/T 16783.1-2014; Petroleum Industry Standardization Technical Committee. Petroleum and Natural Gas Industries-Field Testing of Drilling Fluids-Part 1: Water-Based Drilling Fluids. Quality Inspection Press: Shanghai, China, 2014.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.