Energy Analysis in the PVC Shoe-Sole Production Process: From Raw Material to Final Product

Abstract

1. Introduction

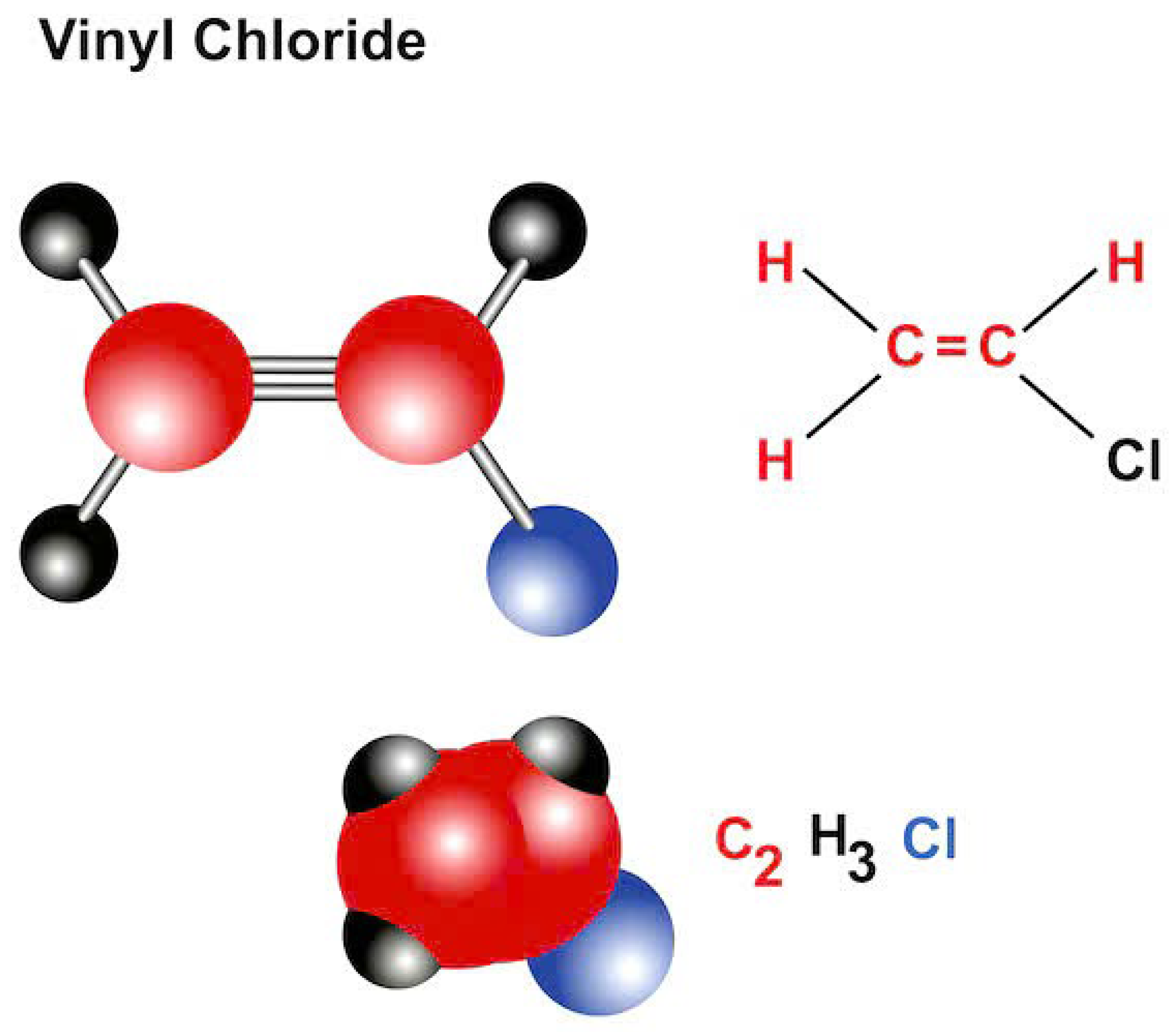

PVC Production Process

2. Materials and Methods

2.1. PVC Molding

- compression molding (direct),

- transfer molding (indirect) and

- injection molding (injection molding).

- injection unit

- mold clamping unit (press).

2.2. Technological Process of Suspension PVC Production

2.3. Technological Process of Shoe-Sole Injection Molding

3. Results

3.1. Energy Analysis of the Technological Production Process of Suspension PVC

3.2. Analysis of Fuel Combustion Products in the PVC Production Process

3.3. Electricity Consumption During Shoe Soles Injection Molding

3.4. Share of the Price of Electricity in the Production Process

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gnanasundaram, S.; Ranganathan, M. Footwear. In Encyclopedia of Polymer Applications; Mishra, M., Ed.; CRC Press: Boca Raton, FL, USA; Taylor and Francis Group: Abingdon, UK, 2019; Volume 2, pp. 1444–1469. ISBN 978-1-4987-2993-2. [Google Scholar]

- Golubeva, O.; Pogorelova, A. Analysis of the quality of modern polymer materials of sole. In E3S Web of Conferences: Proceedings of the XIV International Scientific and Practical Conference “State and Prospects for the Development of Agribusiness-INTERAGROMASH 2021”, Rostov-on-Don, Russia, 24–26 February 2021; Rudoy, D., Olshevskaya, A., Ugrekhelidze, N., Eds.; EDP Sciences: Les Ulis Cedex A, France, 2021; Volume 273, pp. 1–7. [Google Scholar] [CrossRef]

- Karkalic, R.; Radulovic, J.; Jovanovic, D. Characteristics of polyurethane and elastomer parts for shoe industry produced by liquid injection molding technology. Vojn. Glas. 2017, 65, 948–967. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamentals of Modern Manufacturing: Materials, Processes and Systems, 4th ed.; John Wiley and Sons Inc.: Hoboken, NJ, USA, 2010; ISBN 978-0470-467002. [Google Scholar]

- Kovačić, T.; Andričić, B. Suspension poly(vinyl chloride) and the risks of its production. Polymers 2005, 26, 128–132. [Google Scholar]

- Eyerer, P.; Weller, M.; Hübner, C. (Eds.) Polymers–Opportunities and Risks II: Sustainability, Product Design and Processing; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 978-3-642-02796-3. [Google Scholar]

- Grossman, R.F. (Ed.) Handbook of Vinyl Formulating; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2008; ISBN 978-0-471-71046-2. [Google Scholar]

- Janović, Z. Polimerizacije i Polimeri; Hrvatsko Društvo Kemijskih Inženjera i Tehnologa (HDKI): Zagreb, Croatia, 1997; ISBN 9789539604156. [Google Scholar]

- Suresha, B.; Hemanth, R.; Nithin, K.S. Automotive Applications: Reinforced Material Components. In Encyclopedia of Polymer Applications; Mishra, M., Ed.; CRC Press: Boca Raton, FL, USA; Taylor and Francis Group: Abingdon, UK, 2019; Volume 1, pp. 1444–1469. ISBN 978-1-4987-2993-2. [Google Scholar]

- Chanda, M.; Roy, S.K. Plastics Fundamentals, Properties, and Testing; CRC Press: Boca Raton, FL, USA; Taylor and Francis Group: Abingdon, UK, 2009; ISBN 978-1-4200-8060-5. [Google Scholar]

- Wypych, G. Handbook of Polymers; ChemTec Publishing: Toronto, ON, Canada, 2012; ISBN 978-1-895198-47-8. [Google Scholar]

- Akovali, G. Advances in Polymer Coated Textiles; Smithers Rapra Technology Ltd.: Shawbury, UK, 2012; ISBN 978-1-84735-497-6. [Google Scholar]

- Patrick, S. Practical Guide to Polyvinyl Chloride; Smithers Rapra Technology Ltd.: Shawbury, UK, 2005; ISBN 1-85957-511-01. [Google Scholar]

- Sen, A.K. Coated Textiles: Principles and Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA; Taylor and Francis Group: Abingdon, UK, 2008; ISBN 978-1-4200-5345-6. [Google Scholar]

- Mishra, M.K.; Yagci, Y. Handbook of Vinyl Polymers: Radical Polymerization, Process, and Technology, 2nd ed.; CRC Press: Boca Raton, FL, USA; Taylor and Francis Group: Abingdon, UK, 2009; ISBN 978-0-8247-2595-2. [Google Scholar]

- Mishra, M.K.; Yagci, Y. Handbook of Radical Vinyl Polymerization; Marcel Dekker, Inc.: New York, NY, USA, 1998; ISBN 0-8247-9464-8. [Google Scholar]

- Klein, P.; Kennedy, M. Fundamentals of Plastics Thermoforming; Springer Nature: Berlin/Heidelberg, Germany, 2009; ISBN 978-3-031-63527-4. [Google Scholar]

- Biron, M. Thermosets and Composites: Technical Information for Plastics Users; Elsevier Ltd.: Oxford, UK, 2004; ISBN 1856174115. [Google Scholar]

- The European Council of Vinyl Manufacturers (ECVM) and Plastics Europe. Eco-Profiles of the European Plastics Industry: POLYVINYL CHLORIDE (PVC) (SUSPENSION POLYMERISATION). 2005. Available online: https://www.inference.org.uk/sustainable/LCA/elcd/external_docs/spvc_60635d04-5246-45d7-90a5-59a203bd9369.pdf (accessed on 13 April 2025).

- Elduque, A.; Elduque, D.; Pina, C.; Clavería, I.; Javierre, C. Correction: Elduque, A., et al. Electricity Consumption Estimation of the Polymer Material Injection-Molding Manufacturing Process: Empirical Model and Application. Materials 2020, 13, 2548. [Google Scholar] [CrossRef] [PubMed]

- Socks, M. The Promise of All-Electric Injection Molding Machines: A Promise Kept? ACEEE Summer Study on Energy Efficiency in Industry. 2005. Available online: https://www.aceee.org/files/proceedings/2005/data/papers/SS05_Panel01_Paper15.pdf (accessed on 29 November 2025).

- Chen, J.-Y.; Yang, K.-J.; Huang, M.-S. Optimization of clamping force for low-viscosity polymer injection molding. Polym. Test. 2020, 90, 106700. [Google Scholar] [CrossRef]

- Ferreira, É.J.; Dias, M.D.M.; Schneider, E.L. Analysis of Non-Uniform Expansion Behavior of Injected EVA. Acad. J. Polym. Sci. 2018, 1, 555569. [Google Scholar] [CrossRef]

- Herrera-Rodríguez, T.C.; Ramos-Olmos, M.; González-Delgado, Á.D. A joint economic evaluation and FP2O technoeconomic resilience approach for evaluation of suspension PVC production. Results Eng. 2024, 24, 103069. [Google Scholar] [CrossRef]

- Aguilar-Vásquez, E.; Ramos-Olmos, M.; González-Delgado, Á.D. A Joint Computer-Aided Simulation and Water-Energy-Product (WEP) Approach for Technical Evaluation of PVC Production. Sustainability 2023, 15, 8096. [Google Scholar] [CrossRef]

- Šiprak, L. Energy Analysis of the Shoe Sole Production Process. Master’s Thesis, Faculty of Textile Technology, University of Zagreb, Zagreb, Croatia, 2025. [Google Scholar]

- Olapiriyakul, S. Assessing Water Consumption of S-PVC Resin Manufacturing Process by Life Cycle Assessment. Adv. Mater. Res. 2014, 931–932, 619–623. [Google Scholar] [CrossRef]

- Mihelić-Bogdanić, A.; Špelić, I. Energy Conversion and Process Optimization in the Process Industry, Textbook with Examples of Solved Problems. Školska knjiga d.d: Zagreb, Croatia, 2022; ISBN 978-953-0-30899-2. [Google Scholar]

- Mihelić-Bogdanić, A.; Špelić, I. Energy efficiency optimization in polyisoprene footwear production. Sustainability 2022, 14, 10799. [Google Scholar] [CrossRef]

- Eurostat. Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics#Electricity_prices_for_non-household_consumers (accessed on 5 August 2025).

- Reduced Energy Consumption in Plastics Engineering–2005 European Benchmarking Survey of Energy Consumption and Adoption of Best Practice. 2005. Available online: https://pieweb.plasteurope.com/members/pdf/P204063.PDF (accessed on 29 November 2025).

- Firth, A.; Zhang, B.; Yang, A. Quantification of global waste heat and its environmental effects. Appl. Energy 2019, 235, 1314–1334. [Google Scholar] [CrossRef]

- Viswanathan, V.V.; Davies, R.W.; Holbery, J.D. Opportunity Analysis for Recovering Energy from Industrial Waste Heat and Emissions; U.S. Department of Energy, Office of Scientific and Technical Information (OSTI): Washington, DC, USA, 2006.

- BusinessEurope. High Cost of Energy. World Wide Web. Available online: https://www.businesseurope.eu/media-room/data-hub/high-cost-of-energy/ (accessed on 27 October 2025).

- Mianehrow, H.; Abbasian, A. Energy monitoring of plastic injection molding process running with hydraulic injection molding machines. J. Clean. Prod. 2017, 148, 804–810. [Google Scholar] [CrossRef]

- Muralitharan, T. Energy Conservation in Plastic Injection Moulding Machines. Int. J. Appl. Eng. Res. 2015, 10, 769–782. [Google Scholar]

- Polyvinyl Chloride Market Size & Share Analysis-Growth Trends & Forecasts (2025–2030). Available online: https://www.mordorintelligence.com/industry-reports/polyvinyl-chloride-pvc-market (accessed on 8 May 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Špelić, I.; Mihelić-Bogdanić, A.; Šiprak, L. Energy Analysis in the PVC Shoe-Sole Production Process: From Raw Material to Final Product. Processes 2025, 13, 3936. https://doi.org/10.3390/pr13123936

Špelić I, Mihelić-Bogdanić A, Šiprak L. Energy Analysis in the PVC Shoe-Sole Production Process: From Raw Material to Final Product. Processes. 2025; 13(12):3936. https://doi.org/10.3390/pr13123936

Chicago/Turabian StyleŠpelić, Ivana, Alka Mihelić-Bogdanić, and Lucija Šiprak. 2025. "Energy Analysis in the PVC Shoe-Sole Production Process: From Raw Material to Final Product" Processes 13, no. 12: 3936. https://doi.org/10.3390/pr13123936

APA StyleŠpelić, I., Mihelić-Bogdanić, A., & Šiprak, L. (2025). Energy Analysis in the PVC Shoe-Sole Production Process: From Raw Material to Final Product. Processes, 13(12), 3936. https://doi.org/10.3390/pr13123936