Quantitative Evaluation Methods and Applications for Gravel Characteristics Distribution in Conglomerate Reservoirs

Abstract

1. Introduction

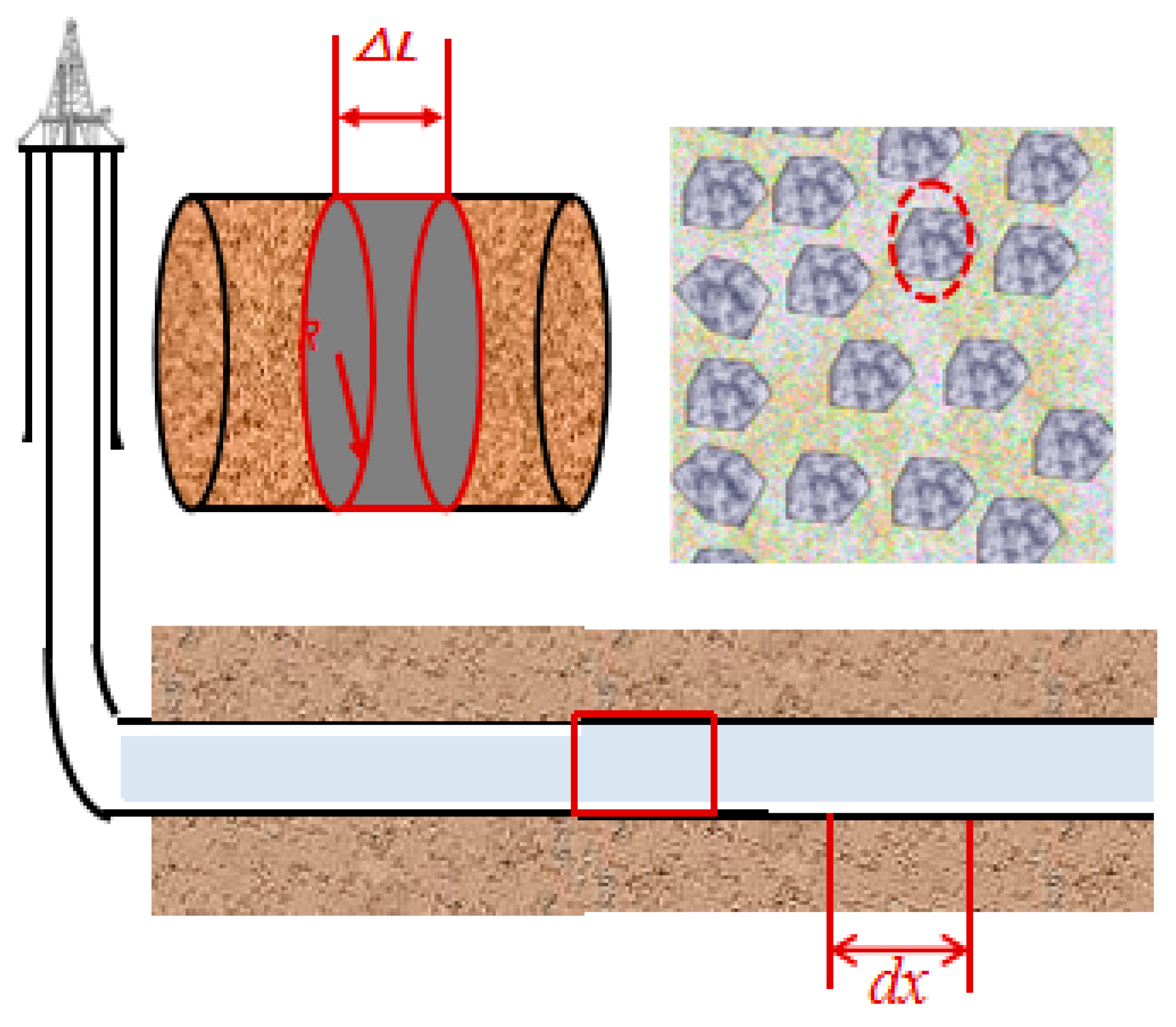

2. Establishment of the Model for Characterizing the Distribution Characteristics of Gravel Around Wells

3. Method for Assessing Gravel Distribution Characteristics

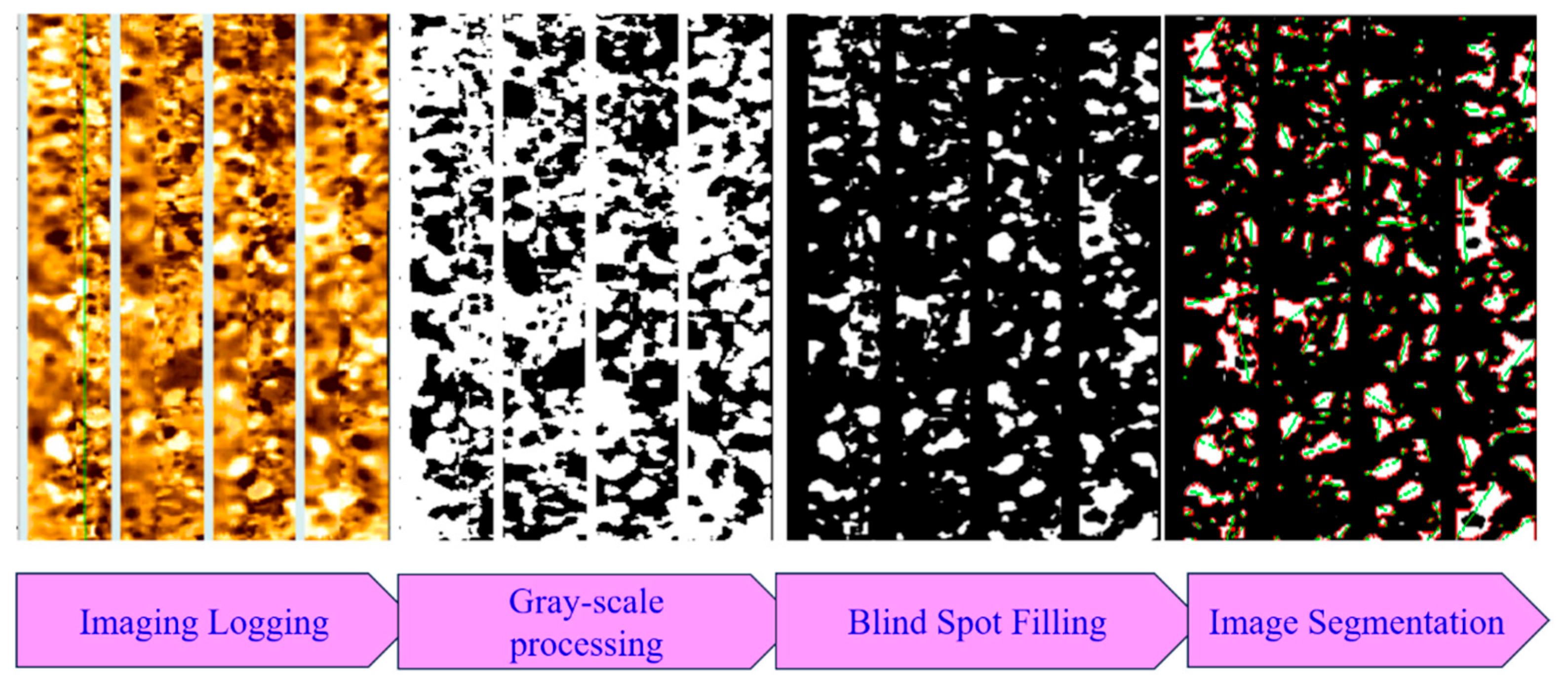

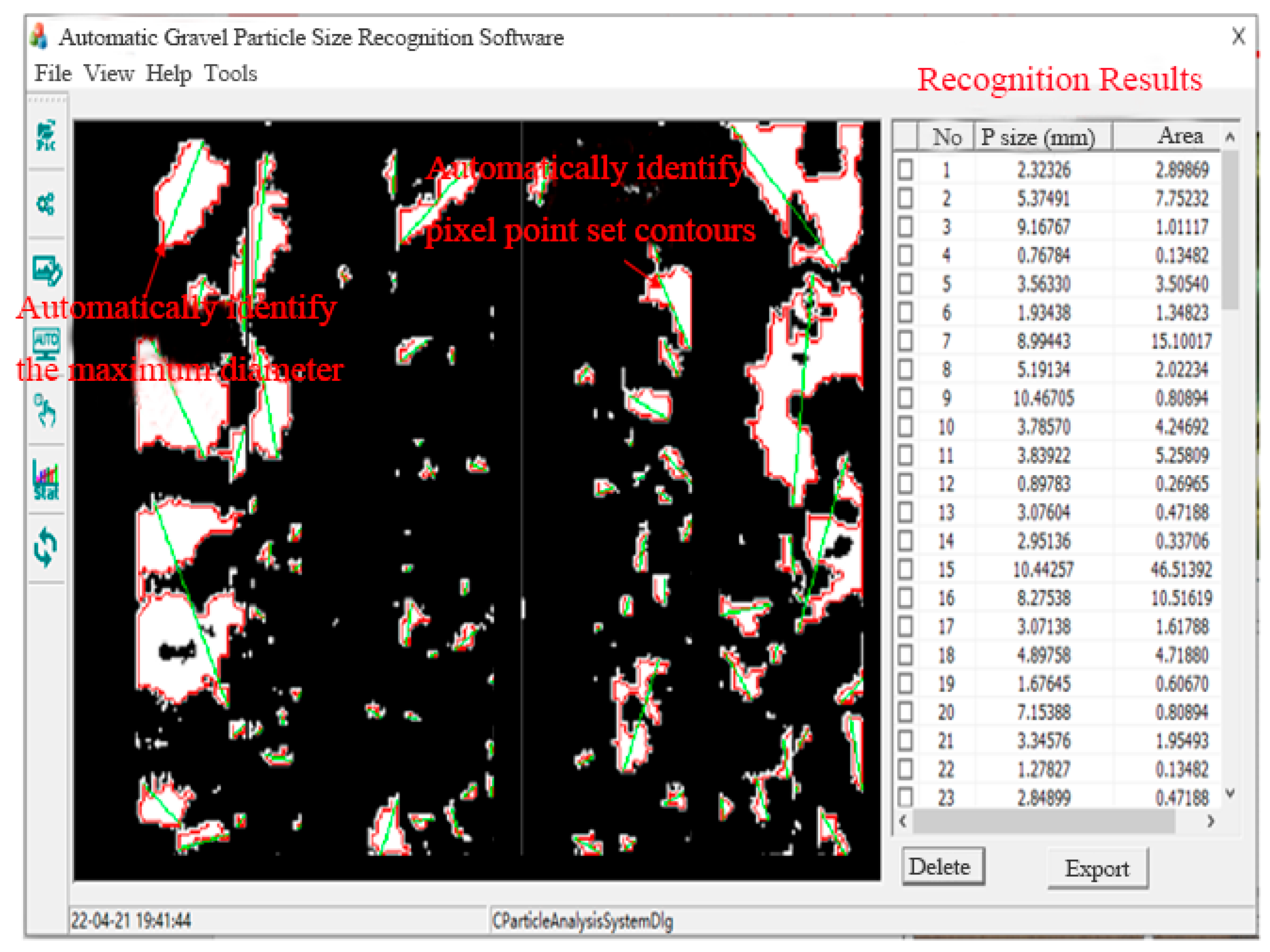

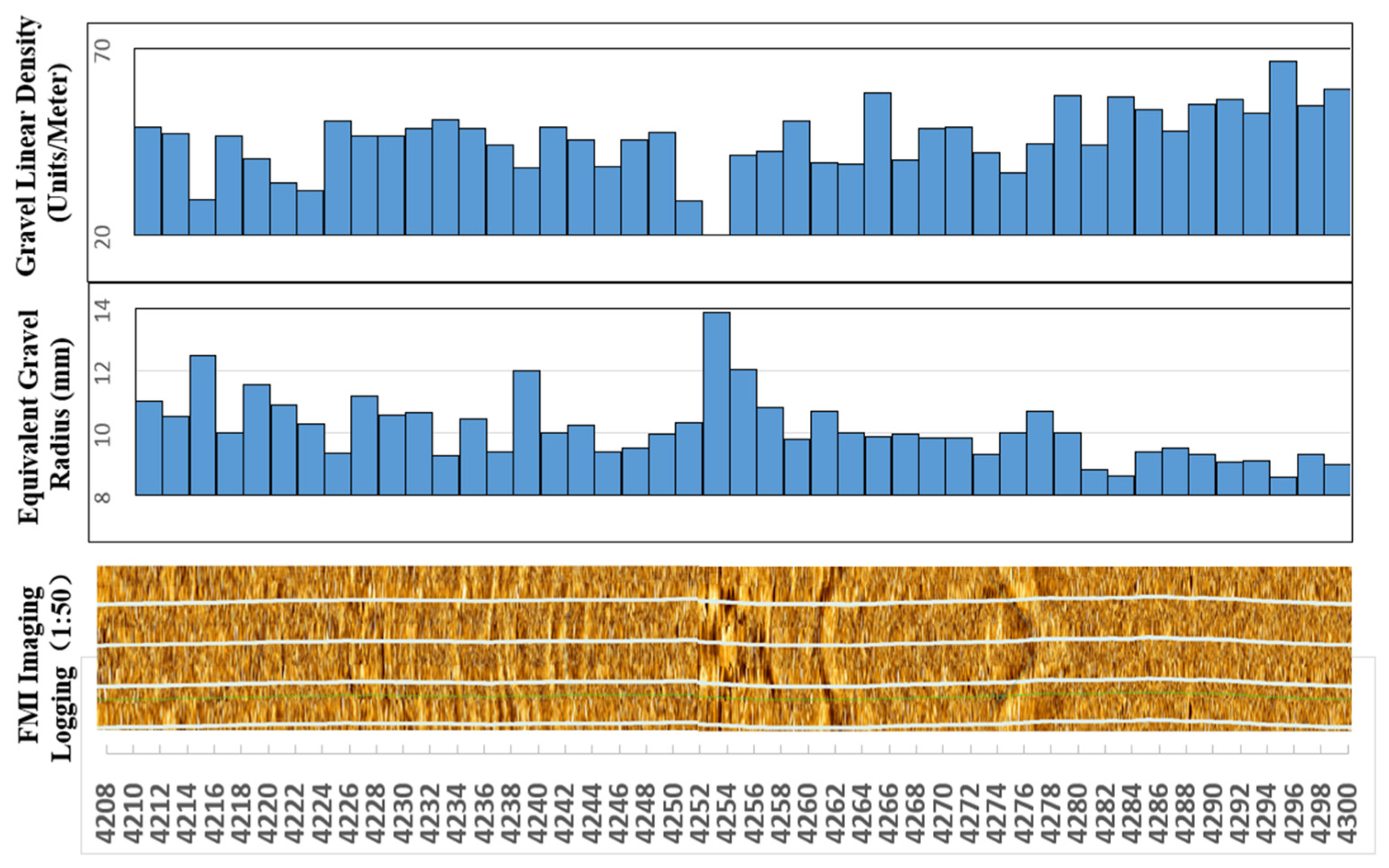

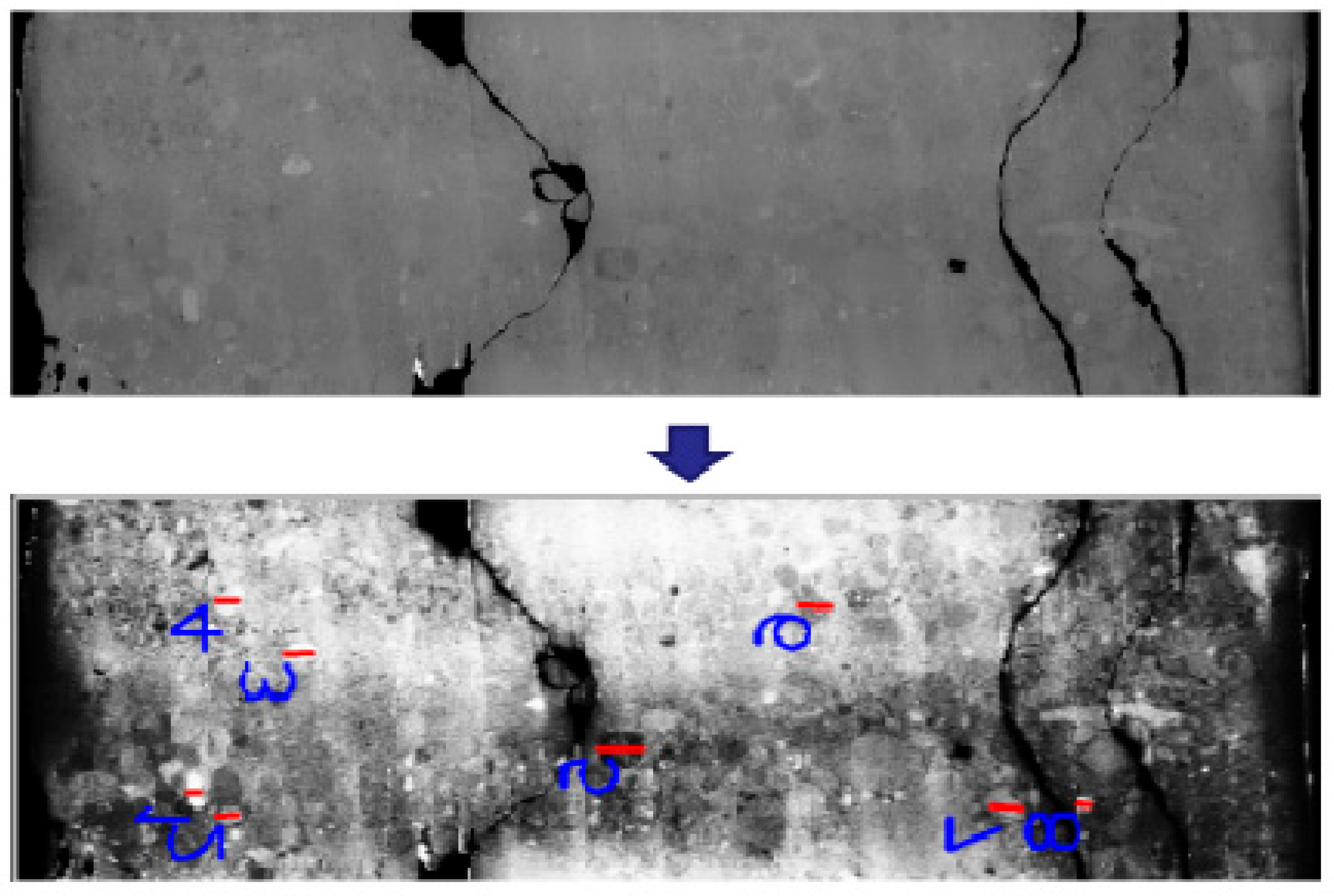

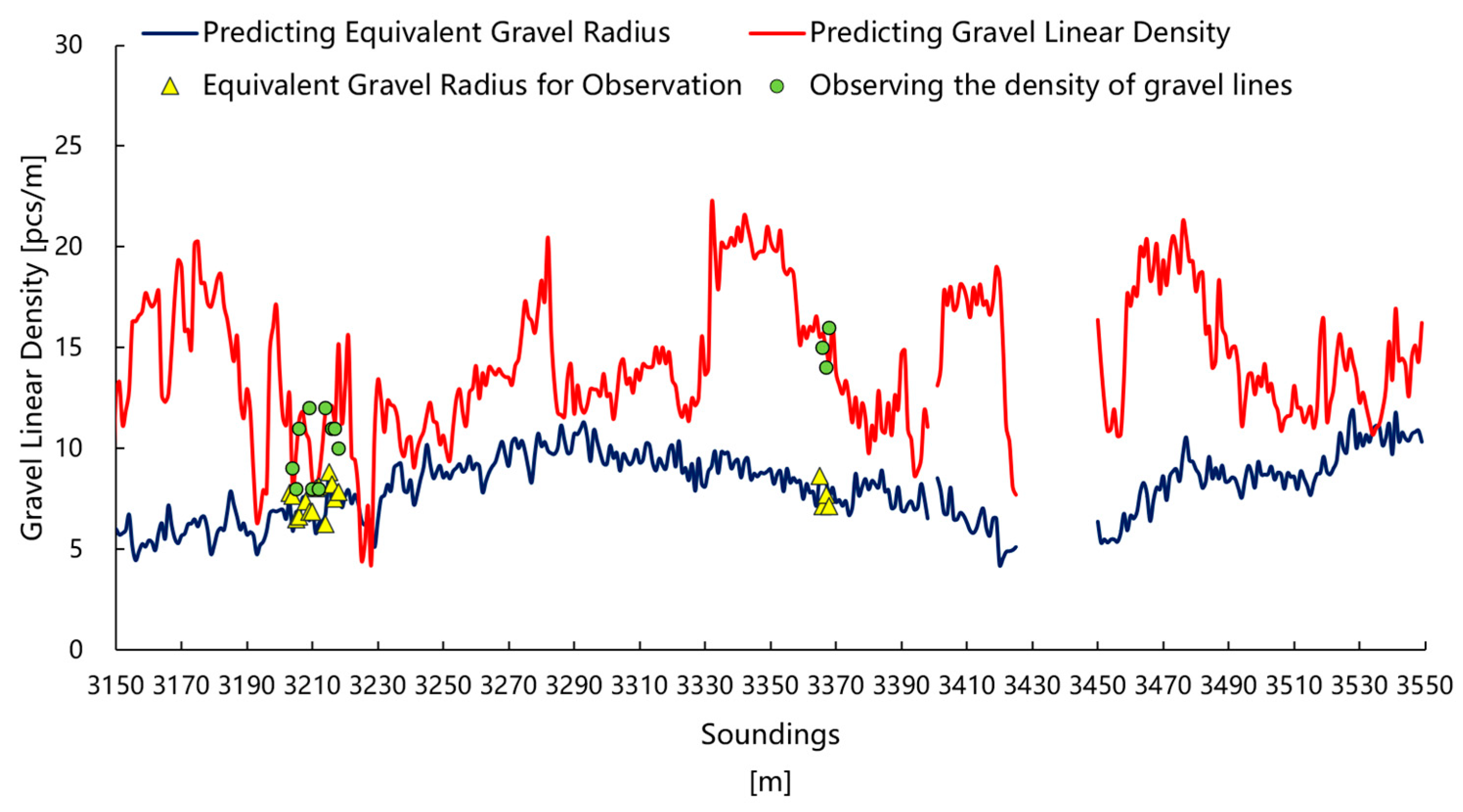

3.1. Method for Characterizing Axial Gravel Distribution in Boreholes Based on Imaging Logging

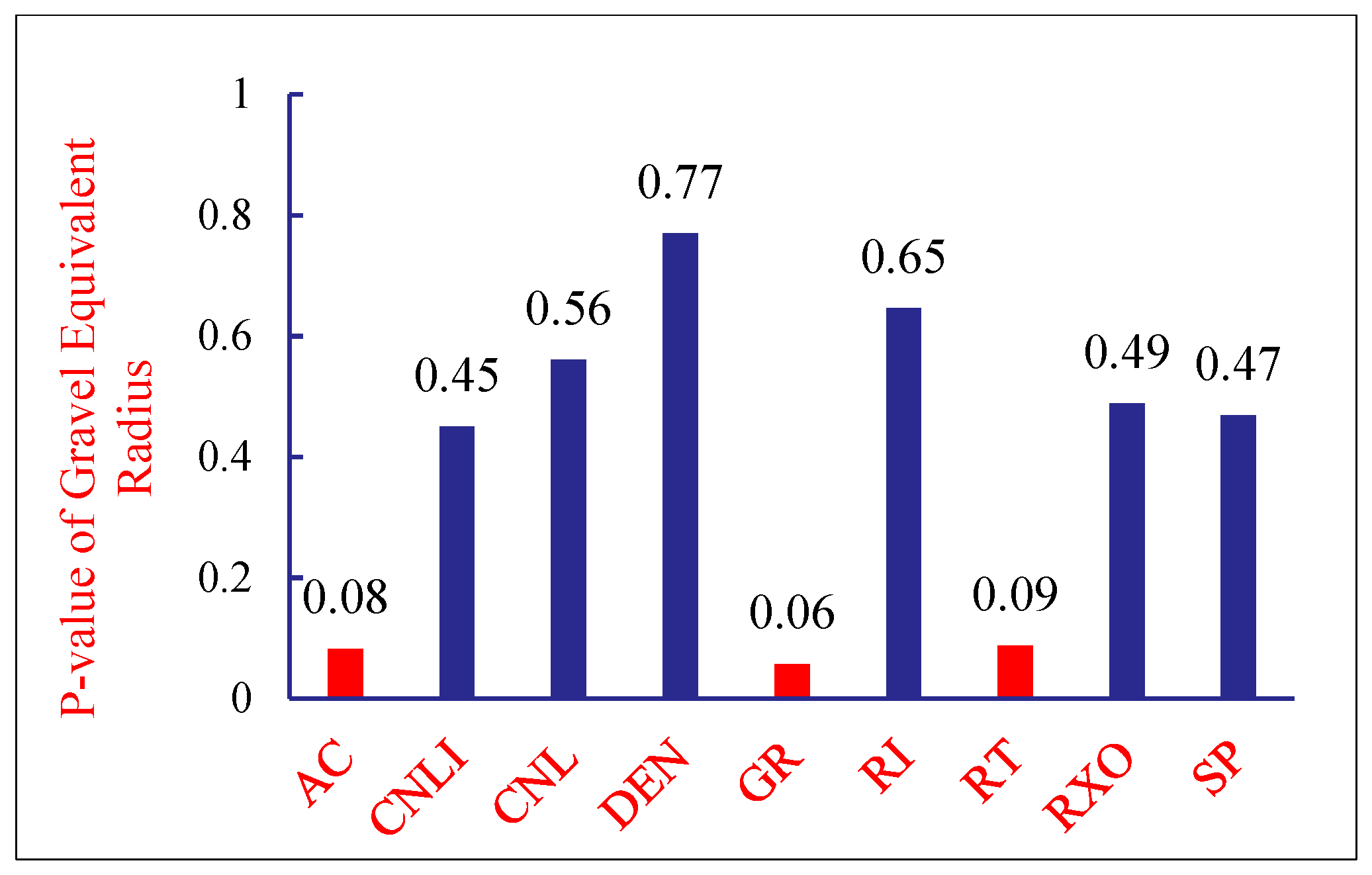

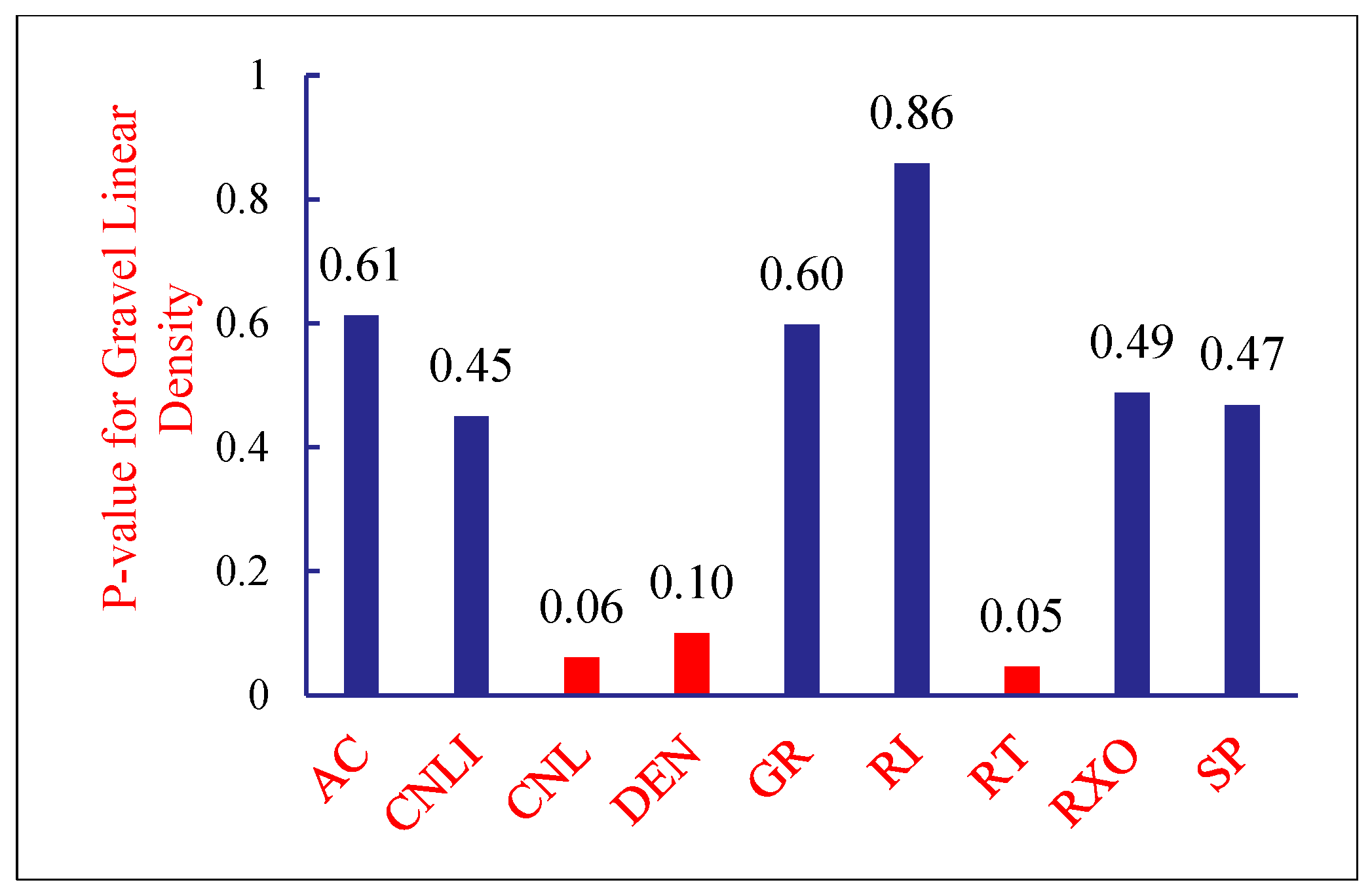

3.2. Method for Characterizing Axial Gravel Distribution in Boreholes Based on Logging Data

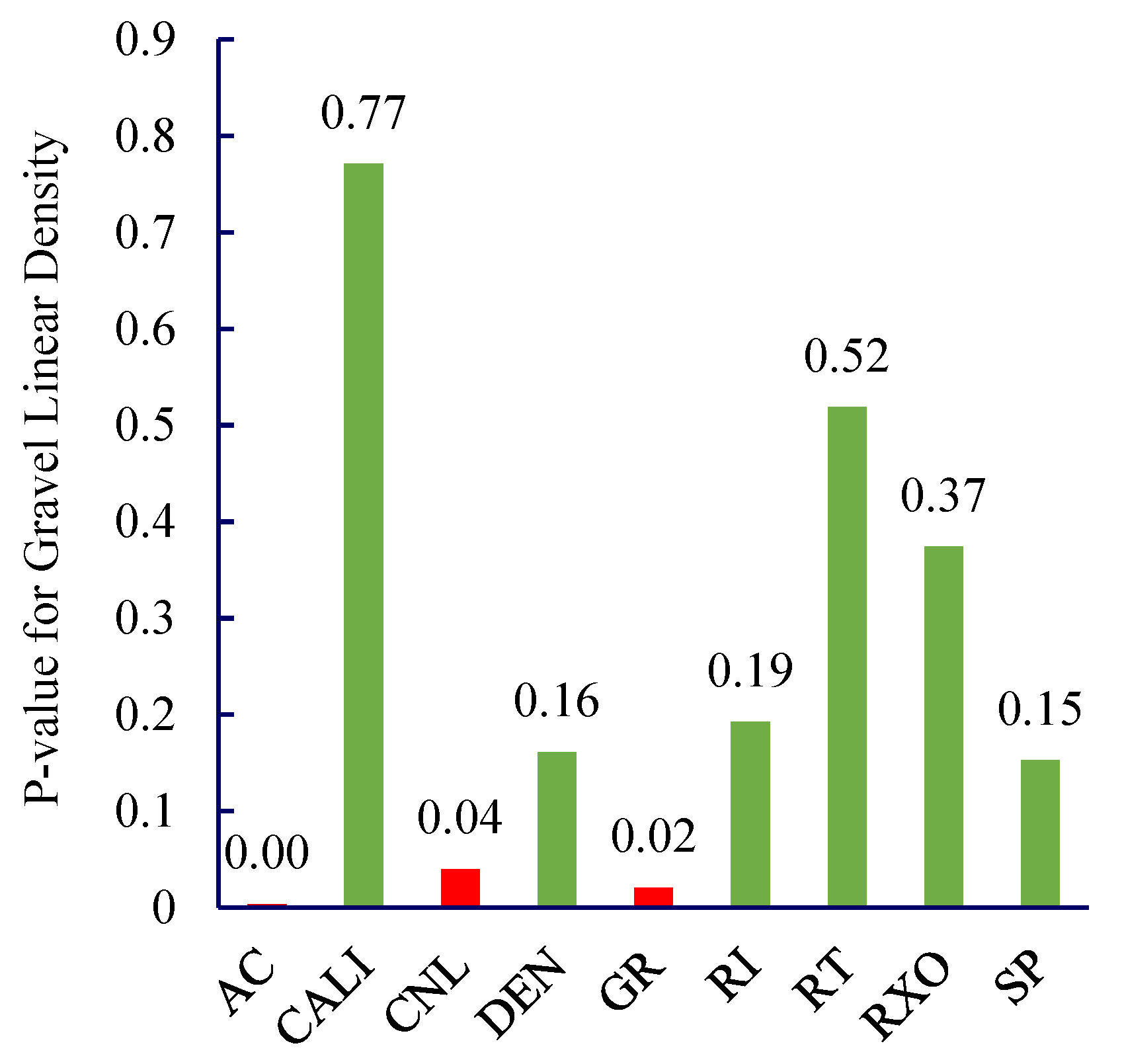

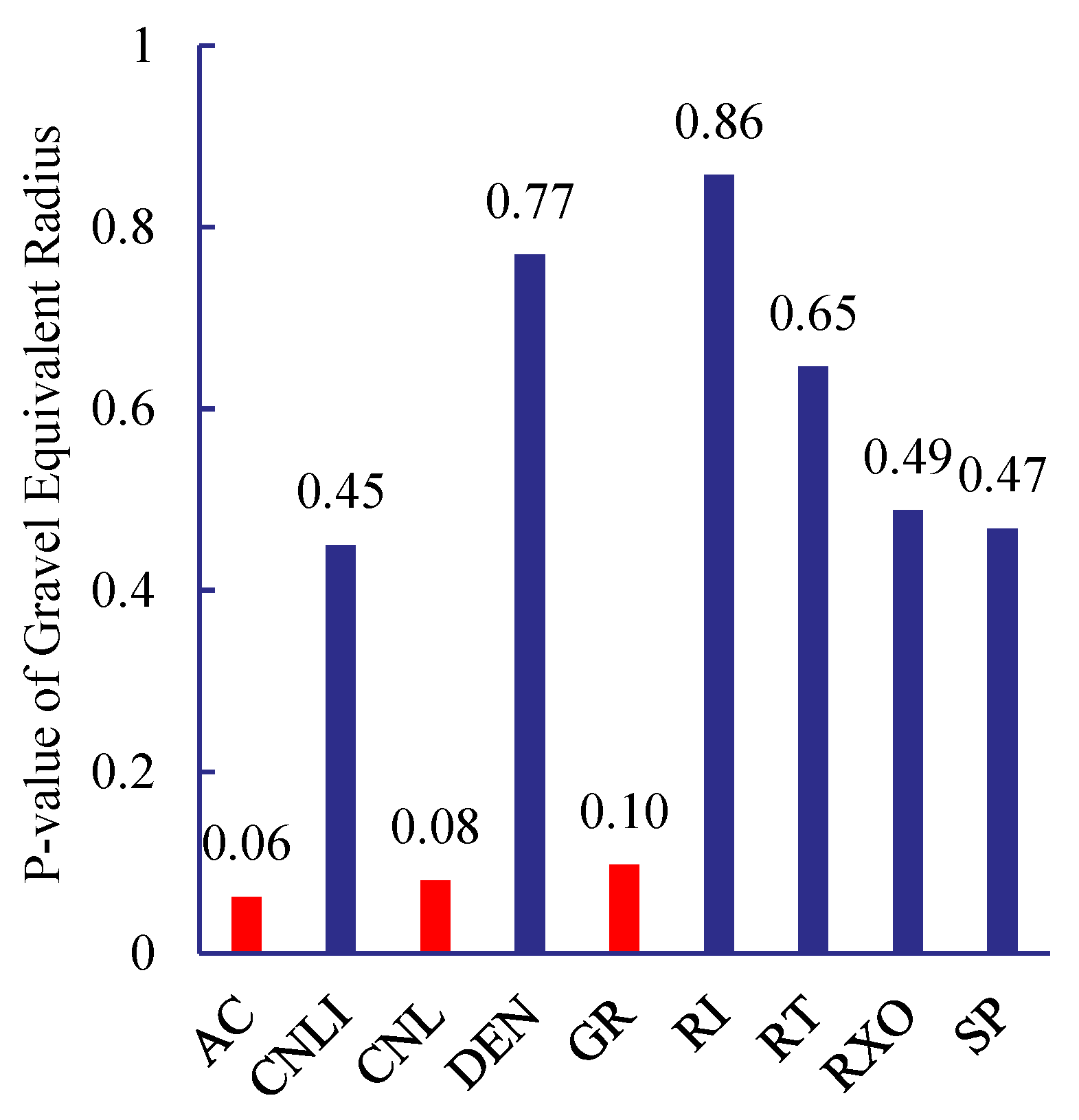

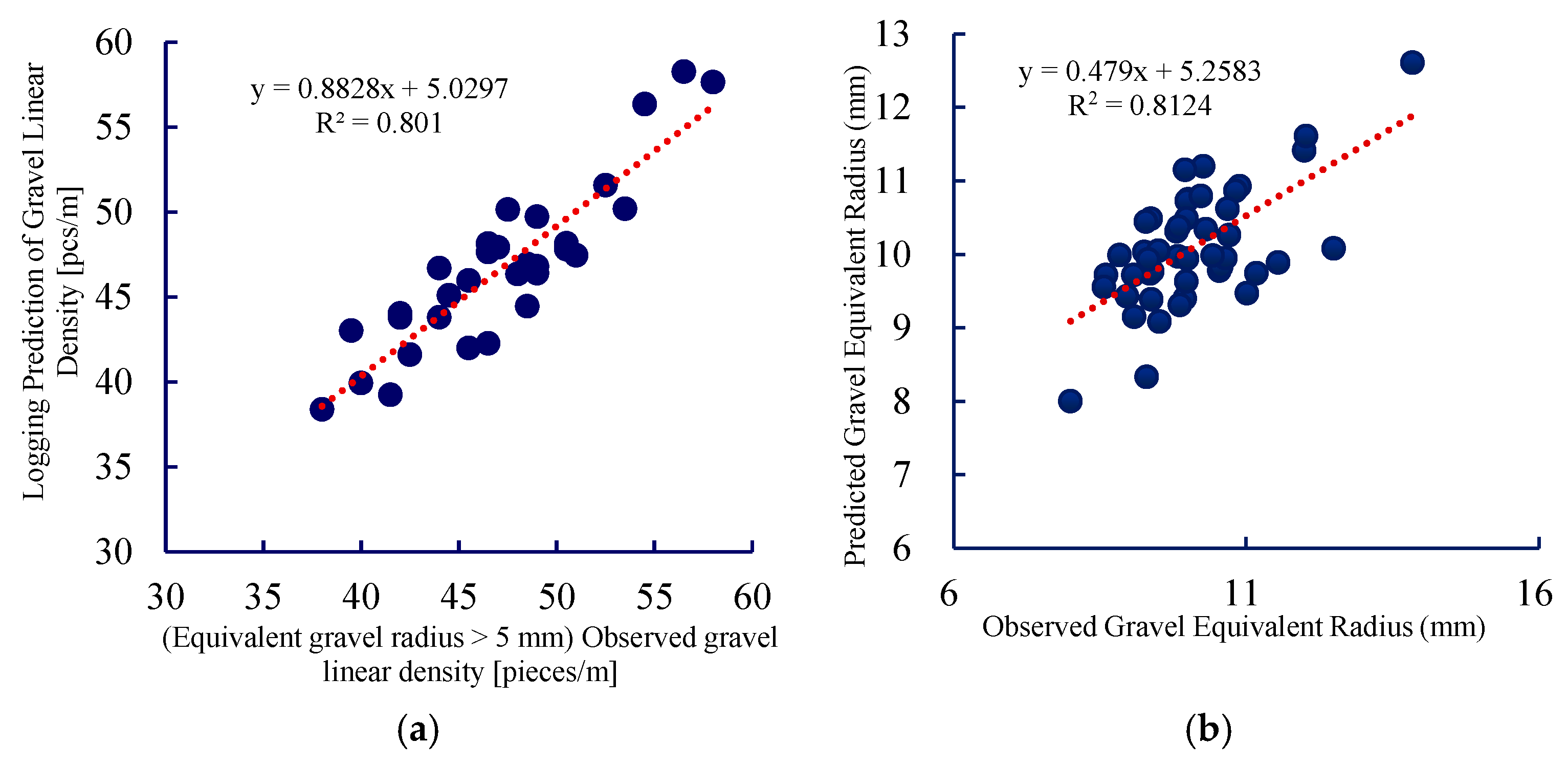

3.3. Data Standardization and Regression Diagnostics

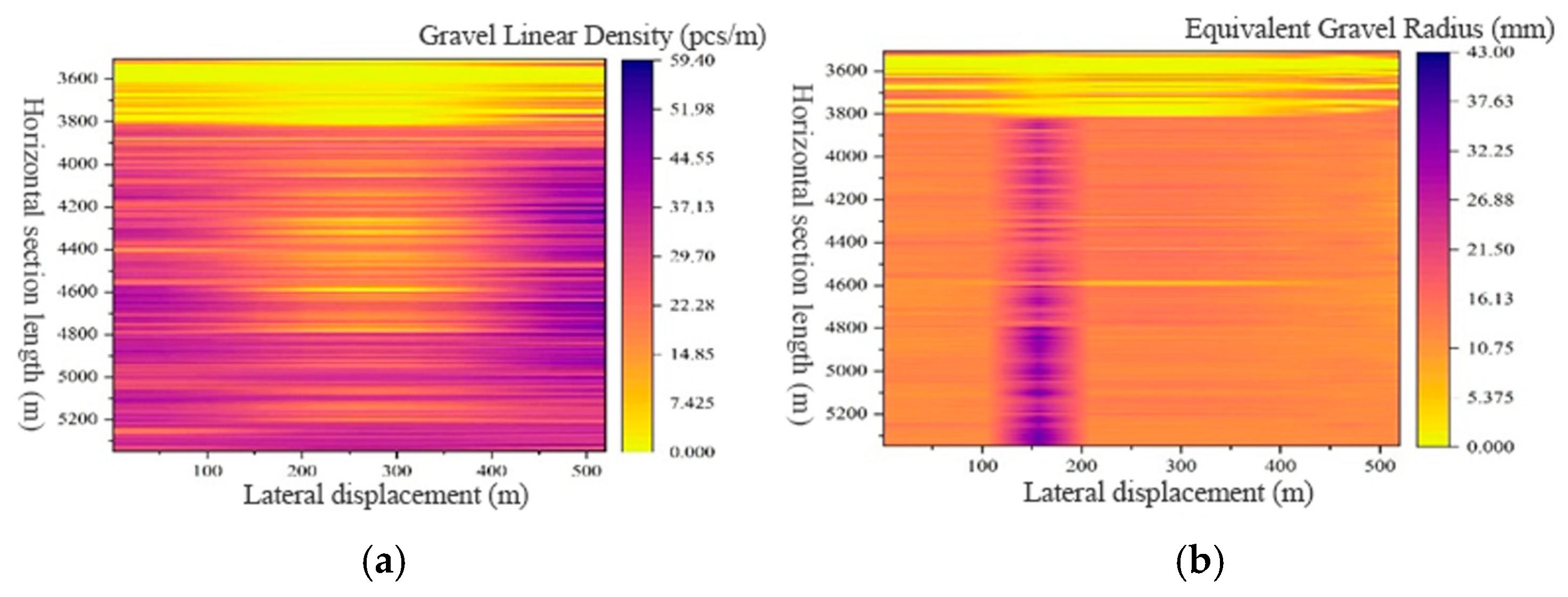

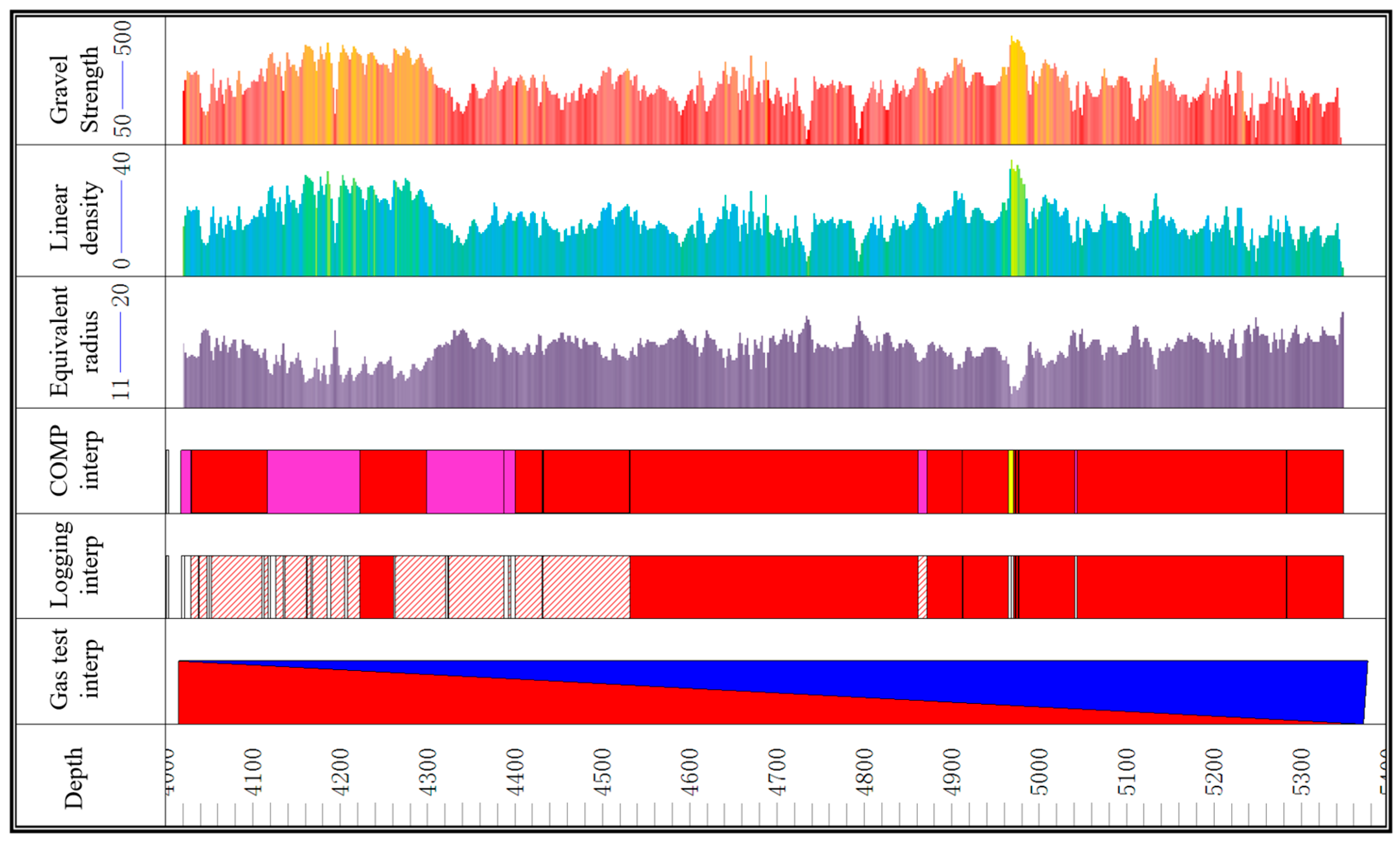

3.4. Regional Gravel Characteristic Distribution Characterization

4. Model Validation

4.1. Imaging Logging Verification

4.2. Eagle-Eye Monitoring Results Comparison and Verification

4.3. Verification of Underground Core CT Scan Results

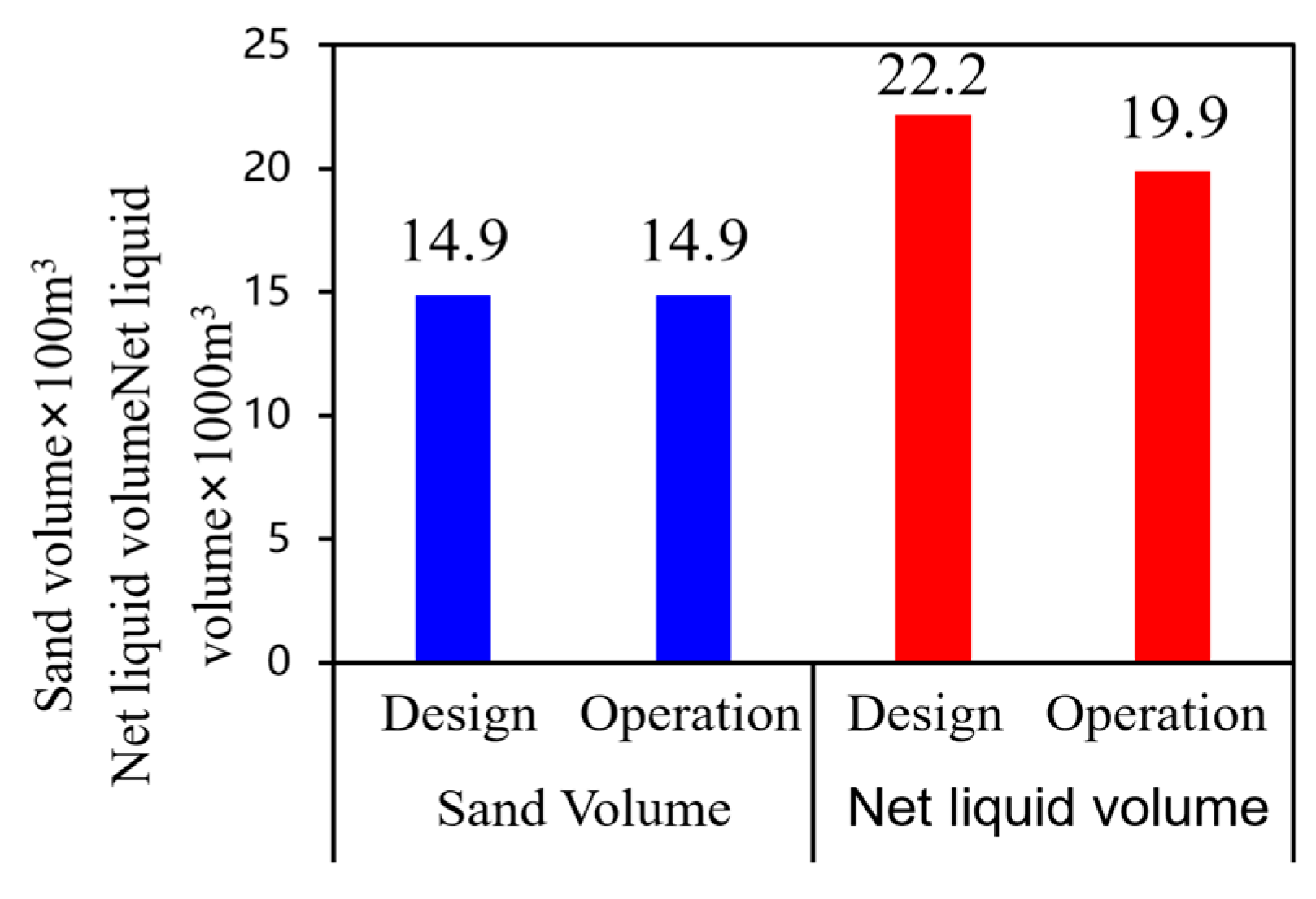

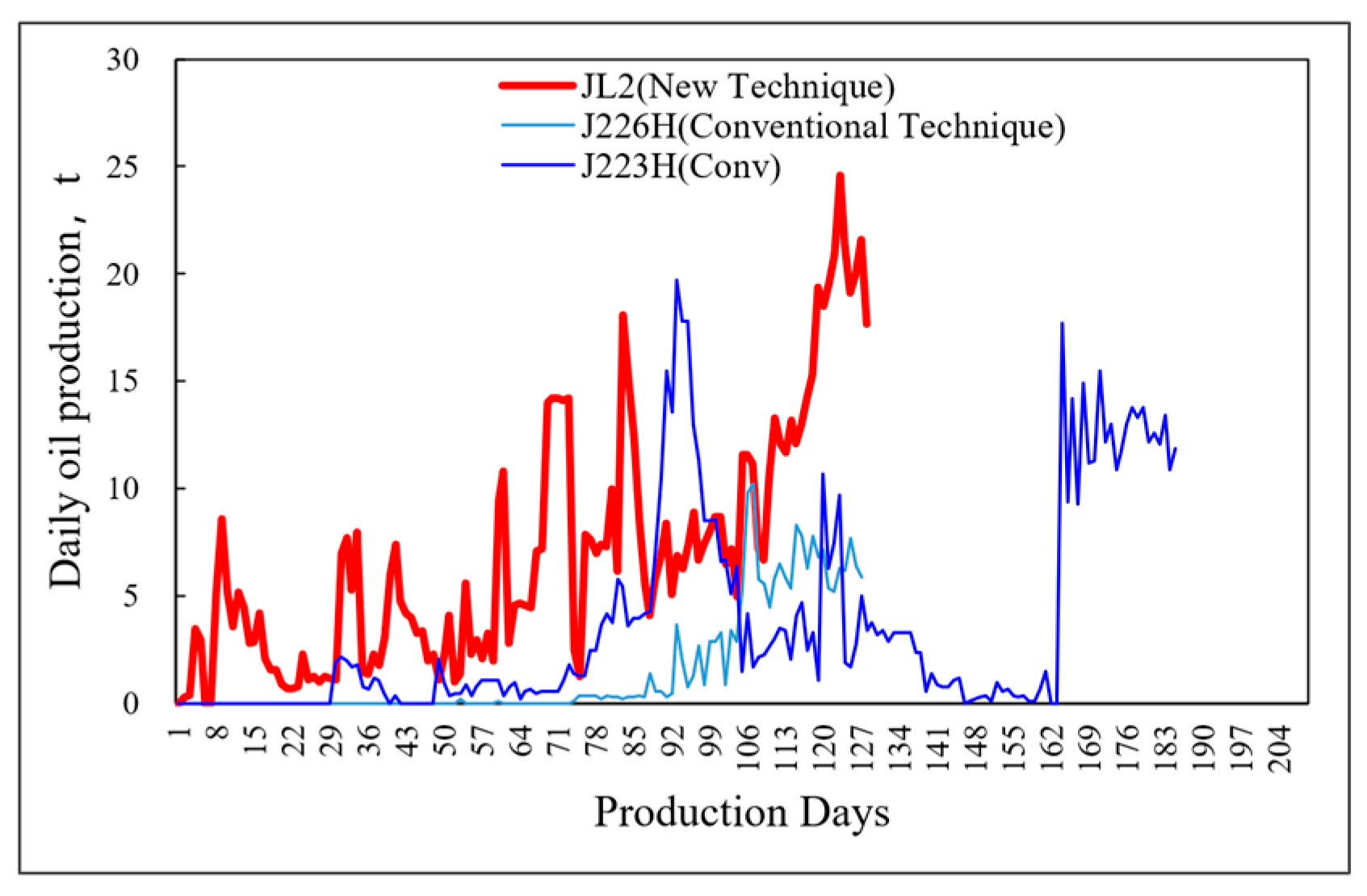

5. Field Application

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, T.; Li, Z.; Zhou, Y.; Zhang, C. Enhanced oil recovery of low-permeability cores by SiO2 nanofluid. Energy Fuels 2017, 31, 5612–5621. [Google Scholar] [CrossRef]

- Dai, C.; Wang, X.; Li, Y.; Lv, W.; Zou, C.; Gao, M.; Zhao, M. Spontaneous imbibition investigation of self-dispersing silica nanofluids for enhanced oil recovery in low-permeability cores. Energy Fuels 2017, 31, 2663–2668. [Google Scholar] [CrossRef]

- Wentworth, C.K. A scale of grade and class terms for clastic sediments. J. Geol. 1922, 30, 377–392. [Google Scholar] [CrossRef]

- Urien, C.M.; Zambrano, J.J. Petroleum Systems in the Neuquén Basin, Argentina. In The Petroleum System—From Source to Trap; Magoon, L.B., Dow, W.G., Eds.; American Association of Petroleum Geologists: Tulsa, OK, USA, 1994; Volume 60, ISBN 978-1-62981-092-8. [Google Scholar]

- Xiao, M.; Wu, S.; Yuan, X.; Xie, Z. Conglomerate Reservoir Pore Evolution Characteristics and Favorable Area Prediction: A Case Study of the Lower Triassic Baikouquan Formation in the Northwest Margin of the Junggar Basin, China. J. Earth Sci. 2021, 32, 998–1010. [Google Scholar] [CrossRef]

- Mello, M.R.; Koutsoukos, E.A.M.; Mohriak, W.U.; Bacoccoli, G. Selected Petroleum Systems in Brazil. In The Petroleum System—From Source to Trap; Magoon, L.B., Dow, W.G., Eds.; American Association of Petroleum Geologists: Tulsa, OK, USA, 1994; Volume 60, ISBN 978-1-62981-092-8. [Google Scholar]

- Zou, Y.; Shi, S.; Zhang, S.; Yu, T.; Tian, G.; Ma, X.; Zhang, Z. Experimental Modeling of Sanding Fracturing and Conductivity of Propped Fractures in Conglomerate: A Case Study of Tight Conglomerate of Mahu Sag in Junggar Basin, NW China. Pet. Explor. Dev. 2021, 48, 1383–1392. [Google Scholar] [CrossRef]

- Yi, Y.; Wang, L.; Li, J.; Chen, S.; Tian, H.; Tian, G. Optimization of Re-Fracturing Method and Fracture Parameters for Horizontal Well in Mahu Conglomerate Oil Reservoir. Front. Energy Res. 2022, 10, 856524. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, J.; Mavko, G.M. Reservoir Characterization Using Perforation Shots: Anisotropy, Attenuation and Uncertainty Analysis. Geophys. J. Int. 2019, 216, 470–485. [Google Scholar] [CrossRef]

- Wu, J.; Yang, S.; Gan, B.; Cao, Y.; Zhou, W.; Kou, G.; Wang, Z.; Li, Q.; Dong, W.; Zhao, B. Pore Structure and Movable Fluid Characteristics of Typical Sedimentary Lithofacies in a Tight Conglomerate Reservoir, Mahu Depression, Northwest China. ACS Omega 2021, 6, 23243–23261. [Google Scholar] [CrossRef] [PubMed]

- Han, B.; Wang, B.; Luo, F.; Zhang, Y.; Han, B.; Xia, Y.; Ding, W. Analysis and Application of Seismic Velocity Characteristics in Areas with near Surface Conglomerate Development: A Case Study in YKB Area in Kuqa Piedmont Zone. China Pet. Explor. 2023, 28, 117–125. [Google Scholar] [CrossRef]

- Fu, Y.; Cheng, R.; Gao, Y.; Zhou, Y.; Xu, Z. Early Cretaceous Sedimentary Records of the Early-Stage Continental Rifting in the Songliao Basin, NE China. J. Asian Earth Sci. 2024, 259, 105913. [Google Scholar] [CrossRef]

- Yuan, R.; Yang, B.; Huang, L.; Hu, W. Utilizing Borehole Electrical Images to Evaluate Sorting of Conglomeratic Formation: Example from Lower Triassic Baikouquan Formation in Well M152, Mahu Depression, Junggar Basin, China. Arab. J. Geosci 2020, 13, 408. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Chai, Y.; Xin, Y.; Wu, Q.; Zhang, X.; Sun, Y. Deep Burial Diagenesis and Reservoir Quality Evolution of High-Temperature, High-Pressure Sandstones: Examples from Lower Cretaceous Bashijiqike Formation in Keshen Area, Kuqa Depression, Tarim Basin of China. AAPG Bull. 2017, 101, 829–862. [Google Scholar] [CrossRef]

- Zhou, Z.; Hilterman, F.J. A Comparison between Methods That Discriminate Fluid Content in Unconsolidated Sandstone Reservoirs. Geophysics 2010, 75, B47–B58. [Google Scholar] [CrossRef]

- Yuan, R.; Zhang, L.; Xu, Q.; Feng, Y.; An, Z.; Wu, J.; Zhao, K.; Liu, S.; Huang, P. Utilizing Borehole Electrical Image and Conventional Logs to Characterize Petrology of Mixed Volcanic and Sedimentary Rocks in Jiamuhe Formation at JL2 Wellfield, Zhongguai Uplift, Junggar Basin, NW China. Arab. J. Geosci. 2020, 13, 1209. [Google Scholar] [CrossRef]

- Kumara, G.H.A.J.J.; Hayano, K.; Ogiwara, K. Image Analysis Techniques on Evaluation of Particle Size Distribution of Gravel. GEOMATE J. 2012, 3, 290–297. [Google Scholar] [CrossRef]

- Yu, S.Y.; Li, S.H.; Li, J.; Song, D.W.; Shi, J.H. An Algorithm for Particle Size Analysis of Gravel Image by Using Gray-Value Vibration Frequency. Appl. Mech. Mater. 2013, 318, 253–256. [Google Scholar] [CrossRef]

- Wang, L.; Lu, J.; Luo, Y.; Ren, B.; Li, A.; Zhao, N. An Automated Quantitative Methodology for Computing Gravel Parameters in Imaging Logging Leveraging Deep Learning: A Case Analysis of the Baikouquan Formation within the Mahu Sag. Processes 2024, 12, 1337. [Google Scholar] [CrossRef]

- Xie, F.; Xiao, C.; Liu, R.; Zhang, L. Multi-threshold de-noising of electrical imaging logging data based on the wavelet packet transform. J. Geophys. Eng. 2017, 14, 900–908. [Google Scholar] [CrossRef]

- Guimaraes, C.; Piazza, R. Optimizing Image Logging Acquisition with Deep Learning. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 23–25 September 2024. [Google Scholar] [CrossRef]

- de Jesus, C.M.; Compan, A.L.M.; Surmas, R. Permeability Estimation Using Ultrasonic Borehole Image Logs in Dual-Porosity Carbonate Reservoirs. Petrophysics 2016, 57, 620–637. Available online: https://onepetro.org/petrophysics/article/57/06/620/171448/Permeability-Estimation-Using-Ultrasonic-Borehole (accessed on 9 November 2025).

- Aghli, G.; Moussavi-Harami, R.; Mohammadian, R. Reservoir Heterogeneity and Fracture Parameter Determination Using Electrical Image Logs and Petrophysical Data (a Case Study, Carbonate Asmari Formation, Zagros Basin, SW Iran). Pet. Sci. 2020, 17, 51–69. [Google Scholar] [CrossRef]

- Xie, F.; Zhang, C.; Liu, R.; Xiao, C. Production Prediction for Fracture-Vug Carbonate Reservoirs Using Electric Imaging Logging Data. Pet. Explor. Dev. 2018, 45, 369–376. [Google Scholar] [CrossRef]

- Zohreh, M.; Junin, R.; Jeffreys, P. Evaluate the Borehole Condition to Reduce Drilling Risk and Avoid Potential Well Bore Damages by Using Image Logs. J. Pet. Sci. Eng. 2014, 122, 318–330. [Google Scholar] [CrossRef]

- Wood, D.A. Expanding Role of Borehole Image Logs in Reservoir Fracture and Heterogeneity Characterization: A Review. Adv. Geo-Energy Res. 2024, 12, 194–204. [Google Scholar] [CrossRef]

- Dias, L.O.; Bom, C.R.; Faria, E.L.; Valentín, M.B.; Correia, M.D.; de Albuquerque, M.P.; de Albuquerque, M.P.; Coelho, J.M. Automatic Detection of Fractures and Breakouts Patterns in Acoustic Borehole Image Logs Using Fast-Region Convolutional Neural Networks. J. Pet. Sci. Eng. 2020, 191, 107099. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Wang, S.; Cao, J.; Li, M.; Pang, X.; Han, C.; Fan, X.; Yang, L.; He, Z.; et al. A Review on the Applications of Image Logs in Structural Analysis and Sedimentary Characterization. Mar. Pet. Geol. 2018, 95, 139–166. [Google Scholar] [CrossRef]

- Li, N.; Liu, P.; Wu, H.; Li, Y.; Zhang, W.; Wang, K.; Feng, Z.; Wang, H. Development and Prospect of Acoustic Reflection Imaging Logging Processing and Interpretation Method. Pet. Explor. Dev. 2024, 51, 839–851. [Google Scholar] [CrossRef]

- Du, L.; Lu, X.; Li, H. Automatic Fracture Detection from the Images of Electrical Image Logs Using Mask R-CNN. Fuel 2023, 351, 128992. [Google Scholar] [CrossRef]

- Fernández-Ibáñez, F.; DeGraff, J.M.; Ibrayev, F. Integrating Borehole Image Logs with Core: A Method to Enhance Subsurface Fracture Characterization. AAPG Bull. 2018, 102, 1067–1090. [Google Scholar] [CrossRef]

- Xiao, L.; Li, J.; Mao, Z.; Yu, H. A Method to Evaluate Pore Structures of Fractured Tight Sandstone Reservoirs Using Borehole Electrical Image Logging. AAPG Bull. 2020, 104, 205–226. [Google Scholar] [CrossRef]

- Huang, J.; Peng, S.; Wang, X.; Xiao, K. Applications of Imaging Logging Data in the Research of Fracture and Ground Stress. Acta Pet. Sin. 2006, 27, 65–69. [Google Scholar] [CrossRef]

- Roussel, N.P.; Sharma, M.M. Optimizing Fracture Spacing and Sequencing in Horizontal-Well Fracturing. SPE Prod. Oper. 2011, 26, 173–184. [Google Scholar] [CrossRef]

- Waters, G.; Dean, B.; Downie, R.; Kerrihard, K.; Austbo, L.; McPherson, B. Simultaneous Hydraulic Fracturing of Adjacent Horizontal Wells in the Woodford Shale. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 19–21 January 2009. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, H.; Liu, X.; Liu, X.; Luo, P.; Liang, L. Numerical Analysis of the Hydraulic Fracture Propagation Behavior Encountering Gravel in Conglomerate Reservoirs. Sci. Rep. 2025, 15, 1869. [Google Scholar] [CrossRef]

- Tian, F.; Liu, Z.; Zhou, J.; Shao, J. Rock Cracking Simulation in Tension and Compression by Peridynamics Using a Novel Contact-Friction Model with a Twin Mesh and Potential Functions. J. Rock Mech. Geotech. Eng. 2025, 17, 3395–3419. [Google Scholar] [CrossRef]

- Zheng, Y.; Baudet, B.A. Evolution of Nano-Pores in Illite-Dominant Clay during Consolidation. Acta Geotech. 2024, 19, 71–83. [Google Scholar] [CrossRef]

- Al-Kobaisi, M.; Ozkan, E.; Kazemi, H. A Hybrid Numerical/Analytical Model of a Finite-Conductivity Vertical Fracture Intercepted by a Horizontal Well. SPE Reserv. Eval. Eng. 2006, 9, 345–355. [Google Scholar] [CrossRef]

- Raghavan, R.S.; Chen, C.-C.; Agarwal, B. An Analysis of Horizontal Wells Intercepted by Multiple Fractures. SPE J. 1997, 2, 235–245. [Google Scholar] [CrossRef]

- Daneshy, A. Analysis of Horizontal Well Fracture Interactions, and Completion Steps for Reducing the Resulting Production Interference. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018. [Google Scholar] [CrossRef]

- Chen, J. The Influence of Tensile Strength Difference with Variable Gravel Sizes on the Hydraulic Fracture Propagation in the Conglomerate Reservoir. Geofluids 2022, 2022, 5290189. [Google Scholar] [CrossRef]

- Ozkan, E.; Brown, M.; Raghavan, R.; Kazemi, H. Comparison of Fractured Horizontal-Well Performance in Conventional and Unconventional Reservoirs. In Proceedings of the SPE Western Regional Meeting, San Jose, CA, USA, 24–26 March 2009. [Google Scholar] [CrossRef]

- Ozkan, E.; Brown, M.; Raghavan, R.; Kazemi, H. Comparison of Fractured-Horizontal-Well Performance in Tight Sand and Shale Reservoirs. SPE Reserv. Eval. Eng. 2011, 14, 248–259. [Google Scholar] [CrossRef]

- Daneshy, A.; King, G. Horizontal Well Frac-Driven Interactions: Types, Consequences, and Damage Mitigation. J. Pet. Technol. 2019, 71, 45–47. [Google Scholar] [CrossRef]

- Kumar, D.; Ghassemi, A. A Three-Dimensional Analysis of Simultaneous and Sequential Fracturing of Horizontal Wells. J. Pet. Sci. Eng. 2016, 146, 1006–1025. [Google Scholar] [CrossRef]

- Lei, Q.; Xu, Y.; Cai, B.; Guan, B.; Wang, X.; Bi, G.; Li, H.; Li, S.; Ding, B.; Fu, H.; et al. Progress and Prospects of Horizontal Well Fracturing Technology for Shale Oil and Gas Reservoirs. Pet. Explor. Dev. 2022, 49, 191–199. [Google Scholar] [CrossRef]

- Li, Y.; Hubuqin; Wu, J.; Zhang, J.; Yang, H.; Zeng, B.; Xiao, Y.; Liu, J. Optimization Method of Oriented Perforation Parameters Improving Uneven Fractures Initiation for Horizontal Well Fracturing. Fuel 2023, 349, 128754. [Google Scholar] [CrossRef]

- Liu, N.; Zhang, Z.; Zou, Y.; Ma, X.; Zhang, Y. Propagation Law of Hydraulic Fractures during Multi-Staged Horizontal Well Fracturing in a Tight Reservoir. Pet. Explor. Dev. 2018, 45, 1129–1138. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, A.; Tang, Y.; Wang, X.; Xiong, J. Investigation on the Influences of Gravel Characteristics on the Hydraulic Fracture Propagation in the Conglomerate Reservoirs. Nat. Gas Ind. B 2022, 9, 232–239. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, J.; Ren, C.; Elbaz, K.; Zhu, D.; Cai, Y. Fatigue Behaviour Characteristics and Life Prediction of Rock under Low-Cycle Loading. Int. J. Min. Sci. Technol. 2025, 35, 737–752. [Google Scholar] [CrossRef]

- Fan, X.; Wang, G.; Dai, Q.; Li, Y.; Zhang, F.; He, Z.; Li, Q. Using Image Logs to Identify Fluid Types in Tight Carbonate Reservoirs via Apparent Formation Water Resistivity Spectrum. J. Pet. Sci. Eng. 2019, 178, 937–947. [Google Scholar] [CrossRef]

- Lai, J.; Pang, X.; Xiao, Q.; Shi, Y.; Zhang, H.; Zhao, T.; Chen, J.; Wang, G.; Qin, Z. Prediction of Reservoir Quality in Carbonates via Porosity Spectrum from Image Logs. J. Pet. Sci. Eng. 2019, 173, 197–208. [Google Scholar] [CrossRef]

| Gravel Parameters | FMI Observation of Gravel Parameters | Frequency | Logging for Predicting Gravel Parameters | Frequency | Error | Standard Deviation |

|---|---|---|---|---|---|---|

| Equivalent radius of gravel (mm) | 7–8 | 0 | 7–8 | 1 | / | 0.5099 |

| 8–9 | 1 | 8–9 | 0 | / | ||

| 9–10 | 13 | 9–10 | 13 | 0% | ||

| 10–11 | 16 | 10–11 | 18 | 13% | ||

| 11–12 | 10 | 11–12 | 9 | 10% | ||

| 12–13 | 3 | 12–13 | 3 | 0% | ||

| 13–14 | 1 | 13–14 | 0 | / | ||

| other | 1 | other | 1 | / | ||

| Gravel Linear Density (pcs/m) | 20–25 | 1 | 20–25 | 1 | / | 1.3595 |

| 30–35 | 4 | 30–35 | 3 | 25% | ||

| 35–45 | 10 | 35–45 | 9 | 10% | ||

| 45–55 | 19 | 45–55 | 18 | 5% | ||

| 55–60 | 9 | 55–60 | 10 | 11% | ||

| other | 2 | other | 1 | / |

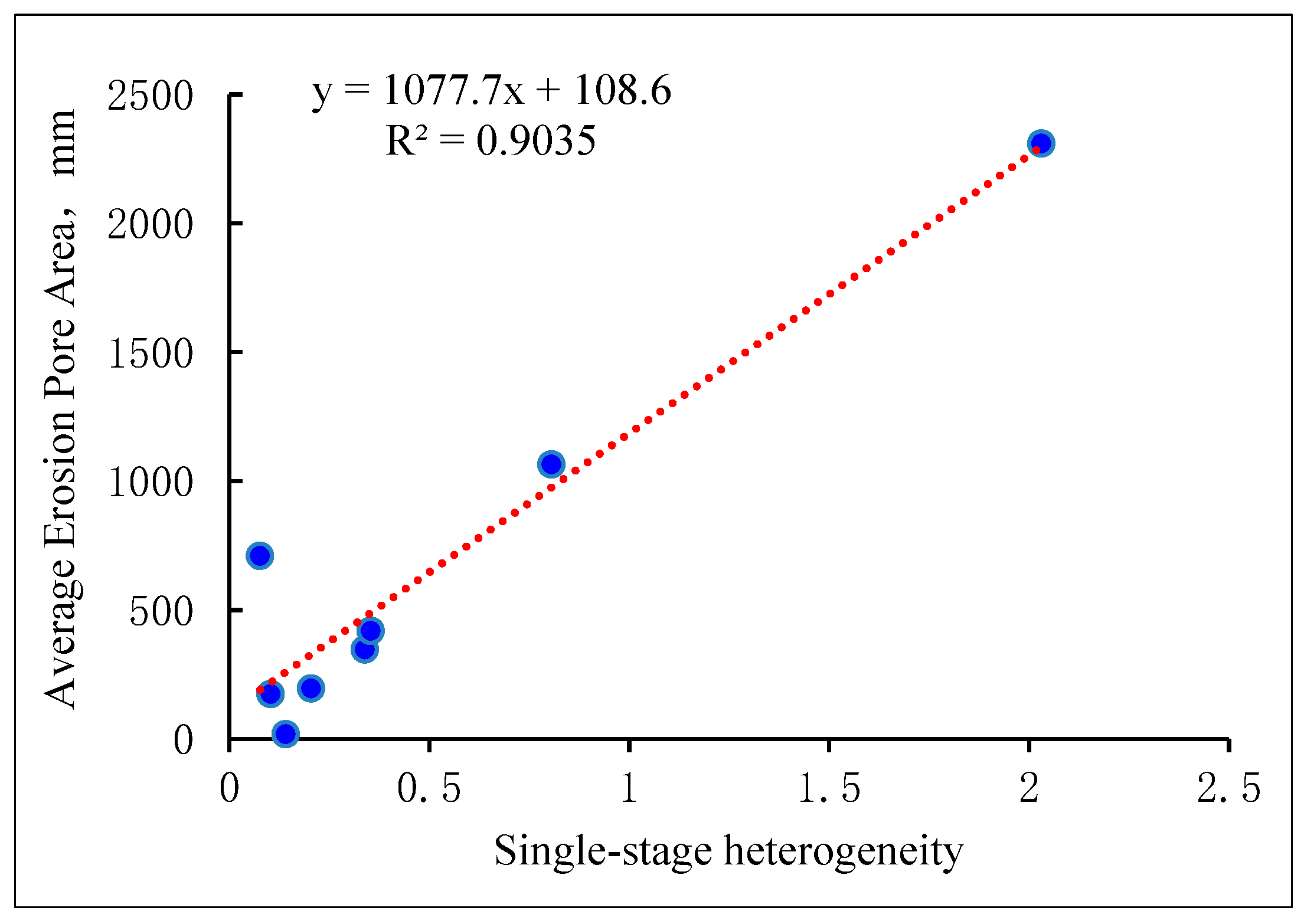

| Series | Average Gravel Linear Density (Pieces/m) | Average Gravel Radius (mm) | Gravel Linear Density Variance | Gravel Radius Variance | Average Erosion Area (mm) |

|---|---|---|---|---|---|

| 2 | 8.0 | 16.6 | 27.3 | 0.8 | 1064.7 |

| 3 | 17.2 | 15.0 | 11.7 | 0.3 | 346.3 |

| 4 | 17.7 | 15.0 | 2.6 | 0.1 | 709.7 |

| 5 | 16.4 | 15.2 | 6.9 | 0.2 | 195.8 |

| 10 | 9.5 | 16.4 | 3.5 | 0.1 | 174.1 |

| 11 | 14.1 | 15.6 | 12.0 | 0.4 | 418.3 |

| 12 | 11.7 | 16.0 | 4.8 | 0.1 | 18.4 |

| 13 | 11.6 | 15.6 | 13.2 | 2.0 | 2308.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Z.; Xu, J.; Liang, T.; Li, P.; Chen, X.; Cheng, H.; Zhang, Y. Quantitative Evaluation Methods and Applications for Gravel Characteristics Distribution in Conglomerate Reservoirs. Processes 2025, 13, 3911. https://doi.org/10.3390/pr13123911

Lv Z, Xu J, Liang T, Li P, Chen X, Cheng H, Zhang Y. Quantitative Evaluation Methods and Applications for Gravel Characteristics Distribution in Conglomerate Reservoirs. Processes. 2025; 13(12):3911. https://doi.org/10.3390/pr13123911

Chicago/Turabian StyleLv, Zhenhu, Jietao Xu, Tianbo Liang, Ping Li, Xiaolu Chen, Hao Cheng, and Yupeng Zhang. 2025. "Quantitative Evaluation Methods and Applications for Gravel Characteristics Distribution in Conglomerate Reservoirs" Processes 13, no. 12: 3911. https://doi.org/10.3390/pr13123911

APA StyleLv, Z., Xu, J., Liang, T., Li, P., Chen, X., Cheng, H., & Zhang, Y. (2025). Quantitative Evaluation Methods and Applications for Gravel Characteristics Distribution in Conglomerate Reservoirs. Processes, 13(12), 3911. https://doi.org/10.3390/pr13123911