Abstract

This script discusses a qualitative analysis of the characteristics of coals burned in the combustion chambers of thermal power plants in Serbia. The study includes the following coal characteristics (mass fraction): moisture () ash (), combustible materials () and lower heating power (). Based on the collected data, statistical modeling was conducted, which included the calculation of the mean value (), standard deviation (), and coefficient of variation () for each of the listed characteristics. The results indicate that all analyzed characteristics exhibit significant deviations from their mean values, as confirmed by the high values of the coefficient of variation (moisture 70.20%, ash 62.21%, combustible matter 43.33%, and lower heating value 44.10%). Large mass fraction deviations (), (), and around the mean value may negatively impact the operation of boiler plants and electrostatic precipitators of thermal power plants in Serbia, where the considered coals are burned. Large oscillations of ash (62.21%) around the mean value (17.00%) suggests that it is not feasible to implement dry flue-gas desulfurization (FGD) processes, due to the additional amount of ash. Distribution testing confirmed that all examined parameters can be reasonably approximated by a normal distribution. Subsequent statistical modeling using Student’s t-test at a 0.05 significance level demonstrated strong agreement between the coal characteristics from Serbia and corresponding parameters of coals from Bosnia and Herzegovina and Montenegro. The obtained results enable reliable quality comparison of coals, particularly lignites, across different basins. These findings establish a solid foundation for further energy and technological valorization of these fuel resources.

1. Introduction

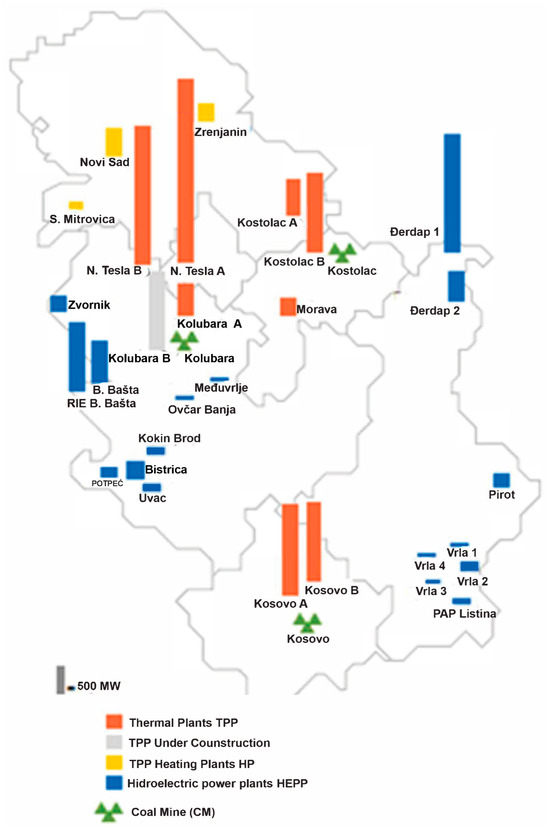

The development of industry, especially energy, has the greatest impact on the environment, and energy saving and environmental protection measures are constantly being improved. Coal is one of the main resources for electricity production. The largest consumption of coal in the energy sector is in the USA, China and India, with a share of as much as 70% [1], and some estimates of world coal reserves indicate that it can be used for another 200 years [2]. Serbia has large reserves of coal, especially lignite, which are used in the boilers of domestic thermal power plants. According to some estimates, coal production in Serbia is about 40 million tons per year, and is the leading one in Europe. In thermal power plants, coal accounts for about 65% of electricity production in Serbia [3], and the remaining 35% of coal production is used in other industries. It is estimated that there are 5773 MW installed in thermal power plants in Serbia. Figure 1 shows a map of thermal power plants (thermal power plants) in Serbia.

Figure 1.

Energy system of Serbia [4].

Table 1 presents thermal power plants in Serbia, with their basic characteristics. It can be seen that the thermal power plants are quite old, and all of them use lignite for electricity production. Lignite is a lower quality coal, so the production of electricity in various thermal power plants results in the creation of large amounts of harmful substances such as ash, slag, SO2, NO2, CO2 and waste water.

Table 1.

Basic data on thermal power plants in Serbia [5].

In the process of revitalization, thermal power plants in Serbia will have to adapt to the new quality of coal, which in practice is often a mixture (homogenization) of coal [6,7].

Recent research on the influence of moisture, ash and various impurities (chlorine, alkali) by the authors [8,9,10] indicates that coal moisture worsens combustion, reduces flame temperatures and boiler efficiency, high ash content leads to deposits in the boiler and smoke channels and poor heat exchange, and impurities accelerate corrosion and form harmful deposits. In addition, coal characteristics such as weight (W), ash (A) and coal calorific value (Hd) directly affect combustion efficiency and gas emissions:

- Higher moisture in coal reduces the heat value of coal and increases coal consumption, which increases CO2 emissions.

- Higher ash content in coal can increase NO2 emissions, due to changes in flame temperature, and also causes deposits on equipment and reduces efficiency.

- The heat value of coal determines how much energy is obtained from combustion; lower heat value requires more fuel, which increases emissions.

- The sulfur content of coal affects SO2 emissions, which is proportional to the amount of sulfur burned.

In practice, these characteristics are key for the selection of appropriate combustion technology, emission control measures, and optimization of thermal power plant operations, in order to reduce pollution and increase efficiency.

In this regard, the aim of this paper is a qualitative analysis of coals burned in boiler plants of thermal power plants in Serbia. The analysis would determine the quality of the coals used and the possibility of applying the obtained results in practice (coal homogenization, optimization of electrostatic precipitators, reduction of SO2 in flue gas, design of flue-gas desulfurization devices, etc.). In the qualitative analysis of coals in Serbia, the following characteristics are included: moisture, ash, combustible matter and lower heating value. Table 2 shows the technical and elemental analysis of coals burned in the combustion chambers of thermal power plants in Serbia. The variability of coal characteristics (Table 2) affects the choice of devices for controlling the emission of gaseous components and solid particles (ash), such as the following:

Table 2.

Characteristics of Serbian coal [11].

- Filters, electrostatic precipitators and cyclones are more effective for coals with high ash content.

- Wet/dry Scrubber removes SO2 and high sulfur content in coal requires higher capacities.

- NO2 control (SCR/SNCR) depends on combustible components and flame temperature.

2. Qualitive Rating of Cooling Characteristics in Serbia

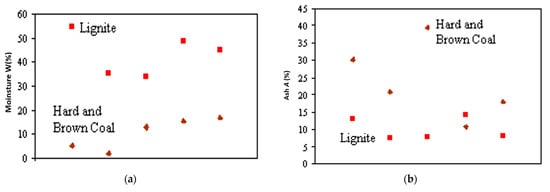

Figure 2 shows the distribution of basic characteristics of moisture, ash, and combustible components, and the lower heating value of Serbian coals used in thermal power plant combustion chambers. Large differences in the quality of lignite, hard coal and brown coal can be observed.

Figure 2.

Distribution of moisture (W) (a) ash (A), (b) combustible (Vg), and (c) lower calorific value (Hd), (d) of Serbian coals.

We have determined the following statistic parameters [12,13]:

of which

—number of elements of sample characteristics;

—value of considered coal characteristics;

—mean interval of coal characteristics.

Pearson’s criterium will check whether the coal samples are in concordance with the assumption that a random variable (coal characteristics) X has the function of distribution (normal distribution), or the deviations are large so the assumption has to be discarded. When determining the value of Pearson’s criterium, the following is used:

of which

—number of intervals;

—size of an interval;

—probability that the random variable takes the value in the interval;

—replacement (alternation) of variables;

—Laplas function.

Testing of the mean values of coal characteristics has been carried out by using Student’s t-test at the level of significance (risk), and the following expressions have been used:

of which

—number of degrees of freedom;

—variable which is determined from the table for Student’s distribution at the selected level of significance (trust) and for the degree of freedom .

By using numerical values of coal characteristics from Table 2 and the expressions from (1) to (4), the calculation of some parameters of coal “moisture” is

In Table 3, the statistical results of calculation for the coals of Serbia are shown.

Table 3.

Qualitative characteristics of Serbian coals.

Variations coefficient (Cv) refers to deviations of the observed coal characteristics from the mean value. The largest deviation from the mean value refers to the coal characteristic moisture (W), which is 70.20%, and ash (A) of 62.21%. The variability of coal characteristics (high values of the coefficient of variation) (Table 3) can make it difficult to continuously comply with emission and particulate matter limits (European Union standards set maximum emission limits for SO2, NO2 and particulate matter), so, in practice, the following is often used:

- Coal mixing (coal homogenization) to reduce the variability of coal characteristics;

- Automatic regulation of combustion and emissions.

All of this can adversely affect the operation of boiler plants and electric filter plants in thermal power plants such as power plants.

This indicates larger oscillations of mass contents of ash and moisture in coals of Serbia, which can adversely influence the function of a boiler plant and an electric filter plant in thermal power plant objects such as power plants.

Based on Equations (5)–(11), for the characteristic of coal moisture (W) the calculation of individual parameters is

k = 1 + 3.3 · lgn = 1 + 3.3 · lg10 = 4.30 ≈ 4

The lowest value of standardised variable has been replaced with , and the largest value of standardised variable with , since the random variable has been defined in the interval All the calculations have been arranged are and shown in Table 4.

Table 4.

Result of calculations for the feature (characteristic) of coal, “moisture (W)”.

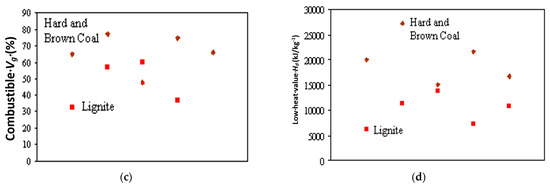

The calculation resulted . From the tables for distribution for the significance level value and the number of degrees of freedom,, a critical value is . Since < , the assumption of a normal distribution of the moisture (W) characteristic of coal in Serbia can be adopted. In a similar way, it can be shown that the other characteristics of coal, ash (A), combustible components (Vg) and lower heating value (Hd), are also ruled by the normal distribution law. The normal distribution of coal characteristics (W, A, Hd, Vg) means that the behavior of the coal can be predicted and controlled, allowing for more efficient combustion, lower emissions and reduced equipment wear. This is a key advantage in industrial applications, especially in thermal power plants.

The theoretical density distribution function of the characteristics of coal (W), (A), (Vg), and (Hd) is shown in Figure 3.

Figure 3.

Comparison of the theoretical distribution density function of the characteristics of (a) W, (b) A, (c) Vg and (d) Hd of coal from the empirical distribution with the data presented in Table 2.

A good approximation of the theoretical normal distribution with the empirical distribution with the numerous values of the distribution of coal characteristics W, A, Vg and Hd, shown in Table 2, is observed.

Now, we will determine the range of the real value of the coal “moisture” characteristic, with the probability of 95%. The number of degrees of freedom , the level of significance , and the Student’s table of distribution reveals that , i.e., according to the expression (11):

or

For other coal characteristics (A, Vg, Hd), the intervals of reliability are shown in Table 5. If the mean values of coal characteristics belong to the calculated intervals (Table 5), then possible differences can be considered accidental; otherwise, they are significant.

Table 5.

Calculation results of determining intervals of reliability for coal characteristics.

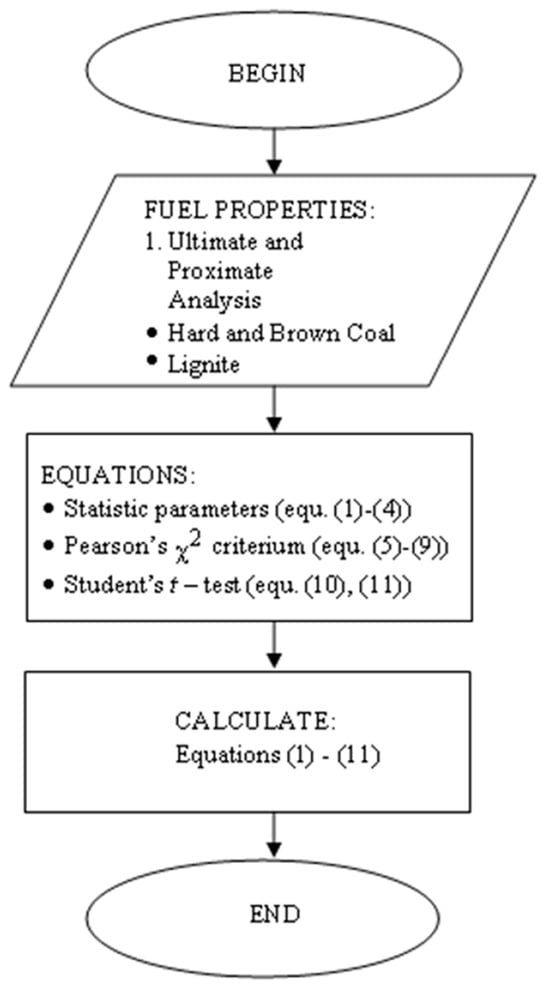

The algorithm for solving the system of Equations (1)–(11) is shown in Figure 4. The system of equations was solved in the programming language C++.

Figure 4.

Algorithm for solving the system of Equations (1)–(11).

3. Results

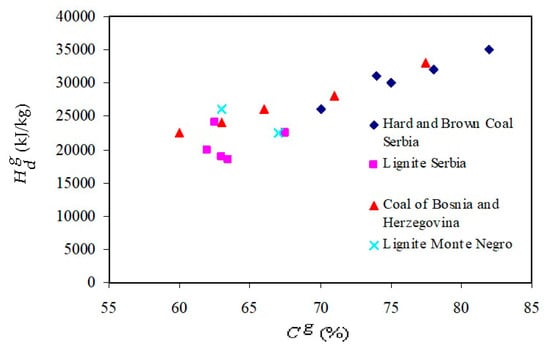

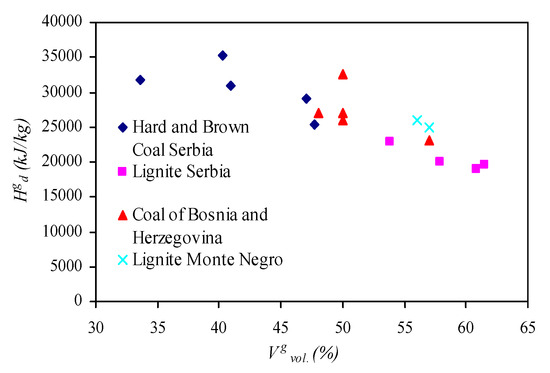

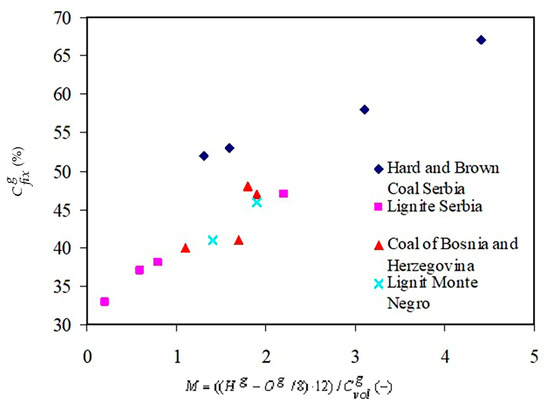

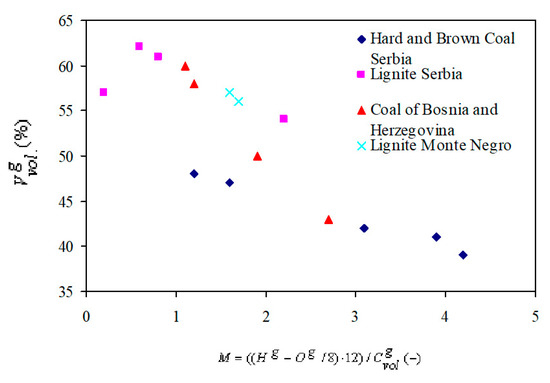

The results of the characteristics of Serbian coals were compared with coals from Bosnia and Herzegovina [14] and Montenegro [15]. Figure 5, Figure 6, Figure 7 and Figure 8 show the dependence of the lower calorific value (Hd), carbon (C), fixed carbon (Cfix), and volatile components (Vvol) reduced (reduced) on the fuel mass (mass without moisture and ash). It can be seen that the characteristics of Serbian coals do not deviate much from the characteristics of coals used in the combustion chambers of thermal power plants in Bosnia and Herzegovina and Montenegro. Therefore, the obtained results can be applied not only to thermal power plants in Serbia, but also to thermal power plants in Bosnia and Herzegovina and Montenegro. This is particularly important, because it can represent a starting point in the phase of engineering calculations of boiler process parameters and flue-gas emissions, especially SO2 and NO2, as well as emissions of solid particles into the atmosphere.

Figure 5.

Dependence of upper heating value of coal and carbon reduced to combustible mass.

Figure 6.

Dependence of the upper heating value of coal and volatile components reduced to combustible mass.

Figure 7.

Dependence of fixed carbon and coefficient M reduced to combustible mass.

Figure 8.

Dependence of volatile components and coefficient M reduced to combustible mass.

4. Conclusions

Based on the qualitative analysis of coal burned in the combustion chambers of thermal power plants in Serbia, the following conclusions can be drawn:

- There are significant deviations in coal characteristics: moisture 70.20%, ash 62.21%, combustible materials 43.33% and lower heat capacity 44.10% deviation from the mean values, which is shown by the coefficient of variation Cv (Table 3).

- If the mean values of coal characteristics belong to the calculated intervals (Table 5), then for possible warriors, may be assumed coincidental, otherwise they are significant.

- Large fluctuations in coal characteristics around their mean values can negatively affect the operation of the boiler and electrostatic precipitator plants in Serbian thermal power plants. This also indicates the impossibility of applying dry flue-gas desulfurization (FGD) processes, due to the additional quantity of ash.

- The lack of uniformity in the quality of coal used in thermal power plant combustion plants in Serbia indicates the need for homogenization (mixing) of coals with different characteristics. Usage of homogenized coal would cause a wide range of positive effects, such as increased thermal power, reduced moisture and ash in coal, which results in better coal combustion, lower ash emissions, lower SOx and NOx emission values, and greater stability of electricity production.

The findings outlined in this paper, along with prior conclusions, are consistent with the measurements and tests conducted on electrostatic precipitators in Serbia’s thermal power plants. This evidence highlights the necessity for both the refurbishment of existing coal-fired thermal power plants and the establishment of new ones, aligning with Serbia’s energy strategy. In addition, a comparative analysis of coal from Serbia with coal from Bosnia and Herzegovina and Montenegro can serve as a basis for joint energy strategies and optimization of lignite combustion and processing technologies in the region.

Author Contributions

Conceptualization, S.D.; methodology, S.D. and M.J.; formal analysis, S.D. and M.C.; implementation of algorithms, N.D. and G.K.; data management, S.D., M.C., M.M., G.K. and N.D.; writing, S.D., M.M. and G.K.; reviewing and editing of original drafts, S.D., G.K. and N.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was not funded by any National Institution. All research and finances were carried out by the authors of the paper.

Data Availability Statement

The data used are available in the article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| A | ash mass content in coal, % |

| C | carbon mass content in coal, % |

| Cfix | mass content of fixed carbon in coal, % |

| Cv | variation coefficient, % |

| Cg | carbon mass in coal reduced to combustible mass, % |

| mass content of fixed carbon in coal reduced to combustible mass, % | |

| fi | frequency |

| H | mass portion of hydrogen in coal, % |

| Hd | lower heating value of coal, kJ∙kg−1 |

| lower heating value of coal reduced to combustible mass, kJ∙kg−1 | |

| I | interval size |

| K | number of intervals |

| L | number of degrees of freedom |

| N | number of degrees of freedom |

| N | number of elements in a sample |

| M | auxiliary size |

| O | mass portion of oxygen in coal, % |

| mass portion of oxygen in coal reduced to combustible mass, % | |

| pi | probability of random variable taking value within interval |

| R | absolute range, % |

| S | mass portion of sulphur in coal, % |

| S | standard deviation, % |

| variable determined from the table for Student’s distribution at the selected level of significance (trust) α and the degree of freedom l = n − 1 | |

| ui | replacement (alternation) of variables |

| Vg | combustible matter, % |

| Vvol | mass portion of volatile components in coal, % |

| mass portion of volatile components in coal reduced to combustible mass, % | |

| arithmetic mean, % | |

| values of considered (features) characteristics of coal, % | |

| centers of intervals of coal characteristics, % | |

| Φ(ui) | Laplas function |

References

- U. S. Energy Information Administration (EIA). International Enrgy Outlook 2017 Washington, US Energy DC: Information Administration; Report Number: DOE/EIA-0484 (2017); U.S. Energy Information Administration (EIA): Washington, DC, USA, 2017.

- Singh, Y. Fly Ash Utilization in India, 2011. India, 2018. Available online: http://www.wealthywaste.com/fly-ash-utilization-in (accessed on 4 April 2024).

- Matić, D.; Čolić, Z. Coal is a strategic energy source. Kolubarski Sind. 2018, 168. [Google Scholar]

- Electric Power Industry of Serbia. Technical Yearbook; Electric Power Industry of Serbia: Belgrade, Serbia, 2023. [Google Scholar]

- EE Systems-Serbia. 2025. Available online: https://www.electricpower.info (accessed on 4 April 2024).

- Lazarević, V.; Lončar, S.; Mesarović, M. Equalizing the Quality of Coal for Thermal Power Plants. Thermotechnics 2007, 33, 13–19. [Google Scholar]

- Kazagić, A.; Smajević, I.; Duić, N. Selection of sustainable technologies for combustion of Bosnian coals. Therm. Sci. 2010, 14, 715–727. [Google Scholar] [CrossRef]

- Askarova, A.S.; Bolegenova, S.A.; Maximov, V.J.; Gabitova, Z.K.; Leithner, R.; Müller, H.; Heierle, Y. Numerical simulation of high-ash coal combustion with different moisture content at Aksu Thermal Power Plant. Int. J. Math. Phys. 2014, 5, 29–32. [Google Scholar] [CrossRef]

- Siddhartha, B.M. Effect of Ash in Coal on the Performance of Coal Fired Thermal Power Plants–Part I, High-Ash Coal. Prim. Energy Eff. 2006, 28, 25–41. [Google Scholar]

- Adi, P.; Feti, K.; Ghazidin, H.; Ruhiyat, A.S.; Adelia, N.; Prayoga, M.Z.E.; Romelan, R.; Utomo, S.M.; Cahyo, N.; Hartono, J.; et al. Ash deposition behavior during co-combustion of solid recovered fuel with different coals. Therm. Sci. Eng. Prog. 2024, 48, 102404. [Google Scholar] [CrossRef]

- Bogner, M. Thermotechnics 1; SMEITS: Beograd, Serbia, 2004. [Google Scholar]

- Jay, L.D.; Kenneth, N.M.; Matthew, A.C. Modern Mathematical Statistics with Applications; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Dennis, D.W.; Willian, M.; Richard, L.S. Mathematical Statistics with Applications; Cengange Learning: South Melbourne, Australia, 2018. [Google Scholar]

- Study of the Energy Sector in Bosnia and Herzegovina, Module 8—Coal Mines; Energy Institute Hrvoje Požar: Croatia, Zagreb, 2008.

- Energy Development Strategy of the Republic of Monte Negro Until 2025, Book C; Development of the Coal, Oil and Gas system of the Republic of Monte Negro, Energy Institute Hrvoje Požar: Ljubljana, Slovenia, 2006.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).