Abstract

The ceramic pastes of ca. 31 samples recovered from the Almaraz archaeological site, located in the south bench of Tagus River, were studied in detail using XRF, micro-Raman and GSDR spectroscopies, as well as the XRD technique. The ceramic sherds could be grouped into six categories, red slip tableware, decorated tableware, yellow slip tableware, grey tableware, common tableware, and handmade pottery. Our studies of the mineralogic composition of the sherds’ body indicate all ceramics were produced locally, using siliceous clays in most cases and calcareous clays in a few ones. Micro-Raman and ground state diffuse reflectance absorption spectroscopy provided useful information regarding the materials used to produce the coloured ceramics: hematite and brookite for the red slip and decorated ceramics, jacobsite or carbon black for the black decoration or grey ceramics. For the yellow slip tableware, a simple engobe rich in yellow clay was used. XRF spectroscopic studies provided the elemental composition of all samples, and biplots of the potassium (K) versus calcium (Ca) contents, normalized to the silicon content of each ceramic paste, clearly show Pliocene and Miocene local clays sources were used to produce most ceramics. Only one sherd can be considered a Lisbon production.

1. Introduction

The first millennium BC marks a moment of significant cultural and socio-economic changes that ultimately led to the emergence of early forms of urban life in the Tagus Estuary [1]. Our understanding of this period has seen notable progress in recent years, allowing us to expand our comprehension of the profound transformations that followed the arrival of Phoenician populations in the region in the 8th century BC, according to conventional chronology [2,3]. In the context of the arrival of these exogenous groups, a new regional reality took shape, leading to a series of changes in material culture and productive practices that to be well consolidated by the 7th century BC. Several factors illustrate this situation, including the development of wheel-pottery production in the Lower Tagus, which emerged between the 8th century and the early 7th century BC and witnessed a progressive intensification and diversification throughout the Iron Age [4].

The advent of the potter’s wheel, coupled with advanced kilns that ensured precise temperature control and predominantly oxidizing firing atmospheres, led to a significant upswing in ceramic production [5]. In contrast to preceding moments, the focus of production shifted towards commercialization, primarily at a regional level, although supra-regional trade was also practiced. Furthermore, the new technologies allowed the development of a wide range of formal styles and unprecedented aesthetic finishes. The new ceramic corpus, which includes storage containers, transport vessels, tableware, and everyday ceramics, exhibits a notable degree of standardization and consistency, spanning the entire southern region of the Iberian Peninsula [6].

Nevertheless, concrete evidence regarding production contexts in the Tagus Estuary is currently limited and, as of now, no identifiable production center has been pinpointed. A few isolated structures possibly linked to a low-scale ceramic production were, however, already identified, namely the Miroiço kiln in the Cascais area [7] and the Rua dos Correeiros structure, in the central area of Lisbon [4]. In addition to these elements, the presence of objects referred to as “ceramic prisms” suggests the existence of additional production areas along the Tagus Estuary. These artifacts, designed for tasks related to the drying and firing phases—specifically, stabilizing and separating ceramic objects—are well-documented in the Tagus Estuary. Examples include findings at Quinta da Marquesa II in Vila-Franca de Xira [8] and, precisely, in Almaraz.

Given the limited number of data available, analytical approaches, especially those rooted in systematic studies of ceramic assemblages, become particularly important for characterizing ceramic production [9]. These approaches enable the identification of the origins of the ceramics and the reconstruction of various aspects of production, such as raw material selection, treatment methods, composition of surface decorations, and firing temperature, which contribute to a deeper understanding of the technical developments associated with this period.

Previous compositional studies of pottery ceramic pastes, clay raw materials, and firing experiments enabled us to establish a limited number of clay sources and formulations for the Phoenician potteries found at S. Jorge Castle and amphorae from the Almaraz archaeological site [10,11,12,13]. Pliocene ceramic pastes (highly siliceous) or Miocene ceramic pastes (with a high content of calcium carbonate) were detected. Potters settled preferentially in areas with clayey soils. We could corroborate the identification of the sources of clay with the presence of nearby archaeological finds.

One should emphasize in the Lisbon region, Miocene clays can be found in the North and South of the Tagus River, while Pliocene clays only exist on the South bank [12,13,14,15].

The systematic study of the ceramic assemblage from the Quinta do Almaraz archaeological site, conducted as part of a multi-annual research project, has yielded analytic data that provide further insights into the characterization of this local and regional ceramic production. It is precisely these new data that will now be presented in detail.

2. Archaeological Context and Framework

The settlement of Quinta do Almaraz is located in a long spur on the left bank of the Tagus mouth, opposite Lisbon. Discovered in 1986, the site saw an initial phase of archaeological research conducted until 2001 [16]. This was followed by a period of limited research activity, which was only resumed with the start of the project named Proj.In.QA, in 2020.

The assortment of artifacts recovered through the excavations distinctly emphasizes the Phoenician cultural imprint on the site. This influence is evident through the presence of characteristic ceramic types from this period, such as red slip and grey ware, pithoi, Cruz del Negro type urns, and amphorae. Furthermore, the architectural features provide additional validation of this influence, manifesting in the layout of domestic structures, construction techniques, and the defensive system, all exhibiting a visible Mediterranean influence [17].

Almaraz played a crucial role in the economic and commercial framework of the Tagus Estuary, a reality that is substantiated by a notable collection of imported artifacts such as the Egyptian scarab, alabaster vases, ivory plaques, and Middle Corinthian ceramic fragments [18,19], as well as by the set of lead weights, some of which are affiliated with the oriental measurement system [20]. Moreover, evidence strongly suggests the settlement served as an important center for metallurgical production [21], which along with other production activities indicated by a diverse range of artifacts such as pottery, weaving, and fishing implements, underscores the economic importance of the settlement during the Iron Age [17].

Based on the available data, it is evident the settlement of Almaraz came into existence between the latter part of the 8th century BC and the early 7th century BC, experiencing a significant phase of growth around the 6th century BC. However, this scenario underwent a shift at some point during the 5th century BC, marked by a progressive decline in the settlement’s vitality. This transition was reflected in various ways, including the deactivation of the defensive structure and the abandonment of the residential area adjacent to the river [22].

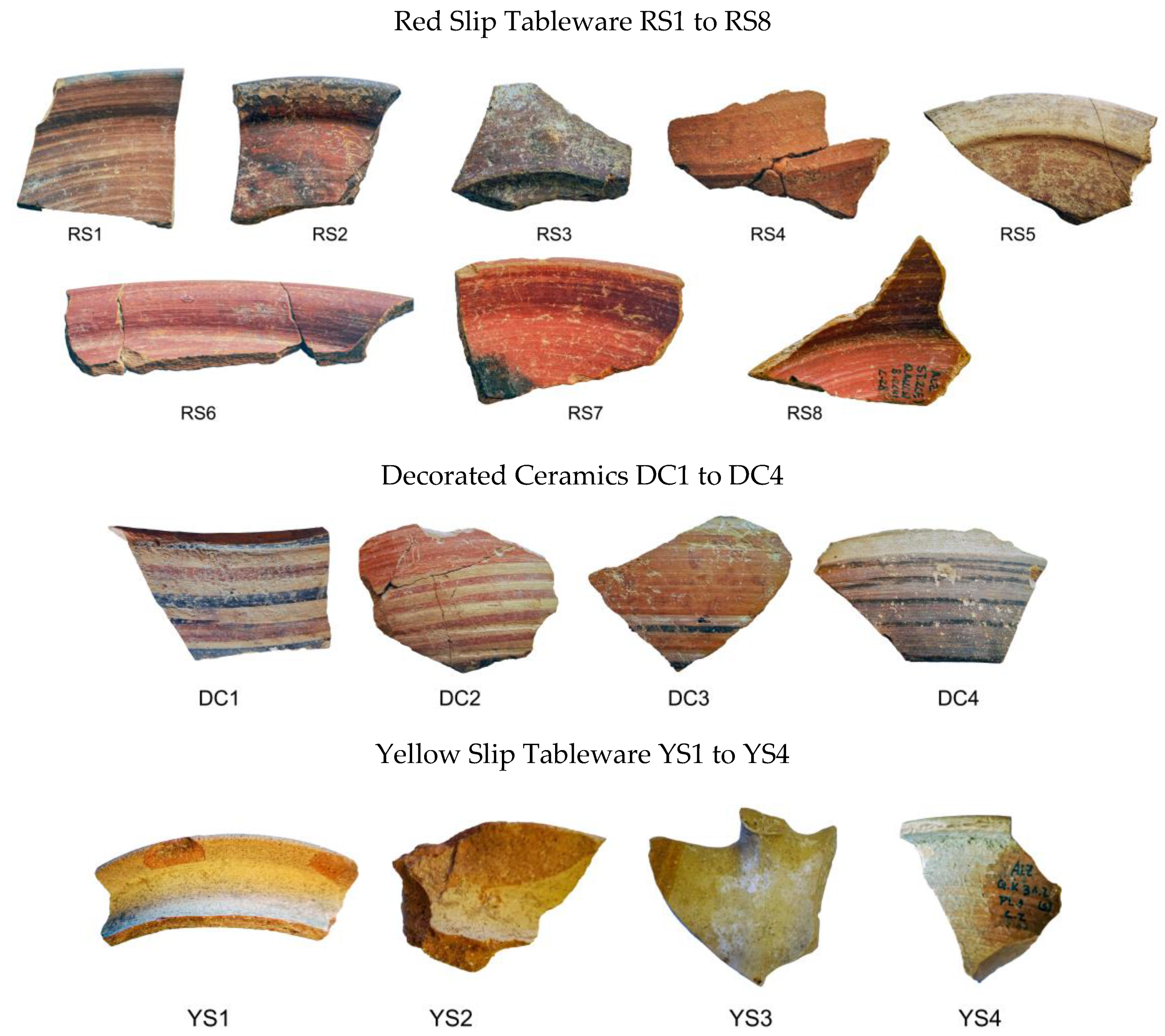

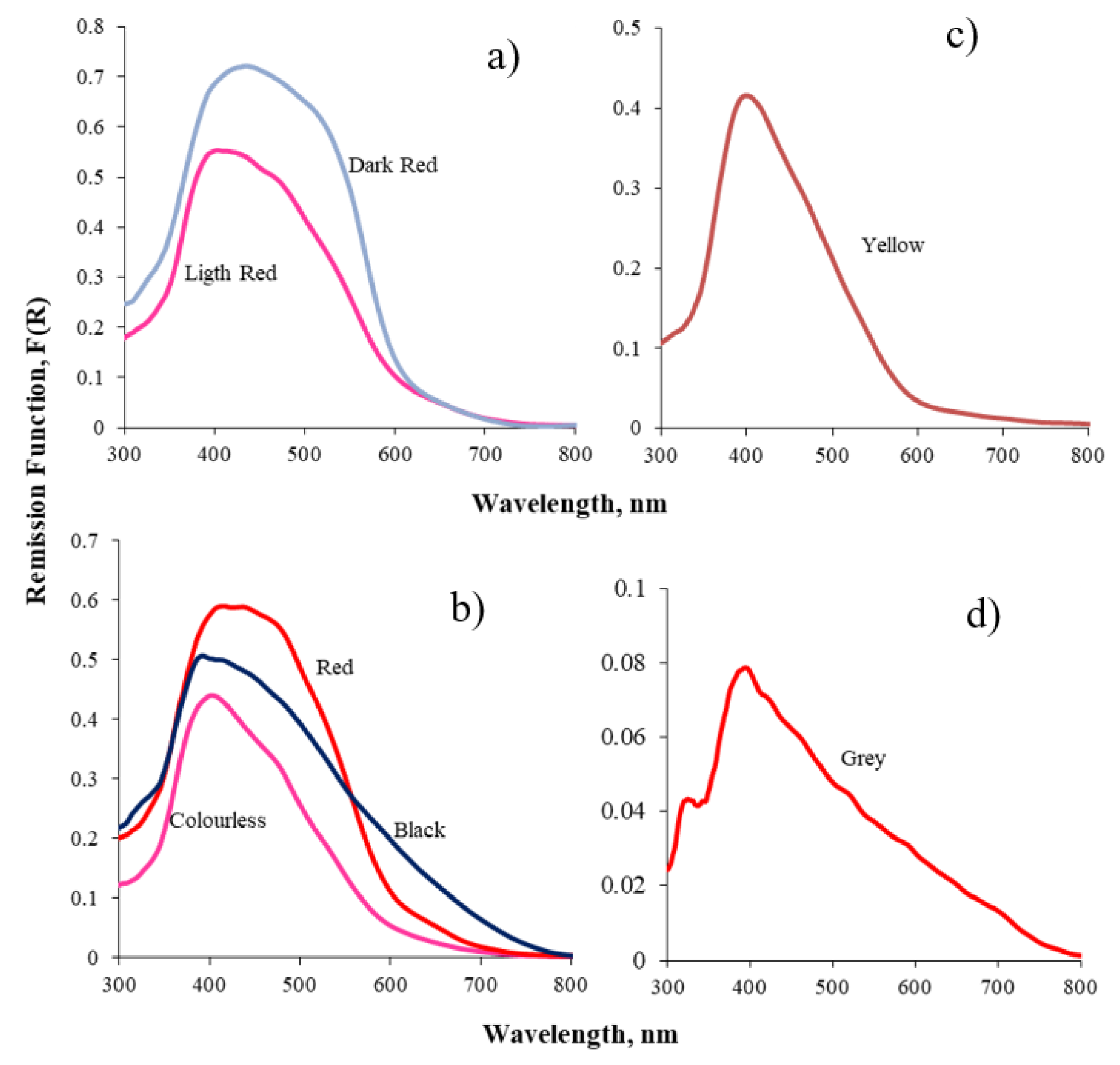

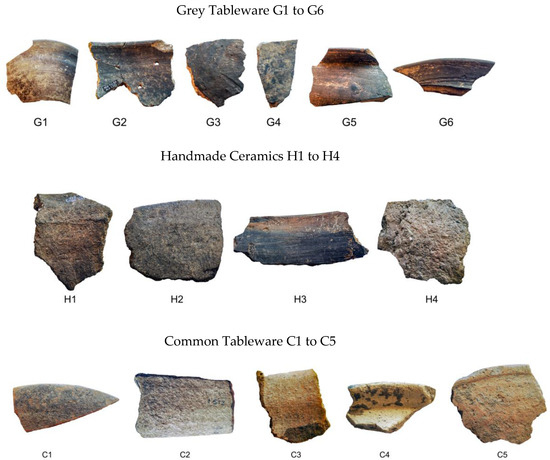

Until recently, most of the ceramic assemblage of Almaraz remained unknown, with only the amphorae having undergone a complete and comprehensive study [23], which was further subjected to an archaeometric approach [12]. However, within the scope of the new research project, it was possible to conduct a detailed study and categorization of the entire ceramic assemblage, which included common ware, red slip ware, painted ware, grey ware, and handmade pottery. It is precisely these ceramic categories that form the focus of the archaeometric analyses presented in this paper in Figure 1.

Figure 1.

Phoenician ceramic sherds collected from the Almaraz archaeological site.

3. The Ceramic Samples—Selection Methodology

The selection process began with a comprehensive macroscopic analysis of the various ceramic categories identified in Almaraz. The goal was to delineate the productive and technical diversity inherent to each category and subsequently propose preliminary Manufacturing Groups (MG).

To this end, we applied a set of criteria established within the realm of ceramic studies for the macroscopic characterization of MGs [24,25]. These criteria encompassed factors such as the nature of the clay material, the color of both the external and interior surface, the appearance of the production in terms of hardness and texture, the frequency of inclusions, the presence of voids and cracks, as well as the firing technique.

These first observations led us to the identification of eight MGs for red slip ware, four MGs for painted pottery, four MGs for yellow slip pottery, six MGs for grey ware, four MGs, five MGs for common ware, and for handmade pottery. From these groups, specific samples from different contexts were chosen for the current analysis. Additionally, samples of coating techniques, specifically red slip and yellow slip engobe surfaces, were also subjected to archaeometric analysis.

4. Experimental Techniques under Use

The X-ray diffraction (XRD) analyses were conducted utilizing a Panalytical X’ PERT PRO diffractometer system equipped with a copper source. This method furnishes essential insights into the mineralogical and phase composition of the ceramic body of the sherds or raw materials. Micro-Raman investigations were carried out employing a Renishaw InVia Confocal Raman equipment in a backscattering configuration, using a 532 nm laser excitation. These spectra provide both complementary information and confirmation of the mineralogical composition provided by the XRD data. For elemental composition on the studied pastes, X-ray fluorescence (XRF) analyses were performed using a Niton XL3T GOLDD spectrometer from Thermo Scientific. Ground state diffuse reflectance absorption spectra spectroscopy (GSDR) experiments were conducted employing a custom-built diffuse reflectance setup, incorporating three standards: Spectralon white and grey disks, and barium sulfate powder. Data treatment starts with the calculation of the reflectance versus wavelength, followed by the calculation of the remission function, which is a function of the concentration of the absorbing species. This technique provides spectral information regarding the absorption bands in the UV and Visible region that correlates with the coloured surfaces.

Further details regarding all these techniques were described in previous publications [10,11,12,13].

5. Results and Discussion

5.1. XRD Studies

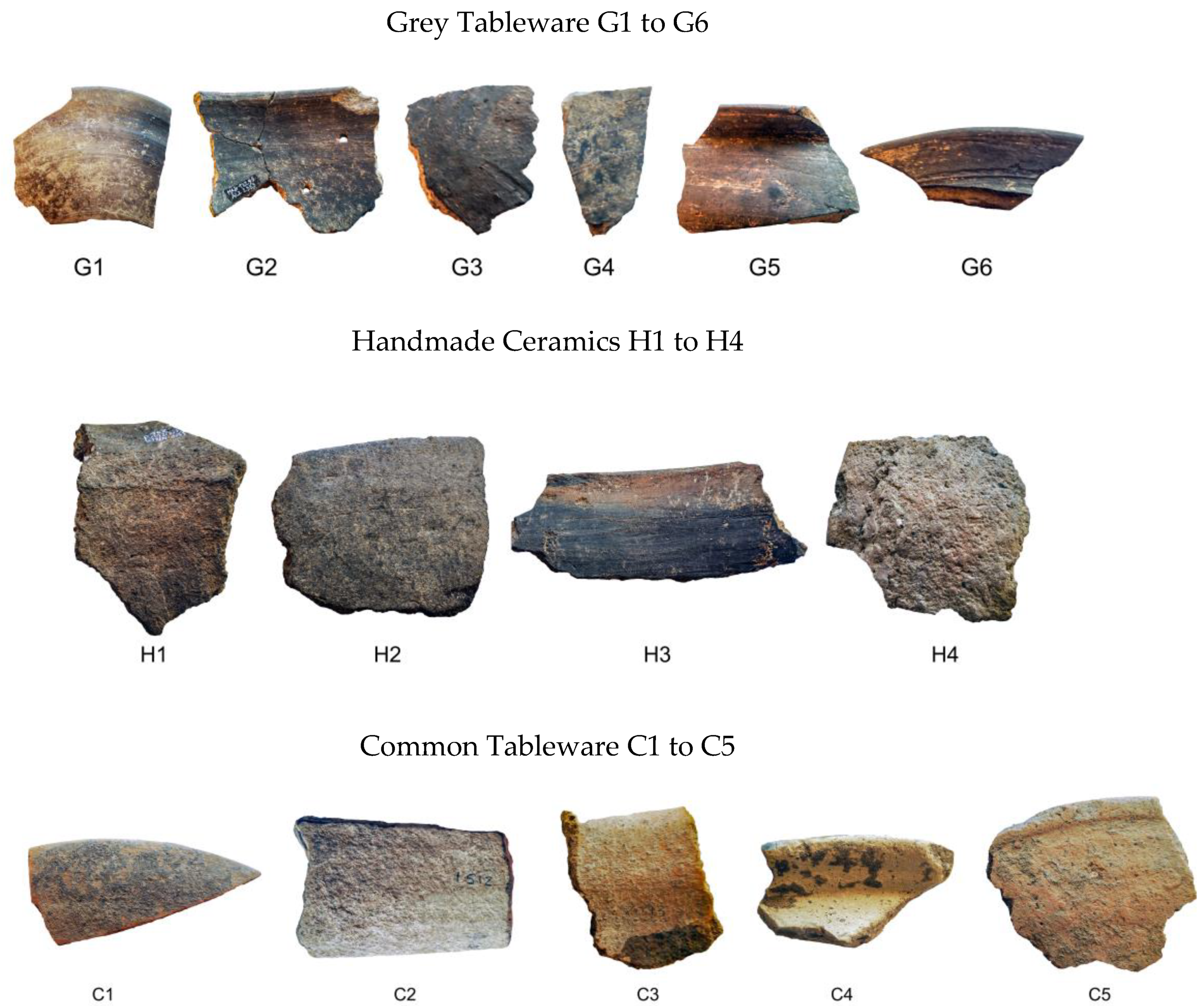

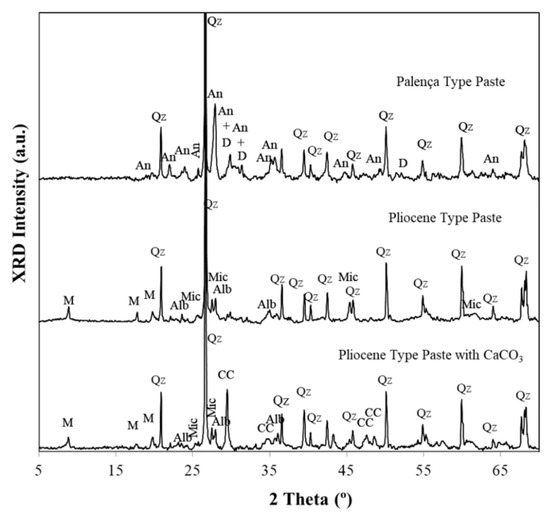

Ceramic bodies of the pottery recovered from the Almaraz archaeological site were grouped into two main types (Figure 2). XRD diffractograms enabled us to establish the main characteristics of each type. The main XRD peaks observed for each sample are presented in Table 1.

Figure 2.

Representative XRD patterns for ceramic bodies of sherds from the Almaraz archaeological site: Palença (Miocene) and Pliocene type pastes. XRD peaks: Quartz (Qz), anorthite (An), diopside (D), illite (I) or muscovite (M), albite (Alb), calcite (CC) and microcline (Mic). (All diffractograms were normalized to the quartz peak at 2θ = 21.0 (constant intensity), to allow comparisons of the relative amounts of all the other minerals).

Table 1.

XRD main peaks used to identify the minerals in the diffractograms of all ceramic bodies.

The Pliocene type pastes exhibit quartz (Q), albite (Alb)—a sodium alumino silicate and microcline (Mic)—a potassium alumino silicate, (see Figure 2), consistent with the use of high siliceous Pliocene clays as raw materials. Muscovite (M) was also detected, but muscovite and illite diffractograms were indistinguishable. Nowadays, it is still possible to collect the Pliocene clays in the surrounding areas of Almaraz. The presence of muscovite in the ceramic body shows the firing temperatures inside the kiln did not exceed 850 °C, because above that value all muscovite (or illite) becomes unstable [10,11,12].

The third diffractogram in Figure 2 exhibits a considerable amount of calcium carbonate. Again, it is possible to collect some clays in the left margin of the Tagus River that exhibit a Pliocene pattern but also include a large amount of calcium carbonate (calcite). Despite being less typical, these clays exhibit a Pliocene XRD pattern.

Very similar diffractograms were obtained in a previous study of red slip ware from the archaeological site of São Jorge Caste (samples R1 to R5 in the paper ref. [10]. This means most probably the workshops that produced this Phoenician pottery were located at Almaraz, since these Pliocene clays did not exist in the right margin of the Tagus River. No traces of kilns were found at Almaraz thus far, but some trivets of triangular section were recovered from local pits, pointing to the existence of local workshops with kilns at Almaraz.

Palença type pastes were produced with clays of Miocene origin from sources located in the left margin of the Tagus River. These ceramic bodies have complex diffractograms, as Figure 2 shows. Quartz is the major mineral component, and anorthite (An), a calcium alumino silicate, is the second major component and appears as a typical fingerprint of the Palença ceramic bodies. The absence of calcite (CC) and the presence of Diopside (D), a calcium and magnesium silicate, implies Tf ≥ 850 °C [10,26]. Diopside formation implies the existence of magnesium in the raw materials. Anorthite’s formation needs very high firing temperatures in the kiln (above ~900–950 °C) together with a long-lived firing [10,26].

Samples RS1 to RS8, DC1 to DC4, G1 to G6, H1 to H4, and C1 to C3 have siliceous pastes (Pliocene) while samples YS1 to YS4 and C5 are Palença (Miocene) type. Sample RS 5 is an exception because it is siliceous but it has a high level of calcium carbonate. Sample C4 exhibited a different diffractogram, not presented in Figure 2, was produced in Lisbon workshops as can be seen in previously published diffractograms [12].

5.2. XRF Studies

The XRF results achieved for the ceramic bodies of sherds from the Almaraz archaeological site are presented in Table 2.

Table 2.

Chemical composition of the powdered pastes of the ceramic fragments collected in the Almaraz archaeological site, obtained by XRF. Data are presented as wt.% for major and minor constituents and ppm for trace elements. (nd: not detected; nq: not quantified).

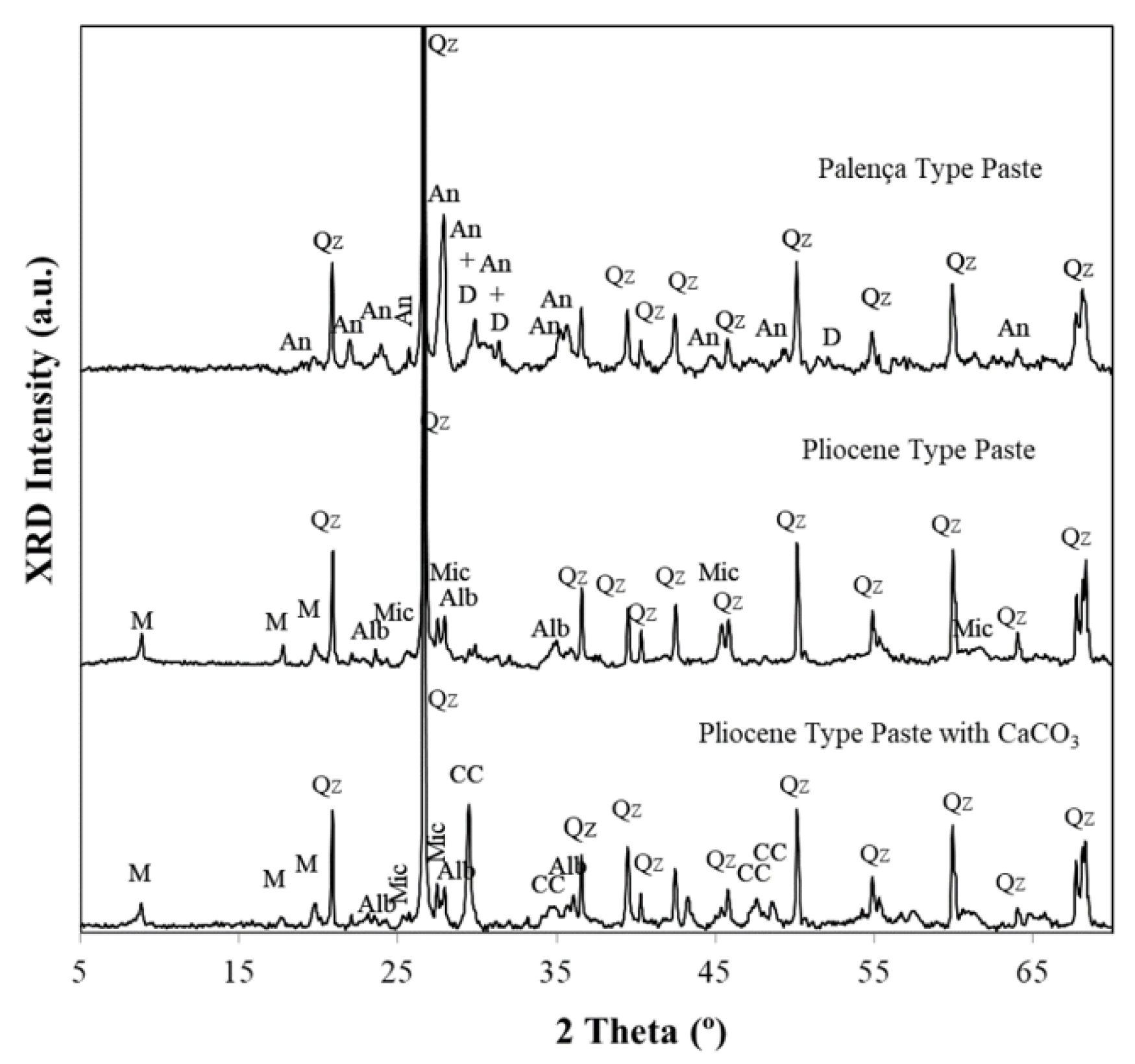

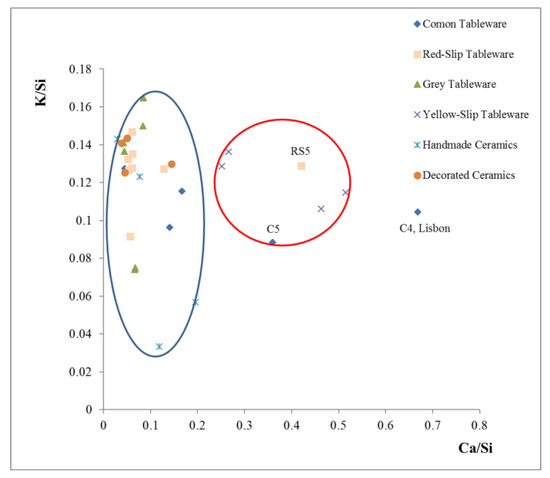

Scatterplots for K/Si versus Ca/Si (% wt ratio) for all sherds (Figure 3) clearly exhibit two groups: Pliocene type sherds, with low calcium content, and Miocene type sherds with a much higher calcium content. Only one sherd is separated from these two groups, the sherd from tableware produced in the Lisbon workshops, the one with the highest calcium content. The ratio, R, defined by:

was used in previous papers of our group [10,11,12,13], to quantify the relative amounts of the structural components of the ceramic pastes, (SiO2 + Al2O3 + K2O), related to calcium fractions (CaO).

R = (SiO2 + Al2O3 + K2O)/CaO

Figure 3.

Scatterplot of K/Si versus Ca/Si count ratios for the studied ceramic. Pliocene type pastes—Blue ellipse. Miocene type pastes—Red ellipse. The contents of K and Ca measured by XRF were normalized to the Si content [27].

The plot in Figure 3 allows us to view the differences between the ceramic bodies with clays of Pliocene origin (highly siliceous and calcium depleted, in most cases) in which the R parameter is very high (R = 10 to 70—blue ellipse) [10,11]. Palença ceramic bodies produced with Miocene clays show much smaller R values: R = 5 to 10 (red ellipse). The Lisbon (C4) sample exhibits an R = 3. The compositional profile of decorative ceramics shows very low compositional variability, revealing the careful selection of raw materials and the manufacturing process. In contrast, handmade and common ceramics exhibit the maximum dispersion of values in certain chemical components, indicating a less standardized approach (Table 2). For handmade pastes, compositional differences are mainly dependent on the quartz, Illite/muscovite, and alkaline feldspars proportions. For common ceramics, the carbonate fraction of the pastes is very variable.

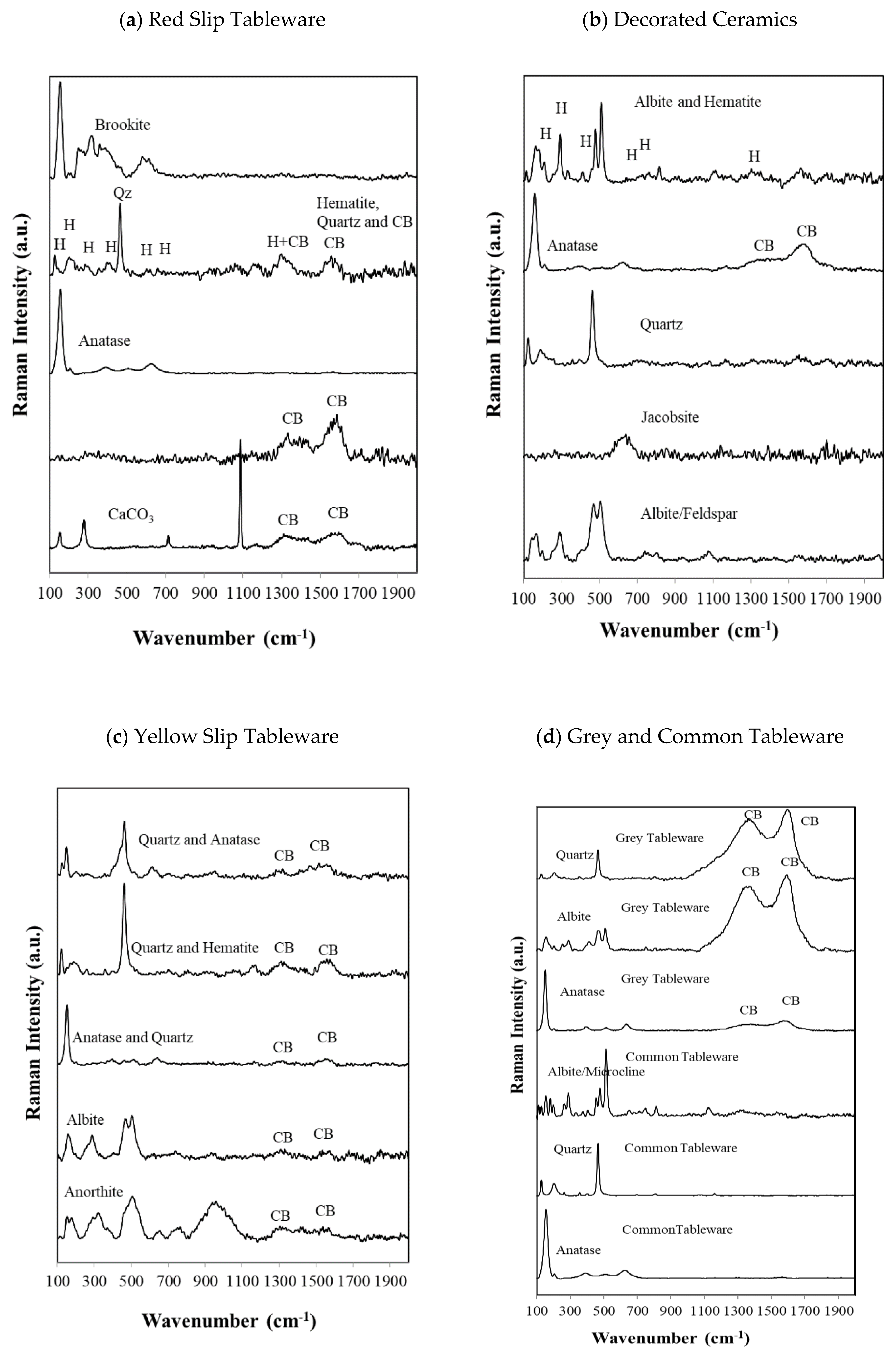

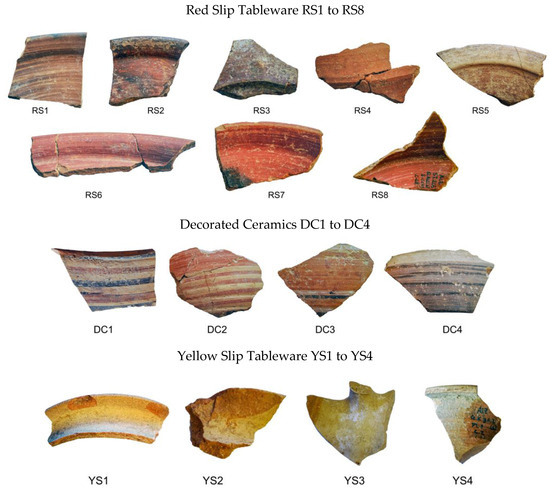

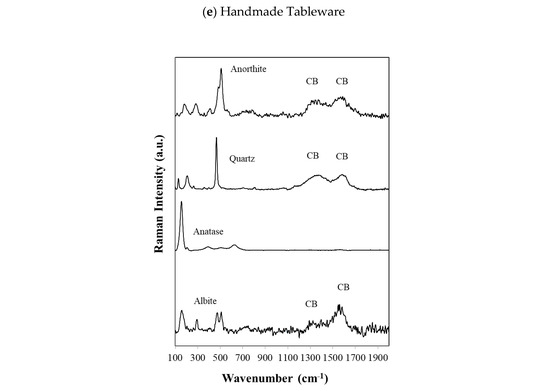

5.3. Micro-Raman Studies

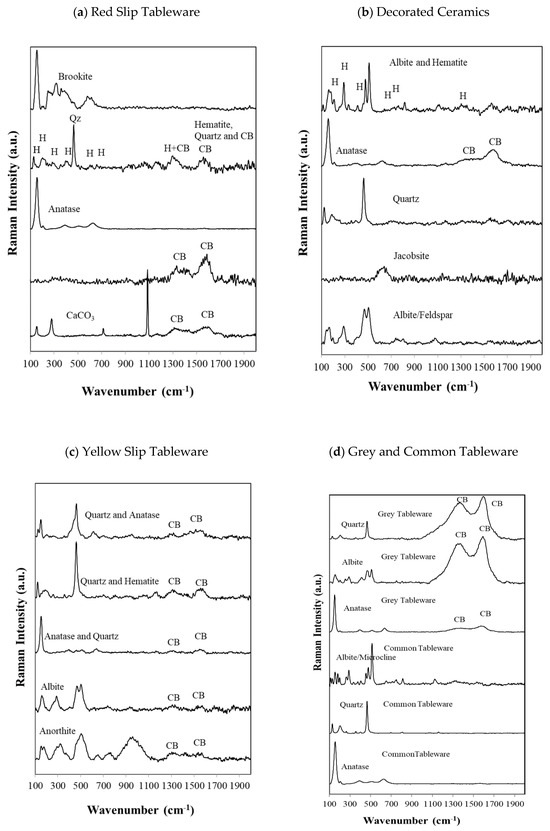

Micro-Raman spectroscopy is an excellent technique to identify the compounds used to decorate the surface of the ceramic or the engobes. In the case of the red slip tableware, the red colour is due to the use of hematite (H, α-Fe2O3) associated with brookite (TiO2). All the red slip ware ceramics were made with Pliocene clays, highly siliceous, so the detection of quartz in all samples is no surprise. Also, the red engobe exhibits anatase (TiO2) and carbon black in the darker surfaces. In some special cases, a remarkable amount of calcium carbonate was detected, as shown in Figure 2 and also in the fifth curve of Figure 4a).

Figure 4.

Micro-Raman spectra from the surface colours of all sherds under study. H is hematite, CB is carbon black.

The major differences in the Raman in the case of the decorated ceramics (Figure 4b) is that part of the surface is decorated, and another part is not. In the black stripes, the potters used the mineral jacobsite (Mn2+Fe3+2O4), in the red stripes hematite and albite (NaAlSi3O8,) could be detected. Non-surprisingly, anatase, quartz, and albite/feldspar were detected in the non-coloured surface.

All yellow slip tableware sherds were obtained with the use of a yellow clay engobe (Figure 4c). So, the Raman spectra reflect the mineralogical composition of this engobe, of siliceous nature in two samples (YS1 and YS2—the first four curves) and also the Miocene nature of the ceramic bodies (YS3 and YS4 samples), where anorthite is abundant—fifth curve. Anorthite was observed in the parts of the sherds that are not covered with the engobe.

Grey and common tableware Raman spectra are presented in Figure 4d. No engobe exist in these two groups of ceramics, so the Raman reflects the ceramic body composition of the siliceous pastes, with a major difference: huge amounts of carbon black is present in the grey tableware, which reflects the reductive conditions of the firing process inside the kiln.

Handmade tableware—anorthite exists in the Palença type sherds H2 and H3 (of Miocene origin). The other curves of Figure 4e reflect the siliceous nature of the other two samples.

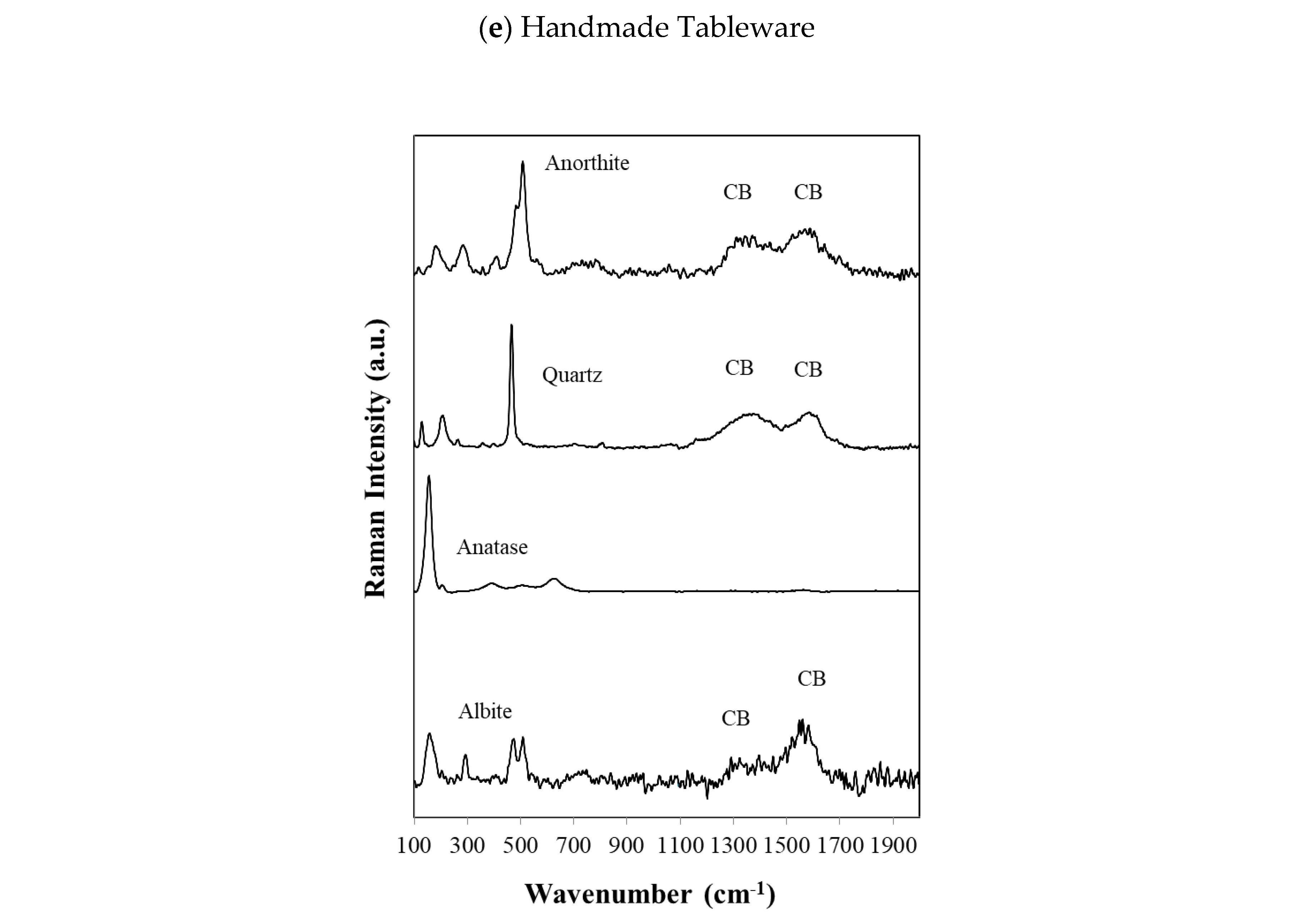

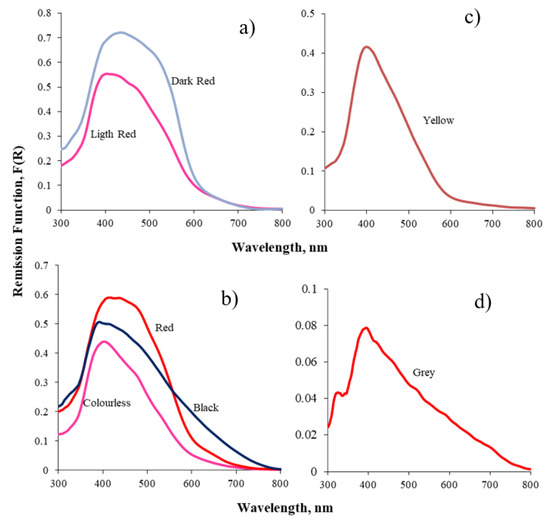

5.4. GSDR Studies

Ground state diffuse reflectance absorption spectra for all coloured samples in Figure 1 are presented in Figure 5, where the remission function is presented as an ordinate and the wavelength in nm is the abscissa. Figure 5a shows the absorption spectra of the red slip ware. The absorption of red maximizes at ca. 530 nm which is the green colour, the complementary colour of red. This absorption is larger in the dark red when compared with the light red.

Figure 5.

GSDR absorption spectra of: (a) red slip tableware; (b) decorated tableware; (c) yellow slip tableware; (d) grey tableware.

Figure 5b presents the three colours, which exist in the surface of the decorated ceramics: the red curve is similar to the one of Figure 5a and a clear distinction can be observed for the colourless surface, which maximizes its absorption in the UV range at about 400 nm. This contrasts with the black absorption which is broad in all the wavelength range under study. Yellow tableware (Figure 5c) shows the engobe which covers all the ceramic body and absorbs in the blue region, so it appears as a yellow surface. Finally, the grey absorption (Figure 5d) is similar to the black curve of the decorated ceramic.

6. Conclusions

The mineralogical study of the pastes of all ceramic fragments found at Almaraz showed two main types of pastes. The largest group was made with Pliocene clays collected south of the Tagus River, usually presenting a very low calcium content. In this case, the dominant minerals detected in the diffractograms were quartz, microcline, and albite. The second group, also produced in local workshops, used Miocene clays from Palença clay sources. Quartz, diopside, and anorthite were detected as dominant mineral components of the second group.

Micro-Raman studies of the surfaces of the sherds revealed for the red slip tableware, the engobe colour was due to the use of hematite (H, α-Fe2O3) associated with brookite (TiO2). For the decorated ware, the black stripes evidence the use of a manganese mineral, jacobsite, and the red stripes evidence hematite. For the yellow slip group, the engobe is a yellowish clay, and for the grey tableware, the siliceous ceramic body evidences a high content of carbon black, entrapped into the ceramic body in the firing process in reductive conditions. The surface colour of the handmade and common wares varies with the origin of the raw materials used in each specific case.

Regarding the red pigment, with the association of hematite and brookite, its existence/production in the Lisbon region can be considered hypothetical, depending on terra rossa or levels of alteration of volcanic rocks. However, the black pigment, consisting of the manganese oxide jacobsite, does not occur in the geological formations of this region; therefore, its origin must be considered external. Despite the presence of various mineral deposits with manganese oxides exposed in Portuguese territory, especially in the South of Portugal, the origin of this type of pigment cannot be established now. Subsequent comparative studies with samples of ores and artifacts from various sources may help clarify this matter.

Our studies of the mineralogic composition of the sherds body indicate all ceramics were produced in local kilns, mostly located south of the Tagus River.

Author Contributions

Conceptualization, L.F.V.F., I.L.F.M., A.O.; investigation, L.F.V.F., I.L.F.M., M.F.C.P.; writing—original draft preparation, L.F.V.F., I.L.F.M., A.O.; writing—review and editing, L.F.V.F., I.L.F.M., A.O., M.F.C.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundação para a Ciência e a Tecnologia (FCT). Projects UID/NAN/50024/2019, UIDB/04028/2020, M-ERA-MNT/0002/2015. A.O. was funded by a doctoral scholarship (SFRH/BD/146563/2019).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author/s.

Acknowledgments

Thanks are due to FCT, Portugal, for the funding of projects and scholarship above mentioned.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Arruda, A. Los Fenicios en Portugal: Fenicios y Mundo Indígena en el Centro y sur de Portugal (Siglos VIII–VI a.C.); Universitat Pompeu Fabra: Barcelona, Spain, 1999–2000. [Google Scholar]

- Arruda, A. A Idade do Ferro Orientalizante no vale do Tejo: As duas margens de um mesmo rio. In Territorios Comparados: Los valles del Guadalquivir, el Guadiana y el Tajo em Época Tartésica; Celestino Pérez, S., Rodríguez González, E., Eds.; Consejo Superior e Investigaciones Científicas: Mérida, Spain, 2015; pp. 283–294. [Google Scholar]

- Soares, A.; Arruda, A. Cronologia de radiocarbono para a Idade do Ferro Orientalizante no território português. Uma leitura crítica dos dados arqueométricos e arqueológicos. In IberCrono 2016 Cronometrías Para la Historia de la Península Ibérica (Chronometry for the History of the Iberian Peninsula)-Actas del Congreso de Cronometrias para la Historia de la Península Ibérica, Barcelona, 17–19 de octubre 2016; Barcleó, J., Bogdanovic, I., e Morell, B., Eds.; Autonomas University of Barcelona: Bellaterra, Spain, 2017; pp. 235–259. [Google Scholar]

- Sousa, E. A ocupação pré-romana da foz do Estuário do Tejo. In Estudos & Memórias; Uniarq-Centro de Arqueologia da Universidade de Lisboa: Lisboa, Portugal, 2014. [Google Scholar]

- Mielke, D. Between transfer and interaction: Phoenician pottery technology on the Iberian Peninsula. In The Transmission of Technical Knowledge in the Production of Ancient Mediterranean Pottery; Gauss, W., Klebinder-Gauss, G., von Rüden, C., Eds.; Österreichisches Archäologisches Institut: Wien, Austria, 2015; pp. 257–276. [Google Scholar]

- Groot, B. Material Methods; Considering Ceramic Raw Materials and the Spread of the Potter‘s Wheel in Early Iron Age Southern Iberia. Interdiscip. Archaeol. 2021, XII, 331–342. [Google Scholar] [CrossRef]

- Cardoso, G.; Encarnação, J. O povoamento pré-romano de Freiria-Cascais. Cira Arqueol. 2013, 2, 133–180. [Google Scholar]

- Pimenta, J.; Mendes, H. Novos dados sobre a presença fenícia no Vale do Tejo. As recentes descobertas na área de Vila Franca de Xira. Estud. Arqueol. Oeiras 2011, 18, 591–618. [Google Scholar]

- Tite, M. Ceramic production, provenance and use—A review. Archaeometry 2008, 50, 216–231. [Google Scholar] [CrossRef]

- Vieira Ferreira, L.F.; de Sousa, E.; Pereira, M.F.C.; Guerra, S.; Ferreira Machado, I. An archaeometric study of the Phoenician ceramics found at the São Jorge Castle’s hill in Lisbon. Ceram. Int. 2020, 46, 7659–7666. [Google Scholar] [CrossRef]

- Vieira Ferreira, L.F.; Barros, L.; Ferreira Machado, I.; Pereira, M.F.C.; Casimiro, T.M. An archaeometric study of a Late Neolithic cup and coeval and Chalcolithic ceramic sherds found in the São Paulo Cave, Almada, Portugal. J. Raman Spectrosc. 2020, 51, 483–492. [Google Scholar] [CrossRef]

- Vieira Ferreira, L.F.; Barros, L.; Machado, I.; Gonzalez, A.; Pereira, M.F.C.; Casimiro, T. Spectroscopic characterization of amphorae from the 8th to the 7th c. BCE found at the Almaraz settlement in Almada, Portugal. J. Archaeol. Sci. Rep. 2018, 21, 166–174. [Google Scholar] [CrossRef]

- Vieira Ferreira, L.F.; Gonzalez, A.; Pereira, M.F.C.; Santos, L.F.; Casimiro, T.M.; Ferreira, D.P.; Conceição, D.S.; Ferreira Machado, I. Spectroscopy of 16th century Portuguese tin-glazed earthenware produced in the region of Lisbon. Ceram. Intern. 2015, 41, 13433–13446. [Google Scholar] [CrossRef]

- Lepierre, C. Estudo Chimico e Technologico sobre a Cerâmica Portuguesa Moderna; Imprensa Nacional: Lisboa, Portugal, 1899. [Google Scholar]

- Zbyszewski, G. Carta Geológica dos Arredores de Lisboa na Escala 1/50,000—Notícia Explicativa da Folha 4—Lisboa; Serviços Geológicos de Portugal: Lisboa, Portugal, 1963. [Google Scholar]

- Barros, L.; Henriques, F. Almaraz, primeiro espaço urbano em Almada. In Actas do 3º Encontro Nacional de Arqueologia Urbana; Henriques, F., Santos, M., António, T., Eds.; Divisão dos Museus-Núcleo de Arqueologia e História: Almada, Portugal, 2002; pp. 295–311. [Google Scholar]

- Olaio, A. Economia, produção e comércio na Quinta do Almaraz (Almada, Portugal) durante o 1º milénio a.n.e.—Balanço e perspectivas de investigação. In Actas IX Congreso Internacional de Estudios Fenicios y Púnicos; Celestino Pérez, S., e Rodríguez González, E., Eds.; MYTRA 5: Mérida, Spain, 2020; pp. 1375–1388. [Google Scholar]

- Cardoso, J. A Baixa Estremadura dos Finais do IV Milénio A. C. até à Chegada dos Romanos: Um Ensaio de História Regional; Estudos Arqueológicos de Oeiras: Oeiras, Portugal, 2004; p. 12. [Google Scholar]

- Arruda, A.O. 1º milénio a.n.e. no Centro e Sul de Portugal: Leituras possíveis no início de um novo século. O Arqueólogo Port. 2005, 4–5, 9–156. [Google Scholar]

- Vilaça, R. Ponderais do Bronze Final-Ferro Inicial do Ocidente peninsular: Novos dados e questões em aberto. In Barter, Money and Coinage in the Ancient Mediterranean (10th–1st Centuries BC), Anejos de AEspA LVIII; García-Bellido, M.P., e Jiménez Díez, A., Eds.; Consejo Superior de Investigaciones Cientificas: Madrid, Spain, 2011; pp. 139–167. [Google Scholar]

- Melo, A.; Valério, P.; Barros, L.; Araújo, M. Práticas metalúrgicas na Quinta do Almaraz 698–711. (Cacilhas, Portugal): Vestígios orientalizantes. In Fenícios e Púnicos, Por Terra e Mar. Actas do VI Congresso Internacional de Estudos Fenícios e Púnicos; Arruda, A.M., Ed.; UNIARQ: Lisbon Portugal, 2014; pp. 136–149. [Google Scholar]

- Olaio, A.; Angeja, P.; Soares, R.; Valério, P. A ocupação da Idade do Ferro de Cacilhas (Almada, Portugal). Onoba 2019, 7, 133–159. [Google Scholar] [CrossRef]

- Olaio, A. O povoado da Quinta do Almaraz no âmbito da ocupação do Baixo Tejo durante o 1º milénio a.n.e.: Os dados do conjunto anfórico. Spal 2018, 27-2, 125–163. [Google Scholar] [CrossRef]

- Picon, M. Introduction à l’Étude Technique des Céramiques Sigillées de Lezoux: Centre de Recherches sur Techniques Gréco-Romaines; Université de Dijon: Dijon, France, 1973. [Google Scholar]

- Almeida, R. Las Ánforas del Guadalquivir en “Scallabis” (Santarém, Portugal): Una aportación al conocimiento de los tipos minoritários. In Colección Instrumenta; Universitat de Barcelona: Barcelona, Spain, 2008; p. 28. [Google Scholar]

- Porras, A.G.; Capelli, C.; Cabella, R.; Pastor, J.R.; Cardell, C. Ceramic production in Granada and in southeast of the Iberian Peninsula during the late Middle Ages: Clays, tools and pots—Some preliminary notes. Mediev. Pottery 2012, 33, 29–42. [Google Scholar]

- Simsek, G.; Casadio, F.; Colomban, P.; Bellot-Gurlet, L.; Faber, K.T.; Zelleke, G.; Milande, V.; Moinet, E. On-site identification of early Böttger red stoneware made at Meissen using portable XRF: 1, body analysis. J. Am. Ceram. Soc. 2014, 97, 2745–2754. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).