1. Introduction

The first and second editions of the Special Issue entitled “Industrial Chemistry Reaction: Kinetics, Mass Transfer and Industrial Reactor Design” have both been successful. Two volumes have been published, each containing 11–12 different papers of high quality. It can be verified on the Processes website that the average number of paper downloads for the first volume as of June 2023 was 2600, with a range between a minimum of 1101 and a maximum of 7901. The second volume, although the deadline has recently expired, collected an average number of paper downloads of 1325 for each article, with a range of 359–3822. These data demonstrate that the papers published in Special Issues I and II have had great visibility at an international level. For this reason, the Guest Editors have decided to promote a third edition of this Special Issue with a slight modification to the original title; it is thus entitled “Industrial Chemistry Reactions (3rd Edition): Kinetics, Mass and Heat Transfer in View of the Industrial Reactors Design”.

The aim of this proposed Special Issue is the same as those of the previous editions, that is, to collect contributions from experts worldwide in the field of industrial reactor design based on kinetic and mass transfer studies. The following areas/topics will be covered in this Special Issue:

- Kinetic studies for complex reaction schemes (multiphase systems);

- Kinetics and mass transfer in multifunctional reactors;

- Reactions in a mass-transfer-dominated regime (fluid–solid and intraparticle diffusive limitations);

- Kinetics and mass transfer modeling with alternative approaches (e.g., stochastic modeling);

- Pilot plant and industrial-size reactor simulation and scale-up based on kinetic studies (lab-to-plant approach).

Thus, in this Special Issue, original manuscripts that stand as examples to the scientific and technological communities of the modern approach to the investigation of industrial chemistry reactions are welcome.

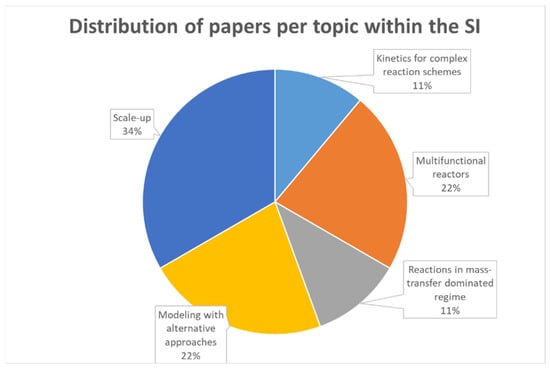

The Special Issue allowed the collection of eight research articles and one review article, that could be framed within different macro-areas, whose distribution is depicted in Figure 1.

Figure 1.

Statistical information related to the Special Issue “Industrial Chemistry Reactions (3rd Edition): Kinetics, Mass and Heat Transfer in View of the Industrial Reactors Design”: distribution of papers per macro-area.

As revealed, the distribution is well-balanced along five different macro-areas: (i) kinetics for complex reaction schemes; (ii) multifunctional reactors; (iii) reactions in mass-transfer-dominated regimes; (iv) modeling with alternative approaches; and (v) scale-up. In the following sections, the main efforts published in the SI are reviewed and summarized, highlighting the point of novelty per macro-area.

2. Kinetics for Complex Reaction Schemes

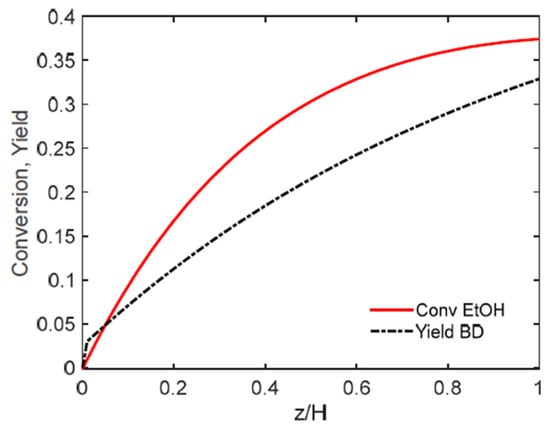

One article was published in the field of kinetics for complex reaction schemes. In detail, Dimian et al. conducted an in-depth numerical investigation for the ethanol to butadiene process simulating both conversion and main product selectivity at different reaction conditions (see Figure 2), drawing the key steps for developing a future process, focusing the attention on both reaction kinetics and thermodynamics (Contribution 1).

Figure 2.

Ethanol conversion and butadiene selectivity vs. the reactor length (Contribution 1).

3. Multifunctional Reactors

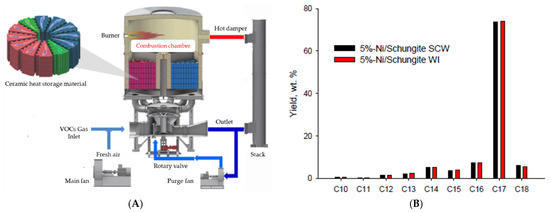

Two papers were published in the field of multifunctional reactors technologies. Park et al. implemented an improved 100 CMM regenerative thermal oxidizer (RTO) for low-emission combustion, designing the combustion chamber as a rotating-plate-driving device, which was also improved in terms of energy efficiency (Contribution 6). Figure 3A shows the hydrogen concentration profiles with residence time, illustrating that the model is also able to predict instability regions for the operation, making it a valuable tool in reactor design (see sketch in Figure 3A), allowing an efficient removal of TF of 98%.

Figure 3.

(A) Configuration of RTO 3D model (Contribution 6). (B) Product yields at 100% conversion of stearic acid working at a temperature of 280 °C, hydrogen partial pressure of 1.5 MPa, and catalyst loading of 13.2 mol of stearic acid per mol of Ni (Contribution 9).

Schipanskaya et al. proposed a catalytic biomass transformation to hydrocarbons under supercritical conditions over Ni-based catalysts, demonstrating that it is possible to achieve high yields in C17 when working in supercritical conditions (Figure 3B) (Contribution 9).

4. Reactions in Mass-Transfer-Dominated Regimes

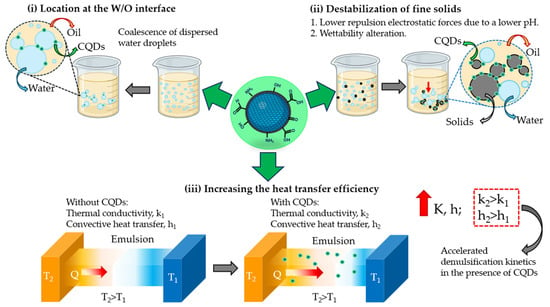

One article was published in the field of chemical reactions in the presence of mass-transfer limitations. In particular, Gallego et al. published a paper on the optimization of the demulsification performance of a carbon quantum dot (CQD)-enhanced chemical demulsifier in industrial emulsions under thermal, mechanical, and thermomechanical effects (see Figure 4), highlighting possible synergistic effects of the three tested techniques for the demulsification technology (Contribution 2).

Figure 4.

Schematic representation of the three main demulsification mechanisms of the CQDs: (i) location of the W/O interface and coalescence of water droplets, (ii) destabilization of fine solids, and (iii) increasing heat transfer efficiency (Contribution 2).

5. Modeling with Alternative Approaches

Within this Special Issue, Raponi et al. published a paper on a CFD modeling and population balance model for an innovative precipitation reactor, demonstrating the value of combining advanced CFD modeling with PBM to support the smart manufacturing of crystallization (Figure 5A) (Contribution 8).

Figure 5.

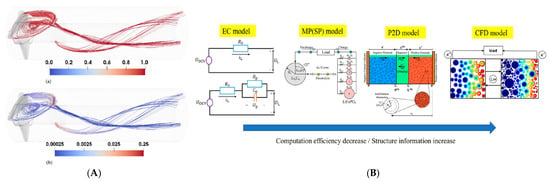

(A) Visualization of the mixture fraction (a) and its variance (b) for the configuration of the two nozzles (Contribution 8). (B) Logic diagram of mechanism models (Contribution 5).

Ji et al. published a review article on lithium-ion battery modeling, starting from mechanism-based models (Figure 5B) and ending with data-driven perspectives, highlighting how the two approaches can compensate each other’s limitations (Contribution 5).

6. Scale-Up

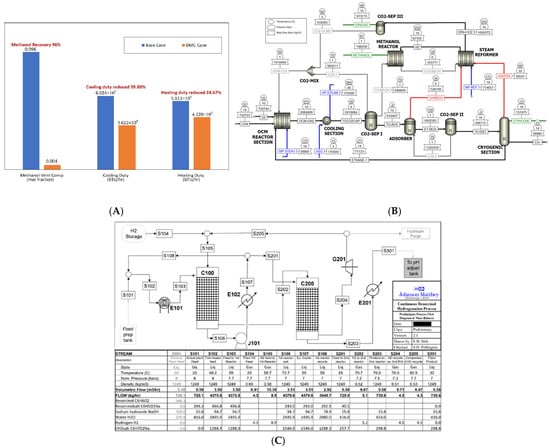

Three articles are devoted to the scale-up. Haque et al. proposed an advanced process control system for methanol production from natural gas, demonstrating that it is possible to optimize the energy demand of the main units (Figure 6A) (Contribution 4). Godini et al. proposed a process and techno-economic analysis of ethylene adsorptive separation in the oxidative coupling of methane. The authors proposed a detailed flowsheet (see Figure 6B) that was a model to optimize the operation conditions of the whole plant (Contribution 3). Finally, Pollington et al. proposed a process for resorcinol hydrogenation, passing from batch to continuous operation. The authors proposed a detailed flowsheet (see Figure 6C) based on the experimental finding collected in batch investigation (Contribution 7).

Figure 6.

(A) Comparison of the classical and optimized controlled case results (Contribution 4). (B) Ethylene adsorptive separation in oxidative coupling of methane flowsheet (Contribution 3). (C) Resorcinol hydrogenation flowsheet (Contribution 7).

7. Conclusions

Starting from the success of the first two editions, the Special Issue entitled “Industrial Chemistry Reactions: Kinetics and Mass and Heat Transfer in View of Industrial Reactor Design (III)” was launched and gained attention. Also, in this case, the success was because different options could be obtained when chemical reactions, catalysis, kinetics, transport phenomena, and multiphase systems were considered. The high quality of the collected papers, together with the high interdisciplinary approach, allowed the production of relevant papers in the sector and will be a reference for future research.

Author Contributions

Conceptualization, all authors equally; writing—review and editing, all authors equally. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The present Special Issue was possible thanks to the dedication of Elio Santacesaria, who passed away in December 2024. His charisma and worldwide-recognized scientific value enabled this series of Special Issues. Unfortunately, he did not live enough to contribute to the present editorial.

Conflicts of Interest

The authors declare no conflicts of interest.

List of Contributions

- Dimian, A.C.; Bozga, G.; Banu, I. Linking Catalyst Development and Chemical Reactor Design with Ethanol to Butadiene Processes. Processes 2025, 13, 1024. https://doi.org/10.3390/PR13041024.

- Gallego, J.F.; Medina, O.E.; Tengono, J.A.; Mazo, C.; Maya, A.F.; Caro, C.; Cortés, F.B.; Franco, C.A. Demulsification of Water-in-Oil Emulsion with Carbon Quantum Dot (CQD)-Enhanced Demulsifier. Processes 2025, 13, 575. https://doi.org/10.3390/PR13020575.

- Godini, H.R.; Huy, N.D.; Ramponi, L.; Son, N.X.; Mokhtarani, B.; Repke, J.U.; Penteado, A.; Manzolini, G.; Orjuela, A.; Gallucci, F. Techno-Economic Analysis of Ethylene Adsorptive Separation Using Zeolite 13X in Oxidative Coupling of Methane Integrated Process. Processes 2024, 12, 1759. https://doi.org/10.3390/PR12081759.

- Haque, M.E.; Palanki, S. Advanced Process Control Strategies for Efficient Methanol Production from Natural Gas. Processes 2025, 13, 424. https://doi.org/10.3390/PR13020424.

- Ji, C.; Dai, J.; Zhai, C.; Wang, J.; Tian, Y.; Sun, W. A Review on Lithium-Ion Battery Modeling from Mechanism-Based and Data-Driven Perspectives. Processes 2024, 12, 1871. https://doi.org/10.3390/PR12091871.

- Park, H.M.; Jung, H.M.; Lee, D.H.; Park, H.N.; Lim, T.Y.; Yoon, J.H.; Yoon, D.H. Implementation of an Improved 100 CMM Regenerative Thermal Oxidizer to Reduce VOCs Gas. Processes 2024, 12, 2814. https://doi.org/10.3390/PR12122814.

- Pollington, S.D.; Kalirai, B.S.; Stitt, E.H. Batch to Continuous: From Laboratory Recycle Trickle Bed Test Reactor Data to Full-Scale Plant Preliminary Design—A Case Study Based on the Hydrogenation of Resorcinol. Processes 2024, 12, 859. https://doi.org/10.3390/PR12050859.

- Raponi, A.; Fida, D.; Vicari, F.; Cipollina, A.; Marchisio, D. Computational Fluid Dynamics and Population Balance Model Enhances the Smart Manufacturing and Performance Optimization of an Innovative Precipitation Reactor. Processes 2025, 13, 1721. https://doi.org/10.3390/PR13061721.

- Schipanskaya, E.O.; Stepacheva, A.A.; Markova, M.E.; Bykov, A.V.; Sidorov, A.I.; Matveeva, V.G.; Sulman, M.G.; Kiwi-Minsker, L. Catalytic Biomass Transformation to Hydrocarbons under Supercritical Conditions over Nickel Supported on Schungite. Processes 2024, 12, 1503. https://doi.org/10.3390/PR12071503.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).