Abstract

This paper explores the evolution of first-generation solar cells by analysing the selection and engineering of materials that led to innovations. It also addresses the potential of using materials other than silicon and issues related to innovative recycling technologies. The paper presents the evolution of the Romanian photovoltaic sector and assesses the life cycle of photovoltaic panels, focusing on the recovery of high-quality raw materials and their reintroduction into the production process to improve the circular economy in this field. As the number of installed panels grows exponentially, so does the need to manage waste efficiently at the end of their life cycle. Photovoltaic panel recycling is slowly but surely becoming a rapidly developing field that is essential for the sustainability of the solar industry. With the growth of production in the Romanian photovoltaic sector, it has been identified that the need for recycled raw materials will increase from 900 prosumers in 2019 to over 100,000 in 2024. In the future, it will be imperative to develop strategies for recovering, recycling and reintroducing materials, which will bring major benefits. This paper’s specific contributions include a bibliometric mapping of EoL-PV research trends, a technology-recycling matrix for modern cell architectures, and a perspective on the Romanian market contextualised within EU policies.

1. Introduction

The amount of solar energy reaching the Earth in one hour exceeds the entire global population’s energy consumption for a year. This astonishing fact highlights the vast potential of solar energy, which is often underestimated [1]. So why rely on limited, polluting resources when we have an inexhaustible, clean source in the form of photovoltaic (PV) panels? The evolution of solar panels is therefore exponential, driven by established research and innovation. Over time, this has transformed solar energy from a scientific curiosity into one of the world’s most important sources of renewable energy [2,3].

The evolution of PV panels in Romania has been marked by periods of pioneering, stagnation and, more recently, accelerated growth. Contrary to expectations, Romania was a major player in the solar industry in the 1970s and 1980s. It is estimated that around 800,000 m2 of solar collectors were installed during this period, mainly for hot water but also for some ‘inferior quality’ PVs [4], placing the country third worldwide in terms of total PV cell area.

Following the events of 1989, the solar energy sector entered a period of relative stagnation [4]. Although research and development projects continued, the adoption of PV panels remained limited [1]. The PV market began to develop with small-scale installations (under 30 kW) around 2006. However, PV capacity remained relatively unchanged until the end of 2011 [5]. The country’s first two industrial-scale solar parks, the 1 MW Singureni Solar Park and the 1 MW Scornicești Solar Park, were completed in December 2010 and December 2011, respectively [4,6].

In 2003, Romania adopted the “Strategy for the Exploitation of Renewable Energy Resources” [7], approved by Government Decision (GD) 1535/2003. The provisions of Directive 2001/77/EC were transposed into national legislation through GD 443/2003 regarding the promotion of electricity production from renewable energy sources. Through GD 1892/2004, with amendments from GD 958/2005, a system of mandatory quotas, combined with the green certificate trading system, was established. The introduction of these legislative support mechanisms (green certificates) significantly stimulated the Romanian PV market, which began to grow rapidly in the second half of 2012. In 2013, Romania ranked fourth in Europe for year-over-year newly installed PV capacity, with a total installed capacity of 1151 MW/year [8].

Unfortunately, negative legislative changes and a reduction in the number of green certificates for solar energy, which came into force on 1 January 2015, have drastically slowed the growth rate of the Romanian PV market [9]. Since 1 January 2019, Romanians have been able to produce and feed electricity generated by solar panels into the grid, effectively becoming ‘prosumers’, and this measure has stimulated growth in the number of residential installations [10].

The years 2022 and 2023 marked a spectacular revival of the PV sector in Romania. This growth was driven by high energy prices, government funding programmes such as Casa Verde Fotovoltaice and RePowerEU, and increased Romanian interest in energy independence [11].

In 2023, Romania installed a new solar capacity of over 1 GW, setting an absolute record and bringing the total cumulative capacity to over 2.85 GW [8]. This figure represents a 308% increase compared to the previous year’s installed capacity [12]. The prosumer segment was the main driver of this growth, with more than 80,000 households, businesses and institutions becoming prosumers by the end of the year, totalling almost 1.2 GW of installed capacity [8].

Alongside this revival, new trends are emerging, such as agrivoltaics (PV systems integrated with agriculture) and floating PVs (floatovoltaics), with the first pilot projects and regulations in this regard, as Romania has significant solar potential, with approximately 210 sunny days per year. The government has ambitious plans to increase the installed capacity to 8 GW by 2030, supported by new support mechanisms, including Contracts for Difference (CfD) and facilities for Power Purchase Agreements (PPAs) [6].

The rapid expansion of the solar energy sector has made the life cycle of PV panels a critical subject of scientific research [13]. This introduction explores the modern approach to PV panels, from initial design and manufacturing to use and recycling [14]. A modern approach to sustainability requires us to reconsider the entire cycle, moving away from the traditional linear model in order to minimise ecological impact and maximise the value of materials [15].

Consequently, the first generation of ‘aging’ solar panels is only now reaching the end of its life. As these units are approaching the end of their service life, experts are calling for urgent action. Without recycling processes in place, we will have 60 million tonnes of PV panel waste in landfills globally by 2050 [16].

Given the complexity and rapid evolution of the field, an analysis of the scientific literature is imperative to identify current and future research directions. Therefore, an essential component of the present work is a detailed bibliometric analysis of recent publications from the Web of Science, which maps the intellectual structure, thematic trends, and co-occurrence dynamics of keywords in the field.

The purpose of this work is to reconsider the entire cycle and to provide a complete introduction to PV panels, from initial design and manufacturing to their use and recycling, in order to minimise ecological impact and maximise the value of reusable materials.

2. Mapping the Research Landscape

In the context of the PV sector’s rapid expansion and the urgent need for efficient recycling solutions, analysing the scientific literature is crucial for identifying current and future research directions [17]. This section outlines the methodology employed for the bibliometric analysis, which was used to map the scientific landscape, pinpoint significant thematic trends and assess research endeavours within this field.

A precise search formula was used to query the database and extract relevant publications. The rationale behind each step of the formula is detailed in Table 1.

Table 1.

Query formulation and its justification.

The bibliometric data was retrieved from the Web of Science (WoS) Core Collection database in August, 2025.

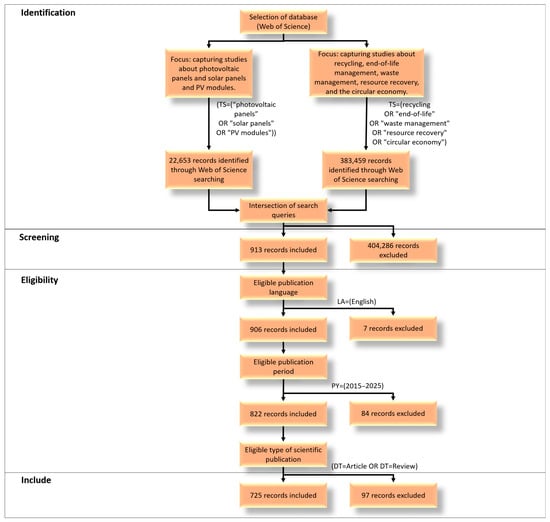

The initial query yielded 589 records. The data was then exported for further processing. Duplicate records were removed using reference management software VOSviewer, version 1.6.20. The remaining records were screened based on title and abstract to ensure direct relevance to the EoL management of PV panels, excluding articles focused solely on manufacturing, performance, or policy without a clear link to recycling or circularity. This filtering and exclusion process, which follows the principles of a PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) workflow, resulted in a final corpus of 725 publications for analysis (Figure 1).

Figure 1.

PRISMA workflow.

The study was guided by a set of specific research questions, the answers to which were obtained by applying a detailed bibliometric analysis methodology using VOSviewer software, version 1.6.20 (Table 2). The mapping parameters in VOSviewer were selected to balance detail with clarity; a minimum co-occurrence threshold of 3 for any keyword was established to filter out incidental terms and focus the analysis on significant research themes. The normalisation method used was association strength, which provides insights into the relative relationships between keywords. This systematic approach enabled precise mapping of the scientific landscape, clear identification of thematic trends and objective evaluation of research efforts in the field.

Table 2.

Research questions and associated bibliometric analyses.

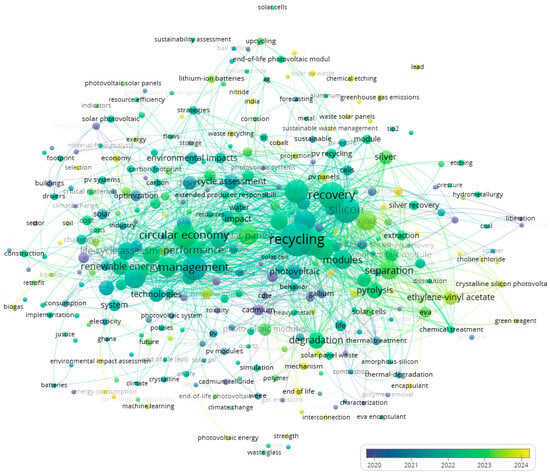

Data analysis was carried out using the VOSviewer software, version 1.6.20, focusing on a co-occurrence analysis of keywords to identify the main research themes and trends. To answer the question “What are the main research themes and trends?”, an analysis of all keywords (Figure 2) from the dataset was performed. Of the 2756 keywords, 312 met the occurrence threshold.

Figure 2.

Overlay visualisation of co-occurrence of All Keywords.

The most frequent keywords were ‘recycling’ (137 occurrences), ‘recovery’ (90 occurrences), and ‘management’ (75 occurrences), indicating a dominant focus on material recovery processes and the general organisation of waste. Other important terms include ‘silicon’ (84 occurrences), ‘waste’ (85 occurrences), and ‘end-of-life’ (67 occurrences), reflecting interest in specific materials and the final stage of the panels’ life cycle. With a lower, yet still significant, frequency, terms such as ‘circular economy’ (73 occurrences), ‘pyrolysis’ (32 occurrences), ‘sustainability’ (47 occurrences), and ‘life cycle assessment’ (52 occurrences) emerge, indicating a holistic approach and an increasing concern for environmental aspects.

The temporal analysis, visualised on the co-occurrence map, shows that the terms appearing in yellow are the most recent, indicating current research trends. These include words such as ‘nitride’, ‘gas emissions’, ‘choline’, ‘chloride’, ‘economy’, ‘end-of-life’, and ‘encapsilant’.

The presence of the word ‘end-of-life’ among both the most frequent and the most recent terms suggests an intensification of studies dedicated to this stage of the panels’ life cycle.

These trends indicate an evolution in research from a general approach focused on basic recycling processes towards an increasing specialisation in specific aspects, such as the analysis of materials at a chemical level, a detailed evaluation of environmental impact, and the integration of solutions into broader economic contexts.

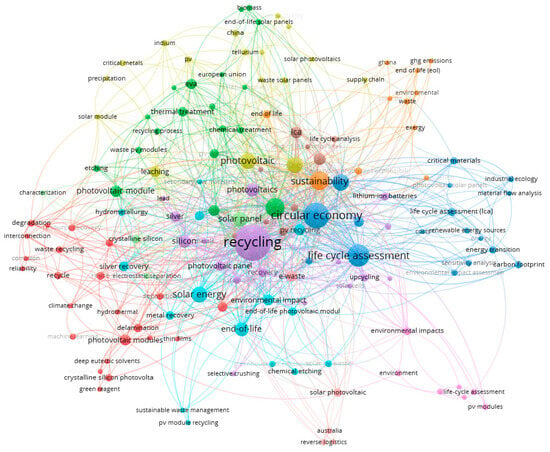

To answer the question “Which aspects of PV panel recycling have attracted the most academic interest?”, an Author Keywords analysis (Figure 3) was performed, which directly reflects the research interests declared by the authors. Out of a total of 1054 keywords, 185 met the minimum occurrence threshold.

Figure 3.

Overlay visualisation of the co-occurrence of Author Keywords.

The network visualisation analysis of author keywords reveals a thematic structure of the research. At the base of this structure is a central yellow cluster, dominated by terms such as ‘recycling’, ‘e-waste’ and ‘silicon’, which represents the fundamental focus of the research on basic material recovery processes and on the key materials in panels. Closely related to this, the purple cluster highlights a concern for the concepts of ‘circular economy’ and ‘sustainability’, indicating the integration of recycling into a sustainable development framework. Furthermore, a distinct research area, represented by the red cluster, focuses on the technical and chemical aspects of the end-of-life (EoL) stage, including terms such as ‘leaching’, ‘hydrometallurgy’ and ‘thermal treatment’. Another theme, visible in the green cluster, is focused on the technology and processing of panels, with keywords such as ‘photovoltaic’, ‘pyrolysis’ and ‘separation’. At the same time, two thematic areas concerning impact and organisation are noteworthy: the blue cluster, centred on ‘life cycle assessment’ and ‘environmental impact’, focuses on the ecological impact assessment of the processes, while the orange cluster focuses on the practical aspects of waste management. Together, these clusters demonstrate complex and interconnected research, which addresses equally the technical, economic and environmental aspects of PV panel recycling.

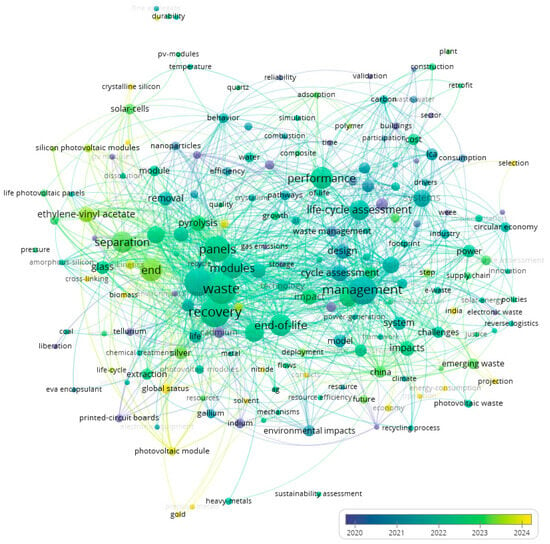

To identify emerging research directions and to answer the question “What are the emerging research directions?”, the KeyWords Plus analysis and the temporal visualisation of keyword co-occurrence were used (Figure 4).

Figure 4.

Overlay visualisation of the co-occurrence of KeyWords Plus.

This method offers a perspective on the evolution of research themes by assigning a colour to each keyword based on the average publication year of the documents in which it is mentioned. As such, keywords marked with a blue colour indicate older research themes, while shades of yellow represent more recent trends.

The temporal visualisation analysis of KeyWords Plus co-occurrence confirms the evolution of research in the field. The initial themes, represented by shades of blue and green, focused on practical aspects and waste management, including terms such as ‘end-of-life’, ‘photovoltaic waste’, ‘management’ and ‘recovery’. This approach reflected an initial concern for the logistics and basic waste treatment processes. Subsequently, the interest shifted towards more complex and holistic aspects. Emerging themes, visible in shades of yellow, include circular economy, sustainability and life cycle assessment (LCA), indicating a transition in research towards the evaluation of the environmental impact and economic viability of the processes. This evolution suggests a maturation of the field, where the focus shifts from “How do we recycle?” to “What is the most sustainable and efficient way to do it, considering the entire life cycle?”.

The conclusion of this bibliometric analysis underlines a clear evolution and a maturation of the research landscape in the field of PV panel recycling. The field has progressed from an initial concern for the fundamental, technical, and logistical aspects of waste management towards an integrated and holistic approach. This transition is demonstrated by the emergence and consolidation of new research themes, such as circular economy, sustainability and LCA. The thematic structure, visible in the identified clusters, shows a close interconnection between material engineering solutions, environmental impact, and profitability.

3. Installed Solar Energy Capacity in Romania (MW)

Until around 2010, the installed solar energy capacity in Romania was practically zero, and the market was non-existent. Growth began slowly in the early part of 2013–2014 and only accelerated after the first support schemes were introduced. Thus, the period after 2014 saw a boom in large-scale PV parks, stimulated by the green certificate scheme. Total capacity reached approximately 1200 MW by the end of 2014, according to data presented by the Ministry of Energy—the Green Certificate support scheme (Table 3).

Table 3.

Number of certificates by accreditation year [18].

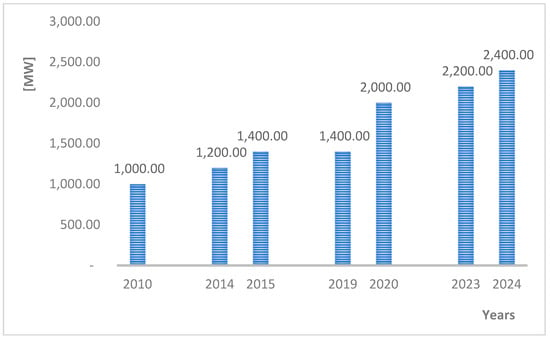

The period from 2015 to 2019 saw stagnation, as can be seen in Figure 5, where there were insufficient incentives for new major investments and capacity remained relatively constant. The year 2020 marked a significant turning point due to the introduction of the legal framework for prosumers; as a result, the market began to develop in a new segment, reaching an installed capacity of over 2000 MW by 2023. Installed capacity continued to grow exponentially, reaching over 2400 MW from prosumers alone by 2024 [18].

Figure 5.

Evolution of solar parks in Romania.

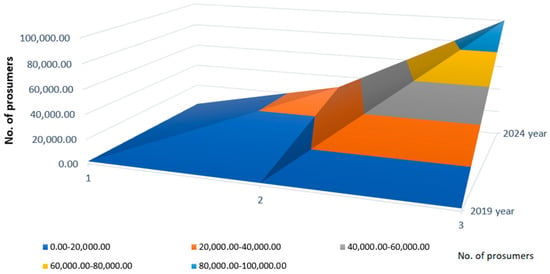

The evolution of the number of prosumers, as shown in Figure 6, is perhaps the best indicator of the installation rate in the residential and small commercial segment. As such, their number was insignificant in 2019, just under 1000, but in 2022 the number exploded, exceeding 30,000 prosumers. The year 2024 brings exponential growth, with the number of prosumers surpassing 100,000 [17].

Figure 6.

Evolution of prosumers number in Romania.

To quantify the upcoming wave of PV waste and justify the need for recycling capacity, a preliminary stock-and-flow model was developed. Based on the cumulative installed capacity of 2.85 GW at the end of 2023, and assuming an average module weight of 18 kg for a 400 Wp panel (i.e., 45 kg/kW), the current installed stock in Romania is approximately 128,250 tonnes. Using a standard module lifespan of 25 years and a conservative early failure/replacement rate of 1% per year, it is estimated that Romania will generate approximately 1280 tonnes of PV waste annually from the current stock alone. As the installed base continues to grow towards the 8 GW target for 2030, and as the initial wave of installations from 2012 to 2014 begins to reach its EoL after 2037, the annual flow of PV waste is projected to increase significantly, potentially reaching over 5000 tonnes per year by 2040. This estimation highlights the urgent need to establish a robust collection and recycling infrastructure to manage the anticipated EoL wave.

4. Materials

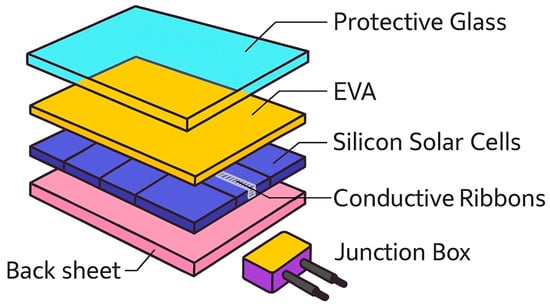

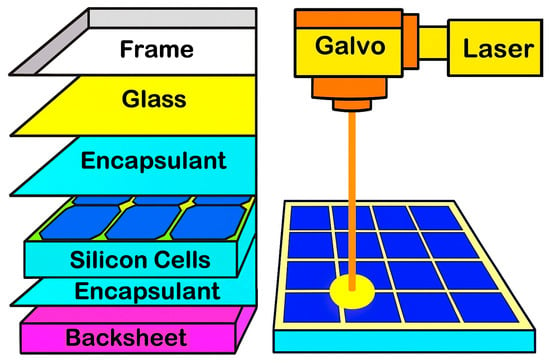

The choice of materials for PV solar cells is important. Not only do these materials dictate a cell’s efficiency and performance, but they also create unique challenges and opportunities for recycling once the cell reaches the end of its life. Each type of solar cell, from traditional crystalline silicon to newer thin-film technologies, relies on a specific set of materials to convert sunlight into energy [19]. Therefore, before we can move on to the recycling of PV panels and detail the eco-innovative technologies, we must first understand the composition of a PV panel and the materials used in its construction, as shown in Figure 7.

Figure 7.

Components of general PV.

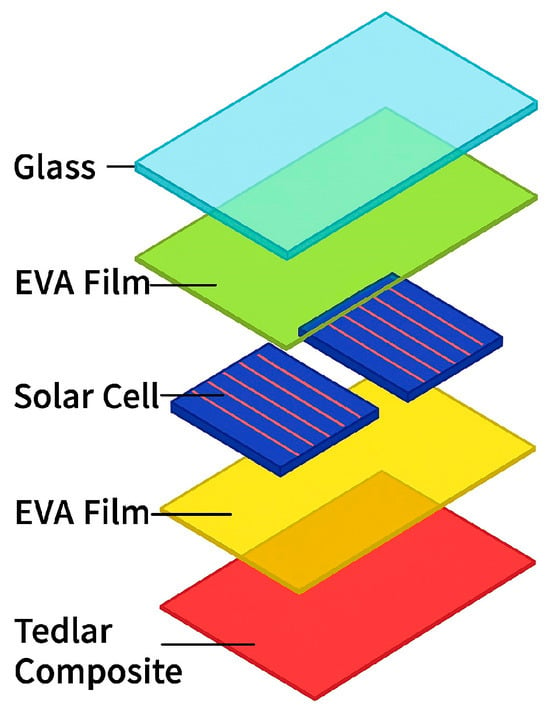

A modern PV panel is a complex system, made up of several layers (Figure 8), each with a specific role in generating and protecting electrical energy:

Figure 8.

EVA and TPT layer.

- -

- Front glass—This is a 3–4 mm thick tempered glass, which is the top layer most exposed to the sun [20]. It is treated to be resistant to impact, scratches, and extreme weather conditions (hail, strong winds) [21]. It allows sunlight to pass through with minimal loss, while also protecting the fragile solar cells from external factors. The majority of panels use low-iron glass to maximise light transmission [22].

- -

- Encapsulation film (EVA—Ethylene-Vinyl-Acetate)—This is a thermoplastic polymer film, which is transparent and UV-resistant [23]. It is placed both above and below the solar cells, acting as an adhesive and a sealing material [24]. At high temperatures, it melts and hermetically encapsulates the cells, protecting them from moisture, oxygen, and dust. This is a critical element for the panel’s durability and longevity [25].

- -

- PV cells—These are the heart of the panel, made from a semiconductor material, most commonly crystalline silicon (mono- or polycrystalline). The cells are connected in series and parallel to achieve the desired voltage and current. They convert light energy (photons) directly into electrical energy (direct current) through the PV effect [26].

- -

- Conductive ribbons—These are thin metal strips, usually made of copper coated with tin or silver, which connect the cells to each other and transfer the electrical current. They collect the current generated by each cell and transport it to the junction box [27].

- -

- Bracksheet—This is a plastic layer (typically a combination of polymers such as PET, PVF) that forms the back of the panel. It provides structural integrity, protects the panel from mechanical shocks, and facilitates its mounting on various structures (roof, ground) [28].

- -

- Junction box—This is a weather-resistant plastic box, mounted on the back of the panel. It contains the bypass diodes and connection points. All cell circuits are connected here. These bypass diodes prevent energy losses caused by partial shading of some cells, allowing the current to bypass the blocked cells [29]. It also serves as the connection point for the output cables (MC4 cables).

Each individual component of the PV panel represents valuable raw materials which, through advanced processing and recycling technologies, can be recovered and reintegrated into various industrial sectors [30].

5. High-Tech Manufacturing Technologies

The leading manufacturers of latest-generation PV panels are focusing on advanced technologies such as TOPCon, HJT (Heterojunction), and IBC (Interdigitated Back Contact). These are outperforming P-type PERC (Passivated Emitter and Rear Cell) cells, which have dominated the market in recent years. Table 4 provides a representative picture of the direction in which the China’s PV industry is heading and the innovation efforts of top manufacturers.

Table 4.

Laboratory efficiency records for the most advanced PV panel technologies.

Therefore, we can briefly detail each technology in turn to provide an overview of the manufacturing technology in relation to the power output.

5.1. ABC Technology

ABC technology represents a major innovation in PV cell design and is considered one of the most advanced technologies on the market [30,31]. The basic principle of this technology is to move all electrical contacts (both positive and negative) to the back of the solar cell [32]. By contrast, in a conventional solar cell, the metallic contact lines are visible on the front, where they absorb light and create partial “shading” that prevents the sun from reaching the silicon cells, resulting in lower efficiency [33].

ABC technology completely eliminates these front contacts, so the entire cell surface is free and can absorb 100% of the incident light [34]. Once generated, electrons are guided to the back of the cell, where they are collected by the electrical contacts. By moving the contacts to the back, the cells are also less susceptible to micro-cracks caused by mechanical or thermal stress, resulting in increased reliability [35].

5.2. HBC Tehnology

HIBC is a hybrid technology that integrates the benefits of both HJT and IBC [36], as follows:

- HJT refers to the internal structure of the cell. It uses a combination of crystalline silicon (for the cell body) with very thin layers of amorphous silicon on both faces [35]. This ensures excellent surface passivation, significantly reducing energy losses caused by electron recombination. The result is a higher open-circuit voltage and improved efficiency [35,37].

- IBC refers to the design of the electrical contacts, where all metallic contacts (both positive and negative) are moved to the back of the cell, leaving the front completely free [33]. This eliminates front-side shading and allows the cell to absorb the entire amount of incident light. The contacts are arranged in intertwined “fingers” (interdigitated), optimising current collection [35].

Therefore, by combining these two principles, HIBC achieves an extremely high level of efficiency by maximising light absorption (thanks to the IBC design) and by minimising internal energy losses (thanks to the HJT structure).

5.3. TOPCon

TOPCon technology is a revolutionary evolution of PERC solar cells. It is considered a bridge between traditional and more advanced cells (such as HJT or ABC), offering an excellent balance between high efficiency and controllable production costs [38].

The basic principle of TOPCon involves adding a passivated contact layer to the back of the cell. Unlike PERC cells, which have a single passivation layer, TOPCon cells use a more complex structure consisting of two layers [38]:

- A tunnel oxide layer, which is an ultra-thin (1–2 nanometres) layer of silicon dioxide (SiO2), so thin that it allows electrons to pass through it using a quantum phenomenon [35]. Its main role is to dramatically reduce energy losses caused by electron recombination.

- A polysilicon layer, which is deposited on top of the oxide layer. It acts as an electrical contact, collecting electrons while simultaneously preventing recombination [39]. Through this structure, TOPCon achieves superior passivation of the cell’s rear surface. Essentially, the tunnel oxide layer acts as a shield that allows electrons to pass through but blocks electrical “holes,” which increases the cell’s voltage and, consequently, its efficiency [38].

We can draw a parallel between the two: TOPCon vs. PERC. TOPCon is seen as an evolution of PERC, as represented in Table 5, because most manufacturers have been able to adapt their existing PERC production lines to produce TOPCon cells with relatively small additional investments.

Table 5.

Parallel between the two technologies: TOPCon vs. PERC.

As shown in Table 5, TOPCon technology has delivered significant improvements over PERC, offering higher efficiency, lower degradation, and superior performance at high temperatures, with production costs that are becoming increasingly competitive.

5.4. Tandem Perovskite-Silicon Technology

This technology is considered to be the “next step” in the evolution of solar energy, with the potential to surpass the theoretical efficiency limits of traditional PV cells [34]. This innovative technology does not replace silicon; it complements it, forming a hybrid structure in which two PV cells are designed to capture a specific portion of the light spectrum.

The tandem Perovskite-Silicon solar cell consists of a top cell and a bottom cell:

- Top cell: This is made from a Perovskite-based material, a compound with a crystalline structure that has revolutionised research in the last decade [35]. Perovskite is extremely efficient at absorbing high-energy light (the blue and green part of the spectrum) [35,40].

- Bottom cell: This is a traditional crystalline silicon cell that has been optimised to efficiently capture lower-energy light (the red and infrared part of the spectrum) that has passed through the perovskite layer [35,41].

5.5. IBC Technology

This IBC technology is an advanced solar cell design method that was developed to maximise the amount of absorbed light and increase efficiency [42]. Here too, the metallic contacts on the front of the cell have been eliminated, as with ABC technology [43].

Therefore, in an IBC solar cell, both the positive and negative contacts are arranged in an “intertwined” (interdigitated) pattern on the back of the cell. By moving all the contacts to the back, the front of the cell remains completely unobstructed by metallic lines, maximising the amount of captured energy [42]. The electrons and “holes” generated by the light absorbed on the front diffuse through the cell and are collected by the metallic contacts on the back [31,43]. The short distance between contacts and the cell’s optimised structure ensures efficient current collection [42]. This structure not only improves performance but also provides a superior aesthetic appearance, with a uniform black front surface.

6. Recycling Methods and Technologies

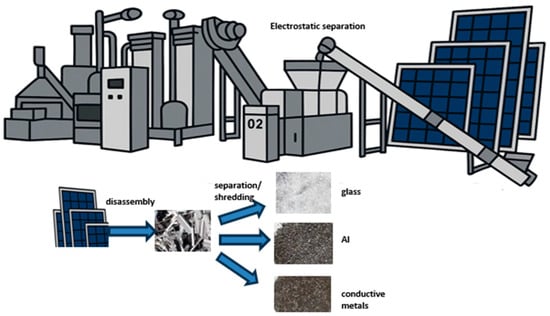

These methods represent the first stage of most recycling processes and are considered the most eco-friendly in terms of energy consumption and emissions [44]. This stage consists of two main steps:

- automated disassembly and shredding of components;

- density-based and electrostatic separation.

Disassembly is largely performed by industrial lines (Figure 9) [45], which separate the aluminium frame [44]. The rest of the panel is then shredded into small pieces. After shredding, the materials are sorted based on density (for example, glass is heavier than plastic) and electrostatic properties [46].

Figure 9.

The process of recycling a solar panel.

Advanced technologies use optical sensors and artificial intelligence (AI)-based algorithms to identify and separate materials with very high precision [30]. The use of these advanced technologies for recovering the main materials from PV panels leads to reduced energy consumption, while the absence of chemical reagents minimises the environmental impact [30].

6.1. Thermal Methods

Thermal methods such as pyrolysis are used to separate the glass and silicon cells from the EVA plastic film that holds them together. The shredded panels are heated in a special furnace to temperatures of approximately 500 °C in an oxygen-free environment. This process breaks down the EVA polymers, allowing for a clean separation of the silicon cells and glass [47]. The resulting materials, such as silicon and silver, can then be purified [48].

This method provides an efficient recovery of silicon and metals, especially silver, which has a high economic value. Modern furnaces are equipped with advanced filtration systems to prevent toxic emissions [35], such as gas scrubbers and particulate filters that capture volatile organic compounds and hazardous substances released during polymer decomposition.

6.2. Chemical Methods

These hydrometallurgical techniques are used to recover precious metals from the silicon cells after they have been separated through a “leaching” process (controlled dissolution) [48]. The silicon cells are placed in chemical solutions, usually acids or bases, to selectively dissolve the thin layers of metals like silver, copper, and lead, without damaging the silicon [49]. The resulting solution, which contains the dissolved metals, is then processed to recover and purify them. This method allows for the recovery of precious metals with very high purity, maximising the economic value of the recycled materials [34].

Innovative technologies, such as Laser Delamination and turn-key solutions, represent major advances in the industry, enabling faster, more precise and more efficient processes.

6.3. Laser Delamination

Laser delamination is an emerging technology that uses a laser to precisely detach the metal layers from the silicon cells (Figure 10) [47]. By using this process, silver can be recovered in the form of nanoparticles, which have an even higher value than standard silver [50].

Figure 10.

Laser delamination.

6.4. Turn-Key

On the Romanian market, there are already companies that offer fully automated modular recycling systems, or “turn-key” solutions, which combine all these methods into a single integrated system [30,51]. These solutions are designed to be scalable and to adapt to large quantities of waste panels [35].

The smart combination of these technologies allows for the recovery of up to 95–98% of a PV panel’s materials, although these rates are typically achieved under optimised laboratory or pilot-scale conditions for specific module types and material purity targets [46]. This process transforms a potentially hazardous waste into a valuable source of raw materials.

Currently, the latest innovations in PV panel recycling are technologies that focus on increasing efficiency, recovering materials with higher purity, and integrating artificial intelligence and robotics to automate the process through [45,48]:

- AI and robotics-assisted disassembly: Modern recycling systems integrate AI and industrial robots to identify and separate panel components. The robots use visual and hyperspectral sensors to scan each panel to determine its exact composition and condition (for example, the type of silicon, the presence or absence of defects) [30]. Robotic arms are programmed to precisely remove the aluminium frame, junction box, and cables, optimising the process to preserve the integrity of the materials [52].

- Advanced delamination methods: These focus on recovering valuable materials with a high enough purity to be reintroduced into the production of new panels [47]. After shredding, the silicon dust is treated through chemical (hydrometallurgical) or plasma processes to be purified to the standards required for the manufacturing of new cells [53]. Silver is recovered through advanced electrolytic methods (based on applying an electric current), which can recover up to 99.9% of the silver from the cells [48], a precious metal that adds significant economic value to the process [49].

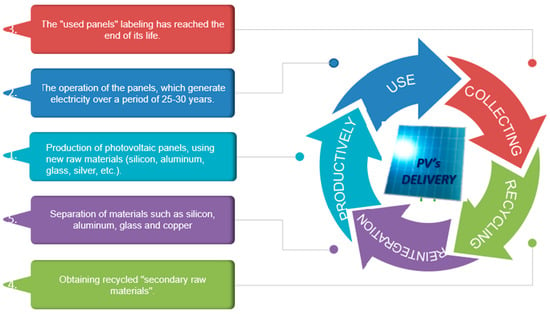

7. Recovery, Recycling and Reintegration Strategies

This strategy, also known as the 3R strategy—Recovery, Recycling, and Reuse—is also referred to as the circular economy [18,46]. It is based on three essential principles, namely:

- -

- Recovery is responsible for the collection of PV panels at the end of their lifespan;

- -

- Recycling is responsible for the disassembly of panels, the separation of materials into categories, processing them using various eco-technologies, and the recycling of valuable materials (silicon, silver, copper, aluminium, and glass);

- -

- Reintegration is responsible for integrating valuable materials obtained from recycling and reuse into the production of new PV panels (silicon) or into other industries (aluminium).

The main way this strategy reduces the demand for new materials is by leveraging existing resources [35,46]. Instead of continuously extracting raw materials from nature (such as silicon from quartz sand or metals from ores), materials recovered from old panels are used [46]. However, the quality of the recycled materials at the end of the recovery operations can sometimes be inferior, as can be seen in Figure 11.

Figure 11.

The strategy of EoL—PV recycling.

It is a known fact that the process of recycling PV panels is complex and expensive, and current technologies cannot recover 100% of the materials [48,53]. This is because glass can be recovered at a rate of 90%, whereas silicon is more difficult to purify and has a lower efficiency [44,54]. In order to contribute to the implementation of strategies for the recovery of primary materials, we must have a thorough understanding of their material composition [35]. The materials used in the production of PV cells are essential not only for their performance, but also for the challenges and opportunities of recycling. Crystalline silicon cells, which dominate the market, contain, as we have seen, silicon, glass, aluminium, copper, and silver, and their recycling is difficult due to the EVA adhesive that binds the layers, requiring complex processes to recover valuable materials. On the other hand, thin-film cells, such as those based on cadmium telluride (CdTe) or copper indium gallium selenide (CIGS), use toxic (cadmium) or rare (indium, gallium) materials, which requires specialised and controlled recycling to prevent pollution and recover precious elements [10,12,18]. All these recycling efforts contribute to a circular economy, reducing dependence on virgin resources and minimising environmental impact.

ABC panels, like the latest-generation PV panels, have a material composition very similar to that of classic monocrystalline panels [47]. The major difference is not in the types of materials, but in how the internal layers are arranged (for example, the metallic contacts on the back) [46].

Some manufacturers, such as AIKO [55], have developed silver-free (Ag-free) technologies on the front of the panel for ABC technology, which reduces costs and has a positive impact on recycling by simplifying the purification process. Although the materials are the same, the ABC structure makes the delamination process essential for recovering the silicon cell, where the silver (if present) and copper contacts are also located.

Similar to ABC technology, the HIBC innovation consists of moving the metallic contacts (silver and copper) to the back of the cell [56]. This does not change the percentage of materials, but it makes the delamination process important for recovering these valuable metals with the highest possible purity. Due to the heterojunction structure (using amorphous silicon), HIBC cells are more stable and have less degradation. From a recycling perspective, this means that the recovered materials are of excellent quality.

TOPCon cells use N-type silicon, which has higher purity and is more resistant to impurities [57]. This makes the silicon recovered from a TOPCon panel have a potentially higher value on the recycled materials market. The technological difference of TOPCon, namely the tunnel oxide and doped polysilicon layers, does not change the bulk composition of the panel, but it does influence the cell’s structure, which makes silicon purification important techniques.

In Table 6 we will represent an estimated percentage of recoverable materials from a PV panel using specified manufacturing technologies.

Table 6.

Estimated percentage of recoverable materials from a PV panel using TOPCon manufacturing technology.

As with other advanced technologies, the recycling process focuses on the efficient delamination of layers. The initial goal is to recover the silicon cell and the metallic contacts on the back (which include silver and copper) without contaminating them with plastics. TOPCon’s technological difference, specifically the tunnel oxide and doped polysilicon layers, does not change the panel’s bulk composition but does influence the cell’s structure. This makes high-quality, latest-generation silicon purification techniques important for high-quality recycling.

The unique materials and cell architectures of modern technologies such as TOPCon, HJT/HIBC, IBC, and Perovskite-Si tandems require specific recycling approaches. Table 7 provides a detailed matrix correlating these technologies with their major EoL obstacles and suitable recycling routes. This analysis highlights the necessity for advanced recycling processes tailored to recover valuable materials and manage complex components, thus ensuring an effective transition to a circular economy within the energy sector.

Table 7.

Technology-recycling matrix for modern PV modules.

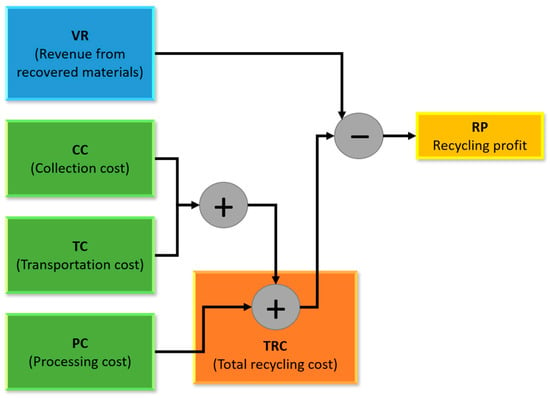

Recycling costs are an important and complex element in determining the economic viability of any waste management operation, and in the case of PV panels, they are far from a simple sum as sown in Equations (1) and (2). They are influenced by a network of variable and interconnected parameters [58]. In essence, the total recycling cost is made up of three distinct stages (Figure 12). The first stage is collection cost, which depends on factors such as pickup logistics, volume, and waste density within a specific geographical area. For instance, collecting a few panels from private homes involves a much higher per-unit logistical cost than collecting hundreds of panels from a solar farm. The second stage, transportation cost, is directly influenced by the distance to the recycling centre, the volume and weight of the panels, and the strict regulations governing the transport of waste electrical and electronic equipment. The third and most complex stage is processing cost, which directly reflects the technology used. While mechanical processes are relatively cheap, they have a low recovery rate for valuable materials like silicon, whereas chemical or thermal processes are far more efficient but involve huge investments in specialised equipment, high energy consumption, and the use of expensive chemical reagents. Therefore, a detailed analysis of each parameter is essential to optimise the operation and ensure that the profit from the sale of recovered materials consistently exceeds the total costs, thus transforming an environmental necessity into a viable business.

Figure 12.

Formula flowchart. The Total Recycling Cost (TRC) is obtained by adding (the “+” symbol) the Collection Cost (CC), the Transportation Cost (TC), and the Processing Cost (PC). The final Recycling Profit (RP) is calculated by subtracting (the “–” symbol) the TRC from the Revenue from Recovered Materials (VR).

An accurate economic analysis requires a specific feasibility study for a particular location and technology, so we can provide a concept of the total cost which is the sum of the individual costs [59], and the profit is the difference between the income from the recovered materials and the processing costs, specified in the following equations:

where

- CTC—total recycling cost;

- CC—collection cost which depends specifically on the logistics of taking over the panels;

- TC—transport cost which varies depending on the distance to the recycling centre but also on the volume of recycled products;

- PC—processing and machining cost which includes all technological steps from disassembly to chemical processing.

- RP—represents the recycling profit;

- VR—represents the total value of materials sold after recycling (aluminium, glass, copper, silver, etc.).

- TRC—represent the total recycling cost.

For recycling to become a viable economic activity, VR must be higher than CTR, and the current challenge is that, for many high-tech technologies and a low volume of end-of-life materials, CTR exceeds VR, making the process unprofitable, hence the name “unicorns” for recycling plants.

The strategies for PV panel recycling in Romania are intrinsically linked to the European Union’s legal framework, specifically the Waste Electrical and Electronic Equipment (WEEE) Directive (2012/19/EU) [60]. Since 2012, PV panels have been included within the scope of the WEEE Directive, classifying them as e-waste and mandating their separate collection and recycling. The cornerstone of this policy is the principle of Extended Producer Responsibility (EPR), which makes manufacturers and importers financially and logistically responsible for the EoL management of the products they place on the market. This includes financing collection, transport, and recycling operations to meet specific recovery targets. While the EU framework provides a strong foundation, implementation in Romania faces challenges. There is currently a gap in the national infrastructure for specialised PV panel collection and a limited number of high-capacity, advanced recycling facilities. This creates an opportunity for investment in dedicated recycling plants and the development of efficient, nationwide collection schemes to fulfil EPR obligations and capitalise on the growing volume of EoL panels from the prosumer market.

As mentioned, global production of PV panels is increasing at a very rapid pace [47]. Even though some materials are recovered through recycling, the total demand for new materials remains high to support this expansion [18]. Therefore, we can say that the recovery and recycling strategy contributes to better resource management and a reduced ecological footprint [46]. Although its current impact on global demand for new materials is relatively small, its role will become increasingly important as the PV panel industry matures and the volume of waste increases [61].

Applying the principles of a circular economy in the PV panel industry generates synergistic benefits, both economically and ecologically [62]. From an economic perspective, advanced recycling strategies allow for the recovery of critical raw materials such as high-purity silicon, silver, and copper [47]. This approach significantly reduces the dependence on the extraction of primary resources, the price volatility of which can affect market stability [46]. By reintegrating these materials into the production cycle, the costs of acquiring raw materials are lowered, and, implicitly, the industry’s long-term competitiveness is increased [62].

From an ecological perspective, the circular process contributes to reducing the sector’s carbon footprint [61]. In other words, by avoiding the extraction and processing of new materials, less energy is consumed, which leads to a decrease in associated carbon dioxide (CO2) emissions [62]. In addition, efficient recycling prevents the accumulation of waste PV panels, which could end up in landfills, and minimises the risk of soil and water contamination with potentially toxic elements [47]. Thus, it ensures responsible management of electronic waste, and the capture, storage, and transmission of solar energy will be a truly sustainable solution for the global energy transition [46].

The strengths of the PV panel recycling industry (Table 8) are closely tied to global trends and the inherent value of the materials. A key factor is the growing demand, driven by regulations like the EU’s WEEE Directive and increasing public awareness. This demand turns an environmental problem into a business opportunity. Moreover, PV panel recycling proves to be profitable, given that valuable materials such as aluminium, glass, copper, silver, and most importantly, silicon, can be recovered. This material value also ensures a stable long-term feedstock for recycling plants, thanks to the 25–30-year lifespan of panels installed in large numbers in previous decades. Technological innovations, such as advanced sorting systems based on artificial intelligence, enhance the efficiency and purity of recovered materials.

Table 8.

Strengths and weaknesses of the PV panel recycling industry.

However, the industry faces significant challenges. One of the biggest weaknesses is the high operational costs of recycling processes, which often require specialised equipment and high energy consumption (Table 8). This problem is exacerbated by a lack of infrastructure for recycling, making it expensive and inefficient to transport panels to the few available centres. Additionally, the industry is highly dependent on market fluctuations, where a drop in the price of recovered raw materials can directly impact profitability. There are also technological risks associated with handling hazardous components (such as lead or cadmium) that require costly processes to prevent environmental contamination.

The PV panel recycling industry stands at a critical juncture, with numerous opportunities for growth (Table 9). Government support and funding from nations promoting a circular economy can accelerate the development of new recycling capabilities. This evolution is essential for integration into the circular economy, where recovered materials can be used to produce new panels, reducing the reliance on virgin resources. Process innovation is paving the way for more efficient and cost-effective technologies that can recover materials that current methods cannot. Ultimately, the exponential growth of the solar panel market guarantees a massive volume of waste in the coming decades, creating a market with huge growth potential.

Table 9.

Opportunities and threats of the PV panel recycling industry.

On the other hand, the threats to the industry are just as significant (Table 9). The biggest threat is a rapid technology shift, as new technologies (such as perovskite-based cells) could replace silicon in just a few years. Although the flow of old silicon panels will continue for a while, a decline in new silicon panel installations could compromise the long-term viability of plants specialising in this material’s recycling. Therefore, massive investments in current silicon recycling technologies could become unprofitable. Also, the long lifespan of panels is a short-to-medium-term threat, as the “waste boom” will only occur in 15–20 years, making a major investment at present risky. Last but not least, a decrease in the price of virgin silicon could make the recycled material less economically competitive, affecting the industry’s profitability.

8. Discussions

Before detailing the conclusions and practical implications of our study, it is imperative to situate our findings within the current academic context by directly comparing them with the existing specialised literature. This chapter aims to explore how our contribution aligns with or differs from similar studies. Our contribution provides an integrated analysis of the local Romanian market, the evolution of cutting-edge technologies, and recycling solutions. While much of the research focuses on technical or economic aspects without interconnecting them in a geographically specific manner, the present paper seeks to highlight its uniqueness by integrating bibliometric data with a national context marked by the exponential growth of the prosumer segment, offering a strategic and applicable perspective. Through this comparative approach, we can validate the relevance of our study and identify future directions in which research can be expanded and deepened.

Luu, L.Q. et al. [16], presents a paper applying LCA to quantify the material demand of the Italian solar PV sector, as well as the contribution of EoL strategies for solar PV panels to the improvement of the circular economy. They found that the material intensity of the Italian solar PV sector is set to increase from 4.67 g Sb equivalent to 5.20 g Sb equivalent per MWh by 2040, primarily due to a change in technology. Concurrently, total material demand, as well as demand for specific materials, increases from 2008 to 2040. The strategy regarding the recovery, recycling and reintegration of materials reduces the demand for materials slightly, from 816 to 814 tons of Sb equivalent in 2040. However, this paper does not address eco-innovative recycling methods and technologies for these panels.

Vasiliev, M. [63], addresses the electricity generation capacity and long-term performance differences of solar greenhouses. This paper presents the field performance of PV windows in the context of agrivoltaics, providing details on performance differences measured for various solar window models depending on the glazing materials used. However, this paper does not address eco-innovative recycling methods and technologies for these PV panels.

Piedrahita, A. [64], examines the solar panel supply chain, highlighting critical stages, waste generation sources, existing management practices, and potential areas for improvement. The paper classifies these wastes, each requiring specific management strategies, but it does not detail the technologies used for recycling these EoL panels. This study offers important insights for policymakers, industry stakeholders, and researchers focused on improving circularity and sustainability in the PV sector.

The present paper provides an integrated analysis of photovoltaic panel recycling, combining technological, economic, and national market aspects in Romania, which differentiates it from existing studies that focus on isolated elements [64]. Global research, such as that reviewed in bibliometric analyses, shows that technologies like TOPCon, ABC, and HIBC improve recycling efficiency, enabling the recovery of valuable materials, but these are often neglected in traditional European studies [6,27].

Recent studies from Romania highlight an increase in recycling capacity, with new plants processing photovoltaic panels to address economic challenges, such as high decommissioning costs and reuse opportunities, contributing to an expanding market [64,65]. Unlike the specialised approaches in the literature, which are limited to chemical methods or European regulations, the proposed integrated analysis includes global trends, such as the impact of the growing number of prosumers on the local market.

From an economic perspective, PV panel recycling in Europe in 2025 involves environmental and financial benefits, reducing the dependence on new raw materials and promoting the circular economy, although challenges include high initial costs [66,67]. TOPCon, ABC, and HIBC technologies increase the value of recycling by efficiently recovering silicon and other materials, which is essential for the emerging Romanian market.

The analysis of economic challenges is given mainly by the costs of primary materials vs. recycled materials. Currently, we can say that recycling such photovoltaic panels on a large scale is very expensive due to the complex technologies proposed but also the small volume of waste currently in Romania. Costs for recovered glass and aluminium can be competitive, but materials such as silicon or silver require expensive hydrometallurgical processes that can make new (virgin) material cheaper. The rapid evolution of PV technologies (PERC, HJT, CIGS cells) complicates the recycling process, as each type of panel requires a specific method. This technological variety prevents the creation of a standardised and efficient process.

The major costs of acquiring specialised equipment (lasers, thermal ovens, shredding systems, and others) make the initial investment for an industrial-scale recycling facility very high, making such stations “unicorns”. Currently, the small number of such photovoltaic panels at the end of their life cycle in Romania makes it difficult to achieve the economies of scale necessary for recycling to become profitable, but we are convinced that this situation will change in the next 5–10 years, when the volume of photovoltaic waste will increase exponentially.

Global bibliometric analysis shows an exponential growth in research on recycling, with a focus on integrating technological and economic aspects, but European studies remain fragmented, ignoring the national context of Romania. This holistic approach, which links legislation, technology, and the market, offers practical solutions for local challenges, such as managing waste from prosumers.

The novelty of this article stems from a complex and integrated approach, combining a detailed analysis of the evolution of the PV sector in Romania with an in-depth study of modern recycling technologies. The paper distinguishes itself by conducting a bibliometric analysis of recent publications from the Web of Science database, a method noted as missing from other mentioned works. This analysis identified a clear evolution in research from basic technical aspects towards a more holistic approach, which includes the circular economy and LCA.

The article also provides a unique perspective on the Romanian market, detailing its journey from a pioneering role in the 1970s and 1980s to the recent, spectacular growth in the number of ‘prosumers’. This regional contextualisation adds relevance and novelty, as the exponential rise in installed panels simultaneously increases the need for efficient waste management at the end of their life cycle.

From a technical standpoint, the article provides a detailed description of the components of a PV panel and the challenges associated with recycling valuable materials such as glass, aluminium, silicon, silver, and copper. Another significant contribution is the presentation and analysis of latest-generation manufacturing technologies, such as ABC, TOPCon, and HIBC, and their impact on the recycling process. The article describes in detail the eco-innovative recycling methods, including mechanical, thermal (pyrolysis), and chemical (hydrometallurgical) processes, as well as emerging technologies like laser delamination. It highlights how innovations such as AI and robotics contribute to a better recovery of high-purity materials with significant economic value.

Finally, the article extends beyond the technical scope by integrating the recycling process into the broader circular economy concept, based on the 3R strategy: Recovery, Recycling, and Reintegration. It highlights the economic and ecological benefits of this approach, including reduced dependence on virgin resources, a lower carbon footprint, and the creation of new business opportunities.

9. Conclusions

As the PV industry expands rapidly and panels reach the end of their useful life, efficient recycling is becoming a critical component of global energy sustainability. The recycling of latest-generation panels, such as those based on ABC, TOPCon, and HIBC technologies, is no longer a simple waste management process but a complex and essential circular economy strategy.

The modern recycling process is a synergy of advanced methods, transforming waste into valuable raw materials. Each method has a well-defined role:

- -

- The use of robots and AI-based systems ensures a rapid and precise disassembly, which recovers high-volume and high-value materials like glass and the aluminium frame.

- -

- The use of innovations such as laser delamination and hydrometallurgical methods allows for the separation of silicon components from the EVA adhesive and the recovery of precious metals. This is the main stage for recovering silicon and, in particular, silver and copper, which, despite their small proportion, hold significant economic value.

- -

- The use of new technologies allows for the purification of recovered materials to a quality level high enough to be reused directly in the manufacturing of new PV cells or in other industries.

The recycling of latest-generation panels generates a number of major economic and ecological benefits and opportunities, such as:

- -

- Resource sustainability by recycling materials reduces the dependence on the extraction of raw materials, which is an energy-intensive process with a high environmental impact. By recovering N-type silicon (used in TOPCon and HJT), with its superior purity, a valuable source of material is created for future panels.

- -

- Carbon footprint reduction by reintegrating recycled materials into production leads to a significant reduction in CO2 emissions, compared to using new raw materials.

- -

- Business opportunities by the emergence of new “turn-key” recycling technologies transform waste management into new business models, creating a profitable and ecological circular industry.

In conclusion, a transition towards a sustainable solar economy is inseparable from the continuous development of recycling technologies. The integration of technological innovations, economic efficiency, and ecological awareness transforms the recycling process from an obligation into a strategic pillar of the global energy future.

This review has several limitations that should be acknowledged. First, the bibliometric analysis, while systematic, is confined to the Web of Science database and may not capture all the relevant literature from other sources or in other languages. The heterogeneity of data across different studies, particularly concerning recovery rates, which vary by technology and scale, makes direct comparisons challenging. Second, the stock-and-flow estimation for Romania is a first-order model based on public data and general assumptions; a more granular analysis is needed for precise infrastructure planning. Third, many of the advanced recycling techniques discussed have not yet been validated at a large commercial scale, and the material bill of modules continues to evolve across generations. Future work should focus on several concrete steps: conducting a compact LCA or Techno-Economic Analysis (TEA) for a specific recycling pathway tailored to the Romanian context; validating the projected EoL waste flows with industry-specific data on module failure and replacement rates; and performing pilot-scale studies to test the efficacy of recycling routes for next-generation modules like perovskite-silicon tandems.

Given the challenges and opportunities discussed, future research should focus on three key areas: process optimisation, material innovation, and economic sustainability. An essential area to explore is the integration of AI and robotics to automate the disassembly and sorting process. Implementing these technologies could significantly increase the efficiency and purity of recovered materials while reducing costs and safety risks. Furthermore, research should expand into the development of new, small-scale processing methods that are cost-effective for smaller waste volumes, particularly in rural areas. This would help reduce transportation costs and create a more decentralised, accessible recycling network. It is also vital to conduct an LCA of emerging PV technologies, such as perovskite-based cells, to ensure that future green energy solutions do not create a new waste problem. Finally, future studies should investigate more efficient circular business models and policies, such as mandatory “take-back” schemes for manufacturers. This would secure a stable and predictable flow of waste for recycling facilities, helping to stabilise the market and encourage investment.

Beyond an in-depth analysis of technologies and the market, the present study justifies its usefulness through its direct relevance to several categories of stakeholders. For policy-makers in Romania, the data presented on the exponential increase in the number of prosumers represents a wake-up call and, at the same time, an essential guide for formulating coherent public policies. The implicit recommendations aim to create a legislative and economic framework that stimulates the development of a national infrastructure for the collection and recycling of photovoltaic panels, before the wave of waste becomes a major problem. At the same time, for the business community, this paper offers a strategic vision of investment opportunities in “eco-innovative” recycling technologies, paving the way for new business models based on circular economy principles. Last but not least, for the scientific community, the bibliometric analysis identifies gaps in current research, suggesting promising directions for further study, from optimising techniques for separating valuable materials to integrating second-generation panels into recycling processes, thereby contributing to continuous progress adapted to the local specificities of Romania.

Author Contributions

Conceptualisation, V.-D.B. and R.-M.N.; methodology, V.-D.B. and R.-M.N.; software, R.-M.N.; validation, V.-D.B., R.-M.N. and S.-E.I.; formal analysis, S.-E.I.; investigation, V.-D.B. and S.-E.I.; resources, V.-D.B.; data curation, S.-E.I.; writing—original draft preparation, V.-D.B.; writing—review and editing, V.-D.B., R.-M.N.; visualisation, S.-E.I.; supervision, S.-E.I.; project administration, V.-D.B.; funding acquisition, V.-D.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by Ministry of Education and Research—National Research Au-thority (Romania), CCDI—UEFISCDI, Project number: PN 23 43 05 02—17N/2023—“IoT architecture for soil monitoring/IoT-SOL”.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

This work has been supported by: (1) CERMISO Center—Project Contract no.159/2017, Program POC-A.1-A.1.1.1.1-F; (2) Support Center for International RDI Projects in Mechatronics and Cyber Mix-Mechatronics, Contract no. 323/22.09.2020, project co-financed by the European Regional Development Fund through the Competitiveness Operational Program (POC) and the national budget. The authors thank the Department of Theory of Mechanisms and Robots at the Faculty of Industrial Engineering and Robotics, UNST POLITEHNICA Bucharest, Romania, for their support in this research. Special thanks are extended to Liviu-Marian Ungureanu, Lecturer Elisabeta Niculae, and Lecturer Alexandra Rotaru for their fundamental contributions, including valuable scientific suggestions on drafting and visualisation, as well as project supervision and securing funding.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 3R | Recovery, Recycling, and Reuse |

| ABC | All Back Contact |

| AI | Artificial Intelligence |

| CfD | Contracts for Difference |

| CIGS | Copper Indium Gallium Selenide |

| CO2 | Carbon Dioxide |

| EoL | End-of-Life |

| EPR | Extended Producer Responsibility |

| EVA | Ethylene-Vinyl-Acetate |

| GD | Government Decision |

| HJT | Heterojunction |

| HIBC | Heterojunction Interdigitated Back-Contact |

| IBC | Interdigitated Back Contact |

| IoT | Internet of Things |

| LCA | Life Cycle Assessment |

| LID | Light-Induced Degradation |

| PERC | Passivated Emitter and Rear Cell |

| PET | Polyethylene Terephthalate |

| PPA | Power Purchase Agreements |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| PV | Photovoltaic |

| PVF | Polyvinyl Fluoride |

| TEA | Techno-Economic Analysis |

| TOPCon | Tunnel Oxide Passivated Contact |

| WEEE | Waste Electrical and Electronic Equipment |

| WoS | Web of Science |

References

- Coroian, A.; Ivascu, L.; Cisma, T.; Ardelean, M.; Saptebani, N.-I. The Application of Solar Energy in Romania’s Automotive Fiel. Ann. Ser. Eng. Sci. (Acad. Rom. Sci.) 2024, 16, 41–54. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. Review of Solar Refrigeration and Cooling Systems. Energy Build. 2013, 67, 286–297. [Google Scholar] [CrossRef]

- Shrestha, N.; Zaman, A. Decommissioning and Recycling of End-of-Life Photovoltaic Solar Panels in Western Australia. Sustainability 2024, 16, 526. [Google Scholar] [CrossRef]

- Ministerul Energiei. A Brief History of Renewables. Available online: https://energie.gov.ro/home/informatii-de-interes-public/surse-regenerabile-de-energie-in-romania/scurta-istorie-a-regenerabilelor/ (accessed on 10 August 2025).

- Avăcăriței, G. The Current State of Large-Scale PV Projects in Romania: A Comprehensive Overview; energynomics.ro: Bucharest, Romania, 2025. [Google Scholar]

- Bulgaru, I.A.; Nedelcu, A.; Stănciulescu, R.-I.; Paraschiv, D.-M. The Importance of Photovoltaic Solar Panel Recycling in Romania: Aligning with the Green Deal and Fit for 55 Strategies. Proc. Int. Conf. Bus. Excell. 2024, 18, 715–724. [Google Scholar] [CrossRef]

- Ministerul Energiei. European and National Legislation. Available online: https://energie.gov.ro/home/informatii-de-interes-public/surse-regenerabile-de-energie-in-romania/legislatie-primara/ (accessed on 10 August 2025).

- Komnos, A. The Romania Energy & Infrastructure Platform for Southeast Europe. Available online: https://energyworld.ro/2024/04/03/romanias-solar-power-sector/ (accessed on 5 September 2025).

- Rotaru, C.-L.; Timiş, D.; Grădinaru, G.-I. Efficient Capture of Solar Energy in Romania: Approach in Territorial Profile Using Predictive Statistical Techniques. Proc. Int. Conf. Bus. Excell. 2023, 17, 1519–1533. [Google Scholar] [CrossRef]

- Ciobotea, M.; Dobrotă, E.-M.; Stan, M.; Bălăcian, D.; Stanciu, S.; Dima, A. Data–Driven Analysis of Romania’s Renewable Energy Landscape and Investment Uncertainties. Heliyon 2024, 10, e27334. [Google Scholar] [CrossRef]

- Todorović, I. Battery Storage Project Pipeline in Romania in Rapid Expansion. Available online: https://balkangreenenergynews.com/battery-storage-investors-in-romania-rapidly-expanding-project-pipeline/ (accessed on 12 August 2025).

- Romanian Photovoltaic Industry Association Solar Energy in Romania: Growth at a Glance. Available online: https://rpia.ro/ (accessed on 12 August 2025).

- Fan, H.-H.; Salas-Redondo, C.; Chalaux, A. Life Cycle Assessment of an Innovative High-Value-Recovery Crystalline Silicon Photovoltaic Recycling Process—The Environmental Impacts and Benefits. EPJ Photovolt. 2024, 15, 35. [Google Scholar] [CrossRef]

- Mao, D.; Yang, S.; Ma, L.; Ma, W.; Yu, Z.; Xi, F.; Yu, J. Overview of Life Cycle Assessment of Recycling End-of-Life Photo-voltaic Panels: A Case Study of Crystalline Silicon Photovoltaic Panels. J. Clean. Prod. 2024, 434, 140320. [Google Scholar] [CrossRef]

- Bajenaru, V.-D. Recycling Processes for Waste Electrical and Electronic Equipment from the Automotive Industry; Editura CEFIN: Bucharest, Romania, 2004; ISBN 978-606-8261-30-0. [Google Scholar]

- Luu, L.Q.; Nguyen, T.Q.; Khakpour, S.; Cellura, M.; Nocera, F.; Nguyen, N.H.; Bui, N.H. Material Demand and Contributions of Solar PV End-of-Life Management to the Circular Economy: The Case of Italy. Sustainability 2025, 17, 6592. [Google Scholar] [CrossRef]

- Lee, S.-H.; Jang, Y.-C. Analysis for End-of-Life Solar Panel Generations by Renewable Energy Supply towards Car-bon Neutrality in South Korea. Energies 2023, 16, 8039. [Google Scholar] [CrossRef]

- Ministerul Energiei. The Green Certificate Market. Available online: https://energie.gov.ro/home/informatii-de-interes-public/surse-regenerabile-de-energie-in-romania/piata-certificatelor-verzi-cerere-si-oferta/ (accessed on 13 August 2025).

- Abdo, D.M.; El-Shazly, A.N.; Medici, F. Recovery of Valuable Materials from End-of-Life Photovoltaic Solar Panels. Materials 2023, 16, 2840. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Deng, C.; Li, C.; Zhu, T.; Liu, D.; Bai, Y.; Chen, Q.; Huang, J.; Li, G. Towards Efficient, Scalable and Stable Perovskite/Silicon Tandem Solar Cells. Nat. Photon. 2025, 19, 913–924. [Google Scholar] [CrossRef]

- Intal, D.; Ebong, A.U. Thin-Film Solar Photovoltaics: Trends and Future Directions. In Proceedings of the 2024 IEEE 21st International Conference on Smart Communities: Improving Quality of Life Using AI, Robotics and IoT (HONET), Doha, Qatar, 3–5 December 2024. [Google Scholar]

- Ren, X.; Jin, Y.; Hu, R.; Xie, D.; Huang, X.; Wen, H.; Sun, Y.; Huang, Z.; Huang, W. Gradient Vertical Morphology Engineering Enabling 18.51% Efficient All-Polymer Solar Cells through Sequential Deposition Strategy. Mater. Today Energy 2025, 52, 101954. [Google Scholar] [CrossRef]

- Luo, R.; Miao, J.; Zhao, Y.; Chen, S.; Yang, Y.; Lu, Q.; Hu, B.; Zhang, B.; Liu, J. The Swelling Mechanism of Ethylene-Vinyl Acetate Polymer in Different Solvents via Molecular Dynamics and Experimental Studies. Soft Matter 2025, 21, 708–718. [Google Scholar] [CrossRef]

- McIntosh, K.R.; Cotsell, J.N.; Cumpston, J.S.; Norris, A.W.; Powell, N.E.; Ketola, B.M. An Optical Comparison of Silicone and EVA Encapsulants for Conventional Silicon PV Modules: A Ray-Tracing Study. In Proceedings of the 2009 34th IEEE Photovoltaic Specialists Conference (PVSC), Philadelphia, PA, USA, 7–12 June 2009; pp. 544–549. [Google Scholar]

- Ballif, C.; Haug, F.-J.; Boccard, M.; Verlinden, P.J.; Hahn, G. Status and Perspectives of Crystalline Silicon Photovoltaics in Research and Industry. Nat. Rev. Mater. 2022, 7, 597–616. [Google Scholar] [CrossRef]

- Ionescu, C.; Patrascu, R.; Sandu, M.R. Integrated operation analysis of a geothermal-solar hybrid system for sustainable thermal energy supply: A case study in the Politehnica Bucharest campus. UPB Sci. Bull. Ser. C 2024, 86, 405–416. [Google Scholar]

- Cordell, J.J.; Woodhouse, M.; Warren, E.L. Technoeconomic Analysis of Perovskite/Silicon Tandem Solar Modules. Joule 2025, 9, 101781. [Google Scholar] [CrossRef]

- Oproescu, M.; Schiopu, A.-G.; Calinescu, V.-M.; Fidelus, J.D. Enhanced Efficiency of Polycrystalline Silicon Solar Cells Using ZnO-Based Nanostructured Layers. Crystals 2025, 15, 398. [Google Scholar] [CrossRef]

- Karade, V.C.; He, M.; Song, Z.; Abudulimu, A.; Park, Y.; Song, D.; Yan, Y.; Hyeok Kim, J.; Ellingson, R.J.; Ho Yun, J.; et al. Opportunities and Challenges for Emerging Inorganic Chalcogenide–Silicon Tandem Solar Cells. Energy Environ. Sci. 2025, 18, 6899–6933. [Google Scholar] [CrossRef]

- Badran, G.; Lazarov, V.K. From Waste to Resource: Exploring the Current Challenges and Future Directions of Photovoltaic Solar Cell Recycling. Solar 2025, 5, 4. [Google Scholar] [CrossRef]

- Wu, L.; Chen, X.; Zhang, D. Iron-Only Metasurface Broadband Absorber for Solar Energy Harvesting. Nanomaterials 2025, 15, 1263. [Google Scholar] [CrossRef] [PubMed]

- Bošnjaković, M. Advance of Sustainable Energy Materials: Technology Trends for Silicon-Based Photovoltaic Cells. Sustainability 2024, 16, 7962. [Google Scholar] [CrossRef]

- Popescu, V.-S.; Popescu, I.-M. Impact of uv post processing on simple 3D printed parts using masked stereolithography. Int. J. Mechatron. Appl. Mech. 2024, 18, 86–92. [Google Scholar] [CrossRef]

- Olteanu, A.D.; Gheorghe, S. The performance of solar photovoltaic panels in different environmental conditions. UPB Sci. Bull. Ser. C 2024, 26, 359–370. [Google Scholar]

- McGovern, L.; van der Zwaan, B. Policies for Promising Prospects of Photovoltaics. Solar 2025, 5, 22. [Google Scholar] [CrossRef]

- Su, Q.; Lin, H.; Wang, G.; Xu, M.; Duan, J.; Deng, X.; Wu, H.; Wang, T.; Han, G.; Xue, C.; et al. Contactless characterization of polarity boundary recombination on silicon heterojunction back contact solar cells. Sol. Energy Mater. Sol. Cells 2025, 291, 113738. [Google Scholar] [CrossRef]

- Sezgin-Ugranlı, H.G. Photovoltaic System Performance Under Partial Shading Conditions: Insight into the Roles of Bypass Diode Numbers and Inverter Efficiency Curve. Sustainability 2025, 17, 4626. [Google Scholar] [CrossRef]

- Gebhardt, P.; Marletti, S.; Markert, J.; Kräling, U.; Tu, M.; Haedrich, I.; Philipp, D. Comparison of commercial TOPCon PV modules in accelerated aging tests. IEEE J. Photovolt. 2024, 15, 24–29. [Google Scholar] [CrossRef]

- Brancoveanu, A.P.; Plamanescu, R.; Dumitrescu, A.M.; Albu, M. Variability assessment of net power profiles for prosumers with pv generation. UPB Sci. Bull. Ser. C 2024, 86, 339–348. [Google Scholar]

- Mahmoudysepehr, M.; Sivoththaman, S. Harnessing Nanoplasmonics: Design Optimization for Enhanced Optoelectronic Performance in Nanocrystalline Silicon Devices. Micromachines 2025, 16, 540. [Google Scholar] [CrossRef]

- Tayari, F.; Teixeira, S.S.; Graca, M.P.F.; Nassar, K.I. Progress and Developments in the Fabrication and Characterization of Metal Halide Perovskites for Photovoltaic Applications. Nanomaterials 2025, 15, 613. [Google Scholar] [CrossRef]

- Li, X.; Fang, Y.; Zhao, J. Optimizing Inorganic Cs4CuSb2Cl12/Cs2TiI6 Dual-Absorber Solar Cells: SCAPS-1D Sim-ulations and Machine Learning. Nanomaterials 2025, 15, 1245. [Google Scholar] [CrossRef]

- Maisun Solar. Available online: https://www.maysunsolar.com/blog-ibc-technology-a-revolution-in-primary-solar-cell-efficiency-and-aesthetics/ (accessed on 20 August 2025).

- Wen, J.; Yue, Q.; Qi, Z.; Gong, Z.; Ba, Y. A Novel Approach to Manufacturing an Antioxidant Material, GT-Ag@MSN, Using Recycled Silver and Silicon from Scrapped Photovoltaic Panels. Sustainability 2025, 17, 4557. [Google Scholar] [CrossRef]

- Poschmann, H.; Brüggemann, H.; Goldmann, D. Disassembly 4.0: A Review on Using Robotics in Disassembly Tasks as a Way of Automation. Chem. Ing. Tech. 2020, 92, 341–359. [Google Scholar] [CrossRef]

- Alqahtani, M.F.; Afy-Shararah, M. Integrating Circular Economy Practices into Renewable Energy in the Manufacturing Sector: A Systematic Review of the Literature. Sustainability 2025, 17, 7301. [Google Scholar] [CrossRef]

- Ghorbanpour, P.; Romano, P.; Shalchian, H.; Vegliò, F.; Ippolito, N.M. Sustainable Metal Recovery from Photovoltaic Waste: A Nitric Acid-Free Leaching Approach Using Sulfuric Acid and Ferric Sulfate. Minerals 2025, 15, 806. [Google Scholar] [CrossRef]

- Gajec, M.; Król, A.; Holewa-Rataj, J.; Kukulska-Zając, E.; Kuchta, T. Electrolytic Recovery of Indium from Copper Indium Gallium Selenide Photovoltaic Panels: Preliminary Investigation of Process Parameters. Recycling 2025, 10, 86. [Google Scholar] [CrossRef]

- Miaosi, L.; Fangyang, L.; Zhe, Z.; Liangxing, J.; Ming, J.; Yanqing, L.; Jie, L.; Zongliang, Z. A comprehensive hydrometallurgical recycling approach for the environmental impact mitigation of EoL solar cells. J. Environ. Chem. Eng. 2021, 9, 106830. [Google Scholar] [CrossRef]

- Ghahremani, A.; Adams, S.D.; Norton, M.; Khoo, S.Y.; Kouzani, A.Z. Delamination Techniques of Waste Solar Panels: A Review. Clean Technol. 2024, 6, 280–298. [Google Scholar] [CrossRef]

- Olaitan, O.F.; Okoh, I.; Onuche, P.U.O.; Alabi, J.O.; Sone, P.E.; Kalyanaraman, K.K.; Ukanu, J.; Arthur, C. The Role of Organic Solar Cells in U.S. Energy Transition: Technical Advances, Deployment Challenges, and Policy Pathways. J. Environ. Clim. Ecol. 2025, 2, 49–60. [Google Scholar] [CrossRef]

- Yue, Z.; Mo, Q.; Duc, T.P.; Roger, D.; Farzaneh, G.; Yongquan, Z.; Yongjing, W. Robotic disassembly of electric vehicle batteries: Technologies and opportunities. Comput. Ind. Eng. 2024, 198, 110727. [Google Scholar] [CrossRef]

- Bulińska, S.; Sujak, A.; Pyzalski, M. Sustainable Management of Photovoltaic Waste Through Recycling and Material Use in the Construction Industry. Materials 2025, 18, 284. [Google Scholar] [CrossRef]

- Zagorski, M.; Dimitrov, K.; Kamburov, V.; Nikolov, A.; Stoichkov, K.; Stoyanova, Y. An Innovative Approach for Delamination of Solar Panels Using a Heated Metal Wire. Recycling 2025, 10, 104. [Google Scholar] [CrossRef]

- AIKO Solar Techology, N-Type ABC Technology. Available online: https://aikosolar.com/en/techbreakthroughs/ (accessed on 15 August 2025).

- LONGI. Maximized Solar Power for Homes and Businesses. Available online: https://eu.longi.com/hi-mo-X10 (accessed on 15 August 2025).

- Benick, J. TOPCon—Overcoming Fundamental Bottlenecks to a New World-Record Silicon Solar Cell; Fraunhofer Institute for Solar Energy Systems ISE, Department of Energy (USA): Atlanta, GA, USA, 2016. [Google Scholar]

- Markert, E.; Celik, I.; Apul, D. Private and Externality Costs and Benefits of Recycling Crystalline Silicon (c-Si) Photovoltaic Panels. Energies 2020, 13, 3650. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, C.; Zheng, S. Investment and pricing in solar photovoltaic waste recycling with government intervention: A supply chain perspective. Comput. Ind. Eng. 2023, 177, 109044. [Google Scholar] [CrossRef]

- Directive 2012/19/EU; On waste electrical and electronic equipment (WEEE) (Recast). Official Journal of the European Union: Brussels, Belgium, 2012.

- Alzahmi, W.; Ndiaye, M. A Multi-Criteria AHP Framework for Solar PV End-of-Life Management. Sustainability 2025, 17, 1828. [Google Scholar] [CrossRef]