Abstract

The textile industry is progressively shifting towards more sustainable solutions, particularly in the field of printing technologies. This study reports the development and evaluation of water-based pigment inks formulated with bio-based pigments derived from intermediates produced via bacterial fermentation. Two pigments—indigo (blue) and quinacridone (red)—were incorporated into ink formulations and applied on cotton and polyester fabrics through valve-jet inkjet printing (ChromoJet). The physical properties of the inks were analyzed to ensure compatibility with the equipment, and printed fabrics were assessed as to their color fastness to washing, rubbing, artificial weathering, and artificial light. The results highlight the good performance of the bio-based inks, with excellent light and weathering fastness and satisfactory wash and rub resistance. The effect of different pre-treatments, including a biopolymer and a synthetic binder, was also investigated. Notably, the biopolymer pre-treatment enhanced pigment fixation on cotton, while the synthetic binder improved wash fastness on polyester. These findings support the integration of biotechnologically sourced pigments into eco-friendly textile digital printing workflows.

1. Introduction

Textile printing, an ancient technique, has a significant impact on the economies of countries [1]. It traditionally uses thick pastes of synthetic dyes or pigments to create patterns on fabrics. This industry is one of the top manufacturing sectors on this planet and is also considered one of the most polluting ones [2]. Conventional textile printing is associated with high consumption of chemicals such as dyes, binders, solvents, and surfactants, many of which are considered environmentally hazardous. Additionally, traditional processes require substantial water and energy inputs, generating large volumes of effluents loaded with harmful substances [3]. Among these limitations, digital textile printing has emerged as a more sustainable alternative. Recent innovations highlight its advantages, including high precision, excellent print fastness, and the ability to reproduce a vast range of colors [1,4,5]. Integrating advanced software and hardware into digital processes and optimising treatments enables the production of high-quality, customised products with reduced environmental impact [1,3,6,7].

In textile printing, pre-treatment is an important step that prepares the fabric for the application of dyes or pigments, making the surface more receptive and ensuring optimal print results [8]. The specific pre-treatment process can vary depending on the type of fabric and the printing method employed, but typically involves the use of agents such as cationic polymers, thickeners, or biopolymers to enhance ink adhesion and control ink migration. Proper pre-treatment not only improves the fixation of dyes or pigments but also leads to brighter and more vibrant colors in the printed design, as well as sharper image definition and improved color fastness [9].

Water-based inks are gaining attention due to their eco-friendly profile. These inks are less toxic, reduce atmospheric pollution through lower volatile organic compound (VOC) emissions, pose fewer fire risks, and simplify cleaning operations [3,10]. Within this category, pigment-based inkjet inks are especially promising, offering good stability and improved fastness properties, such as wash and light fastness [1,6]. Pigments, unlike dyes, are insoluble molecules that do not form chemical bonds with textile fibres, and they are deposited on the fabric surface. Their dispersion into nanoscale particles is essential to avoid clogging of the printheads and increase print quality. However, the nanoparticle pigment is thermodynamically unstable and can easily re-aggregate due to the desorption of the dispersant [11]. Consequently, the success of pigment ink formulations relies not only on the pigment itself but also on the performance of various auxiliary compounds. These include pH adjusters, humectants, polymeric binders, defoamers, surfactants, biocides, and rheology modifiers, all of which influence ink stability, application, and print quality. Although synthetic pigments currently dominate the market due to their reproducibility, affordability, and wide color range, concerns related to their environmental footprint are increasingly being raised. The production of synthetic dyes and pigments often involves harsh chemicals, high temperatures, and non-renewable resources such as petroleum, raising issues related to waste generation, energy consumption, and toxicity [6,12]. These factors have driven significant research into environmentally friendly and non-toxic alternatives. Natural pigments are especially promising, as they align with consumer preferences and support sustainable development goals [13].

Natural colorants are increasingly valued for their non-toxic, biodegradable, and non-carcinogenic properties, with sources ranging from plants and insects to minerals and microorganisms. However, large-scale plant-based dye production faces challenges such as high costs, long cultivation periods, and batch variability, and can threaten biodiversity by depleting valuable species. As an alternative, microbial pigments—particularly those produced by bacteria—have gained attention due to their rapid growth and independence from seasonal and climatic factors. Bacterial pigment production is further enhanced by the ability to use agro-industrial wastes as substrates, making the process more sustainable and cost-effective. These advantages position bacterial pigments as promising candidates for replacing both synthetic and plant-derived colorants [13,14].

This study focuses on the development and evaluation of water-based pigment inks formulated with bio-based pigments, indigo and quinacridone, produced via bacterial fermentation. By assessing parameters such as physical properties, print quality, and color fastness properties, the study aims to contribute to the advancement in greener digital textile printing technologies.

2. Materials and Methods

2.1. Materials

The textiles used, as examples of natural and synthetic fibres, were two woven fabrics used in the fashion industry, based on cotton (99% cotton and 1% elastane; 370 g/m2; reference TRUE) and polyester (100% polyester; 295 g/m2; reference DORSET), supplied by RIOPELE (Vila Nova de Famalicão, Portugal).

The polymers used in the pre-treatments were a biopolymer based on a cationic polysaccharide (viscosity 600–1200 mPa·s; turbidity ≤ 30 NTU), and a synthetic polymer (Binder A) based on polyurethane (PU) comprising an aliphatic polycarbonate–polyether backbone (non-ionic aqueous dispersion; viscosity < 1.000 mPa·s; density around 1.1 g/cm3; pH value 6.0–8.0).

The pigments used included indigo (blue) and quinacridone (red) pigments in powder form, supplied by PILI (Toulouse, France) and produced via bacterial fermentation using a patented process.

2.2. Methods

2.2.1. Pre-Treatment

An aqueous solution was prepared by diluting Binder A to a concentration of 50% (v/v) with distilled water. In parallel, an acidic solution was prepared with 1% (w/v) of the biopolymer in aqueous acetic acid (0.5 M; pH 4.0–5.0). The textile substrates were pre-treated using foulard impregnation (wet pick-up ~80%) with each solution. Following impregnation, the fabrics were subjected to a drying process at 100 °C for 3–5 min to ensure fixation and the removal of excess moisture.

2.2.2. Ink Formulation

The ink formulation comprises 15–20% biodegradable binder (polyurethane in aqueous dispersion, Achitex Minerva (Vaiano Cremasco, Italy)), 2.5–5.0% crosslinking agent (water based aliphatic blocked polyisocyanate, Covestro (Leverkusen, Germany)), 45.0–65.0% distilled water, 15.0–25.0% hygroscopic agent (alcohol diol, VWR (Radnor, PA, USA)), 3.0–6.0% wetting agents (alcohol alkoxylates, BYK (Wesel, Germany)), 0.5–1.5% anti-foam agent (polyether-modified polydimethylsiloxane, BYK (Wesel, Germany)), and 0.5–1.0% (w/w) pigment (indigo or quinacridone, PILI (Toulouse, France)). All the components were mixed at room temperature using an overhead stirrer.

2.2.3. Characterization

The physical properties of the ink were analyzed as follows: viscosity (smart series rotational viscosimeter by Fungilab(Barcelona, Spain), density (calculated dividing the mass by volume), surface tension (pendant drop method in the optical tensiometer Theta Flex by Biolin Scientific (Gothenburg, Sweden)), particle size (Zetasizer NanoSeries Nano ZS90 by Malvern Panalytical (Malvern, UK).

2.2.4. Printing

The pre-treated and untreated textile fabrics were printed using inkjet printing technology, with a valve-jet printhead (ChromoJet from Zimmer (Kufstein, Austria)). The design was printed at a resolution of 25.4 dpi using a line pressure of 2 atm, a velocity of 0.85 m/s, and a dot spacing of 0.0 point, resulting in fully overlapping dots.

After printing, the samples were dried at 100 °C for 3–5 min, followed by thermofixation at 150 °C for 5 min.

2.2.5. Printing Characterization

The printed fabrics were characterized regarding their color appearance through spectrophotometric analysis using CIELAB coordinates, color fastness to washing (domestic washing at 40 °C, and up to 20 cycles, internal method according to [15]) to artificial light [16], to artificial weathering [17] and to rubbing, dry and wet [18].

3. Results

This study aimed to determine the viability of bio-based pigments as sustainable alternatives to conventional synthetic pigments in digital textile printing. This section presents the experimental results concerning the physical characterization of the inks; printing performance on different substrates; and the evaluation of color fastness under washing, rubbing, and artificial light and weathering exposure. To promote pigment fixation to the textile substrates, two distinct pre-treatment approaches were explored, which are also presented.

3.1. Physical Properties of the Inks

Table 1 summarizes the key physical parameters of the inks formulated with 1.0% indigo and 0.5% quinacridone bio-based pigments.

Table 1.

Properties of the inks developed with indigo and quinacridone pigments in powder form, and requirements of the valve-jet printhead.

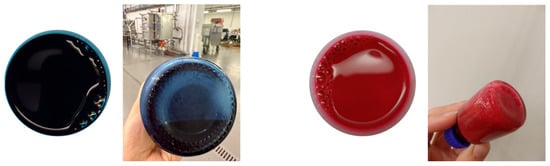

The indigo-based ink showed a viscosity of 5.29 cP and a surface tension of 34.6 mN/m, with particle sizes between 320 and 350 nm. The quinacridone-based ink exhibited slightly higher viscosity (6.81 cP) and lower density (0.93 g/cm3), with particle sizes below 5 µm. Although both inks were considered suitable for use with ChromoJet equipment, the pigment dispersion stability differed significantly between them. The indigo ink showed visible sedimentation and pigment agglomeration after resting. In contrast, the quinacridone ink demonstrated excellent dispersion stability and homogeneity, with no visible signs of sedimentation over time (Figure 1).

Figure 1.

Inks made with 1.0% indigo pigment (left) and 0.5% quinacridone pigment (right) in powder form and their respective deposits.

3.2. Printability and Fabric Interaction

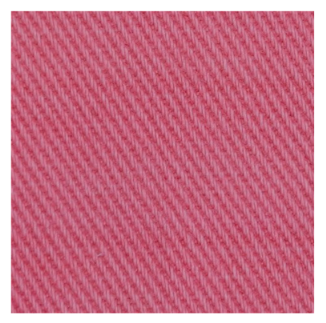

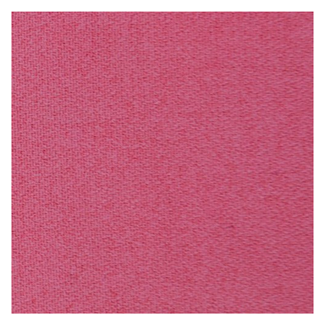

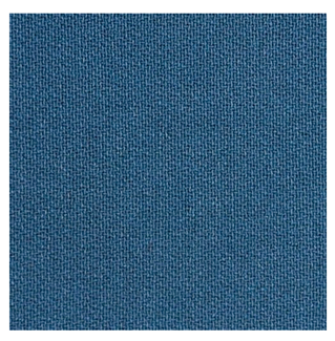

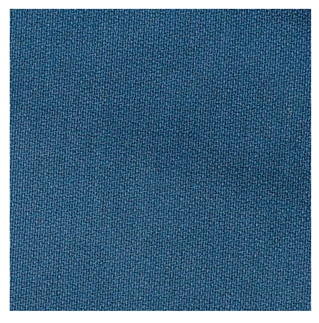

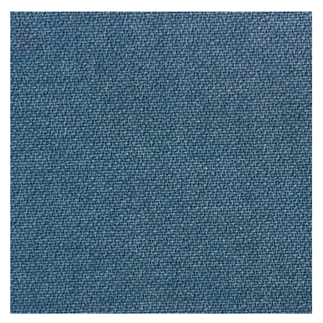

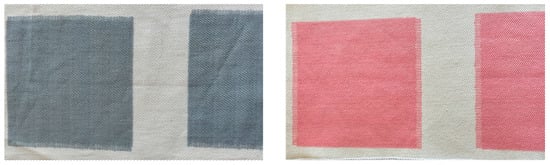

Printing trials were conducted on untreated and pre-treated cotton and polyester fabrics. Figure 2 shows examples of the printed samples.

Figure 2.

Cotton samples printed with inks containing 1.0% indigo pigment (left) and 0.5% quinacridone pigment (right).

Table 2 shows photographs of each printed sample, demonstrating that color intensity and uniformity are significantly influenced by both the type of substrate and the pre-treatment applied. These visual observations are corroborated by the CIELAB color coordinates reported in Table 3. The color coordinates were not determined for the indigo samples without pre-treatment, as these samples exhibited non-uniform printing.

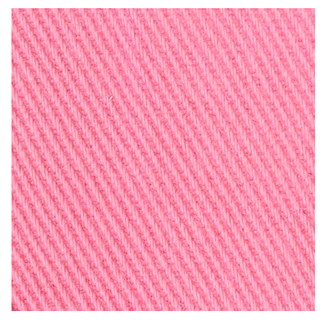

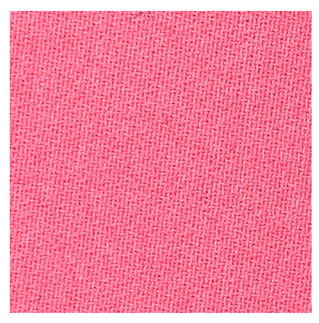

Table 2.

Textile samples with different pre-treatments, printed with inks containing 1.0% indigo and 0.5% quinacridone pigments.

Table 3.

Color coordinates of inkjet-printed samples with indigo and quinacridone inks.

For the indigo ink, the lightness (L*) values indicate that cotton treated with biopolymer (L* = 53.40) produces a print slightly lighter than when treated with Binder A (L* = 50.12), which may suggest a less dense pigment deposition with the biopolymer pre-treatment. On polyester, however, the L* values are very similar between biopolymer (L* = 50.06) and Binder A (L* = 51.97), and the closeness of these values does not allow for any reliable conclusion regarding brightness differences. Regarding the a* coordinate, which represents the red–green axis, all the indigo samples exhibit negative values, indicating a greenish tone. The green component appears more pronounced on polyester (a* = −4.99 for biopolymer; −4.84 for Binder A) than on cotton (a* = −2.56 and −1.87, respectively). Nevertheless, given the small differences between treatments, especially on polyester, it is not possible to affirm a significant variation in the intensity of the green hue. The b* values, corresponding to the yellow-blue axis, are negative for all the indigo samples, denoting a blue hue. On polyester, the biopolymer-treated fabric shows a distinctly stronger blue component (b* = −10.59) compared to Binder A (b* = −5.95), suggesting that biopolymer may enhance blue saturation. On cotton, the difference is less pronounced (b* = −6.99 for biopolymer vs. −5.27 for Binder A), and although a tendency for increased blue intensity is observed with biopolymer, the proximity of the values limits the certainty of this observation.

In contrast, the quinacridone pigment displays a distinctly different chromatic profile. The lightness values are higher across all the samples compared to indigo, indicative of lighter color shades. On cotton, the untreated sample presents the highest L* value (L* = 72.18), with biopolymer (L* = 70.29) and Binder A (L* = 71.65) causing a slight reduction. However, the narrow range among these values hinders definitive conclusions about the impact of the treatment on brightness. A similar pattern is observed on polyester, with L* values ranging from 67.94 (untreated) to 68.55 (biopolymer), again suggesting comparable lightness levels. The a* values for quinacridone are strongly positive in all the cases, confirming a vivid red hue. On cotton, biopolymer treatment yields the highest red intensity (a* = 26.90), followed by Binder A (a* = 23.56) and untreated fabric (a* = 22.49), indicating a possible enhancement of the red component by the biopolymer. On polyester, the a* values are slightly higher overall, with biopolymer again leading (a* = 29.37), followed by untreated (a* = 28.27) and Binder A (a* = 26.66). Nonetheless, the differences across the treatments are relatively modest and should be interpreted with caution, as they may not represent significant perceptual differences. Finally, the b* values for quinacridone are positive and relatively low (ranging from 3.06 to 4.70), suggesting a subtle yellowish hue accompanying the dominant red. Although Binder A generally results in slightly higher b* values, which may indicate a marginally warmer tone, the limited variation does not allow for strong conclusions regarding treatment influence on the yellow component.

3.3. Printing Characterization Results

Color fastness tests were conducted following standardized methods to evaluate the performance of the printed fabrics.

3.3.1. Indigo Pigment

The results of the fastness tests carried out on the samples printed with indigo ink are shown in Table 4.

Table 4.

Color fastness properties of inkjet-printed samples with indigo ink (grayscale evaluation).

For the indigo-based ink, the wash fastness results on cotton ranged from grade 3 (untreated and Binder A) to 3–4 (biopolymer-treated), with a gradual decline in performance after 10 to 20 cycles. The polyester pre-treated with Binder A showed better resistance to washing, with a rating of 4–5 up to 5 cycles and a rating of 4 up to 10 cycles. In rubbing tests, both cotton and polyester achieved good dry rubbing resistance (grade 4–5), while wet rubbing results were slightly lower (grade 3–4). Light fastness was performed only in one sample to assess the performance of the pigment, and the result was acceptable for most textile applications (3–4), while the color fastness to weathering gave slightly better results (4), indicating the good behavior of this pigment/ink even under high humidity conditions.

Table 5 presents photographs of the cotton and polyester samples printed with indigo pigment inks and pre-treated with the different treatments, after the washing cycles.

Table 5.

Results of color fastness tests to washing on samples printed with 1.0% indigo ink.

3.3.2. Quinacridone Pigment

The results of the fastness tests carried out on the samples printed with the quinacridone ink are shown in Table 6.

Table 6.

Color fastness properties of inkjet-printed samples with quinacridone ink (grayscale evaluation).

The quinacridone ink exhibited excellent color fastness to weathering across all the pre-treatments used, consistently achieving ratings exceeding five. In terms of wash fastness, the cotton samples demonstrated superior resistance, maintaining ratings of 5 to 4–5 for up to 10 washing cycles, with a slight reduction to 3–4 after 20 cycles. Rubbing fastness values, under both dry and wet conditions, followed a comparable trend. Among the cotton substrates, the untreated samples exhibited enhanced pigment fixation and superior fastness performance.

For polyester substrates, the overall wash fastness performance was also high, with ratings ranging from 5 to 4 up to 10 washing cycles. The samples treated with Binder A exhibited the highest fastness values in both washing and rubbing tests. In contrast, the untreated samples showed better wash fastness but lower wet rubbing resistance. Meanwhile, the samples pre-treated with biopolymer showed a slight decline in wash fastness, suggesting that Binder A may be the most effective auxiliary to improve durability.

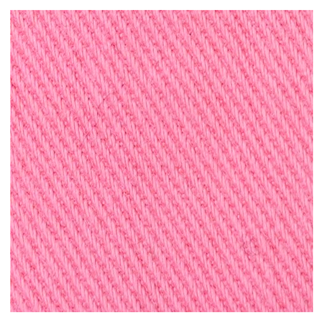

Table 7 presents photographs of the cotton and polyester samples printed with quinacridone pigment inks and pre-treated with the different treatments after the washing cycles.

Table 7.

Results of color fastness tests to washing on samples printed with 0.5% quinacridone ink.

4. Discussion

The development of water-based pigment inks using bio-based pigments derived from bacterial fermentation presents a promising step towards sustainable digital textile printing. The results of this study confirmed the viability of incorporating such pigments in powder form directly in inkjet formulations, particularly when applied through valve-jet technology (ChromoJet), which is typically more tolerant to pigment particle sizes than piezoelectric print heads.

Regarding ink stability and formulation, the indigo-based ink demonstrated some limitations in terms of dispersion stability. Indigo pigment, whether produced microbially or synthetically, consists of two indole-derived rings linked via a double bond, forming a planar, conjugated structure responsible for its deep blue color [19]. This pigment is sensitive to redox equilibria, which can affect dispersion stability, as the pigment, for dyeing processes, must be reduced to its water-soluble leuco form and then oxidized back to its insoluble state [20,21]. Its structure confers stability to form supramolecular aggregates with intra- and intermolecular hydrogen bonds and π-conjugation [22], which in this work was reflected by its relatively large particle size (320–350 nm) and crystalline aggregation tendency, which, in turn, contributed to limited dispersion homogeneity in aqueous medium [23]. After standing, noticeable sedimentation of the pigment in the ink was observed, indicating the need for further formulation optimization, either to increase the shelf-life of the ink or to use it in other printhead technologies, such as the piezoelectric. This could be achieved possibly through the incorporation of additional dispersing agents or the use of milling techniques to reduce particle size and prevent agglomeration.

In contrast, the quinacridone-based ink showed excellent dispersion and did not exhibit sedimentation, highlighting its superior compatibility with our aqueous inkjet systems. Despite the pigment’s linear, planar, and highly conjugated aromatic structure, which enables strong intermolecular hydrogen bonding and π–π stacking, leading to a dense crystal packing, which reflects in its insolubility in water and most organic solvents, and increased propensity to aggregate, in our ink no sedimentation, i.e., no large aggregates, was observed after standing, suggesting that the combination of dispersants and wetting agents used in the ink have successfully avoided quinacridone aggregation, overcoming a reported challenge with this pigment [24].

The results clearly show that the fabric pre-treatment significantly influences print quality and fastness properties. Indigo pigment tends to produce darker, cooler shades with a distinct blue-green hue, which is intensified by biopolymer pre-treatment, especially on polyester. Quinacridone pigment results in lighter, warmer red shades, with biopolymer pre-treatment enhancing red chroma on both cotton and polyester.

In terms of color fastness, both inks performed exceptionally well. The quinacridone ink showed outstanding weathering fastness (grade >5). This superior fastness can be attributed to the highly stable crystal lattice structure of quinacridone, which imparts remarkable chemical resistance as well as outstanding thermal and photostability. As a result, the pigment maintains its integrity under elevated processing temperatures and prolonged light exposure, exhibiting minimal degradation [25,26]. The indigo ink also achieved good light and weathering fastness (grades 3–4 and 4), suggesting potential for some applications.

In summary, the biopolymer pre-treatment, based on a polysaccharide, significantly improved pigment fixation on cotton substrates, likely due to enhanced electrostatic interactions and film formation at the fibre surface. This resulted in higher color intensity and improved wash and rub fastness. In contrast, Binder A was more effective on polyester, providing superior wash durability, which can be attributed to its film-forming properties and higher compatibility with hydrophobic fibres.

These results were within acceptable industrial ranges, particularly for fashion applications, and improved with the use of appropriate pre-treatments. While the indigo ink requires further formulation refinement to enhance stability and performance consistency, the quinacridone ink already meets key performance indicators for textile printing.

5. Conclusions

This work demonstrates the successful formulation and application of water-based digital inks using bio-based pigments produced through bacterial fermentation. The inks were effectively applied to cotton and polyester fabrics using valve-jet technology and evaluated for color fastness to washing, rubbing, and artificial light and weathering.

The quinacridone ink showed excellent dispersion and overall superior performance, particularly in weathering fastness and uniformity of the printed fabrics. The indigo ink, while slightly less stable, also achieved good results, especially in polyester fabrics pre-treated with a synthetic binder.

The pre-treatment played a pivotal role in optimizing pigment–substrate interactions. Biopolymer treatments improved wash fastness and color intensity on cotton fabrics, while the polyurethane-based binder enhanced performance on polyester, particularly for indigo. These findings underscore the critical role of substrate-specific pre-treatment in ensuring successful pigment fixation and durability.

While the study confirms the technical feasibility of incorporating bio-based pigments into digital textile inks, some limitations remain. The indigo pigment exhibited dispersion instability and sedimentation over time, indicating the need for improved formulation strategies—such as fine milling or the use of high-performance dispersants. Moreover, the evaluation was limited to valve-jet technology; future studies should investigate the compatibility of these inks with other inkjet systems. Another key aspect study in future work would be the biodegradability of these inks after application.

From an economic perspective, the use of bio-based pigments introduces both opportunities and challenges. On one hand, microbial fermentation offers the potential for scalable, renewable pigment production using low-cost substrates, including agro-industrial waste streams. On the other hand, the current market cost of bio-based pigments remains higher than their synthetic counterparts due to limitations in production yields, downstream processing, and regulatory approvals. However, as biotechnological platforms mature and the demand for sustainable materials increases, the economic feasibility is expected to improve—especially when factoring in long-term environmental and regulatory benefits.

Overall, these findings contribute to the bioeconomy by demonstrating the direct application of bacterial-derived indigo and quinacridone pigments in water-based inkjet formulations using valve-jet technology. It provides comprehensive insight into how pigment chemistry, ink formulation, and fabric pre-treatment synergistically influence print performance and durability. Moreover, by integrating bio-based colorants with bio-based auxiliaries (e.g., biopolymer pre-treatment), the research advances a holistic approach towards sustainable digital textile printing. These findings set the stage for further innovation in pigment biotechnology and eco-friendly surface design in the textile industry.

Author Contributions

Conceptualization, J.A. and H.V.; methodology, J.A., M.L. and B.M.; investigation, J.A., M.L., B.M. and A.S.; writing—original draft preparation, J.A., M.L. and B.M.; writing—review and editing, H.V.; supervision, A.S. and C.J.S.; project administration, H.V. and C.J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was carried out under the Waste2BioComp project—Converting organic waste into sustainable bio-based components, GA 101058654, funded under the topic HORIZON-CL4-2021-TWIN-TRANSITION-01-05 of the Horizon Europe 2021–2027 program.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ragab, M.M.; Othman, H.A.; Hassabo, A.G. An Overview of Printing Textile Techniques. Egypt. J. Chem. 2022, 65, 749–761. [Google Scholar] [CrossRef]

- De Felice, F.; Fareed, A.G.; Zahid, A.; Nenni, M.E.; Petrillo, A. Circular Economy Practices in the Textile Industry for Sustainable Future: A Systematic Literature Review. J. Clean. Prod. 2025, 486, 144547. [Google Scholar] [CrossRef]

- Tkalec, M.; Glogar, M.I.; Sutlovic, A. Ecological sustainability of digital textile printing. In Economic and Social Development; Baracskai, Z., Katanec, I.B., Hublin, T., Eds.; ProQuest: Ann Arbor, MI, USA, 2022; pp. 105–115. [Google Scholar]

- Vodyashkin, A.A.; Makeev, M.O.; Mikhalev, P.A. Inkjet Printing Is a Promising Method of Dyeing Polymer Textile Materials. Polymers 2025, 17, 756. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Zhendong, W.; Chuanxiong, Z.; Ruobai, X.; Wenliang, X. A Study on the Applicability of Pigment Digital Printing on Cotton Fabrics. Text. Res. J. 2021, 91, 2283–2293. [Google Scholar] [CrossRef]

- Hassabo, A.; Abd El-Salam, N.; Mohamed, N.; Gouda, N.; Khaleed, N.; Shaker, S.; Abd El-Aziz, E. Naturally Extracted Inks for Digital Printing of Natural Fabrics. J. Text. Color. Polym. Sci. 2024, 21, 109–119. [Google Scholar] [CrossRef]

- Cao, T.; Yang, Z.; Zhang, H.; Wang, Y. Inkjet Printing Quality Improvement Research Progress: A Review. Heliyon 2024, 10, e30163. [Google Scholar] [CrossRef] [PubMed]

- Repon, R.; Islam, T.; Paul, T.K.; Jurkonienė, S.; Haji, A.; Shukhratov, S.; Toki, G.F.I. Natural Dyes in Textile Printing: Parameters, Methods, and Performance. Environ. Sci. Pollut. Res. 2024, 31, 47552–47583. [Google Scholar] [CrossRef] [PubMed]

- Biswas, T.; Yu, J.; Nierstrasz, V. Effective Pretreatment Routes of Polyethylene Terephthalate Fabric for Digital Inkjet Printing of Enzyme. Adv. Mater. Interfaces 2021, 8, 2001882. [Google Scholar] [CrossRef]

- Yeo, Y.; Shin, Y. Inkjet Printing of Textiles Using Biodegradable Natural Dyes. Fibers Polym. 2023, 24, 1695–1705. [Google Scholar] [CrossRef]

- Nagose, S.; Rose, E.; Joshi, A. Study on Wetting and Dispersion of the Pigment Yellow 110. Prog. Org. Coat. 2019, 133, 55–60. [Google Scholar] [CrossRef]

- Tawiah, B.; Howard, E.K.; Asinyo, B.K. The Chemistry of Inkjet Inks for Digital Textile Printing-Review. BEST J. 2016, 4, 61–78. [Google Scholar]

- Huang, X.; Gan, L.; He, Z.; Jiang, G.; He, T. Bacterial Pigments as a Promising Alternative to Synthetic Colorants: From Fundamentals to Applications. J. Microbiol. Biotechnol. 2024, 34, 2153–2165. [Google Scholar] [CrossRef] [PubMed]

- Venil, C.K.; Zakaria, Z.A.; Ahmad, W.A. Bacterial Pigments and Their Applications. Process Biochem. 2013, 48, 1065–1079. [Google Scholar] [CrossRef]

- ISO 105-C06:2010; Textiles—Tests for Colour Fastness—Part C06: Colour Fastness to Domestic and Commercial Laundering. International Organization for Standardization: Geneva, Switzerland, 2010.

- ISO 105-B02:2014; Textiles—Tests for Colour Fastness—Part B02: Colour Fastness to Artificial Light: Xenon arc Fading Lamp Test. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 105-B04:2024; Textiles—Tests for Colour Fastness—Part B04: Colour Fastness to Artificial Weathering: Xenon arc Fading Lamp Test. International Organization for Standardization: Geneva, Switzerland, 2024.

- ISO 105-X12:2016; Textiles—Tests for Colour Fastness—Part X12: Colour Fastness to Rubbing. International Organization for Standardization: Geneva, Switzerland, 2016.

- Volkov, V.V.; Chelli, R.; Righini, R.; Perry, C.C. Indigo Chromophores and Pigments: Structure and Dynamics. Dye. Pigment. 2020, 172, 107761. [Google Scholar] [CrossRef]

- Harriman, A. A Perspective on Indigo: An Iconic Colorant. Colorants 2025, 4, 12. [Google Scholar] [CrossRef]

- Lohtander, T.; Durandin, N.; Laaksonen, T.; Arola, S.; Laaksonen, P. Stabilization of Natural and Synthetic Indigo on Nanocellulose Network—Towards Bioactive Materials and Facile Dyeing Processes. J. Clean. Prod. 2021, 328, 129615. [Google Scholar] [CrossRef]

- Bützer, P.; Brühwiler, D.; Bützer, M.R.; Al-Godari, N.; Cadalbert, M.; Giger, M.; Schär, S. Indigo—A New Tribological Substance Class for Non-Toxic and Ecological Gliding Surfaces on Ice, Snow, and Water. Materials 2022, 15, 883. [Google Scholar] [CrossRef] [PubMed]

- Behary, N.; Volle, N. Durable Textile Dyeing/Printing Using Natural Indigo Dyes and Leaves, and Mayan-Inspired Blue Indigo Pigments. Colorants 2025, 4, 2. [Google Scholar] [CrossRef]

- Saito, Y.; Iwamoto, S.; Tanaka, Y.; Hontama, N.; Endo, T. Suppressing Aggregation of Quinacridone Pigment and Improving Its Color Strength by Using Chitosan Nanofibers. Carbohydr. Polym. 2021, 255, 117365. [Google Scholar] [CrossRef] [PubMed]

- Herbst, W.; Hunger, K.; Wilker, G.; Ohleier, H.; Winter, R. Industrial Organic Pigments: Production, Properties, Applications, 3rd ed.; Wiley-VCH: Weinheim, Germany, 2004. [Google Scholar] [CrossRef]

- Hunger, K. (Ed.) Industrial Dyes: Chemistry, Properties, Applications; Wiley-VCH: Weinheim, Germany, 2002. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).