Abstract

Traditional power management for organic electroluminescent (OLED) displays is performed by two different converters, providing both positive and negative power rails and thus raising fabrication costs due to the usage of two inductors, in addition to efficiency being dependent on one of the two converters while also suffering from high-voltage stress. This paper introduces a bipolar converter that only uses a single inductor to generate both power rails for OLED displays, along with two additional flying capacitors to reduce inductor currents and voltage stress placed on the power switches. The proposed design implemented in the 180 nm CMOS process occupies a chip area of 0.98 mm2 and achieves a peak efficiency of 93% at 350 mA load current. Furthermore, the ripple voltage is greatly reduced using both common-mode and differential-mode feedback loops in the PWM control scheme, with a maximum ripple of 20 mV across a 100–500 mA current range.

1. Introduction

With increasing demand for larger display sizes and improved quality, OLED displays have gained a reputation as a cost-effective solution in recent years. As usual, a significant portion of the power consumed by electronic devices is used by the displays, making compact, highly efficient DC-DC converter solutions critical for IoTs and wearable devices.

Traditional OLED display power supplies, although practical and straightforward, struggle with on-chip integration due to two bulky inductors since they consist of two different power converters, a boost and an inverting buck–boost converter, to generate both positive and negative voltage. The simplicity of conventional OLED display power supplies comes at the cost of enormous inductor sizes. At the same time, their performance is tied to the efficiency of their internal buck–boost converter, which also suffers from high-voltage stress on power switches. This combination of downsides has driven up fabrication costs and limited circuit performance [1,2,3].

Conventional single-inductor bipolar-output (SIBO) converters have been widely adopted for OLED applications due to their reduced component count; however, they suffer from several inherent limitations, including cross-regulation between positive and negative outputs, increased inductor current ripple under unbalanced loads, and limited efficiency at light-load conditions. These issues have been reported in prior works [4,5,6].

Alternative solutions to SIBO converters include dual-inductor, dual-output converters [4] and switched-capacitor-based bipolar converters [7]. While these approaches can mitigate cross-regulation or improve efficiency under certain conditions, they generally incur higher silicon area, increased external component count, or degraded transient performance. In particular, prior flying-capacitor-assisted SIBO architectures have typically incorporated only a single capacitor [8,9,10]. While effective in reducing switch voltage stress and inductor current to some degree, they leave room for further optimization of inductor current ripple and conduction loss, especially under significant load imbalance. The selection of power switches—using large-sized NMOS transistors for switches connected to lower-voltage nodes (like S2, S3, and S4) to minimize on-resistance RON, and PMOS transistors for switches connected to higher-voltage rails (like S1, S5, and S6)—is critical for reducing conduction loss and managing voltage stress across different phases of operation.

Recent hybrid bipolar-output converter designs have favored single-inductor bipolar-output (SIBO) topologies, which now require only a single inductor for both power rails, significantly reducing production costs and product size [4,11,12]. However, they still possess drawbacks. First, the voltage stress on power switches is often greater than 5 V, requiring high-voltage devices. Second, instead of two conducting paths for each inductor, there is now only a single current path; consequently, the inductor current increases, and a larger inductor with a lower DC resistance is needed to avoid conduction loss, ensuring high current and optimal inductance [10,11]. To mitigate these problems, the designs in [12,13,14] have added a flying capacitor, effectively dividing the conduction path into two, charging both the inductor and the flying capacitor, reducing inductor current while simultaneously sharing a voltage of VIN with the flying capacitor, thus decreasing the |VIN + VON| stress placed on power switches in conventional SIBO converters.

The principal novelty of this work is the introduction of a second flying capacitor on the VOP output line, forming a dual flying-capacitor architecture. This modification, combined with a PWM control scheme featuring an adaptive ramp generator, creates a more effective dynamic feedback loop. This approach achieves a greater reduction in peak inductor current and output-voltage ripple compared to single flying-capacitor SIBO topologies, without the increase in circuit complexity or silicon area. In this paper, we propose a hybrid bipolar-output converter that uses a single inductor and two flying capacitors to reduce voltage stress and inductor current, employing a PWM control scheme with an adaptive ramp generator to form a dynamic feedback loop, thereby minimizing inductor current and output-voltage ripple on both power rails. Implemented in the 180 nm CMOS process, the converter achieves a 93% peak efficiency at a 350 mA load current and an 84% average efficiency over 150–500 mA, with an output-voltage ripple under 20 mV at any given condition and load.

2. Circuit Implementation

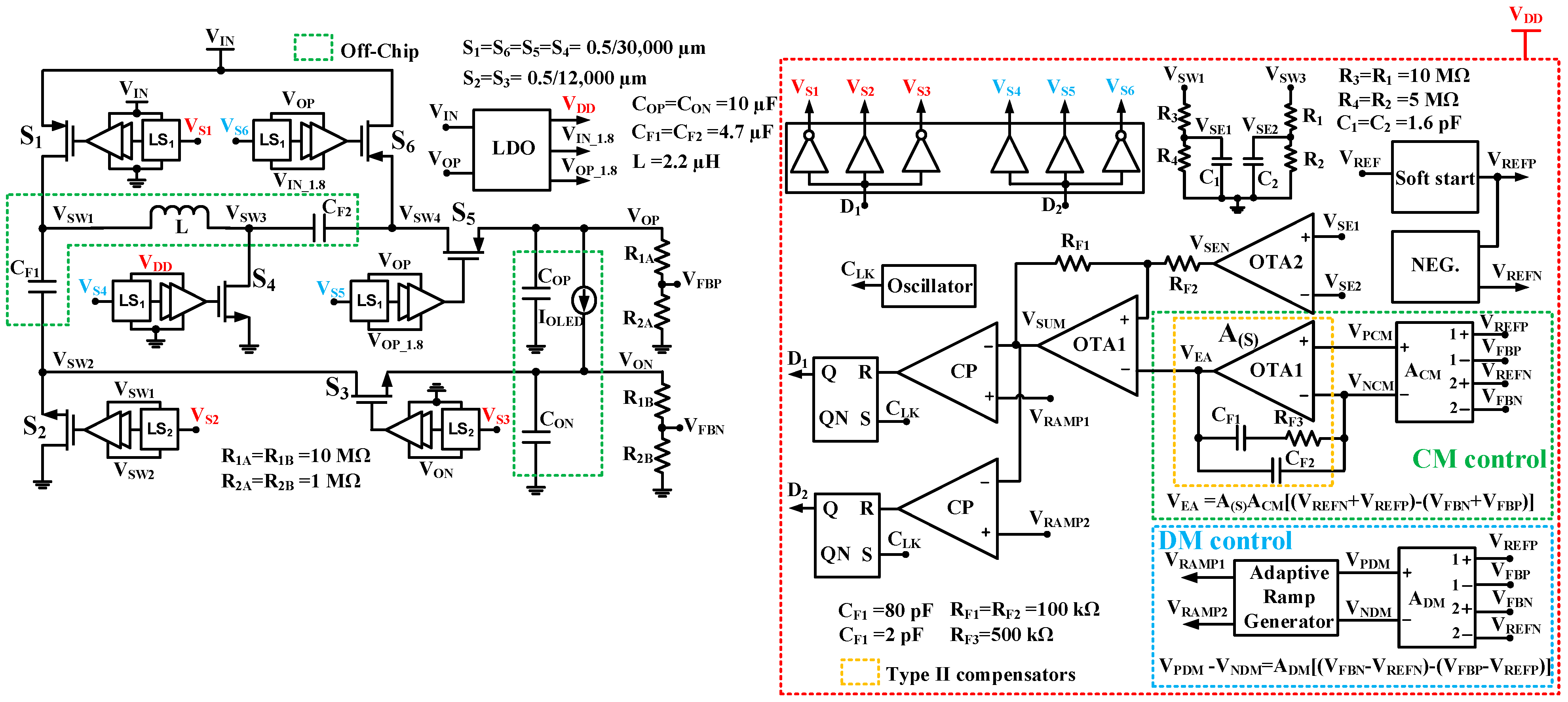

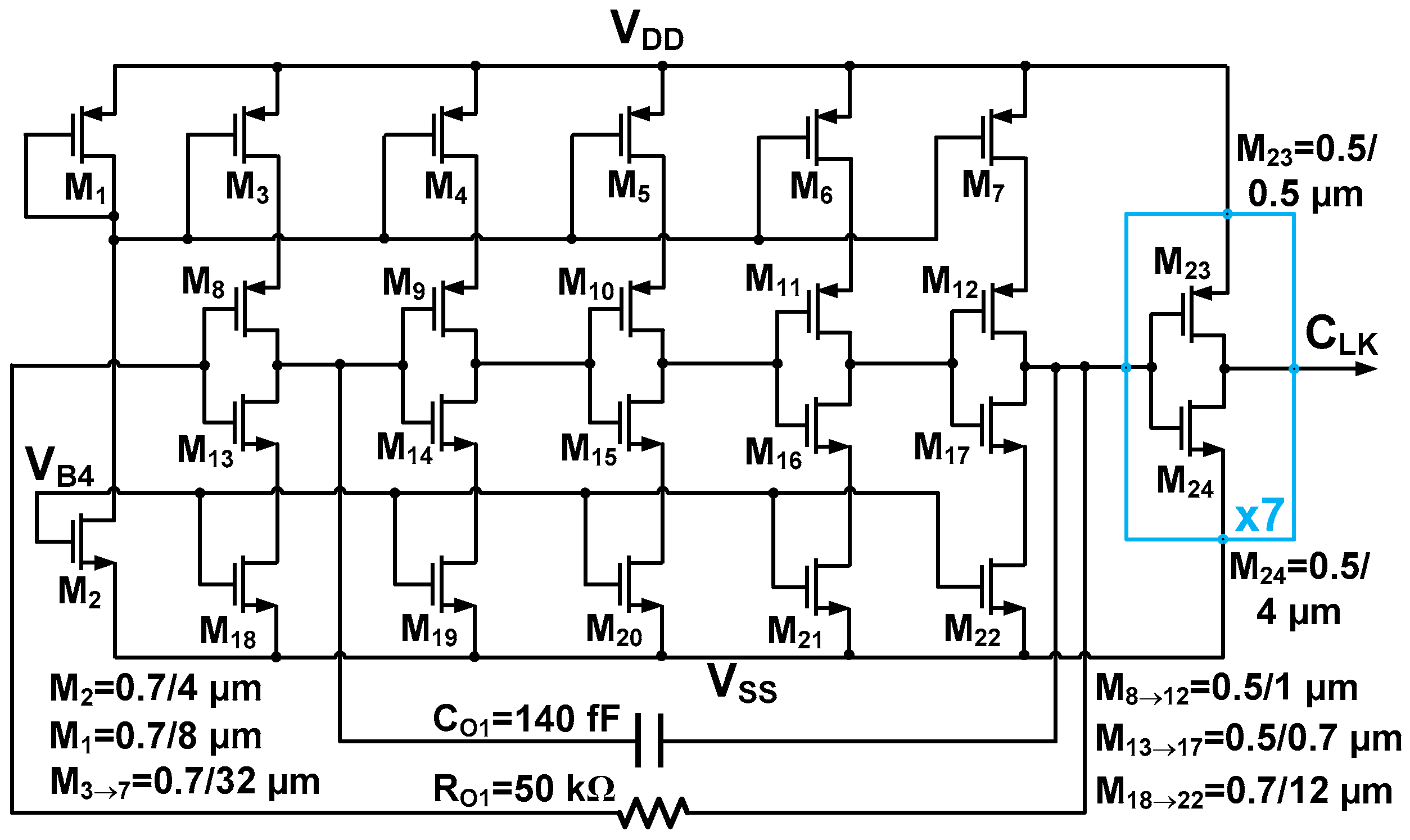

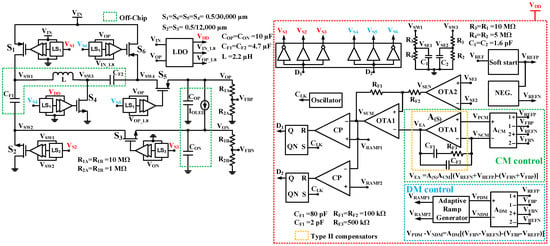

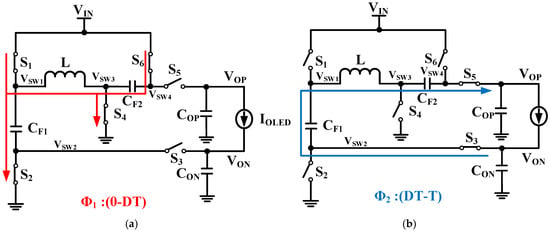

Figure 1 illustrates the overall architecture of the designed SIBO converter. The converter generates output voltages VOP and VON of 4.9 V and −4.7 V, respectively, from a 3.7 V battery supply. The core operational principle involves time-multiplexing the single inductor between the positive and negative output rails across the following four distinct switching phases: two main phases Φ1 and Φ2 for balanced energy delivery and two auxiliary phases ΦP and ΦN for correcting load imbalance. Switches S1÷3 and S4÷6 are controlled by a PWM controller, generating two symmetric main phases and two auxiliary phases for balancing the IOP and ION currents. During the main phases, energy is transferred from the input to both outputs in a balanced manner. The auxiliary phases are selectively activated by the control loop to direct energy preferentially to the output rail with higher demand, thereby maintaining voltage regulation under unbalanced load conditions. Large passive components are the inductor L = 2.2 µH and capacitors CF1 = CF2 = 4.7 µF; they are all implemented off-chip and connected to the integrated circuit via the PCB after fabrication and packaging. All switches and level shifters (LSs) are powered internally from VIN, VON, VOP, or the CF1/CF2 capacitors, eliminating the need for external supply rails. A dedicated level shifter (LS2) ensures proper operation of the S2 gate driver across the voltage swing on capacitor CF1. Similarly, level shifter LS3 is designed for S3 to translate signals from 0 V to the VON level, ensuring a sufficient VGS for switching. In contrast, switches S4–S6 are driven by an on-chip LDO generating VOP_1.8, VIN_1.8, and VDD, while S1’s driver is supplied directly by VIN. In the power stage, switches S2, S3, and S4 are implemented with large-sized NMOS transistors to minimize on-resistance, while S1, S5, and S6 use PMOS transistors.

Figure 1.

Overview of the converter.

The inductor value L is determined by limiting the inductor current ripple, which is given based on the work in [15]:

To ensure continuous conduction and limit the current ripple to approximately 30% of the average inductor current under maximum load conditions, an inductance in the range of 1.8–2.5 µH is required for a 1 MHz switching frequency. Therefore, an inductance of 2.2 µH is selected as a trade-off between current ripple, conduction loss, and transient response. The flying capacitor is chosen based on the voltage ripple caused by charge transfer, which is calculated in [16]:

Under the maximum load current, maintaining the flying-capacitor voltage ripple below a few millivolts requires a minimum capacitance of approximately 4 µF. Consequently, a 4.7 µF flying capacitor is selected to provide sufficient margin against load variation and process mismatch. The switching frequency is set to 1 MHz to balance switching loss, passive component size, and output-voltage ripple. Operating at this frequency enables compact passive components while maintaining high efficiency and low ripple, which are critical for OLED display applications.

The converter operates through four distinct states (two primary and two auxiliary phases), requiring at least two PWM control signals. As shown in Table 1, switches S1–S3 maintain identical or complementary switching states across all four phases, allowing them to be driven by a single PWM signal (PWM1, duty cycle D1). The same principle applies to switches S4–S6, which are controlled by a second, synchronized PWM signal (PWM2, duty cycle D2).

Table 1.

Power switch states in each phase.

In the designed bipolar-output DC-DC converter for OLED displays, it is ideal for the VOP and VON sources to have perfectly balanced power. The separate current balancing for the VOP and VON outputs underscores the requirement for identical energy delivery. However, load current imbalance can arise from internal circuits drawing different currents from VOP and VON, or from specific application requirements for independent regulation of these rails. For instance, during startup, the output capacitors (COP and CON) are discharged to 0V and can be charged to different values, leading to a voltage imbalance. If VOP is lower than |VON|, it indicates a greater energy demand for VON, resulting in a higher load current for VON (ION) compared to VOP (IOP), and vice versa.

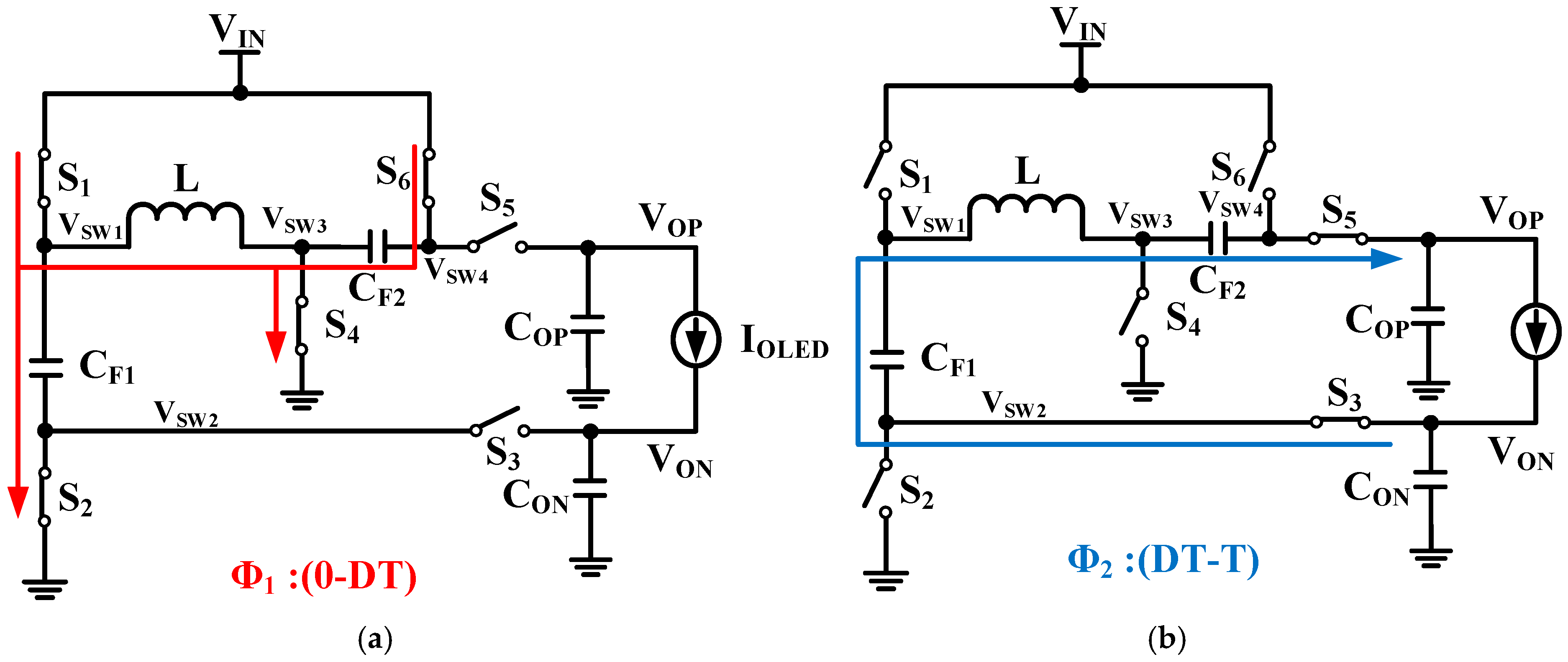

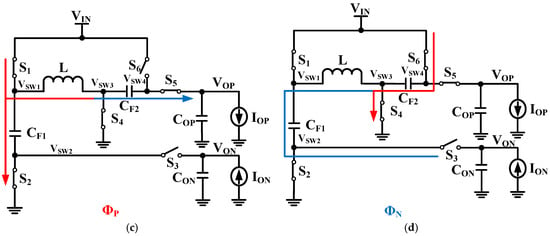

To address this potential imbalance, dedicated auxiliary phases are implemented to transfer energy specifically to VOP or VON. When IOP > ION, indicating a higher energy demand for VOP, the phase ΦP is activated, turning on switches S1, S2, and S5 to transfer energy exclusively to VOP. Conversely, phase ΦN is activated to transfer energy only to VON via switches S3, S4, and S6. These two phases are illustrated in Figure 2c,d.

Figure 2.

The power stage switching operation in (a) Φ1 and (b) Φ2, (c) auxiliary phase ΦP where IOP > ION when more energy is transferred to VOP, and (d) auxiliary phase ΦN where IOP < ION when more energy is transferred to VON.

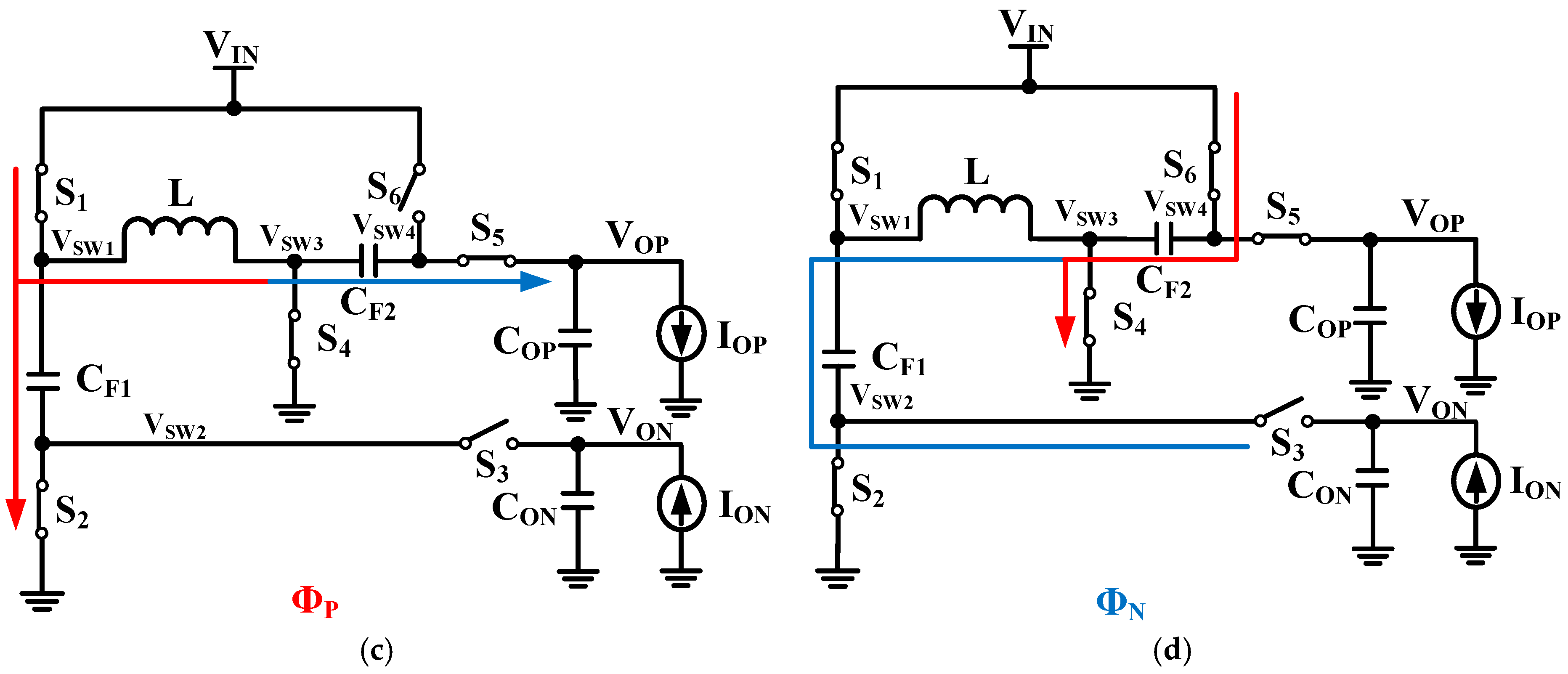

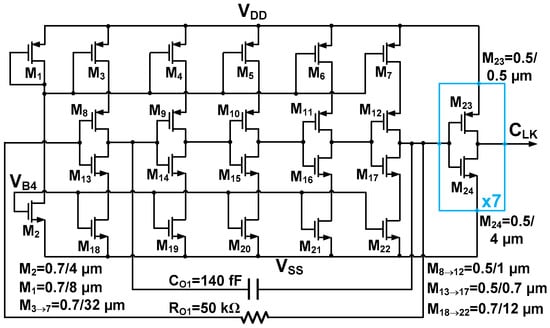

Figure 3 shows the oscillator block, a ring of cross-coupled inverters M23,24, controls the charge/discharge cycle of timing capacitor CO1. Resistor RO1 sets the discharge rate. The output at node CLK is a 1 MHz clock signal used to create the control triangle waves, VRAMP1 and VRAMP2, which are essential for regulating the converter’s output voltage. A ring of cross-coupled inverter gates charges and discharges capacitor CO1 in a stable, continuous cycle. The values of CO1 and RO1 determine the oscillation frequency. Transistors M23 and M24 function as inverters without a constant-current source, connected in series to minimize noise and achieve the sharpest possible transition slope. The oscillator, supplied by VDD, was designed with the parameters shown in Figure 3. To achieve a target TON period of 210 ns, transistor M24 was sized to have a high on-resistance. This intentionally introduces a turn-on delay, creating a small duty cycle where TON is less than the whole clock period.

Figure 3.

The oscillator schematic.

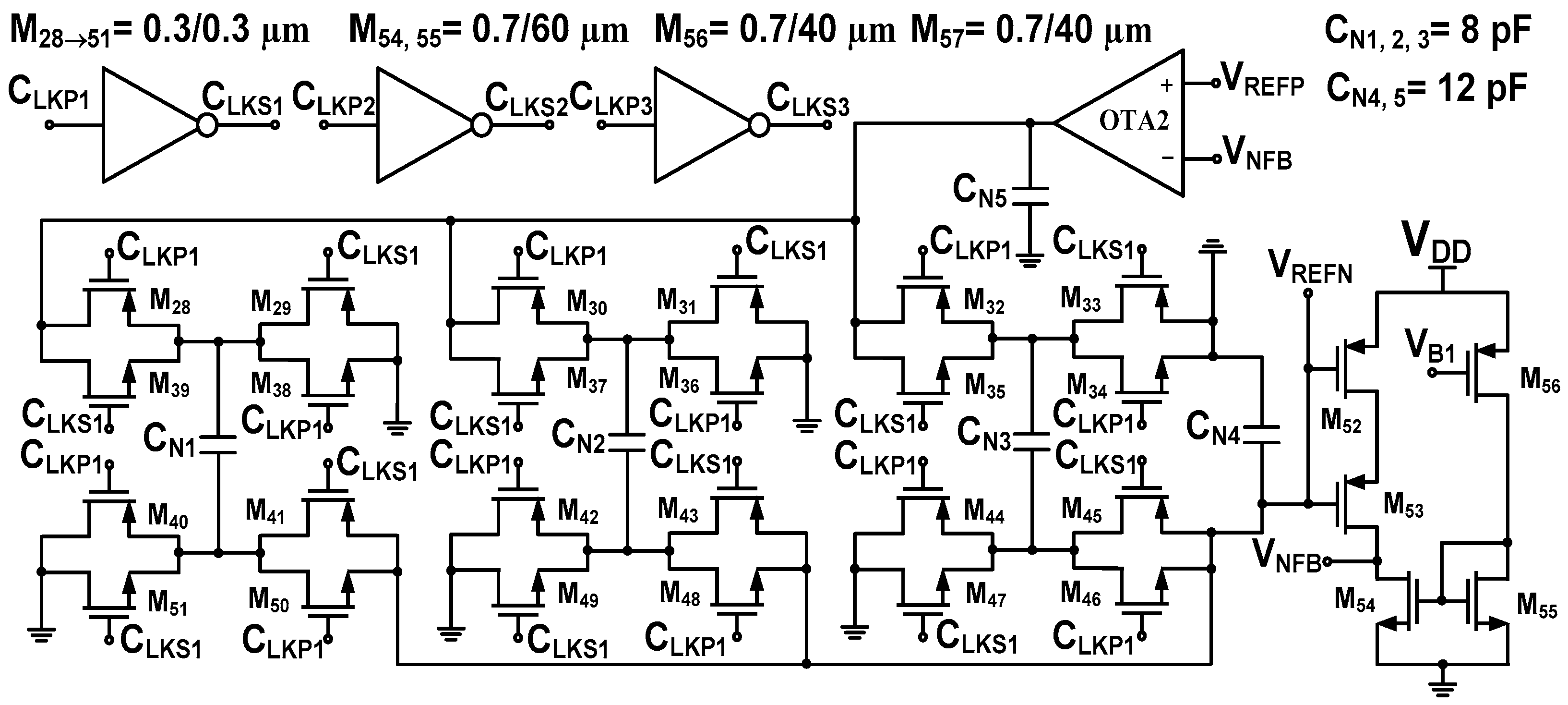

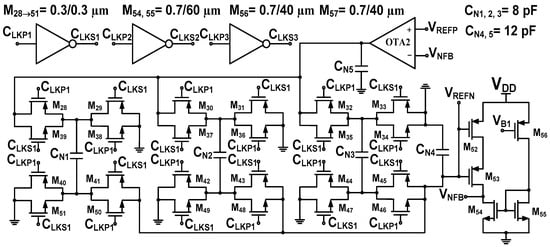

Figure 4 shows the schematic for our negative voltage reference circuit; the operation is sequenced by three non-overlapping clock signals CLKP1,2,3 controlling T-gate switches similar to M28,39. The charge-pump stage creates VREFN, which is then regulated via feedback through PMOS switches M52,53 and operational transconductance amplifier OTA2, in which three control clock signals CLKP1,2,3 have a 110 ns pulse width and are turned on sequentially in incremental order of their numbering. A default symmetrical negative voltage is generated using the fundamental principle of a capacitor’s two plates. To create a negative voltage, a positive voltage is first stored across a capacitor. This voltage is then inverted to a negative value at the opposite plate via charge transfer. This charging and inverting process requires precisely timed clock signals to control the switching sequence. The circuit employs T-gate switches M28 and M39, which use complementary CMOS pairs to achieve lower on-resistance than conventional switches. Three clock signals CLKP1,2,3 with the same frequency but a 90-degree phase shift between each other are used to generate a negative voltage VREFN with minimal ripple. The generated VREFN is fed through PMOS switches M52,53 to regulate the VNFB node. In operation, any variation in VREFN due to load changes is detected. The operational transconductance amplifier (OTA2) then outputs an error voltage to stabilize VREFN through this closed-loop feedback mechanism. This ensures VNFB remains stable and symmetrical to the positive reference voltage VREFP. VREFN and VREFP serve as the converter’s built-in reference voltages. Conventional converters that lack an integrated negative reference generator require an external reference, increasing the off-chip component area and overall system size.

Figure 4.

The schematic of the negative voltage reference generator.

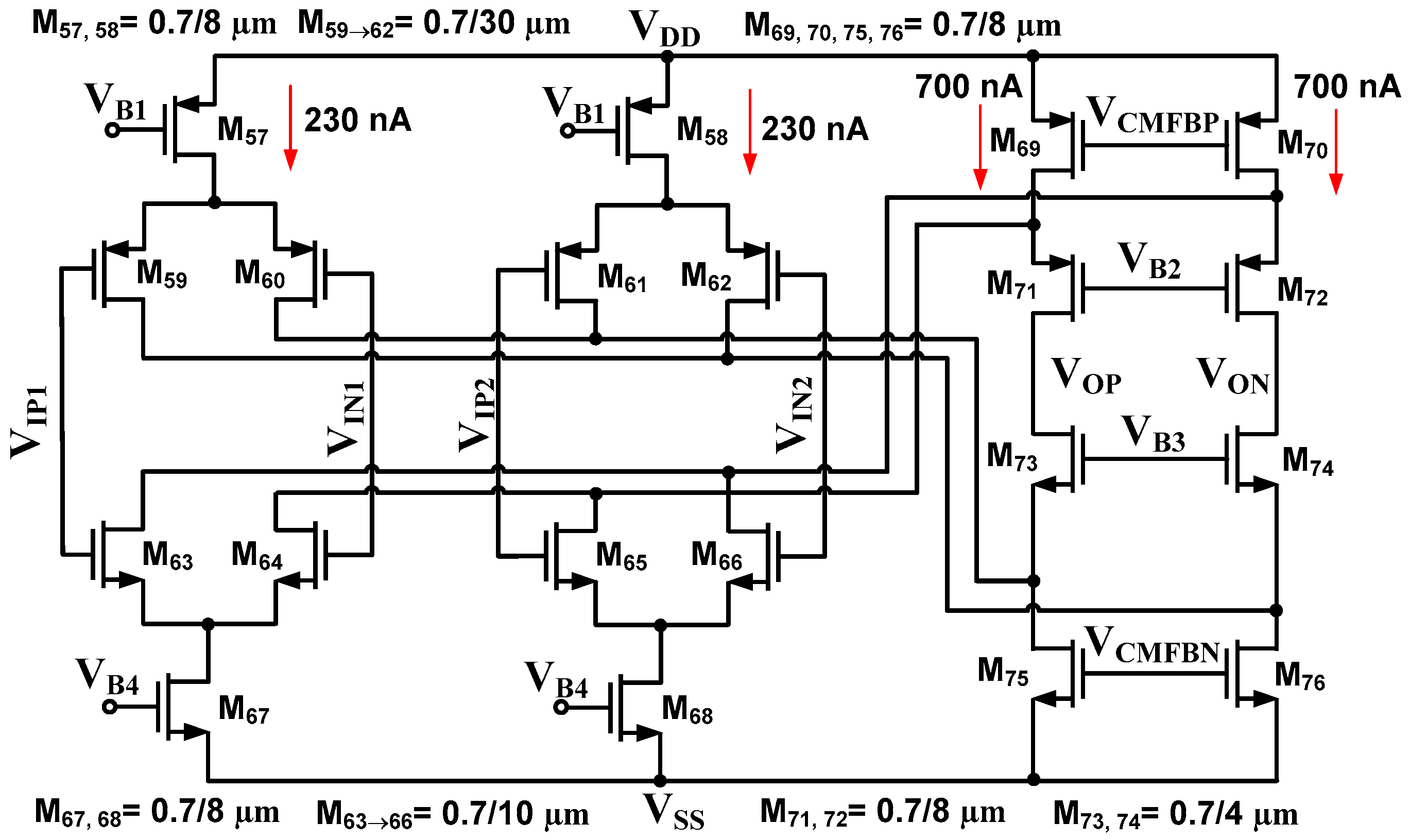

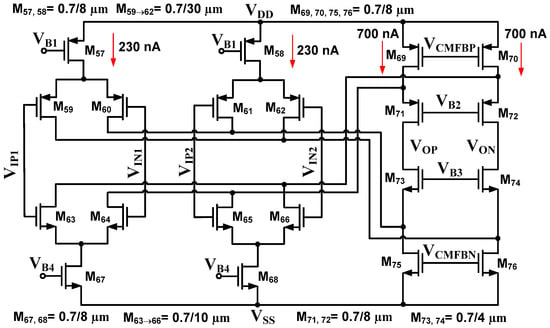

A differential amplifier with four inputs and two outputs, VPCM and VNCM, are shown in Figure 5 to perform signal summation and generate the required error voltages. The amplifier core is based on a stacked folded cascode topology, incorporating PMOS M59,60,61,62 and NMOS M63,64,65,66 differential input pairs. This configuration enhances precision by applying the input signal to both PMOS and NMOS transistors, thereby extending the input common-mode range and achieving higher gain. The designed amplifier, denoted as ACM, consumes a low quiescent power of 6.3 µW. It achieves a high gain of over 90 dB with a small bandwidth of 1.3 kHz, which will help limit amplification at high frequencies and instead compare only low-frequency DC signal differences.

Figure 5.

The schematic of the common-mode amplifier ACM.

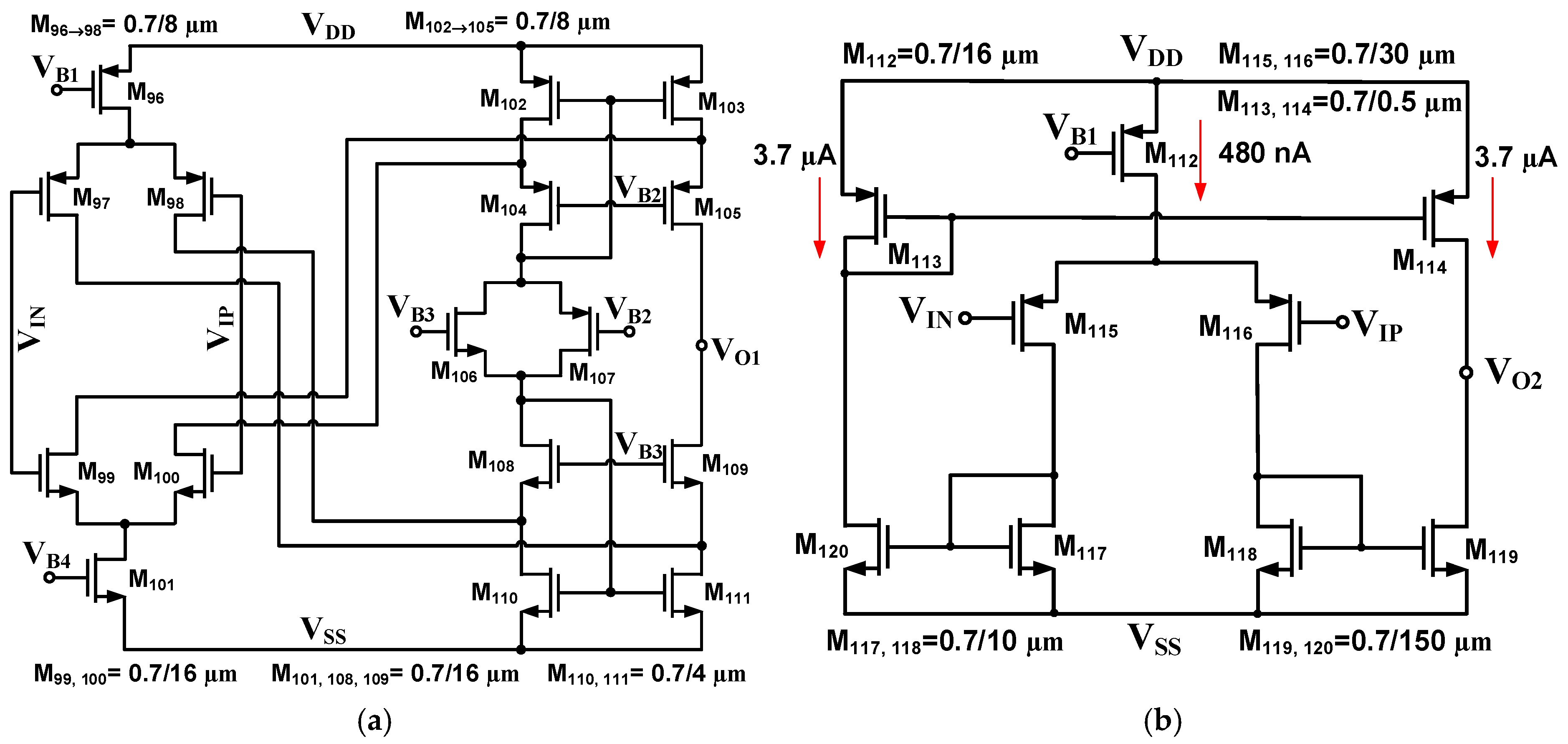

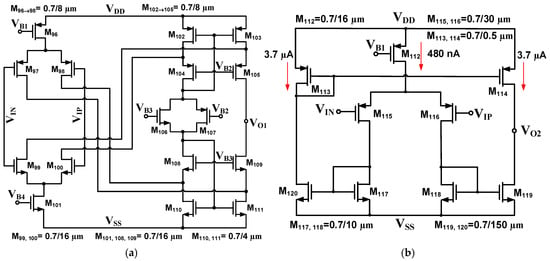

As shown in Figure 6, OTA1 is a single-stage OTA with two inputs, VIN and VIP, and one output VO1. The design in Figure 6a employs both PMOS and NMOS differential input pairs to enhance precision, providing a wide input range and high gain. Switches M106,107 are biased to serve as active resistors. They create different reference voltages for the folded-cascode transistors M102,103 and M101,111 to control the current consumption in the stacked stage. OTA1 is designed for low power consumption and low bandwidth, as it is intended for integration within a Type II compensator network. OTA2 utilizes a current-mirror OTA architecture. The schematic in Figure 6b shows the design of OTA2, where the quiescent current in each branch M113,114 is set to 3.7 μA to provide sufficient drive strength. Both OTAs are designed to create stable, fast, and precise current-controlled circuits.

Figure 6.

The schematic of (a) the amplifier OTA1 and (b) the amplifier OTA2.

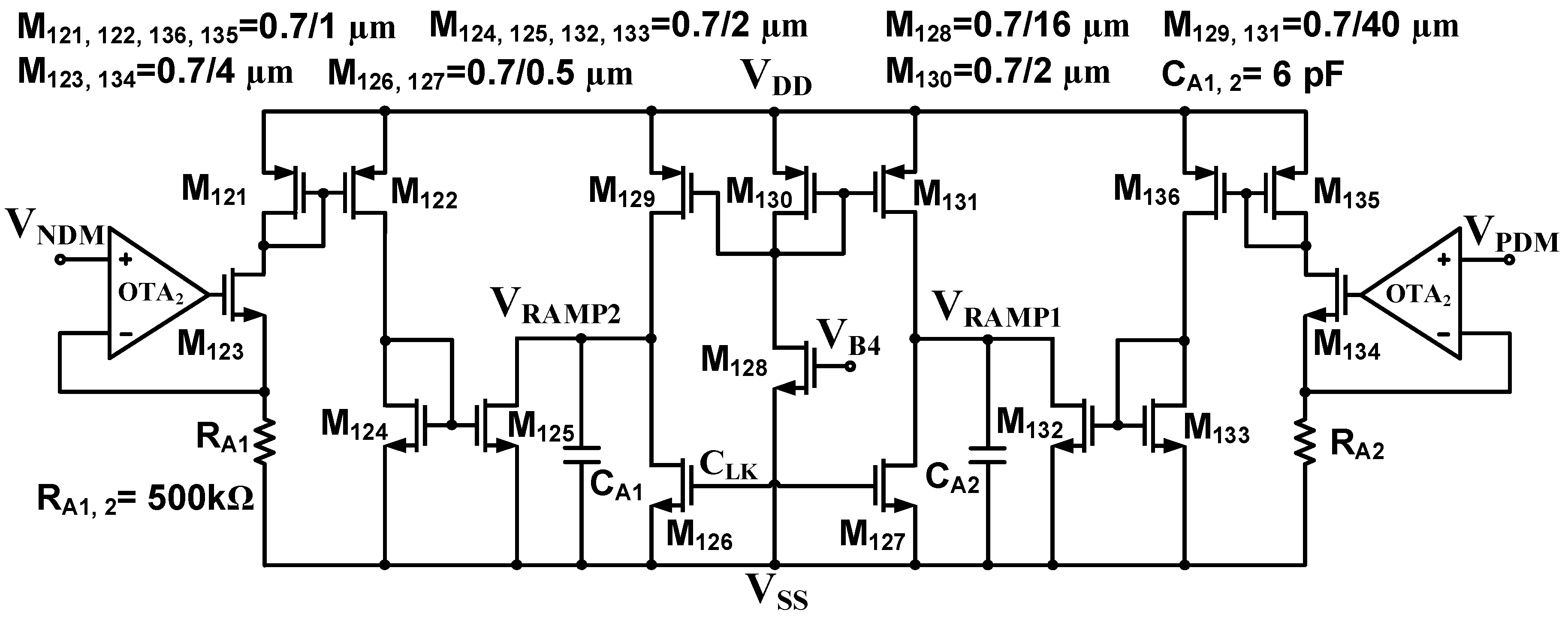

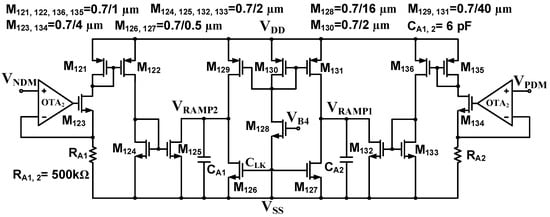

In a bipolar-output DC-DC converter, the VOP and VON voltages can become imbalanced due to constantly varying output loads. To mitigate the difference between the ION and IOP currents, a triangle-wave generator with an adaptive pulse width is implemented; it responds to changes in the VNDM and VPDM control signals. Figure 7 shows the schematic and design parameters of this adaptive pulse triangle-wave generator. The circuit uses the previously designed OTA2 as a controlled current source, acting as a small LDO whose output is modulated by the VNDM and VPDM voltages. A fixed bias current is provided, ensuring the ramp signal is never completely turned off during startup, even when VPDM and VNDM are at the VSS or VDD rails. The ramp signal is generated by exploiting the charging and discharging characteristics of capacitors CA1 and CA2, which are controlled by the clock signal CLK from the oscillator block.

Figure 7.

The adaptive ramp generator schematic.

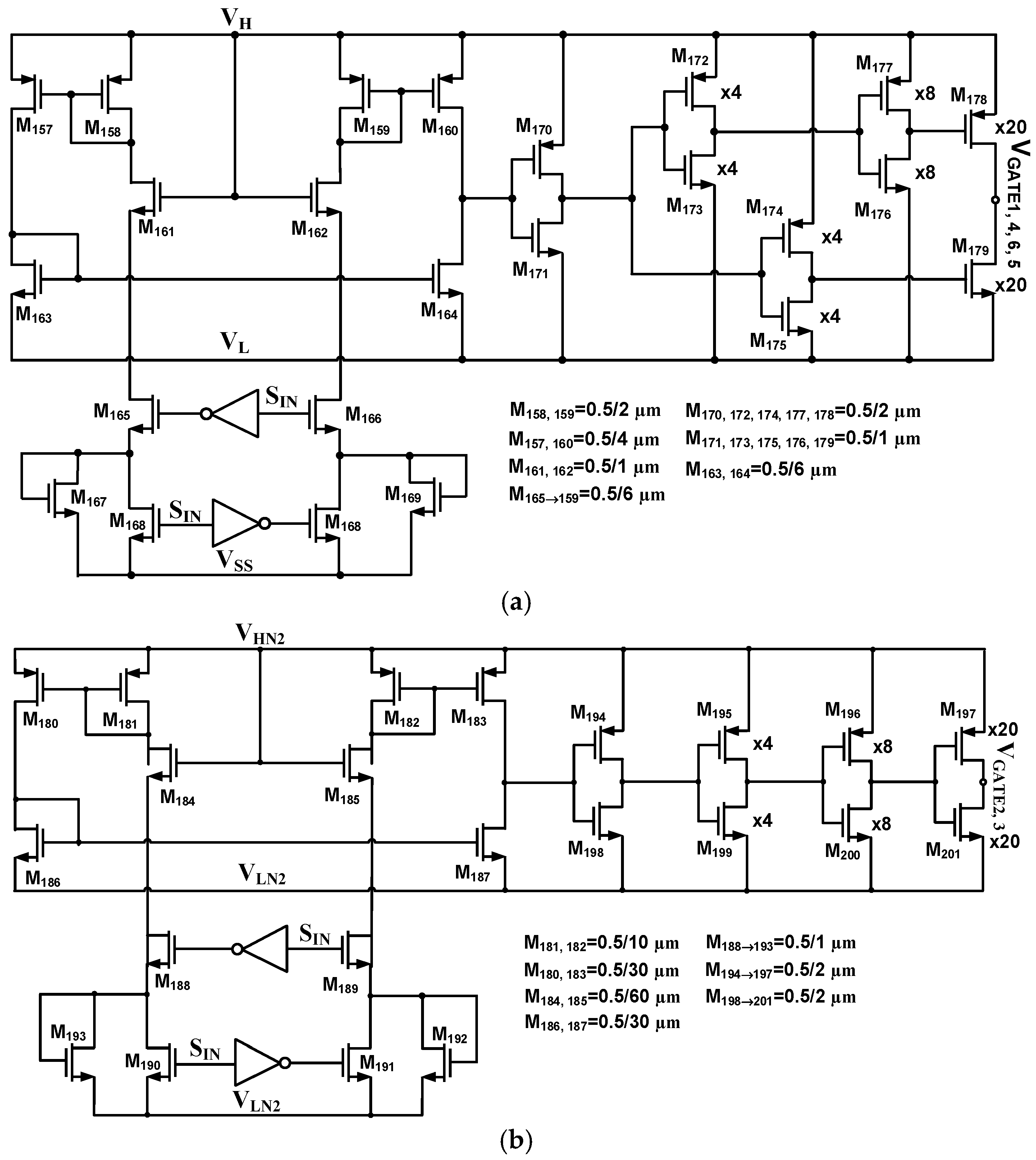

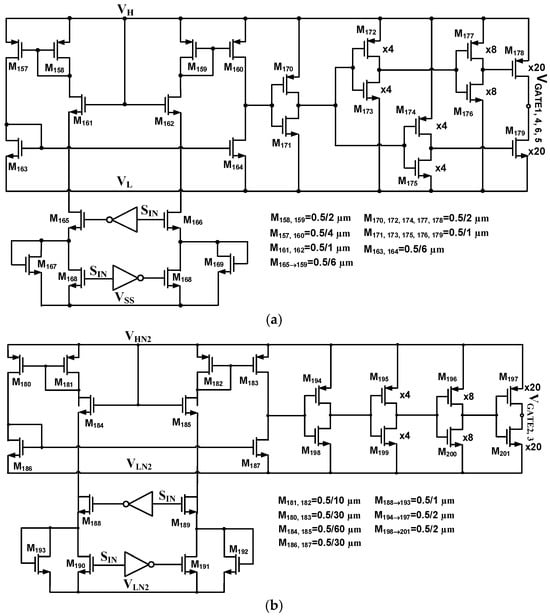

In Figure 8a, the schematic of the first level shifter LS1 is shown. It converts an input square wave SIN with a 1.8 V upper rail and a 0 V lower rail to an output wave whose rails are defined by the applied voltages VH and VL, spanning from VIN down to 0 V. Furthermore, Figure 8b presents the schematic of the second level shifter LS2. While its input is also a 1.8 V/0 V square wave, LS2 is supplied with a negative voltage at VLN2 and a positive voltage at VHN2. This is because the LS2 block is designed to drive switches S2 and S3 with a negative ON voltage VON.

Figure 8.

The schematic of level shifter (a) LS1 and (b) LS2.

Both the LS1 and LS2 blocks employ a current-mirror structure. When the SIN signal transitions, the control switches toggle, creating a voltage imbalance. The current-mirror configuration detects this minute change and swiftly generates the corresponding output-voltage levels (VH/VL for LS1 and VHN2/VLN2 for LS2). To ensure the level-shifted output signal has sufficient current strength to drive the switches S1÷6, the core inverter stages within the shifter are sized up to increase the charging current.

3. Results

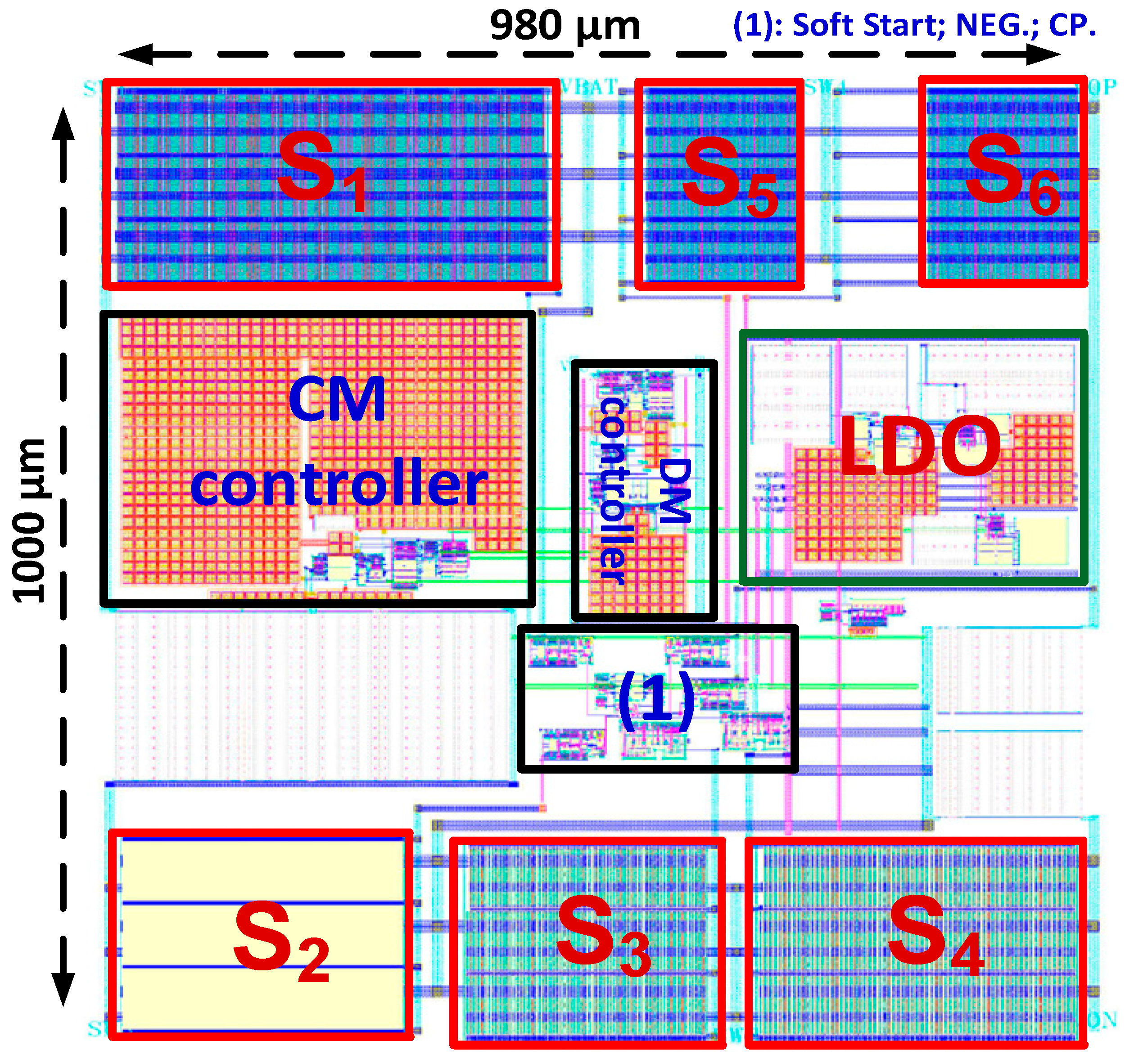

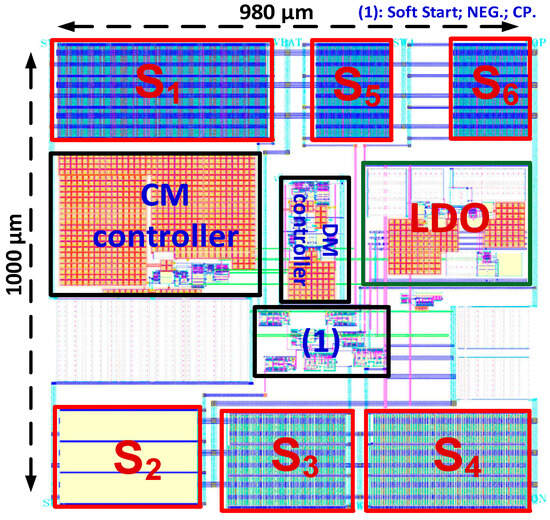

Figure 9 illustrates the layout arrangement of the complete bipolar-output DC-DC converter, including the placement of the power switches S1÷6. With a chip area of 0.98mm2, the converter consists of two main control blocks, namely the DM (differential mode) controller and the CM (common mode) controller, which are placed at the center of the chip in order to deliver control clock signals to other blocks, mainly the level shifters, with as little delay time as possible. The power switches S1÷6 are placed on the outskirt of the chip for easy access to I/O pads. The layout was verified using Calibre through LVS and DRC checks. Parasitic components in the layout were carefully optimized to ensure high accuracy and reliability during fabrication.

Figure 9.

The layout of the proposed converter.

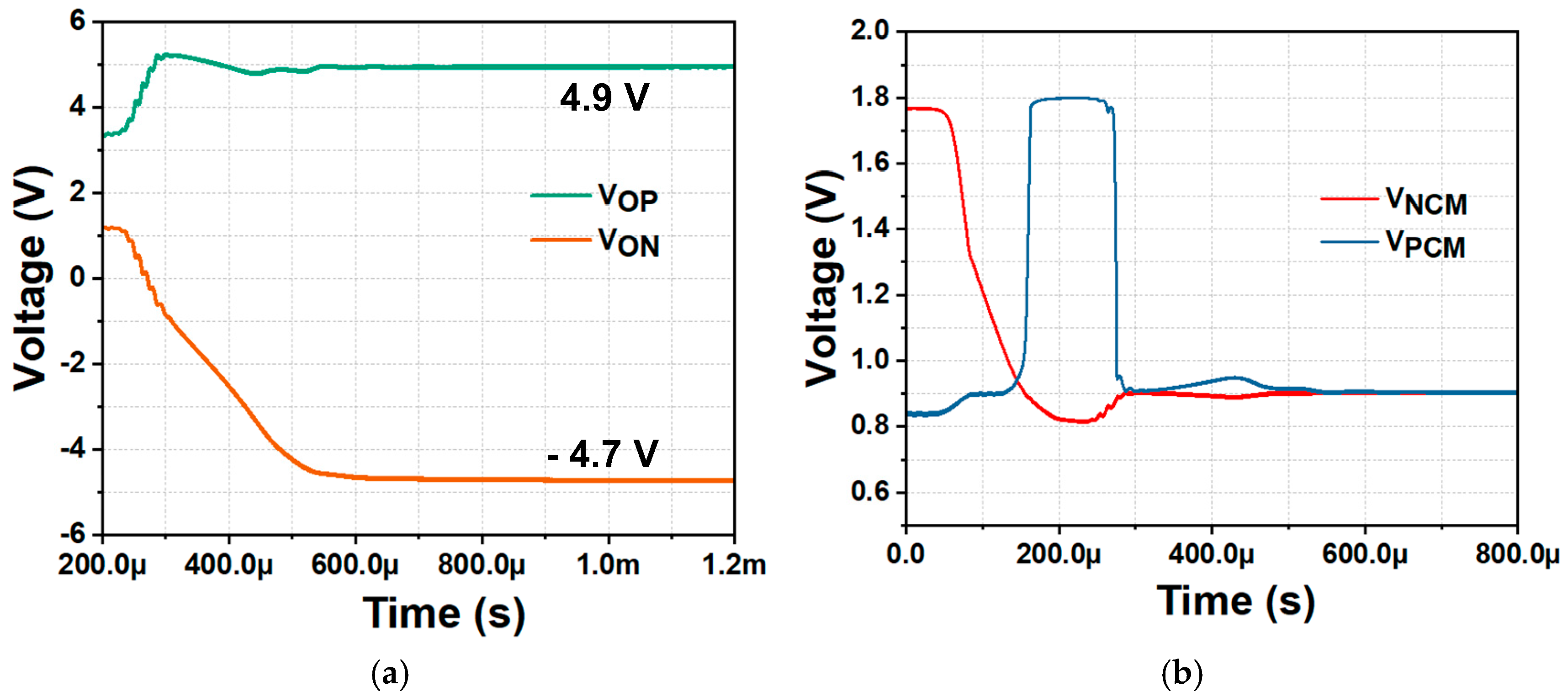

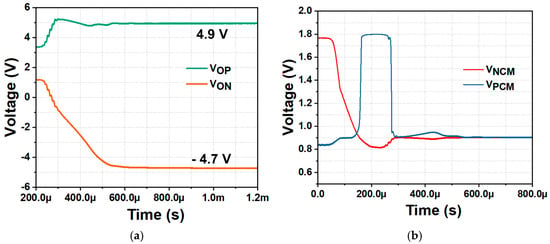

Figure 10a shows that the output voltages require approximately 500 μs to stabilize from startup, reaching steady-state values of VOP = 4.9 V and VON = −4.7 V. The simulation was performed using 0.18 μm technology node with the following parameters: a default positive reference voltage VREFP = 450 mV, a negative reference voltage VREFN = −430 mV, an inductor L = 2.2 μH, output capacitors COP = CON = 10 μF, a switching frequency of 1 MHz, and a supply voltage of 3.7 V. Figure 10b shows the VPCM and VNCM signals during the stable operation of the bipolar-output DC-DC converter. At initial startup, the voltage difference between VFBN/VFBP and VREFN/VREFP is large, causing the ACM block to act as a comparator. Once the converter stabilizes at the desired output voltages, the VPCM and VNCM signals become equal.

Figure 10.

The outputs VOP and VON in steady state (a); ACM amplifier output waveforms (b).

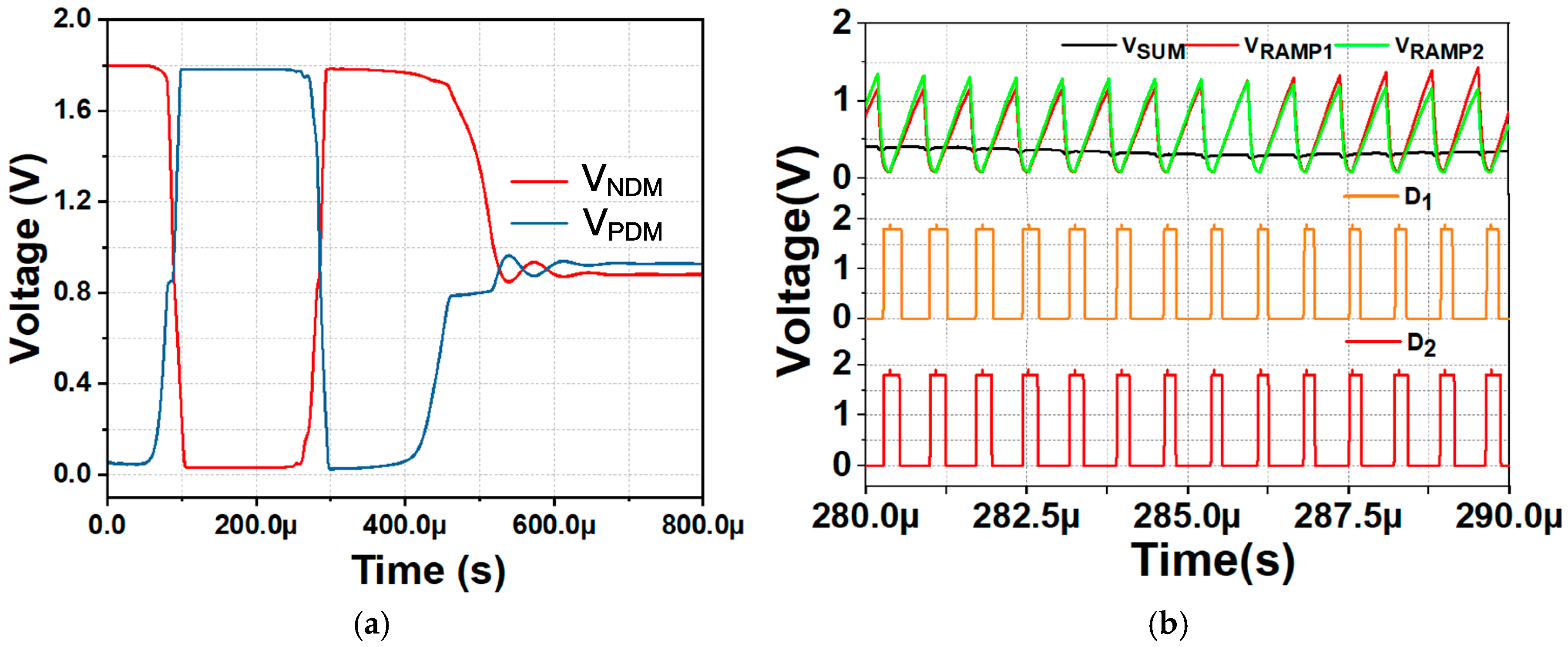

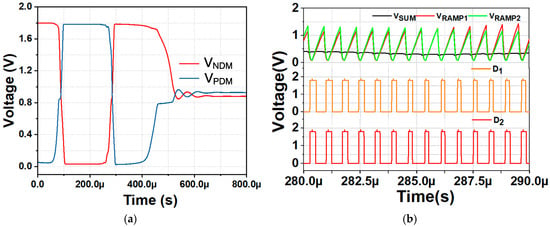

Figure 11a shows the waveforms of VPDM and VNDM. During the initial startup phase, these signals continuously adjust to balance the IOP and ION currents by controlling the auxiliary phases of the power switches network. Figure 11b illustrates the corresponding modulation of the D1 and D2 duty cycles to correct any imbalance between IOP and ION. A disparity between the D1 and D2 duty cycles triggers the automatic activation of an auxiliary phase to restore balance. This balancing occurs both at startup and during load transients, such as transitions from high to low load. The modulation is achieved by varying the peak of the triangle wave while keeping the VSUM signal constant, necessitating adjustments to the D1 and D2 duty cycles.

Figure 11.

VNDM and VPDM waveforms (a); ramp waveform correlating with D1,2 signals (b).

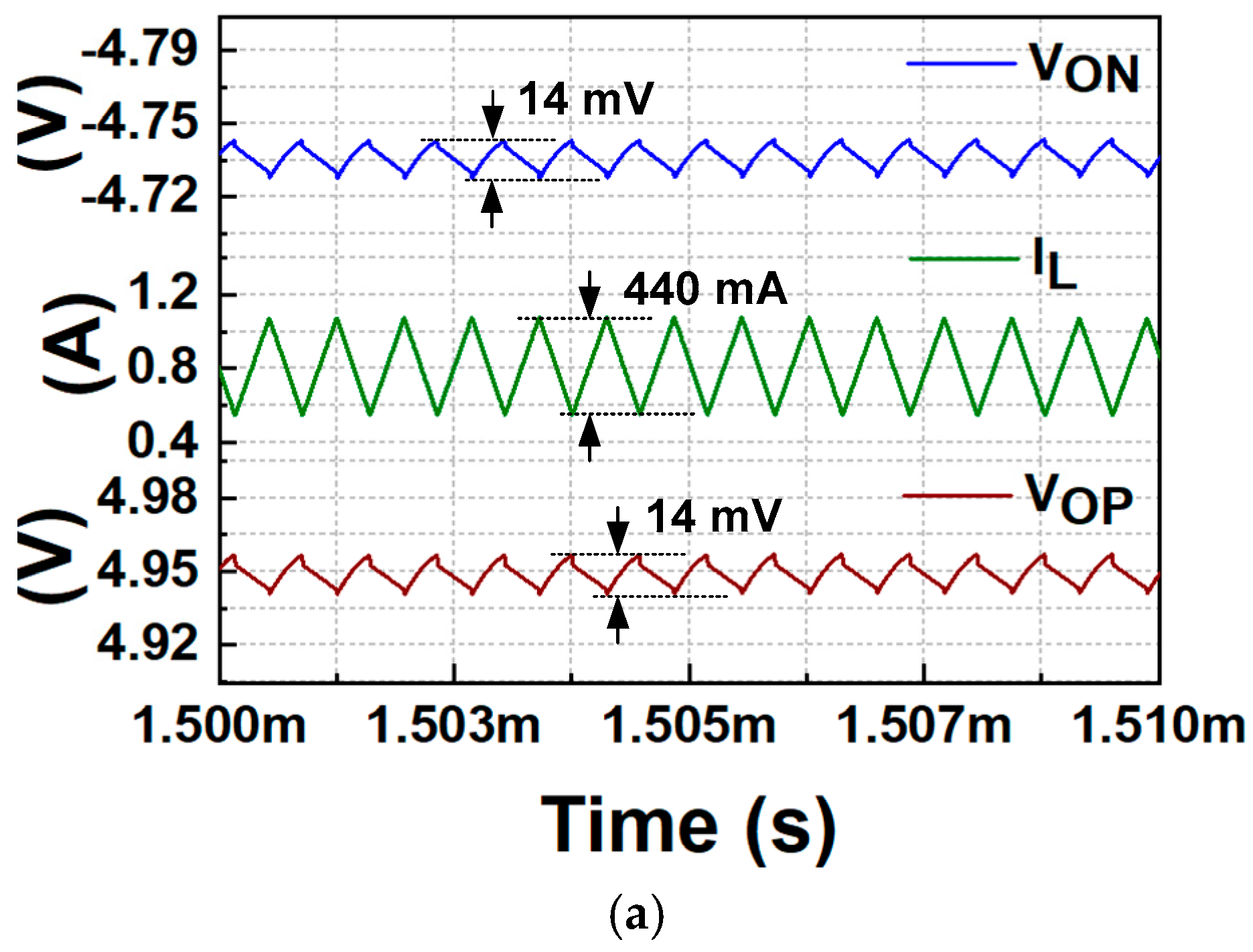

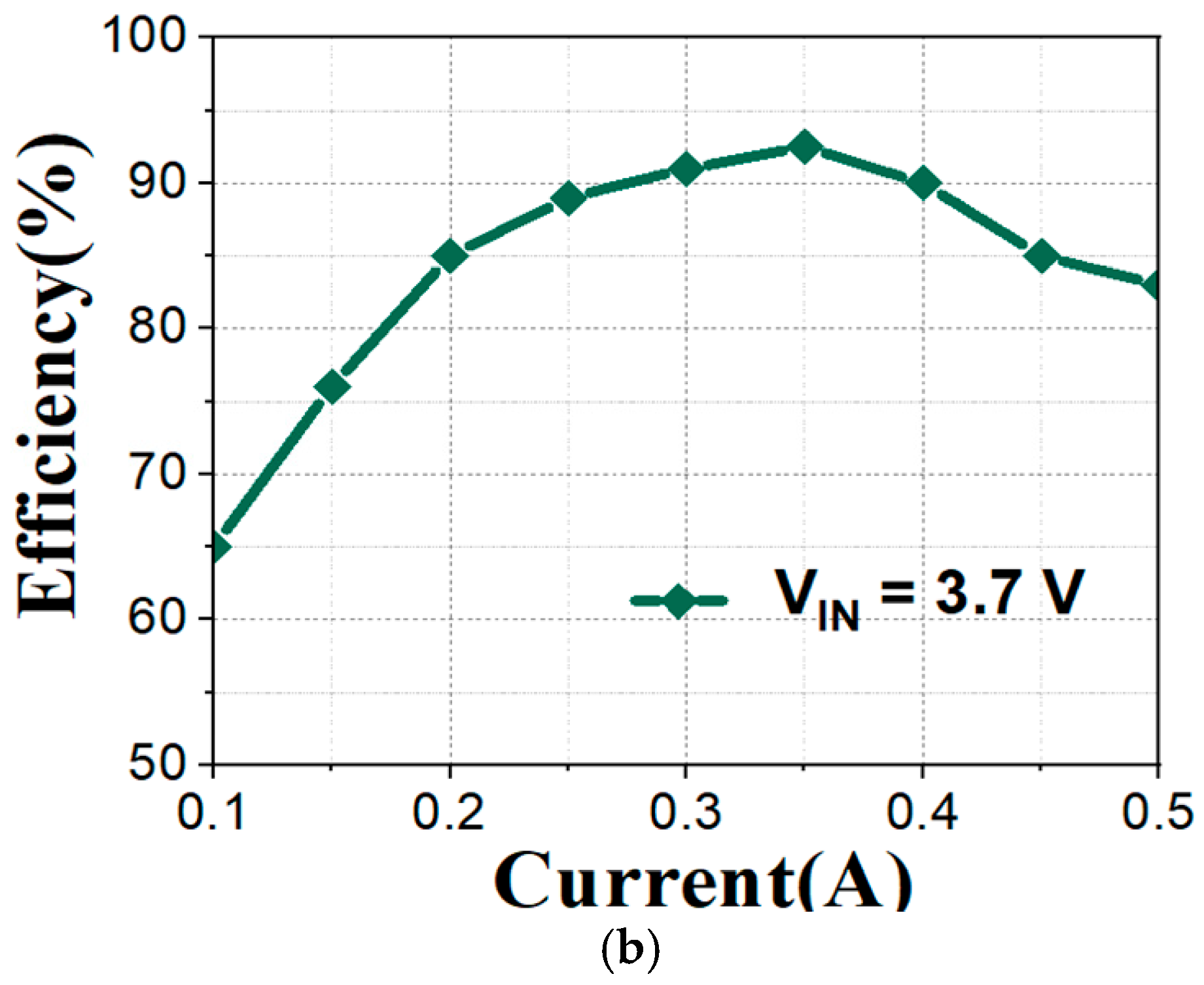

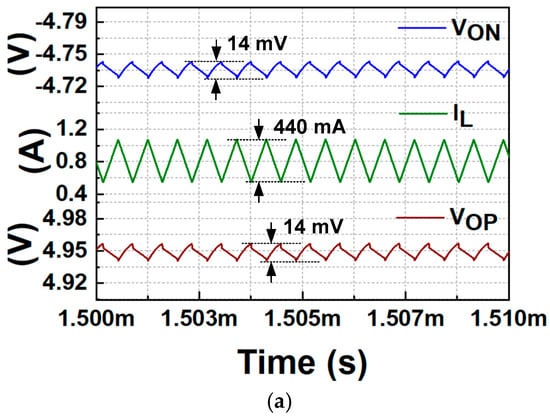

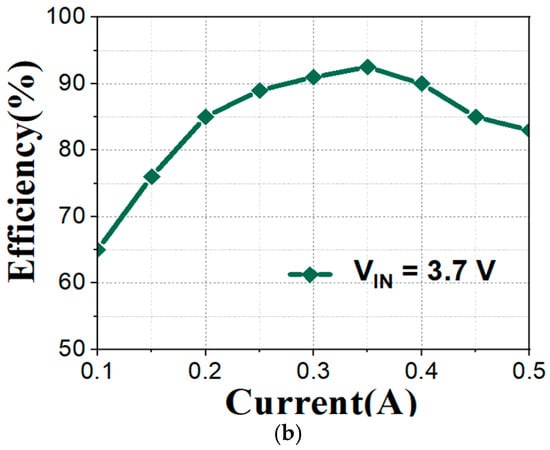

Figure 12a shows the waveforms of VON, VOP, and the inductor current under a 300 mA load. The voltage ripple on VON and VOP is 14 mV, and the inductor current ripple is 440 mA. It can be observed that, despite variations in load current, VON and VOP remain stable at approximately −4.7 V and 4.9 V, respectively. Furthermore, a lower load current results in reduced voltage ripple on VON and VOP, as the inductor current ripple decreases. Figure 12b shows the converter’s efficiency as a function of the load current. This result was plotted with all the losses accounted for, including the power consumptions of different blocks (gate driver, level shifter, ….) as well as switching loss and conduction loss inflicted onto the MOSFETs inside the power stage. The peak efficiency is 93%, which occurs at an output current of 0.35 A.

Figure 12.

VON, VOP, and IL waveforms at 300 mA load current (a); conversion efficiency (b).

Table 2 presents a performance comparison between the proposed converter and similar state-of-the-art SIBO converters. The proposed design, implemented in a 0.18 µm CMOS process, achieves a peak efficiency of 93% at 350 mA, which is competitive with the 94% efficiency of [13] and superior to the 88–89% efficiencies of [17,18]. A key advantage of this work is its significantly wider output current range of 100–500 mA, supporting heavier loads than the compared designs. Furthermore, it accomplishes this with a substantially smaller inductor value of 2.2 µH, a reduction of over 75% compared to the 10 µH required by [13,17,18], which is crucial for system miniaturization. This design also achieves the smallest active chip area of 0.98 mm2, demonstrating a more area-efficient integration despite not using the most advanced process node.

Table 2.

Performance comparison.

4. Conclusions

The designed bipolar-output DC-DC converter, implemented in a 180 nm CMOS process, achieves a peak efficiency of 93%. It provides stable output voltages of VON = −4.7 V and VOP = 4.9 V, effectively supporting a load current range of 0.1–0.5 A. The converter’s primary application is to supply a symmetric voltage for OLED displays, enhancing their luminous efficiency and stability. The topology utilizes two flying capacitors in parallel with the inductor, enabling a significant reduction in the inductor’s size. Despite the use of external flying capacitors and on-chip switches, the converter core occupies a compact area of 0.98 mm2. Furthermore, the implemented PWM control scheme ensures a fast transient response to load variations.

Author Contributions

Conceptualization, X.T.P. and M.T.N.; methodology, X.T.P. and M.T.N.; software, X.T.P.; validation, M.T.N.; formal analysis, O.A. and A.L.S.; investigation, O.A. and A.L.S.; writing—original draft preparation, X.T.P.; writing—review and editing, M.T.N., O.A. and A.L.S.; supervision, X.T.P. and O.A.; project administration, O.A. and A.L.S.; funding acquisition, O.A. and A.L.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the European Union—Next Generation EU in the framework of PRIN 2022 under grant 20222RWCJJ; project title Hybrid Energy hArVesting systEms for multiple and irregular ambieNt sources (Next Generation EU, Mission 4 Component 1 CUP B53D23002170006). Also, this work has received funding from the European Union’s Horizon Europe research and innovation program under the Marie Sklodowska-Curie grant agreement No. 101086359.

Data Availability Statement

Data is contained within the article. The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- TPS65130; Split-Rail Converter with Dual, Positive and Negative Outputs (300 mA Type). Texas Instruments Incorporated: Dallas, TX, USA, 2025. Available online: https://www.ti.com/product/TPS65130 (accessed on 27 January 2026).

- LTC3265; Low Noise Dual Supply with Boost and Inverting Charge Pumps. Analog Devices: Wilmington, MA, USA, 2015. Available online: https://www.analog.com/en/products/ltc3265.html (accessed on 27 January 2026).

- STOD02; Dual DC-DC Converter for Powering AMOLED Display. STMicroelectronics: Shenzhen, China, 2009. Available online: https://www.st.com/en/power-management/stod02.html (accessed on 27 January 2026).

- Lu, D.D.-C.; Wu, M.; Cheng, T. Using cross regulation in single-switch single-inductor dual-output CCM boost converter to simplify controller design. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 14–17 March 2016. [Google Scholar]

- Patra, P.; Ghosh, J.; Patra, A. Control Scheme for Reduced Cross-Regulation in Single-Inductor Multiple-Output DC–DC Converters. IEEE Trans. Ind. Electron. 2013, 60, 5095–5104. [Google Scholar] [CrossRef]

- Yeh, W.-T.; Cai, M.-X.; Tsai, C.-H. A Single-Inductor Bipolar-Output DC-DC Converter With Tunable Asymmetric Power Distribution Control (APDC) for AMOLED Applications. IEEE Access 2024, 13, 6810–6819. [Google Scholar] [CrossRef]

- Ning, G.; Chen, J.; Liu, Y.; Xu, G.; Xiong, W.; Su, M. Coupled-Inductor-Based Buck-Type Converter With Autonomous Voltage Balancing for Bipolar DC Microgrid. IEEE Trans. Power Electron. 2024, 39, 11937–11942. [Google Scholar] [CrossRef]

- Lin, K.-L. A single-inductor bipolar-output DC/DC converter with high efficiency over wide load range for active matrix OLED. In Proceedings of the SID Symposium Digest of Technical Papers, San Diego, CA, USA, 1–6 June 2014; pp. 1183–1186. [Google Scholar]

- Kwak, B.-C.; Kwon, O.-K. A 2822-ppi resolution pixel circuit with high luminance uniformity for OLED microdisplays. J. Disp. Technol. 2016, 12, 1083–1088. [Google Scholar] [CrossRef]

- Jin, J.; Zhou, Y.; Chen, C.; Han, X.; Xu, W.; Cheng, L. A 98.6% peak-efficiency 1.47A/mm2-current-density buck-boost converter with always reduced conduction loss. In Proceedings of the 2023 IEEE International Solid-State Circuits Conference (ISSCC), San Francisco, CA, USA, 19–23 February 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 440–448. [Google Scholar]

- Hardy, C.; Ramadass, Y.; Scoones, K.; Le, H.-P. A flying-inductor hybrid DC–DC converter for 1-cell and 2-cell smart-cable battery chargers. IEEE J. Solid-State Circuits 2019, 54, 3292–3305. [Google Scholar] [CrossRef]

- Wang, S.-W.; Woo, Y.-J.; Yuk, Y.-S.; Cho, G.-H.; Cho, G.-H. High efficiency Single-Inductor Boost/Buck Inverting Flyback converter with hybrid energy transfer media and multi level gate driving for AM OLED panel. In Proceedings of the Symposium on VLSI Circuits, Honolulu, HI, USA, 16–18 June 2010. [Google Scholar]

- Hong, S.-W. 11.6 A 1.46 mm2 Simultaneous Energy-Transferring Single-Inductor Bipolar-Output Converter with a Flying Capacitor for Highly Efficient AMOLED Display in 0.5 µm CMOS. In Proceedings of the IEEE International Solid-State Circuits Conference (ISSCC), San Francisco, CA, USA, 16–20 February 2020. [Google Scholar]

- Wang, S.-W.; Woo, Y.-J.; Yuk, Y.-S.; Lee, B.; Cho, G.-H.; Cho, G.-H. Efficiency enhanced single-inductor boost-inverting flyback converter with dual hybrid energy transfer media and a bifurcation free comparator. In Proceedings of the ESSCIRC, Seville, Spain, 14–16 September 2010; IEEE: Piscataway, NJ, USA, 2020; pp. 450–453. [Google Scholar]

- Biswas, M.; Majhi, S.; Nemade, H.B. A High Step-Down DC–DC Converter With Reduced Inductor Current Ripple and Low Voltage Stress. IEEE Trans. Ind. Appl. 2021, 57, 1559–1571. [Google Scholar] [CrossRef]

- Mihajlovic, Z.; Lehman, B.; Sun, C. Output ripple analysis of switching DC-DC converters. IEEE Trans. Circuits Syst. I Regul. Pap. 2004, 51, 1596–1611. [Google Scholar] [CrossRef]

- Kwak, B.-C.; Hong, S.-K.; Kwon, O.-K. A Highly Power-Efficient Single-Inductor Bipolar-Output DC-DC Converter Using Hysteretic Skipping Control for OLED-on-Silicon Microdisplays. IEEE Trans. Circuits Syst. II Express Briefs 2021, 65, 2017–2021. [Google Scholar] [CrossRef]

- Mao, F.; Lu, Y.; Bonizzoni, E.; Boera, F.; Huang, M.; Maloberti, F.; Martins, R.P. A Power-Efficient Hybrid Single-Inductor Bipolar-Output DC-DC Converter with Floating Negative Output for AMOLED Displays. In Proceedings of the IEEE Custom Integrated Circuits Conference (CICC), Boston, MA, USA, 22–25 March 2020. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.