Abstract

Because of their exceptional strength, corrosion resistance, and low weight, materials such as titanium, aluminum, and others are becoming increasingly popular. The application scope of additive manufacturing (AM) in the aerospace sector continues to expand. Because of its high performance and low coefficient of thermal expansion, AlSi10Mg processed by laser-based powder bed fusion (LPBF) is becoming increasingly popular in lightweight aerospace component design. Nonetheless, the AM technique has a number of benefits; poor surface quality is the only drawback, necessitating post-processing. This study aims to focus on the machinability of AlSi10Mg under three distinct environmental conditions (dry, minimum quantity lubrication (MQL), and SL-MQL). The experimental investigations were centered on chip morphology, flank wear (Vb), surface roughness (Ra), and cutting temperature (Tc). SL-MQL reduced the roughness by 53–57% over dry machining and 23–29% over MQL condition, and in a similar way lessened the flank wear by 36–40% over dry machining and 12–15% over MQL condition. In addition, to check the predictive accuracy and optimize machining parameters, four machine learning models were used: Gaussian Process Regression (GPR), Bagging, Multilayer Perceptron (MLP), and Random Forest (RF). In both the training and testing stages, MLP consistently demonstrated superior performance across all parameters in comparison to other algorithms, achieving high levels of accuracy and low error rates.

1. Introduction

AM has been becoming increasingly important in high-end industries like aerospace, automotives, and biomedicine in recent years. Particle sintering is used in the AM technique to build up the materials layer by layer [1]. It can create intricate geometric objects and produce parts that traditional manufacturing techniques could not [2]. AM is primarily used in aerospace applications, where it helps reduce weight and improve performance, both of which lower space mission costs [3]. However, by assessing the flaws arising from its mechanical characteristics, it has become vital to examine the intrinsic imperfections of this technology. Aluminum alloys are utilized in the space industry because of their inexpensive cost and high strength-to-weight ratio, which results in improved mechanical performance [4]. Although AlSi10Mg was the most widely used alloy in the AM process, it was more difficult to manufacture using AM than titanium and stainless steel alloys [5]. According to Zimmermann et al. [6], a promising method for creating metallic components with a near-net shape is LPBF. Nevertheless, the final components frequently have low dimensional accuracy and high surface roughness, necessitating post-processing through grinding or milling. L-PBF materials have an impact on subtractive processes like machining because of their distinct microstructure and anisotropic characteristics. The study examines the machinability of AlSi10Mg made using LPBF in comparison to material that is cast conventionally [6].

When machining MMCs, there is a noticeable difference from traditional materials and alloys because of the presence of reinforcements, which are extremely abrasive. This causes damage to the workpiece (W/p) and causes the cutting tool to wear down quickly [7]. The reinforcement is hard and abrasive and comes into direct contact with the cutting tool alternately, which causes fluctuating tool load and ultimately fatigue failure [8]. During machining, material separation happens due to brittle fracturing rather than plastic deformation. This is the reason for the excessive tool wear [9]. Bhardwaj et al. [10] examined how the dry turning of AA-6061 reinforced with 6% and 8% weight of TiC particles of size 2 microns affected the output performance of surface roughness (Ra) and metal removal rate (MRR) in relation to input parameters, specifically feed rate (fr), spindle speed (Ss), and depth of cut (DOC). According to the results, Ss had the biggest impact on Ra and MRR for 6% TiC composites, followed by DOC and fr. In the past, a number of investigations have been conducted to look into how cutting fluids (CFs) affect MMC machinability. There was a lack of consistency in the findings reported. During the drilling of MMCs that were reinforced with various particles such as SiC, B4C, and Al2O3, it was found that the tool life was reduced. When the identical material was milled, the authors reported the same results [11]. Coolant lowers the cutting zone’s temperature and helps the matrix maintain its strength, which increases tool wear. The effect of CF on the machinability of MMCs was investigated by Hung et al. [12]. Their findings were contradictory to the earlier research conducted by Cronjager et al. [11]. Coolant application was shown to have no effect on tool life, and when using a new tool for machining, cutting forces and surface finish were found to be sensitive to cutting speed (Vc). The cost of flood-cooling machining might reach 17% of the entire product cost [13]. Additionally, chips create an obstacle that prevents CFs from reaching the cutting region completely. Thus, the use of MQL is an alternative method for CF application. When machining with the MQL technique, a very small amount of CF with a high heat convective coefficient is employed at a flow rate of 50–600 mL/h. This method creates a mist or aerosol that is delivered between the chip and the tool of the machining zone by atomizing a mixture of high-pressure air and CF. In addition to addressing environmental concerns, MQL is known to lessen the amount of CF, as well as the risks to operators and the costs over the long run.

Machine learning (ML) is the study of computer algorithms that enable computers to automatically learn from data to identify patterns and predict outcomes without the need for human interference [14]. There are many worries regarding the prospects of CNC machining processes and how these ideas will change future projects of manufacturing companies, especially with regard to ML and artificial intelligence (AI) [15]. In order to reduce costs and save time, as well as to boost overall profits in each production period, CNC machining procedures need to be optimized. For the purpose of predicting the surface quality of machined parts, challenging algorithms for ML, such as linear regression (LR), RF, and decision tree (DT), were utilized. Ross et al. [16] studied the machinability of steel under distinct cooling conditions. The dual-MQL method was assessed and contrasted with dry and MQL cutting strategies. The study found that the MLP was the best prediction model, and that MLP and RF complemented each other in classification. Using actual production data, Brillinger et al. [17] used several decision tree algorithms to forecast the energy consumption of CNC machining operations without conducting specialized experiments. It was concluded that through the use of the RF, it is possible to create the most precise estimates of energy consumption [17]. The surface roughness was evaluated by Dubey et al. [18] by comparing the experimental results to the predicted outcomes provided by three ML-based models. The models evaluated were support vector machine (SVM), LR, and RF. The mean square error (MSE), mean absolute percentage error (MAPE), and coefficient of determination (R2) were employed to assess the accuracy of the predicted values. Compared to the other two models, RF performed better [18].

In this research, AlSi10Mg was fabricated and subsequently milled under three distinct environmental conditions (dry, MQL, and SL-MQL). Key parameters such as cutting temperature (Tc), surface roughness (Ra), flank wear (Vb), and chip morphology were measured. The experimental results were analyzed and predicted using four ML models, which are GPR, Bagging, MLP, and RF.

2. Materials and Methods

2.1. Fabrication and Machining

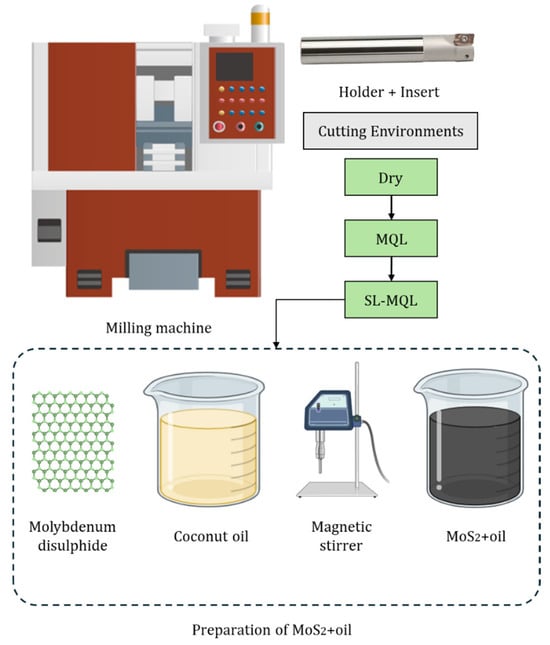

AlSi10Mg samples were prepared using an EOS M280 system with the LPBF process. The main processing parameters were a laser power of 370 W, a layer thickness of 30 μm, a scanning speed of 1300 mm/s, and a hatching distance of 190 μm. The electro-optical system solidified the powder according to CAD designs, and each cycle included laser calibration. After fabricating the AlSi10Mg alloy, a milling operation was carried out to evaluate its machinability characteristics. Milling was performed on a Feeler FV 1000 vertical machining center (Make-Taiwan), a robust CNC machine known for its precision and efficiency in material removal processes. The cutting tool used was a BAP 300R tool holder, fitted with APMT 1135 carbide inserts, which are widely recognized for their excellent cutting performance, wear resistance, and durability when machining. The process parameters, including Vc, fr, and depth of cut (DOC), were selected based on extensive reviews of the previous literature to ensure optimal cutting conditions and minimize tool wear while achieving a good surface finish, as shown in Table 1. Figure 1 presents a schematic of the experimental settings.

Table 1.

Experimental details and parameters.

Figure 1.

Schematic of experimental setting.

2.2. Cooling Conditions

Three distinct environmental conditions were employed to study the machinability of the fabricated LPBF-AlSi10Mg and to evaluate its performance. No external coolant or lubrication setup is employed for dry cutting. Although dry machining is environmentally friendly, it leads to increased cutting temperature and wear. Castor oil was used as the lubricant for MQL, and an MQL setup was utilized to spray the oil in small droplets close to the cutting area. Castor oil lowers cutting temperatures, improves surface smoothness, and lessens the friction at the tool–W/p contact due to its greater lubricating qualities and biodegradability. SL-MQL involved adding MoS2 to the castor oil in the MQL system. MoS2 was introduced in fine particulate form (size ~2 µm) and a density of 4.7–4.8 g/cm3 to enhance the lubricating properties of the oil. In this study, 2 wt% of MoS2 was added to castor oil. This level balances atomization quality, dispersion stability, and tribological effectiveness. MoS2 is renowned for its superior anti-friction qualities, which considerably lower the coefficient of friction. These properties make it highly effective in reducing tool wear and improving the machinability of alloys.

2.3. Measurements

A non-contact IR thermometer (Model-IRX-63, Manufacturer-HTC, China) was used to note the cutting heat at the tool–W/p contact area, a vital element impacting thermal stress and tool wear. The device was calibrated prior to testing against a traceable blackbody over the operating range, and consecutive readings (three) at each point were averaged. The combined measurement uncertainty was at 95% confidence (emissivity sensitivity ± 0.02 ≈ [Δ] °C). The Ra that determines the quality of the machined surface was measured using the SE3120 roughness tester, capable of providing reliable values for Ra. Before testing, slip gauges were used to check the error of the instrument. Five sampling lengths (each cut-off length = 0.8 mm) were measured and averaged to obtain the reported Ra. Vb is a key indicator of tool life and efficiency, which was assessed by employing an OPTIV optical microscope. In addition, images of the chip were also taken with the help of the same microscope. In this study, each trial was repeated 3 times. A thorough examination of machinability, as well as information on the influence of lubrication techniques on machining performance, was offered by these measurements.

3. Results and Discussions

3.1. Temperature

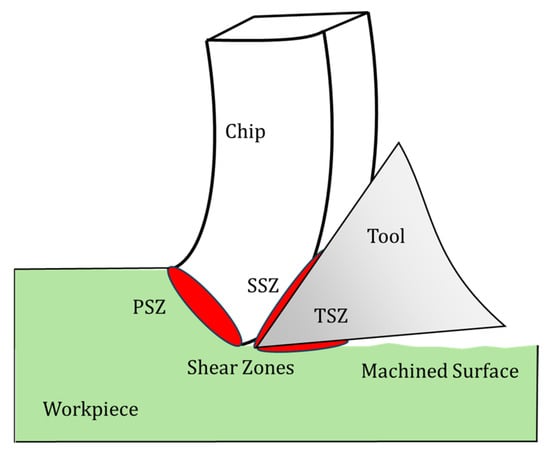

A key aspect in machining performance is the cutting temperature (Tc), which is affected by fr, lubrication conditions, and Vc. In metal cutting, shear zones are closely associated with temperature generation and distribution, significantly influencing machining performance [19]. Figure 2 displayed the schematic of the tool–W/p interaction at the cutting area. The primary shear zone (PSZ), where the workpiece material undergoes intense deformation to form a chip, experiences a sharp temperature rise due to plastic deformation and shear stresses. This temperature impacts the material flow and chip formation process. The secondary shear zone (SSZ), located at the chip–tool interface, is a major source of heat as friction and compression between the chip and tool generate high temperatures, which can lead to tool wear and affect the chip’s surface integrity. The tertiary shear zone (TSZ), at the tool–workpiece interface near the cutting edge, also contributes to temperature increases due to frictional heating during sliding and compression. Effective heat dissipation in these zones is crucial for maintaining tool life, machining accuracy, and the quality of the machined surface [20].

Figure 2.

Schematic of tool interaction with the W/p.

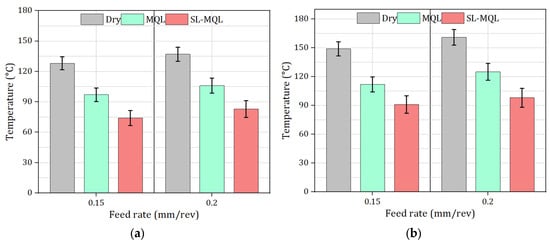

Figure 3 presents the variation in Tc under distinct cutting strategies. If no lubrication is used under dry cutting, this causes a considerable amount of friction at the tool–W/p junction that produces an enormous amount of heat. At a Vc of 45 m/min, dry machining produced Tc of 128 °C at a fr of 0.15 mm/rev and 137 °C at 0.2 mm/rev, highlighting the rise in heat generation with higher frs. The introduction of MQL lowers Tc considerably by creating a lubricating coating that lessens friction and increases heat dissipation. For the same Vc, Tc decreased to 97 °C at 0.15 mm/rev and 106 °C at 0.2 mm/rev under MQL. With the lowest Tcs of 74 °C and 83 °C at frs of 0.15 mm/rev and 0.2 mm/rev, respectively, SL-MQL offered even better thermal management because of its improved L/C qualities [21]. As a result of enhanced energy dissipation at the cutting junction, the Tcs increased over the course of every instance when the Vc was increased to 60 m/min. The maximum temperatures achieved by dry machining were 149 °C and 161 °C at frs of 0.15 mm/rev and 0.2 mm/rev, respectively. Meanwhile, SL-MQL maintained its superior performance by reaching the lowest Tcs of 91 °C and 98 °C, and MQL with slightly higher values of 112 °C and 125 °C. These findings show that, even at higher frs and Vcs, SL-MQL efficiently reduces Tc and improves thermal stability.

Figure 3.

Variation in Tc: (a) Vc = 45 m/min and (b) Vc = 60 m/min.

3.2. Surface Roughness

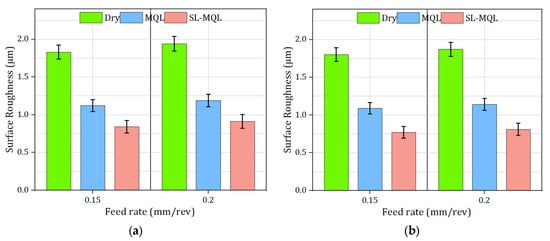

Ra is a crucial indicator of machining performance that is directly impacted by heat production, material deformation, friction, and lubrication effectiveness [22]. It is calculated as the arithmetic mean of the absolute values of the surface height deviations from the mean line, within a specified evaluation length. Figure 4a,b presents the variation in Ra under distinct cutting strategies. Under dry conditions, the Ra value ranges from 1.8 to 1.94 µm; for the MQL condition, it ranges from 1.09 to 1.19 µm; and for SL-MQL, it ranges from 0.77 to 0.91 µm for distinct feed–speed combinations. The friction at the tool–W/p junction is higher with dry cutting because of the lack of coolant. Friction during dry cutting causes the W/p to thermally expand and speeds up cutter wear. At lower Vc, the heat generated is insufficient to soften the material effectively, which worsens the irregularities in the machined surface [23]. Although the lack of lubrication still restricts its efficiency, the increased cutting heat at higher Vc (60 m/min) can soften the material significantly, lowering cutting resistance and slightly enhancing Ra. By lowering friction and more efficiently dissipating heat, the application of lubrication using MQL significantly enhances surface quality. MQL stabilizes the cutting process and reduces mechanical and thermal stresses that cause surface imperfections. MQL lowers tool wear and improves Ra significantly compared to dry machining [24]. Sustainable lubrication with SL-MQL uses lubricants with exceptional film strength and heat conductivity. This guarantees better cooling, increased chip evacuation, and reduced friction. Thus, SL-MQL excels compared to both dry and MQL techniques, achieving the lowest Ra values under every condition. Ra also depends on fr. At a fr of 0.15 mm/rev, the cutter’s depth of engagement is limited, which produces a smooth surface. At a higher fr (0.2 mm/rev), the load of the chip and shearing forces increase, thus affecting the surface quality. These negative consequences are lessened by SL-MQL’s exceptional lubrication and cooling (L/C) characteristics, which maintain outstanding performance even at greater speeds. This combination reduces tool wear, friction, and thermal distortions, resulting in steady cutting conditions with consistent material removal [25].

Figure 4.

Variation in Ra: (a) Vc = 45 m/min and (b) Vc = 60 m/min.

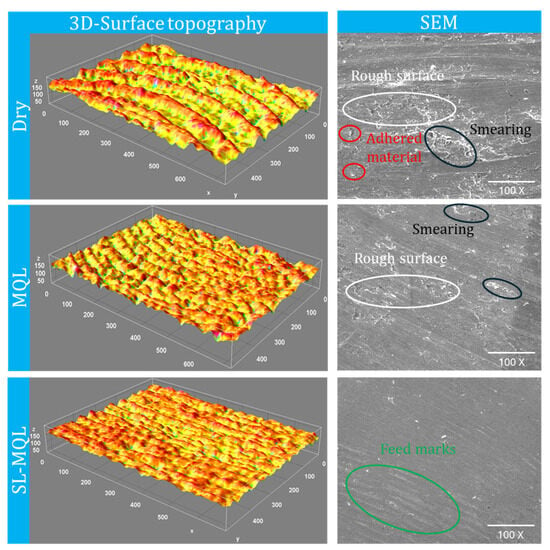

Figure 5 presents the 3D surface topography and SEM image of the LPBF-AlSi10Mg milled under distinct coolant conditions. Due to irregular material removal and thermal distortion, dry cutting caused significant friction and higher temperatures, which resulted in noticeable peaks and valleys on the milled surface. A rough surface with smearing and adherent material was seen in the SEM image under dry conditions. This was because of localized material softening and redeposition caused by inadequate chip evacuation and cooling. MQL conditions decreased friction and enhanced cooling. However, the milled surface retained some roughness, since the heat dissipation was not enough to completely remove smearing. In addition, the 3D topography showed reduced peaks and valleys in relation to the dry cutting strategy. With MoS2 as a solid lubricant, SL-MQL offered better thermal management and lubrication, reducing friction and efficiently dispersing heat. Because of this, the material was removed uniformly, leaving a smooth surface with only a few feed marks on the machined surface. This is a sign of stable cutting dynamics and fewer interactions with adhesive at the tool–W/p junction.

Figure 5.

Three-dimensional surface topography and SEM image of the machined surface at Vc = 60 m/min and fr = 0.2 mm/rev.

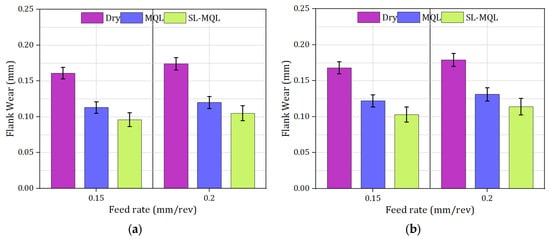

3.3. Tool Wear

The Vc, fr, and lubrication all have a major impact on the amount of Vb, which is an essential component in determining the durability of a tool and the performance of its machining capabilities. Figure 6a,b presents the variation in Ra under distinct cutting strategies. Elevated friction and heat generation at the tool–W/p junction are caused by the absence of lubrication under dry conditions [26]. This leads to faster wear at the cutting edge. Due to increased cutting forces and longer tool–W/p contact, the Vb increased when the fr increased from 0.15 mm/rev to 0.2 mm/rev. In dry cutting, Vb values were the highest for both Vcs (45 m/min and 60 m/min). At 45 m/min, Vb reached 0.161 mm at the lower fr and 0.174 mm at the higher fr, while at 60 m/min, these values increased to 0.168 mm and 0.179 mm, respectively, demonstrating the increased mechanical and thermal stresses with higher Vcs. When MQL was introduced, it formed a lubricating lining that decreased heat generation and friction, and greatly improved the tool’s performance. Under MQL, Vb decreased across all conditions when compared to dry cutting, showing measurements of 0.113–0.122 mm at the lower fr and 0.120–0.131 mm at the higher fr. L/C through SL-MQL delivered even better wear resistance, accomplishing the lowest Vb measures of 0.096–0.103 mm at the lower fr and 0.105–0.114 mm at the higher fr across both Vcs. Wear mechanisms were mitigated by SL-MQL’s improved lubricating qualities and increased thermal conductivity, which decreased friction, lowered chip adherence to the tool, and more efficiently dissipated heat. Furthermore, SL-MQL continued to operate well regardless of Vc and fr, demonstrating its capacity to regulate mechanical and thermal stresses to improve cutting conditions and prolong tool life [21].

Figure 6.

Variation in Vb: (a) Vc = 45 m/min and (b) Vc = 60 m/min.

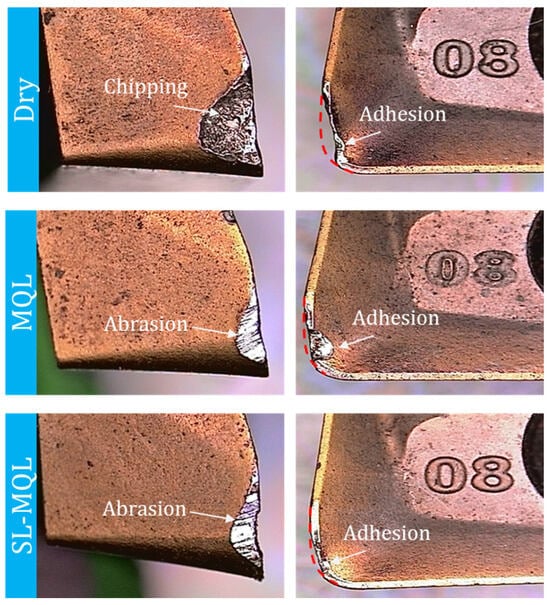

Because of the intense contact between the cutting tool and the W/p, wear mechanisms like abrasion, adhesion, and chipping happen during metal cutting [27]. Hard particles or asperities on the W/p surface rub against the tool during abrasion, causing wear on the tool. Contact pressure and cutting forces have an impact on this, which is typical when cutting hard or abrasive materials. High heat and pressure cause the W/p’s material to stick to the tool surface, creating a built-up edge (BUE) that finally separates and takes tool material with it. Excessive heat and inadequate lubrication worsen this mechanism. The term “chipping” describes the brittle breaking of the cutting edge because of severe mechanical stresses. This is frequently brought on by thermal shocks, interrupted cuts, or excessive tool wear, and it leads to severe tool damage [28]. It is important to note that the influence of each mechanism on tool life and surface quality is distinct, and the degree of these effects varies depending on the lubrication and cutting environments. Under various cutting environments, distinct wear processes were noted at a fr of 0.2 mm/rev and a Vc of 60 m/min (Figure 7). In dry machining, lack of coolant resulted in significant mechanical and thermal stresses that caused adhesion because of the high temperatures that encouraged material transfer from the W/p to the tool and chipping at the cutting edge because of brittle fracture and strong mechanical forces. When reducing heat and friction, MQL’s lubricating film reduced chipping, but the lubricant was insufficient to completely eradicate the wear mechanisms, adhesion and abrasion were seen. The improved L/C capabilities under SL-MQL greatly decreased adhesion and abrasion by maintaining a constant temperature and reducing friction at the tool–W/p contact region [21].

Figure 7.

Tool wear at Vc = 60 m/min and fr = 0.2 mm/rev.

3.4. Chip Morphology

When milling the AlSi10Mg alloy, chip morphology varied significantly under distinct cooling strategies due to unique frictional and thermal behavior at the cutting area. Figure 8a–c present the chip morphology under dry, MQL, and SL-MQL conditions at a Vc of 60 m/min and a fr of 0.20 mm/rev. Dry machining caused considerable friction and heat at the tool–W/p junction. Higher temperatures weakened the material, making it more ductile and forming longer, thicker chips. The cutting process’s inability to handle heat caused continual deformation and reduced chip breaking. The high shear plane angle in dry cutting raised the chip thickness by allowing the material to flow continuously [29]. A lubricating film reduced friction and cooled the cutting region effectively during MQL machining. Moderate shear zone Tc reduced material ductility compared to dry cutting and produced medium chips. In comparison to dry conditions, the L/C property of castor oil improved heat dissipation, enabling better chip formation and more stable cutting performance. The combination of castor oil and MoS2 greatly increased L/C efficiency in SL-MQL. Because of its superior lubricating qualities and great thermal conductivity, the SL decreased friction and heat at the cutting area [30]. These optimized conditions made the material brittle, resulting in shorter and thinner chips. Better chip segmentation and lessened thermal deformation demonstrated the ability of SL-MQL to manage cutting conditions, improving milling effectiveness and the quality of the surface.

Figure 8.

Chip structure: (a) dry, (b) MQL, and (c) SL-MQL at Vc = 60 m/min and fr = 0.2 mm/rev.

4. Machine Learning

Computers can learn from data and make decisions without explicit programming thanks to ML. Because the computer recognizes trends and improves with time, it is a crucial technique for automating difficult tasks [17]. Machine learning drives smart factories in Industry 4.0 by improving quality control, identifying when equipment may break down, and streamlining processes. It allows for customized production while also streamlining supply chains and decreasing waste. ML aids industries in becoming more effective, sustainable, and flexible through the analysis of data from interconnected systems [31]. The workflow for ML is presented in Figure 9.

Figure 9.

Workflow for machine learning.

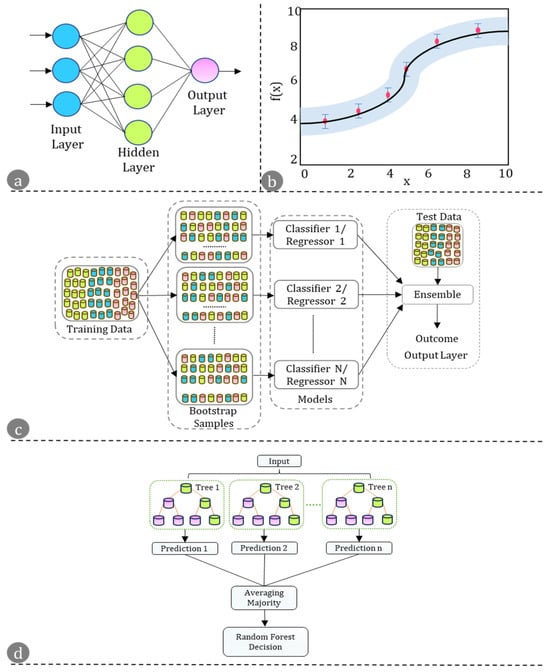

Multi-Layer Perceptron: Figure 10a presents the illustration of MLP. One popular ANN type for predictive modeling is MLP [32]. Each layer is composed of interconnected neurons and includes an i/p, one or more hidden layers, and an o/p. By modifying the weights of connections, the model iteratively reduces mistakes while identifying trends in the data through backpropagation. Both regression and classification applications can benefit from MLP’s ability to simulate intricate relationships between i/ps and o/ps. The number of hidden layers, neurons, and learning rate are some of the hyperparameters that can affect the performance of MLP.

Figure 10.

Illustration of (a) MLP, (b) GPR, (c) bagging, and (d) RF.

Gaussian Process Regression: Figure 10b presents the illustration of GPR. The GPR method is a probabilistic ML technique that is utilized for regression tasks [33]. By modeling the link between input (i/p) and output (o/p) as a continuous smooth function, GPR makes the assumption that the data points follow a Gaussian distribution. In order to generate a posterior distribution, this method defines an earlier distribution over functions and updates it in light of the observed data. GPR gives each prediction a confidence interval and is very good at capturing prediction uncertainties. Because it depends on the inversion of a covariance matrix, it can be computationally difficult to use for large datasets, but it goes well with small ones.

Bagging: Figure 10c presents the illustration of bagging. Bootstrap Aggregating, or “bagging,” is an ensemble learning model that increases an ML model’s accuracy and stability [34]. Using random sampling with replacement, the technique creates several subsets of the original dataset and then trains distinct models on each subset. The final prediction is resolved either by majority vote or by averaging. Bagging is especially useful for high-variance models like decision trees since it lowers variance and helps avoid overfitting. Bagging is a fundamental method in ML because of its ease of use and stability.

Random Forest: Figure 10d presents the illustration of RF. RF is an ensemble learning technique that generates predictions by combining the o/ps of several decision trees that are constructed during training [35]. To create variation among the trees, a random subset of the features and data is used to build each tree. Whereas the average of the o/ps from each individual tree determines the final prediction for regression, majority voting governs the final prediction. RF is reliable, accurate, and can handle numerical and categorical data. It lessens overfitting in relation to single decision trees due to its ensemble methodology.

4.1. Prediction with ML Models

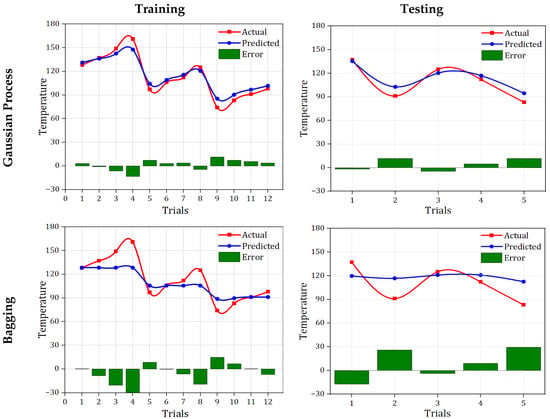

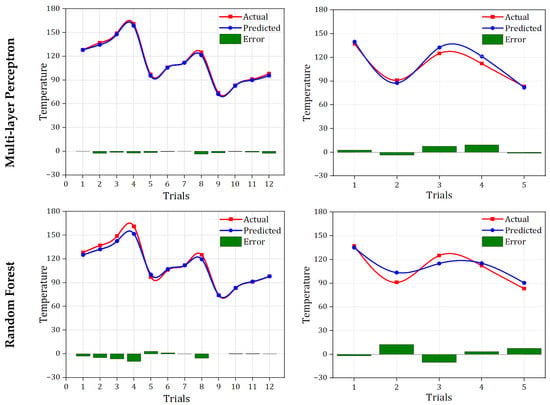

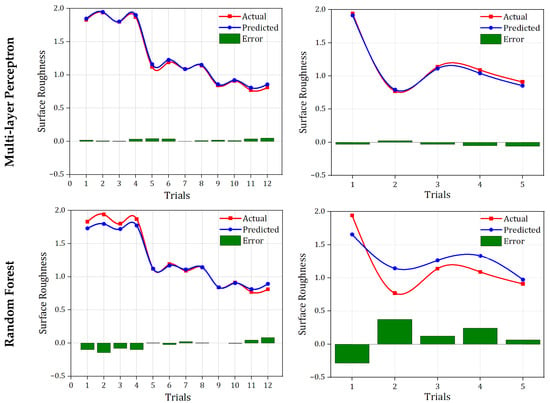

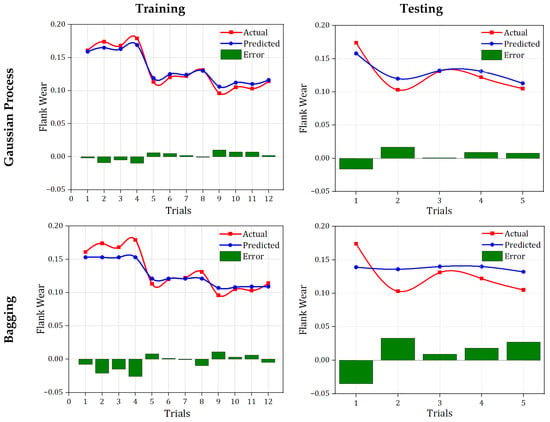

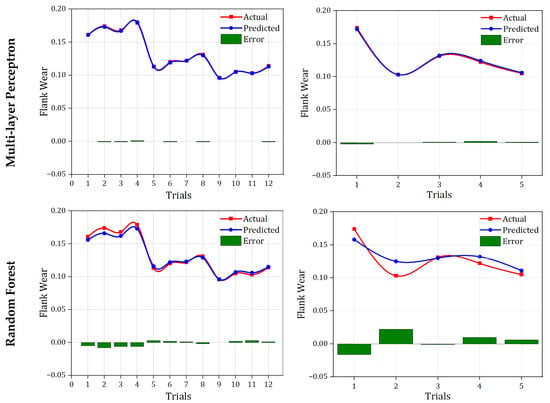

Prediction was performed for three outcomes, i.e., Tc, Ra, and Vb, using four ML algorithms, GPR, Bagging, MLP, and RF. The dataset was partitioned into 80% for training and 20% for testing, and model performance was evaluated on both sets to assess learning quality. Figure 11, Figure 12 and Figure 13 present the Prediction of Training and Testing of distinct ML models for Tc, Ra, and Vb, respectively. With a substantially lower error than the other algorithms, MLP distinguished itself from others by consistently generating predictions that were closer to the measured values for every outcome. MLP performs better due to its design and capacity to model complicated and non-linear interactions. MLP uses layers with interconnected neurons to learn data and relationships. By using the activation function (ReLU), MLP is able to identify complex correlations that may be missed by other approaches. Furthermore, because MLP continuously modifies the weights of its connections during its training period to minimize error, it can handle a variety of datasets with efficiency. On the other hand, algorithms such as Bagging and RF, although resistant to overfitting, depend on combining simpler models (decision trees), which may ignore more complex, non-linear interactions. Similar to this, GPR can have trouble with multidimensional datasets. These variations show why MLP performed so well during this investigation, proving its ability to produce remarkably accurate predictions for all possible outcomes.

Figure 11.

Prediction of training and testing of distinct ML models for Tc.

Figure 12.

Prediction of training and testing of distinct ML models for Ra.

Figure 13.

Prediction of training and testing of distinct ML models for Vb.

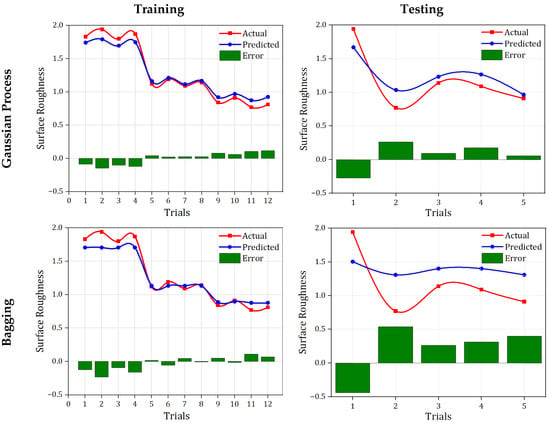

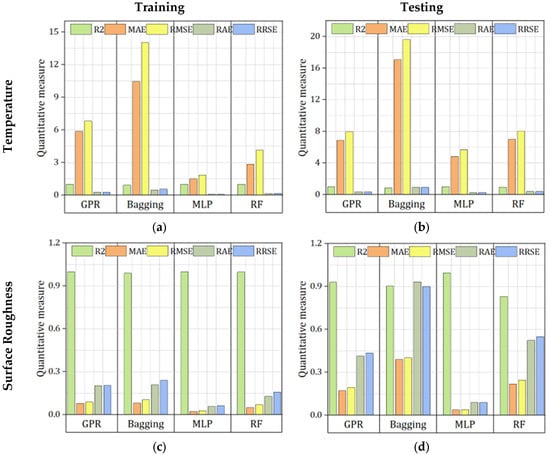

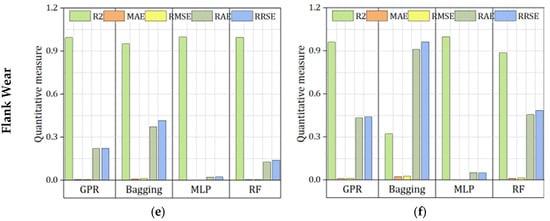

4.2. Quantitative Analysis with ML Models

The performance of four ML models (GPR, Bagging, MLP, and RF) was evaluated for Tc, Ra, and Vb prediction using training and testing datasets. The metrics employed for the evaluation are correlation coefficient (R2), mean absolute error (MAE), root mean squared error (RMSE), relative absolute error (RAE), and root relative squared error (RRSE). The measure of R2 should be between 0 and 1; if the R2 measure is closer to 1, the prediction is perfect. The reverse is true for MAE, RMSE, RAE, and RRSE. Figure 14 presents the quantitative measure (Figure 14a,b) training and testing for Tc, (Figure 14c,d) training and testing for Ra, and (Figure 14e,f) training and testing for Vb. In this research work, 5-fold cross validation was performed to validate the model’s capacity. For Tc, MLP demonstrated strong predictive agreement, yielding an R2 of 0.9803. Error magnitudes were low, with an MAE of 5.1529 and an RMSE of 5.8211, corresponding to relative errors of 22.03% (RAE) and 20.69% (RRSE). Across folds, for Ra, MLP delivered the most accurate predictions, with the lowest absolute and relative errors (MAE 0.063, RMSE 0.0759; RAE 15.28%, RRSE 16.42%) and a high correlation coefficient (R2 = 0.9924). For Vb, MLP also tracked the targets very closely, with an R2 of 0.9964. The errors were small—MAE 0.0023 and RMSE 0.003—which translate to relative errors of 8.50% (RAE) and 9.84% (RRSE).

Figure 14.

Quantitative measure (a,b) training and testing for Tc, (c,d) training and testing for Ra, and (e,f) training and testing for Vb.

With the highest R2 measures (0.9992 for training and 0.987 for testing) and the lowest errors (MAE: 1.4879 for training and 4.8162 for testing; RMSE: 1.8277 for training and 5.684 for testing), MLP outscored the other models for Tc. RF also performed well, with R2 values of 0.9971 for training and 0.9493 for testing and moderate error metrics. GPR showed strong results in training (R2 of 0.9923), but experienced an increase in error during testing (MAE was 6.8769 and RMSE was 7.9445). Bagging exhibited the weakest performance, with lower R2 values (0.9178 for training and 0.8255 for testing) and significantly higher error rates, particularly during testing (MAE was 17.0913 and RMSE was 19.6115).

With the lowest error metrics, such as MAE (0.0223 for training and 0.0372 for testing) and RMSE (0.027 for training and 0.0396 for testing), as well as the highest R2 values (0.9988 for training and 0.9952 for testing), MLP performed better than other models for Ra. It also had minimal RAE (5.72% for training and 8.92% for testing) and RRSE (6.22% for training and 8.89% for testing). While GPR performed well in training (R2 was 0.9988 and MAE was 0.0781), its accuracy decreased in testing (R2 was 0.9291 and MAE was 0.1722). Bagging’s accuracy dropped dramatically during testing (R2 was 0.9021, MAE was 0.3889; RAE was 93.30%) but remained moderate throughout training (R2 was 0.9896). Although RF demonstrated strong training performance (R2 was 0.9966 and MAE was 0.0499), its testing accuracy was somewhat lower (R2 was 0.8293 and MAE was 0.218).

For Vb, MLP exhibited exceptional accuracy, with almost perfect outcomes in both testing (R2 was 0.9990, MAE was 0.0012, RMSE was 0.0013, RAE was 5.09%, and RRSE was 4.93%) and training (R2 was 0.9998, MAE was 0.0006, RMSE was 0.0007, RAE was 2.24%, and RRSE was 2.33%). Although its testing accuracy was marginally lower (R2 was 0.9617 and MAE was 0.0104), GPR displayed strong performance, especially in training (R2 of 0.9944 and MAE of 0.0056). RF scored well during training (R2 of 0.9968 and MAE of 0.0032), but during testing (R2 of 0.8866 and MAE of 0.011), it displayed lower accuracy. With testing R2 falling to 0.3218 and larger error measures (MAE of 0.0244, RMSE of 0.0262, RAE of 01.07%, and RRSE of 96.30%), bagging lagged further behind. When it came to temperature, Ra, and Vb predictions, MLP was the most reliable and effective model.

5. Conclusions

In this investigation, LPBF-AlSi10Mg was fabricated and milled under dry, MQL, and SL-MQL conditions. Tc, Ra, Vb, and chip morphology were analyzed to study the machinability of LPBF-AlSi10Mg. In addition, the experimental outcomes were analyzed and predicted using GPR, Bagging, MLP, and RF. The following outcomes were derived.

- In comparison to other cutting strategies (dry and MQL), SL-MQL achieved the lowest Tc of 83 °C. Even at higher Vc (60 m/min), SL-MQL maintained superior thermal stability with Tcs of 91 °C and 98 °C, demonstrating its effectiveness in enhancing thermal management and machining efficiency.

- The enhanced L/C capabilities of SL-MQL ensured uniform material removal and decreased thermal distortion, resulting in the lowest Ra values (0.77–0.91 µm). MQL moderately improved Ra by stabilizing cutting conditions, while dry cutting resulted in the highest Ra with surface irregularities.

- The use of dry cutting produced rough surfaces that included peaks, valleys, and smearing, whereas the use of MQL considerably decreased the imperfections. Because of its effective reduction in friction and heat dissipation, SL-MQL has established itself as the most effective method for the removal of material in a consistent and uniform way.

- Dry machining resulted in the highest Vb values due to elevated friction and heat generation. SL-MQL exhibited superior performance, achieving the lowest Vb values of 0.096–0.114 mm across all conditions. This demonstrates SL-MQL’s ability to reduce wear mechanisms, improve thermal stability, and extend tool life under a variety of machining conditions.

- SL-MQL successfully reduced friction and thermal deformation, leading to chips that are well-segmented and thinner. This enhancement of machining stability and surface quality over dry and MQL conditions highlights the importance of improved lubrication.

- MLP continuously excelled in all metrics in relation to other algorithms, attaining excellent accuracy and low error rates during the training and testing stages. Although RF and GPR demonstrated competitive training outcomes, they struggled significantly in the testing stage. Since bagging lagged considerably when compared to other models, MLP turned out to be the best model in this investigation for Vb, Ra, and temperature.

6. Future Works

Future work will broaden the machining design space (cutting speed, feed, depth of cut) and assess additional tool materials/coatings, LPBF build orientations, and heat treatments. Real-time sensing of forces and temperature, together with thermo-mechanical modeling, will be used to clarify mechanisms governing chip formation, surface finish, and wear. The ML pipeline will be expanded with larger multi-source datasets, cross-validation, and uncertainty quantification, alongside sustainability and cost assessments.

Author Contributions

Conceptualization, Z.D. and K.G.; methodology, Z.D.; software, Z.D.; validation, X.H. and Z.D.; formal analysis, K.G. and J.S.; investigation, Z.D.; resources, J.S.; data curation, X.H.; writing—original draft preparation, Z.D.; writing—review and editing, X.H. and J.S.; visualization, X.H.; supervision, J.S.; project administration, X.H.; funding acquisition, K.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Civil Aerospace Technology Pre-research Project (D020110), Key R&D Program of Shandong Province (2022CXGC020202), Shandong Province Enterprise Innovation Enhancement Project (2022TSGC2568), Taishan Young Scholar of Shandong Province (tsqn202408041), and Jining Key Research and Development Program (2022KJHZ013).

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| AM | Additively manufactured |

| LPBF | Laser powder bed fusion |

| MQL | Minimal quantity lubrication |

| GPR | Gaussian process regression |

| ML | Machine learning |

| LR | Linear regression |

| DT | Decision tree |

| MLP | Multi-layer perceptron |

| RF | Random Forest |

| MRR | Metal removal rate |

| fr | Feed rate |

| Ss | Spindle speed |

| DOC | Depth of cut |

| CFs | Cutting fluids |

| SVM | Support vector machine |

| MSE | Mean square error |

| MAPE | Mean absolute percentage error |

| PSZ | Primary shear zone |

| SSZ | Secondary shear zone |

| TSZ | Tertiary shear zone |

| MAE | Mean absolute error |

| RMSE | Root mean squared error |

| RAE | Relative absolute error |

| RRSE | Root relative squared error |

References

- Tofail, S.A.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Rab, S.; Singh, R.P.; Suman, R.; Kumar, L. Significant potential and materials used in additive manufacturing technologies towards sustainability. Sustainable Oper. Comput. 2023, 4, 172–182. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; Du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Liu, H.; Gu, D.; Xi, L.; Zhang, H.; Shi, K.; Wu, B.; Zhang, R.; Qi, J. High-performance aluminum-based materials processed by laser powder bed fusion: Process, microstructure, defects and properties coordination. Addit. Manuf. Front. 2024, 3, 200145. [Google Scholar] [CrossRef]

- Ramoni, M.; Shanmugam, R.; Ross, N.S.; Gupta, M.K. An experimental investigation of hybrid manufactured SLM based Al-Si10-Mg alloy under mist cooling conditions. J. Manuf. Process. 2021, 70, 225–235. [Google Scholar] [CrossRef]

- Zimmermann, M.; Müller, D.; Kirsch, B.; Greco, S.; Aurich, J.C. Analysis of the machinability when milling AlSi10Mg additively manufactured via laser-based powder bed fusion. Int. J. Adv. Des. Manuf. Technol. 2021, 112, 989–1005. [Google Scholar] [CrossRef]

- Gururaja, S.; Ramulu, M.; Pedersen, W. Machining of MMCs: A review. Mach. Sci Technol. 2013, 17, 41–73. [Google Scholar] [CrossRef]

- Chen, J.P.; Gu, L.; He, G.J. A review on conventional and nonconventional machining of SiC particle-reinforced aluminium matrix composites. Adv. Manuf. 2020, 8, 279–315. [Google Scholar] [CrossRef]

- Mir, A.; Luo, X.; Sun, J. The investigation of influence of tool wear on ductile to brittle transition in single point diamond turning of silicon. Wear 2016, 364, 233–243. [Google Scholar] [CrossRef]

- Bhardwaj, A.R.; Vaidya, A.M.; Meshram, P.D.; Bandhu, D. Machining behavior investigation of aluminium metal matrix composite reinforced with TiC particulates. Int. J. Interact. Des. Manuf. 2024, 18, 2911–2925. [Google Scholar] [CrossRef]

- Cronjäger, L.; Meister, D. Machining of fibre and particle-reinforced aluminium. CIRP Ann. 1992, 41, 63–66. [Google Scholar] [CrossRef]

- Hung, N.P.; Yeo, S.H.; Oon, B.E. Effect of cutting fluid on the machinability of metal matrix composites. J. Mater. Process. Technol. 1997, 67, 157–161. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suvin, P.S.; Kailas, S.V.; Sankar, M.R. Hard machining performance of indigenously developed green cutting fluid using flood cooling and minimum quantity cutting fluid. J. Clean. Prod. 2019, 206, 108–123. [Google Scholar] [CrossRef]

- Naveen Venkatesh, S.; Arun Balaji, P.; Elangovan, M.; Annamalai, K.; Indira, V.; Sugumaran, V.; Mahamuni, V.S. Transfer Learning-Based Condition Monitoring of Single Point Cutting Tool. Comput. Intell. Neurosci. 2022, 2022, 3205960. [Google Scholar] [CrossRef]

- Ross, N.S.; Sheeba, P.T.; Shibi, C.S.; Gupta, M.K.; Korkmaz, M.E.; Sharma, V.S. A novel approach of tool condition monitoring in sustainable machining of Ni alloy with transfer learning models. J. Intell. Manuf. 2024, 35, 757–775. [Google Scholar] [CrossRef]

- Ross, N.S.; Mashinini, P.M.; Mishra, P.; Ananth, M.B.J.; Mustafa, S.M.; Gupta, M.K.; Korkmaz, M.E.; Nag, A. Enhancing surface quality and tool life in SLM-machined components with Dual-MQL approach. J. Mater. Res. Technol. 2024, 31, 1837–1852. [Google Scholar] [CrossRef]

- Brillinger, M.; Wuwer, M.; Hadi, M.A.; Haas, F. Energy prediction for CNC machining with machine learning. CIRP J. Manuf. Sci. Technol. 2021, 35, 715–723. [Google Scholar] [CrossRef]

- Dubey, V.; Sharma, A.K.; Pimenov, D.Y. Prediction of surface roughness using machine learning approach in MQL turning of AISI 304 steel by varying nanoparticle size in the cutting fluid. Lubricants 2022, 10, 81. [Google Scholar] [CrossRef]

- Banerjee, N.; Sharma, A. Improving machining performance of Ti-6Al-4V through multi-point minimum quantity lubrication method. Proc. Inst. Mech. Eng. Part B 2019, 233, 321–336. [Google Scholar] [CrossRef]

- La Monaca, A.; Murray, J.W.; Liao, Z.; Speidel, A.; Robles-Linares, J.A.; Axinte, D.A.; Hardy, M.C.; Clare, A.T. Surface integrity in metal machining-Part II: Functional performance. Int. J. Mach. Tools Manuf. 2021, 164, 103718. [Google Scholar] [CrossRef]

- Sartori, S.; Ghiotti, A.; Bruschi, S. Solid lubricant-assisted minimum quantity lubrication and cooling strategies to improve Ti6Al4V machinability in finishing turning. Tribol. Int. 2018, 118, 287–294. [Google Scholar] [CrossRef]

- Ross, N.S.; Mashinini, P.M.; Ananth, M.B.J.; Srinivasan, N.; Gupta, M.K.; Korkmaz, M.E. Tribology-driven strategies for tool wear reduction and surface integrity enhancement in cryogenic CO2-cooled milling of laser metal deposited Ti64 alloy. Tribol. Int. 2024, 198, 109906. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Z.; Wang, B.; Wang, C.; Cheung, C.F. Friction behaviors in the metal cutting process: State of the art and future perspectives. Int. J. Extrem. Manuf. 2022, 5, 012002. [Google Scholar] [CrossRef]

- Kaynak, Y. Evaluation of machining performance in cryogenic machining of Inconel 718 and comparison with dry and MQL machining. Int. J. Adv. Manuf. Technol. 2014, 72, 919–933. [Google Scholar] [CrossRef]

- Hedayati, H.; Mofidi, A.; Al-Fadhli, A.; Aramesh, M. Solid lubricants used in extreme conditions experienced in machining: A comprehensive review of recent developments and applications. Lubricants 2024, 12, 69. [Google Scholar] [CrossRef]

- Ross, N.S.; Mashinini, P.M.; Rai, R.; Gupta, M.K. Carbon nano dots mixed rice bran oil as a cutting fluid for enhanced lubrication/cooling in milling of additively manufactured 316 stainless steel. J. Mol. Liq. 2023, 391, 123200. [Google Scholar] [CrossRef]

- Jamil, M.; He, N.; Gupta, M.K.; Zhao, W.; Khan, A.M. Tool wear mechanisms and its influence on machining tribology of face milled titanium alloy under sustainable hybrid lubri-cooling. Tribol. Int. 2022, 170, 107497. [Google Scholar] [CrossRef]

- Wang, R.; Yang, D.; Wang, W.; Wei, F.; Lu, Y.; Li, Y. Tool wear in nickel-based superalloy machining: An overview. Processes 2022, 10, 2380. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Günay, M.; Boy, M.; Yaşar, N.; Demirsoez, R.; Ross, K.N.S.; Abbas, Y. Comprehensive analysis of tool wear, surface roughness and chip morphology in sustainable turning of Inconel-601 alloy. J. Manuf. Process 2023, 103, 156–167. [Google Scholar] [CrossRef]

- Singh, R. Progress of environment friendly cutting fluids/solid lubricants in turning-A review. Mater. Today Proc. 2021, 37, 3577–3580. [Google Scholar] [CrossRef]

- Karabacak, Y.E. Intelligent milling tool wear estimation based on machine learning algorithms. J. Mech. Sci Technol. 2024, 38, 835–850. [Google Scholar] [CrossRef]

- Orrù, P.F.; Zoccheddu, A.; Sassu, L.; Mattia, C.; Cozza, R.; Arena, S. Machine learning approach using MLP and SVM algorithms for the fault prediction of a centrifugal pump in the oil and gas industry. Sustainability 2020, 12, 4776. [Google Scholar] [CrossRef]

- Prashanth, G.S.; Sekar, P.; Bontha, S.; Balan, A.S.S. Grinding parameters prediction under different cooling environments using machine learning techniques. Mater. Manuf. Process. 2023, 38, 235–244. [Google Scholar] [CrossRef]

- De Zarzà, I.; De Curtò, J.; Hernández-Orallo, E.; Calafate, C.T. Cascading and ensemble techniques in deep learning. Electronics 2023, 12, 3354. [Google Scholar] [CrossRef]

- Zhang, L.; Huettmann, F.; Liu, S.; Sun, P.; Yu, Z.; Zhang, X.; Mi, C. Classification and regression with random forests as a standard method for presence-only data SDMs: A future conservation example using China tree species. Ecol. Inform. 2019, 52, 46–56. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).