Abstract

Fe and Cu powders were mixed at a 50:50 ratio. Then, Fe-Cu alloys were prepared using the ball milling technique with different milling times of 6, 12, 18, 24, 30, 36, and 42 h. The crystalline structure was analyzed using X-ray diffraction (XRD), and it was found that the optimum milling time was 30 h. The homogeneity of the Fe and Cu elements in the Fe–Cu alloys was analyzed using the scanning electron microscopy with energy dispersive X-ray spectroscopy (SEM–EDX) mapping technique. Additionally, the crystal orientation of the Fe–Cu alloys was investigated using transmission electron microscopy (TEM). To fabricate the cathode for nitrate removal via electrolysis, an Fe–Cu alloy milled for 30 h was deposited onto a copper substrate using mechanical milling, then annealed at 800 °C. A pulsed DC electrolysis method was developed to test the nitrate removal efficiency of the Fe–Cu-coated cathode. The anode used was an Al sheet. The synthesized wastewater was prepared from KNO3. Nitrate removal experiments from the synthesized wastewater were performed for durations of 0–4 h. The results show that the nitrate removal efficiency at 4 h was 96.90% compared to 74.40% with the Cu cathode.

1. Introduction

General wastewater sources often have a significant accumulation of nitrogen compounds. The occurrence of nitrogen compounds in water sources comes from various sources, including wastewater from communities generated from the use of tap water or groundwater for household activities, such as cooking, dishwashing, and cleaning. Nitrogen compounds in this type of wastewater typically arise from the decomposition of organic substances contaminating the water. Wastewater from industrial factories originates from production processes involving chemicals that may be released without proper treatment. Agricultural wastewater can result from the use of nitrogen fertilizers and insecticides, such as neonicotinoid pesticides. These chemicals remaining on the soil surface can flow into water sources due to runoff or rainwater washing, leading to the accumulation of nitrogen compounds in water sources [1,2,3].

Nitrogen compound accumulation in water sources leads to a process called nitrification, where these compounds are converted into nitrate . This process occurs in two stages. The first stage is ammonia oxidation, where bacteria from the ammonia-oxidizing bacterial group, such as Nitrosomonas, oxidize ammonia or ammonium produced from the decomposition of organic matter in the water, into nitrite . The second stage is nitrite oxidation, where the nitrite formed in the first stage is further oxidized into nitrate, which is a stable form that can dissolve in water [4].

Various technologies have been developed and used to remove nitrate from wastewater, including biological denitrification, physical processes, and electrochemical denitrification [5,6,7]. In the biological denitrification process, bacteria are used to transform nitrate into nitrogen gas and release it into the air [8]. For wetlands, wastewater treatment systems, aquatic plants, and microorganisms are used to absorb and treat nitrate in water. Biological denitrification is the cheapest method for nitrate removal in wastewater. However, this process takes a long time because the conversion of nitrate into nitrogen gas occurs naturally. Moreover, for industrial wastewater, biological denitrification greatly affects microbial activity, and therefore, this technique is not suitable for nitrate removal from industrial wastewater [9].

Among the physical processes, ion exchange and reverse osmosis are the most widely applied treatment methods for nitrate removal [5]. The electrochemical denitrification process has been recognized as a promising method for nitrate removal through oxidative and reductive reactions into water, nitrogen, and oxygen [10]. These methods include electroreduction and electrocoagulation [5,7,11]. In every electrochemical process, the electrode material is a key variable to study [6,12]. Good electrode materials should have a high catalytic activity, high stability, good corrosion resistance, and low cost [13,14,15]. In addition, the pulsed-electrocoagulation process for the treatment of various wastewaters has been widely studied [9,16,17]. This is because pulsed electrocatalysts consume lower energy than DC electrocatalysts and can reduce corrosion on the anode surface [16,17,18].

The water electrolysis process has recently received significant attention due to its potential application in wastewater treatment. This method involves the use of electrical energy to split water molecules into oxygen and hydrogen gases, effectively removing nitrate contaminants without the need for chemical additives. One of the primary advantages of this method is its straightforward operation and ease of control, making it highly adaptable to various treatment requirements. Additionally, the flexibility in system design allows for integration into diverse wastewater treatment processes, enhancing its applicability and scalability [19,20,21,22].

In electrochemical processes, the electrode material is an essential part that directly affects the removal rate of nitrate from wastewater [23,24]. Metal electrodes with low resistance and high activity have been widely studied for nitrate removal from wastewater. Various electrode materials have been used as cathodes, such as Cu, Pt, Fe, Ti, and Sn. Various metallic electrodes, such as Cu, Ni, Pb, Fe, Al, and stainless steel (SS), have been investigated for the electrolytic reduction of nitrate [24,25]. Consequently, bimetallic alloy electrodes, such as Cu–Ni, Ni–Fe, Cu–Pt, Cu–Sn, and FeCu/CC, have been widely studied [26,27,28,29]. Xu et al. [5] summarized the efficiency of different types of metallic electrodes and bimetallic alloys on nitrate electroreduction. They found that bimetallic alloy electrodes could reduce nitrate with higher efficiency than metallic electrodes. However, most previous studies on electrochemical nitrate removal often require chemical additives or strict pH control during operation, increasing operational complexity and cost and reducing sustainability for practical applications.

In recent years, the bimetallic Fe–Cu alloy has gained significant interest for use as an electrode due to its high strength, good electrical conductivity, and high-efficiency catalytic properties [30,31,32]. Fe–Cu nanoparticles can be synthesized using two different methods: the top-down or the bottom-up method [33]. The top-down method involves breaking down the bulk material into nanoparticles. This method includes ball milling, grinding, and crystal etching. Meanwhile, the bottom-up method involves building up a material from the bottom. Among the various methods available, ball milling is one of the most widely used techniques for synthesizing several alloys, including Fe–Cu alloys [30,34,35,36]. Additionally, Fe–Cu alloys can be utilized for wastewater treatment [34,37]. While some studies have investigated Fe–Cu colloids and electrodeposited coatings for electrochemical denitrification, the use of Fe–Cu alloy-coated electrodes fabricated through mechanical alloying remains largely unexplored.

It is well-known that the cathode material plays an important role in nitrate electrochemical removal [5,38,39]. The reactions at the cathode (reduction site) are represented by Equations (1)–(3), in which nitrate is reduced to nitrite , ammonia (), or nitrogen gas (N2)

For the reactions at the anode (oxidation site), only water oxidation occurs, as shown in Equation (4):

Although aluminum is prone to oxidation, in systems without pH control, the aluminum electrode becomes passivated by a layer of Al(OH)3 or Al2O3, particularly under alkaline conditions. During electrolysis, the reduction of nitrate and its derivatives at the cathode generates the ions, raising the solution’s pH and alkalinity. This high pH encourages the formation of a protective passive layer on the aluminum surface, which limits further oxidation. Consequently, the primary anodic reaction is the oxidation of water (oxygen evolution) rather than the dissolution of aluminum, and the anode does not play an important role in the nitrate electrochemical removal process.

This study focuses on synthesizing Fe–Cu alloys through mechanical ball milling over various durations, followed by annealing to improve alloy formation. The optimal alloy was then coated onto a copper sheet, which served as a cathode in an electrochemical cell, with aluminum acting as the anode. Importantly, our study is one of the first to fabricate a solid Fe–Cu alloy cathode using mechanical milling and annealing and to assess its effectiveness for electrochemical nitrate removal without the use of chemical additives or pH adjustments during the treatment process. This straightforward, cost-effective method offers a promising and environmentally friendly alternative to traditional electrochemical systems, which often depend on expensive materials or additional reagents.

2. Materials and Methods

2.1. Synthesis of Fe–Cu Alloy

Fe powders (99% purity) with a grain size of 864 µm and Cu powders (99.99% purity) with a grain size of 10 µm (Thermo Fisher Scientific Inc., Waltham, MA, USA) were used as the starting materials. Fe–Cu alloys were prepared using a planetary ball mill (ZcyGrinding, Zcynyx Materials and Technology Co., Ltd., Lamphun, Thailand). Sample powders of Fe and Cu were prepared with a 50:50 mixing ratio. Each powder weighed 10 g, and they were combined to obtain a mixture of 20 g. Zirconium dioxide (ZrO2) milling balls (∅ 5 mm) with a weight of 120 g were prepared. That is, the ratio of the Fe–Cu powders to the ZrO2 milling balls was 1:6. All materials were loaded into the grinding jar, which was made of polypropylene and had a volume of 100 mL. The ball milling machine was run at 600 rpm. Samples of ground Fe–Cu alloys were obtained after different milling times of 6, 12, 18, 24, 30, 36, and 42 h. During the ball milling process, the machine was paused for 10 min after every 30 min of milling until the specific time for each sample was completed.

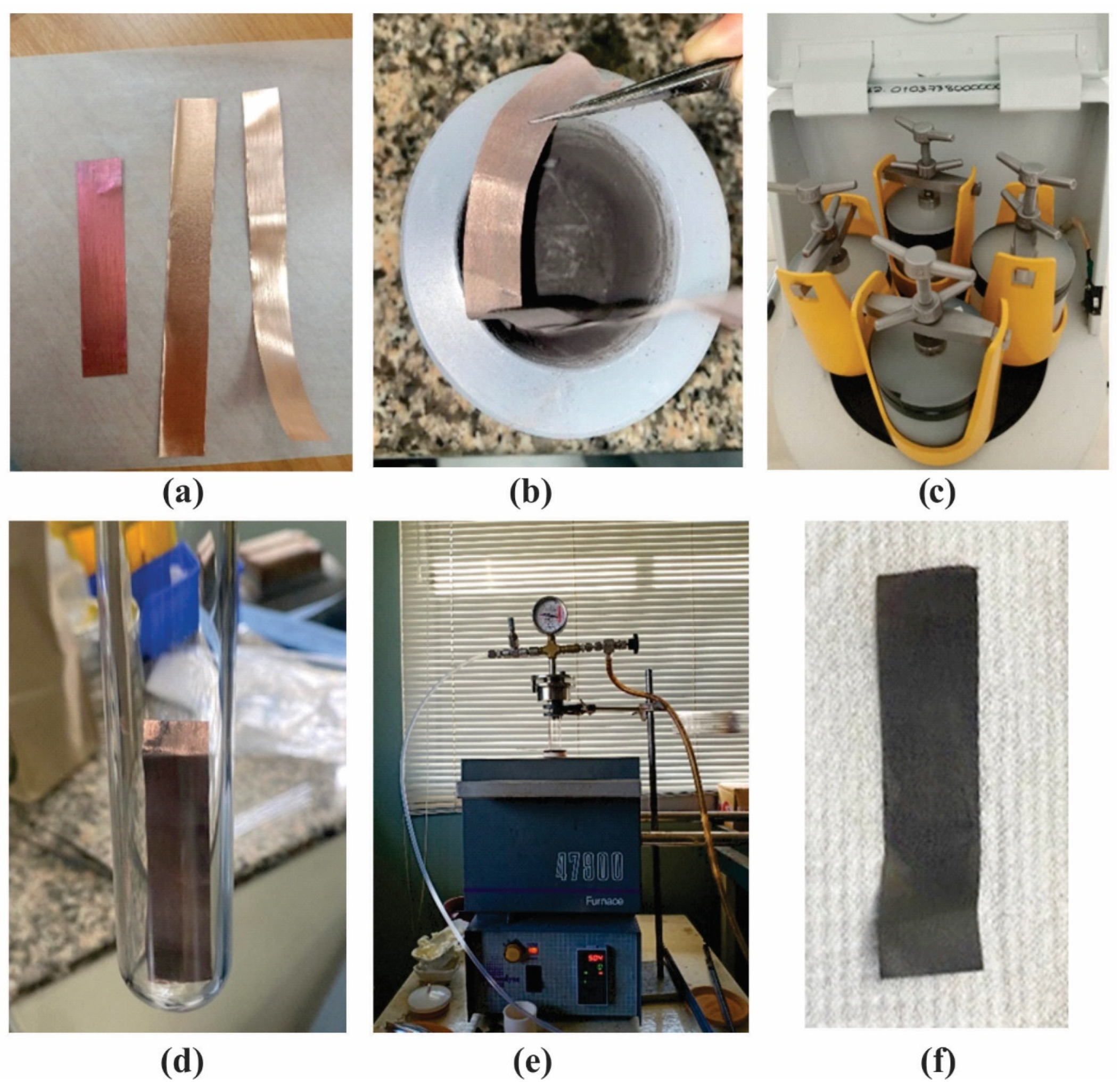

2.2. Fabrication of Fe–Cu–Coated Electrode

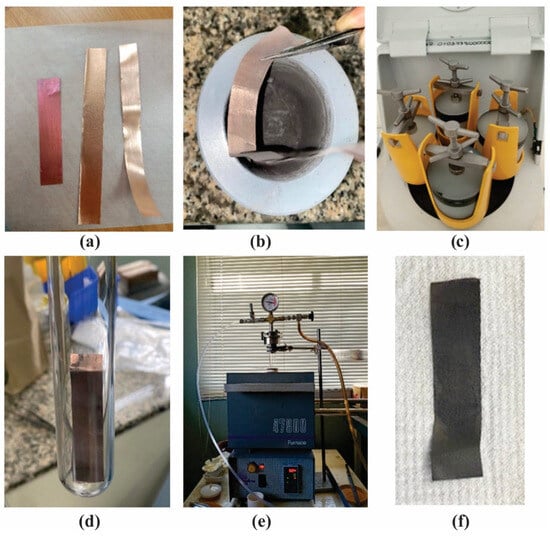

A Cu sheet (99.9% purity) with a thickness of 0.05 mm was cut into a rectangular shape with a size of 2.5 × 15 cm2 (Figure 1a). This Cu sheet, utilized as a substrate, was rolled and fixed on the inner wall of the polypropylene grinding jar (Figure 1b). Then, 3 g of the Fe–Cu alloy prepared with a milling time of 6 h was placed in the grinding jar of the milling machine without milling balls (Figure 1c). The machine was run with a milling speed of 600 rpm for 2 h. The centrifugal force from this rotating speed was enough to coat the substrate with the Fe–Cu alloy, but the powder did not strongly bind to the Cu surface. Hence, the obtained Fe–Cu alloy-coated Cu substrate was placed in a quartz tube (Figure 1d) and annealed in an electric furnace under an Ar gas atmosphere at 800 °C for 2 h (Figure 1e). Finally, Cu electrodes coated with Fe–Cu alloy were obtained, as shown in Figure 1f. The above process was repeated with the Fe–Cu alloys prepared with milling times of 12, 18, 24, 30, 36, and 42 h.

Figure 1.

Photographs showing the synthesis of Cu electrodes coated with Fe–Cu alloys: (a) Cu sheet, (b) Cu sheet fixed on the inner wall of the grinding jar, (c) the grinding jar with Cu sheet and Fe–Cu alloy powder were ground with a milling machine for different times, (d) the Cu sheet coated with the Fe–Cu alloy powder, (e) the Cu sheet coated with the Fe–Cu alloy powder annealed at 800 °C, (f) the Cu sheet coated with the Fe–Cu alloy powder after annealing.

2.3. Characterization

The crystalline structures of the ground Fe-Cu alloys obtained with different milling times of 6, 12, 18, 24, 30, 36, and 42 h (Section 2.1) were investigated using X-ray diffract ometer (XRD; SmartLab SE, Rigaku Corporation, Akishima, Tokyo, Japan) with CuKα radiation (λ = 0.1541 nm). The equipment was operated at an accelerating voltage of 40 kV and a current of 15 mA. The XRD spectra were recorded in the 2q range of 20° to 90° with a step size of 0.01°.

The surface morphology of the Fe-Cu alloys was investigated using a scanning electron microscope (SEM; Quanta 250 FEG, FEI Company, Hillsboro, OR, USA). Additionally, an energy dispersive X-ray spectrometer (EDX; Oxford X-Max 50; Oxford Instruments plc., Abingdon, Oxfordshire, UK) was used to determine the composition of Fe and Cu elements in the alloys. The homogeneity of the Fe and Cu elements in the alloys was analyzed using the SEM–EDX mapping technique. SEM and EDX were performed at an operating voltage of 15 kV.

The crystal orientation of the Fe–Cu alloys was investigated using a transmission electron microscope (TEM; JEM-2100Plus, JEOL Ltd., Akishima, Tokyo, Japan) working at 160 kV. Prior to the TEM study, the Fe–Cu alloys were ultrasonically dispersed in isopropyl alcohol for 5 min. These suspended Fe–Cu alloys were then dropped on a TEM carbon-coated Au grid.

The surface roughness of the Cu substrate and the Cu substrate coated with the Fe-Cu alloys was investigated using the atomic force microscopy (AFM; Park FX40, Park Systems Corp., Suwon, Gyeonggi-do, South Korea) technique in the non-contact mode at room temperature. The surface morphology of the Fe–Cu alloy-coated Cu substrate was observed using the SEM.

2.4. Synthesis of Wastewater

Wastewater with a concentration of potassium nitrate (KNO3) of 45 mg/L was used to study the nitrate removal efficiency of the Fe–Cu alloy–coated electrode. KNO3 (99% purity) was purchased from Merck, Germany and prepared by diluting 0.0371 g of KNO3 in 500 mL of deionized water.

2.5. Experimental Setup for Nitrate Removal from Synthesized Wastewater

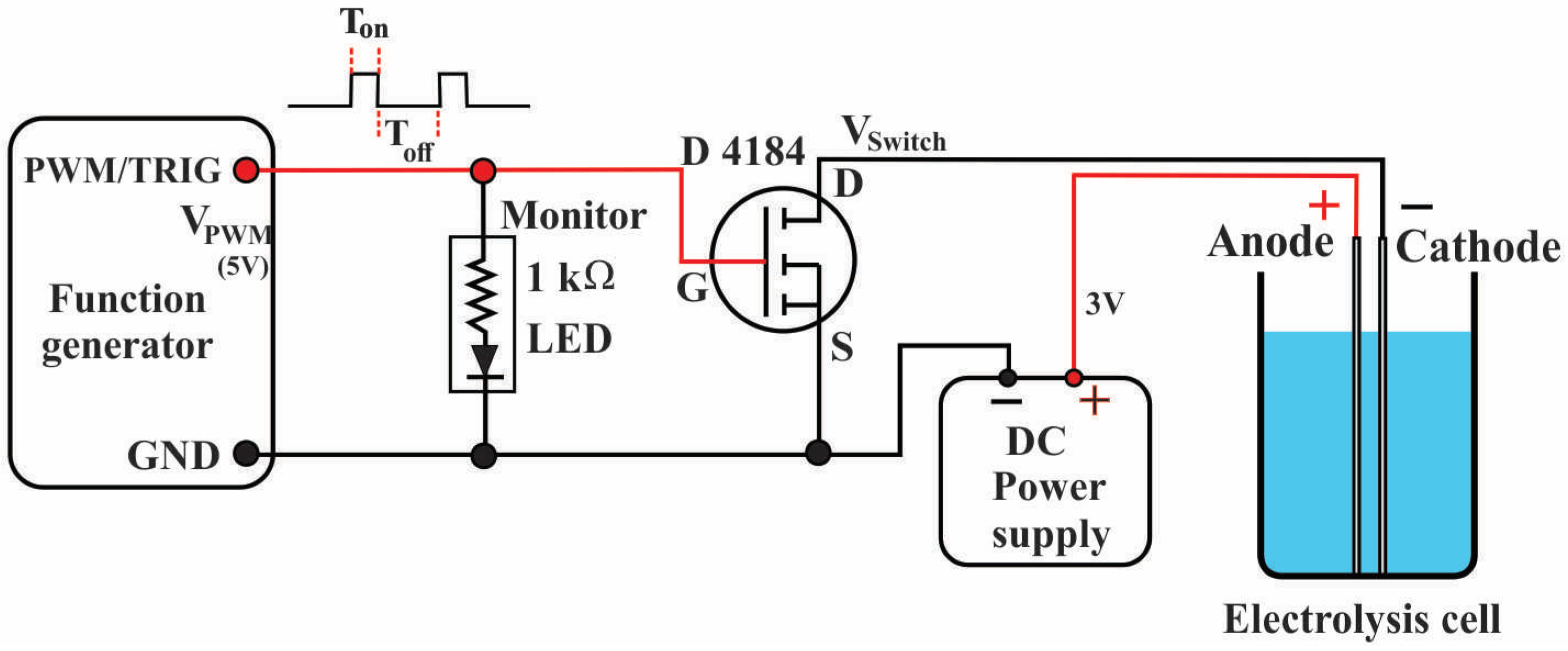

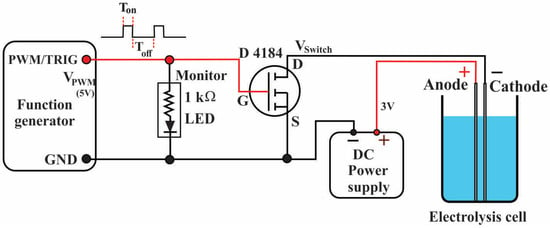

In this work, pulsed DC electrolysis was used to test the nitrate removal efficiency of the Fe–Cu alloy-coated electrode. Figure 2 shows the schematic diagram of the experimental setup. The components consisted of a function generator (SG1003, MCP Lab Electronics, Gdańsk, Poland), a DC power supply (PSW 30-36; Good Will Instrument Co., Ltd., Taipei, Taiwan), an electronic switch (MOSFET D4184), and an electrolysis cell.

Figure 2.

Schematic of pulsed DC electrolysis setup.

The function generator can generate a PWM signal with an adjustable frequency range from 1 Hz to 20 kHz. It was used as the on–off switch by sending the PWM signal to the gate leg (G) of the MOSFET D4184. The PWM signal controlled the switching behavior of the MOSFET. When the PWM signal was in a high state, the MOSFET closed the circuit (ON), allowing the current from the DC supply to flow through the MOSFET to the electrolysis cell. When the PWM signal was in a low state, the MOSFET opened the circuit (OFF), stopping the current from flowing. The switching behavior of the MOSFET, according to the characteristics of the PWM, caused the current to flow to the electrolysis cell in the form of pulses. The duty cycle (D) of the pulse refers to the proportion of time that a waveform spends in the active state (Ton) compared to the total time of one complete cycle (period, T). It is often expressed as a percentage, as shown in Equation (5):

Therefore, an 80% duty cycle means that the waveform is on 80% of the time and off 20% of the time. The DC supply model PSW 30–36 can supply a maximum voltage of 30 V and a maximum current of 36 A. The positive power from the DC supply was connected to the anode of the electrolysis cell.

The electrolysis cell was a 100 mL beaker with a diameter of 5 cm and a height of about 7 cm. The electrode of the electrolysis cell consisted of an aluminum (Al) sheet, used as the anode, and the Fe–Cu alloy–coated Cu, used as the cathode. In order to compare the removal efficiency, 2 metal types (Cu, and Fe/Cu-coated Cu) were used as cathodes. The dimensions of both the anode and cathode were 2.5 × 7.5 cm2. The beaker was filled with wastewater synthesized from KNO3 until the electrode was immersed to a depth of 5 cm. Therefore, the active area of the electrode during the wastewater treatment was 7.5 cm2. Before installing the electrodes in the electrolysis cell, each electrode was ultrasonically cleaned in acetone for 3 min. For all the tests, the duration time (3 h), solution temperature (30 ± 2 °C), electrode distance (5 mm), electrode voltage (12 V), and starting pH of the treatment were kept constant.

The nitrate concentration in the synthesized wastewater was measured using a UV–Vis spectrophotometer (UV-2600, Shimadzu Corporation, Kyoto, Japan). The absorbance at a wavelength of 218 nm correlated with the nitrate concentration. The nitrate concentration was determined using the equation obtained from the calibration curve. The nitrate removal efficiency ) was calculated using Equation (6) [40].

where is the initial nitrate concentration, and is the nitrate concentration at a given time during the electrolysis process.

3. Results and Discussion

3.1. Fe–Cu Alloys

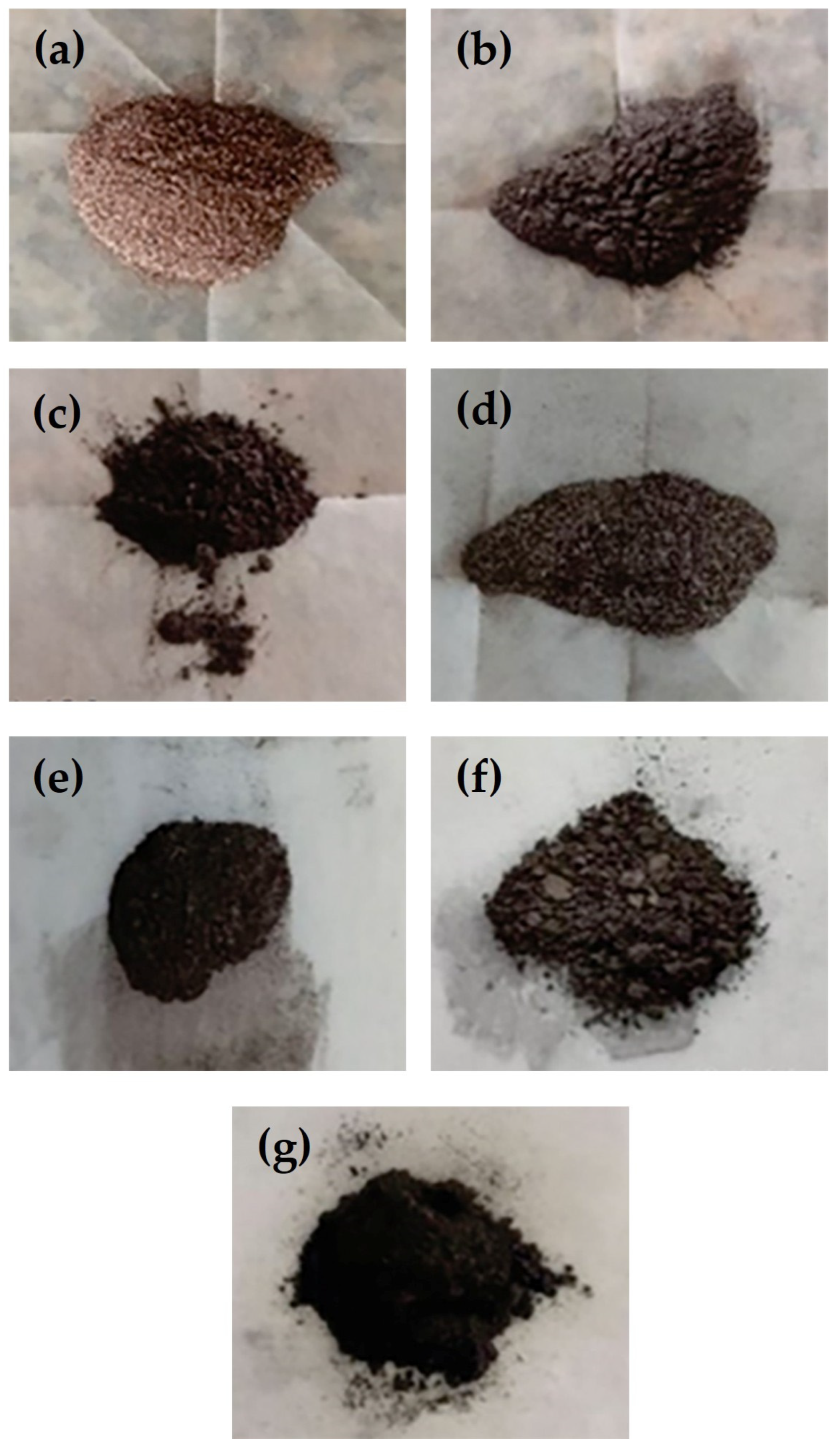

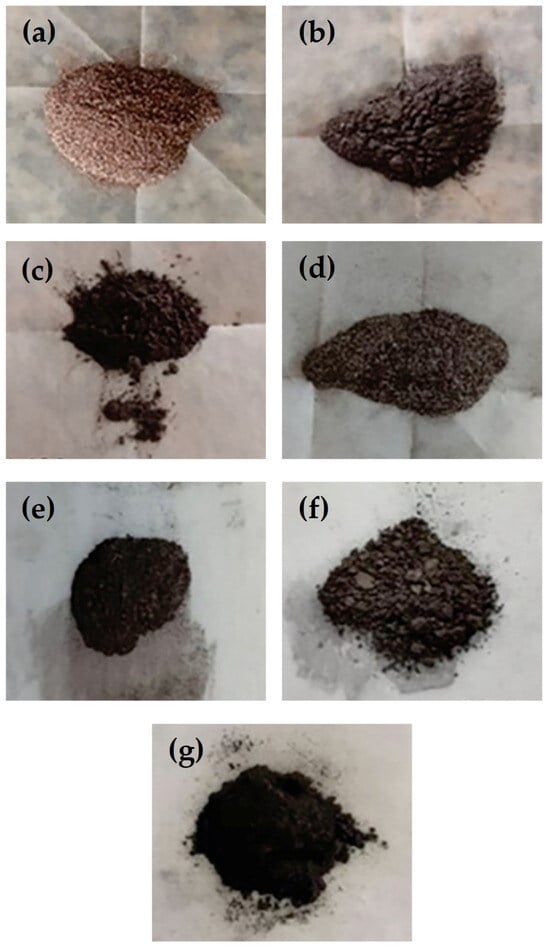

Figure 3 shows photographs of the as-synthesized Fe–Cu alloys. It can be seen that the color and particle size of the alloys varied with the milling time, but did not significantly vary after 18 h. The alloy color changed from brown to dark brown to black as the milling time increased.

Figure 3.

Fe–Cu alloys obtained from ball milling machine at a rotating speed of 600 rpm with various milling times of (a) 6, (b) 12, (c) 18, (d) 24, (e) 30, (f) 36, and (g) 42 h.

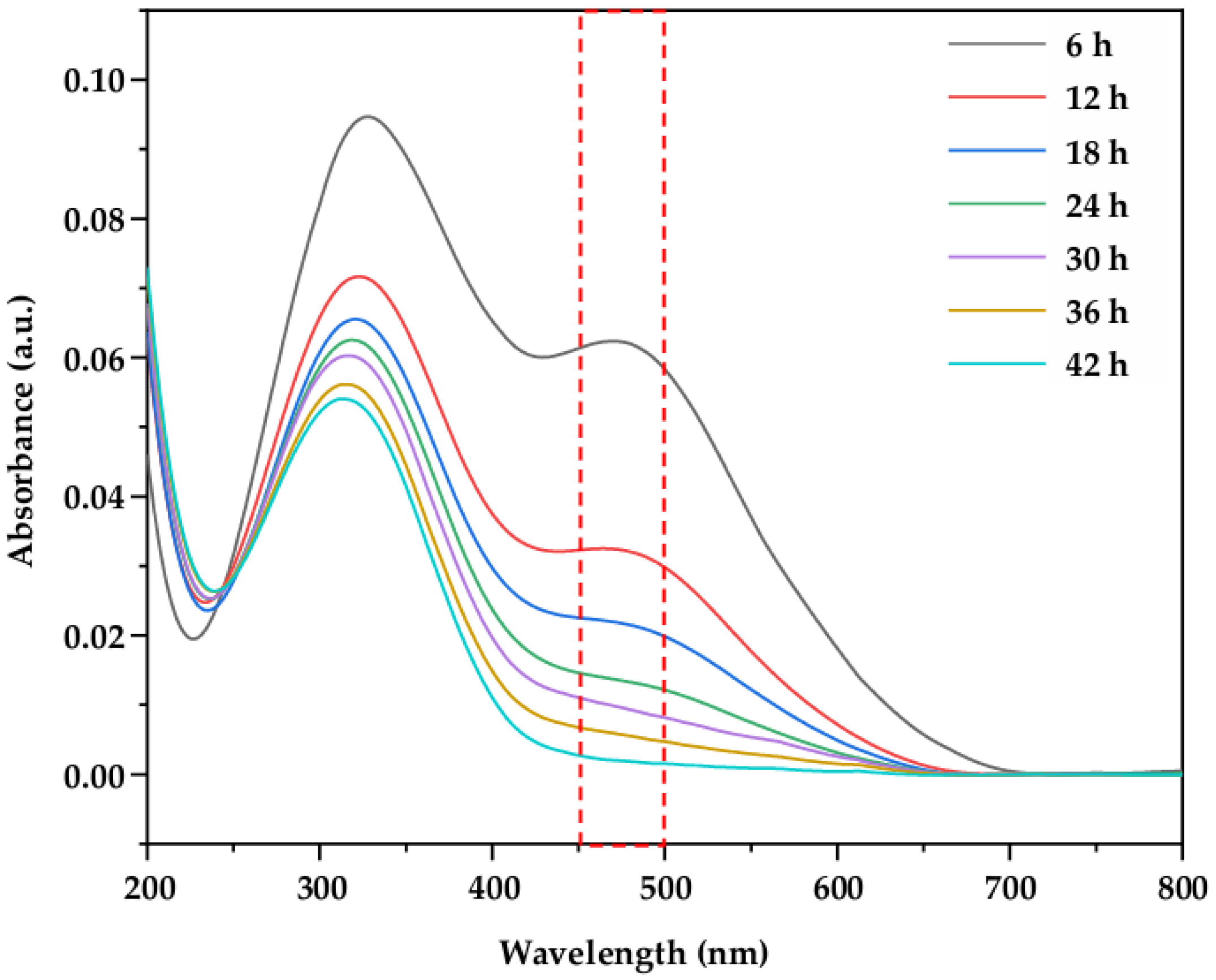

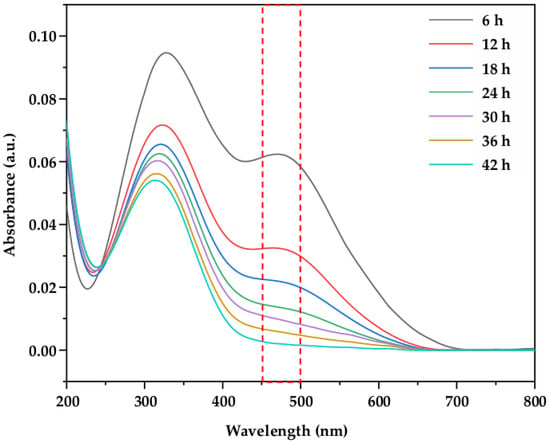

The color of the Fe–Cu alloy samples was analyzed in the wavelength range from 200 to 800 nm using a UV–visible spectrometer for Pt-Co (Evolution 220, Thermo Fisher Scientific Inc., Waltham, MA, USA). The absorbance spectra of all samples are shown in Figure 4. In Figure 4, the black line on the graph represents the sample powder after 6 h of ball milling, and a broad absorption band can be observed in the wavelength range of 450–500 nm. This corresponds to the absorption of light in the blue–green region, resulting in the powder appearing brown. The peak intensity in this region decreased with prolonged milling from 6 to 18 h, indicating a reduction in light absorption in the blue–green region, which caused the powder to appear darker brown. For the samples milled for 24–42 h, no peak appeared in the 450–500 nm range, indicating broad absorption across all wavelengths. This resulted in the powder appearing black. It can be concluded that the colors observed using the UV–visible spectrometer are consistent with the photographic results shown in Figure 3. In addition, the color change in the Fe–Cu alloy samples could indicate a decrease in particle size. To confirm this, the particle sizes of the Fe–Cu alloy samples milled for different times were investigated.

Figure 4.

Absorbance spectra of Fe–Cu alloy samples.

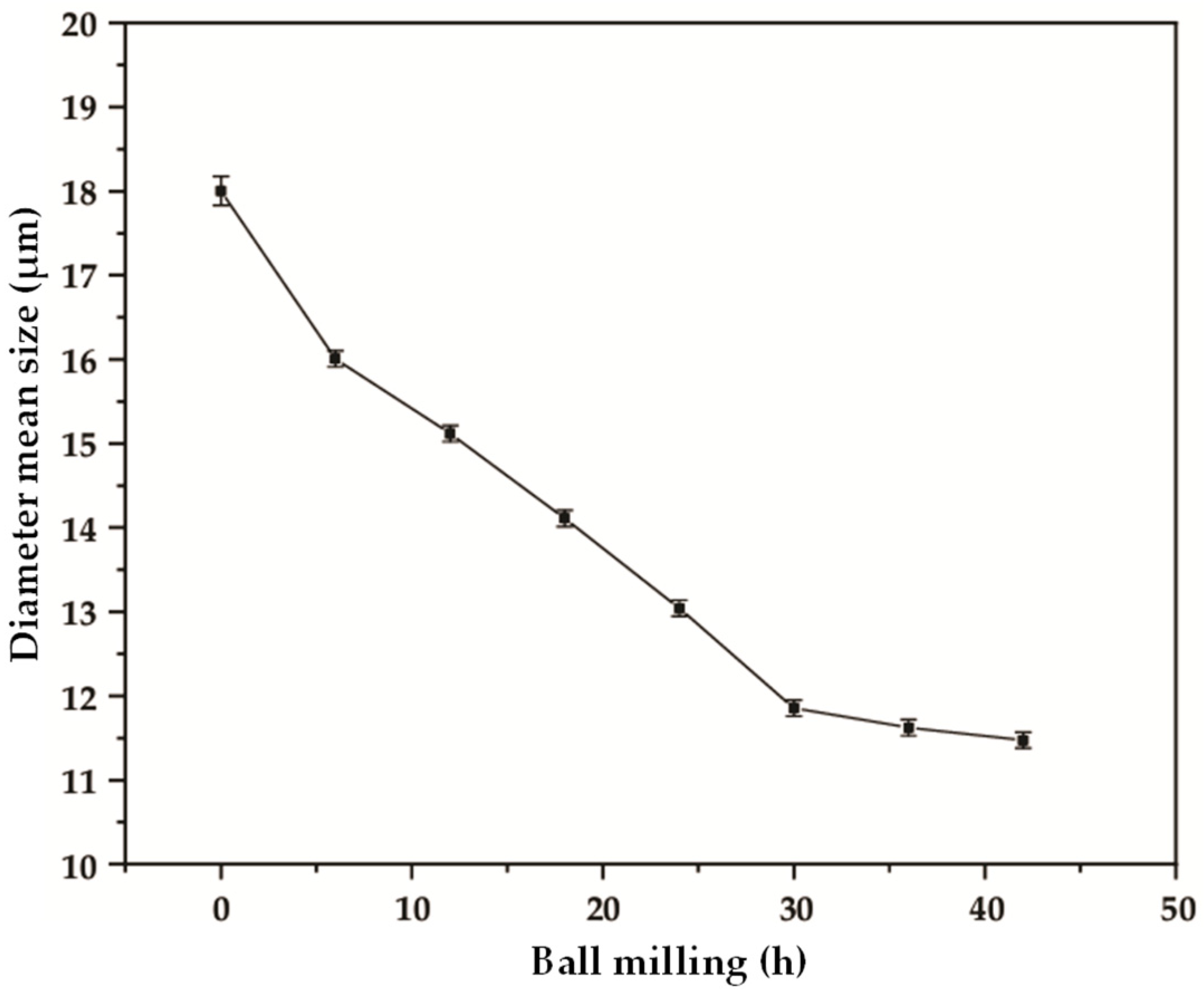

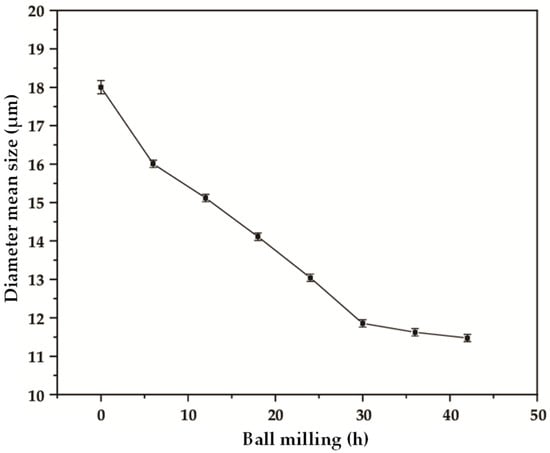

The particle sizes of the unmilled sample and the samples milled for 6–42 h were analyzed using a particle size distribution analyzer (CA-960, HORIBA, Ltd., Kyoto, Japan), and the results are shown in Figure 5.

Figure 5.

Mean diameters of Fe–Cu alloy samples milled for different times.

As shown in Figure 5, the mean diameter of the unmilled sample was 18.003 µm. After ball milling for 6 to 30 h, the mean diameter of the particles rapidly decreased from 16.007 to 11.856 µm, indicating that the mechanical force of the ball mill effectively reduced the particle size of the powder. However, after milling for 36 and 42 h, the particle size decreased only slightly. The decreases in the mean diameter corresponded to the color changes in the Fe–Cu alloy samples from brown to black, as shown in the photographs (Figure 3) and UV–visible spectra results (Figure 4). These results indicate that the decreases in particle size resulted in higher light absorption [41].

3.2. Crystalline Structure of Fe–Cu Alloys

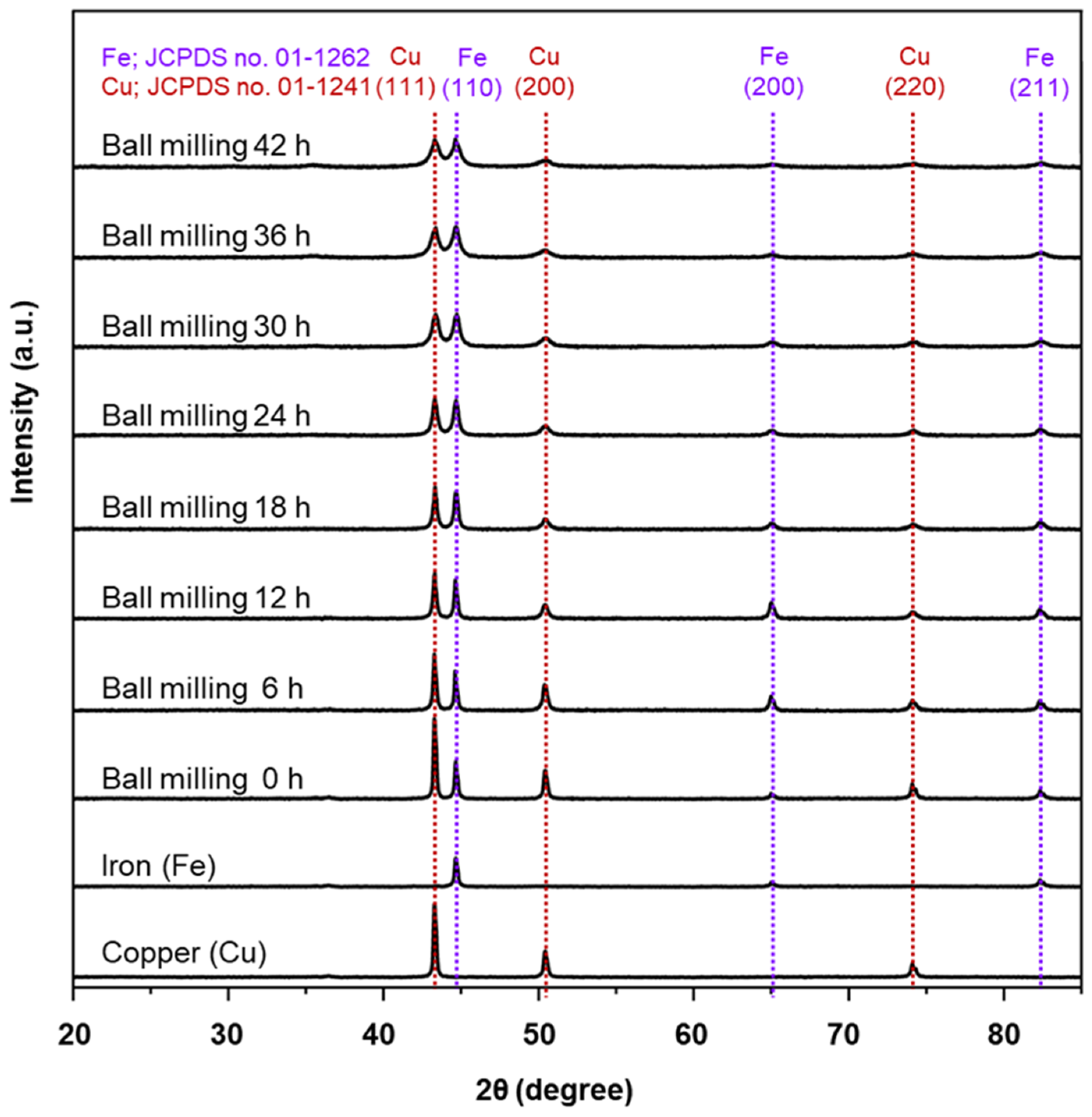

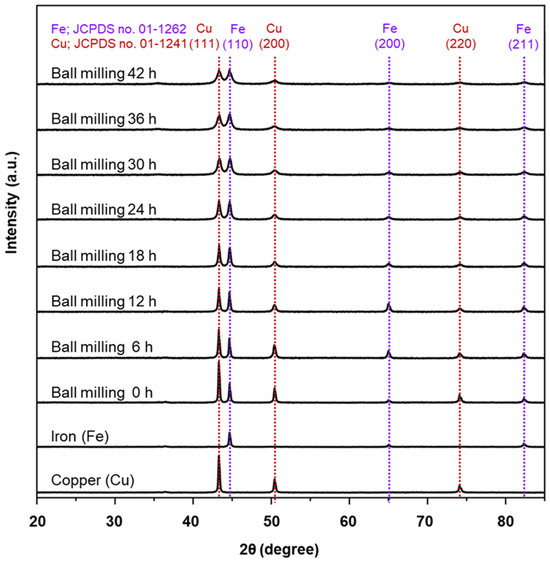

Figure 6 shows the XRD patterns of Fe and Cu powders before mixing and grinding. The XRD patterns of Cu reveal that its crystal structure was consistent with the reference document JCPDS No. 01-1241 [42], with a min. peak appearing at a diffraction angle of 43.28°, corresponding to the (111) plane. The crystal structure of Fe was consistent with the reference document JCPDS No. 01-1262 [43], with the main peak at a diffraction angle of 44.66°, corresponding to the (110) plane.

Figure 6.

X-ray diffraction patterns of Fe–Cu alloys.

The XRD patterns of both Cu and Fe were observed after they were mixed together without grinding. Subsequently, Fe and Cu were mixed and ground using the ball milling method for different durations: 6, 12, 18, 24, 30, 36, and 42 h. It was found that in the early stage of milling, up to 6 h, the X-ray intensity at the main peak position of Cu decreased rapidly, while the intensity at the main peak position of Fe slightly decreased. From 12 to 24 h of milling, the X-ray intensity at the main peaks of both Cu and Fe continued to decrease. At 30 h of milling, the intensities at the main peaks of Cu and Fe became nearly equal. However, in the samples milled for 36 to 42 h, the X-ray intensities at the main peak positions of Cu and Fe continued to decline. The experimental results indicate that the X-ray intensity at the main peak positions of both Cu and Fe decreased with the increasing ball milling time.

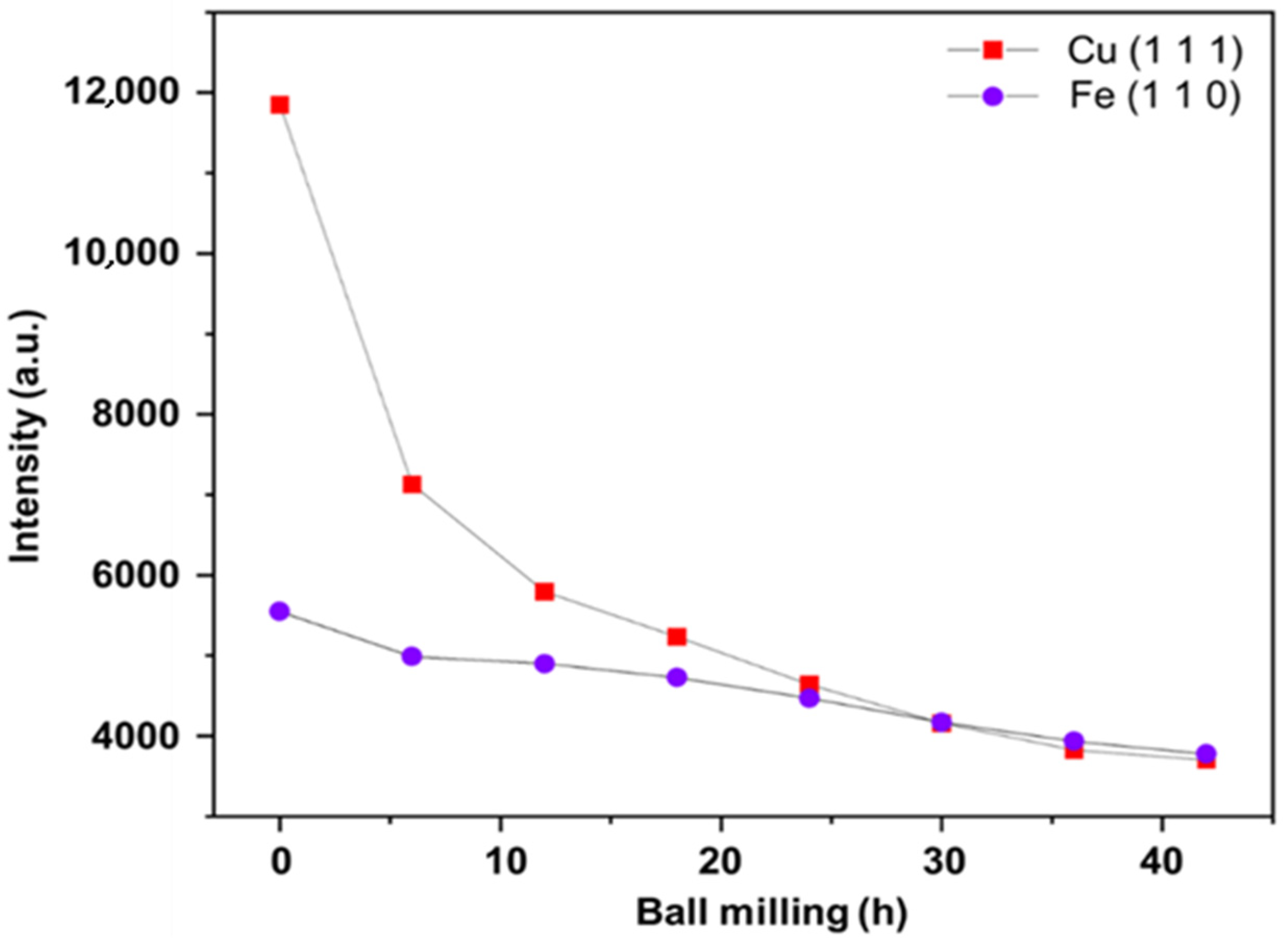

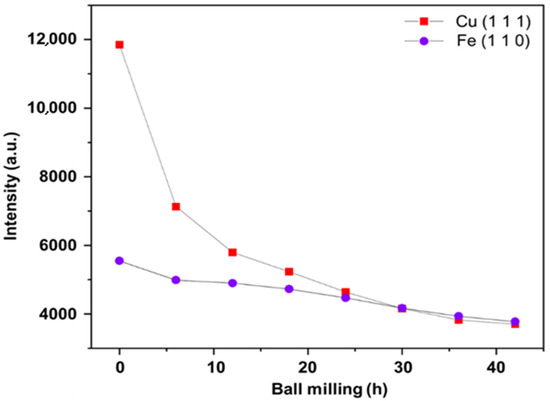

The above observations were confirmed by determining the intensity of the main peaks of Fe and Cu, and the results are shown in Figure 7. It can clearly be observed that the main peaks in intensity of Fe and Cu were approximately equal after the mixed sample was milled for 30 h. The main peak intensity was determined and plotted, as shown in Figure 7. The main peak intensity of the Cu alloy sample significantly decreased between 0 and 24 h. Meanwhile, the main peak intensity of the Fe alloy sample was decreased slightly in between 0 and 42 h. These results indicate that the Cu alloy sample was more brittle than the Fe alloy sample. In addition, the decreases in the main peak intensity of the Fe and Cu alloy samples directly resulted in the crystallite size.

Figure 7.

Intensity of Fe (110) peak and Cu (111) peak.

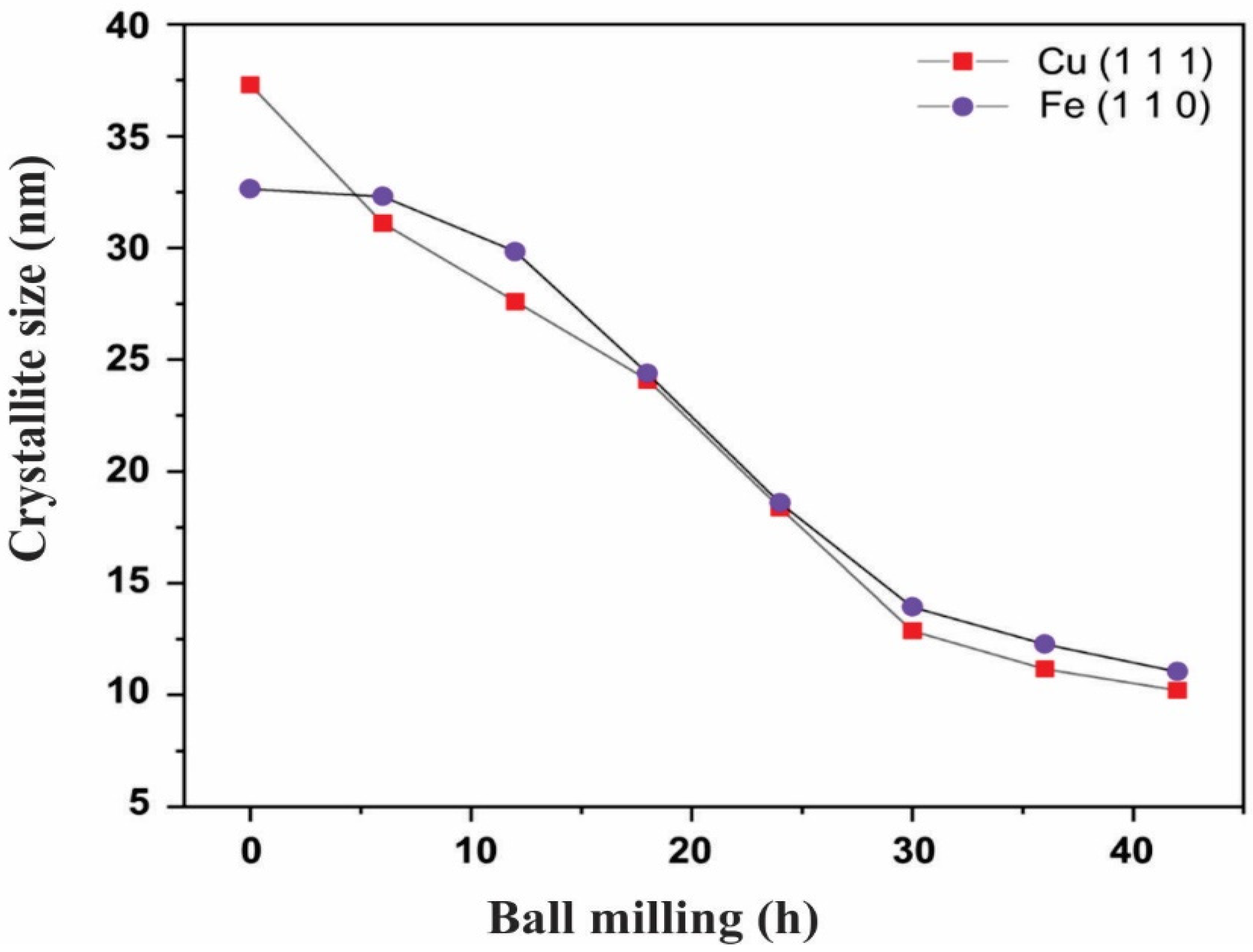

The crystallite sizes of the Fe and Cu were determined from the full width at half-maximum (FWHM) of the X-ray diffraction peak using Scherrer’s formula:

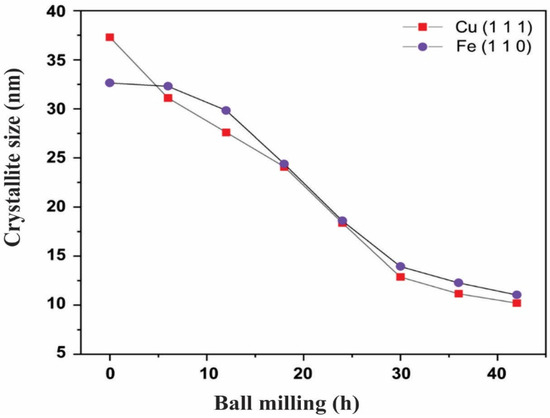

where λ is the X-ray wavelength, β is the FWHM of a diffraction peak, and θ is the diffraction angle. Figure 8 shows the crystallite sizes of Fe and Cu after milling for 0, 6, 12, 18, 24, 30, 36, and 42 h. It can clearly be seen that the crystallite sizes of both Fe and Cu decreased as the milling time increased.

Figure 8.

Crystallite sizes of Fe and Cu after milling for different times.

It can be concluded from the XRD results that the suitable milling time to produce Fe–Cu alloys is 30 h. Therefore, the Fe–Cu alloy milled for 30 h will be further characterized for surface morphology using SEM and for crystal orientation using TEM in Section 3.3 and Section 3.4, respectively.

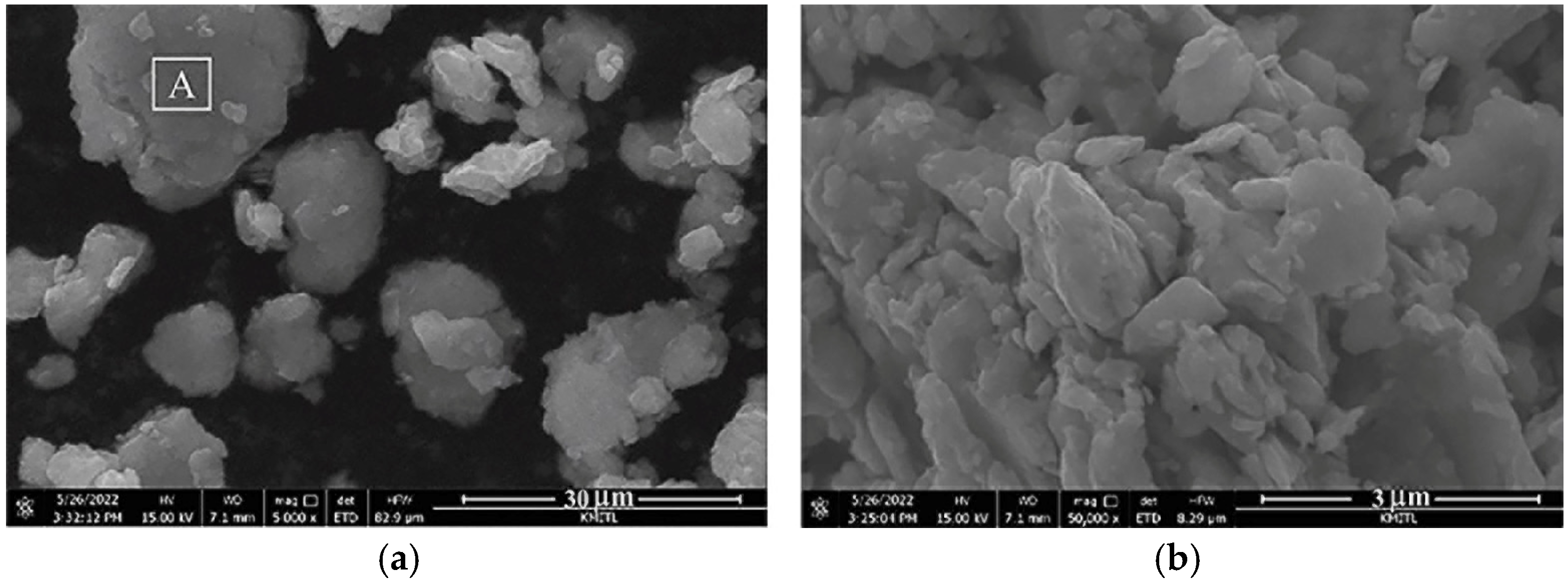

3.3. Surface Morphology of Fe–Cu Alloys

The surface morphology of the Fe–Cu alloy milled for 30 h was investigated using SEM-EDX. A SEM micrograph of the Fe–Cu alloy at a magnification of 5,000× is shown in Figure 9a. It can be seen that Fe and Cu agglomerated into many small clusters with some bigger clusters. Figure 9b shows a close-up view of area A on one big cluster in Figure 9a at a magnification of 50,000×. It can be observed that Fe and Cu agglomerated and formed a dense powder, possibly due to the impact and attrition of ball milling.

Figure 9.

SEM images of Fe–Cu alloy at magnifications of (a) 5,000× and (b) 50,000×.

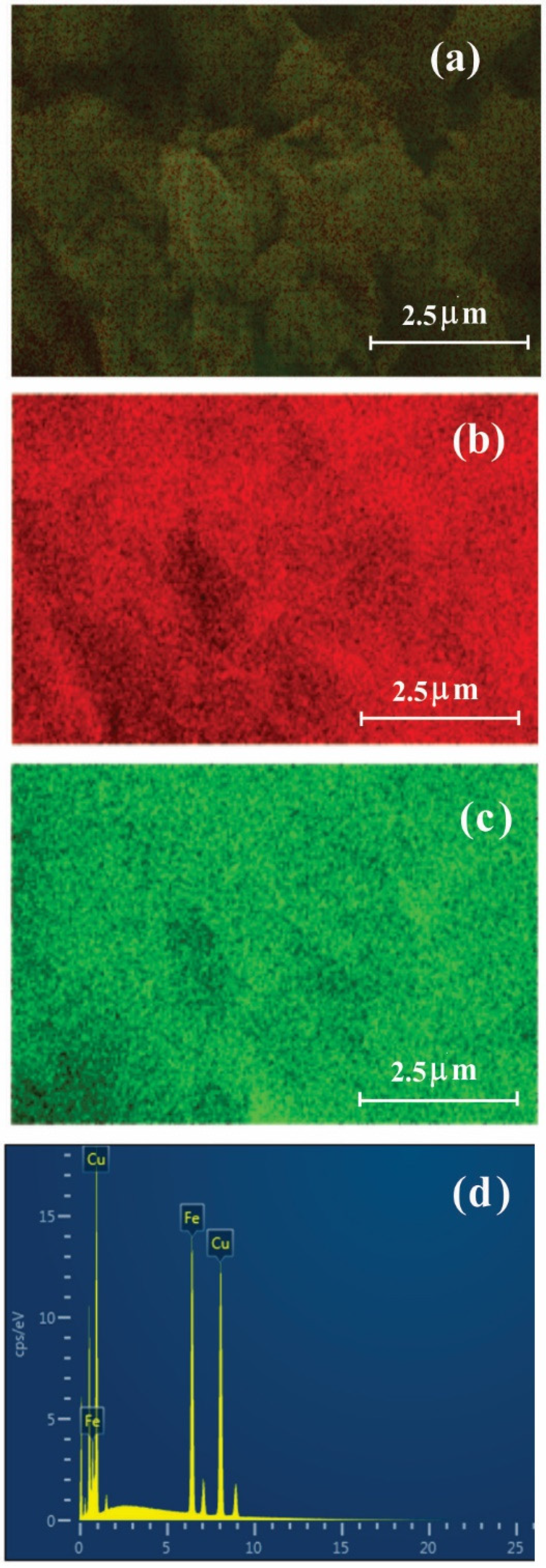

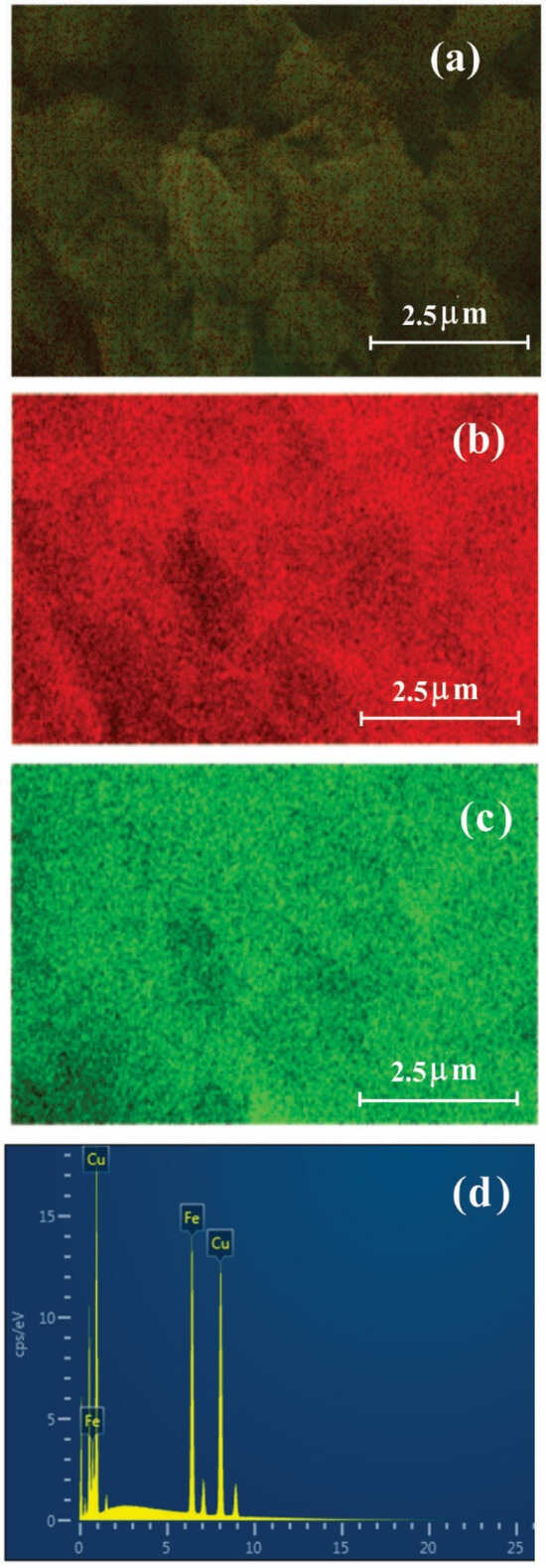

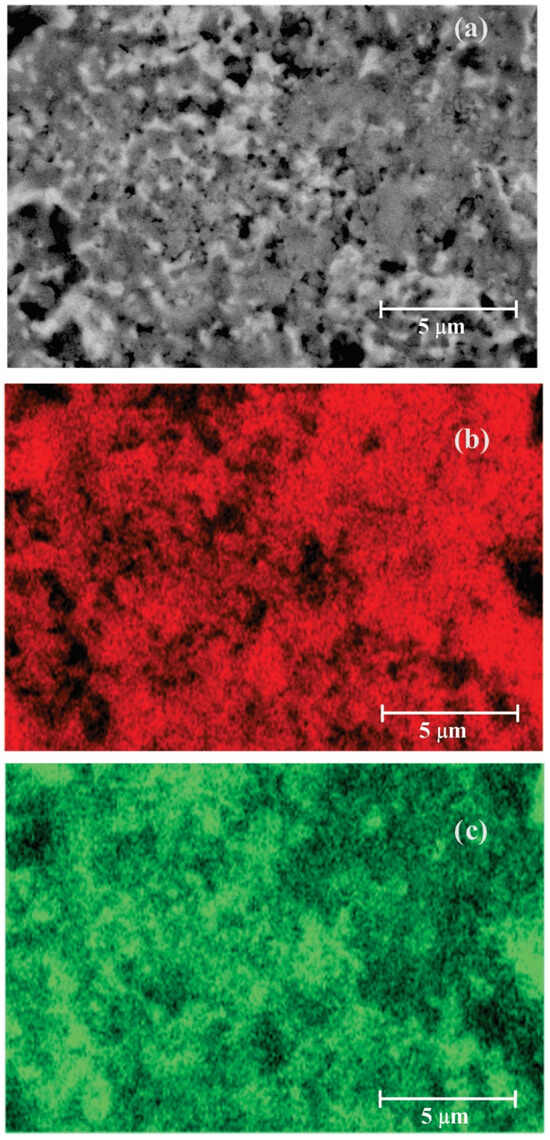

The homogeneity of Fe and Cu elements in the Fe–Cu alloy milled for 30 h was analyzed using the SEM–EDX mapping technique. Figure 10a–c show SEM images with EDX mapping of the Fe–Cu alloy, Fe, and Cu, respectively. Figure 10d shows the EDX spectra of Fe and Cu. The weight and atomic percentages of Fe and Cu elements in the alloys were calculated, and the results are shown in Table 1. It can be seen that the percentages of Fe and Cu elements in the Fe–Cu alloy milled for 30 h were 50.18 and 49.82 wt%, respectively, which is in good agreement with the XRD results. In Figure 10, the mapping picture reveals that the dispersion of Fe and Cu in the Fe–Cu alloy milled for 30 h was homogeneous throughout the sample volume.

Figure 10.

SEM images with EDX mapping of (a) Fe–Cu alloys, (b) Fe elements, (c) Cu elements, and (d) EDX spectrum.

Table 1.

Percentages of Fe and Cu elements in the alloys.

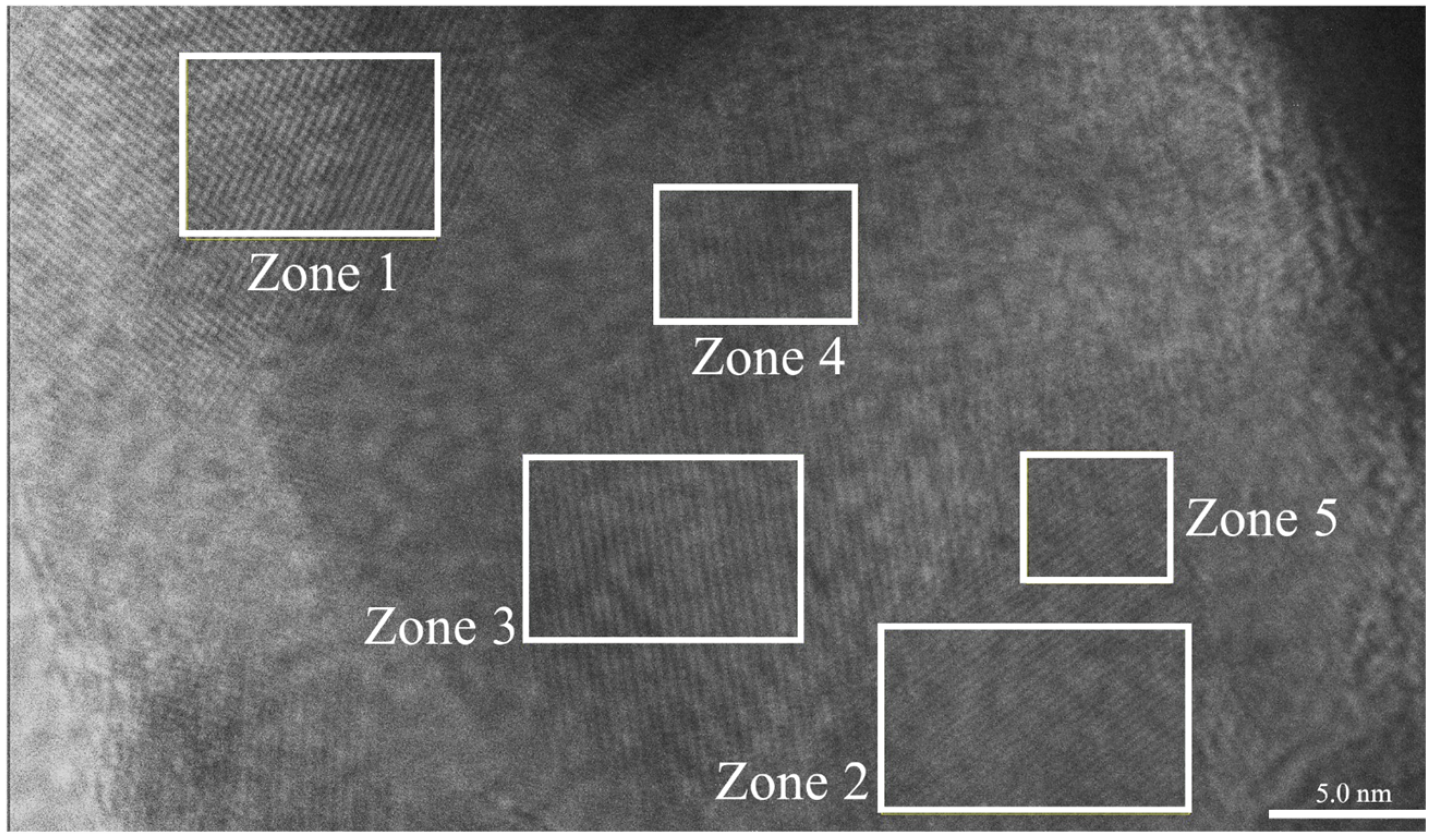

3.4. TEM of Fe–Cu Alloys

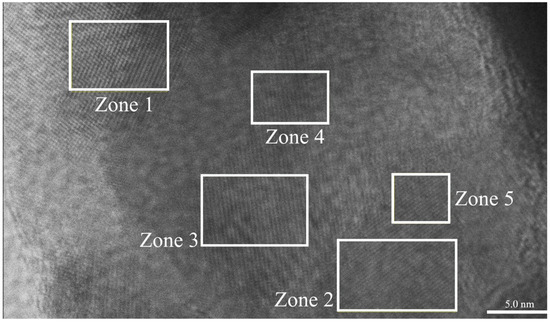

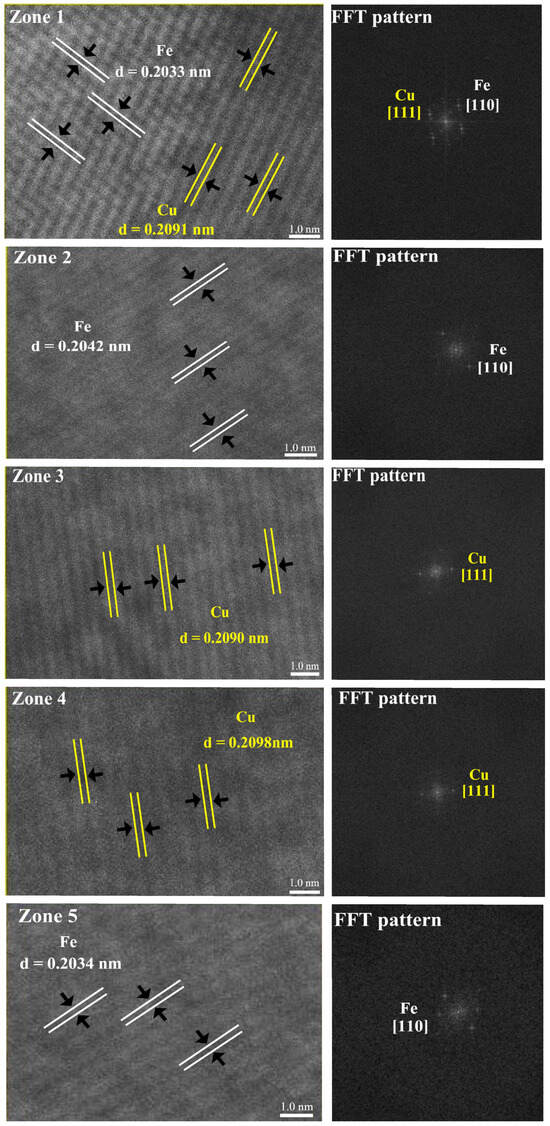

The crystal orientation of the Fe–Cu alloy milled for 30 h was investigated using transmission electron microscopy (TEM). Figure 11 shows a high-resolution transmission electron microscopy (HRTEM) image of the Fe–Cu alloy. The random orientation of several lattice planes, marked as Zones 1–5, was observed.

Figure 11.

HRTEM image of Fe–Cu alloy milled for 30 h.

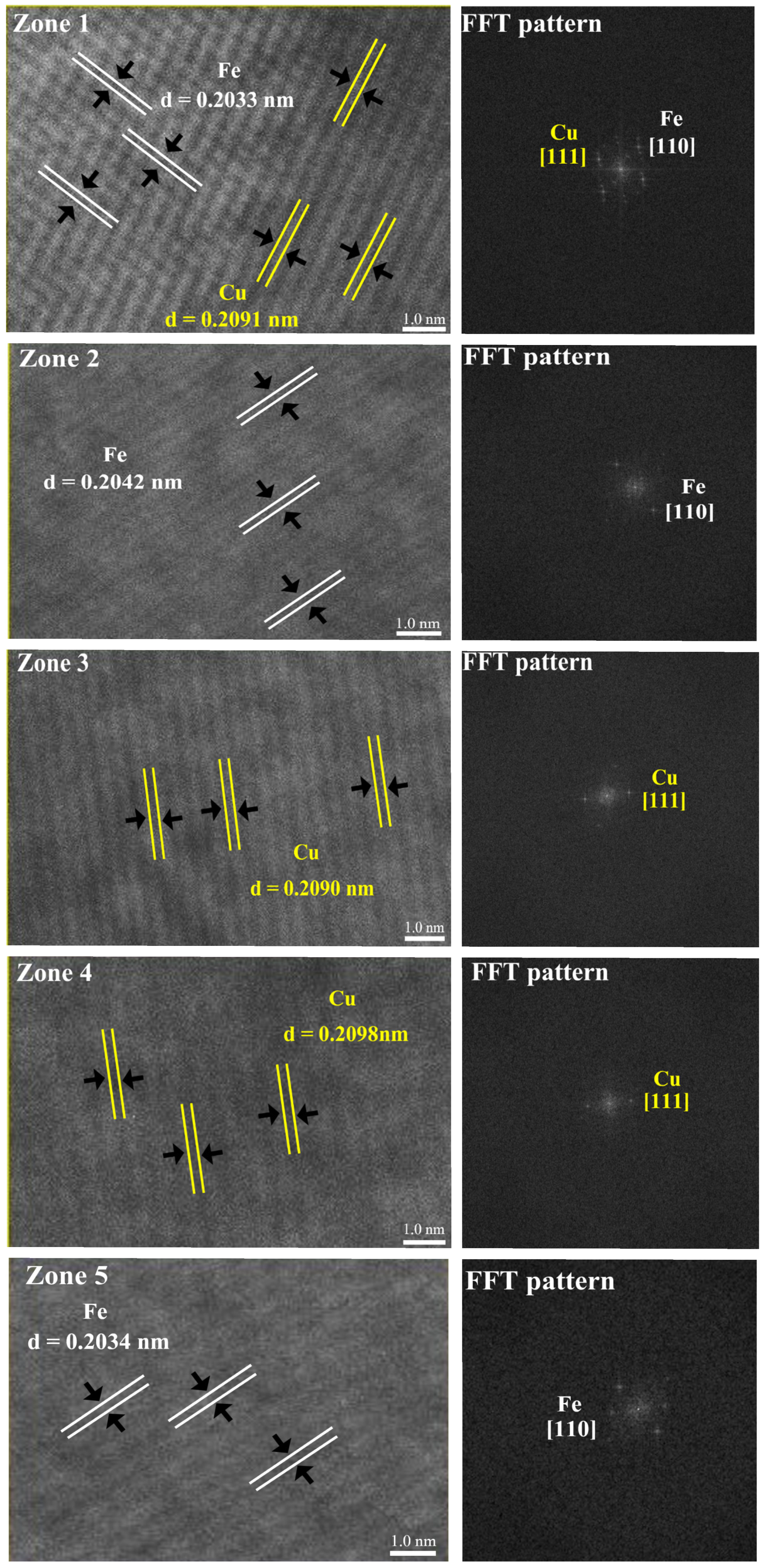

In Zone 1, lattice planes are visible in two directions, whereas in Zones 2, 3, 4, and 5, lattice planes are visible in only one direction. The lattice plane in each zone was analyzed to determine the spacing between the planes using fast Fourier transform (FFT) in the ImageJ software (version 1.54g, National Institutes of Health, Bethesda, MD, USA). The analyzed FFT patterns of each Zone are illustrated in Figure 12.

Figure 12.

FFT patterns of Fe and Cu in Zones 1–5 with corresponding d-spacing in each zone.

In Zone 1, the FFT pattern shows two distinct sets of diffraction spots. When performing inverse FFT, the distances between the diffraction spots were measured to be 0.2033 nm and 0.2091 nm. When comparing these distances with the atomic spacing (d-spacing) from the JCPDS files used in XRD analysis, the 0.2033 nm spacing corresponds to the d-spacing of Fe, while the 0.2091 nm spacing matches the d-spacing of Cu.

In Zones 2 and 5, the distances between the diffraction spots were found to be 0.2042 nm and 0.2034 nm, respectively, which align with the d-spacing of Fe. Meanwhile, in Zones 3 and 4, the diffraction spot spacings were 0.2090 nm and 0.2098 nm, respectively, corresponding to the d-spacing of Cu.

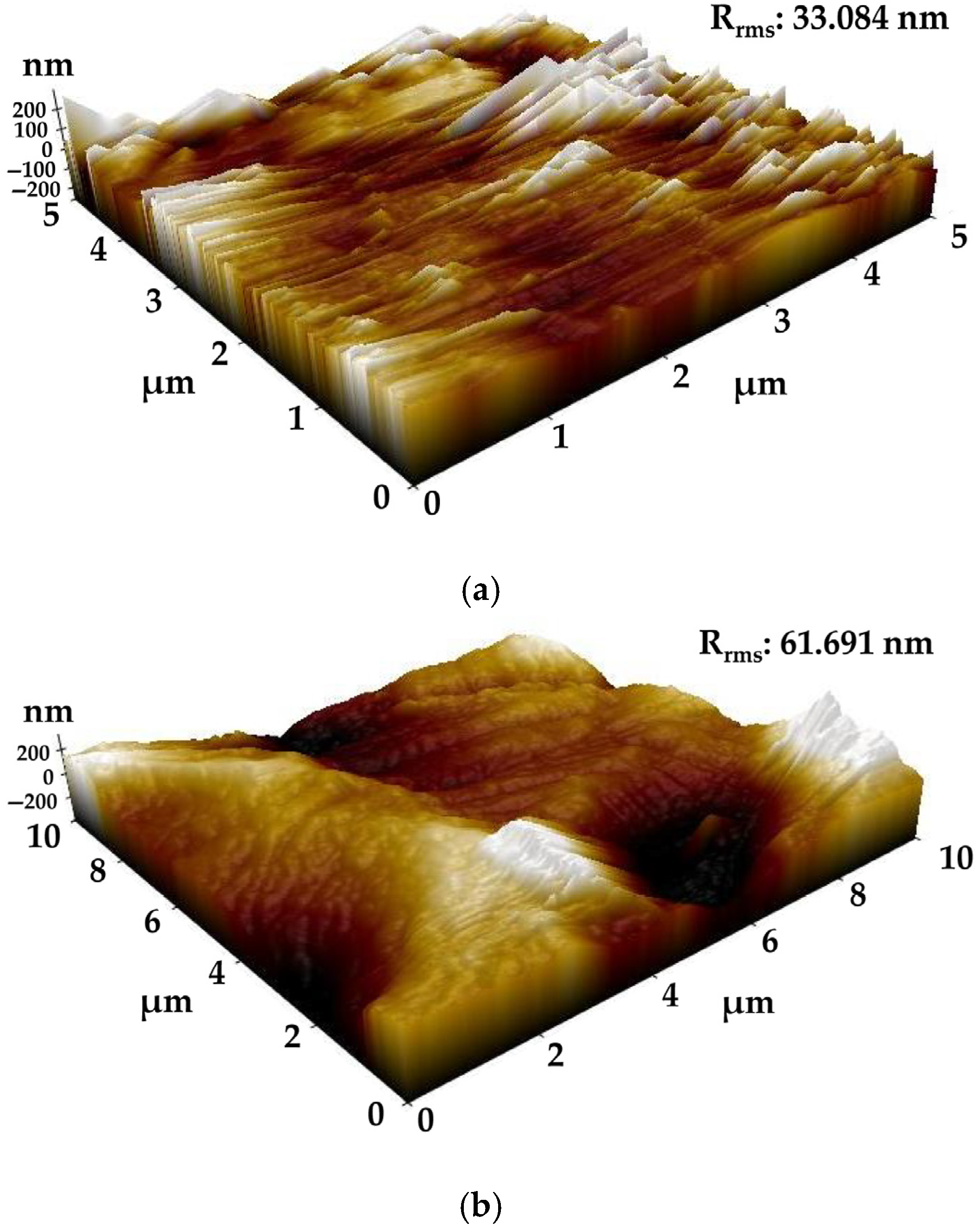

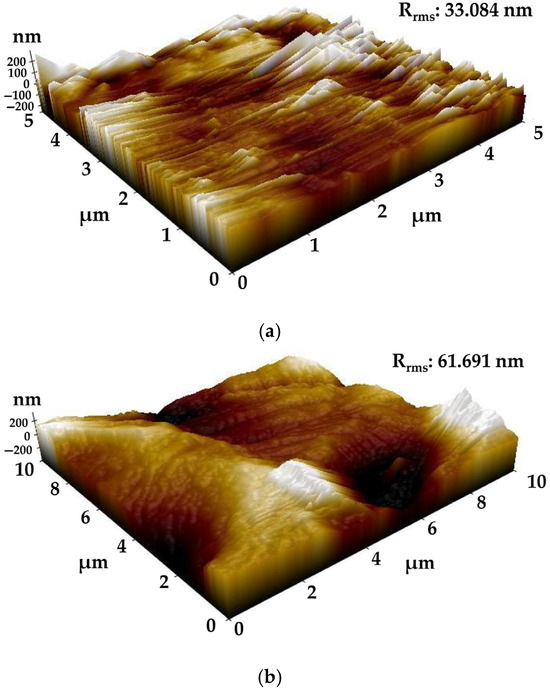

3.5. AFM of Cu and Fe–Cu Alloy-Coated Cu

The surface roughness of the Cu sheet and the Cu sheet coated with the Fe–Cu alloy prepared with a milling time of 30 h and annealed at 800 °C for 2 h was investigated using the atomic force microscopy (AFM) technique in the non-contact mode at room temperature. Figure 13 shows AFM images of the Cu sheet and the Cu sheet coated with the Fe–Cu alloy. It was found that the root mean square roughness (Rrms) values of the Cu sheet and the Fe–Cu alloy-coated Cu sheet were 33.084 and 61.691 nm, respectively. These results indicate that the roughness increased after the formation of the Fe–Cu alloy, leading to a larger active surface area.

Figure 13.

AFM images of (a) Cu sheet and (b) Cu sheet coated with Fe–Cu alloy.

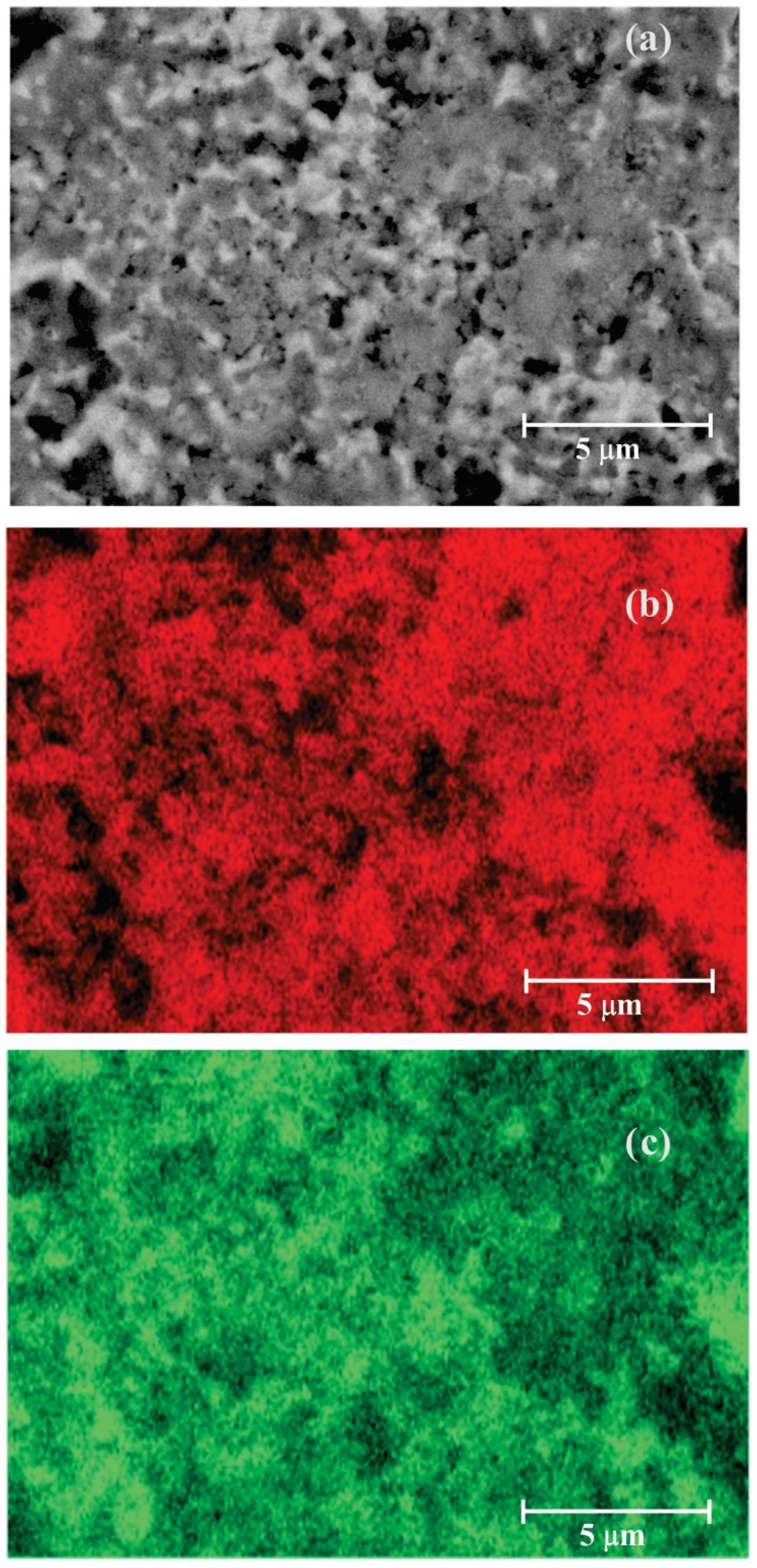

3.6. Surface Morphology of Fe–Cu Alloy-Coated Cu Substrate

The surface morphology of the Cu substrate coated with the Fe–Cu alloy prepared with a milling time of 30 h and annealed at 800 °C for 2 h was examined using SEM and is shown in Figure 14. It can be observed in Figure 14a that the Fe–Cu alloy adhering to the Cu substrate was homogeneous. The Fe and Cu particles were closely packed due to annealing at 800 °C for 2 h after being coated on the Cu substrate. Figure 14b,c reveal that the dispersion of the Fe and Cu on the Cu substrate was homogeneous.

Figure 14.

SEM images with EDX mapping of (a) Fe–Cu alloy coated on Cu substrate, (b) Fe element, and (c) Cu element.

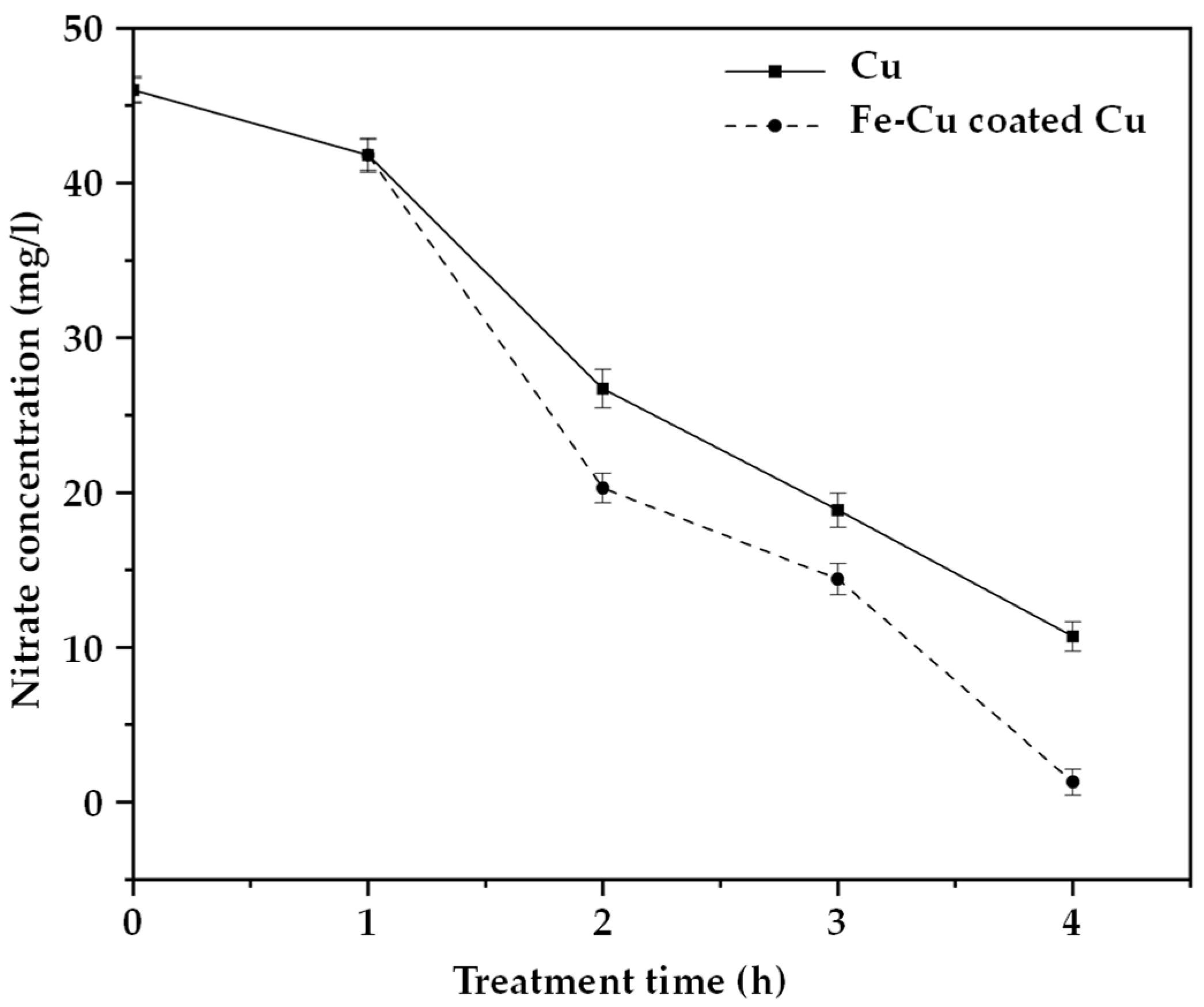

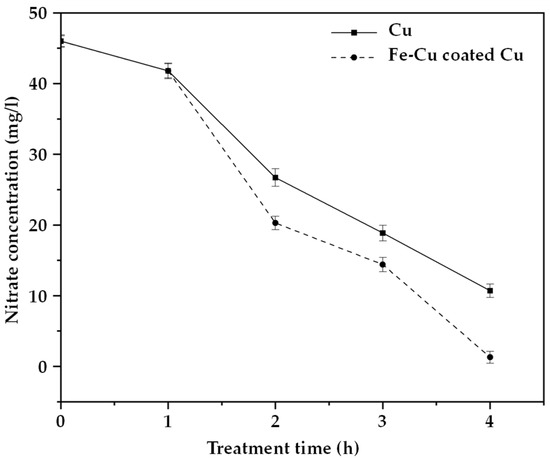

3.7. Experimental Test for Nitrate Removal from Synthesized Wastewater

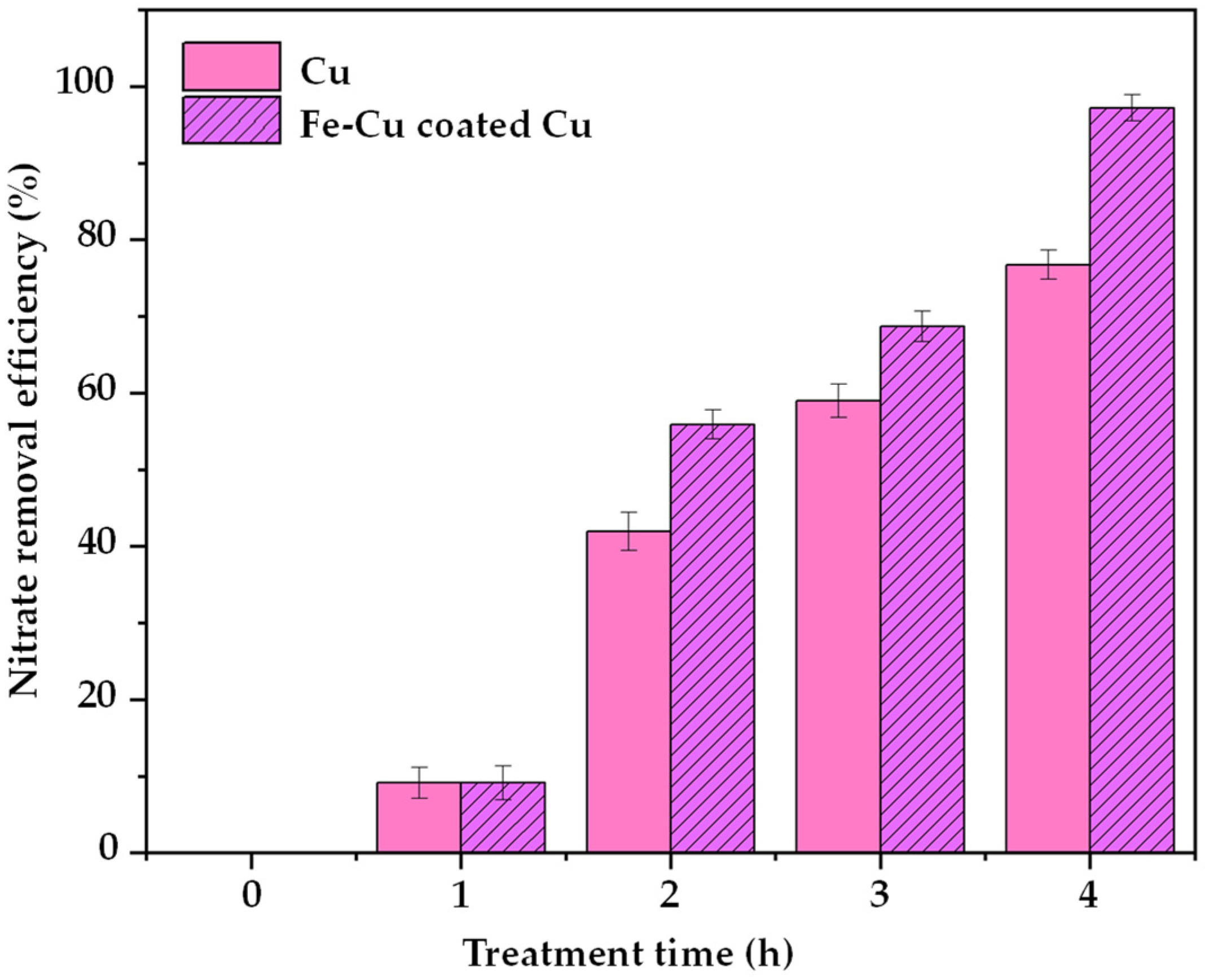

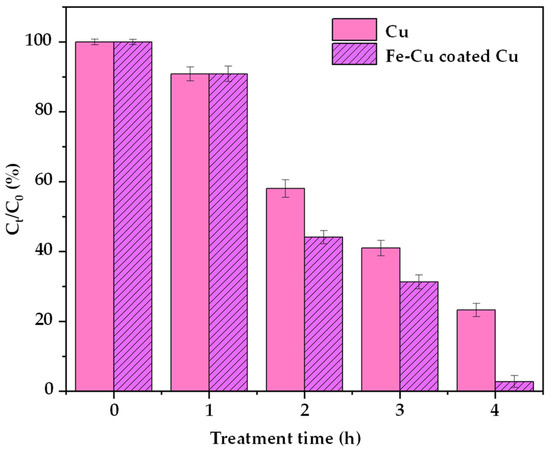

After the Fe–Cu alloy-coated Cu was prepared, it was used as the cathode in the electrolysis cell, with the setup details given in Section 2.5. The anode used was aluminum (Al). For comparison, a pure Cu sheet was also used as a cathode. Synthesized wastewater was prepared as described in Section 2.4. The nitrate concentration in the synthesized wastewater was measured at treatment times of 0, 1, 2, and 3 h. Three replicates were performed for each cathode. The experimental setup for nitrate removal from synthesized wastewater using the Fe–Cu-coated and pure Cu cathodes was described in Section 2.5. The average nitrate concentrations for the Fe–Cu-coated cathode and the pure Cu cathode at 0, 1, 2, and 3 h were found to be 41.80, 20.29, 14.40, and 1.28 mg/L and 41.80, 26.70, 18.86, and 10.70 mg/L, respectively. The plots of these values are given in Figure 15.

Figure 15.

Variations in the nitrate concentration as a function of the treatment time.

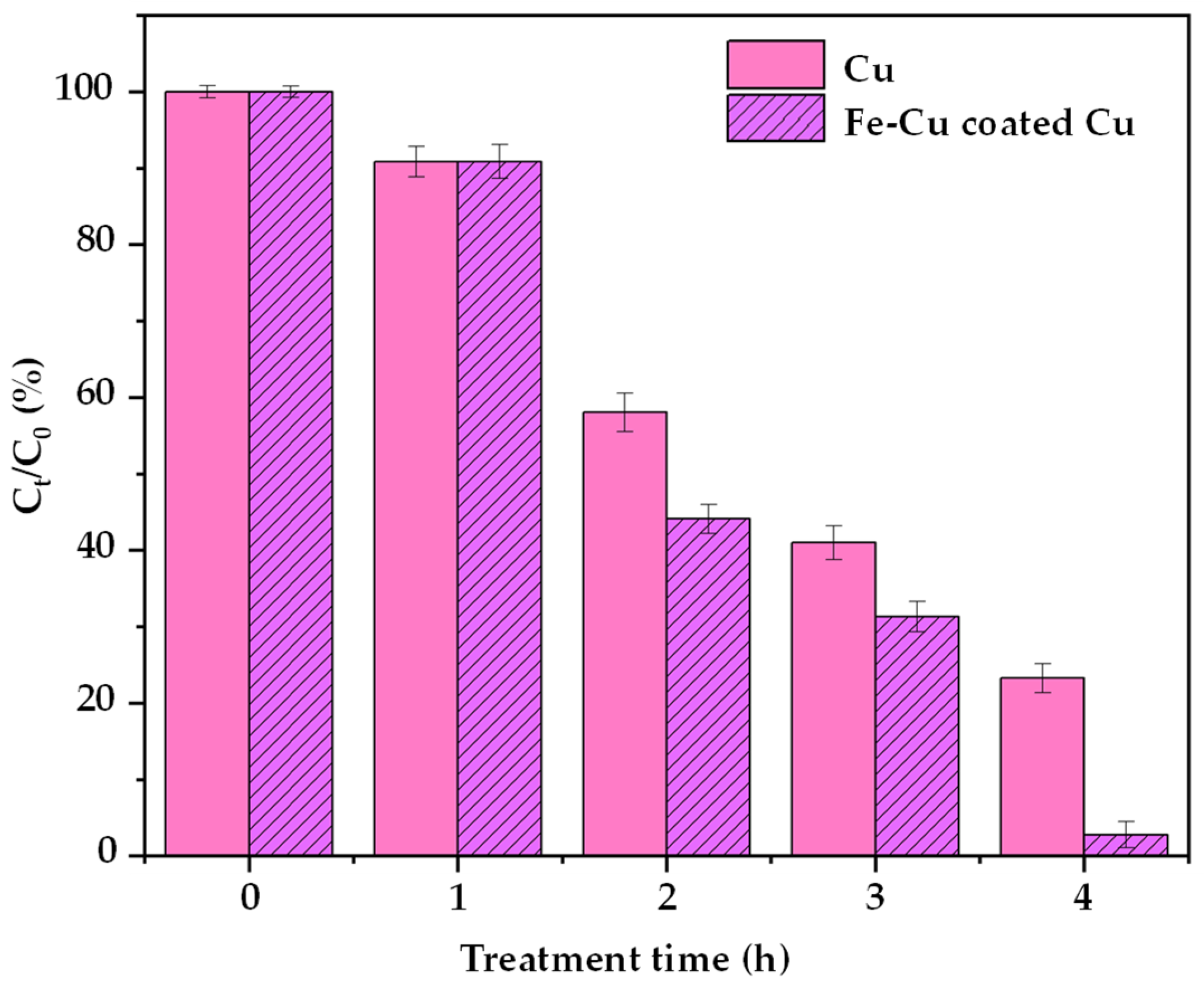

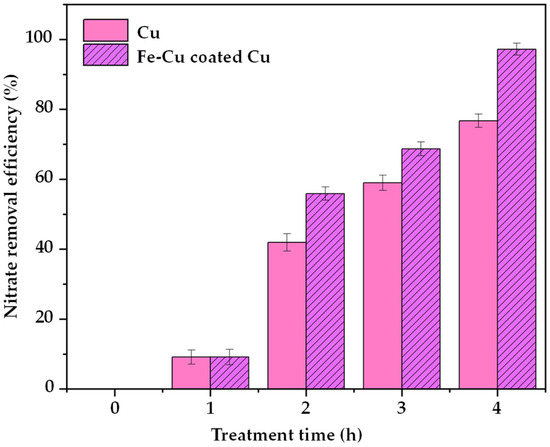

It can clearly be observed that the nitrate concentration using the Fe–Cu-coated cathode decreased at a higher rate than with the Cu cathode. The nitrate removal efficiencies at 4 h for the Fe–Cu-coated cathode and the Cu cathode, as calculated using Equation (6), were found to be 96.90 and 74.40, respectively. It can be concluded that the Fe–Cu-coated cathode fabricated in this work provided an adequate reaction rate against wastewater treatment without the need for chemical intervention, in contrast to cathodes and other nitrate treatment methods reported in the literature (Table 2). It is worth noting that in this work, pulsed DC electrolysis was used in the nitrate removal tests. The pulsed DC system was operated at an 80% duty cycle, achieving a maximum nitrate removal efficiency of 96.90%. If the test had been performed using conventional DC electrolysis, the Fe–Cu-coated cathode fabricated in this work would be expected to achieve a removal efficiency higher than 96.90%. In addition, the kinetic of the Fe–Cu-coated cathode and the Cu cathode were investigated. The kinetic of this was calculated using the first-order kinetic according to Fick’s first law via the following equation [38,44].

where C0 is the initial concentration of nitrate, and Ct is the concentration of nitrate at a given time in the electrolysis process. The kinetic of this study is shown in Figure 16. The results show that 1 h of the electrolysis process decreases nitrate to 90.87% of the Fe–Cu-coated cathode and the Cu cathode. After 2 h of the electrolysis process, the Fe–Cu-coated cathode and the Cu cathode experience decreases of 44.11 and 58.04%, respectively, while 3 h of the electrolysis process causes 31.30 and 41.00% nitrate decreases for the Fe–Cu-coated cathode and the Cu cathode, respectively. After 4 h of the electrolysis process, the Fe–Cu-coated cathode and the Cu cathode were shown to have 2.78 and 23.26% nitrate concentrations. According to the results, the Fe–Cu-coated cathode showed a significant decrease in nitrate removal as compared with the Cu cathode in the electrolysis process. Then, in all periods of time in the electrolysis process, the nitrate removal efficiency was calculated using Equation (6) and is shown in Figure 17. After 1 h of the electrolysis process, both the Fe-Cu-coated cathode and the Cu cathode increased to 9.13% of the nitrate removal efficiency. After 2 h of the electrolysis process, the Fe–Cu-coated cathode can improve the nitrate removal efficiency to 55.89%, while the Cu cathode can increase it to 49.6%. After 3 h of the electrolysis process, the Fe–Cu-coated cathode can improve the nitrate removal efficiency to 68.69%, and 59.00% for the Cu cathode. In the last 4 h of the electrolysis process, the Fe–Cu-coated cathode enhanced the nitrate removal efficiency up to 96. 90%, whereas it was only 76.74% for the Cu cathode. This implies that the Fe and Cu powders have an important role in enhancing the nitrate removal efficiency as compared with only the Cu cathode in this electrolysis process.

Ct/C0 = exp(−kt)

Table 2.

Comparison of removal with other cathodes.

Figure 16.

The kinetic behavior of the Fe–Cu-coated cathode and the Cu cathode in electrolysis process.

Figure 17.

The nitrate removal efficiency of the Fe–Cu-coated cathode and the Cu cathode in electrolysis process.

The high performance of nitrate removal with the Fe–Cu coated cathode is related to the other results obtained, such as the particle size distribution, crystallite size and orientation, morphology, element dispersion, and surface roughness. All results can be explained as follows: Regarding particle size distribution on the Fe–Cu alloy, the particle size rapidly decreased between 6 and 30 h and slightly decreased between 30 and 42 h (Figure 5). The decrease in the particle size led to an increase in the surface area, resulting in more interaction between the Fe–Cu alloy and . Meanwhile, the XRD results (Figure 6) show that the main XRD peak of the Cu particles significantly decreased after milling for 30 h due to the brittleness of the Cu particles. The brittleness and fragmentation of the Cu particles led to an increase in crystal defects, which can help enhance the capture of Additionally, the brittleness and fracture of the Cu particles contributed to a decrease in the crystallite size and an increase in the surface area. The SEM results (Figure 9 and Figure 14) indicate that the mixture of Cu and Fe particles with a 30 h milling time had a fine and homogeneous structure, resulting in an increased surface area. The Rrms roughness, according to the AFM results (Figure 13), was higher in the Cu substrate coated with the Fe–Cu alloy than in the uncoated Cu substrate, indicating a larger active surface area. The lattice planes (d-spacing) observed in the TEM results (Figure 12) confirm the crystal structure identified in the XRD results. In addition, the d-spacing indicates that the Fe and Cu particles were homogeneously dispersed in the Fe–Cu alloy clusters. Subsequently, the increased surface area and homogeneity of the Fe–Cu alloy led to a high performance for removal. Moreover, the Cu particles had high crystal stability, making them a catalyst for removal without degradation.

3.8. Cost-Effectiveness and Pros of the Fe–Cu Treatment Process

The comparative study of the conventional and proposed systems is summarized in Table 3, to clarify the advantages and costs of the treatment system. The Fe–Cu alloy cathode was manufactured from low-cost base metals using a scalable mechanical milling and annealing method. During the electrolysis process with the Fe–Cu cathode, the treatment system does not require additional chemicals, such as catalysts, supporting electrolytes, or pH control agents. These significantly reduce both material costs and the environmental impact. Therefore, this system represents a promising low-cost and environmentally sustainable alternative to conventional nitrate removal technologies.

Table 3.

Comparison of conventional electrochemical nitrate removal and the proposed Fe–Cu alloy-based chemical-free process.

4. Conclusions

This study focused on the preparation of a cathode coated with Fe–Cu alloy prepared at a 50:50 ratio using the ball milling technique. The Fe–Cu alloy particle size decreased with an increasing ball milling time. The crystallite sizes of the Fe and Cu particles were similar after ball milling for 30 h. In addition, the Fe and Cu particles from the ball milling time of 30 h retained a fine particle size with a high surface area. The morphology and element dispersion of the Fe–Cu alloy powder showed that the mixture was homogeneous, which was confirmed with d-spacing calculations. The Fe–Cu alloy powder was coated onto a Cu substrate using the ball milling technique. The surface roughness of the Fe–Cu alloy-coated substrate was higher than that of the pure Cu substrate. Both the coated and uncoated substrates were used as cathodes for nitrate removal from synthesized wastewater using pulse DC electrolysis. The experimental results indicate that the nitrate removal efficiency of the Fe–Cu alloy-coated substrate was 96.90%, compared with the uncoated Cu substrate, which achieved only 74.40%. This experiment demonstrated the successful cathode synthesis of an Fe–Cu alloy-coated Cu substrate for wastewater removal.

5. Future Work

Future studies should focus on the long-term electrochemical stability and corrosion resistance of the Fe–Cu alloy cathode under continuous operation. Moreover, performance evaluation using real wastewater containing competing ions is essential for practical application. Additional work could also explore the effect of the current density, electrode configuration, and flow-through cell designs to optimize treatment efficiency at a larger scale.

Author Contributions

Conceptualization, H.H. and P.S.; methodology, A.S. and P.S.; validation, H.H., B.K. and N.S.; data curation, B.K. and N.S.; writing—original draft preparation, H.H. and K.N.; writing—review and editing, K.N., A.S. and P.L.; supervision, P.S. and P.L.; project administration, A.S. and P.S.; funding acquisition, P.S. All authors have read and agreed to the published version of the manuscript.

Funding

The Research on “Research Title: Synthesis of Fe–Cu Alloys via Ball Milling for Electrode Fabri-cation Used in Elec-trochemical Nitrate Removal from Wastewater ” at King Mongkut’s Institute of Technology Ladkrabang (KMITL) has received funding support from the NSRF (FRB660065/0258-RE-KRIS/FF66/58).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

Hannanatullgharah Hayeedah thanks the School of Science, King Mongkut’s Institute of Technology Ladkrabang for providing a Research Assistant Scholarship for Industry, Contract No. IA-2564-M-001.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chen, Y.; Ling, J.; Yu, W.; Zhang, L.; Wu, R.; Yang, D.; Qu, J.; Jin, H.; Tao, Z.; Shen, Y.; et al. Identification of point and nonpoint emission sources of neonicotinoid pollution in regional surface water. Water Res. 2024, 248, 120863. [Google Scholar] [CrossRef] [PubMed]

- Han, W.; Tian, Y.; Shen, X. Human exposure to neonicotinoid insecticides and the evaluation of their potential toxicity: An overview. Chemosphere 2018, 192, 59–65. [Google Scholar] [CrossRef] [PubMed]

- Rajta, A.; Bhatia, R.; Setia, H.; Pathania, P. Role of heterotrophic aerobic denitrifying bacteria in nitrate removal from wastewater. J. Appl. Microbiol. 2020, 128, 1261–1278. [Google Scholar] [CrossRef] [PubMed]

- Focht, D.D.; Chang, A.C. Nitrification and denitrification processes related to waste water Treatment. Adv. Appl. Microbiol. 1975, 19, 153–186. [Google Scholar]

- Xu, D.; Li, Y.; Yin, L.; Ji, Y.; Niu, J.; Yu, Y. Electrochemical removal of nitrate in industrial wastewater. Front. Environ. Sci. Eng. 2018, 12, 9. [Google Scholar] [CrossRef]

- Zhang, L.; Yin, D.; Zhai, S.; Liu, Y.; Dou, C.; Chen, P.; Huang, G. Electrochemical behaviors and influence factors of copper and copper alloys cathode for electrocatalytic nitrate removal. Water Environ. Res. 2019, 91, 1589–1599. [Google Scholar] [CrossRef]

- Moussa, D.T.; El-Naas, M.H.; Nasser, M.; Al-Marri, M.J. A comprehensive review of electrocoagulation for water treatment: Potentials and challenges. J. Environ. Manag. 2017, 186, 24–41. [Google Scholar] [CrossRef] [PubMed]

- Sui, M.; Li, Y.; Jiang, Y.; Wang, L.; Zhang, W.; Sathishkumara, K.; Zakaria, H. Sediment-based biochar facilitates highly efficient nitrate removal: Physicochemical properties, biological responses and potential mechanism. Chem. Eng. J. 2021, 405, 126645. [Google Scholar] [CrossRef]

- Asefaw, K.T.; Bidira, F.; Desta, W.M.; Asaithambi, P. Investigation on pulsed-electrocoagulation process for the treatment of wet coffee processing wastewater using an aluminum electrode. Sustain. Chem. Environ. 2024, 6, 100085. [Google Scholar] [CrossRef]

- Koparal, A.S.; Öğütveren, Ü.B. Removal of nitrate from water by electroreduction and electrocoagulation. J. Hazard. Mater. 2002, 89, 83–94. [Google Scholar] [CrossRef]

- Govindan, K.; Noel, M.; Mohan, R. Removal of nitrate ion from water by electrochemical approaches. J. Water Process. Eng. 2015, 6, 58–63. [Google Scholar] [CrossRef]

- Lacasa, E.; Cañizares, P.; Llanos, J.; Rodrigo, M.A. Removal of nitrates by electrolysis in non-chloride media: Effect of the anode material. Sep. Purif. Technol. 2011, 80, 592–599. [Google Scholar] [CrossRef]

- Duca, M.; Sacré, N.; Wang, A.; Garbarino, S.; Guay, D. Enhanced electrocatalytic nitrate reduction by preferentially-oriented (100) PtRh and PtIr alloys: The hidden treasures of the “miscibility gap”. Appl. Catal. B Environ. 2018, 221, 86–96. [Google Scholar] [CrossRef]

- Zhang, R.; Shuai, D.; Guy, K.; Shapley, J.; Strathmann, T.; Werth, C. Elucidation of nitrate reduction mechanisms on a Pd-In bimetallic catalyst using isotope labeled nitrogen species. ChemCatChem 2013, 5, 313–321. [Google Scholar] [CrossRef]

- Pérez-Gallent, E.; Figueiredo, M.; Katsounaros, I.; Koper, M. Electrocatalytic reduction of nitrate on copper single crystals in acidic and alkaline solutions. Electrochim. Acta 2016, 227, 77–84. [Google Scholar] [CrossRef]

- Ren, M.; Song, Y.; Xiao, S.; Zeng, P.; Peng, J. Treatment of berberine hydrochloride wastewater by using pulse electro-coagulation process with Fe electrode. Chem. Eng. J. 2011, 169, 84–90. [Google Scholar] [CrossRef]

- Vasudevan, S. Effects of alternating current (AC) and direct current (DC) in electrocoagulation process for the removal of iron from water. Can. J. Chem. Eng. 2012, 90, 1160–1169. [Google Scholar] [CrossRef]

- Karamati-Niaragh, E.; Alavi Moghaddam, M.R.; Emamjomeh, M.M.; Nazlabadi, E. Evaluation of direct and alternating current on nitrate removal using a continuous electrocoagulation process: Economical and environmental approaches through RSM. J. Environ. Manag. 2019, 230, 245–254. [Google Scholar] [CrossRef]

- Hariri, M.B.; Botte, G.G. Simultaneous removal of ammonia and nitrate from wastewater using a pulse electrolysis technique. J. Electrochem. Soc. 2023, 170, 053502. [Google Scholar] [CrossRef]

- Atkins, A.P.; Lennox, A.J.J. Application of pulsed electrolysis in organic electrosynthesis. Curr. Opin. Electrochem. 2024, 44, 101441. [Google Scholar] [CrossRef]

- Li, S.; Zheng, C.; Yang, S.; Ma, T.; Yang, L.; Gao, Y. Reduction of nitrogen and phosphorus loading from polluted sediment by electrolysis. Ecol. Eng. 2021, 159, 106088. [Google Scholar] [CrossRef]

- Demir, N.; Kaya, M.F.; Albawabiji, M.S. Effect of pulse potential on alkaline water electrolysis performance. Int. J. Hydrogen Energy. 2018, 43, 17013–17020. [Google Scholar] [CrossRef]

- Jiang, C.J.; Liu, L.F.; Crittenden, J.C. An electrochemical process that uses an FeO/TiO2 cathode to degrade typical dyes and antibiotics and a bio-anode that produces electricity. Front. Environ. Sci. Eng. 2016, 10, 15. [Google Scholar] [CrossRef]

- Ghazouani, M.; Akrout, H.; Bousselmi, L. Efficiency of electro chemical denitrification using electrolysis cell containing BDD electrode. Desalin. Water Treat. 2015, 53, 1107. [Google Scholar] [CrossRef]

- Li, L.; Yun, Y.; Zhang, Y.; Huang, Y.; Xu, Z. Electrolytic reduction of nitrate on copper and its binary composite electrodes. J. Alloys Compd. 2018, 766, 157–160. [Google Scholar] [CrossRef]

- Paliwal, A.; Bandas, C.D.; Thornburg, E.S.; Haasch, R.T.; Gewirth, A.A. Enhanced nitrate reduction activity from cu-alloy electrodes in an alkaline electrolyte. ACS Catal. 2023, 13, 6754–6762. [Google Scholar] [CrossRef]

- Li, W.; Yin, Q.; Liu, C.; Yang, S.; Jin, D.; Wang, X.; Song, L. Fabrication of FeCu/CC composite for efficient removal of nitrate for aqueous solution via electrochemical reduction process. ChemCatChem 2024, 16, 202401017. [Google Scholar] [CrossRef]

- Jia, Z.; Feng, T.; Ma, M.; Li, Z.; Tang, L. Emerging advances in Cu-based electrocatalysts for electrochemical nitrate reduction (NO3RR). Surf. Interfaces 2024, 48, 104294. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Zhang, S.; Chen, D.; Yan, S.; Xie, R. Efficient electrochemical nitrate reduction with CoFe@Cu foam electrode: Experimental study and high N2 selectivity. Ionics 2025, 31, 3525–3536. [Google Scholar] [CrossRef]

- Alami, A.H.; Hawili, A.A. Synthesis, characterization and applications of FeCu alloys. Appl. Surf. Sci. Adv. 2020, 1, 100027. [Google Scholar] [CrossRef]

- Xu, H.; Bao, H.; Li, Y.; Bai, H.; Ma, F. Atomic scale insights into the rapid crystallization and precipitation behaviors in FeCu binary alloys. J. Alloys Compd. 2021, 882, 160725. [Google Scholar] [CrossRef]

- Lozhkomoev, A.S.; Lerner, M.I.; Pervikov, A.V.; Naidenkin, E.V.; Mishin, I.P.; Vorozhtsov, A.B.; Apkarian, A.S.; Eskin, D.G. The formation of Fe–Cu composite based on bimetallic nanoparticles. Vacuum 2019, 159, 441–446. [Google Scholar] [CrossRef]

- Swiatkowska-Warkocka, Z. Bimetal CuFe nanoparticles-synthesis, properties, and applications. Appl. Sci. 2021, 11, 1978. [Google Scholar] [CrossRef]

- Shang, X.; Wang, X.; Chen, S. Effects of ball milling processing conditions and alloy components on the synthesis of Cu-Nb and Cu-Mo alloys. Materials 2019, 12, 1224. [Google Scholar] [CrossRef]

- Alami, A.H.; Abed, J.; Almheiri, M.; Alketbi, A.; Aokal, C. Fe–Cu metastable material as a mesoporous layer for dye-sensitized solar cells. Energy Sci. Eng. 2016, 4, 166–179. [Google Scholar] [CrossRef]

- Naoui, Y.; Settar, A.; Chetehouna, K.; Bouleklab, M.C.; Revo, S.; Hamamda, S. Effect of multiwall carbon nanotube (MWCNT) content on thermal and structural properties enhancement of FeCu-MWCNT nanocomposites synthesized by high-energy ball milling. Appl. Phys. A Mater. Sci. Process. 2020, 126, 283. [Google Scholar] [CrossRef]

- Jiang, D.; Huang, D.; Lai, C.; Xu, P.; Zeng, G.; Wan, J.; Tang, L.; Dong, H.; Huang, B.; Hu, T. Difunctional chitosan-stabilized Fe/Cu bimetallic nanoparticles for removal of hexavalent chromium wastewater. Sci. Total Environ. 2018, 644, 1181–1189. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Chen, Z.; Wang, L.; Zhou, L.; Wu, P.; Wang, F.; Ou, P. Fe/Cu composite electrode prepared by electrodeposition and its excellent behavior in nitrate electrochemical removal. J. Electrochem. Soc. 2018, 165, E420–E428. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, Z.; Xu, J. Electrochemical mechanisms and optimization system of nitrate removal from groundwater by polymetallic nanoelectrodes. Int. J. Environ. Res. Public Health 2023, 20, 1923. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, M.; Feng, L.; Liu, Y. Electrochemical simultaneous denitrification and removal of phosphorus from the effluent of a municipal wastewater treatment plant using cheap metal electrodes. Environ. Sci. Water Res. Technol. 2022, 6, 1095–1105. [Google Scholar]

- Wang, Y.; Wang, Q.; Chang, Q.; Hu, S.; Wang, X.; Yang, K. Effect of particle size on the blue chromate pigment CoAl2O4. J. Ceram. Sci. Technol. 2018, 9, 43–46. [Google Scholar]

- Liu, Y.; Qiao, Y.; Nie, Q.; Xiong, L.; Zeng, Q.; Wang, B.; Lv, H.; Yu, H.; Yang, G. High photoelectric performance of Cu-based AZO multilayer films deposited via TiO2 barrier layer and oxygen-containing atmosphere. Ceram. Int. 2019, 45, 24303–24308. [Google Scholar]

- Wang, X.; Tang, L.; Yang, T.; Shi, Y.; Liu, F.; Jiang, H. Remediation of bensulfuron methyl polluted water and soil by Fe2O3/Fe3O4@C activating peroxymonosulfate: Chloride enhancement effect and phytotoxicity assessment. Chem. Eng. J. 2023, 474, 145439. [Google Scholar] [CrossRef]

- Guettari, F.; Rehamnia, R. Electrochemical removal kinetics of nitrate ions on copper from acidic medium. Pol. J. Environ. Stud. 2023, 32, 5061–5069. [Google Scholar] [CrossRef]

- Vilardi, G.; Di Palma, L. Kinetic study of nitrate removal from aqueous solutions using copper-coated iron nanoparticles. Bull. Environ. Contam. Toxicol. 2017, 98, 359–365. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Ying, D.; Ye, D.; Zhang, R.; Guo, Q.; Wang, Y.; Jia, J. Electrochemical study of enhanced nitrate removal in wastewater treatment using biofilm electrode. Bioresour. Technol. 2018, 252, 134–142. [Google Scholar] [CrossRef]

- Gao, W.; Gao, L.; Li, D.; Huang, K.; Cui, L.; Meng, J.; Liang, J. Removal of nitrate from water by the electrocatalytic denitrification on the Cu-Bi electrode. J. Electroanal. Chem. 2018, 817, 202–209. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).