Environmentally Sustainable Flame Retardant Surface Treatments for Textiles: The Potential of a Novel Atmospheric Plasma/UV Laser Technology

Abstract

:1. Introduction

1.1. Background

1.2. Atmospheric Plasma Treatments

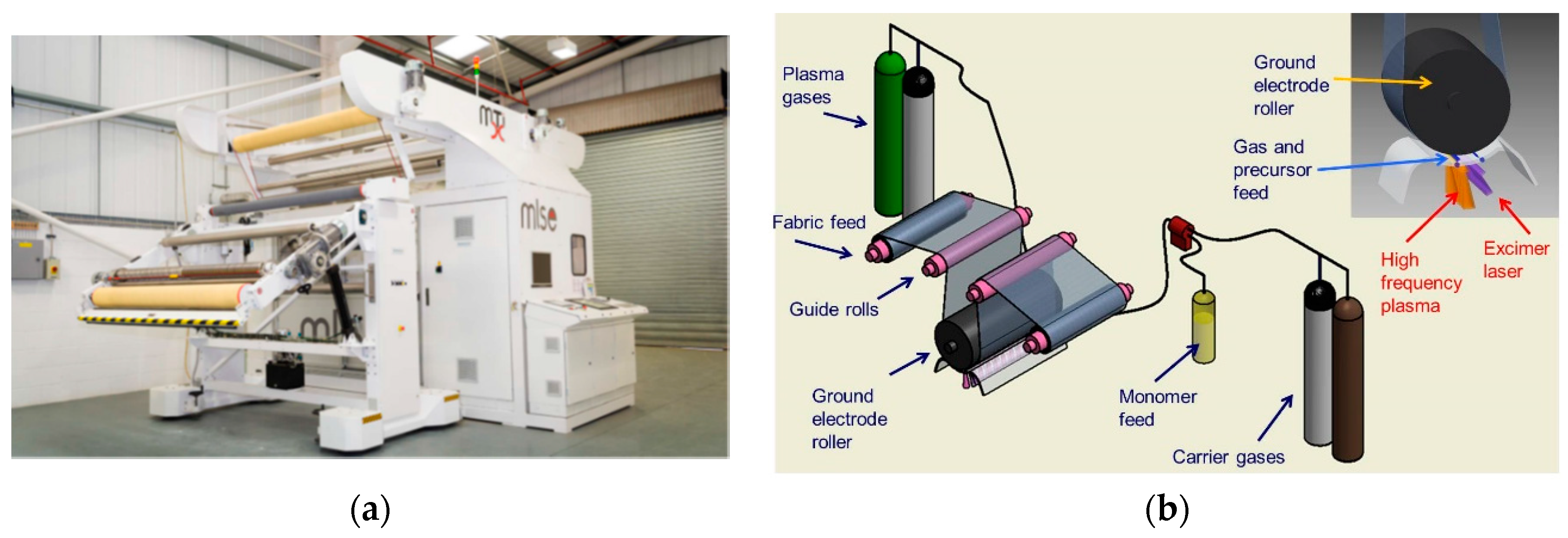

1.3. A Combined Atmospheric Plasma/UV Laser or Multiplexed Laser Surface Enhancement (MLSE) System

2. Materials and Methods

2.1. Materials and Preparation

2.2. Atmospheric Plasma/UV Laser (MLSE) Conditions

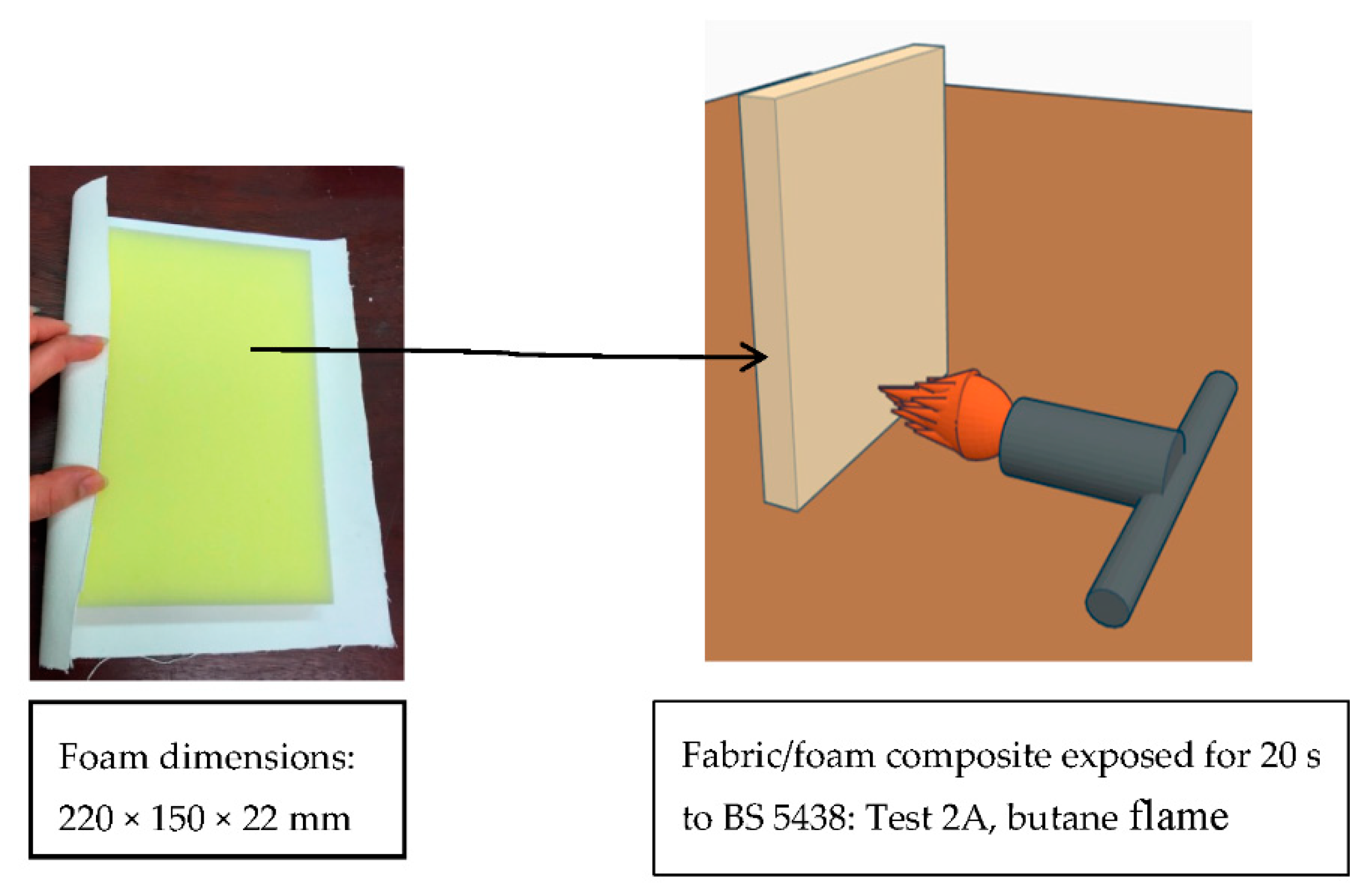

2.3. Flammability Testing

2.4. Thermal Analysis

2.5. Scanning Electron Microscopy and EDX

3. Results

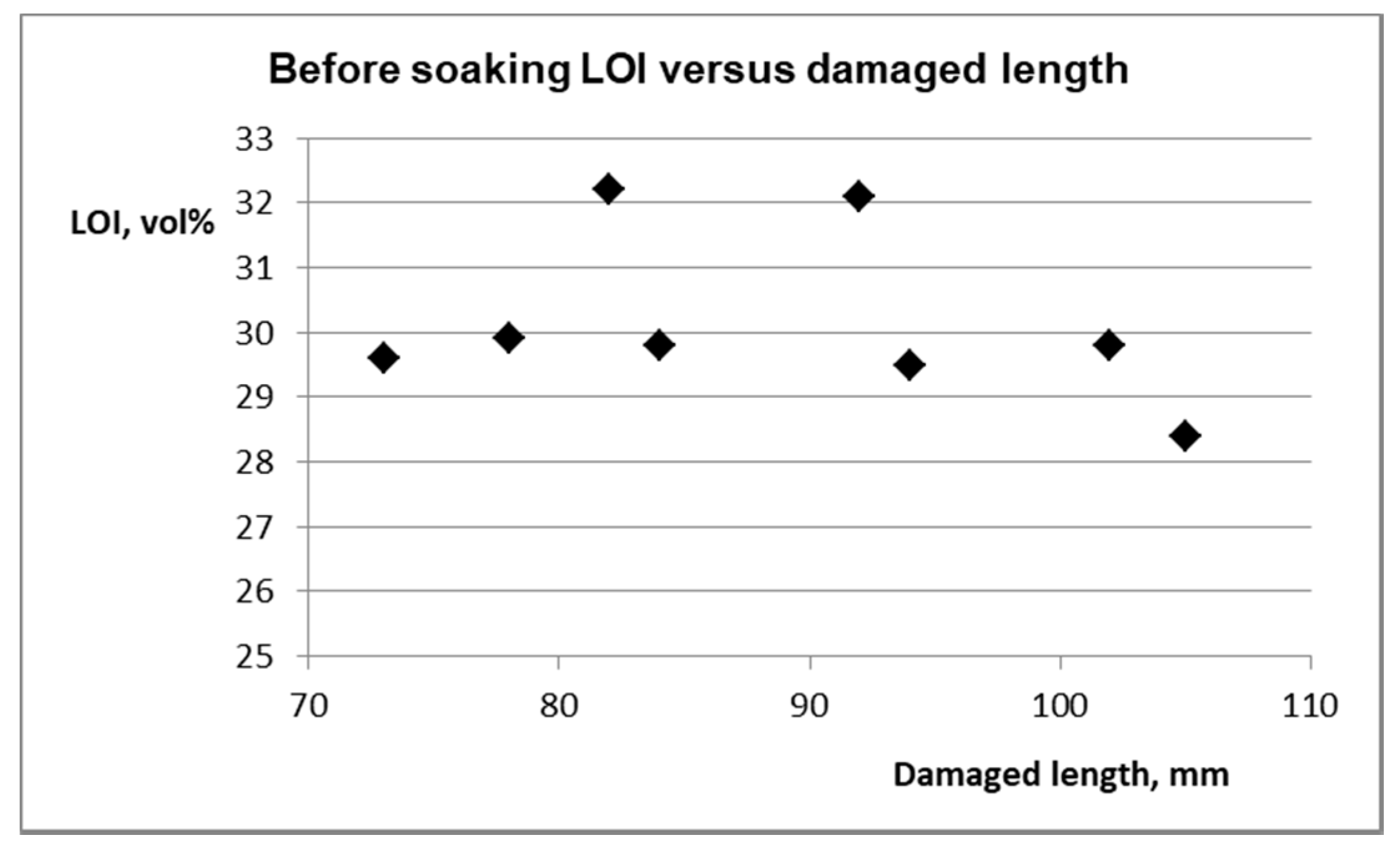

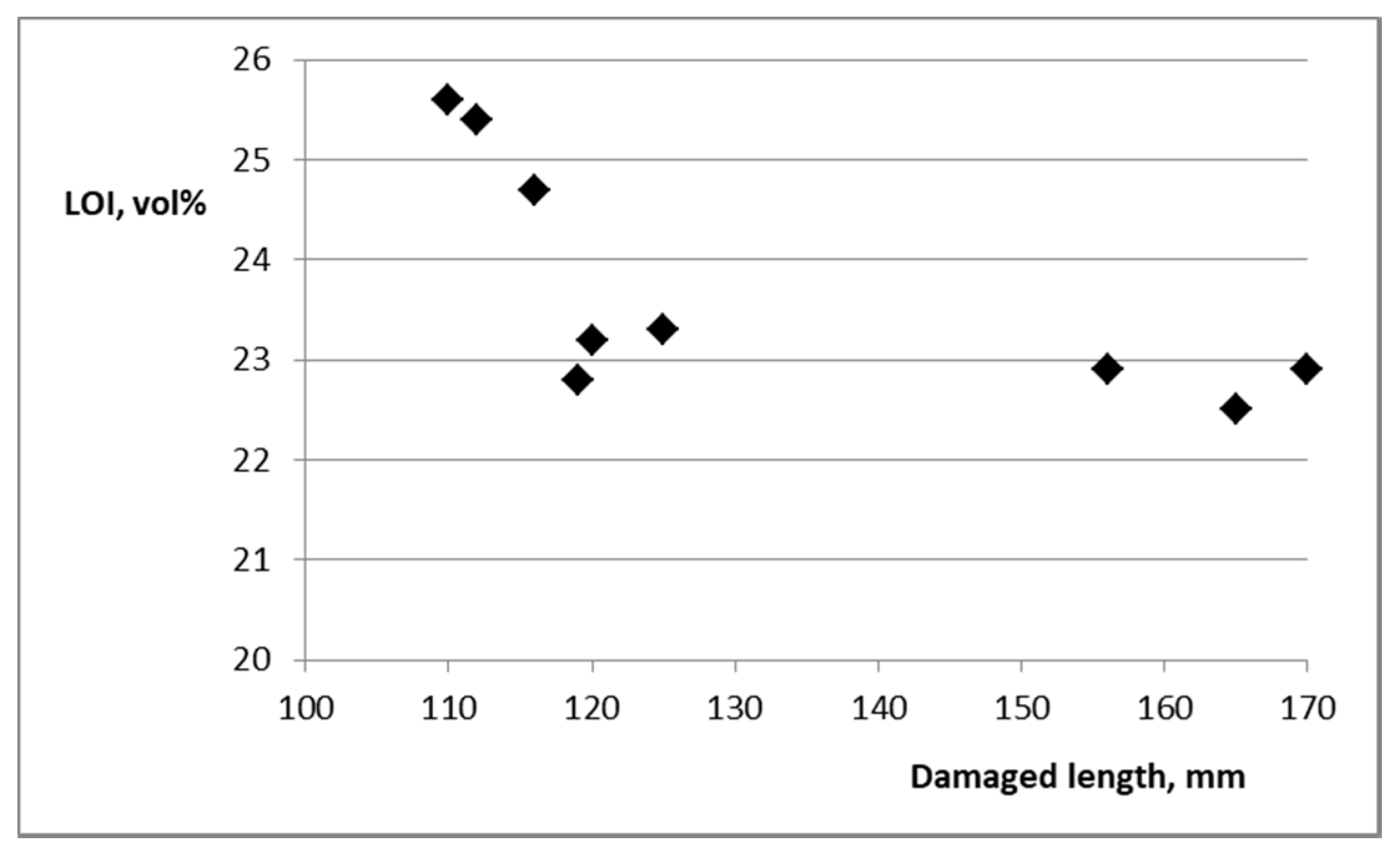

3.1. Flammability Testing

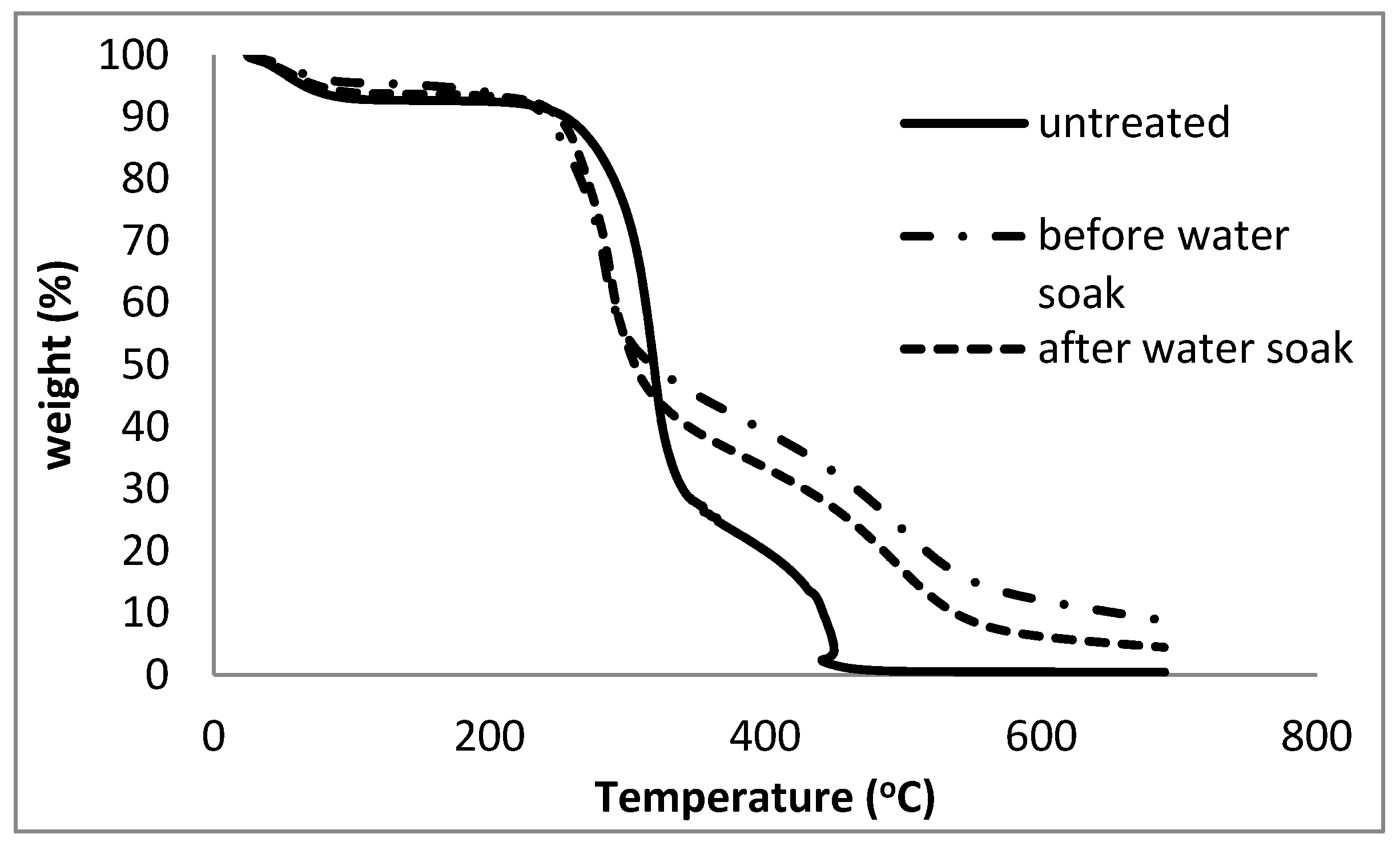

3.2. Thermal Analysis

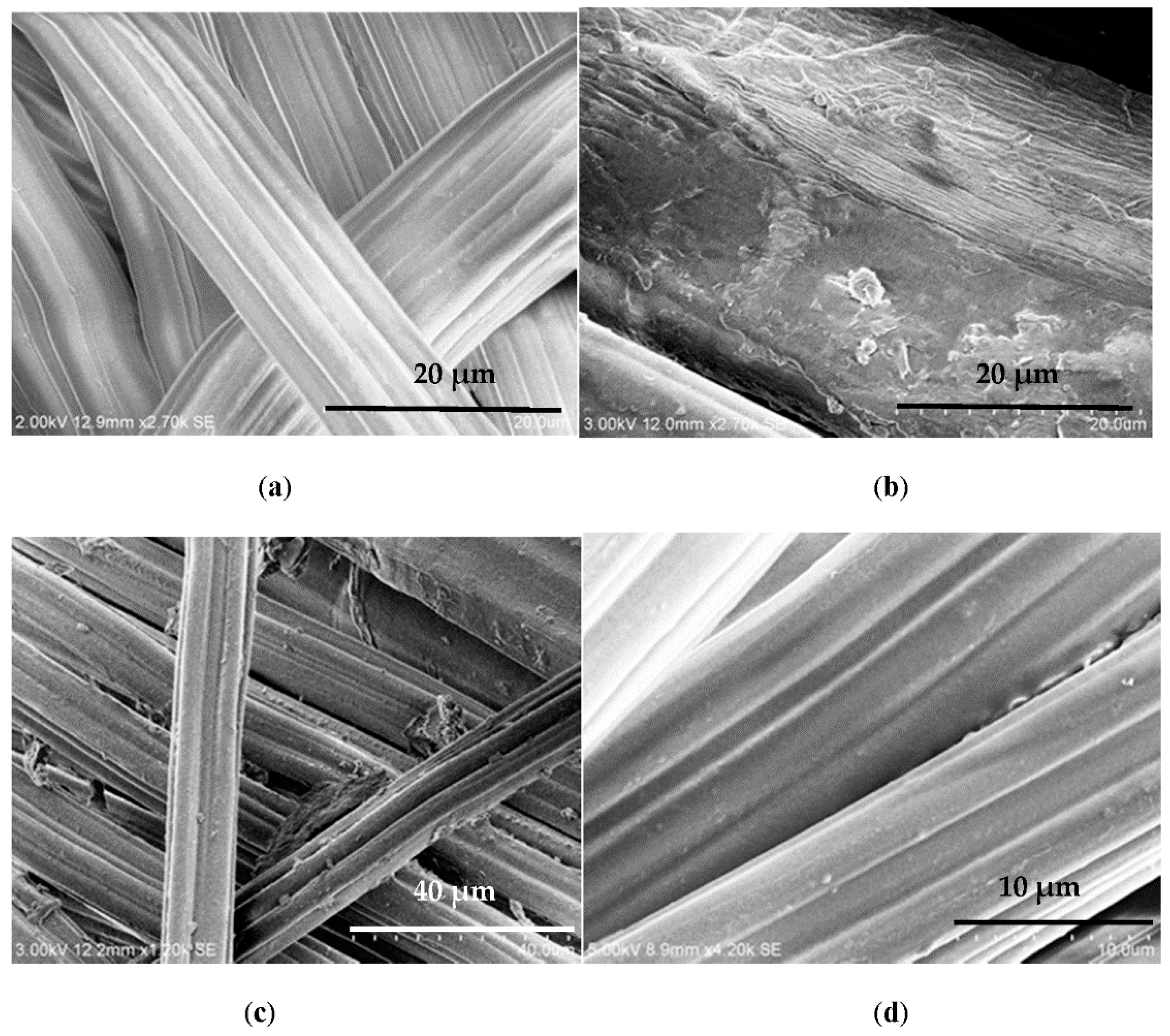

3.3. Fibre Surface Morphologies

4. Discussion and Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- McAllister, D.L. Brominated flame retardants: Current issues and future prospects. In Flame Retardants ’92; The Plastics and Rubber Institute, Ed.; Elsevier: London, UK, 1992; pp. 149–154. ISBN 1-85166-758-X. [Google Scholar]

- Horrocks, A.R. Flame retardant challenges for textiles and fibres: New chemistry versus innovatory solutions. Polym. Degrad. Stab. 2011, 96, 377–392. [Google Scholar] [CrossRef]

- Horrocks, A.R. Overview of traditional flame-retardant solutions. In Update on Flame Retardant Textiles: State of the Art, Environmental Issues and Innovative Solutions; Alongi, J., Horrocks, A.R., Carosio, F., Malucelli, G., Eds.; Smithers Rapra: Shawbury, UK, 2013; pp. 123–178. [Google Scholar]

- Consumer Protection Act (1987), the Furniture and Furnishings (Fire) (Safety) Regulations, 1988, SI1324 (1988), 1988; HMSO: London, UK, 1988; Amended in 1989, 1993 and 2010.

- Alongi, J.; Carioso, F.; Malucelli, G. Smart (nano)coatings. In Update on Flame Retardant Textiles: State of the Art, Environmental Issues and Innovative Solutions; Alongi, J., Horrocks, A.R., Carosio, F., Malucelli, G., Eds.; Smithers Rapra: Shawbury, UK, 2013; pp. 263–318. [Google Scholar]

- Horrocks, A.R. Flame Retardant finishes. In Textiles: Current Developments and Future Trends; Bahners, T., Mittal, K., Eds.; Scrivener Publishing LLC: Beverly, MA, USA, 2017; pp. 69–128. [Google Scholar]

- Leistner, M.; Abu-Odeh, A.A.; Rohmer, S.C.; Grunlan, J.C. Water-based chitosan/melamine polyphosphate multilayer nanocoating that extinguishes fire on polyester-cotton fabric. Carbohydr. Polym. 2015, 130, 227–232. [Google Scholar] [CrossRef] [PubMed]

- Haile, M.; Leistner, M.; Sarwar, O.; Toler, C.M.; Henderson, R.; Grunlan, J.C. A wash-durable polyelectrolyte complex that extinguishes flames on polyester-cotton fabric. RSC Adv. 2016, 6, 33998–34004. [Google Scholar] [CrossRef]

- Shishoo, R. (Ed.) Plasma Technologies for Textiles; Woodhead Publishing: Cambridge, UK, 2007. [Google Scholar]

- Herbert, T. Atmospheric-pressure cold plasma processing technology. In Plasma Technologies for Textiles; Shishoo, R., Ed.; Woodhead Publishing: Cambridge, UK, 2007; pp. 79–128. [Google Scholar]

- Horrocks, A.R.; Nazaré, S.; Masood, R.; Kandola, B.K.; Price, D. Surface modification of fabrics for improved flash-fire resistance using atmospheric pressure plasma. Polym. Adv. Technol. 2011, 22, 22–29. [Google Scholar] [CrossRef]

- Tata, J.; Alongi, J.; Frache, A. Optimization of the procedure to burn textile fabrics by cone calorimeter: Part II. Results on nanoparticle-finished polyester. Fire Mater. 2012, 36, 527–537. [Google Scholar]

- Carosio, F.; Alongi, J.; Frache, A. Influence of surface activation by plasma and nanoparticle adsorption on the morphology, thermal stability and combustion behavior of PET fabrics. Eur. Polym. 2011, 47, 893–902. [Google Scholar] [CrossRef]

- Totolin, V.; Sarmadi, M.; Manolache, S.O.; Denes, F.S. Environmentally friendly flame-retardant materials produced by atmospheric pressure plasma modifications. J. Appl. Polym. Sci. 2012, 124, 116–122. [Google Scholar] [CrossRef]

- Edwards, B.; El-Shafaei, A.; Hauser, P.; Malshe, P. Towards flame retardant cotton fabrics by atmospheric pressure plasma-induced graft polymerization: Synthesis and application of novel phosphoramidate monomers. Surf. Coat. Technol. 2012, 209, 73–79. [Google Scholar] [CrossRef]

- Mistry, P.; (Assigned to MTIX Ltd., UK). Treating Materials with Combined Energy Sources. U.S. Patent 9605376 B2, 28 May 2017. [Google Scholar]

- Heywood, D. (Ed.) Textile Finishing; Society of Dyers and Colourists: Bradford, UK, 2003. [Google Scholar]

- Peters, R.H. Textile Chemistry; Elsevier: Amsterdam, The Netherlands; London, UK; New York, NY, USA, 1967; Volume 2, pp. 91–92. [Google Scholar]

- Wang, M.Y.; Horrocks, A.R.; Horrocks, S.; Hall, M.E.; Pearson, J.S.; Clegg, S. Flame retardant textile back-coatings. Part 1: Antimony-halogen system interactions and the effect of replacement by phosphorus-containing agents. J. Fire Sci. 2000, 18, 265–294. [Google Scholar]

- Tang, W.K.; Neill, W.K. Effect of flame retardants on pyrolysis and combustion of α-cellulose. J. Polym. Sci. Part C 1964, 6, 65–81. [Google Scholar] [CrossRef]

- Moncrieff, R.W. Man-Made Fibres, 6th ed.; Newnes-Butterworth: London, UK, 1975; pp. 194–200. ISBN 0 408 00129 1. [Google Scholar]

- Hearle, J.W.S. Physical Properties of Textile Fibres, 2nd ed.; Textile Institute: Manchester, UK, 1975; pp. 1–50. ISBN 1 870812 41 7. [Google Scholar]

- Colom, X.; Carrillo, F. Crystallinity changes in lyocell and viscose-type fibres by caustic treatment. Eur. Polym. J. 2002, 38, 2225–2230. [Google Scholar] [CrossRef]

- Duchemin, B.; Thuault, A.; Vicente, A.; Rigaud, B.; Fernandez, C.; Eve, S. Ultrastructure of cellulose crystallites in flax textile fibres. Cellulose 2012, 19, 1837–1854. [Google Scholar] [CrossRef]

- Ross, K.; Mazza, G. Characteristics of lignin from flax shives as affected by extraction conditions. Int. J. Mol. Sci. 2010, 11, 4035–4050. [Google Scholar] [CrossRef] [PubMed]

- Gotoh, K. Surface functionalisation of synthetic textiles by atmospheric plasma. In Textile Finishing. Developments and Future Trends; Mittal, K., Bahners, T., Eds.; Scrivener Publishing LLC: Beverly, MA, USA, 2017; pp. 237–260. [Google Scholar]

- Vesel, A.; Mozetic, M.; Strnad, S.; Peršin, Z.; Stana-Kleinschek, K.; Hauptman, N. Plasma modification of viscose textile. Vacuum 2009, 84, 79–82. [Google Scholar] [CrossRef]

- Kan, C.W.; Yuen, C.W.M. Influence of low temperature plasma treatment on the properties of tencel and viscose rayon fibers. IEEE Trans. Plasma Sci. 2009, 37, 1615–1619. [Google Scholar] [CrossRef]

- Peršin, Z.; Vesel, A.; Kleinschek, K.S.; Mozetič, M. Characterisation of surface properties of chemical and plasma treated regenerated cellulose fabric. Text. Res. J. 2012, 82, 2078–2089. [Google Scholar] [CrossRef]

- Kramar, A.D.; Žekić, A.A.; Obradović, B.M.; Kuraica, M.M.; Kostić, M.M. Study of interaction between nitrogen DBD plasma-treated viscose fibers and divalent ions Ca2+ and Cu2+. Cellulose 2014, 21, 3279–3289. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Eid, B.M.; Abdel-Aziz, M.S. Effect of plasma superficial treatments on antibacterial functionalization and coloration of cellulosic fabrics. Appl. Polym. Sci. 2017, 392, 1126–1133. [Google Scholar] [CrossRef]

| Fabrics | Treatment | Sample | Area Density, g/m2 | Plasma/UV-Exposed Fabric Add-Ons, % (Before Water Soaking) |

|---|---|---|---|---|

| 1. | Pad/dry/plasma | Cellulosic blend | 413 | 13.8 |

| 2. | Pad/dry/plasma | Cellulosic blend | 417 | 12.7 |

| 2a. | Pad/dry | 6.0 * | ||

| 2b. | Pad/dry/cure (150 °C) | 6.0 * | ||

| 3. | Pad/dry/plasma | Cellulosic blend | 406 | 12.1 |

| 4. | Pad/dry/plasma | Cellulosic blend | 421 | 8.5 |

| 5. | Pad/dry/plasma | Cellulosic blend | 410 | 13.4 |

| 6. | Pad/dry/plasma | Cellulosic blend | 388 | 11.1 |

| 7. | Pad/dry/plasma | Cellulosic blend | 332 | 27.7 |

| 8. | Pad/dry/plasma | Cellulosic blend | 337 | 23.0 |

| 9. | Pad/dry/plasma | Cellulosic blend | 447 | 14.0 |

| Fabrics | Initial Area Density (g/m2) | Simulated Match Test over PU Foam Before Water Soaking | Simulated Match Test over PU Foam After Water Soaking | LOI, vol % | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AFT, s | FaDL, mm | FoDD, mm | AFT, s | FaDL, mm | FoDD, mm | Non FR | FR/Plasma/UV | |||

| Before Soak | After Soak | |||||||||

| Water-Soaking | ||||||||||

| 1. | 413 | 0 | 105 | 5 | 5 | 119 | 10 | 18.9 | 28.4 | 22.8 |

| 2. | 417 | 0 | 84 | 9 | 7 | 116 | 9 | 19.3 | 29.8 | 24.7 |

| 2a. | 2 | 85 | 5 | Fully burnt | - | - | 19.3 | 31.2 | 19.7 | |

| 2b. | 0 | 72 | 2 | 13 | 110 | 10 | 19.3 | 31.2 | 21.9 | |

| 3. | 406 | 0 | 69 | 9 | 15 | 165 | 9 | 19.0 | 29.7 | 22.5 |

| 4. | 421 | 0 | 73 | 14 | 11 | 120 | 9 | 18.8 | 29.6 | 23.2 |

| 5. | 410 | 0 | 78 | 10 | 23 | 170 | 8 | 18.9 | 29.9 | 22.9 |

| 6. | 388 | 0 | 94 | 9 | 11 | 125 | 9 | 18.9 | 29.5 | 23.3 |

| 7. | 332 | 0 | 92 | 9 | 1 | 112 | 12 | 19.1 | 32.1 | 25.4 |

| 8. | 337 | 0 | 82 | 8 | 1 | 110 | 9 | 19.2 | 32.2 | 25.6 |

| 9. | 447 | 0 | 102 | 9 | 18 | 156 | 14 | 19.0 | 29.8 | 22.9 |

| Samples | Tonset (5% Weight Loss) | Tmax1, °C | Tmax2, °C | Residue at 400 °C, % | Residue at 550 °C, % | |

|---|---|---|---|---|---|---|

| 1. | Untreated | 60 | 330 | 450 | 20 | 0.5 |

| Before soak | 147 | 334 | 500 | 39 | 15 | |

| After soak | 67 | 320 | 496 | 33 | 8 | |

| 2. | Untreated | 57 | 330 | 453 | 19 | 0.6 |

| Before soak | 91 | 333 | 500 | 37 | 13 | |

| After soak | 79 | 317 | 494 | 31 | 7 | |

| 3. | Untreated | 64 | 335 | 454 | 20 | 1 |

| Before soak | 89 | 333 | 500 | 38 | 14 | |

| After soak | 78 | 326 | 500 | 31 | 6 | |

| 4. | Untreated | 62 | 336 | 454 | 20 | 1 |

| Before soak | 168 | 294 | 498 | 42 | 19 | |

| After soak | 85 | 320 | 497 | 34 | 10 | |

| 5. | Untreated | 65 | 334 | 452 | 20 | 0.9 |

| Before soak | 107 | 336 | 500 | 40 | 16 | |

| After soak | 91 | 317 | 491 | 32 | 7 | |

| 6. | Untreated | 60 | 334 | 460 | 21 | 0.2 |

| Before soak | 116 | 333 | 500 | 41 | 17 | |

| After soak | 113 | 319 | 496 | 35 | 10 | |

| 7. | Untreated | 86 | 340 | 464 | 18 | 0 |

| Before soak | 191 | 302 | 500 | 40 | 15 | |

| After soak | 216 | 312 | 500 | 37 | 11 | |

| 8. | Untreated | 82 | 336 | 436 | 19 | 0 |

| Before soak | 217 | 331 | 497 | 42 | 19 | |

| After soak | 225 | 307 | 497 | 35 | 8 | |

| 9. | Untreated | 64 | 330 | 435 | 19 | 0 |

| Before soak | 136 | 342 | 494 | 40 | 16 | |

| After soak | 82 | 321 | 494 | 37 | 12 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horrocks, A.R.; Eivazi, S.; Ayesh, M.; Kandola, B. Environmentally Sustainable Flame Retardant Surface Treatments for Textiles: The Potential of a Novel Atmospheric Plasma/UV Laser Technology. Fibers 2018, 6, 31. https://doi.org/10.3390/fib6020031

Horrocks AR, Eivazi S, Ayesh M, Kandola B. Environmentally Sustainable Flame Retardant Surface Treatments for Textiles: The Potential of a Novel Atmospheric Plasma/UV Laser Technology. Fibers. 2018; 6(2):31. https://doi.org/10.3390/fib6020031

Chicago/Turabian StyleHorrocks, A. Richard, Sara Eivazi, Maram Ayesh, and Baljinder Kandola. 2018. "Environmentally Sustainable Flame Retardant Surface Treatments for Textiles: The Potential of a Novel Atmospheric Plasma/UV Laser Technology" Fibers 6, no. 2: 31. https://doi.org/10.3390/fib6020031

APA StyleHorrocks, A. R., Eivazi, S., Ayesh, M., & Kandola, B. (2018). Environmentally Sustainable Flame Retardant Surface Treatments for Textiles: The Potential of a Novel Atmospheric Plasma/UV Laser Technology. Fibers, 6(2), 31. https://doi.org/10.3390/fib6020031