Decarbonizing Rural Off-Grid Areas Through Hybrid Renewable Hydrogen Systems: A Case Study from Turkey

Abstract

1. Introduction

2. Materials and Methods

2.1. Modeling and Optimization

2.1.1. Load Profile Assessment

2.1.2. Deferrable Load

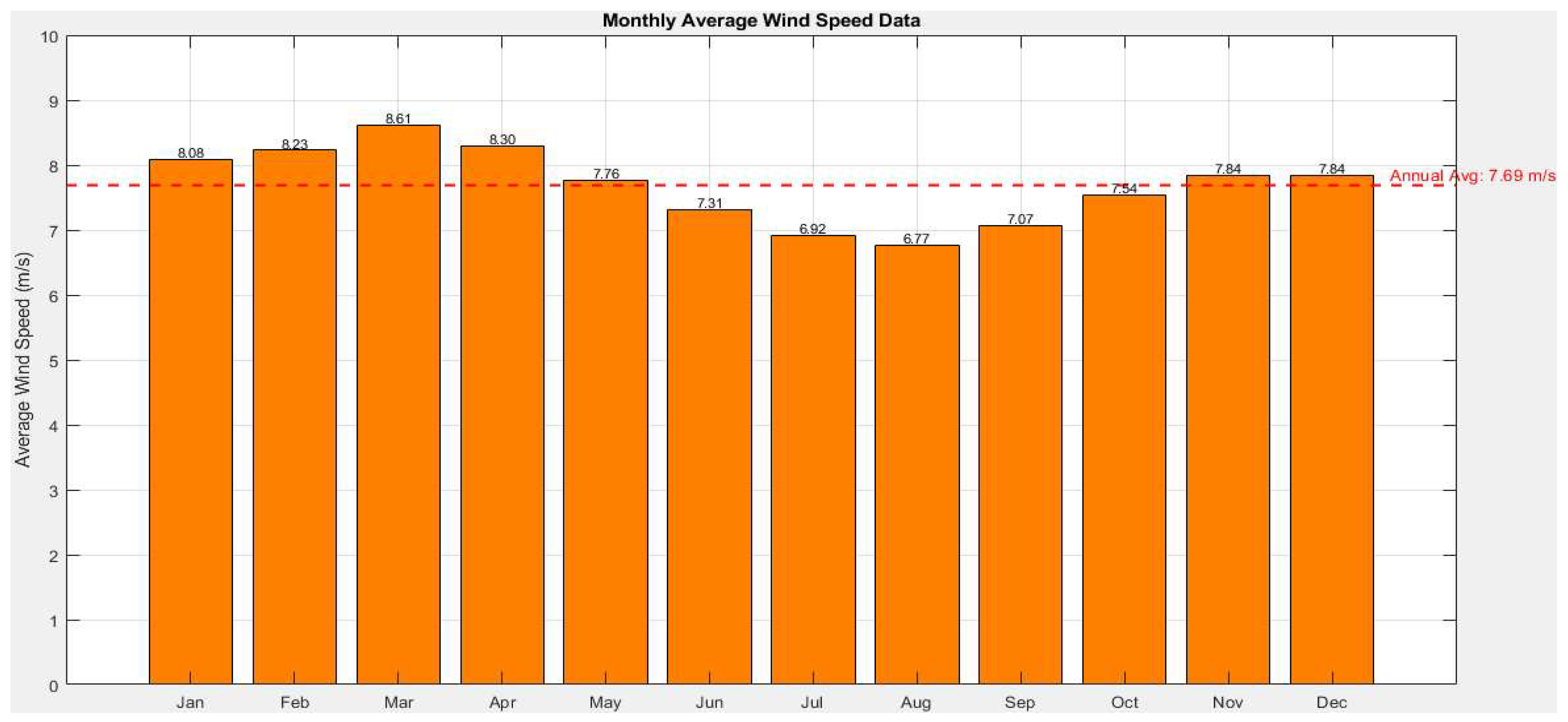

2.1.3. Solar Panel and Wind Turbine Selection

2.1.4. Hydrogen Energy Storage System Components

- Hydrogen is preferred because of its ability to flexibly balance seasonal production–consumption imbalances and its long-term storage capability. In the system, the electrolysis of water is carried out by means of an electrolyzer powered by excess electricity obtained from solar and wind resources and the hydrogen obtained is stored in tanks under certain pressure conditions [44].

- In this study, a proton exchange membrane (PEM) electrolyzer, the default model of HOMER Pro 3.14.2, was used. PEM technology is more suitable than alkaline electrolyzers due to its rapid response to variable production profiles of renewable energy sources, compact design, and high purity hydrogen production. The capital cost for the electrolyzer is defined as USD 1000/kW, with a replacement cost of USD 800/kW and an annual maintenance cost of USD 15/year. This value is in line with the recommended range of USD 900–1500/kW for commercial scale PEM electrolyzers reported by the International Energy Agency [45].

- For hydrogen tanks, capital cost is taken as USD 700/kg, replacement cost as USD 600/kg, and annual operating cost as USD 30/tank. These values correspond to the average of the estimates reported by IRENA [46] and a conservative approach has been adopted, taking into account regional cost differences and supply uncertainties.

- The capital cost of the fuel cell is USD 3000/kW, the refurbishment cost is USD 2400/kW, and the hydrogen cost is USD 3.5/kg. These costs are in line with the center range of values reported by the International Energy Agency [47]. This choice aimed to provide a balanced assumption for the study region, without extremes.

2.1.5. Converter

2.2. System Architecture

2.3. Life Cycle Assessment (LCA) and Impact Analysis of Hydrogen Leakage

3. Results and Discussions

3.1. Energy Production and Supply Reliability

3.2. Hydrogen Storage Performance and System Continuity

3.3. Comparative Energy Efficiency Analysis of Hybrid Systems

3.4. Impact of H2 Leakage on Carbon Equivalent Emissions: A Scenario Based Analysis

3.5. Life Cycle (LCA) Emission Analysis of the System

3.6. Literature Comparison

3.7. Critical Evaluation and Limitations of the Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| CC | Cycle Charging |

| CO2 | Carbon dioxide |

| COE | Cost of Energy |

| DC | Direct Current |

| EF | Emission Factor |

| GHG | Greenhouse Gas |

| GHI | Global Horizontal Irradiance |

| GWP | Global Warming Potential |

| H2 | Hydrogen |

| HOMER | Hybrid Renewable and Distributed Generation System Design Software |

| IEA | International Energy Agency |

| IICEC | International Center for Energy and Climate |

| LCA | Life Cycle Analysis |

| LCE | Life Cycle Emission |

| LF | Load Following |

| NPC | Net Present Cost |

| NREL | National Renewable Energy Laboratory |

| OH | Hydroxyl |

| PV | Photovoltaic |

References

- Osman, A.I.; Chen, L.; Yang, M.; Msigwa, G.; Farghali, M.; Fawzy, S.; Rooney, D.W.; Yap, P.S. Cost, environmental impact, and resilience of renewable energy under a changing climate: A review. Environ. Chem. Lett. 2023, 21, 741–764. [Google Scholar] [CrossRef]

- IEA. Global Energy Review 2025; IEA: Paris, France, 2025; Available online: https://www.iea.org/reports/global-energy-review-2025 (accessed on 29 June 2025).

- T.C. Ministry of Energy and Natural Resources. Turkey Electricity Generation Report 2024; Ministry of Energy and Natural Resources Publications: Ankara, Turkey, 2024. Available online: https://enerji.gov.tr/bilgi-merkezi-enerji-elektrik (accessed on 30 June 2025).

- Turkish Statistical Institute (TurkStat). Greenhouse Gas Emissions Statistics, 1990–2023; Turkish Statistical Institute. Available online: https://data.tuik.gov.tr/Bulten/Index?p=Sera-Gazi-Emisyon-Istatistikleri-1990-2023-53974 (accessed on 29 June 2025).

- Sabanci University Istanbul Policy Center. Turkey’s Decarbonization Pathway Net Zero in 2050; Sabanci University Publications: Istanbul, Turkey, 2022; Available online: https://ipc.sabanciuniv.edu/Content/Images/CKeditorImages/20240808-10085077.pdf (accessed on 29 June 2025).

- IEA. Renewables 2024; IEA: Paris, France, 2024; Available online: https://www.iea.org/reports/renewables-2024 (accessed on 28 June 2025).

- IEA. Net Zero by 2050; IEA: Paris, France, 2021; Available online: https://www.iea.org/reports/net-zero-by-2050 (accessed on 28 June 2025).

- International Renewable Energy Agency (IRENA). Renewable Capacity Statistics 2024; IRENA: Abu Dhabi, United Arab Emirates, 2024; Available online: https://www.smartenergydecisions.com/wp-content/uploads/2025/04/irena_re_capacity_statistics_2024.pdf (accessed on 28 June 2025).

- Amrouche, S.O.; Rekioua, D.; Rekioua, T.; Bacha, S. Overview of energy storage in renewable energy systems. Int. J. Hydrogen Energy 2016, 41, 20914–20927. [Google Scholar] [CrossRef]

- Yue, M.; Lambert, H.; Pahon, E.; Roche, R.; Jemei, S.; Hissel, D. Hydrogen energy systems: A critical review of technologies, applications, trends and challenges. Renew. Sustain. Energy Rev. 2021, 146, 111180. [Google Scholar] [CrossRef]

- Ocko, I.B.; Hamburg, S.P. Climate consequences of hydrogen emissions. Atmos. Chem. Phys. 2022, 22, 9349–9368. [Google Scholar] [CrossRef]

- IEA. Global Hydrogen Review 2021; International Energy Agency: Paris, France, 2021; Available online: https://www.iea.org/reports/global-hydrogen-review-2021 (accessed on 1 July 2025).

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef]

- Reiter, G.; Lindorfer, J. Global warming potential of hydrogen and methane production from renewable electricity via power-to-gas technology. Int. J. Life Cycle Assess. 2015, 20, 477–489. [Google Scholar] [CrossRef]

- Ocko, I.B.; Hamburg, S.P. Climate consequences of hydrogen leakage. Atmos. Chem. Phys. Discuss. 2022, 2022, 1–25. [Google Scholar]

- IICEC. Turkey Green Hydrogen Future Report; Sabancı University Istanbul International Energy and Climate Center (IICEC): Istanbul, Turkey, 2022; Available online: https://iicec.sabanciuniv.edu/sites/iicec.sabanciuniv.edu/files/inline-files/IICEC_T%C3%BCrkiye%20Ye%C5%9Fil%20Hidrojen%20Gelece%C4%9Fi.pdf (accessed on 2 July 2025).

- Turkish Electricity Transmission A.Ş. (TEİAŞ). Installed Power Report. 2023. Available online: https://www.teias.gov.tr (accessed on 1 July 2025).

- Republic of Turkey Ministry of Environment, Urbanization and Climate Change. Climate Change Strategy Document. 2023. Available online: https://webdosya.csb.gov.tr/db/iklim/editordosya/iklim_degisikligi_stratejisi_EN(2).pdf (accessed on 2 July 2025).

- Republic of Turkey Ministry of Energy and Natural Resources. Turkey National Hydrogen Technologies Strategy and Roadmap. 2021. Available online: https://www.enerji.gov.tr (accessed on 2 July 2025).

- Arat, H.T.; Baltacıoğlu, M.K. A perspective on hydrogen energy research, development and innovation activities in Turkey. Int. J. Energy Res. 2020, 44, 588–593. [Google Scholar] [CrossRef]

- SHURA. Priority Areas for a National Hydrogen Strategy for Turkey; Sabancı University: Istanbul, Turkey, 2022. [Google Scholar]

- Dincer, I.; Javani, N.; Karayel, G. The Role of Hydrogen in the Energy Mix: A Scenario Analysis for Turkey Using OSeMOSYS. Energies 2021, 17, 6348. [Google Scholar]

- Barlaz, F.; Akıl, Y.; Haydaroglu, C.; Kılıç, H. Renewable energy and hydrogen storage system analysis for carbon neutral campuses with Homer. Türk Doğa Fen Derg. 2025, 14, 136–145. [Google Scholar] [CrossRef]

- Yadav, S.; Kumar, P.; Kumar, A. Techno-economic assessment of hybrid renewable energy system with multi energy storage system using HOMER. Energy 2024, 297, 131231. [Google Scholar] [CrossRef]

- Ogarek, P.; Stec, A.; Słyś, D. Technical and economic analysis of an autonomous hybrid photovoltaic-hydrogen energy system for academic buildings with the focus on energy Independence–A case study for Poland. Appl. Energy 2025, 392, 125985. [Google Scholar] [CrossRef]

- Al-Ghussain, L.; Ahmad, A.D.; Abubaker, A.M.; Mohamed, M.A. An integrated photovoltaic/wind/biomass and hybrid energy storage systems towards 100% renewable energy microgrids in university campuses. Sustain. Energy Technol. Assess. 2021, 46, 101273. [Google Scholar] [CrossRef]

- Singh, A.; Baredar, P.; Gupta, B. Techno-economic feasibility analysis of hydrogen fuel cell and solar photovoltaic hybrid renewable energy system for academic research building. Energy Convers. Manag. 2017, 145, 398–414. [Google Scholar] [CrossRef]

- Zhang, W.; Maleki, A.; Rosen, M.A.; Liu, J. Optimization with a simulated annealing algorithm of a hybrid system for renewable energy including battery and hydrogen storage. Energy 2018, 163, 191–207. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Islam, M.S.; Taura, U.H.; Barhoumi, E.M.; Mansir, I.B.; Das, B.K.; Ali Sulaiman, M.M.B.; Agyekum, E.B.; Bahadur, I. A techno-economic analysis of renewable hybrid energy systems for hydrogen production at refueling stations. Int. J. Hydrogen Energy 2024, 78, 68–82. [Google Scholar] [CrossRef]

- Gökçek, M.; Kale, C. Techno-economical evaluation of a hydrogen refuelling station powered by Wind-PV hybrid power system: A case study for İzmir-Çeşme. Int. J. Hydrogen Energy 2018, 43, 10615–10625. [Google Scholar] [CrossRef]

- Komninos, N. Net zero energy districts: Connected intelligence for carbon-neutral cities. Land 2022, 11, 210. [Google Scholar] [CrossRef]

- Li, Y.; Liu, F.; Chen, K.; Liu, Y. Technical and economic analysis of a hybrid PV/wind energy system for hydrogen refueling stations. Energy 2024, 303, 131899. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Barhoumi, E.M.; Mansir, I.B.; Emori, W.; Uzoma, P.C. Techno-economic analysis and optimization of solar and wind energy systems for hydrogen production: A case study. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 9119–9134. [Google Scholar] [CrossRef]

- Barhoumi, E.M. Optimal design of standalone hybrid solar-wind energy systems for hydrogen-refueling station Case study. J. Energy Storage 2023, 74, 109546. [Google Scholar] [CrossRef]

- Oymak, A.; Tur, M.R. A Short Review on the Optimization Methods Using for Distributed Generation Planning. Int. J. Smart Grid-IJSMARTGRID 2022, 6, 54–64. [Google Scholar]

- Tur, M.R. Reliability assessment of distribution power system when considering energy storage configuration technique. IEEE Access 2020, 8, 77962–77971. [Google Scholar] [CrossRef]

- Lambert, T.; Gilman, P.; Lilienthal, P. Micropower system modeling with HOMER. In Integration of Alternative Sources of Energy; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2006. [Google Scholar]

- International Renewable Energy Agency. World Energy Transitions Outlook 2022: 1.5 °C Pathway; IRENA: Abu Dhabi, United Arab Emirates, 2022; Available online: https://www.spr.pe/wp-content/uploads/2022/04/IRENA_World_Energy_Transitions_Outlook_2022.pdf (accessed on 1 July 2025).

- HOMER Energy. HOMER Pro User Manual, 2021; HOMER Energy: Boulder, CO, USA, 2021. [Google Scholar]

- Turkish Statistical Institute (TurkStat). Energy Consumption Statistics—Household 2022. Available online: https://data.tuik.gov.tr (accessed on 1 July 2025).

- Google Earth. Geospatial Location of the Proposed Hybrid Energy System Site near Soma, Manisa, Türkiye [Satellite Imagery]. Available online: https://earth.google.com/web/search/Geospatial+Location+of+the+Proposed+Hybrid+Energy+System+Site+near+Soma,+Manisa%E3%80%82Turkey/@39.191523,27.637724,137.41467887a,637.42123316d,35y,0h,0t,0r/data=CskBGpoBEpMBCiUweDE0Yjc2MTU0MDcyN2YwNGY6MHg2NGIyZTRhMTdhMGYxOTVmGRUZHZCEmENAIeu3wC8_oztAKlhHZW9zcGF0aWFsIExvY2F0aW9uIG9mIHRoZSBQcm9wb3NlZCBIeWJyaWQgRW5lcmd5IFN5c3RlbSBTaXRlIG5lYXIgU29tYSwgTWFuaXNh44CCVHVya2V5GAIgASImCiQJMKZ5vfin4b8RChSr3J40JcAZ1F-qwHo8ZUAhHzaD7tU8ZcBCAggBOgMKATBCAggASg0I____________ARAA?authuser=0 (accessed on 1 July 2025).

- International Renewable Energy Agency. Renewable Power Generation Costs in 2023; IRENA: Abu Dhabi, United Arab Emirates, 2024. [Google Scholar]

- Bergey Wind Power, Excel 10-R Product Specifications. Available online: https://bergey.com/products/wind-turbines/excel-10/ (accessed on 1 July 2025).

- International Renewable Energy Agency. Global Hydrogen Trade: Geopolitical and Market Implications of Emerging Hydrogen Economies; IRENA: Abu Dhabi, United Arab Emirates, 2022. [Google Scholar]

- International Energy Agency (IEA). Electrolysers. Energy System—Low-Emission Fuels, 2025. Available online: https://www.iea.org/energy-system/low-emission-fuels/electrolysers (accessed on 6 July 2025).

- International Renewable Energy Agency. Green Hydrogen: A Guide to Policy Making; IRENA: Abu Dhabi, United Arab Emirates, 2022. [Google Scholar]

- International Energy Agency. Global Hydrogen Review 2023; IEA: Paris, France, 2023. [Google Scholar]

- Buttler, A.; Spliethoff, H. Current status of water electrolysis for energy storage, grid balancing and sector coupling via power-to-gas and power-to-liquids: A review. Renew. Sustain. Energy Rev. 2018, 82, 2440–2454. [Google Scholar] [CrossRef]

- Skeie, R.B.; Sandstad, M.; Krishnan, S.; Myhre, G.; Sand, M. Sensitivity of climate effects of hydrogen to leakage size, location, and chemical background. EGUsphere 2024, 2024, 1–22. [Google Scholar] [CrossRef]

- Field, R.A.; Derwent, R.G. Global warming consequences of replacing natural gas with hydrogen in the domestic energy sectors of future low-carbon economies in the United Kingdom and the United States of America. Int. J. Hydrogen Energy 2021, 46, 30190–30203. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Ardente, F.; Beccali, M.; Cellura, M.; Lo Brano, V. Energy performances and life cycle assessment of an Italian wind farm. Renew. Sustain. Energy Rev. 2008, 12, 200–217. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Life cycle assessment of hydrogen energy systems: A review of methodological choices. Int. J. Life Cycle Assess. 2017, 22, 346–363. [Google Scholar] [CrossRef]

- Warwick, N.; Griffiths, P.; Keeble, J.; Archibald, A.; Pyle, J.; Shine, K. Atmospheric Implications of Increased Hydrogen Use. 2022. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1067144/atmospheric-implications-of-increased-hydrogen-use.pdf (accessed on 7 July 2025).

- International Energy Agency. Life Cycle Assessment of Electricity Generation Technologies; IEA-PVPS: Paris, France, 2020; Available online: https://iea-pvps.org (accessed on 8 July 2025).

- Wei, X.; Sharma, S.; Waeber, A.; Wen, D.; Sampathkumar, S.N.; Margni, M.; Maréchal, F. Comparative life cycle analysis of electrolyzer technologies for hydrogen production: Manufacturing and operations. Joule 2024, 8, 3347–3372. [Google Scholar] [CrossRef]

- Clemente, M.; Maharjan, P.; Salazar, M.; Hofman, T. Meta-analysis of Life Cycle Assessments for Li-Ion Batteries Production Emissions. arXiv 2025, arXiv:2506.05531. [Google Scholar]

- Gandiglio, M.; Marocco, P.; Bianco, I.; Lovera, D.; Blengini, G.A.; Santarelli, M. Life cycle assessment of a renewable energy system with hydrogen-battery storage for a remote off-grid community. Int. J. Hydrogen Energy 2022, 47, 32822–32834. [Google Scholar] [CrossRef]

- Maniscalco, M.P.; Longo, S.; Cellura, M.; Miccichè, G.; Ferraro, M. Critical review of life cycle assessment of hydrogen production pathways. Environments 2024, 11, 108. [Google Scholar] [CrossRef]

- Oymak, A.; Demirel, I.H.; Tur, M.R. Evaluation of Energy Storage Solutions in Microgrids: A Comparison in Terms of Flexibility and Economics. In 2024 Global Energy Conference (GEC); IEEE: New York, NY, USA, 2024; pp. 299–303. [Google Scholar]

| Reference | Aim | Analysis Method | Advantages | Disadvantages |

|---|---|---|---|---|

| [23] | Design and evaluate a hybrid renewable energy system integrating PV, wind, batteries, electrolyzers, and hydrogen storage to provide carbon-neutral electricity supply for university campuses. | HOMER Pro | - Carbon neutral energy solution - Local data-driven model - Ensuring seamlessness with H2 | - LCOE high (USD 10.66/kwh) - High system cost |

| [24] | To conduct a techno-economic assessment of an isolated microgrid hybrid renewable energy system with PV, wind, battery, fuel cell, electrolyzers, and hydrogen storage, focusing on reliability and cost effectiveness. | HOMER | - Low NPC and COE - Providing reliable energy with 0% and 1% capacity shortage - Flexible storage with combination of H2 and battery | High initial investment cost |

| [25] | To compare on-grid and off-grid hybrid photovoltaic-hydrogen energy system scenarios for an academic building in Poland, with emphasis on energy independence and CO2 reduction. | HOMER Pro | 100% off-grid system - 11,815 kg/year CO2 reduction with H2 | - LCOE: PV-on-grid system EUR 0.132/kWh; alternative scenarios EUR 1.00/kWh and EUR 1.17/kWh. - High investment cost |

| [26] | To develop an integrated PV-wind-biomass hybrid system with battery and pumped storage to meet the electricity, heating, and hot water demands of university campuses with 100% renewable energy. | Meteonorm v7.1 dataset, GRG algorithm, campus scale modeling | - USD 0.1626/kWh low COE - Heating and hot water needs are also met - Carbon neutral energy planning at campus level | - High initial cost - Limited economic utilization of excess energy |

| [27] | To analyze the techno-economic feasibility of a solar PV-hydrogen fuel cell hybrid renewable energy system aiming to reduce excess electricity and improve night supply for academic research buildings. | HOMER Pro + Fuzzy Logic powered optimization | - Contribution of the H2 system to the night load - Low rate of excess electricity (15.7%) - Economic CoE (USD 0.203/kWh) | High cost |

| [28] | Optimizing multiple hybrid configurations combining PV, wind and battery, or hydrogen storage using advanced algorithms aimed at improving cost efficiency and system reliability. | Optimization with improved Chaotic Search + Simulated Annealing + HS algorithms | - Battery-based systems offer lower LCC and higher reliability - Robust algorithm with less than 11% error rate | - Low fuel cell and electrolyzer efficiency |

| [29] | Techno-economic analysis of PV-wind-electrolyzer-H2 tank-battery systems for hydrogen production at refueling stations under different operational scenarios. | HOMER Pro | - Low cost result with USD 0.0158/kWh and USD 0.401/kg H2 | Hydrogen demand scenario static |

| [30] | To evaluate the techno-economic performance of a hydrogen refueling station powered by a PV-wind hybrid power system, using a case study for Izmir-Çeşme. | HOMER Pro simulation | - LCOE: USD 0.146/kWh - LCOH: USD 7.526/kg | - %41 excess electricity |

| [31] | Developing a net zero energy district model that integrates PV generation with smart city and nature-based solutions for urban carbon neutrality. | Modeling + simulation + threshold analysis | - Comprehensive system approach for carbon neutralization - NZED possible with PV + behavioral change | - Declining yields at high population density - Storage required |

| [32] | To analyze the technical and economic feasibility of a grid-connected PV-wind-electrolyzer-H2 tank system for hydrogen refueling stations, focusing on demand-driven operation. | HOMER Pro + Monte Carlo demand simulation | - Economically favorable NPC (USD 8.35 M) obtained with demand-driven design - Production of 40,000 kg of green hydrogen per year | High NPC, requires large-scale infrastructure |

| [33] | Optimizing solar-wind hybrid energy systems for hydrogen production under specific regional conditions, evaluating LCOH, COE, and economic feasibility. | HOMER Pro Simulation | - LCOH: Lowest hydrogen cost at USD 1.15/kg - COE: USD 0.19/kWh - Economic feasibility study for Salalah region provided | - NPC value is higher than other systems - LCA, leakage and environmental emissions not included |

| [34] | Design and optimize a standalone hybrid PV–wind–battery–electrolyzer–H2 tank system for hydrogen fueling stations, targeting continuous supply and carbon neutrality. | Economic and technical optimization with HOMER Pro software | - Provides a carbon neutral energy solution - Uninterrupted energy supply with hydrogen storage | - LCOE USD 8.76/kWh - System investment cost is high |

| Architecture | Dispatch | NPC (USD) | COE (USD) | Operating Cost (USD/yr.) | Initial Capital (USD) | Ren Fraction (%) | Total Fuel (kg/yr.) |

|---|---|---|---|---|---|---|---|

| PV50-WT2-FC10-EL50-HT80-CONV25 | CC | 297,419 | 0.34 | 7849 | 212.5 | 100 | 1841 |

| PV60-WT2-FC10-EL50-HT80-CONV25 | CC | 301,126 | 0.345 | 8035 | 214.5 | 100 | 2011 |

| WT4-FC10-EL50-HT80-CONV25 | LF | 30,438 | 0.35 | 8122 | 216.5 | 100 | 1535 |

| WT4-FC10-EL50-HT80-CONV25 | LF | 311,538 | 0.356 | 8236 | 222.5 | 100 | 1380 |

| Parameter | Scenario 1 (PV + Wind + Battery + H2) | Scenario 2 PV + Wind + H2) | Scenario 3 (Wind + H2) | Scenario 4 Wind + Battery + H2) |

|---|---|---|---|---|

| Total Production (kWh/yr.) | 187,538 | 206,303 | 193,967 | 191,609 |

| PV Production (kWh/yr.) | 78,751 (42%) | 94,502 (45.8%) | — | — |

| Wind Generation (kWh/yr.) | 87,589 (46.7%) | 87,589 (42.5%) | 175,178 (90.3%) | 175,178 (91.4%) |

| Fuel Cell Production (kWh/yr.) | 21,198 (11.3%) | 24,213 (11.7%) | 18,790 (9.69%) | 16,432 (8.58%) |

| Total Consumption (kWh/yr.) | 175,719 | 185,541 | 162,660 | 155,128 |

| AC Primary Load (kWh/yr.) | 59,561 | 59,345 | 59,213 | 59,612 |

| Deferrable Load (kWh/yr.) | 21,360 | 21,360 | 21,241 | 21,240 |

| Excess Electricity (kWh/yr.) | 8625 (4.6%) | 17,760 (8.61%) | 26,310 (13.6%) | 31,777 (16.6%) |

| Unmet Electric Load (kWh/yr.) | 769 (0.94%) | 986 (1.21%) | 1236 (1.51%) | 838 (1.03%) |

| Capacity Shortage (kWh/yr.) | 1488 (1.82%) | 2282 (2.79%) | 2357 (2.88%) | 1466 (1.79%) |

| Components | Energy Production (kWh/yr.) | Fuel Cell Production | Hydrogen Annual Energy Flow (kWh/yr.) | Inverter Losses (kWh/yr.) | Rectifier Losses (kWh/yr.) | Hydrogen Efficiency (%) |

|---|---|---|---|---|---|---|

| PV + Wind + Hydrogen + Battery | 187,538 | 21,198 | 61,376 | 1517 | 1608 | 34.5 |

| PV+ Wind + Hydrogen | 206,303 | 24,213 | 67,032 | 1527 | 1475 | 36.1 |

| Wind + Hydrogen | 193,967 | 18,790 | 51,183 | 806 | 4192 | 36.7 |

| Wind + Hydrogen + Battery | 191,609 | 16,432 | 45,987 | 781 | 3873 | 35.7 |

| Scenarios | H2 Consumption (kg/yr.) | Leakage Rate (%) | Leaking H2 (kg/yr.) | CO2 Equivalent Emission (kg/yr.) |

|---|---|---|---|---|

| Scenario 1 | 1841 | 1 | 18.41 | 607.53 |

| 5 | 92.05 | 3052.5 | ||

| 10 | 184.1 | 6075.3 | ||

| Scenario 2 | 2011 | 1 | 20.11 | 663.63 |

| 5 | 100.55 | 3318.5 | ||

| 10 | 201.1 | 6636.3 | ||

| Scenario 3 | 1535 | 1 | 15.35 | 506.55 |

| 5 | 76.75 | 2532.75 | ||

| 10 | 153.5 | 5065.5 | ||

| Scenario 4 | 1380 | 1 | 13.80 | 455.4 |

| 5 | 69 | 2277 | ||

| 10 | 138 | 4554 |

| Component | Unit Capacity | Emission Factor (kg CO2-eq/kW or kg) | Lifespan (yr.) | Scenario 1 (50 kW PV + H2 + 2 WT + 4 kWh Battery) Annual Emission (kg CO2-eq) | Scenario 2 (60 kW PV + H2 + 2 WT) Annual Emission (kg CO2-eq) | Scenario 3 (4 WT+ H2) Annual Emission (kg CO2-eq) | Scenario 4 (4 WT + H2 + 4 kWh Battery) Annual Emissions (kg CO2-eq) |

|---|---|---|---|---|---|---|---|

| PV Panel | kW | 1000 [56] | 25 | 2000 | 2400 | 0 | 0 |

| Wind Turbine | units | 1300 [42] | 20 | 130 | 130 | 260 | 260 |

| Fuel Cell | kW | 10 [13] | 20 | 5 | 5 | 5 | 5 |

| Electrolyzer | kW | 453 [57] | 15 | 1510 | 1510 | 1510 | 1510 |

| H2 Tank | kg | 875 [46] | 20 | 3500 | 3500 | 3500 | 3500 |

| Lithium-Ion Battery | kWh | 63 [58] | 10 | 25.2 | 0 | 0 | 25.2 |

| Inverter | kW | 50 | 15 | 83.33 | 83.33 | 83.33 | 83.33 |

| H2 Leakage | kg/yr. | 33 | 607.53 | 663.63 | 506.55 | 455.4 | |

| Total Emission | kg CO2-eq | 7861.063 | 8291.96 | 5864.88 | 5838.93 | ||

| Specific CO2 emissions | g CO2-eq/kWh | 44.74 | 44.69 | 36.05 | 37.64 |

| Study | System Components | COE (USD/kWh) | Excess Electricity (%) | Specific Emission (g CO2-eq/kWh) | Notes |

|---|---|---|---|---|---|

| This study | PV + Wind + H2 + Battery | 0.340 | <10 | 44.74 | Rural community, LCA, has H2 efficiency |

| [24] | PV + Wind + H2 | 0.189 | >20 | N/A | Grid-connected, large-scale |

| [25] | PV + H2 + Battery | 1 (€/kwh) | >25 | N/A | Urban, off-grid |

| [27] | PV + H2 + Fuel Cell | 0.177 | N/A | N/A | No LCA analysis |

| [30] | PV + Wind + H2 (Refueling) | 0.146 | 41 | N/A | Transportation-oriented, no housing burden |

| [32] | PV+ Wind+ H2 | N/A | >25 | ~50–65 | Mains connected, LCA available |

| [34] | PV + Wind+ H2 | 7.4 (€/kwh) | >25 | N/A | Transportation oriented |

| [59] | PV + Wind + Diesel + H2 | – | ~15 | ~70–90 | Includes LCA, island application |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oymak, A.; Tur, M.R. Decarbonizing Rural Off-Grid Areas Through Hybrid Renewable Hydrogen Systems: A Case Study from Turkey. Processes 2025, 13, 2909. https://doi.org/10.3390/pr13092909

Oymak A, Tur MR. Decarbonizing Rural Off-Grid Areas Through Hybrid Renewable Hydrogen Systems: A Case Study from Turkey. Processes. 2025; 13(9):2909. https://doi.org/10.3390/pr13092909

Chicago/Turabian StyleOymak, Aysenur, and Mehmet Rida Tur. 2025. "Decarbonizing Rural Off-Grid Areas Through Hybrid Renewable Hydrogen Systems: A Case Study from Turkey" Processes 13, no. 9: 2909. https://doi.org/10.3390/pr13092909

APA StyleOymak, A., & Tur, M. R. (2025). Decarbonizing Rural Off-Grid Areas Through Hybrid Renewable Hydrogen Systems: A Case Study from Turkey. Processes, 13(9), 2909. https://doi.org/10.3390/pr13092909