Modeling of the Mutual Placement of Thermoanemometer Sensors on a Flat Surface of an Air Flow

Abstract

1. Introduction

2. Materials and Methods

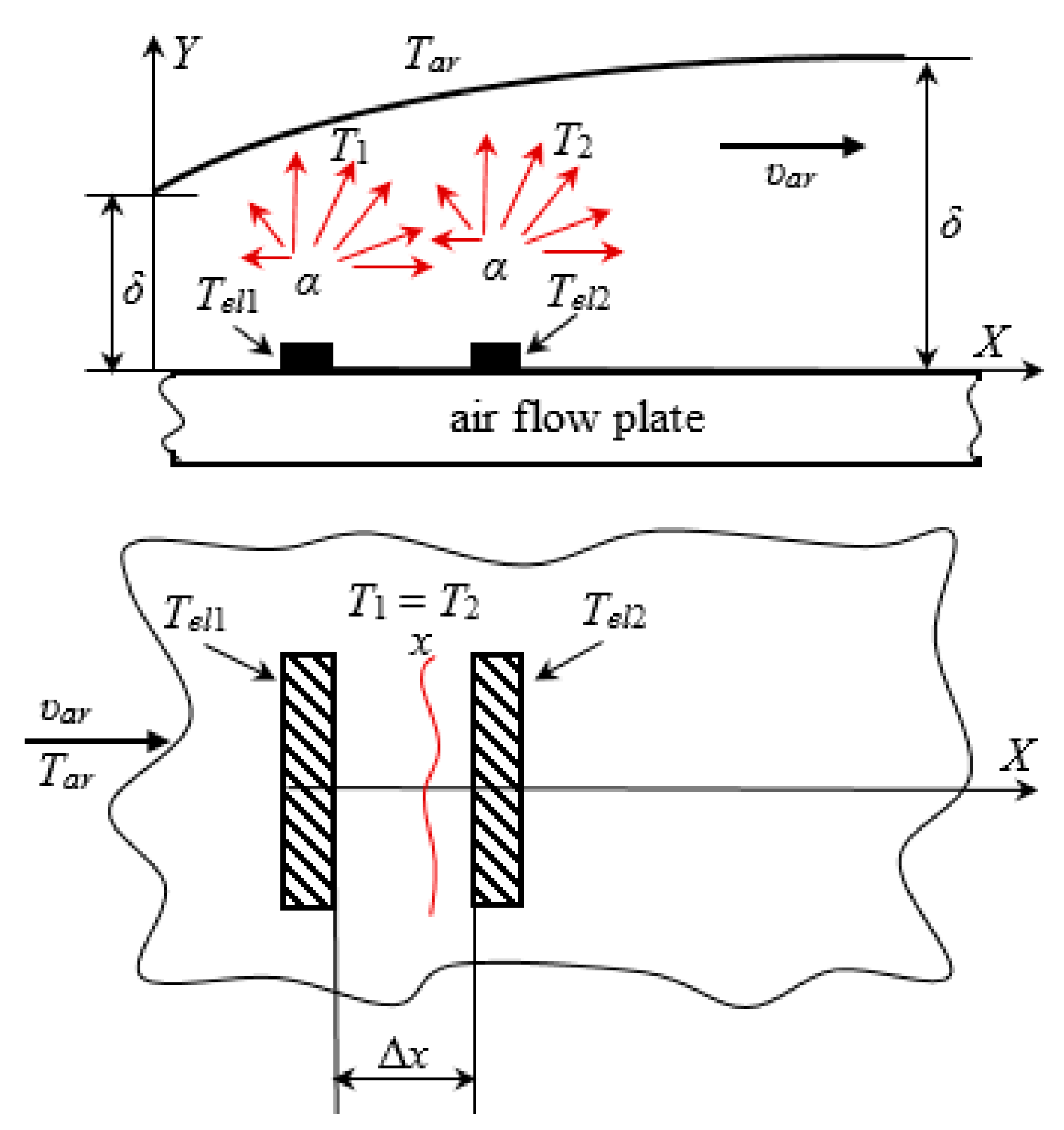

2.1. Mathematical Model of the Thermoanemometer

2.2. Mathematical Model of Temperature Distribution in the Boundary Layer of a Streamlined Surface

2.3. Justification of the Spacing Between the Sensing Elements of the Sensor

3. Results

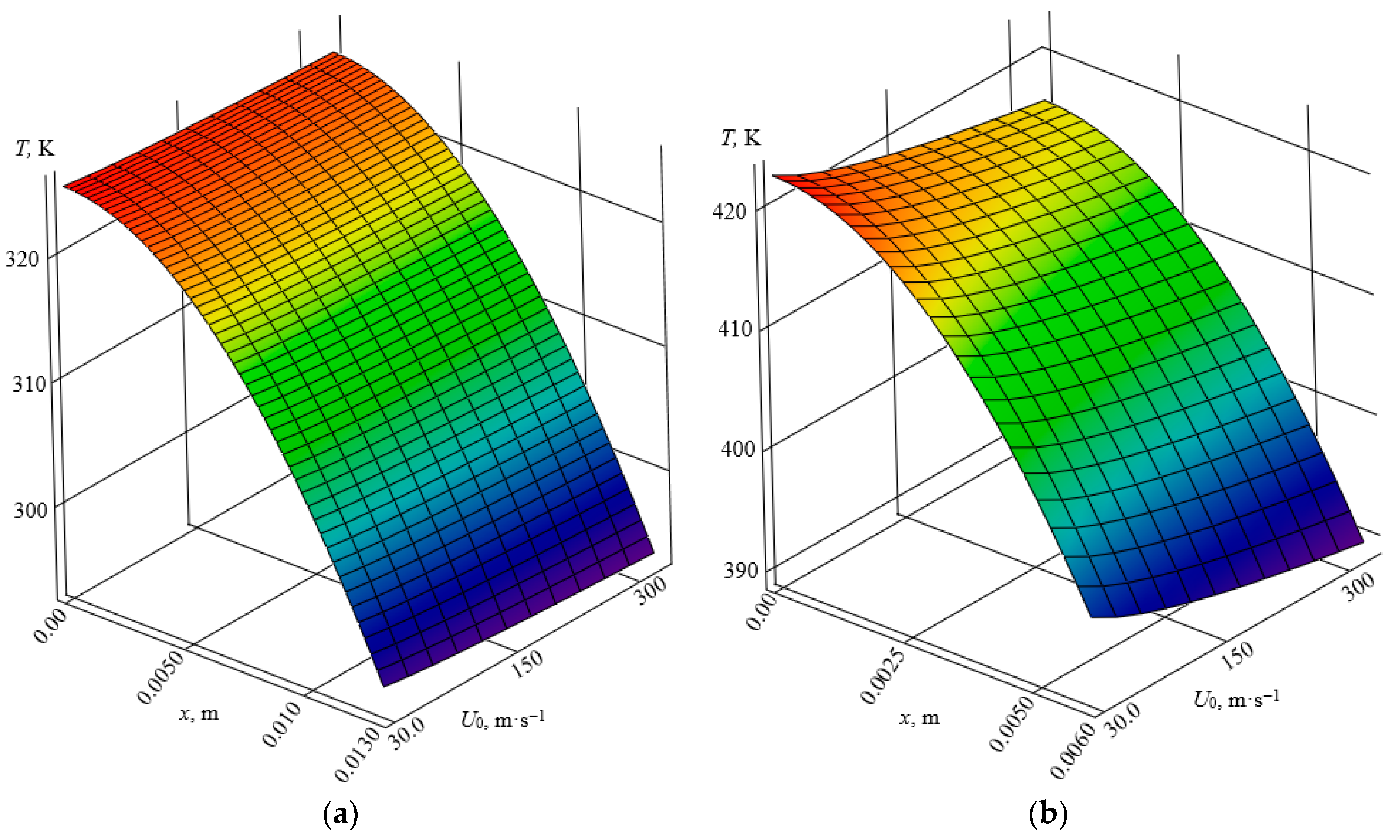

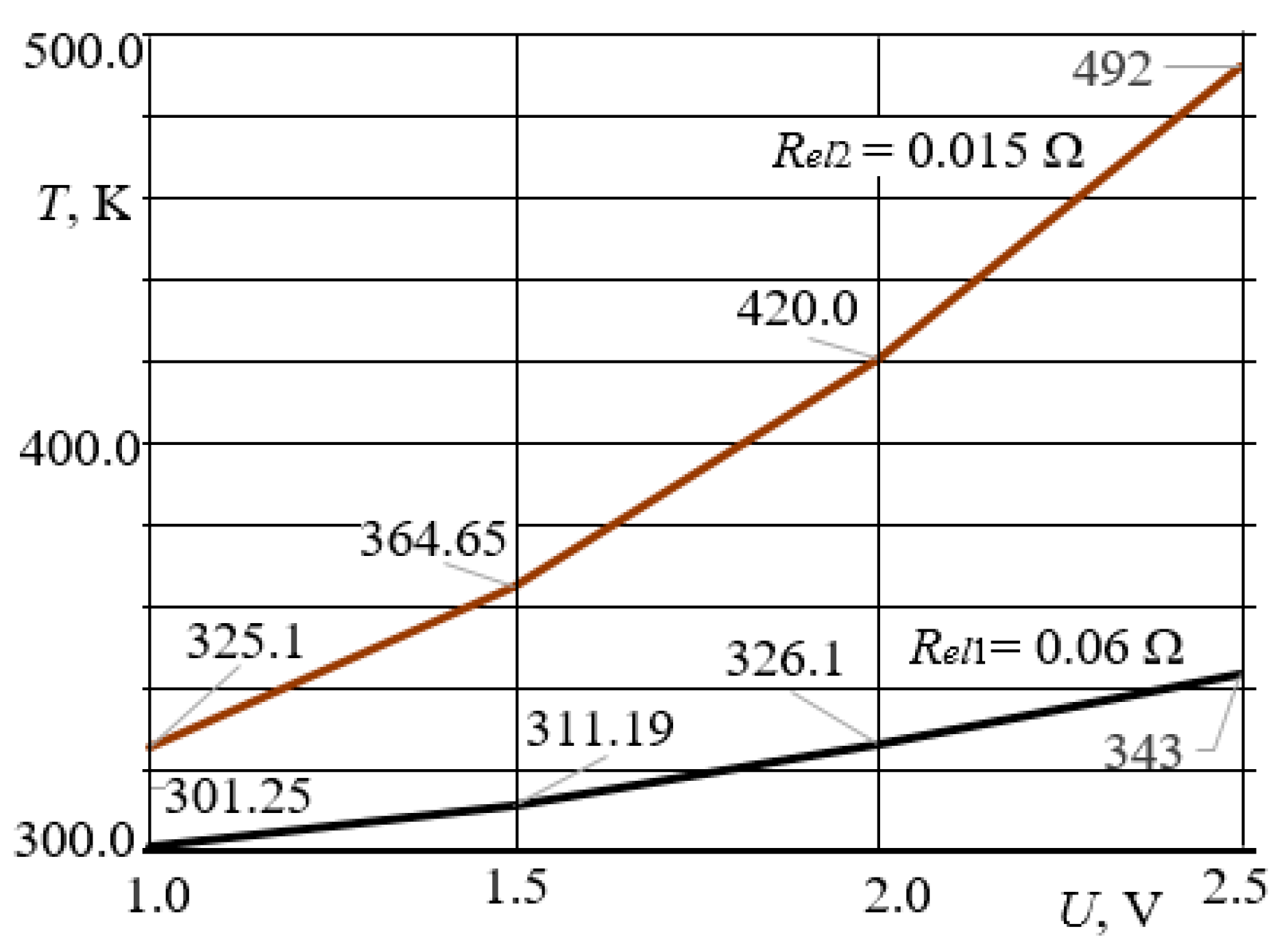

3.1. Distribution of the Temperature Field of the Sensing Elements of the Thermoanemometer in the Near-Wall Surface of the Boundary Layer of Air Flow

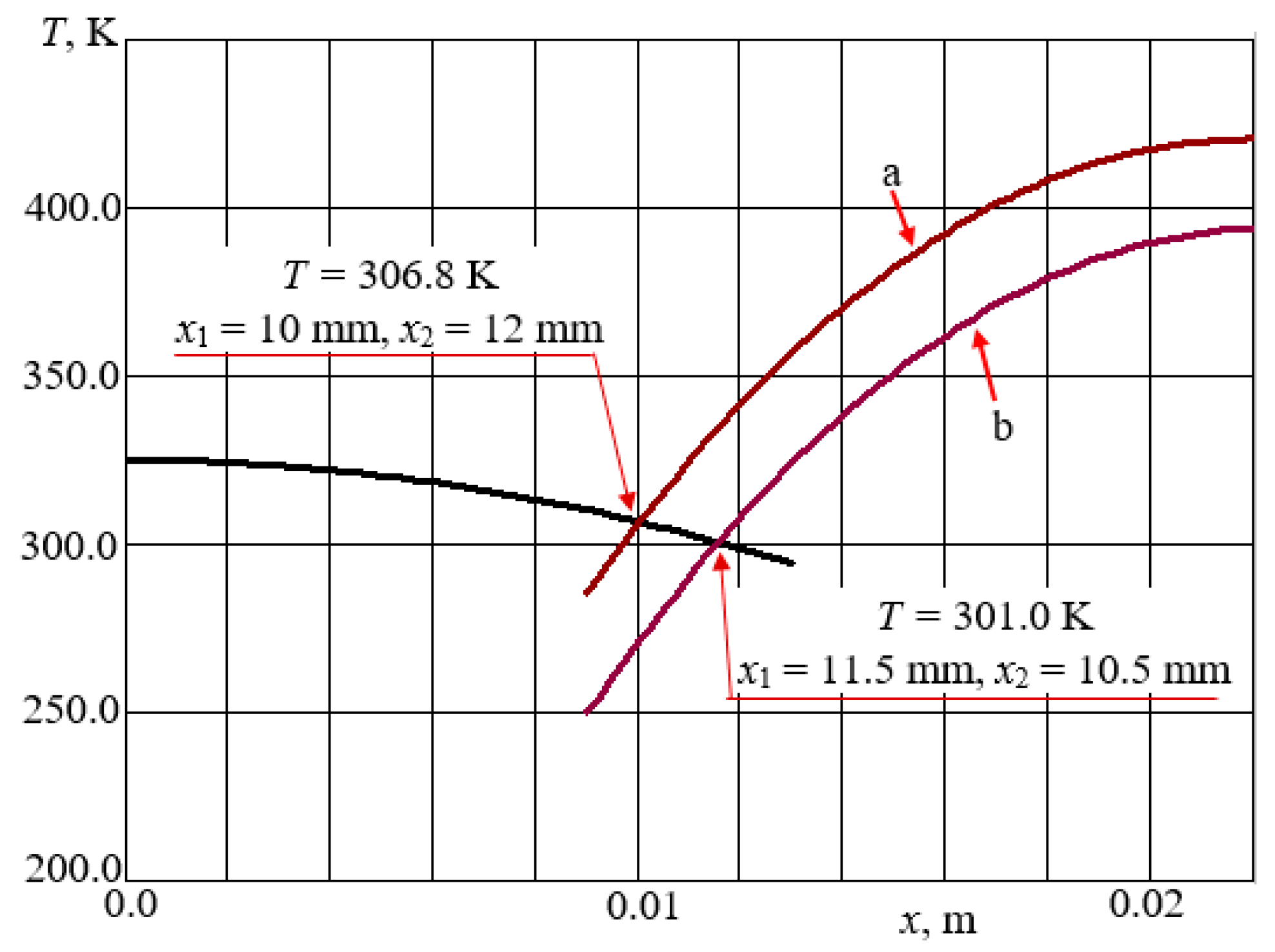

3.2. Modeling the Air Temperature at the Boundary of the Temperature Fields of the Sensing Elements of the Thermoanemometer in the Near-Wall Surface of the Boundary Layer of the Air Flow

4. Discussion

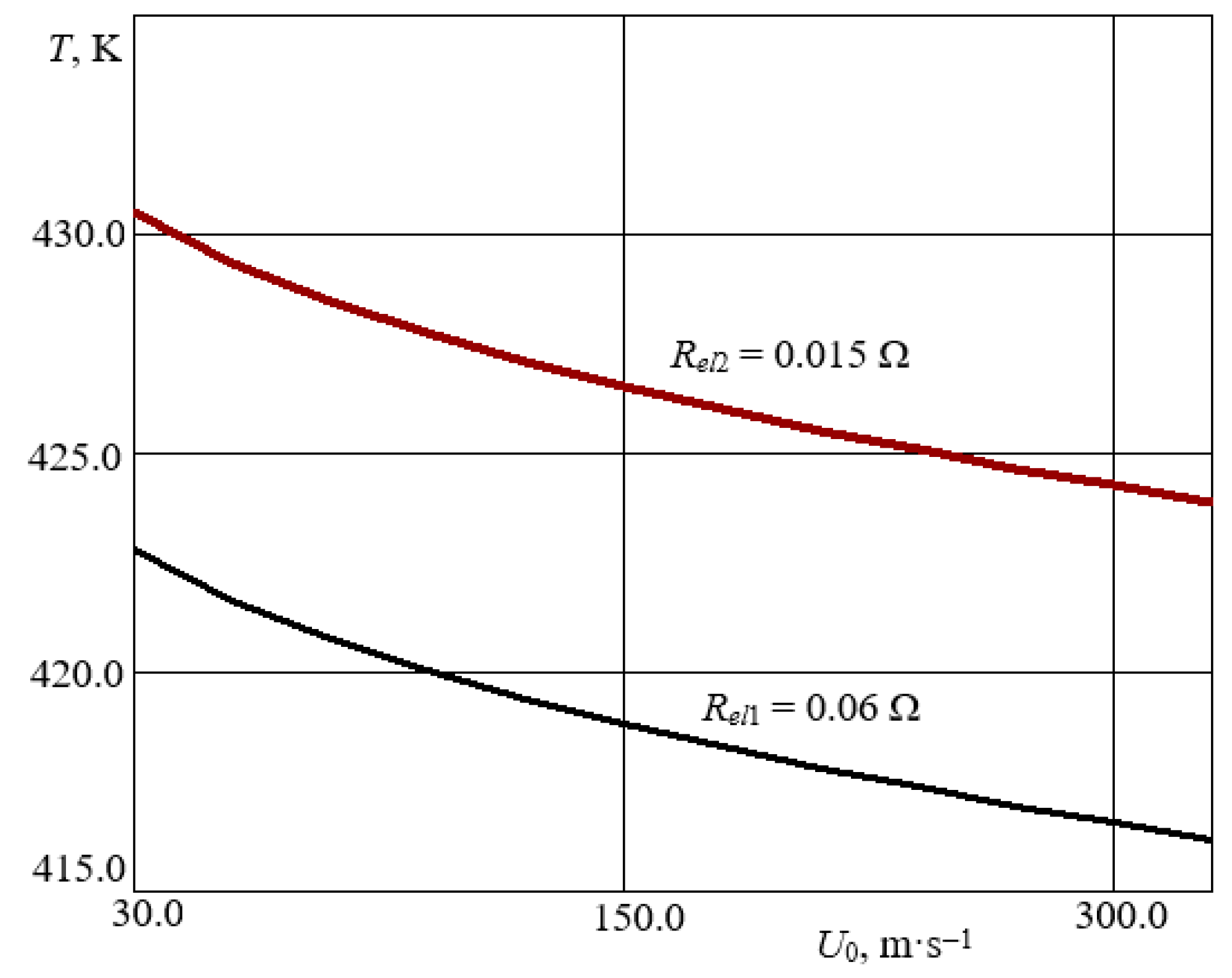

Analysis of the Results of Modeling the Temperature Parameters of the Sensing Elements of the Thermoanemometer

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gomes, R.A.; Niehuis, R. Development of a novel anemometry technique for velocity and temperature measurement. Exp. Fluids. 2018, 59, 142. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, X.; Zhang, J.; Xiong, L.; Dong, X. Sensitivity-Enhanced Hot-Wire Anemometer by Using Cladding-Etched Fiber Bragg Grating. Photonic Sens. 2023, 13, 230305. [Google Scholar] [CrossRef]

- Schniedenharn, M.; Wiedemann, F.; Schleifenbaum, J.H. Visualization of the shielding gas flow in SLM machines by space-resolved thermal anemometry. Rapid Prototyp. J. 2018, 24, 1296–1304. [Google Scholar] [CrossRef]

- Hewes, A.; Mydlarski, L. Design of thermal-anemometry-based probes for the simultaneous measurement of velocity and gas concentration in turbulent flows. Meas. Sci. Technol. 2021, 32, 105305. [Google Scholar] [CrossRef]

- Hewes, A.; Mydlarski, L. Simultaneous measurements of velocity, gas concentration, and temperature by way of thermal-anemometry-based probes. Meas. Sci. Technol. 2022, 33, 015301. [Google Scholar] [CrossRef]

- Pantoli, L.; Paolucci, R.; Muttillo, M.; Fusacchia, P.; Leoni, A. A multisensorial thermal anemometer system. Lect. Notes Electr. Eng. 2018, 431, 330–337. [Google Scholar] [CrossRef]

- Daniel, F.; Peyrefitte, J.; Radadia, A.D. Towards a completely 3D printed hot wire anemometer. Sens. Actuators A Phys. 2020, 309, 111963. [Google Scholar] [CrossRef]

- Atienza, M.-T.; Kowalski, L.; Gorreta, S.; Jiménez, V.; Domínguez-Pumar, M. Thermal dynamics modeling of a 3D wind sensor based on hot thin film anemometry. Sens. Actuators A Phys. 2018, 272, 178–186. [Google Scholar] [CrossRef]

- De Vita, E.; Di Palma, P.; Zahra, S.; Roviello, G.; Ferone, C.; Iadicicco, A.; Campopiano, S. Hot-wire anemometer based on D-shaped Optical Fiber. IEEE Sens. J. 2023, 23, 12845. [Google Scholar] [CrossRef]

- Zhang, J.; Tang, Y.; Xu, P.; Xu, O.; Dong, X. Intensity-interrogated hot-wire anemometer based on chirp effect of a fiber Bragg grating. Opt. Express 2022, 30, 37124–37130. [Google Scholar] [CrossRef] [PubMed]

- Sekine, M.; Furuya, M. Development of Measurement Method for Temperature and Velocity Field with Optical Fiber Sensor. Sensors 2023, 23, 1627. [Google Scholar] [CrossRef] [PubMed]

- Pique, A.; Miller, M.A.; Hultmark, M. Characterization of the wake behind a horizontal-axis wind turbine (HAWT) at very high Reynolds numbers. J. Phys. Conf. Ser. 2020, 1618, 062039. [Google Scholar] [CrossRef]

- Sadeghi, H.; Lavoie, P.; Pollard, A. Effects of finite hot-wire spatial resolution on turbulence statistics and velocity spectra in a round turbulent free jet. Exp. Fluids. 2018, 59, 40. [Google Scholar] [CrossRef]

- Takegawa, N.; Ishibashi, M.; Iwai, A.; Furuichi, N.; Morioka, T. Verification of flow velocity measurements using micrometer-order thermometers. Sci. Rep. 2021, 11, 23778. [Google Scholar] [CrossRef]

- Chen, S.; Shi, Z.; Geng, X.; Zhao, Z.; Chen, Z.; Sun, Q. Study of the transient flow structures generated by a pulsed nanosecond plasma actuator on a delta wing. Phys. Fluids. 2022, 34, 107111. [Google Scholar] [CrossRef]

- Tofan-Negru, A.; Ștefan, A.; Grigore, L.Ú.; Oncioiu, I. Experimental and Numerical Considerations for the Motor-Propeller Assembly’s Air Flow Field over a Quadcopter’s Arm. Drones. 2023, 7, 199. [Google Scholar] [CrossRef]

- Simonetti, M.; Caillol, C.; Higelin, P.; Dumand, C.; Revol, E. Experimental investigation and 1D analytical approach on convective heat transfers in engine exhaust-type turbulent pulsating flows. Appl. Therm. Eng. 2020, 165, 114548. [Google Scholar] [CrossRef]

- Silva, R.L.; Brito, S.X. Experimental evaluation of energy efficiency and velocity fields on a low-pressure axial flow fan (desktop type). Energy Effic. 2019, 12, 697–710. [Google Scholar] [CrossRef]

- Dmytriv, V.T.; Dmytriv, I.V.; Borovets, V.M.; Horodetskyy, I.M.; Kachmar, R.Y.; Dmyterko, P.R. Analytical-experimental studies of delivery rate and volumetric efficiency of rotor-type vacuum pumps for milking machine. INMATEH—Agric. Eng. 2019, 58, 57–62. [Google Scholar]

- Bombek, G.; Hribernik, A. Flow behaviour in vented brake discs with straight and airfoil-shaped radial vanes. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 237, 3448–3464. [Google Scholar] [CrossRef]

- Sip, J.; Lizal, F.; Pokorny, J.; Elcner, J.; Jedelsky, J.; Jicha, M. Automotive cabin vent: Comparison of RANS and LES approaches with analytical-empirical equations and their validation with experiments using Hot-Wire Anemometry. Build. Environ. 2023, 233, 110072. [Google Scholar] [CrossRef]

- Francois, F.; Djeridi, H.; Barre, S.; Klédy, M. Measurements of void fraction, liquid temperature and velocity under boiling two-phase flows using thermal-anemometry. Nucl. Eng. Des. 2021, 381, 111359. [Google Scholar] [CrossRef]

- Taha, M.M.; Said, I.A.; Zeitoun, Z.; Usman, S.; Al-Dahhan, M.H. Effect of non-uniform heating on temperature and velocity profiles of buoyancy driven flow in vertical channel of prismatic modular reactor core. Appl. Therm. Eng. 2023, 225, 120209. [Google Scholar] [CrossRef]

- Antošová, Z.; Trávníček, Z. Stagnation Point Heat Transfer to an Axisymmetric Impinging Jet at Transition to Turbulence. J. Heat Transf. 2023, 145, 023902. [Google Scholar] [CrossRef]

- Faria, A.F.; Avelar, A.C.; Francisco, C.P.F. Transient experimental analysis in the wake of bluff bodies. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 100. [Google Scholar] [CrossRef]

- Hajimirzaie, S.M. Experimental Observations on Flow Characteristics around a Low-Aspect-Ratio Wall-Mounted Circular and Square Cylinder. Fluids 2023, 8, 32. [Google Scholar] [CrossRef]

- Dmytriv, V.; Dmytriv, I.; Dmytriv, T. Research in thermoanemometric measuring device of pulse flow of two-phase medium. Eng. Rural Dev. 2018, 17, 898–904. [Google Scholar] [CrossRef]

- Dmytriv, T.V.; Mykyychuk, M.M.; Dmytriv, V.T. Analytical model of dynamic boundary layer on the surface under laminar flow mode. Mach. Energetics 2021, 12, 93–98. (In Ukrainian) [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids; Oxford University Press: New York, NY, USA, 1959. [Google Scholar]

- Cebula, A. Experimental and numerical investigation of thermal flow meter. Arch. Thermodyn. 2015, 36, 149–160. [Google Scholar] [CrossRef][Green Version]

- Diwate, M.; Tawade, J.V.; Janthe, P.G.; Garayev, M.; El-Meligy, M.; Kulkarni, N.; Gupta, M.; Ijaz Khan, M. Numerical solutions for unsteady laminar boundary layer flow and heat transfer over a horizontal sheet with radiation and nonuniform heat Source/Sink. J. Radiat. Res. Appl. Sci. 2024, 17, 101196. [Google Scholar] [CrossRef]

- Dmytriv, V. Model of forced turbulence for pulsing flow. Diagnostyka 2020, 21, 89–96. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dmytriv, T.; Dmytriv, V.; Bembenek, M. Modeling of the Mutual Placement of Thermoanemometer Sensors on a Flat Surface of an Air Flow. Processes 2025, 13, 2906. https://doi.org/10.3390/pr13092906

Dmytriv T, Dmytriv V, Bembenek M. Modeling of the Mutual Placement of Thermoanemometer Sensors on a Flat Surface of an Air Flow. Processes. 2025; 13(9):2906. https://doi.org/10.3390/pr13092906

Chicago/Turabian StyleDmytriv, Taras, Vasyl Dmytriv, and Michał Bembenek. 2025. "Modeling of the Mutual Placement of Thermoanemometer Sensors on a Flat Surface of an Air Flow" Processes 13, no. 9: 2906. https://doi.org/10.3390/pr13092906

APA StyleDmytriv, T., Dmytriv, V., & Bembenek, M. (2025). Modeling of the Mutual Placement of Thermoanemometer Sensors on a Flat Surface of an Air Flow. Processes, 13(9), 2906. https://doi.org/10.3390/pr13092906