Bio-Waste to Bioenergy: Critical Assessment of Sustainable Energy Supply Chain in Egypt

Abstract

1. Introduction

2. Methodology

2.1. Data Collection for Biomass Waste

2.2. Calculation Methods

2.2.1. Municipal Solid Waste

2.2.2. Agriculture Crop Residues

2.2.3. Animal Wastes

2.2.4. Sewage Wastes

3. Results and Discussion

3.1. Biomass Wastes

3.1.1. Municipal Solid Waste

3.1.2. Agriculture Crop Residues

3.1.3. Animal Wastes

3.1.4. Sewage Wastes

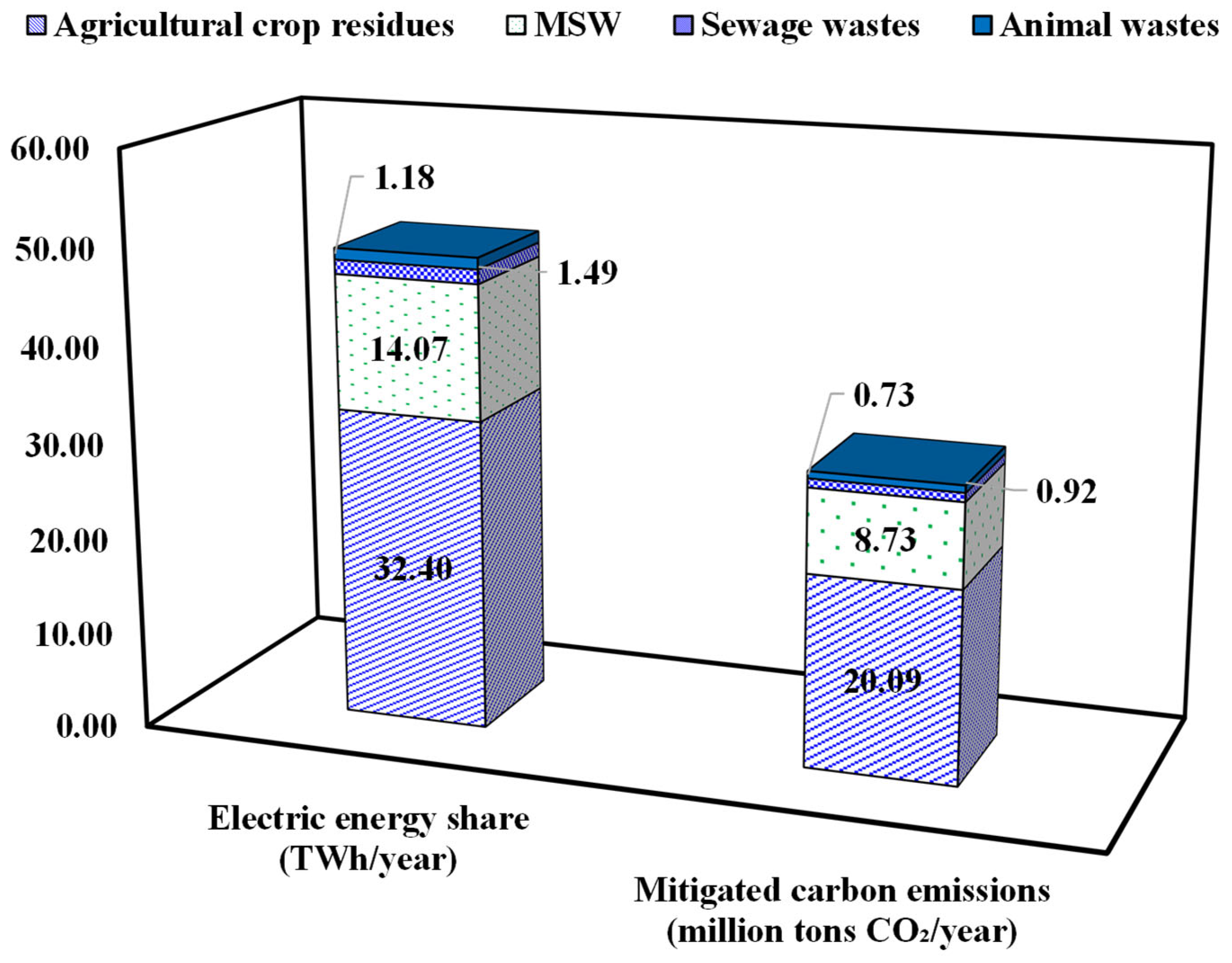

3.2. Energy Contribution and Emissions Mitigation

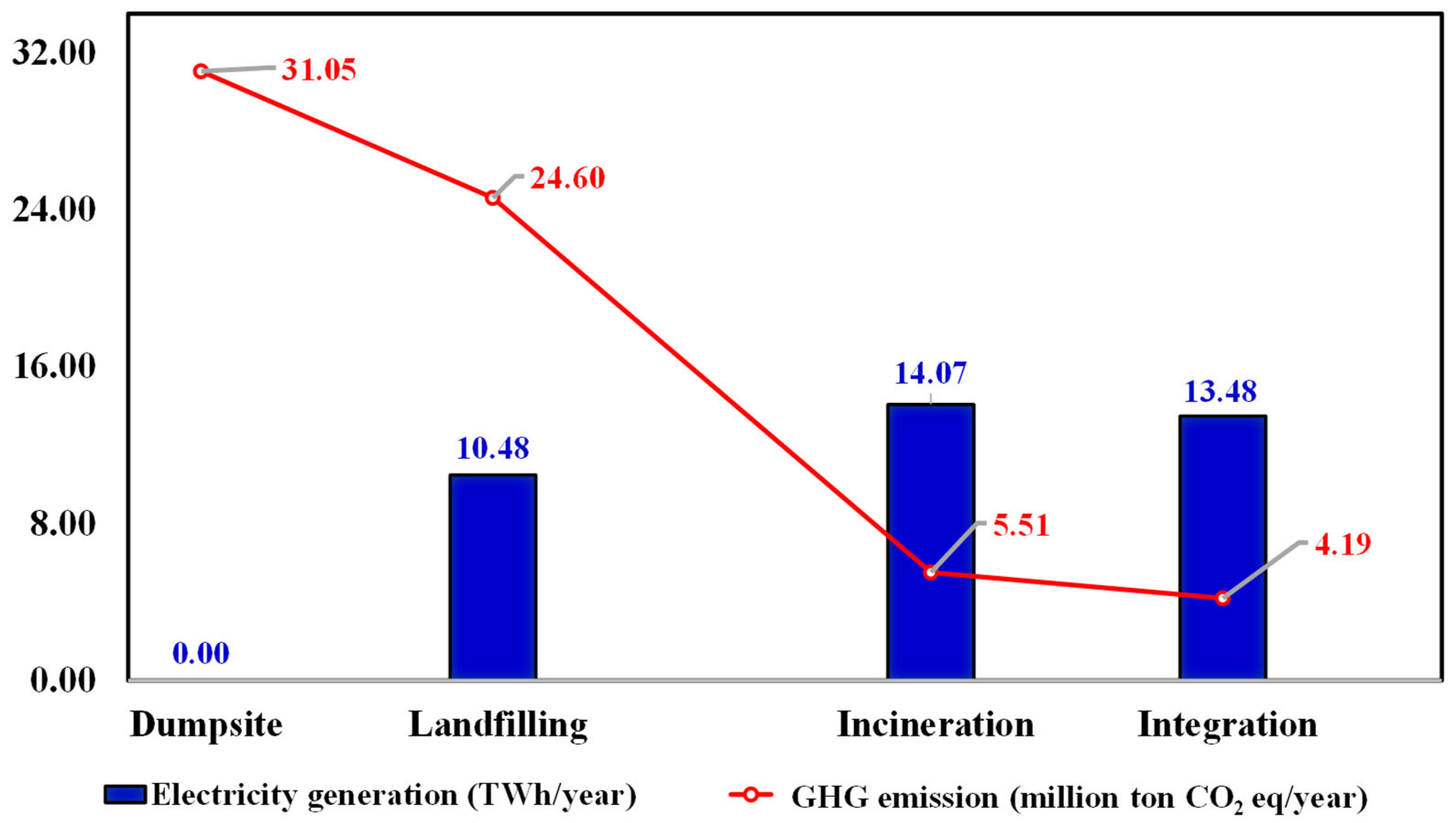

3.3. Technological Advancement Impact

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tazikeh, S.; Mohammadzadeh, O.; Zendehboudi, S.; Saady, N.M.C.; Albayati, T.M.; Chatzis, I. Energy development and management in the Middle East: A holistic analysis. Energy Convers. Manag. 2025, 323, 119124. [Google Scholar] [CrossRef]

- Konbr, U.; Bayoumi, W.; Ali, M.N.; Shiba, A.S.E. Sustainability of Egyptian cities through utilizing sewage and sludge in softscaping and biogas production. Sustainability 2022, 14, 6675. [Google Scholar] [CrossRef]

- Abdel daiem, M.M.; Said, N. Assessment and Contribution of Biomass Residues to Renewable Energy Resources in Egypt. In The Handbook of Environmental Chemistry; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 2024; pp. 345–372. [Google Scholar]

- El-Sayed, S.A.; Ismail, M.A.; Mostafa, M.E.; Noseir, E.H.; Khass, T.M. Availability, sustainability and accessibility of agro crop residue production and solar radiation in Egypt for producing highly chemical products through pyrolysis processes. Clean Energy 2023, 7, 654–670. [Google Scholar] [CrossRef]

- Mostafa, N. Logistics of waste management with perspectives from Egypt. In Waste Management in MENA Regions; Springer International Publishing: Cham, Switzerland, 2020; pp. 171–191. [Google Scholar]

- Mostafa, N.A.; Eldebaiky, O. A Sustainable Two-Echelon Logistics Model with Shipment Consolidation. Logistics 2023, 7, 18. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, F.; Li, R. Assessing supply chain greenness from the perspective of embodied renewable energy–A data envelopment analysis using multi-regional input-output analysis. Renew. Energy 2022, 189, 1292–1305. [Google Scholar] [CrossRef]

- Amiri-Pebdani, S.; Alinaghian, M.; Safarzadeh, S. Time-Of-Use pricing in an energy sustainable supply chain with government interventions: A game theory approach. Energy 2022, 255, 124380. [Google Scholar] [CrossRef]

- Mostafa, N.A.; Grida, M.; Park, J.; Ramadan, H.S. A sustainable user-centered application for residential energy consumption saving. Sustain. Energy Technol. Assess. 2022, 53, 102754. [Google Scholar] [CrossRef]

- Salem, M.; Abd El-Halim, H.; Refky, A.; Nassar, I.A. Potential of waste to energy conversion in Egypt. J. Electr. Comput. Eng. 2022, 2022, 7265553. [Google Scholar] [CrossRef]

- Joshi, N.C.; Sinha, S.; Bhatnagar, P.; Nath, Y.; Negi, B.; Kumar, V.; Gururani, P. A concise review on waste biomass valorization through thermochemical conversion. Curr. Res. Microb. Sci. 2024, 6, 100237. [Google Scholar] [CrossRef]

- Salah, S.I.; Eltaweel, M.; Abeykoon, C. Towards a sustainable energy future for Egypt: A systematic review of renewable energy sources, technologies, challenges, and recommendations. Clean. Eng. Technol. 2022, 8, 100497. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Mahamood, R.M.; Jen, T.-C.; Loha, C.; Akinlabi, E.T. An overview of biomass solid fuels: Biomass sources, processing methods, and morphological and microstructural properties. J. Bioresour. Bioprod. 2023, 8, 333–360. [Google Scholar] [CrossRef]

- CAPMAS Central Agency for Public Mobilization and Statistics. 2024. Available online: https://www.capmas.gov.eg/Pages/Publications.aspx?page_id=5104 (accessed on 21 March 2025).

- Hemidat, S.; Achouri, O.; El Fels, L.; Elagroudy, S.; Hafidi, M.; Chaouki, B.; Ahmed, M.; Hodgkinson, I.; Guo, J. Solid Waste Management in the Context of a Circular Economy in the MENA Region. Sustainability 2022, 14, 480. [Google Scholar] [CrossRef]

- Abdelnaby, A.; Ashour, T.; Ali, S.; Abdelsalam, E.; Gouda, S. Enhancement of Biogas Production: Short-Term Evaluation of Biogas Unit in Egypt. Ann. Agric. Sci. Moshtohor 2023, 61, 357–366. [Google Scholar] [CrossRef]

- Ioannou-Ttofa, L.; Foteinis, S.; Moustafa, A.S.; Abdelsalam, E.; Samer, M.; Fatta-Kassinos, D. Life cycle assessment of household biogas production in Egypt: Influence of digester volume, biogas leakages, and digestate valorization as biofertilizer. J. Clean. Prod. 2021, 286, 125468. [Google Scholar] [CrossRef]

- Samoraj, M.; Mironiuk, M.; Izydorczyk, G.; Witek-Krowiak, A.; Szopa, D.; Moustakas, K.; Chojnacka, K. The challenges and perspectives for anaerobic digestion of animal waste and fertilizer application of the digestate. Chemosphere 2022, 295, 133799. [Google Scholar] [CrossRef]

- Alrowais, R.; Said, N.; Alotaibi, A.; Hatata, A.; Essa, M.A.; Abdel daiem, M.M. Comparing the effect of mesophilic and thermophilic anaerobic co-digestion for sustainable biogas production: An experimental and recurrent neural network model study. J. Clean. Prod. 2023, 392, 136248. [Google Scholar] [CrossRef]

- Abdallah, M.; Shanableh, A.; Arab, M.; Shabib, A.; Adghim, M.; El-Sherbiny, R. Waste to energy potential in middle income countries of MENA region based on multi-scenario analysis for Kafr El-Sheikh Governorate, Egypt. J. Environ. Manag. 2019, 232, 58–65. [Google Scholar] [CrossRef]

- Abdel Wahaab, R.; Mahmoud, M.; van Lier, J.B. Toward achieving sustainable management of municipal wastewater sludge in Egypt: The current status and future prospective. Renew. Sustain. Energy Rev. 2020, 127, 109880. [Google Scholar] [CrossRef]

- Raihan, A.; Rahman, J.; Tanchangya, T.; Ridwan, M.; Rahman, M.S.; Islam, S. A review of the current situation and challenges facing Egyptian renewable energy technology. J. Technol. Innov. Energy 2024, 3, 29–52. [Google Scholar] [CrossRef]

- Said, N.; El-Shatoury, S.A.; Díaz, L.F.; Zamorano, M. Quantitative appraisal of biomass resources and their energy potential in Egypt. Renew. Sustain. Energy Rev. 2013, 24, 84–91. [Google Scholar] [CrossRef]

- Nizami, A.; Rehan, M.; Ouda, O.K.M.; Shahzad, K.; Sadef, Y.; Iqbal, T.; Ismail, I.M.I. An argument for developing waste-to-energy technologies in Saudi Arabia. Chem. Eng. Trans. 2015, 45, 337–342. [Google Scholar]

- Tan, S.T.; Hashim, H.; Lim, J.S.; Ho, W.S.; Lee, C.T.; Yan, J. Energy and emissions benefits of renewable energy derived from municipal solid waste: Analysis of a low carbon scenario in Malaysia. Appl. Energy 2014, 136, 797–804. [Google Scholar] [CrossRef]

- Islam, K.M.N. Municipal solid waste to energy generation: An approach for enhancing climate co-benefits in the urban areas of Bangladesh. Renew. Sustain. Energy Rev. 2018, 81, 2472–2486. [Google Scholar] [CrossRef]

- Elwardany, M.; Nassib, A.M.; Mohamed, H.A. Exergy analysis of a gas turbine cycle power plant: A case study of power plant in Egypt. J. Therm. Anal. Calorim. 2024, 149, 7433–7447. [Google Scholar] [CrossRef]

- Ouda, O.K.M.; Raza, S.A.; Nizami, A.S.; Rehan, M.; Al-Waked, R.; Korres, N.E. Waste to energy potential: A case study of Saudi Arabia. Renew. Sustain. Energy Rev. 2016, 61, 328–340. [Google Scholar] [CrossRef]

- Jiang, Y.; Havrysh, V.; Klymchuk, O.; Nitsenko, V.; Balezentis, T.; Streimikiene, D. Utilization of crop residue for power generation: The case of Ukraine. Sustainability 2019, 11, 7004. [Google Scholar] [CrossRef]

- Fulgencio-Medrano, L.; García-Fernández, S.; Asueta, A.; Lopez-Urionabarrenechea, A.; Perez-Martinez, B.B.; Arandes, J.M. Oil production by pyrolysis of real plastic waste. Polymers 2022, 14, 553. [Google Scholar] [CrossRef]

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental impact of biogas: A short review of current knowledge. J. Environ. Sci. Health Part A 2018, 53, 899–906. [Google Scholar] [CrossRef]

- Yang, Q.; Han, F.; Chen, Y.; Yang, H.; Chen, H. Greenhouse gas emissions of a biomass-based pyrolysis plant in China. Renew. Sustain. Energy Rev. 2016, 53, 1580–1590. [Google Scholar] [CrossRef]

- Said, N.; Alblawi, A.; Hendy, I.A.; Abdel Daiem, M.M. Analysis of Energy and Greenhouse Gas Emissions of Rice Straw to Energy Chain in Egypt. BioResources 2020, 15, 1510–1520. [Google Scholar] [CrossRef]

- Shahzad, H.M.A.; Asim, Z.; Khan, S.J.; Almomani, F.; Mahmoud, K.A.; Mustafa, M.R.U.; Rasool, K. Thermochemical and biochemical conversion of agricultural waste for bioenergy production: An updated review. Discov. Environ. 2024, 2, 134. [Google Scholar] [CrossRef]

- Alrowais, R.; Abdel daiem, M.M.; Nasef, B.M.; Said, N. Activated Carbon Fabricated from Biomass for Adsorption/Bio-Adsorption of 2, 4-D and MCPA: Kinetics, Isotherms, and Artificial Neural Network Modeling. Sustainability 2024, 16, 299. [Google Scholar] [CrossRef]

- Alrowais, R.; Said, N.; Mahmoud-Aly, M.; Helmi, A.M.; Nasef, B.M.; Abdel daiem, M.M. Influences of straw alkaline pretreatment on biogas production and digestate characteristics: Artificial neural network and multivariate statistical techniques. Environ. Sci. Pollut. Res. 2024, 31, 13638–13655. [Google Scholar] [CrossRef]

- Molina-Guerrero, C.E.; Sanchez, A.; Vázquez-Núñez, E. Energy potential of agricultural residues generated in Mexico and their use for butanol and electricity production under a biorefinery configuration. Environ. Sci. Pollut. Res. 2020, 27, 28607–28622. [Google Scholar] [CrossRef]

- Demirel, S.; Öz, H.Ö.; Güneş, M.; Çiner, F.; Adın, S. Life-cycle assessment (LCA) aspects and strength characteristics of self-compacting mortars (SCMs) incorporating fly ash and waste glass PET. Int. J. Life Cycle Assess. 2019, 24, 1139–1153. [Google Scholar] [CrossRef]

- Bentsen, N.S.; Felby, C.; Thorsen, B.J. Agricultural residue production and potentials for energy and materials services. Prog. Energy Combust. Sci. 2014, 40, 59–73. [Google Scholar] [CrossRef]

- Sidhu, G.K. Engineering properties of cotton stalks (Gossypium hirsitum L.). Indian J. Agric. Res. 2015, 49, 456–459. [Google Scholar] [CrossRef][Green Version]

- Wang, Y.; Cheng, M.; Wright, M.M. Lifecycle energy consumption and greenhouse gas emissions from corncob ethanol in China. Biofuels Bioprod. Biorefining 2018, 12, 1037–1046. [Google Scholar] [CrossRef]

- Soyer, G.; Yilmaz, E. Waste management in dairy cattle farms in Aydın region. Potential Energy Appl. Sustain. 2020, 12, 1614. [Google Scholar]

- Kaur, G.; Brar, Y.S.; Kothari, D.P. Potential of livestock generated biomass: Untapped energy source in India. Energies 2017, 10, 847. [Google Scholar] [CrossRef]

- Siswantara, A.I.; Rizianiza, I.; Mahdi, D.P.; Farhan, T.A.; Widiawati, C.D.; Syafei, M.H.G.; Syuriadi, A. Investigating kinetic and thermodynamic parameters in the pyrolysis of sheep manure using thermogravimetric analysis. J. Sustain. Dev. Energy Water Environ. Syst. 2024, 12, 1–18. [Google Scholar] [CrossRef]

- Parthasarathy, P.; Al-Ansari, T.; Mackey, H.R.; McKay, G. Effect of heating rate on the pyrolysis of camel manure. Biomass Convers. Biorefinery 2023, 13, 6023–6035. [Google Scholar] [CrossRef]

- Grosser, A.; Neczaj, E. Sewage sludge and fat rich materials co-digestion-Performance and energy potential. J. Clean. Prod. 2018, 198, 1076–1089. [Google Scholar] [CrossRef]

- Abdel Daiem, M.M.; Said, N. Energetic, economic, and environmental perspectives of power generation from residual biomass in Saudi Arabia. Alex. Eng. J. 2022, 61, 3351–3364. [Google Scholar] [CrossRef]

- Faragalla, A.; Kotb, H.; Galal, B. Municipal Solid Waste Management Strategies in Egypt. J. Waste Manag. & Dispos. 2025, 8, 1–15. [Google Scholar]

- Eddine, B.T.; Salah, M.M. Solid waste as renewable source of energy: Current and future possibility in Algeria. Int. J. Energy Environ. Eng. 2012, 3, 1–12. [Google Scholar] [CrossRef]

- Gibellini, S.; Abu Qdais, H.; Vaccari, M. Municipal solid waste management in refugee hosting communities: Analysis of a case study in northern Jordan. Waste Manag. Res. 2022, 40, 165–173. [Google Scholar] [CrossRef]

- Welfle, A.; Alawadhi, A. Bioenergy opportunities, barriers and challenges in the Arabian Peninsula–Resource modelling, surveys & interviews. Biomass Bioenergy 2021, 150, 106083. [Google Scholar]

- Nassar, H.; Biltagy, M.; Safwat, A.M. The role of waste-to-energy in waste management in Egypt: A techno-economic analysis. Rev. Econ. Political Sci. 2023, 10, 151–167. [Google Scholar] [CrossRef]

- Abdelhady, S.; Shalaby, M.A.; Shaban, A. Techno-economic analysis for the optimal design of a national network of agro-energy biomass power plants in Egypt. Energies 2021, 14, 3063. [Google Scholar] [CrossRef]

- Mahdavi, M.; Awaafo, A.; Schmitt, K.; Jurado, F.; Vera, D. Potential of Morocco in energy generation from agricultural residues. In Proceedings of the 2023 IEEE International Conference on Environment and Electrical Engineering and 2023 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 6–9 June 2023; pp. 1–6. [Google Scholar]

- Gares, M.; Hiligsmann, S.; Kacem Chaouche, N. Lignocellulosic biomass and industrial bioprocesses for the production of second generation bio-ethanol, does it have a future in Algeria? SN Appl. Sci. 2020, 2, 1–19. [Google Scholar] [CrossRef]

- Myyas, R.N.; Tostado-Véliz, M.; Gómez-González, M.; Jurado, F. Review of bioenergy potential in Jordan. Energies 2023, 16, 1393. [Google Scholar] [CrossRef]

- Abdel Daiem, M.M.; Said, N.; Negm, A.M. Potential energy from residual biomass of rice straw and sewage sludge in Egypt. Proc. Procedia Manuf. 2018, 22, 818–825. [Google Scholar] [CrossRef]

- Ngetuny, J.; Hsaine, J.; Mabrouki, A.; Rachidi, F.; El Asli, A.; Zörner, W. Assessment of agricultural residues for small-scale biogas plants and adoption drivers: A case study of the Fès-Meknès region in Morocco. Biomass Convers. Biorefinery 2025. [Google Scholar] [CrossRef]

- Ghacha, A.; Ben Alla, L.; Ammari, M. Sustainable sewage sludge management in Morocco: Constraints and solutions. J. Water Land Dev. 2020, 71–83. [Google Scholar] [CrossRef]

- Ameri, B.; Hanini, S. Analogous study of cumulative biogas production by anaerobic digestion of sewage treatment plant sludge, the proposal of universal dimensionless models. Energy Sci. Eng. 2023, 11, 2366–2384. [Google Scholar] [CrossRef]

- Maruejols, L.; Höschle, L.; Yu, X. Energy independence, rural sustainability and potential of bioenergy villages in Germany: Machine learning perspectives. Int. Food Agribus. Manag. Rev. 2025, 28, 263–295. [Google Scholar] [CrossRef]

- Statista Distribution of Electricity Consumption in Egypt. 2025. Available online: https://www.statista.com/statistics/1334194/share-of-electricity-consumption-in-egypt-by-sector/ (accessed on 21 March 2025).

- Abdallah, L.; El-Shennawy, T. Evaluation of CO2 emission from Egypt’s future power plants. Euro-Mediterr. J. Environ. Integr. 2020, 5, 49. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, T.; Cheng, M.; Xie, M.; Shi, N.; Liu, T.; Huang, Z.; Zhao, Y.; Huang, Q.; Liu, Z. Recent advances in organic waste pyrolysis and gasification in a CO2 environment to value-added products. J. Environ. Manag. 2024, 356, 120666. [Google Scholar] [CrossRef]

- Abioye, K.J.; Rajamanickam, R.; Ogunjinmi, T.; Paul, S.; Selvasembian, R.; Ighalo, J.O. Advancements in biomass waste conversion to sustainable biofuels via gasification. Chem. Eng. J. 2025, 505, 159151. [Google Scholar] [CrossRef]

- Obileke, K.; Makaka, G.; Tangwe, S.; Mukumba, P. Improvement of biogas yields in an anaerobic digestion process via optimization technique. Environ. Dev. Sustain. 2025, 27, 15025–15051. [Google Scholar] [CrossRef]

- Almendrala, M.C.; Valenzuela, K.A.T.; Santos, S.M.N.B.; Avena-Ardeta, L.G.S. Enhanced Biogas Production via Anaerobic Co-Digestion of Slaughterhouse and Food Waste Using Ferric Oxide as a Sustainable Conductive Material. arXiv 2025, arXiv:2505.04635. [Google Scholar]

- Adnane, I.; Taoumi, H.; Elouahabi, K.; Lahrech, K.; Oulmekki, A. Valorization of crop residues and animal wastes: Anaerobic co-digestion technology. Heliyon 2024, 10, e26440. [Google Scholar] [CrossRef]

- Pulgarín-Muñoz, C.E.; Saldarriaga-Molina, J.C.; Correa-Ochoa, M.A.; Castro-Valencia, J.C. Effect of Cosubstrate Ratio and Temperature on Sewage Sludge and Agro-industrial Fruit and Vegetable Waste Anaerobic Co-digestion. Waste Biomass Valorization 2025. [Google Scholar] [CrossRef]

- Shoukat, M.; Rehman, A.U.; Alam Khan, M.N.; Ali, I.; Farah, M.A.; Khan, S.; Shah, A.A.; Sanam, S.; Elsadek, M.F.; Badshah, M. Enhancement of Biogas Production through Phase Separated Anaerobic Co-Digestion of Cattle Manure with Fruit and Vegetable Waste. Pol. J. Environ. Stud. 2025, 1–8. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Qi, Y.; Fu, L.; Li, G.; Liu, Z.; Bo, L.; Jing, Y. Anaerobic Co-Digestion of Dairy Manure and Cucumber Residues: Methane Production Efficiency and Microbial Community Characteristics. Agronomy 2025, 15, 1610. [Google Scholar] [CrossRef]

- Liu, Y.; Watanabe, R.; Li, Q.; Luo, Y.; Tsuzuki, N.; Ren, Y.; Qin, Y.; Li, Y.-Y. Enhanced biomethane production by thermophilic high-solid anaerobic co-digestion of rice straw and food waste: Cellulose degradation and microbial structure. Chem. Eng. J. 2025, 503, 158088. [Google Scholar] [CrossRef]

- Khan, M.; Chuenchart, W.; Surendra, K.C.; Khanal, S.K. Applications of artificial intelligence in anaerobic co-digestion: Recent advances and prospects. Bioresour. Technol. 2023, 370, 128501. [Google Scholar] [CrossRef]

- Avinash, L.S.; Mishra, A. Comparative evaluation of artificial intelligence based models and kinetic studies in the prediction of biogas from anaerobic digestion of MSW. Fuel 2024, 367, 131545. [Google Scholar] [CrossRef]

- Soni, A.; Gupta, S.K.; Rajamohan, N.; Yusuf, M. Waste-to-energy technologies: A sustainable pathway for resource recovery and materials management. Mater. Adv. 2025, 6, 4598–4622. [Google Scholar] [CrossRef]

- Abouaiana, A.; Battisti, A. Multifunction land use to promote energy communities in Mediterranean region: Cases of Egypt and Italy. Land 2022, 11, 673. [Google Scholar] [CrossRef]

| Year | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Annual crop production (106 tons) | |||||

| Wheat | 8.42 | 8.35 | 8.56 | 9.10 | 9.84 |

| Maize | 8.54 | 8.35 | 7.59 | 7.59 | 8.04 |

| Rice | 4.96 | 3.12 | 4.80 | 4.44 | 4.24 |

| Sugarcane | 15.38 | 15.82 | 15.34 | 15.86 | 15.96 |

| Cotton | 0.26 | 0.43 | 0.28 | 0.23 | 0.49 |

| Sorghum | 0.81 | 0.80 | 0.76 | 0.80 | 0.79 |

| Barley | 0.10 | 0.08 | 0.11 | 0.11 | 0.09 |

| Animal head number (103) | |||||

| Cows | 4387 | 4379 | 2809 | 2745 | 2812 |

| buffaloes | 3433 | 3445 | 1427 | 1348 | 1428 |

| Camels | 156 | 85 | 91 | 79 | 239 |

| Goats | 3974 | 3572 | 977 | 925 | 1131 |

| Sheep | 5305 | 4830 | 2082 | 1936 | 1938 |

| TWW (106 m3/year) | 4282.20 | 4637.30 | 5114.80 | 5135.30 | 5233.60 |

| MSW (103 tons/day) | 76.71 | 82.19 | 100.27 | 74.58 | 76.71 |

| Approach | Parameter | Value | References |

|---|---|---|---|

| Open dumping | GHG emissions | 1.11 tons CO2 eq/ton MSW | [25] |

| Incineration | LHV of MSW Heat recovery efficiency Electricity generation GHG emissions | 9850 MJ/ton MSW 80% 1 MWh/15.65 GJ 0.197 tons CO2 eq/ton MSW | [25,26,27] |

| Landfilling | Methane volume factor Methane LHV GHG emissions | 79.50 m3 CH4/ton MSW 17 MJ/m3 0.88 tons CO2 eq/ton MSW | [25,26] |

| Integrated | |||

| Anaerobic digestion (organic wastes) | Biogas volume Methane content Methane LHV Electric efficiency Energy conversion factor GHG emissions | 180.60 m3/ton organic waste (60–70%) 17 MJ/m3 35% 0.38 to 0.88 0.085 to 0.251 kg CO2 eq/kWh | [24,28,29] |

| Pyrolysis (plastic wastes) | Oil production Oil energy content Electric efficiency Energy conversion factor GHG emissions | 0.71 kg oil/kg plastic 39.60 MJ/kg oil 33% 0.50 to 0.80 0.012 to 0.100 kg CO2 eq/MJ | [24,28,30] |

| RDF combustion (paper + textile + others) | Energy content Electric efficiency GHG emissions | 15.91 MJ/kg waste 18% 0.38 Mt CO2 eq/ton waste | [24,28] |

| Crop Residue | Residue to Production Ratio | Moisture (%) | LHV (MJ/kg) |

|---|---|---|---|

| Wheat straw | 1.00 | 15.00 | 18.20 |

| Maize stalk | 1.00 | 30.00 | 17.90 |

| Rice straw | 1.05 | 15.00 | 17.50 |

| Sugarcane bagasse | 0.23 | 50.00 | 18.00 |

| Cotton stalks | 2.70 | 10.00 | 18.61 |

| Sorghum straw | 1.25 | 15.00 | 12.38 |

| Barley straw | 1.00 | 15.00 | 18.20 |

| References | [14,37,38] | [37,39,40] | [38,39,40] |

| Power Plant | Fuel Product | Power Plant Efficiency (%) | Energy Conversion Factor | GHG Emissions (kg CO2 eq/MJ) |

|---|---|---|---|---|

| Combustion | Gas | 30.00 | ---- | 0.25 to 0.30 |

| Gasification | Syngas | 33.00 | 0.50 to 0.80 | 0.02 to 0.14 |

| Pyrolysis | Bio-oil | 33.00 | 0.50 to 0.80 | 0.01 to 0.10 |

| Anaerobic digestion | Biogas | 35.00 | 0.38 to 0.88 | 0.02 to 0.07 |

| Fermentation | Ethanol | 40.00 | 0.24 to 0.32 | 0.04 to 0.05 |

| References | [29] | [29] | [31,32,41] |

| Parameter | Cows | Buffaloes | Camels | Goats | Sheep | References |

|---|---|---|---|---|---|---|

| Water content of AW (%) | 85–90 | 85–90 | 38–61 | 70–80 | 70–80 | [44,45] |

| Animal head waste (kg fresh dung/animal/day) | 8–15 | 8–15 | 20 | 1–5 | 1 | [42,43] |

| Biogas production (m3/kg fresh dung) | 0.02–0.04 | 0.02–0.04 | 0.03 | 0.05 | 0.04 | [42,43] |

| Electricity generation factor (kWh/m3) | 1.7 | [42] | ||||

| GHG emissions factor (kg CO2 eq/kWh) | 0.09 to 0.25 | [31] | ||||

| Parameter | Value | References |

|---|---|---|

| TWWv (million m3/year) | 5234.10 | [14] |

| Dry sludge factor (kg/m3 TWW) | 0.48 | [44] |

| Biogas production (m3/ton dry sludge) | 350 | [46] |

| Electricity generation factor (kWh/m3) | 1.7 | [42] |

| GHG emissions (kg CO2 eq/kWh) | 0.09 to 0.25 | [31] |

| Year | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|

| Crop residues production (106 tons) | |||||

| Wheat straw | 8.42 | 8.35 | 8.56 | 9.10 | 9.84 |

| Maize stalk | 8.54 | 8.35 | 7.59 | 7.59 | 8.04 |

| Rice straw | 5.19 | 3.27 | 5.03 | 4.65 | 4.44 |

| Sugarcane bagasse | 3.60 | 3.71 | 3.59 | 3.72 | 3.74 |

| Cotton stalks | 0.70 | 1.15 | 0.76 | 0.62 | 1.32 |

| Sorghum straw | 1.01 | 1.01 | 0.95 | 1.00 | 0.99 |

| Barley straw | 0.10 | 0.08 | 0.11 | 0.11 | 0.09 |

| Total | 27.57 | 25.91 | 26.59 | 26.78 | 28.46 |

| Animal waste (106 tons) | |||||

| Cows | 18.41 | 18.38 | 11.79 | 11.52 | 11.80 |

| Buffaloes | 14.41 | 14.46 | 5.99 | 5.66 | 5.99 |

| Camels | 1.14 | 0.62 | 0.66 | 0.58 | 1.74 |

| Goats | 3.63 | 3.26 | 0.89 | 0.84 | 1.03 |

| Sheep | 1.94 | 1.76 | 0.76 | 0.71 | 0.71 |

| Total | 39.53 | 38.48 | 20.10 | 19.31 | 21.28 |

| Dry sewage sludge (106 tons) | 2.06 | 2.23 | 2.46 | 2.46 | 2.51 |

| MSW (106 tons) | 28.00 | 30.00 | 36.60 | 27.22 | 27.95 |

| Waste Type | Waste Amount (106 Tons/Year) | Technology | Electricity Generation (TWh/Year) | GHG Emissions (106 Tons CO2 eq/Year) |

|---|---|---|---|---|

| Organic | 15.65 | Anaerobic digestion | 1.78 | 0.31 |

| Plastic | 3.63 | Pyrolysis | 6.10 | 1.23 |

| Paper+Textile+Others | 6.99 | RDF combustion | 5.60 | 2.66 |

| Glass+Metals | 1.68 | Recycling | ------- | ------- |

| Total | 27.95 | ------- | 13.48 | 4.19 |

| Crop Residue | Energy Potential (PJ/Year) | Electricity Generation (TWh/Year) | |||

|---|---|---|---|---|---|

| Combustion | Gasification/Pyrolysis | Anaerobic Digestion | Fermentation | ||

| Wheat straw | 152.26 | 12.69 | 9.07 | 8.73 | 4.57 |

| Maize stalk | 100.69 | 8.39 | 6.00 | 5.78 | 3.02 |

| Rice straw | 66.06 | 5.51 | 3.94 | 3.79 | 1.98 |

| Sugarcane bagasse | 33.65 | 2.80 | 2.01 | 1.93 | 1.01 |

| Cotton stalks | 22.07 | 2.02 | 1.32 | 1.27 | 0.66 |

| Sorghum straw | 10.44 | 0.87 | 0.62 | 0.60 | 0.31 |

| Barley straw | 1.36 | 0.11 | 0.08 | 0.08 | 0.04 |

| Total energy | 386.53 | 32.40 | 23.03 | 22.17 | 11.60 |

| GHG (106 ton CO2 eq) | 32.07 | 6.63 | 4.64 | 3.75 | 1.86 |

| Animal Type | Animal Waste (106 Tons/Year) | Electricity Production (TWh/Year) | GHG Emissions (106 kg CO2 eq/Year) |

|---|---|---|---|

| Cows | 11.80 | 0.63 | 106.20 |

| Buffaloes | 5.99 | 0.32 | 53.91 |

| Camels | 1.74 | 0.09 | 14.95 |

| Goats | 1.03 | 0.09 | 14.73 |

| Sheep | 0.71 | 0.05 | 8.08 |

| Total | 21.28 | 1.18 | 197.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Said, N.; Alrowais, R.; Abdel-Daiem, M.M.; Mostafa, N.A. Bio-Waste to Bioenergy: Critical Assessment of Sustainable Energy Supply Chain in Egypt. Resources 2025, 14, 131. https://doi.org/10.3390/resources14080131

Said N, Alrowais R, Abdel-Daiem MM, Mostafa NA. Bio-Waste to Bioenergy: Critical Assessment of Sustainable Energy Supply Chain in Egypt. Resources. 2025; 14(8):131. https://doi.org/10.3390/resources14080131

Chicago/Turabian StyleSaid, Noha, Raid Alrowais, Mahmoud M. Abdel-Daiem, and Noha A. Mostafa. 2025. "Bio-Waste to Bioenergy: Critical Assessment of Sustainable Energy Supply Chain in Egypt" Resources 14, no. 8: 131. https://doi.org/10.3390/resources14080131

APA StyleSaid, N., Alrowais, R., Abdel-Daiem, M. M., & Mostafa, N. A. (2025). Bio-Waste to Bioenergy: Critical Assessment of Sustainable Energy Supply Chain in Egypt. Resources, 14(8), 131. https://doi.org/10.3390/resources14080131