Abstract

In this paper, the influences of leakage inductances are investigated for the integrated transformer of an input-series flyback converter, in which each input-series circuit is based on the single-switch flyback topology. First, the configuration of this converter is introduced, and a novel multiple-inductor coupling model is proposed for its flyback integrated transformer. Second, the operational process of this converter is analyzed by considering the leakage inductances between the primary and secondary windings of its integrated transformer. Third, the influences of these leakage inductances are analyzed; on this basis, the essential design considerations of the flyback integrated transformer are summarized. Finally, an experimental prototype of this input-series converter is built. Based on this, the analysis is verified by the experimental comparisons among three flyback integrated transformers with various winding layouts.

1. Introduction

With the continuous development of power electronics techniques, more and more converters with medium or high input voltages (≥1000 V) are needed in various industry applications, especially in renewable energy and transportation applications [1,2,3]. In these converters, the high voltage issue of each component is the most urgent problem to be solved. The input-series structure is a valid scheme to solve the high voltage problem in the converters with medium or high input voltages, and voltage stress of each component in these converters can be reduced substantially as long as the input voltage sharing of each input-series circuit is achieved [4,5].

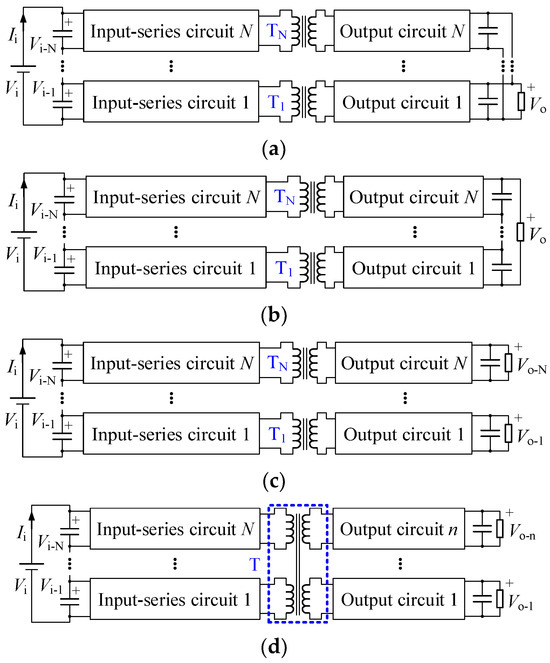

Generally, there are two basic input-series structures: one is the output-parallel strategy, as shown in Figure 1a, and the other one is the output-series strategy, as shown in Figure 1b. In addition to the input voltage sharing, output voltage and current sharing should also be ensured in these two kinds input-series converters [5,6,7]. In past years, many voltage or current sharing strategies have been implemented, and a good voltage or current sharing effect could be achieved for each converter [7,8,9,10,11,12]. These two basic input-series structures can be applied in various power applications, provided the suitable circuit topology is adopted in each input-series circuit. However, their output connections will become more complex when multiple outputs are required, so these two basic input-series structures are not suitable to apply in multiple-output applications.

Figure 1.

Input-series structures. (a) Output-parallel strategy. (b) Output-series strategy. (c) Output-independent strategy. (d) Transformer-integration strategy.

Aiming at multiple-output applications, the output-independent strategy is applied in the input-series converters, as shown in Figure 1c. The input voltage sharing effect of these converters will be serious when the energies transferring through various output circuits are unbalanced, so the output-independent strategy can only be adopted in applications when the energies transferring through different output circuits are balanced [13,14,15,16].

In addition to the output-parallel, output-series, and output-independent strategies, the transformer-integration strategy can also be applied in the input-series converters, as shown in Figure 1d, where all input-series circuits enjoy a common integrated transformer, so the output circuits can be conveniently made in the secondary sides of this integrated transformer [17,18,19,20]. In these input-series transformer integration (ISTI) converters, natural input voltage sharing can be achieved, provided all input-series circuits are operating synchronously. The transformer-integration strategy can also be applied in various power applications, as long as the suitable circuit topology is adopted in each input-series circuit. Compared to the output-parallel or output-series strategies, the transformer-integration strategy is much more suitable to apply when the multiple-output circuits are required, which is a conventional requirement in low-power applications.

Recently, ISTI flyback converters have been investigated systematically in multiple-output low-power applications [18,19]. These investigations provided the following conclusions:

(1) The input voltage sharing of the ISTI flyback converter can be ensured naturally by the coupling relationships of the primary windings in the integrated transformer. The input voltage sharing effects will be achieved more efficiently as the coupling coefficients of the primary windings increase.

(2) Due to inevitable parameter errors, the absolute synchronous operation of all input-series circuits cannot be realized, so input voltage differences occur. The input voltage differences can be reduced through the special design of key parameters, especially the input filter capacitance in each input-series circuit.

(3) Input voltage sharing effects of the ISTI flyback converter cannot be affected by the components in the secondary sides of the integrated transformer. Influences of the coupling relationships among secondary windings in the integrated transformer mainly aim at multiple-output features, which are similar to those in the other traditional flyback converters with multiple-output circuits.

In each ISTI flyback converter, the integrated transformer is the main device, so its design and manufacture are very important. As shown in Figure 1d, there are N (N ≥ 2) primary windings and n (n ≥ 1) secondary windings in each integrated transformer, so the influences of the coupling relationships between two arbitrary windings should be clarified. Based on this, the layouts of these windings can be determined in the design process. Presently, the influences of the coupling relationships among primary windings have been clarified, as well as the coupling relationships among secondary windings. However, the influences of the coupling relationships between primary and secondary windings have not been clarified.

In each traditional flyback transformer, a leakage inductance is used to represent the coupling relationship between the single primary winding and the secondary winding. The energy of this leakage inductance is released by the absorbing circuit in the flyback converter, so additional power loss is introduced. Generally, this leakage inductance should be minimized to decrease the power losses of the flyback converter.

However, there are N primary windings and n secondary windings in the integrated-transformer of each ISTI flyback converter, so numerous leakage inductances are needed to represent the coupling between these primary and secondary windings, and the influences of these leakage inductances and their differences will be more complex. Therefore, the influences of these numerous leakage inductances should be clarified, especially their influences on the voltage sharing effects of each input-series circuit, which are the unique issues of each ISTI flyback converter.

Generally, the coupling relationship between two arbitrary windings should be represented by at least one leakage inductance, so N × n leakage inductances are needed to represent the coupling relationships between N primary windings and n secondary windings, which cannot be realized in the existing model of the flyback integrated transformer. Therefore, in this paper, a novel multiple-inductor coupling model is proposed for this flyback integrated transformer, through which the coupling relationships between primary and secondary windings are analyzed and the essential design considerations of the flyback integrated transformer are summarized.

The remainder of this paper is organized as follows. In Section 2, the ISTI flyback converter and the multiple-inductor coupling model of its integrated transformer are introduced. In Section 3, the operational process of this converter is analyzed based on the proposed model, where the leakage inductances between primary and secondary windings are considered. In Section 4, the influences of the leakage inductances are analyzed; based on this, the essential design considerations of the flyback integrated transformer are summarized. In Section 5, the analysis is verified by experimental comparisons among three flyback integrated transformers with various winding layouts. In Section 6, conclusions are provided.

2. ISTI Flyback Converter and Its Integrated Transformer

2.1. Configuration of the ISTI Flyback Converter

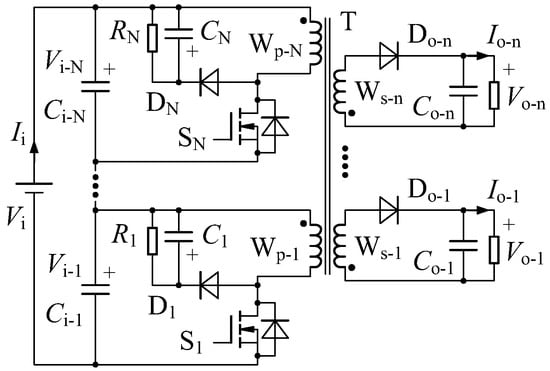

Figure 2 shows the configuration of the ISTI flyback converter, where each input-series circuit is based on the single-switch flyback topology, Vi and Ii are the input voltage and input current, Vi-1, …, Vi-N are the input voltages of the N input-series circuits, and Vo-1, …, Vo-n and Io-1, …, Io-n are the output voltages and output current of the n output-independent circuits.

Figure 2.

Configuration of the ISTI flyback converter.

In the input-series circuits, there are identical components and parameters, including the input filter capacitors (Ci-1 = … = Ci-N), the switches (S1, …, SN), the turn numbers (Np-1 = … = Np-N), and the self-inductances (Lp-1 = … = Lp-N) of the primary windings (Wp-1, …, Wp-N) in the integrated transformer (T) and the absorbing circuits (R1 = … = RN, C1 = … = CN, and D1, …, DN).

In the output-independent circuits, the turn numbers (Ns-1, …, Ns-n) of secondary windings (Ws-1, …, Ws-n) in T, as well as the output rectifier diodes (Do-1, …, Do-n) and output filter capacitors (Co-1, …, Co-n), are designed according to the special output requirements.

2.2. Multiple-Inductor Coupling Model of Flyback Integrated Transformer

In the integrated transformer (T), there are N primary windings and n secondary windings, so the influences of the coupling relationships among these windings should be clarified. On this basis, the layouts of these windings can be determined in the design process. In previous investigations, the influences of the coupling relationships among primary windings have been clarified, as well as the coupling relationships among secondary windings. However, the influences of the coupling relationships between primary and secondary windings have not been clarified.

Generally, the coupling between two arbitrary windings should be represented by at least one leakage inductance, so N × n leakage inductances are needed to represent the coupling between N primary windings and n secondary windings, which cannot be realized in the existing model of the flyback integrated transformer.

To overcome the shortcomings of the existing model, a novel multiple-inductor coupling model is proposed for this flyback integrated transformer, as shown in Figure 3, through which the influences of the coupling relationships between primary and secondary windings are expected to be clarified. This novel model is introduced as follows.

Figure 3.

Multiple-inductor coupling model of the flyback integrated transformer.

(1) The input voltage sharing effects of the ISTI flyback converter cannot be affected by the coupling relationships among the secondary windings of the integrated transformer, and the influences of the coupling relationships among secondary windings are mainly aimed at the multiple-output features, which are similar to those in the other traditional flyback converters with multiple-output circuits. Therefore, to simplify the analysis, an equivalent single secondary winding (Ws-1) is adopted in this model to represent the n secondary windings.

(2) In this model, the equivalent single secondary winding (Ws-1) is divided into N identical parts (Ws-11, …, Ws-1N), and they are used as the secondary windings of the ideal transformers (Ti-1, …, Ti-N). Ti-1, …, Ti-N are connected in parallel in the secondary sides, where their turn ratios are identical (Np-1/Ns-1). Do-11, …, Do-1N are used as the output rectifier diodes.

(3) In this model, a coupled inductor (Lp-1 = … = Lp-N) is adopted to represent the coupling relationships among the N primary windings.

(4) In this model, the leakage inductances (Llk-1, …, Llk-N) are adopted to represent the coupling relationships between the N primary windings (Wp-1, …, Wp-N) and the equivalent single secondary winding (Ws-1), respectively.

3. Operational Process of ISTI Flyback Converter Considering the Leakage Inductances

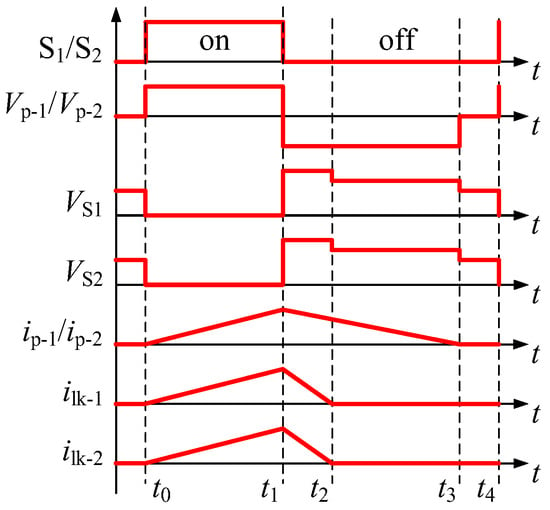

Based on the model provided in Figure 3, the operational process of the ISTI flyback converter is analyzed as follows. To simplify the analysis, the following conditions are assumed: (1) this converter operates in discontinuous current mode (DCM); (2) this converter is composed of two input-series circuits (N = 2) and a single output circuit (n = 1); (3) in addition to the integrated transformer, all devices in this converter are ideal; (4) the asynchronous turning of S1 and S2 is not considered; (5) the input voltage differences between two input-series circuits are not considered (Vi-1 = Vi-2 = Vi/2); and (6) C1, C2, and Co-1 are large enough, so the fluctuations of their voltages (VC1, VC2, and Vo-1) are ignored. During each switching period, there are the following four stages, where the main waveforms in each period are shown in Figure 4 and the equivalent circuit in each stage is shown in Figure 5.

Figure 4.

Main voltage and current waveforms in each period.

Figure 5.

Equivalent circuit in each stage. (a) Stage 1. (b) Stage 2. (c) Stage 3. (d) Stage 4.

Stage 1 (t0~t1): At t0, S1 and S2 are turned on. After t0, the coupled inductor (Lp-1 and Lp-2) is charged by the input voltages, so its current increases. In the absorbing circuits, D1 and D2 are turned off, while C1 and C2 are discharged through R1 and R2, respectively. In the output circuits, Do-11 and Do-12 are turned off, and Io-1 is only provided by Co-1. In this stage, the voltages in the primary or secondary sides of Ti-1 and Ti-2 are Vp-1 = Vi-1 = Vi/2, Vp-2 = Vi-2 = Vi/2, and Vs-11 = Vs-12 = Ns-1Vi/2Np-1. At t1, the current of these inductors increases to the peak value during the whole period, as shown in Equation (1):

where ip-1 (or ip-2) and ilk-1 (or ilk-2) are the currents of Lp-1 (or Lp-2) and Llk-1 (or Llk-2), respectively; Lp-es = 2(1 + k12)Lp-1 is the equivalent series inductance of Lp-1 and Lp-2; k12 is the coupling coefficient between Lp-1 and Lp-2; and Llk-1 (or Llk-2) is much smaller than Lp-es, which are not considered here.

Stage 2 (t1~t2): At t1, S1 and S2 are turned off, and their voltages (VS1 and VS2) increase immediately to Vi-1 + VC1 and Vi-2 + VC2, respectively. The durations of these processes are very small, which are not considered here.

After t1, Do-11 and Do-12 are turned on, and the energies stored in Lp-1 and Lp-2 are transferred to the loads through Ti-1 and Ti-2, respectively. In the absorbing circuits, D1 and D2 are turned on, and the energies stored in Llk-1 and Llk-2 are transferred into C1 and C2, respectively. In this stage, Vs-11 = Vs-12= −Vo-1 and Vp-1 = Vp-2 = −Np-1Vo-1/Ns-1; moreover, the expressions of ip-1 (or ip-2) and ilk-1, ilk-2 can be obtained in Equations (2) and (3), respectively.

where Lp-ep = (1 + k12)Lp-1/2 is the equivalent parallel inductance of Lp-1 and Lp-2.

At the end of this stage, ilk-1 and ilk-2 decrease to zero; D1 and D2 are then turned off accordingly.

Stage 3 (t2~t3): At t2, ilk-1 = ilk-2 = 0. After t2, C1 (or C2) is still discharged through R1 (or R2), and the decrease in ip-1 (or ip-2) is continuous. In this stage, Vp-1, Vp-2, Vs-11, and Vs-12 are fixed; however, VS1 and VS2 are changed into Vi-1 + Vp-1 and Vi-2 + Vp-2, respectively.

Stage 4 (t3~t4): At t3, ip-1 = ip-2 = 0. After t3, Do-11 and Do-12 are turned off, Vp-1 = Vp-2 = 0, Vs-11 = Vs-12 = 0, VS1 = Vi-1 = Vi/2, VS2 = Vi-2 = Vi/2, and Io-1 is only provided by Co-1.

At t4, S1 and S2 are turned on again. After t4, this converter will operate in the next period.

4. Design Considerations of Integrated Transformer Based on the Leakage Inductances

According to the operational process, the influences of leakage inductances (Llk-1 and Llk-2) between the primary windings (Wp-1 and Wp-2) and the equivalent single secondary winding (Ws-1) are analyzed in this section. Based on this, the essential design considerations of this flyback integrated transformer are summarized.

4.1. Influences of the Leakage Inductances

In stage 1, S1 and S2 are turned on, and the coupling relationships of two primary windings (Wp-1 and Wp-2) are represented by the coupled inductor (Lp-1 and Lp-2), by which the input voltage sharing of each input-series circuit is achieved. The leakage inductances (Llk-1 and Llk-2) are adopted to represent the coupling relationships between the primary windings (Wp-1 and Wp-2) and the equivalent single secondary winding (Ws-1), which are much smaller than the equivalent series inductance (Lp-es) of this coupled inductor, so the input voltage sharing process in this stage has almost no relationship with Llk-1 (or Llk-2).

In stage 2, the energies of Llk-1 and Llk-2 are transferred into C1 and C2, respectively, so the energies stored in C1 and C2 can be affected. During the whole switching period, the maximum voltages of S1 and S2 are equal to Vi-1 + VC1 and Vi-2 + VC2, respectively. Therefore, the voltage sharing effect of S1 and S2 can also be affected, which cannot be ensured even if a good input voltage sharing effect has been achieved (Vi-1 = Vi-2 = Vi/2).

In stage 3 and stage 4, the current of Llk-1 (or Llk-2) is zero, so there is almost no influence caused by Llk-1 (or Llk-2) in these stages.

Therefore, the analysis concerning the influence of the leakage inductances (Llk-1 and Llk-2) is implemented in stage 2 as follows, where the simplified equivalent circuit of the ISTI flyback converter in stage 2 is shown in Figure 6.

Figure 6.

Simplified equivalent circuit of the ISTI flyback converter in stage 2 (Vs-11 = Vs-12 = −Vo-1 and Vp-1 = Vp-2 = −Np-1Vo-1/Ns-1).

From operational process of the ISTI flyback converter, it can be obtained that, during the whole switching period, C1 and C2 are discharged through R1 and R2, respectively. Accordingly, the decrease in the energies of C1 and C2 during each switching period can be estimated using Equation (4).

where f is the switching frequency.

In stage 2, the current of Llk-1 and Llk-2 will decrease to zero, and their current decreasing durations can be obtained from Equation (3), as shown in Equation (5).

From Equations (3) and (5), the increase in the energies of C1 and C2 in stage 2 can be estimated using Equation (6), where Tlk-1 (or Tlk-2) is much smaller than T, so the energies released by R1 and R2 are not considered in the estimations.

During the whole switching period, it is required that EC1+ = EC1- and EC2+ = EC2- Therefore, the relationships in Equation (7) can be obtained from Equations (4) and (6).

In stage 2, the energies stored in Llk-1 and Llk-2 are absorbed by C1 and C2, so VC1 > Np-1Vo-1/Ns-1 and VC2 > Np-1Vo-1/Ns-1 should be achieved. Moreover, it is considered that ilk-1(t1) = ilk-2(t1), as shown in Equation (1). Therefore, it can be obtained from Equation (7) that, when the parameters R1 = R2 and C1 = C2 are fixed, VC1 and VC2 are determined by Llk-1 and Llk-2, which will increase as Llk-1 and Llk-2 increase, respectively.

In the ISTI flyback converter, the energies of Llk-1 and Llk-2 are released through the absorbing circuits, and the power losses caused by the leakage inductances (Llk-1 and Llk-2) can be estimated using Equation (8).

It can be seen from Equation (8) that, when the parameters R1 = R2 and C1 = C2 are fixed, Pos-lk1 and Pos-lk1 will increase as VC1 and VC2 increase, respectively. Therefore, it can be concluded from Equations (7) and (8) that the power losses caused by the leakage inductances Llk-1 and Llk-2 are also determined by Llk-1 and Llk-2, which will also increase as Llk-1 and Llk-2 increase, respectively.

4.2. Essential Design Considerations of Flyback Integrated Transformer

The influences of leakage inductances (Llk-1 and Llk-2) can be summarized from two aspects: (1) the voltage sharing effect of the switches (S1 and S2) in various input-series circuits and (2) the power losses caused by the leakage inductances (Llk-1 and Llk-2) in two input-series circuits. They are summarized as follows.

(1) The input voltage sharing effect of each input-series circuit has almost no relationships with Llk-1 and Llk-2; however, the voltage sharing effect of S1 and S2 can be affected by Llk-1 and Llk-2. The maximum voltages of S1 and S2 are equal to Vi-1 + VC1 and Vi-2 + VC2, respectively. When a good input voltage sharing effect is achieved (Vi-1 = Vi-2 = Vi/2), the voltage sharing effect of C1 and C2 should be specifically considered. As shown in Equation (7), VC1 and VC2 are determined by Llk-1 and Llk-2, respectively, and VC1 = VC2 can be achieved when Llk-1 = Llk-2.

(2) The energies stored in Llk-1 and Llk-2 are transferred into C1 and C2 in stage 2, and these energies are released through R1 and R2, respectively, so the power losses caused by Llk-1 and Llk-2 should be considered, which are similar to the other traditional flyback converters. As shown in Equations (7) and (8), the power loss caused by Llk-1 (or Llk-2) will increase as VC1 (or VC2) increases, and VC1 (or VC2) will increase as Llk-1 (or Llk-2) increases.

From the influences of leakage inductances (Llk-1 and Llk-2), essential design considerations of the flyback integrated transformer can be summarized: (1) the difference between Llk-1 and Llk-2 should be suppressed to ensure a good voltage sharing effect of S1 and S2, where Llk-1 = Llk-2 is especially expected to be achieved; and (2) Llk-1 and Llk-2 should be minimized to reduce the power losses.

5. Experimental Verifications

5.1. Experimental Prototype

To verify the aforementioned analysis, a 1000 V/60 W experimental prototype of the ISTI flyback converter was built, as shown in Figure 7. This experimental prototype is composed of two input-series circuits (N = 2) and two output-independent circuits (n = 2), and each input-series circuit is based on the single-switch flyback topology. The main components and parameters of this experimental prototype are shown in Table 1.

Figure 7.

Experimental prototype of the ISTI flyback converter.

Table 1.

Components and parameters of the prototype.

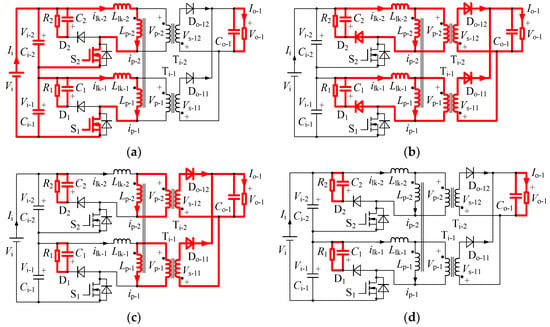

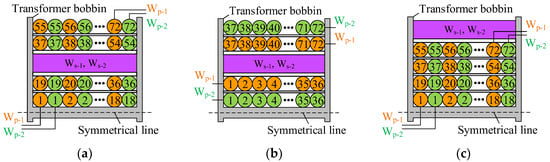

Based on this prototype, three flyback integrated transformers (T1, T2, and T3) with various typical layout schemes for the primary windings (Wp-1 and Wp-2) are designed for the experimental comparisons. The winding layouts of T1, T2, and T3 can be obtained from their cross-sections, as shown in Figure 8, in which only half of the cross-section is given in each illustration, and the number marked on each turn represents its manufacturing sequence.

Figure 8.

Cross-sections of the flyback integrated transformer. (a) The illustration of T1. (b) The illustration of T2. (c) The illustration of T3.

In each flyback integrated transformer, the secondary windings (Ws-1 and Ws-2) are connected in parallel, and they are manufactured intensively to improve their coupling relationship. The layouts of Ws-1 and Ws-2 are identical in T1, T2, and T3, which are not given in Figure 8. Moreover, the other common features of these integrated transformers are shown in Table 2, and the layout schemes of their primary windings (Wp-1 and Wp-2) are explained as follows.

Table 2.

Common features of the integrated transformers.

In T1, Wp-1 and Wp-2 are connected in parallel. The four layers of Wp-1 and Wp-2 are divided into two parts, where Ws-1 and Ws-2 are rounded in the middle of these two parts.

In T2, the layer-by-layer winding layout is selected for Wp-1 and Wp-2. The two layers of Wp-1 (or Wp-2) are divided into two parts, where Ws-1 and Ws-2 are rounded in the middle of these two parts. The two layers of Wp-1 are rounded near Ws-1 and Ws-2, and the two layers of Wp-2 are rounded in the innermost and outermost layers, respectively.

In T3, Wp-1 and Wp-2 are connected in parallel, and they are made in the inner four layers. Ws-1 and Ws-2 are made in the outer layers.

The main parameters of these integrated transformers are measured by the LCR meter (Tonghui/TH2826), including the coupling coefficient (k12) and the leakage inductances (Llk-1 and Llk-2). The measuring results are shown in Table 3. It can be obtained that (1) a high coupling coefficient has been achieved in each integrated transformer; (2) in T1 (or T3), there is almost no difference between Llk-1 and Llk-2, but there is an obvious difference between Llk-1 and Llk-2 in T2; and (3) in T3, Llk-1 (or Llk-2) is much larger than that in T1 (or T2).

Table 3.

Measuring results of the integrated transformer.

According to the aforementioned analysis, the following experimental results can be expected: (1) a good input voltage sharing effect will be achieved for this experimental prototype when any one of the integrated transformers is adopted; (2) when T1 (or T3) is adopted, there is almost no voltage difference between C1 and C2, so a good voltage sharing effect will be achieved between S1 and S2; (3) when T1 (or T2) is adopted, the voltages of C1 and C2 will be lower than those when T3 is adopted; and (4) when T1 (or T2) is adopted, the power losses caused by the leakage inductances will be much lower, so the efficiency of the experimental prototype will be higher than when T3 is adopted.

5.2. Experimental Results

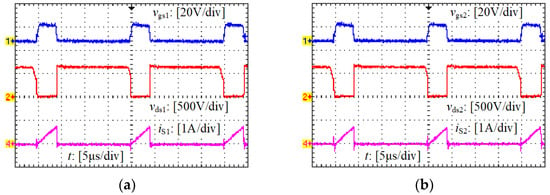

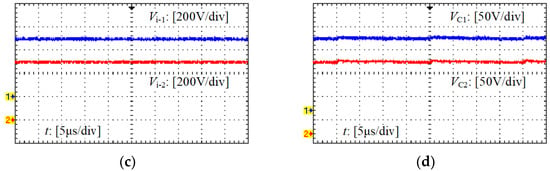

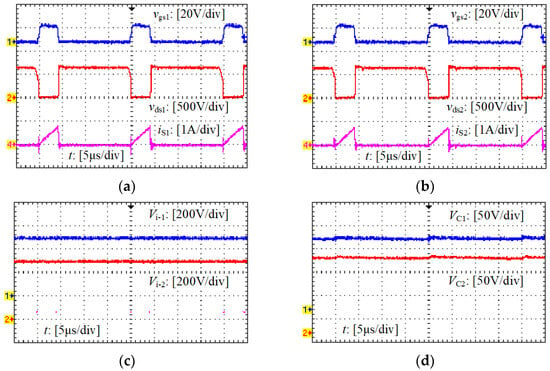

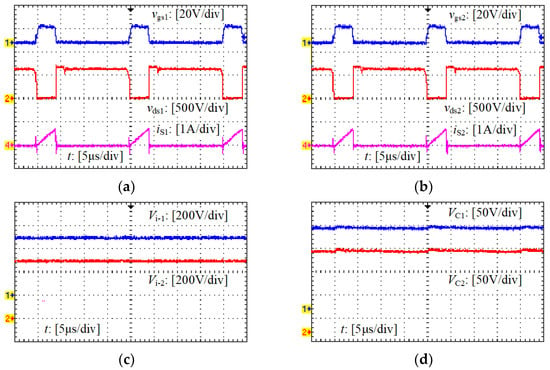

The three flyback integrated transformers (T1, T2, and T3) are used in this experimental prototype one by one, and the main experimental results are shown in Figure 9, Figure 10 and Figure 11 and Table 4.

Figure 9.

Main waveforms of the prototype when T1 is used. (a) Voltage and current of S1. (b) Voltage and current of S2. (c) Input voltages (Vi-1 and Vi-2). (d) Voltages of C1 and C2.

Figure 10.

Main waveforms of the prototype when T2 is used. (a) Voltage and current of S1. (b) Voltage and current of S2. (c) Input voltages (Vi-1 and Vi-2). (d) Voltages of C1 and C2.

Figure 11.

Main waveforms of the prototype when T3 is used. (a) Voltage and current of S1. (b) Voltage and current of S2. (c) Input voltages (Vi-1 and Vi-2). (d) Voltages of C1 and C2.

Table 4.

Main measuring results.

Figure 9 shows the main experimental waveforms when T1 is used, including the driving (vgs1), voltage (vds1), and current (iS1) of S1; the driving (vgs2), voltage (vds2), and current (iS2) of S2; the input voltages (Vi-1 and Vi-2) of two input-series circuits; and the voltages (VC1 and VC2) of two capacitors in the absorbing circuits. Figure 10 and Figure 11 show the main experimental waveforms when T2 and T3 are used. It can be seen from these waveforms that a good input voltage sharing effect has been achieved for this experimental prototype when any one of the integrated transformers is adopted.

Table 4 shows the main measuring results when T1, T2, and T3 are used one by one, including the voltages (VC1 and VC2) of two capacitors in the absorbing circuits and the efficiency (η) of this experimental prototype.

From Figure 9d, Figure 10d and Figure 11d and Table 4, the following can be obtained: (1) when T1 is used, there is almost no voltage difference between the two capacitors (C1 and C2) in the absorbing circuits; (2) when T2 is used, an obvious voltage difference (VC2 – VC1 = 9 V) appears between C1 and C2; and (3) when T3 is used, there is almost no voltage difference between C1 and C2, but the voltage of C1 (or C2) is much higher than that when T1 (or T2) is adopted. Moreover, it can also be obtained from Table 4 that, when T1 (or T2) is used, the efficiency of this experimental prototype is higher than when T3 is adopted.

Therefore, it can be seen that the analysis concerning the influences of leakage inductances has been verified through the above experimental comparisons.

6. Conclusions

In this paper, the influences of leakage inductances between primary and secondary windings are investigated for the integrated transformer in an input-series flyback converter, in which each input-series circuit is based on the single-switch flyback topology. To represent the coupling relationship between primary and secondary windings, a novel multiple-inductor coupling model is proposed for the flyback integrated transformer. The operational process of this converter and the influences of the leakage inductances are analyzed based on this model, and the essential design considerations of the flyback integrated transformer are summarized as follows: (1) the difference in various leakage inductances should be suppressed as much as possible to achieve a good voltage sharing effect for the switches in different input-series circuits; and (2) the leakage inductances should also be reduced to decrease the power losses of this converter, which are similar to the other traditional flyback converters. The results of the investigation are verified by the experimental comparisons among three flyback integrated transformers with various winding layouts.

Author Contributions

Conceptualization, S.L. and T.M.; methodology, T.M. and H.B.; software, W.H. and C.L.; validation, S.L. and W.H.; formal analysis, T.M.; investigation, S.L.; resources, T.M.; data curation, S.L. and W.H.; writing—original draft preparation, S.L.; writing—review and editing, S.L. and T.M.; supervision, T.M. and H.B.; project administration, T.M.; funding acquisition, T.M. and C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Heilongjiang Provincial Natural Science Foundation of China (LH2023E107), Program for Young Talents of Basic Research in Universities of Heilongjiang Province (YQJH2024181), and Heilongjiang University Fundamental Research Funds for the Heilongjiang Province Universities (2024-KYYWF-0114).

Data Availability Statement

Data are provided within the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yoon, D.; Cho, Y.; Bae, S.; Lee, J. An input-series output-series noninverting buck-boost converter for 1500 V dc bus with wide input and output voltage ranges. IEEE Trans. Ind. Electron. 2023, 70, 11231–11241. [Google Scholar] [CrossRef]

- Ren, X.; Xu, Z.; Zhang, Z.; Li, H.; He, M.; Tang, J.; Chen, Q. A 1-kV input SiC LLC converter with split resonant tanks and matrix transformers. IEEE Trans. Power Electron. 2019, 34, 10446–10457. [Google Scholar] [CrossRef]

- Chen, X.; Chen, W.; Yang, X.; Han, Y.; Hao, X.; Xiao, T. Research on a 4000-V-ultrahigh-input-switched-mode power supply using series-connected MOSFETs. IEEE Trans. Power Electron. 2018, 33, 5995–6011. [Google Scholar] [CrossRef]

- Ma, Q.; Huang, Q.; Huang, A. Zero-voltage switching and natural voltage balancing of a 3 kW 1 MHz input-series-output-parallel GaN LLC converter. IEEE Open J. Power Electron. 2024, 5, 1119–1128. [Google Scholar] [CrossRef]

- Ma, D.; Chen, W.; Ruan, X. A review of voltage/current sharing techniques for series-parallel-connected modular power conversion systems. IEEE Trans. Power Electron. 2020, 35, 12383–12400. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, G.; Ruan, X.; Ji, S.; Zhao, Q.; Zhang, X. An input-series-output-parallel converter system exhibiting natural input-voltage sharing and output-current sharing. IEEE Trans. Ind. Electron. 2021, 68, 1166–1177. [Google Scholar] [CrossRef]

- Sha, D.; Guo, Z.; Luo, T.; Liao, X. A general control strategy for input-series-output-series modular dc-dc converters. IEEE Trans. Power Electron. 2014, 29, 3766–3775. [Google Scholar] [CrossRef]

- Qu, L.; Zhang, D.; Zhang, B. Input voltage sharing control scheme for input-series and output-parallel connected dc-dc converters based on peak current control. IEEE Trans. Ind. Electron. 2019, 66, 429–439. [Google Scholar] [CrossRef]

- Wang, L.; Sun, P.; Liang, Y.; Wu, X.; Deng, Q.; Rong, E. Analysis and control design for input-series output-parallel multi-channel inductive power transfer system. IET Power Electron. 2024, 17, 2515–2530. [Google Scholar] [CrossRef]

- Li, S.; Wang, Z.; Yuan, X.; Zhang, Y.; Sun, L.; Wang, K.; Wu, X. A 10 kV/400 V SiC based dc-dc converter with input-series-output-parallel configuration and three-loop control. IEEE Trans. Ind. Appl. 2024, 60, 7013–7029. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H.; Wang, X.; Gang, Y.; Li, Y. Voltage balance scheme for input-series output-series DAB dc-dc converter with bidirectional power flow. IEEE Trans. Power Electron. 2024, 39, 12030–12034. [Google Scholar] [CrossRef]

- Li, J.; Ma, X.; Xie, Y.; Wang, T.; Shu, Z. Power and voltage balance control strategy of series input parallel output type three-level dual active bridge converter. Trans. China Elect. Soc. 2024, 39, 3082–3092. [Google Scholar]

- Hu, Q.; Zane, R. LED driver circuit with series-input-connected converter cells operating in continuous conduction mode. IEEE Trans. Power Electron. 2010, 25, 574–582. [Google Scholar]

- Yang, W.; Zhang, Z.; Yang, S. A new control strategy for input voltage sharing in input series output independent modular dc-dc converters. J. Power Electron. 2017, 17, 632–640. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Z.; Sun, K.; Yang, W.; Yang, S.; Li, F.; Yao, Y. Series input multiple outputs flyback auxiliary power supply for input series-output parallel/input series-output series system. IET Power Electron. 2019, 12, 2285–2294. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; Gao, F.; Liu, D.; Wheeler, P. Auxiliary power supply for input-series output-parallel medium-voltage solid state transformers. IEEE Trans. Power Electron. 2023, 38, 7308–7321. [Google Scholar] [CrossRef]

- Choi, S.; Lee, J.; Lee, J. High-efficiency portable welding machine based on full-bridge converter with ISOP-connected single transformer and active snubber. IEEE Trans. Ind. Electron. 2016, 63, 4868–4877. [Google Scholar]

- Meng, T.; Li, C.; Ben, H.; Zhao, J. An input-series flyback auxiliary power supply scheme based on transformer-integration for high-input voltage applications. IEEE Trans. Power Electron. 2016, 31, 6383–6393. [Google Scholar] [CrossRef]

- Meng, T.; Song, Y.; Wang, Z.; Ben, H.; Li, C. Investigation and implementation of an input-series auxiliary power supply scheme for high-input-voltage low-power applications. IEEE Trans. Power Electron. 2018, 33, 437–447. [Google Scholar] [CrossRef]

- Wang, Y.; Kim, S.; Zhang, H.; Chen, Y.; Park, S. Design and analysis of an input-series quasi-resonant flyback high-voltage SMPS based on an integrated transformer. IET Power Electron. 2022, 15, 1058–1074. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.