Abstract

Producing Class A biosolids is a beneficial way to reuse wastewater treatment solids, but most conventional processes are energy-intensive and expensive. There is growing interest in the use of low-cost, low-tech (LCLT) Class A biosolids treatment processes, especially at small water resource recovery facilities (WRRFs). This study used a holistic sustainability assessment to examine the environmental, economic, and social sustainability of conventional and LCLT processes at small WRRFs. The technologies studied were Direct Heat Drying, Composting, Lagoon Storage, Air Drying, and Temperature-Phased Anaerobic Digestion (TPAD). Environmental impacts were determined by conducting life-cycle assessments for all technologies, which is described in detail in prior published work. Economic impacts were quantified with a life-cycle cost assessment approach over a 25-year time horizon. Potential social impacts of each process were assessed by investigating case studies and surveys of social response to biosolids and estimating a relative impact score in a number of categories reported to be important to stakeholders in this technical domain. Impacts were normalized and compared to assess the best processes under a range of weighting scenarios. TPAD and Air Drying were the most sustainable processes when all domains were weighted equally. TPAD was projected to have low environmental and social impacts, which made up for its relatively high lifetime cost. Air Drying was the least expensive process in our analysis and had a modest environmental footprint, but there is potential for higher social impacts if the process is not sited and maintained properly. Because different communities are likely to prioritize or weight environmental, economic, and social impacts differently, a three-component mixing diagram was used to illustrate that Air Drying (economic), TPAD (environmental), or Direct Heat Drying (social) could become the preferred biosolids treatment process depending on which of the three sustainability domains was prioritized in the analysis.

1. Introduction

In many areas of our economy and society, great attention is being paid to our use of resources, and production of waste, and developing methods to mitigate the harmful impacts of both aspects of our material consumption. In the area of wastewater treatment, the beneficial reuse of waste products to create a valuable co-product has been an ongoing project at some water resource recovery facilities (WRRFs) for many decades. Organic solids resulting from the wastewater treatment process are further processed to produce biosolids, which are high in organic matter and fertilizer nutrients like N, P, and K [1]. These biosolids are often reused as land-applied soil amendments in agricultural settings and for reclamation of damaged land [2] (NEBRA 2011). However, only 55% of wastewater solids produced in the United States are treated and beneficially reused, with the remaining portion either landfilled or incinerated [2]. These missed opportunities to take advantage of biosolids as a useful co-product from WRRFs arise in part because certain standards for pathogen reduction and solids stabilization must be met to produce the “Class A” biosolids that are allowed to be land-applied, as regulated by Title 40 Part 503 of the Code of Federal Regulations (CFR) [3]. Currently, the technologies available for producing Class A biosolids, including the “Processes to further reduce pathogens” (PFRPs), are generally high-tech, can be expensive to operate, and are typically energy-intensive. As a result, small WRRFs are more likely to landfill biosolids, because they do not have the resources to implement these technologies and set up a beneficial reuse program [4].

Low-cost, low-tech (LCLT) pathways for Class A biosolids production that meet regulatory guidelines exist and have been implemented successfully at individual WRRFs [5]. Broader application of such LCLT alternatives would potentially allow more communities to beneficially reuse their wastewater resources. However, for small WRRFs, the decision as to whether or not to upgrade from Class B to Class A biosolids production and what technology to implement (e.g., conventional versus LCLT) is not trivial. In addition to the technical aspects of the processes, WRRF managers and local community leadership (e.g., the WRRF’s Board of Directors, or the Town Council, etc.) need to answer questions related to environmental, economic, and social factors: What are the impacts on my surrounding environment? What are the immediate and long-term costs of this decision? What will my community think about this new operation?

This approach to considering multiple aspects of a potential decision is a relatively recent concept with many different names, but the general idea of multi-criteria decision analysis with a view towards sustainability concerns is increasingly being utilized to make informed decisions about infrastructure-related issues. A multidimensional assessment accounts for multiple dimensions to assess all relevant issues arising from a particular decision and include all stakeholder values into the decision-making process, which results in a more holistic approach to decision-making (e.g., [6]. Several rating systems have emerged in the construction sector for buildings [7], including those focused on Total Quality Assessment (TQA) which include environmental, social, and economic criteria, although they are typically most strongly weighted towards environmental criteria. One exception to this is the German DNGB certification system, which includes several metrics related to sociocultural and functional quality [8].Sal and Garcia [9] used a multidimensional sustainability assessment to characterize different agricultural systems in terms of the effects the required land-use patterns and outcomes would have on cultural, social, economic, productive, and environmental dimensions. In a related context, the implications of utilizing agricultural animal manures and other organic residues as a fertilizer and utility replacement via decentralized anaerobic digestion have been studied using a multidimensional assessment approach [10].

A recent study defined a set of metrics that should be used when making decisions about technologies at WRRFs, by assessing the environmental, economic, technical, and social performance of new wastewater treatment technologies so as to best meet the needs of multiple stakeholders [11]. In addition, multidimensional sustainability assessment has been applied to the wastewater industry in prior studies (e.g., [12] and references therein), but these studies have typically focused on the wastewater treatment train and not on the treatment and management of solids produced during wastewater treatment. For example, Plakas et al. [13] used a multi-criteria analysis to assess different technologies for tertiary treatment of wastewater across environmental, economic, and social criteria.

Many of these studies share similar features, even if their specific choices of relevant indicators across all sustainability dimensions are different, or their execution of the study objectives differs. Environmental attributes are typically assessed through some form of environmental life-cycle assessment (LCA), which is a standardized method of tracking material and energy inputs to a project life cycle and assigning environmental impacts to the full life-cycle inventory of the product or process under study [14]. Economic attributes are typically assessed through a return on investment approach, or a side-by-side comparison of total life-cycle costs, when all costs are expressed as a net present value. Social criteria are typically more qualitative and assessed through stakeholder interviews, expert opinion, or other social science research methods.

The overall goal of the current study was to quantify and compare the environmental, economic, and social impacts of selected conventional and LCLT processes for producing Class A biosolids, through a transparent and flexible multidimensional assessment approach. This will allow for a more informed comparison of the potential benefits and drawbacks of competing technologies that municipal leaders may choose from. Specifically, this study compared five processes that can be used to produce Class A biosolids, including three conventional processes—Composting, Direct Heat Drying, and Temperature-Phased Anaerobic Digestion (TPAD)—and two LCLT processes—Air Drying, and long-term Lagoon Storage followed by Air Drying (hereafter referred to as Lagoon Storage), which are described in more detail in subsequent sections. These processes were selected because they are representative of commonly used processes based on the 2007 National Biosolids Regulation, Quality, End Use & Disposal Survey conducted by the North East Biosolids & Residuals Association (NEBRA) [15] or, in the case of TPAD, because there is potential to improve production of methane and destroy volatile solids relative to conventional mesophilic anaerobic digestion [16]. This study fills a gap in the literature to address the lack of research on LCLT processes in a holistic manner.

To perform this multi-criteria assessment, the following approach was taken: (1) environmental impacts associated with the five processes were incorporated based on the results of a companion study [17]; (2) economic impacts were assessed in net present value terms using the same process descriptions and assumptions as used for the environmental impacts, with added information about labor, utility, materials, and capital costs; and (3) social impact considerations were assessed for each process by reviewing case studies, news articles, surveys, and other sources of information. The results of this evaluation provide insight into the sustainability of each process, which in turn can be used to provide guidance for WRRFs in their decision-making process for choosing a technology to produce Class A biosolids. This publication builds on the research results presented in Brown et al. [17] by considering the same suite of technologies modeled on the same scale and expanding on the assessment to include a multi-criteria sustainability assessment. This multi-criteria assessment strategy can be used to address the primary research question, which is how communities faced with this issue can evaluate their decision in a more holistic manner.

2. Study Methods

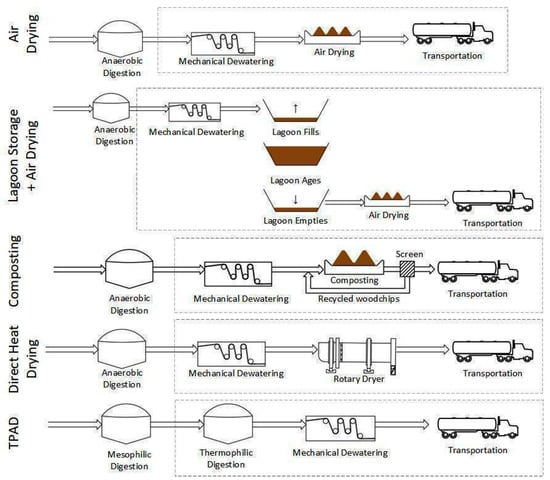

The following subsections provide a brief description of the five processes under consideration for producing Class A biosolids (Figure 1), and how each process was analyzed to determine impacts across environmental, economic, and social dimensions.

Figure 1.

System boundaries for each treatment process under study. Dashed lines represent system boundaries [17].

2.1. Description of Class A Biosolids Processes

More detailed process descriptions for each of the five processes under consideration are provided in [17], the companion manuscript to this study, which also includes a list of material and utility inputs and outputs for each process. As illustrated in Figure 1, the system boundary for each process is assumed to begin after anaerobic digestion of settled solids. Anaerobically digested solids are input into the Class A biosolids process, which ends with the transportation of Class A biosolids to a location where they will be land-applied. The scale of operations in this study and the companion work [17] is consistent. Each biosolids treatment train is designed to produce 200 dry tons of Class A biosolids per year, representative of small WRRFs in the U.S. [15], for a lifetime of 25 years. Decommissioning or repurposing of the technologies at end of life has not been included in the analysis, but these costs are expected to be minimal relative to installation or operational costs.

2.1.1. Air Drying

Air Drying (Figure 1) begins with a belt filter press unit operation, which increases the solids content of the biosolids to 22% total solids. The belt filter requires the addition of a water-soluble polymer to increase the efficiency of mechanical dewatering by flocculating suspended solids and colloidal material [18], as well as electrical power [19]. Air drying produces a liquid waste stream that is returned to the WRRF for treatment. Diesel fuel is needed to transport the biosolids from the belt filter press to the air drying pad in a dump truck, form windrows with a front-end loader, and mix the windrows each week [20]. The impervious surface used for air drying is assumed to be an asphalt mixture of 10% bitumen and 90% gravel and have a lifetime of 25 years.

2.1.2. Lagoon Storage

With Lagoon Storage (Figure 1), mechanical dewatering with a belt filter press occurs first, which includes similar inputs and outputs as the Air Drying scenario, with minor adjustments to account for differences in the amount of incoming material needed to produce 200 dry tons of biosolids per year. The biosolids (22% total solids content) are then transported 2000 feet by a diesel-powered dump truck, where a front-end loader distributes the biosolids in the lagoon. The lagoons are assumed to be constructed using clay and a 40 mil HDPE liner, and four lagoons are required for the facility to be in continuous operation over multiple years. At any given time, one lagoon is filling while the other lagoons are in storage or removal phases of the process. After two years of storage in a lagoon, the biosolids are removed by a front-end loader and transported 500 feet to a drying pad, similar to the Air Drying scenario. Once at the pad, the biosolids are formed into small windrows and mixed periodically for ten weeks. Assuming all Class A standards are met, the biosolids are then transported to their final destination.

2.1.3. Composting

The Composting process (Figure 1) also begins with mechanical dewatering using a belt filter press. The inputs and outputs of mechanical dewatering are similar to the other processes. Biosolids are then transported via dump trucks to the Composting pad, where carbon (sawdust) and structural amendments (woodchips) are added to increase the C/N ratio to 30:1 on a mass basis and to increase the porosity of the windrows, respectively. The Composting asphalt pad is assumed to be constructed using the same mixture as that of the impervious surface of the Air Drying pad, but a smaller quantity is required because the Composting windrows are twice as high as the Air Drying windrows. After the compost is turned three times a week by a mechanical turner for 21 days, it is cured in place for 30 days. Compost is then processed using an electric trommel screen, which separates roughly 30% of the woodchips for reuse. The finished compost is transported to the final destination.

2.1.4. Direct Heat Drying

The Direct Heat Drying process (Figure 1) begins with a belt filter press for which the inputs and outputs are similar to those in the processes above. Dewatered biosolids are transferred to a natural gas-powered rotary dryer. A total of 3.24 to 3.95 MJ is required per kg of water evaporated in the dryer [21]. The final biosolids end product is 95% solids. Higher solids concentrations result in lower biosolids densities and, thus, decrease the transport requirements relative to wetter biosolids. It was assumed that no destruction of volatile solids occurred in the rotary dryer, because these systems are typically operated at temperatures which are suitable to evaporate water, but not so high as to cause combustion of organics [21].

2.1.5. Temperature-Phased Anaerobic Digestion (TPAD)

TPAD is a multistage process (Figure 1) that can be arranged with mesophilic digestion followed by thermophilic digestion (MT), or thermophilic digestion followed by mesophilic digestion (TM) [22]. In the current study, the MT configuration was assumed, and the TPAD system boundary does not include the mesophilic digestion process, because mesophilic digestion occurs immediately before the system boundary in the other process scenarios. Following thermophilic digestion, the biosolids undergo mechanical dewatering as in the other processes. The biosolids produced contain 22% solids, which is relatively low compared to the other processes in the study. The low percentage of solids means there is more water to transport. Other inputs to the TPAD process include electricity, which is necessary for pumping and mixing the thermophilic digester, and some supplemental heat, which is required to heat the digester to the thermophilic temperature range.

2.2. Environmental Impacts

The environmental impacts of each Class A biosolids processing technology were assessed by conducting a life-cycle assessment study on each process, as described in the companion manuscript [17]. Briefly, an inventory of material and energy inputs was developed for each of the processes, along with key outputs of solid, liquid, or gaseous emissions. These life-cycle input data were used to create a life-cycle inventory database using data available within the ecoinvent database [23] and other relevant databases. Several scenarios were developed to estimate the impacts of key process variables with uncertain input data, including final solids transportation distance and biogenic greenhouse gas (GHG) emission rates. SimaPro LCA modeling software (PRé Consultants, version 9.3) was used, along with a modified version of the IMPACT 2002+ environmental impact method, to develop an estimate of the overall environmental impact for each process, with subcategories of Human Health, Ecosystem Quality, Climate Change, and Resource Use all contributing to the overall environmental impact score.

2.3. Economic Impacts

The economic impacts of each process were quantified by a cost analysis that includes the associated capital costs and operational and maintenance (O&M) costs. Inflation adjustments were made for data that came from older references by using the U.S. Bureau of Labor Statistics Consumer Price Index measure of inflation to estimate cost increases between the relevant years.

O&M costs are a combination of the labor, materials, fuel, and utilities needed to run each process. Materials and energy inputs came from the same process analysis that is described in detail in [17].. Labor estimates are conservative and are presented, along with sources of the estimated amounts and the costs of various tasks associated with these processes, in Table 1, Table 2, Table 3, Table 4, Table 5, Table 6 and Table 7. Utility estimates will vary from place to place and over time, but the data used in the economic modeling are representative of values in most of the United States. O&M costs occurring throughout the 25-year time horizon of the study were all placed in terms of Net Present Value by using a real discount rate (excluding impact of inflation) of 3.5%, as is commonly used in government-supported water infrastructure projects [24]. Because no inflation parameters were applied to costs incurred in the future, a real discount rate is the correct discount rate to use, as opposed to a nominal discount rate which would include the impacts of inflation on future costs. A variety of resources were used to obtain cost estimates for transportation, mechanical dewatering, and construction processes. Fewer data were available for developing labor and fuel use estimates for the LCLT processes, but reasonable approximations based on analogous conventional processes were made. For example, the labor requirements for Air Drying (Table 3) were calculated using the EPA cost estimating handbook for mechanical dewatering [19]. Then, the assumed distance to the air drying pad from the belt filter press and the travel speed of the dump truck were used to calculate the labor hours it took to transfer the biosolids to the air drying unit process. The time spent turning the windrows was calculated by using the number of times the windrows are turned, the rate of the turner, and the length and number of windrows. These calculations and others are explained in more detail in Tables S1-S4 in the Supplementary Materials. Across all scenarios, electricity was assumed to cost USD 0.085/kWh [25], diesel fuel was assumed to cost USD 3.55/gal [26], and natural gas was assumed to cost USD 10.00/1000 ft3 [27]. These prices are variable across the United States and fluctuate throughout the year, especially for diesel fuel and natural gas. So caution is warranted when applying these exact figures to any specific case. The assumed values are U.S. averages and are appropriate for illustrating our approach to an economic assessment and ultimately a more comprehensive sustainability assessment of these processes. Transportation of the final biosolids product is assumed to be 50 miles one way, using a truck that has a payload of 25 cubic yards and a fuel economy of 6 miles per gallon (Table 2).

Capital cost items vary for each process (Table 1, Table 3, Table 4, Table 5, Table 6 and Table 7), but, in general, they included installation of any drying pads, storage lagoons, or major equipment like the natural gas-powered dryer in the Direct Heat Drying scenario. It was assumed that the WRRF would already have trucks for moving biosolids, and front-end loaders for on-site moving, so the purchase of those items was not considered. Windrow turners for Air Drying (Table 3) and Composting (Table 4) were included in capital cost purchases. The capital cost of the windrow turner was taken from a commercial vendor [28]. It was also assumed that the Composting and Air Drying processes are not performed under a cover or building, nor do they have an odor control system. The Air Drying, Composting, and Lagoon Storage (Table 5) capital costs include the materials and construction of the impervious pads, which encompasses site clearing, paving, gravel, asphalt, and grading. Lagoon storage also included the construction and materials for the lagoons which included site clearing, liner installation, site grading, compaction, clay, HDPE liner, gravel, and asphalt. TPAD systems can be purchased new or can be made by retrofitting existing digesters, but for this study, it was assumed that a new TPAD system was purchased (Table 6). Capital costs for the belt filter press (Table 1), TPAD system (Table 6), and rotary dryer for Direct Heat Drying (Table 7) were estimated using the EPA’s fact sheets [19,29] and adjusted for inflation. None of the capital cost items had an assumed lifetime of less than 25 years in this study, so no replacement equipment was purchased in later years of this cost analysis. All capital costs were assumed to occur in Year 0 of the project life cycle in each scenario, so no discounting to express costs in present value terms was necessary.

Table 1.

Belt filter press input data and assumptions for economic assessment.

Table 1.

Belt filter press input data and assumptions for economic assessment.

| Cost Category | Item | Number | Unit | Source/Comments |

|---|---|---|---|---|

| Operation and maintenance costs | Total | 29,812 | USD/yr | |

| Labor subtotal | 23,012 | USD/yr | ||

| Belt filter width | 1.0 | m | ||

| Operational days per year | 104 | days/year | ||

| Cost of operational and maintenance labor | 26.39 | USD/h | [30] | |

| Annual O&M labor required | 872 | h/yr | ||

| Electrical energy subtotal | 2571 | USD/yr | ||

| Annual electricity energy required | 30,246 | kWh/year | [31] | |

| Parts and materials subtotal | 4230 | USD/yr | [31] | |

| Capital costs | Total | 173,650 | USD | [31] |

Table 2.

Trucking inputs and assumptions for economic assessment—Air Drying Data shown as example.

Table 2.

Trucking inputs and assumptions for economic assessment—Air Drying Data shown as example.

| Item | Number | Unit | Source/Comments |

|---|---|---|---|

| Distance | 161 | km | Round trip distance |

| Loads | 30 | Loads/year | Payload assumed to be 25 yd3 |

| Total driver time | 96.1 | h/yr | 1.2 h of loading/unloading time, 2.9 h of driving time per round trip |

| Fuel consumption | 1493.8 | L/yr | 6 miles per gallon estimate for WRRF heavy trucks |

| Labor cost | 26.12 | USD/h | [32] |

| Truck maintenance cost | 3045 | USD/yr | 1.29 USD/mile for heavy trucking, after inflation adjustment |

| Annual labor cost | 3011 | USD/yr | |

| Annual fuel cost | 1401 | USD/yr | |

| Total trucking costs | 7458 | USD/yr |

Table 3.

Air Drying input data and assumptions for economic assessment.

Table 3.

Air Drying input data and assumptions for economic assessment.

| Cost Category | Item | Number | Unit | Source/Comments |

|---|---|---|---|---|

| Operation and maintenance costs | Total | 4796 | USD/yr | |

| Labor subtotal | 4112 | USD/yr | ||

| Annual operation labor required | 156 | h/yr | 1 turn per month assumed, 1 week maintenance per year assumed | |

| Cost of operational and maintenance labor | 26.39 | USD/h | [30] | |

| Cost of diesel fuel subtotal | 685 | USD/yr | ||

| Quantity of fuel | 730 | L/yr | Dump truck and front-end loader operation | |

| Capital costs | Total | 281,480 | USD | |

| Site clearing and grading | 11,413 | USD | [33] | |

| Paving | 233,250 | USD | [33] | |

| Windrow turner | 37,500 | USD | [28] |

Table 4.

Composting input data and assumptions for economic assessment.

Table 4.

Composting input data and assumptions for economic assessment.

| Cost Category | Item | Number | Unit | Source/Comments |

|---|---|---|---|---|

| Operation and maintenance costs | Total | 77,333 | USD/yr | |

| Labor subtotal | 12,139 | USD/yr | ||

| Annual operation labor required | 460 | h/yr | Windrows turned 3 times per week for 9 weeks per year. One week per cycle is allotted to place biosolids, sawdust, and woodchips in windrow, and one week per year is allotted for maintenance | |

| Cost of operational and maintenance labor | 26.39 | USD/h | [30] | |

| Cost of amendments subtotal | 63,416 | USD/yr | ||

| Quantity of sawdust | 146 | dry ton/yr | ||

| Price of sawdust | 65.52 | USD/dry ton | [34] | |

| Quantity of woodchips | 1648 | m3 | ||

| Price of woodchips | 32.68 | USD/m3 | [35] | |

| Cost of diesel fuel subtotal | 1679 | USD/yr | ||

| Quantity of fuel | 1790 | L/yr | More frequent turning compared to Air Drying | |

| Cost of electricity subtotal | 99 | USD/yr | ||

| Quantity of electricity | 1169 | kWh/yr | ||

| Capital costs | Total | 299,352 | USD | |

| Site clearing and grading | 11,045 | USD | [33] | |

| Paving | 250,807 | USD | [33] | |

| Windrow turner | 37,500 | USD | [28] |

Table 5.

Lagoon Storage input data and assumptions for economic assessment.

Table 5.

Lagoon Storage input data and assumptions for economic assessment.

| Cost Category | Item | Number | Unit | Source/Comments |

|---|---|---|---|---|

| Operation and maintenance costs | Total | 7457 | USD/yr | |

| Labor subtotal | 6860 | USD/yr | ||

| Annual operation and maintenance labor required | 260 | h/yr | 1 week of maintenance per yr assumed | |

| Cost of operational and maintenance labor | 26.39 | USD/h | [30] | |

| Cost of diesel fuel subtotal | 597 | USD/yr | ||

| Quantity of fuel | 636 | L/yr | ||

| Capital costs | Total | 737,236 | USD | |

| Construction | ||||

| Site clearing and grading | 39,270 | USD | [33] | |

| Liner installation (excavation) | 58,680 | USD | [36] | |

| Compaction | 11,910 | USD | [36] | |

| Paving | 351,130 | USD | [33] | |

| Materials | ||||

| Clay | 32,976 | USD | [37] | |

| Liner | 205,769 | USD | [24] | |

| Equipment | ||||

| Windrow turner | 37,500 | USD | [28] |

Table 6.

TPAD input data and assumptions for economic assessment.

Table 6.

TPAD input data and assumptions for economic assessment.

| Cost Category | Item | Number | Unit | Source/Comments |

|---|---|---|---|---|

| Operation and maintenance costs | Total | 13,820 | USD/yr | |

| Labor subtotal | 5278 | USD/yr | ||

| Cost of operational and maintenance labor | 26.39 | USD/h | [30] | |

| Annual operation and maintenance labor required | 200 | h/yr | ||

| Natural gas cost subtotal | 7063 | USD/yr | ||

| Annual natural gas required | 100 | m3/dry ton biosolids | [38] | |

| Electricity cost subtotal | 1479 | USD/yr | ||

| Electricity needed | 17,400 | kWh/yr | [39] | |

| Capital costs | Total | 16,300,000 | USD | Scaled based on reference case in [29] |

Table 7.

Direct Heat Drying input data and assumptions for economic assessment.

Table 7.

Direct Heat Drying input data and assumptions for economic assessment.

| Cost Category | Item | Number | Unit | Source/Comments |

|---|---|---|---|---|

| Operation and maintenance costs | Total | 76,153 | USD/yr | |

| Labor subtotal | 54,257 | USD/yr | ||

| Operational days per year | 252 | days/year | ||

| Cost of operational and maintenance labor | 26.39 | USD/h | [30] | |

| Annual operation and maintenance labor required | 2056 | h/yr | ||

| Natural gas subtotal | 21,895 | USD/yr | ||

| Annual natural gas energy required | 310 | m3/dry ton biosolids | [21] | |

| Capital costs | Total | 17,365,000 | USD | Scaled based on reference case in [21] |

2.4. Social Impacts

The social impacts of biosolids treatment processes are the most difficult to quantify, because the associated data are often qualitative and can vary from community to community based on geography, climate, or local norms. For this study, case studies, news articles, surveys, and online blogs were reviewed to determine the positive and negative social impacts of the biosolids processes, and a set of social impacts criteria were developed from reviewing the prior literature related to common community concerns. The U.S.-based case studies included the use of biosolids in Houghton, MI; Milwaukee, WI; Loudoun County, VA; and Seattle, WA. The survey used in this research was from two cities in southeastern United States and included questions assessing respondents’ general knowledge of biosolids and their attitudes towards biosolids end use [40]. The survey found that 50% of the 311 residents could not correctly answer a true-or-false type of question designed to test their basic biosolids knowledge. Specifically, more than half of the individuals who were surveyed answered “false” in response to the following question: “The EPA currently regulates the levels of disease-causing bacteria in biosolids” [40]. Through their answers, the residents of these cities also indicated that biosolids should not be applied to gardens, yards, public areas, food crops, and pastures. The majority of the individuals who were surveyed think that the risk to public health and the environment outweighs the benefits of land-applied biosolids. Another key outcome of the survey was the finding that the residents believe they are not adequately informed about biosolids and are not satisfied with the decision-making process [40]. Thus, getting the public to understand and accept biosolids land application may be key to the success of a biosolids reuse program. Odor is the one of the biggest sources of complaints associated with the land application of biosolids and was a public acceptance issue identified in 5 out of the 14 biosolids recycling case studies reviewed by [41]. Others include truck traffic/transportation, the physical appearance of the WRRF facility, and dust. In addition, members of the general public often are concerned about trace metals, other chemicals, and pathogens in the biosolids and their potential impact on air, water, soil, and food quality. Therefore, aesthetics and concern for human health and the environment represent the majority of the social impacts that were assessed in prior work [1,15,40].

All Class A biosolids were assumed to have a potential positive social impact through their beneficial reuse. Accordingly, based on the resources above, the social impacts that were used in scoring the biosolids production systems were the potential negative social impacts of odor, noise, number of trucks, appearances, and dust. The impacts were assessed by giving each process a score between 0 (no negative social impacts) and 3 (greatest negative social impact). The most offensive odors associated with biosolids are a product of inorganic and organic forms of sulfur and nitrogen including mercaptans, ammonia, amines, and organic fatty acids, and are released when biosolids are heated, aerated, and digested [42]. Therefore, processes that could allow these odor-generating chemicals to develop were given a higher impact score for odor. Noise was assumed to primarily result from on-site equipment operation. Hence, processes that involve windrow turning and lots of movement of the biosolids on site were given higher impact scores for noise. Truck traffic can have a number of impacts, including highway safety and road damage, which can result in a cost for community infrastructure [41]. As a surrogate for the volume of truck traffic, the impact rating was based on the volume of the final biosolids. A clean, orderly, and pleasing appearance is one strategy that has been used to gain public acceptance of biosolids recycling programs [41]. The appearances of all systems were rated based on land use and likely visibility to the public. Dust can be produced when biosolids with a high percentage of total solids are stirred, moved, or mixed. Processes that move biosolids with a higher percentage of total solids were assumed to create more dust concerns. Concern for human and environmental health was not included in this assessment, because the concern is not associated with the specific processes; rather, it is with biosolids in general. It is important to note that while this study attempted to assign a social impact score to represent the likely perception of each process, each community is unique and may respond differently to perceived impacts in any of these categories.

3. Results and Discussion

3.1. Environmental Impacts

The overall environmental impacts of each biosolids production process from the companion LCA study [17] are reported as single scores, each of which is the sum of the scores in the four damage categories: resource use, climate change, ecosystem quality, and human health. The companion paper details the specific results for each of the five processes, as well as sensitivity analyses illustrating the impact of different transport distances and emissions production from the biosolids on the scores. Composting had the highest overall score, meaning it would have the largest environmental impacts when considering all damage categories, followed by Direct Heat Drying, Lagoon Storage, Air Drying, and TPAD. The environmental impacts were normalized on a scale of 0 to 10, in which the highest environmental impact score (Composting, 71.1 pt) was given a score of 10.0, and the environmental impact scores for the other processes were normalized accordingly, as summarized in Table 8.

Table 8.

Environmental impacts of biosolids treatment processes.

Out of the four damage categories, climate change was the largest contributor in every process except Direct Heat Drying, for which resource use contributed the most. Biogenic emissions were large contributors to the environmental impacts resulting from Composting, Air Drying, and Lagoon Storage. In addition, the sensitivity analyses demonstrated that transportation impacts cannot be ignored, especially when the biosolids are not locally land-applied. The impacts of transportation are particularly important to consider when the end product has a low percentage of solids or has amendments such as woodchips added to it. These LCA results could vary somewhat depending on region-specific factors such as the generation mix in the electricity grid, but the overall relative results are not likely to change as electricity typically plays a minor role in the total environmental impact score.

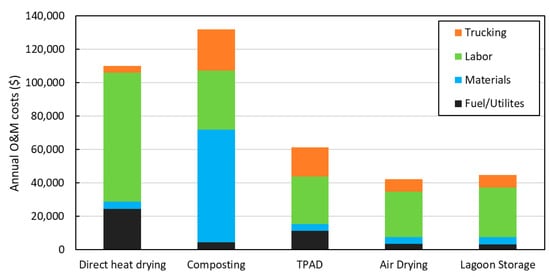

3.2. Economic Impacts

The capital costs of each Class A biosolids treatment process were calculated for the same operating conditions, as summarized in Table 9. As expected, the two LCLT processes, Lagoon Storage and Air Drying, had very low capital costs (USD 932 K and USD 494 K, respectively) relative to the conventional technologies TPAD and Direct Heat Drying, which had total capital costs of USD 16.5 and USD 17.6 million, respectively (Table 9). This is reasonable because, other than a windrow turner, no mechanized equipment has to be purchased for Lagoon Storage or Air Drying. The higher capital cost of Lagoon Storage reflects the need for construction of four lagoons, including the purchase and installation of a six-inch clay liner layer plus a 40 mil. HDPE liner, an air drying pad, and a windrow turner. Air Drying capital costs are limited to the construction of an asphalt pad and the purchase of a windrow turner. In contrast to the LCLT treatment processes, tanks or reaction vessels, heat sources, mixers, and controls are required for both TPAD and Direct Heat Drying, which drive up the capital costs associated with these processes. In particular, the capital cost of a new rotary dryer is millions of dollars. In some cases, it may be possible for WRRFs to retrofit existing tanks for use in TPAD, which could decrease the capital costs. For example, a California WRRF was able to retrofit an existing digester for USD 2.5 million [29], whereas all new construction of the same TPAD system would have likely cost USD 16.5 million. Compared to TPAD and Direct Heat Drying, the conventional technology of Composting had a low capital cost (USD 494 K), which is on the same order as for air drying, because it was assumed that it would be accomplished using the windrow technique. Windrow composting is a simple, less highly controlled technology compared to in-vessel composting. In-vessel composting requires USD 30,000 to USD 75,000 per dry ton in capital costs due to the need to purchase reaction vessels, controls, and other equipment [43]. Although in-vessel requires more upfront costs, windrow composting requires more O&M costs for labor, fuel, and materials. Over the 25-year operational lifetime of the study, the treatment costs per ton of biosolids were lowest for Airy Drying, Lagoon Storage, and Composting (USD 234/ton, USD 334/ton, and USD 534/ton, respectively) and highest for TPAD (USD 3501/ton) and Direct Heat Drying (USD 3875/ton).

Table 9.

Economic assessment results for Class A biosolids processes.

Similarly, the annual O&M costs of each Class A biosolids treatment process were calculated for the same operating conditions, and the NPV of the lifetime O&M costs was determined over a 25-year operating life using a real discount rate of 3.5%, as noted above (Table 9). The total annual O&M costs are of a relatively similar order of magnitude for conventional and LCLT processes (Table 9), with some notable differences in the sources of those costs (Figure 2). For example, Direct Heat Drying has much higher labor and fuel costs, because it was assumed that the smallest feasible unit would be purchased for the facility in an effort to minimize capital costs, which resulted in more operating days per year. Composting was unique because a majority of the O&M costs are due to purchased material amendments for the composting process. It is possible that a municipality may be able to satisfy some of these material requirements internally through use of tree trimmings or other materials that the municipality is generating as waste or low-value products. However, the availability of waste-derived composting feedstocks is variable and would incur additional labor costs associated with increased material handling. The costs required for transportation of the biosolids produced via Composting and TPAD are higher relative to the other processes, because the mass and volume of biosolids produced are larger than for the other technologies, due to the added amendments and a higher moisture content of the finished product. In comparison, the O&M costs associated with transportation of heat-dried biosolids are low because the final product contains 95% total solids, and, thus, relatively little material must be transported. TPAD requires electricity to power mixers and pumps, but in this study, it was determined that the biogas produced via the TPAD process is sufficient to heat both digester phases. If the biogas is used for something else, like power generation and export, the O&M costs will be significantly higher than illustrated here.

Figure 2.

Breakdown of major items contributing to annual O&M costs for each technology.

The total economic impacts of each process were compiled in two ways. In the first approach, the total economic impacts were equally distributed between capital costs and lifetime O&M costs (hereafter referred to as the equal cost distribution approach). To accomplish this, the capital and O&M costs were each normalized on separate scales ranging from 0 to 5, in which the highest-cost process was assigned a score of 5.0 and the other processes were scaled accordingly (Table 9). The normalized scores for Capital costs and O&M costs on the 0 to 5 scale were then summed (maximum possible score = 10) to calculate the total economic impact. By normalizing the O&M and capital costs in this way, differences in the O&M costs, while orders of magnitude smaller than the capital costs, are more strongly reflected in the total economic impacts.

In the second approach to ranking the economic impacts of the biosolids treatment processes, the NPV of the total lifetime Capital and O&M costs was determined, without separating the two categories of costs. Then, the normalization (on a scale of 10) was performed using the total NPV for each process (Table 9). Using this approach, hereafter referred to as the weighted cost distribution approach, capital costs have a greater impact than O&M costs on the NPV.

When considering which economic impact ranking method is most appropriate for a given project, it is important to consider what funding model will be used. For example, projects funded through public–private partnerships (P3) have more access to capital compared to those relying on public funding and may place a higher priority on minimizing O&M costs. This is particularly true if the P3 includes a phase in which the facility will be operated by the private partner, which will seek to maximize profits [44]. In this case, the equal cost distribution approach may be most relevant. Likewise, projects that can take advantage of state grants or revolving funds to offset one-time capital investments may find the equal cost distribution approach most appropriate. In contrast, projects that must rely on public funding may be most concerned with the impact of capital costs on the NPV and thus may find the weighted cost distribution approach most appropriate for ranking economic impacts.

Using the equal cost distribution method, Direct Heat Drying has the highest economic impact, followed by TPAD and Composting. The normalized economic impact scores obtained using this ranking method were similar and low for the LCLT processes. Using the weighted cost distribution ranking method, Direct Heat Drying had the greatest economic impact followed by TPAD. Composting had a much lower normalized score using the weighted cost distribution alternative approach because the high O&M costs for Composting were outweighed by the high capital costs associated with TPAD and Direct Heat Drying.

3.3. Social Impacts

Although every community is unique and has its own attitudes towards biosolids, an attempt to rank the biosolids treatment processes based on their social impacts was performed, with a focus on odor, noise, number of trucks, appearances, and dust (Table 10). It is important to note that this ranking should be used as a general approximation regarding the potential social impacts of biosolids land application programs and an illustration of how this might be performed in a specific community situation, because the scores may not reflect the values or concerns that prevail in a given community.

Table 10.

Social impact scores a for biosolids processes.

The odor category was difficult to score. The most common and most unpleasant odor associated with biosolids comes from reduced sulfur compounds [45], but specific processes have particular odors associated with them. Composted biosolids can produce odors caused by ammonia, amines, sulfur-based compounds, fatty acids, and aromatics [42]. Air-dried biosolids can produce odors caused by small amounts of hydrogen sulfide, mercaptans, and dimethyl sulfide [46](Farrell et al., 2004). Anaerobic digestion produces odors due to the production of hydrogen sulfide and other sulfur-based gases [42]. For these reasons, one point was assigned to Composting, Air Drying, Lagoon Storage, and TPAD in the odor category (Table 10). Because so little material degradation is assumed to occur in the Direct Heat Drying process, the process was given a score of 0 in this category. It is possible that additional odor control technologies can be included in the operation of these systems (e.g., microbial inoculation or biotrickling filters, [47], but as this is not currently common practice at small-scale facilities, we opted to omit these additional operations from our assessment.

Processes were scored in the noise category based on the amount of time mechanical equipment, such as front-end loaders or windrow turners, is used on site. Composting and Air Drying both require more movement and mixing of the biosolids, which is reflected in their higher “noise” scores (Table 10). The final volume of biosolids product determined the number of trucks needed to transport the biosolids to the final destination. The more trucks a process required for biosolids transportation, the higher the score in the “truck traffic” category. As a result, Direct Heat Drying was given the lowest “Trucks” score. The WRRF appearance was scored based on the size of any outdoor biosolids operation. One point was assigned in the “dust” category if a treatment process generated a final biosolids product with a very high total solids and/or biosolids were mixed in windrows.

The individual category scores were summed to give a total Social Impact score for each process. Then, as with the environmental and economic impacts, the social impact scores for each process were normalized on a scale from 0 to 10, with the highest score (Composting) being set to 10, and the other scores for other processes scaled accordingly. Overall, Direct Heat Drying and TPAD have fewer social impacts because they are more contained, engineered technologies with a lower likelihood of producing externalities, like noise or odors, which would be noticed by the public. In contrast, Air Drying, Lagoon Storage, and Composting are performed outdoors, are less controlled, and require more space, and therefore could be more prone to social impacts if the siting and process management are not carefully considered. These are important topics to include in the planning process for any biosolids management systems, because social factors and public perception may be just as likely to hamper acceptance of a biosolids recycling program as other factors [41].

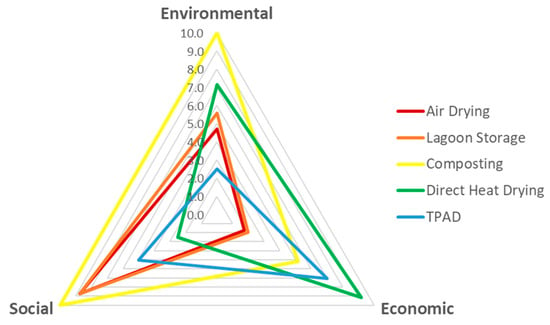

3.4. Overall Comparisons

To combine and compare the environmental, economic, and social impacts of the biosolids processes, each category’s score was normalized on a scale of 0 to 10, as described above, and equally weighted by summing the scores for each of the categories to obtain an overall score for each process, as summarized in Table 11. In this study’s framework, the lowest overall score is considered to be the best, when considering the environmental, economic, and social aspects. It is important to note that it is possible that the three categories of impacts will not be assigned equal weight in the ultimate decision-making process undertaken by a community. Instead, the priority given to each category will be dependent on the particular community’s experience and objectives, with the weight assigned as appropriate, as discussed further below.

Table 11.

Overall environmental, economic and social impact scores.

Using the equal weighting approach for environmental, economic, and social impacts, TPAD and Air Drying scored the best overall with scores of approximately 15 (Table 11). Lagoon Storage ranked third (16.3 points) followed by Direct Heat Drying (18.8 points). Composting had the highest overall score (25.1 points) due to its high environmental and social impacts, as well as its high O&M costs. Figure 3 is a three-axis spider diagram that graphically depicts the scores summarized in Table 11, similar to the approach taken by Plakas et al. [13]. In Figure 3, the smallest triangle represents the process with the best overall combination of the three impact categories. It is notable that the Air Drying and Lagoon Storage triangles are very similar, but the impacts of Air Drying are always equal or slightly lower than those of Lagoon Storage in all impact categories. TPAD scores well in two of the three categories. Direct Heat Drying does not seem particularly favorable based on the scores in Table 11, but Figure 3 highlights that it has relatively low potential for negative social impacts, which is explored in the weighting analysis described below.

Figure 3.

Three-axis spider diagram of all processes according to their normalized score across environmental, economic, and social domains, using the base case economic approach.

If the alternative economic approach is used in the economic analyses, where the capital and lifetime O&M costs are not separated before normalizing, the outcome of the analysis changes somewhat (Table 11). Using this approach, Air Drying is the most favorable process, followed by Lagoon Storage and TPAD, because the two LCLT processes greatly benefit from having low capital costs in this alternative framework. The large O&M costs associated with Composting are not as important in this alternative approach as well, so although Composting is still the worst-performing process, its overall score is more similar to the scores of the other processes.

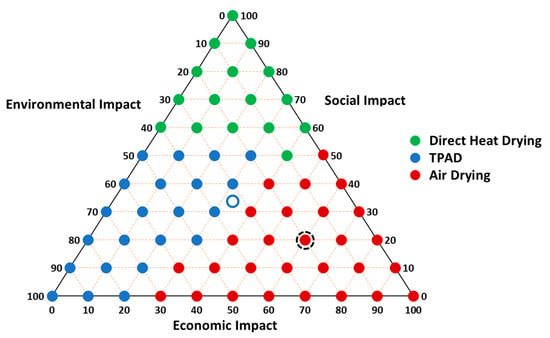

In the assessments above, it was assumed that each of the three categories—environmental, economic, and social impacts—was weighted equally. To illustrate the potential impacts of different weighting preferences that a municipality or a community might have in regard to these sustainability considerations surrounding biosolids production, a three-axis mixing diagram was constructed to show how the preferred technology might change as the weightings of the environmental, economic, and social categories are varied (Figure 4). Each point on the diagram represents a different set of percentages that always sum to 100%. In the base case, with equal weightings of all three categories, the weighting would be 33.3% along each axis, and, as described above, TPAD is slightly preferred over Air Drying (blue open marker in the middle of the mixing triangle in Figure 4). In contrast, a community that is strongly motivated by financial considerations might choose a 20%–60%–20% weighting mix for environmental, economic, and social impacts, respectively. In that case, the best-performing biosolids process would be Air Drying (red marker circled with black dashed line in Figure 4).

Figure 4.

Three-axis mixing diagram indicating the best-performing biosolids process when different weighting factors are used across environmental, economic, and social impact categories. Blue open marker indicates the position of the base case where all domains are equally weighted, black dashed circle indicates the example identified in the text of a 20%–60%–20% weighting of environmental, economic, and social domains where Air Drying is best.

Interestingly, although Lagoon Storage performs well in all categories and is the third-ranked process in our base case results (see Table 11 and Figure 3), in no case does it perform better compared to Air Drying in the impact scores. Therefore, Air Drying is always the preferred option over Lagoon Storage, as indicated by this variable weighting assessment. In fact, a majority of the mixing triangle in Figure 4 is covered by Air Drying, when economic impacts dominate the preferences, or TPAD, when environmental impacts dominate the preferences. Nevertheless, there is also a region of the triangle where Direct Heat Drying is the best-performing system, when social impacts are the dominant part of the preferences. This outcome is not readily obvious from a reading of the overall results in Table 11 because Direct Heat Drying is the second-worst process option in our base case. But because Direct Heat Drying has clear advantages over the other process options in our social impact scores (low odors, low traffic, no visible appearance, etc.), it could become the more preferred option in situations where communities have strong feelings about these impacts, despite the challenges Direct Heat Drying has in the economic and environmental areas. This illustrates the utility of the weighting figure for decision-making, and the dramatic impact local preferences can have on the selection of the best-performing biosolids process for that particular community. In this manner, allowing the weighting of sustainability assessment factors to fluctuate provides a type of sensitivity analysis, to see how strongly individual scores contribute to the overall decision, and how adjusting the relative importance of the individual factors can result in different conclusions being drawn by a given community.

4. Conclusions

A detailed process analysis was used to develop environmental impact and economic impact scores for a series of five processes for producing Class A biosolids. Reviewing the prior literature on the social aspects of biosolids production also allowed us to score and rank the processes in terms of their performance in key social criteria that are often of concern in U.S. communities making decisions regarding biosolids treatment and beneficial reuse. These environmental, economic, and social impact category scores were then combined via a multi-criteria assessment of the processes. The results of this multi-criteria assessment indicate that TPAD, Air Drying, and Lagoon Storage are the three most favorable processes when environmental, economic, and social impacts are considered equally. The two LCLT processes (Air Drying and Lagoon Storage) fared particularly well in their economic performance, with low capital and overhead costs, as well as their environmental performance. They do appear to have the potential to create more social impacts through production of noise, odors, and traffic, so these conditions would have to be managed through careful siting and operations. This multidimensional sustainability assessment indicates that low-cost, low-tech options could be viable options for communities interested in generating Class A biosolids. However, some communities might prefer to weight the environmental, economic, and social impacts differently. To facilitate this, a weighting figure was developed to aid in decision-making and showed that Air Drying is always the preferred option over Lagoon Storage using the variable weighting assessment. With variable weighting, Air Drying becomes the preferred solution when economic impacts dominate the preferences, and TPAD the preferred solution when environmental impacts dominate the preferences. However, when social impacts are the dominant part of the preferences, Direct Heat Drying is the best-performing system because of its low social impact scores including low odors, traffic, and visibility. This highlights the importance of community input in selecting the best choice technology and illustrates the potential for tradeoffs among the sustainability indicators for some of the technologies under study. For instance, Direct Heat Drying has the potential to be the most costly technology but the best-performing in terms of social impacts.

It is possible that changes in the starting anaerobically digested biosolids may have a differential impact on the processes under study here, for example, a higher or lower solids content or organics content, but we do not expect the normal operating ranges of anaerobic digestion systems to produce solids that would be different enough to change our overall results. The TPAD process relies on a mesophilic digester immediately prior to the TPAD operation, and similarly, this operation would be influenced to some degree by changing process conditions inside of the mesophilic reactor. For an actual comparison using this modeling framework, specific biosolids composition should be collected and evaluated for variability over time, to understand how this might affect the proposed downstream operations.

These analyses illustrate the utility of a multi-criteria assessment when selecting the best process for producing Class A biosolids for a given community, and the dramatic impact local preferences can have on the selection of the best-performing biosolids process for that particular community. The approaches developed here can be utilized by WWTPs to guide their own development of specific life-cycle cost, environmental impacts, and social considerations in order to arrive at a choice that best balances these concerns. These results, or the process used to generate the results in a U.S. context, could also be applicable in other small communities around the world where responsible management of WRRF biosolids is an issue of concern.

Future work in this area could be directed in a number of areas. It would be useful to survey communities about WWRF attitudes and preferences in order to more comprehensively address the potential for social impacts from changing operations. Similarly, surveying WRRFs to understand the range of cost factors for infrastructure development and operations would be insightful, along with asking questions of WRRF operators about their views on the opportunities and challenges associated with different Class A biosolids production processes. These are persistent gaps in the literature, which would help improve future studies of this kind. This model could also be used to evaluate a wider range of regional conditions for the technologies under study, to illustrate the potential for variation in the overall impacts and relative ranking of the biosolids technologies.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/resources14080130/s1, Table S1: Trucking Inputs and Assumptions for Economic Assessment—Lagoon Storage Data; Table S2: Trucking Inputs and Assumptions for Economic Assessment—Composting Data; Table S3: Trucking Inputs and Assumptions for Economic Assessment—Direct Heat Drying; Table S4: Trucking Inputs and Assumptions for Economic Assessment—TPAD Data.

Author Contributions

Conceptualization, R.M.H., E.A.S. and J.G.B.; data curation, J.L.B.; formal analysis, J.L.B.; funding acquisition, E.A.S. and J.G.B.; methodology, R.M.H.; supervision, E.A.S. and J.G.B.; writing—original draft, J.L.B.; writing—review and editing, R.M.H., E.A.S. and J.G.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by U.S. EPA Grant Number 00E01979 (EPA Environmental Finance Center for the Great Lakes Region (EPA Region 5)).

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Material. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Correction Statement

This article has been republished with a minor correction to the Data Availability Statement. This change does not affect the scientific content of the article.

References

- Elgarahy, A.M.; Eloffy, M.G.; Priya, A.K.; Yogeshwaran, V.; Yang, Z.; Elwakeel, K.Z.; Lopez-Maldonado, E.A. Biosolids management and utilizations: A review. J. Clean. Prod. 2024, 451, 141974. [Google Scholar] [CrossRef]

- NEBRA. Options for Biosolids Use or Disposal in New England & Eastern Canada, North East Biosolids and Residuals Association. 2011. Available online: https://static1.squarespace.com/static/54806478e4b0dc44e1698e88/t/54a6ede5e4b039f26ff3fcd6/1420226021916/InfoUpdateBsldsOptionsApr11.pdf (accessed on 26 September 2024).

- U.S. Environmental Protection Agency. A Plain English Guide to the EPA Part 503 Biosolids Rule. 1993. Available online: https://www.epa.gov/sites/default/files/2018-12/documents/plain-english-guide-part503-biosolids-rule.pdf (accessed on 7 September 2024).

- Becker, J.G.; Seagren, E.A. A Blueprint for High-Tech Analysis of Low-Tech Methods for Sustainable Class A Biosolids Production: Phase 1; The Water Environment & Reuse Foundation: Alexandria, VA, USA, 2017; 42p. [Google Scholar]

- Jin, C.; Archer, G.; Parker, W. Current status of sludge processing and biosolids disposition in Ontario. Resour. Conserv. Recycl. 2018, 137, 21–31. [Google Scholar] [CrossRef]

- Shaaban, M.; Scheffran, J.; Böhner, J.; Elsobki, M.S. Sustainability assessment of electricity generation technologies in Egypt using multi-criteria decision analysis. Energies 2018, 11, 1117. [Google Scholar] [CrossRef]

- Berardi, U. Sustainability assessment in the construction sector: Rating systems and rated buildings. Sustain. Dev. 2012, 20, 411–424. [Google Scholar] [CrossRef]

- DNGB System Software. Deutsche Gesellschaft für Nachhaltiges Bauen (DGNB, German Sustainable Building Council). 2018. Available online: https://www.dgnb-system.de/en/system/certification_system/ (accessed on 26 January 2024).

- Sal, A.G.; García, A.G. A comprehensive assessment of multifunctional agricultural land-use systems in Spain using a multi-dimensional evaluative model. Agric. Ecosyst. Environ. 2007, 120, 82–91. [Google Scholar]

- Vaneeckhaute, C.; Styles, D.; Prade, T.; Adams, P.; Thelin, G.; Rodhe, L.; Gunnarsson, I.; D’Hertefeldt, T. Closing nutrient loops through decentralized anaerobic digestion of organic residues in agricultural regions: A multi-dimensional sustainability assessment. Resour. Conserv. Recycl. 2018, 136, 110–117. [Google Scholar] [CrossRef]

- Cornejo, P.K.; Becker, J.; Pagilla, K.; Mo, W.; Zhang, Q.; Mihelcic, J.R.; Chandran, K.; Sturm, B.; Yeh, D.; Rosso, D. Sustainability metrics for assessing water resource recovery facilities of the future. Water Environ. Res. 2019, 91, 45–53. [Google Scholar] [CrossRef] [PubMed]

- Balkema, A.J.; Preisig, H.A.; Otterpohl, R.; Lambert, F.J. Indicators for the sustainability assessment of wastewater treatment systems. Urban Water 2002, 4, 153–161. [Google Scholar] [CrossRef]

- Plakas, K.V.; Georgiadis, A.A.; Karabelas, A.J. Sustainability assessment of tertiary wastewater treatment technologies: A multi-criteria analysis. Water Sci. Technol. 2016, 73, 1532–1540. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 7 February 2023).

- NEBRA. A National Biosolids Regulation, Quantity, End Use, and Disposal Survey, Final Report, North East Biosolids and Residuals Association (NEBRA). 2007. Available online: https://static1.squarespace.com/static/54806478e4b0dc44e1698e88/t/5488541fe4b03c0a9b8ee09b/1418220575693/NtlBiosolidsReport-20July07.pdf (accessed on 26 September 2024).

- Nabaterega, R.; Kumar, V.; Khoei, S.; Eskicioglu, C. A review on two-stage anaerobic digestion options for optimizing municipal wastewater sludge treatment process. J. Environ. Chem. Eng. 2021, 9, 105502. [Google Scholar] [CrossRef]

- Brown, J.L.; Handler, R.M.; Seagren, E.A.; Becker, J.G. Environmental Life Cycle Assessment of Class A Biosolids Production Using Conventional and Low-Cost, Low-Tech Processes at Small Water Resource Recovery Facilities. Appl. Sci. 2025, 15, 3482. [Google Scholar] [CrossRef]

- Metcalf & Eddy, Inc.; Tchobanoglous, G.; Stensel, H.D.; Tsuchihashi, R.; Burton, F.L. Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; McGraw-Hill Education: Boston, MA, USA, 2014. [Google Scholar]

- U.S. Environmental Protection Agency. Biosolids Technology Fact Sheet: Belt Filter Press. 2000. Available online: https://www.epa.gov/biosolids/fact-sheet-belt-filter-press (accessed on 7 September 2024).

- Komilis, D.P.; Ham, R.K. Life-Cycle Inventory of Municipal Solid Waste and Yard Waste Windrow Composting in the United States. J. Environ. Eng. 2004, 130, 1390–1400. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Biosolids Technology Fact Sheet: Heat Drying. 2006. Available online: https://www.epa.gov/sites/production/files/2018-11/documents/heat-drying-factsheet.pdf (accessed on 7 April 2022).

- Riau, V.; De la Rubia, M.Á.; Pérez, M. Temperature-Phased Anaerobic Digestion (TPAD) to Obtain Class A Biosolids: A Semi-Continuous Study. Bioresour. Technol. 2010, 101, 2706–27112. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. LCA. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- CalEPA. Guidance for the Water Loss Economic Model. California State Water Resources Control Board, California Environmental Protection Agency. 2021. Available online: https://www.waterboards.ca.gov/conservation/docs/water-loss-model-guidance-12-03-2021.pdf (accessed on 7 September 2024).

- U.S. Energy Information Administration (EIA). Electric Power Monthly. 2024. Available online: https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_5_6_a. (accessed on 15 May 2025).

- U.S. Energy Information Administration (EIA). Petroleum & Other Liquids. 2024. Available online: https://www.eia.gov/petroleum/gasdiesel/ (accessed on 15 May 2025).

- U.S. Energy Information Administration (EIA). U.S. Price of Natural Gas Sold to Commercial Customers. 2024. Available online: https://www.eia.gov/dnav/ng/hist/n3020us3m.htm (accessed on 15 May 2025).

- Unlimited Resources Corporation (URC). Compost Turner Pricing. 2024. Available online: https://urcrecycle.com/category/compost-turners. (accessed on 20 October 2024).

- U.S. Environmental Protection Agency. Biosolids Technology Fact Sheet: Multi-Stage Anaerobic Digestion. 2006. Available online: https://www.epa.gov/biosolids/fact-sheet-multi-stage-anaerobic-digestion (accessed on 7 April 2022).

- U.S. Bureau of Labor Statistics (BLS). Occupational Employment and Wages, May 2023: 51-8031 Water and Wastewater Treatment Plant and System Operators. 2024. Available online: https://www.bls.gov/oes/current/oes518031.htm. (accessed on 7 February 2024).

- Shammas, N.K.; Wang, L.K. Belt Filter Presses. In Biosolids Treatment Processes; Springer: Berlin/Heidelberg, Germany, 2007; pp. 519–539. Available online: https://link.springer.com/chapter/10.1007/978-1-59259-996-7_17 (accessed on 2 October 2024).

- U.S. Bureau of Labor Statistics (BLS). Occupational Employment and Wages, May 2020, 53-3032 Heavy and Tractor-Trailer Truck Drivers. 2022. Available online: https://www.bls.gov/oes/current/oes533032.htm. (accessed on 15 March 2024).

- Coker, C.S.; King, M.; Gilbert, J.; Rivin, J.M.; Wentz, R.; Schwarz, M.; Tyler, R. Composting economics. In The Composting Handbook; Elsevier Academic Press: Amsterdam, The Netherlands, 2022; pp. 913–943. [Google Scholar]

- Agricultural Marketing Research Center (AgMRC). “Sawdust”. 2018. Available online: https://www.agmrc.org/commodities-products/biomass/sawdust. (accessed on 2 February 2024).

- Smith, A. How Much Does Mulch Delivery Cost? 2023. Available online: https://www.kompareit.com/homeandgarden/landscaping-compare-mulch-delivery-costs.html (accessed on 2 October 2024).

- U.S. Environmental Protection Agency. Cost Methodology for the Final Revisions to the National Pollutant Discharge Elimination System Regulation and the Effluent Guidelines for Concentrated Animal Feeding Operation, Section 5.0: Technology Cost Equations. 2002. Available online: https://www3.epa.gov/npdes/pubs/cafo_cost_method_p3.pdf (accessed on 7 April 2022).

- Statista. Average Price of Common Clay from 2010 to 2022. 2023. Available online: https://www.statista.com/statistics/248190/average-price-of-common-clay/ (accessed on 7 February 2024).

- Puchajda, B.; Oleszkiewicz, J. Impact of Sludge Thickening on Energy Recovery from Anaerobic Digestion. Water Sci. Technol. 2008, 57, 395–401. [Google Scholar] [CrossRef] [PubMed]

- Suh, Y.-J.; Rousseaux, P. An LCA of Alternative Wastewater Sludge Treatment Scenarios. Resour. Conserv. Recycl. 2002, 35, 191–200. [Google Scholar] [CrossRef]

- Robinson, K.G.; Robinson, C.H.; Raup, L.A.; Markum, T.R. Public attitudes and risk perception toward land application of biosolids within the south-eastern United States. J. Environ. Manag. 2012, 98, 29–36. [Google Scholar] [CrossRef]

- Beecher, N.; Connell, B.; Epstein, E.; Filtz, J.; Goldstein, N. Public Perception of Biosolids Recycling: Developing Public Participation and Earning Trust. Water Environment Research Foundation (WERF) Report 00-PUM-05; IWA Publishing: London, UK, 2004. [Google Scholar]

- U.S. Environmental Protection Agency. Biosolids and Residuals Management Fact Sheet: Odor Control in Biosolids Management. 2000. Available online: https://www.epa.gov/biosolids/fact-sheet-odor-control-biosolids-management (accessed on 7 September 2024).

- U.S. Environmental Protection Agency. Biosolids Technology Fact Sheet: Use of Composting for Biosolids Management. 2002. Available online: https://www.epa.gov/biosolids/fact-sheet-use-composting-biosolids-management (accessed on 1 October 2024).

- Yu, S.; Dai, T.; Yu, Y.; Zhang, J. Investment decision model of wastewater treatment public–private partnership projects based on value for money. Water Environ. J. 2021, 35, 322–334. [Google Scholar] [CrossRef]

- Becker, J.G.; North, J.M.; Seagren, E.A.; Peot, C.; Ramirez, M.A.; Chikounova, I.Y. Reduced Sulfur Compound Production as an Indicator of Stability in Limed Biosolids. In Residuals and Biosolids Conference 2003; Water Environment Federation: Alexandria, VA, USA, 2003; pp. 672–685. [Google Scholar]

- Farrell, J.B.; Merrill, D.; Schafer, P. Producing Class A Biosolids with Low-Cost, Low-Technology Treatment Processes; IWA Publishing: London, UK, 2004. [Google Scholar]

- Andraskar, J.; Yadav, S.; Kapley, A. Challenges and control strategies of odor emission from composting operation. Appl. Biochem. Biotechnol. 2021, 193, 2331–2356. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).