Abstract

Ta–Al multilayer coatings were fabricated through cyclical gradient concentration deposition by direct current magnetron co-sputtering. The as-deposited coatings presented a multilayer structure in the growth direction. The oxidation behavior of the Ta–Al multilayer coatings was explored. The results specified that Ta-rich Ta–Al multilayer coatings demonstrated a restricted oxidation depth after annealing at 600 °C in 1% O2–99% Ar for up to 100 h. This was attributed to the preferential oxidation of Al, the formation of amorphous Al-oxide sublayers, and the maintenance of a multilayer structure. By contrast, Ta2O5 formed after exhausting Al in the oxidation process in an ambient atmosphere at 600 °C which exhibited a crystalline Ta2O5-amorphous Al-oxide multilayer structure.

1. Introduction

Al-based inter-metallics have been used for high-temperature applications because of their high melting points, strength, and oxidation resistance [,,,,,,,,,,,,,]. For example, Ru–Al alloys have been applied for jet engine components, bond coats for thermal barrier coatings, corrosion- and oxidation-protective coatings, and electrodes [,], whereas Ta–Al alloys have been applied for sulfidation and oxidation-protective coatings [,,], heater materials [,,], and electromagnetic shielding []. A previous paper [] evaluated the oxidation behavior of Ru–Al multilayer coatings in 1% O2–99% Ar at 400–800 °C. In our co-sputtering system [,,,,,], the plasma sources focused on a circular track but not the center of the substrate-holder; thus, a multilayer coating with cyclical gradient concentration formed, as the substrate-holder was rotated in a low speed of 1–7 rpm. Such multilayer coatings were constructed by alloy sublayers with continuous variation in compositions, but not monolithic sublayers of distinct elements. Additionally, the inward diffusion of oxygen during annealing resulted in the coating forming an internally oxidized multilayer structure comprising alternating oxygen-rich and oxygen-deficient sublayers. The execution of internal or external oxidation was affected by the annealing atmosphere and the diffusion of the active elements [,,]. The internal and external oxidation of the Ru–Al multilayer coatings exhibited restricted oxidation depths and overcoats, respectively, which were attributed to the formation of continuous Al2O3 sublayers and scales []. The multilayer structure with O-saturated Al2O3 oxide sublayers benefited to inhibit further oxidation. Moreover, the Ru–Al multilayer films subjected to an ambient atmosphere at 800 °C exhibited a limited oxidation depth []. Considering the merits of oxidation resistance and cost reduction, the feasibility of Ta–Al to replace the Ru–Al multilayer coatings in high-temperature applications was evaluated. The oxidation behavior of the Ta–Al multilayer coatings with cyclical gradient concentrations prepared using direct current (DC) magnetron co-sputtering was investigated at 400–600 °C.

2. Materials and Methods

The Ta–Al coatings with a Ti interlayer were fabricated onto silicon wafers by DC magnetron co-sputtering. A previous study [] illustrated the co-sputtering equipment and the experimental details such as the base pressure, working pressure, and Ar flow. The substrate holder was heated to 400 °C and rotated at 1 rpm. The Ti interlayer was deposited with a DC power of 200 W for 7 min. Then, Ta and Al were co-sputtered onto the Ti interlayer using various sputter powers for 35 min. The deposition rates of Ta and Al at a DC power of 200 W were 9.1 and 21.3 nm/min, respectively. The powers applied on Ta and Al targets were denoted as PTa and PAl, respectively. The total powers of PTa and PAl were fixed at 300 W. The annealing experiments were performed in 1% O2–99% Ar at 400–600 °C for 0.5–100 h, or in air at 600 °C for 1–100 h.

A chemical composition analysis of the samples was conducted using a field-emission electron probe microanalyzer (FE-EPMA; JXA-8500F, JEOL, Akishima, Japan). The thickness evaluation of the coatings was performed using a field emission scanning electron microscope (FE-SEM; S4800, Hitachi, Tokyo, Japan). A conventional X-ray diffractometer (XRD; X’Pert PRO MPD, PANalytical, Almelo, The Netherlands) was adopted to identify the phases using the grazing incidence technique with an incidence angle of 1°. The nanostructure was examined using a transmission electron microscope (TEM; JEM-2010F, JEOL, Tokyo, Japan). The TEM samples with Pt protective layers were prepared by applying a focused ion beam system (FEI Nova 200, Hillsboro, OR, USA) which was transferred to Cu grids. An energy-dispersive spectrometry (EDS; Inca x-sight, Oxford Instruments, Tokyo, Japan) equipped with TEM was used to determine the local chemical compositions. The chemical composition depth profiles were evaluated using an Auger electron spectroscopy (AES; PHI700, ULVAC-PHI, Kanagawa, Japan). The sputter depths in the AES results were correlated with the thicknesses determined by the cross-sectional SEM images.

3. Results and Discussion

3.1. As-Deposited Ta–Al Coatings

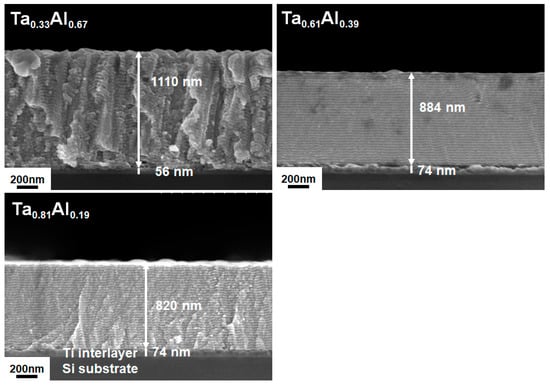

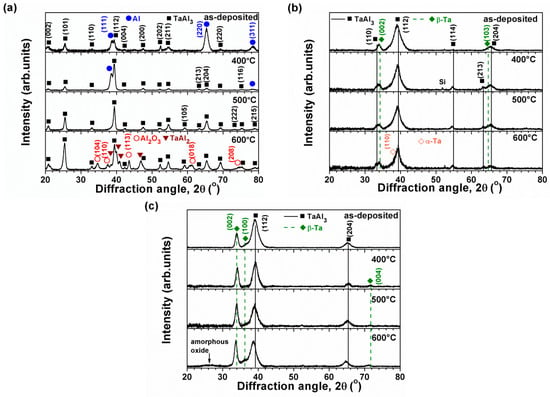

Table 1 lists the sputtering parameters, chemical compositions, and thicknesses of the as-deposited Ta–Al coatings. These samples are denoted as Ta0.33Al0.67, Ta0.61Al0.39, and Ta0.81Al0.19 coatings. Figure 1 depicts these coatings exhibiting evident multilayer structures. The sputtering time was set at 35 min, and the total powers of PTa and PAl were fixed at 300 W; therefore, the deposition rate increased with an increase in the power ratio of the Al target. Figure 2 exhibits the XRD patterns of the as-deposited and 1% O2–99% Ar-annealed Ta–Al coatings. The as-deposited Ta0.33Al0.67 coatings exhibited a tetragonal TaAl3 (ICDD 03–065–2665) phase and a cubic Al (ICDD 00–004–0787) phase, whereas the Ta0.61Al0.39 and Ta0.81Al0.19 coatings were composed of TaAl3 and tetragonal β-Ta (ICDD 00–025–1280) phases. The β-Ta phase is metastable and is observed for the sputtered coatings [,,]. The TaAl3 has been reported to be the preferred aluminide phase in the Ta–Al system [,,] with a formation enthalpy of −36 kJ/mol in the temperature interval of 1050–1350 K []. The Ta-rich and Al-rich Ta–Al films prepared at room temperature by Chung et al. [] had TaAl3–Ta and TaAl3–Al phases, respectively, which exhibited polycrystalline structures. The Ta-rich films showed a remarkable thermal stability after having been annealed in a vacuum at 450–650 °C, whereas the Al-rich films exhibited a phase transformation at 450 °C []. Because the Ta–Al coatings in this study were prepared at 400 °C, no amorphous parts were observed in the as-deposited films.

Table 1.

Sputtering parameters, chemical compositions, and thicknesses of the Ta–Al coatings.

Figure 1.

Cross-sectional SEM images of the as-deposited Ta–Al multilayer coatings.

Figure 2.

XRD patterns of the as-deposited and annealed (a) Ta0.33Al0.67, (b) Ta0.61Al0.39, and (c) Ta0.81Al0.19 coatings (annealing time: 30 min).

3.2. Oxidation of Ta–Al Coatings in 1% O2–99% Ar

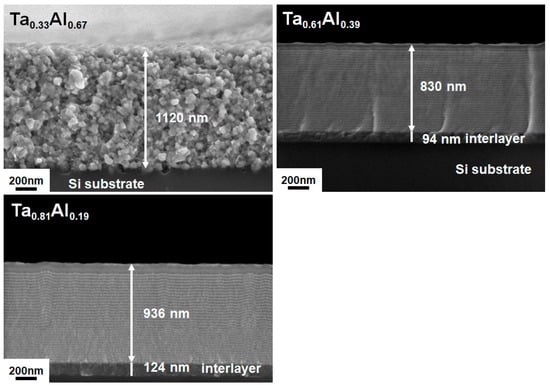

The as-deposited Ta0.33Al0.67 coatings comprised Al and TaAl3 phases with a strong Al(220) reflection, whereas the coatings annealed at 400 °C exhibited a strong TaAl3(112) reflection, and no Al phase was shown by the coatings annealed at 500 °C (Figure 2a). Moreover, the Ta0.33Al0.67 coatings annealed at 600 °C exhibited reflections of TaAl3, TaAl2 (ICDD 00–050–1279), and Al2O3 phases, accompanied with a granular structure, as shown in a cross-sectional SEM image (Figure 3). Because the standard Gibbs free energy levels for the formation of the metal oxides Al2O3 and Ta2O5 at 600 °C are −934,815 and −663,572 J/(mol of O2) [], respectively, Al2O3 is formed preferentially when the Ta–Al coatings are oxidized. The XRD patterns of the Ta0.61Al0.39 and Ta0.81Al0.19 coatings annealed in 1% O2–99% Ar at 400–600 °C for 30 min exhibited reflections similar to those of the as-deposited coatings (Figure 2b,c). A cubic α-Ta (110) reflection (ICDD 00–004–0788) became clear for the Ta0.61Al0.39 coating that had been annealed at 600 °C, whereas one extra broadened reflection, which was attributed to surface oxidation, was observed for the Ta0.81Al0.19 coating that had been annealed at 600 °C. The annealed Ta0.61Al0.39 and Ta0.81Al0.19 coatings maintained multilayered structures (Figure 3); however, the two outermost stacking periods extended their widths. The thicknesses of the Ti interlayers increased after annealing which was attributed to the interdiffusion of the Ti interlayer and Si substrate [].

Figure 3.

Cross-sectional SEM images of Ta–Al coatings annealed in 1% O2–99% Ar at 600 °C for 30 min.

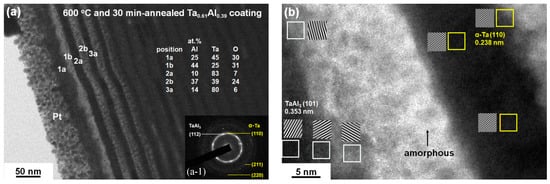

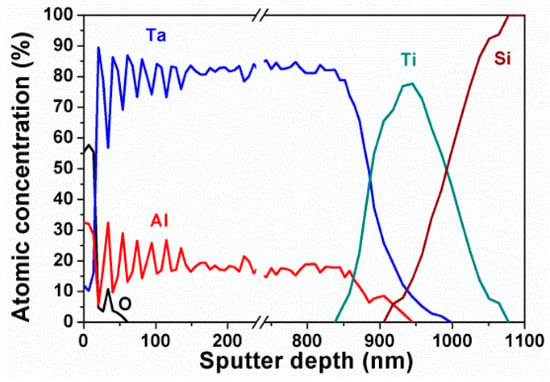

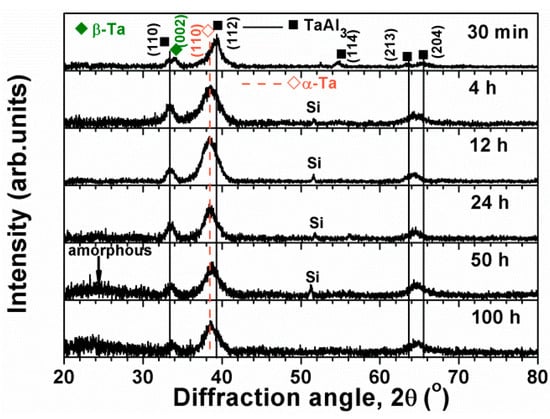

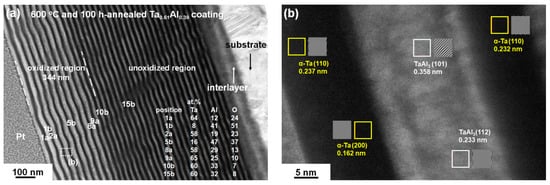

The cross-sectional TEM image (Figure 4a) of the Ta0.61Al0.39 coating annealed at 600 °C for 30 min exhibited a remaining multilayer structure. The EDS analysis verified that the inward diffusion of O tended to accumulate in the outmost stacking periods. The black sublayers (labelled as 1a, 2a, and 3a in Figure 4a) were dominated by Ta, whereas the white sublayers were enriched with Al and O. The selected area diffraction pattern (SADP) of the O-diffused region shows α-Ta and TaAl3 rings without an evident oxide phase, suggesting that the Al oxide was amorphous. A high-resolution TEM image (Figure 4b) illustrates that the black sublayers were the α-Ta phase, whereas the crystalline TaAl3 domains were identified between the Ta-rich sublayers and the amorphous Al-oxide sublayers. Figure 5 shows the AES results of the 600 °C and 4 h annealed Ta0.61Al0.39 coatings. The O diffusion depth was restricted to two or three of the stacking periods. The deviation of the AES analyzed atomic concentration from that examined by EPMA could be attributed to the preferential sputtering effects which were also reported for the Ru–Al system [,]. Moreover, the fluctuation of the profiles in the deeper region seemed unclear, accompanied with a large sampling interval because of a sputter etching rate of 6.76 nm/min. Figure 6 exhibits the XRD patterns of the Ta0.61Al0.39 coatings annealed for 0.5–100 h. The XRD patterns of the Ta0.61Al0.39 coatings that were annealed for 30 min exhibited coexisting α-Ta and β-Ta phases, whereas the α-Ta phase was dominant for the films with annealing times exceeding 4 h; these results implied that the metastable β-Ta in the shallow depth region transformed to the stable α-Ta, because the XRD patterns were recorded using the grazing incidence technique. The XRD patterns of the 4, 12, and 24 h annealed Ta0.61Al0.39 coatings exhibited similar results. By contrast, amorphous oxide signals at two theta angles less than 30° can be observed for the Ta0.61Al0.39 coatings annealed for 50 and 100 h. Figure 7a shows the cross-sectional TEM image of a Ta0.61Al0.39 coating annealed for 100 h; the O signals detected by EDS were observed at the outmost nine stacking periods, accompanied with expanded period widths. The high-resolution TEM image (Figure 7b) illustrates that the black sublayers were an α-Ta phase, whereas the crystalline TaAl3 domains were dispersed in the amorphous Al-oxide matrix, which formed the white sublayers. Because Al and Ta are insoluble in equilibrium states [,], and the Ta–Al coatings were fabricated through a cyclical gradient concentration deposition, the Ta-rich sublayers behaved as a diffusion barrier for Al at 600 °C. Thus, internal oxidation became the main oxidation mechanism, and the preferentially formed Al-oxide sublayers restricted oxidation. Therefore, the Ta0.61Al0.39 coatings that had been annealed up to 100 h exhibited thermal stability and oxidation resistance. By contrast, no Ta-rich sublayers formed during the sublayer stacking of the Ta0.33Al0.67 coatings. Thus, granular Al2O3 formed during annealing at 600 °C, and the multilayer structure was destroyed and partially detached.

Figure 4.

(a) Cross-sectional TEM image and (a–1) selected area diffraction pattern (SADP) and (b) high-resolution TEM image of the Ta0.61Al0.39 coating annealed in 1% O2–99% Ar at 600 °C.

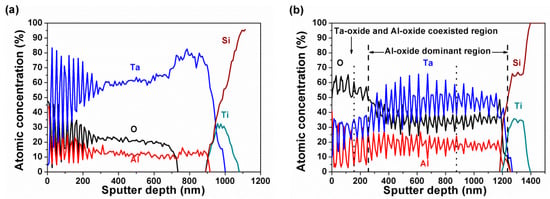

Figure 5.

Auger electron spectroscopy (AES) depth profiles of Ta0.61Al0.39 coatings annealed in 1% O2–99% Ar at 600 °C for 4 h.

Figure 6.

XRD patterns of Ta0.61Al0.39 coatings annealed in 1% O2–99% Ar at 600 °C.

Figure 7.

(a) Cross-sectional and (b) high-resolution TEM images of the Ta0.61Al0.39 coating annealed in 1% O2–99% Ar at 600 °C for 100 h.

3.3. Oxidation of Ta–Al Coatings in Air

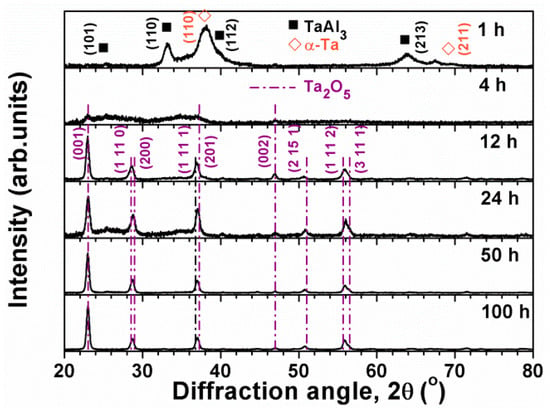

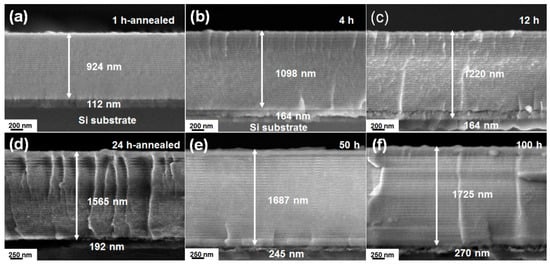

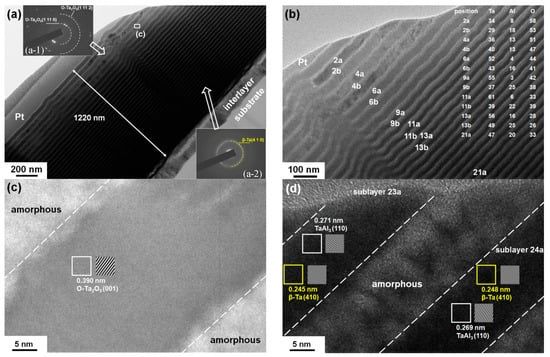

The Ta0.63Al0.37 coatings (60.8 at.% Al + 35.6 at.% Ta + 3.6 at.% O) were prepared using the same sputter parameters for fabricating Ta0.61Al0.39 coatings mentioned in Section 3.2. The two coatings belonged to two batches and exhibited a slight deviation in chemical compositions. Figure 8 shows the XRD patterns of the Ta0.63Al0.37 coatings annealed in air at 600 °C for 1–100 h. The Ta0.63Al0.37 coatings annealed for 1 h exhibited an XRD pattern comprising TaAl3 and α-Ta phases, which was similar to those of the Ta0.61Al0.39 coatings annealed in 1% O2–99% Ar at 600 °C for 4–24 h (Figure 6). The Ta0.63Al0.37 coatings annealed in air for 4 h demonstrated an amorphous and an orthorhombic Ta2O5 (ICDD 00–025–0922) phase. Moreover, the annealed Ta0.63Al0.37 coatings exhibited a Ta2O5 dominant structure after extending the annealing time to 12–100 h. The coating thickness increased from 792 to 924, 1098, 1220, 1565, 1687, and 1725 nm, while increasing the annealing time from 0 to 1, 4, 12, 24, 50, and 100 h by examining the cross-sectional SEM images (Figure 9). The 100 h annealed sample was well adhered on the substrate. Figure 10a,b displays the AES results of the Ta0.63Al0.37 coatings annealed in air at 600 °C for 1 and 12 h, respectively. The O diffused into a depth of 720 and 1220 nm (the entire annealed coating) for the 1 and 12 h annealed Ta0.63Al0.37 coatings, respectively. The variation of the O profile was consistent with the variation of the Al profile for the 1 h-annealed coatings, which indicated that the internal oxidation was conducted by the preferential formation of Al-oxide. However, the AES results of a 12 h annealed Ta0.63Al0.37 coating were classified into two parts. In the interior region, the variations of the O and Al profiles were consistent. By contrast, in the outer region, including six stacking layers, the positions with local maximum O levels were accompanied with high Ta contents, which implied that Ta-oxide formed after the inward diffusion of O, exceeding a demanded stoichiometric level for Al2O3.

Figure 8.

XRD patterns of Ta0.63Al0.37 coatings annealed in air at 600 °C.

Figure 9.

Cross-sectional SEM images of Ta0.63Al0.37 coatings annealed in air at 600 °C for (a) 1, (b) 4, (c) 12, (d) 24, (e) 50, and (f) 100 h.

Figure 10.

AES depth profiles of Ta0.63Al0.37 coatings annealed in air at 600 °C for (a) 1 and (b) 12 h.

Figure 11a shows the cross-sectional TEM image and SADPs of a Ta0.63Al0.37 coating after annealing in air at 600 °C for 12 h. The SADP of the outer region exhibited spots of an orthorhombic Ta2O5 phase which implied that the outer region comprised crystalline Ta2O5 and amorphous Al-oxide phases. By contrast, the SADP of the interior region exhibited a diffused ring of β-Ta phase. Figure 11b shows the EDS analysis results, which exhibit a decrease trend along the depth direction for the O content. The black sublayers exhibited high Ta and low Al compositions related to those of the white sublayers. Figure 11c displays a high-resolution TEM image in the outer region, indicated in Figure 11a, which shows that the black sublayer is crystalline Ta2O5 and the white sublayers are amorphous. Figure 11d illustrates a high-resolution TEM image in the deeper interior region, the sublayers 23 and 24, which shows that the black sublayers comprise lattice fringes of TaAl3 and β-Ta phases, and the white sublayers are amorphous.

Figure 11.

(a) Cross-sectional TEM image and (a–1 and a–2) SADP, (b) EDS analysis results, (c) and (d) high-resolution TEM images of the Ta0.63Al0.37 coating annealed in air at 600 °C for 12 h.

4. Conclusions

The Ta–Al multilayer coatings were prepared by direct current magnetron co-sputtering through cyclical gradient concentration deposition which formed alternatively stacked Ta- and Al-rich sublayers. The preferentially formed oxides were amorphous Al2O3, and then orthorhombic Ta2O5 at 600 °C. The insolubility between Ta and Al resulted in the Ta-rich sublayers obstructing the diffusion of Al, whereas the Al-rich sublayers formed amorphous Al-oxide sublayers after annealing in O2-containing atmospheres which restricted further oxidation; these effects caused the Ta-rich Ta–Al multilayer coatings to exhibit thermal stability and oxidation resistance when they were annealed up to 100 h at 600 °C in a 1% O2–99% Ar atmosphere. Moreover, the multilayer structure of the Ta0.63Al0.37 coatings was maintained after annealing up to 100 h at 600 °C in air. The Ta–Al multilayer coatings exhibited the potential to replace the Ru–Al coatings utilized under oxygen containing atmospheres for high-temperature purposes such as bond coats in thermal barrier systems; therefore, the feature study should focus on the bond coat characteristics of the Ta–Al multilayer coatings, including the formation of a thermally grown oxide layer on the bond coats and the restricted oxidation behavior of multilayer coatings during the deposition of thermal barrier coatings.

Author Contributions

Conceptualization, Y.-I.C.; Funding acquisition, Y.-I.C.; Investigation, N.-Y.L. and Y.-E.K.; Project administration, Y.-I.C.; Validation, Y.-I.C. and Y.-E.K.; Writing—original draft, Y.-I.C.

Funding

This research was funded by the Ministry of Science and Technology, Taiwan, grant number 106-2221-E-019-022-MY3. The APC was funded by the National Taiwan Ocean University.

Acknowledgments

The authors thank Mei-Chen Chiang at Ming Chi University of Technology for technical support with TEM observations. The authors thank Su-Yueh Tsai at the Instrumentation Center at the National Tsing Hua University for technical support with the FE-EPMA analyses.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mücklich, F.; Ilić, N. RuAl and its alloys. Part I. Structure, physical properties, microstructure and processing. Intermetallics 2005, 13, 5–21. [Google Scholar] [CrossRef]

- Mücklich, F.; Ilić, N.; Woll, K. RuAl and its alloys, Part II: Mechanical properties, environmental resistance and applications. Intermetallics 2008, 16, 593–608. [Google Scholar] [CrossRef]

- Mitsui, H.; Habazaki, H.; Hashimoto, K.; Mrowec, S. The sulfidation and oxidation behavior of sputter-deposited Al–Ta alloys at high temperatures. Corros. Sci. 1997, 39, 59–76. [Google Scholar] [CrossRef]

- Habazaki, H.; Mitsui, H.; Ito, K.; Asami, K.; Hashimoto, K.; Mrowec, S. Roles of aluminium and chromium in sulfidation and oxidation of sputter-deposited Al- and Cr-refractory metal alloys. Corros. Sci. 2002, 44, 285–301. [Google Scholar] [CrossRef]

- Gurrappa, I.; Wilson, A.; Datta, P.K. Palladium and tantalum aluminide coatings for high-temperature oxidation resistance of titanium alloy IMI 834. J. Coat. Technol. Res. 2009, 6, 257–268. [Google Scholar] [CrossRef]

- Lee, J.W.; Kuo, Y.C. Cyclic oxidation behavior of a cobalt aluminide coating on Co-base superalloy AMS 5608. Surf. Coat. Technol. 2005, 200, 1225–1230. [Google Scholar] [CrossRef]

- Das, D.K. Microstructure and high temperature oxidation behavior of Pt-modified aluminide bond coats on Ni-base superalloys. Prog. Mater. Sci. 2013, 58, 151–182. [Google Scholar] [CrossRef]

- Wang, C.J.; Chen, S.M. The high-temperature oxidation behavior of hot-dipping Al–Si coating on low carbon steel. Surf. Coat. Technol. 2006, 200, 6601–6605. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Liang, T. Al–Si and Al–Si–Y coatings deposited by HS-PVD for the oxidation protection of γ-TiAl. Surf. Coat. Technol. 2018, 350, 587–595. [Google Scholar] [CrossRef]

- Zhu, L.; Du, G.; Bai, S.; Zhang, H.; Ye, Y.; Ai, Y. Oxidation behavior of a double-layer iridium-aluminum intermetallic coating on iridium at the temperature of 1400–2000 °C in the air atmosphere. Corros. Sci. 2017, 123, 328–338. [Google Scholar] [CrossRef]

- Sen, S.; Lake, M.; Schaaf, P. Experimental investigation of high temperature oxidation during self-propagating reaction in Zr/Al reactive multilayer films. Surf. Coat. Technol. 2018, 340, 66–73. [Google Scholar] [CrossRef]

- Wuu, D.S.; Chan, C.C.; Horng, R.H.; Lin, W.C.; Chiu, S.L.; Wu, Y.Y. Structural and electrical properties of Ta–Al thin films by magnetron sputtering. Appl. Surf. Sci. 1999, 144–145, 315–318. [Google Scholar] [CrossRef]

- Su, P.J.; Chung, C.K. Amorphization of Ta–Al films using magnetron sputtering. Surf. Coat. Technol. 2005, 200, 1664–1668. [Google Scholar] [CrossRef]

- Chung, C.K.; Chang, Y.L.; Chen, T.S.; Su, P.J. Annealing effects on microstructure and properties of Ta–Al thin film resistors. Surf. Coat. Technol. 2006, 201, 4195–4200. [Google Scholar] [CrossRef]

- Hung, F.S. Material application of a transformer box: A study on the electromagnetic shielding characteristics of Al–Ta coating film with plasma-spray process. Coatings 2019, 9, 495. [Google Scholar] [CrossRef]

- Chen, Y.I.; Zhang, Z.T.; Kai, W.; Huang, Y.R. Oxidation behavior of Ru–Al multilayer coatings. Appl. Surf. Sci. 2017, 406, 1–7. [Google Scholar] [CrossRef]

- Chen, Y.I.; Tsai, B.N. Internal oxidation mechanism for Ta–Ru and Mo–Ru coatings. Thin Solid Films 2011, 519, 4974–4980. [Google Scholar] [CrossRef]

- Chen, Y.I. Laminated structure in internally oxidized Ru–Ta coatings. Thin Solid Films 2012, 524, 205–210. [Google Scholar] [CrossRef]

- Chen, Y.I.; Chu, H.N.; Chang, L.C.; Lee, J.W. Internal oxidation and mechanical properties of Ru based alloy coatings. J. Vac. Sci. Technol. A 2014, 32, 02B101. [Google Scholar] [CrossRef]

- Chen, Y.I.; Huang, Y.R.; Chang, L.C. Internal oxidation of laminated Hf–Ru coatings. J. Vac. Sci. Technol. A 2016, 34, 02D103. [Google Scholar] [CrossRef]

- Chen, Y.I.; Lu, T.S.; Zheng, Z.T. Internally oxidized Ru–Zr multilayer coatings. Coatings 2017, 7, 46. [Google Scholar] [CrossRef]

- Kofstad, P. High Temperature Corrosion; Elservier Applied Science Publishing: New York, NY, USA, 1988. [Google Scholar]

- Khanna, A.S. Introduction to High Temperature Oxidation and Corrosion; ASM International: Materials Park, OH, USA, 2002. [Google Scholar]

- Chen, Y.I.; Zheng, Z.T.; Jhang, J.W. Thermal stability of Ru–Al multilayered thin films on Inconel 617. Metals 2018, 8, 514. [Google Scholar] [CrossRef]

- Stavrev, M.; Fischer, D.; Wenzel, C.; Drescher, K.; Mattern, N. Crystallographic and morphological characterization of reactively sputtered Ta, Ta–N and Ta–N–O thin films. Thin Solid Films 1997, 307, 79–88. [Google Scholar] [CrossRef]

- Shin, C.S.; Kim, Y.W.; Gall, D.; Greene, J.E.; Petrov, I. Phase composition and microstructure of polycrystalline and epitaxial TaNx layers grown on oxidized Si(001) and MgO(001) by reactive magnetron sputter deposition. Thin Solid Films 2002, 402, 172–182. [Google Scholar] [CrossRef]

- Chen, Y.I.; Chen, S.M. Annealing effects on nanostructure and mechanical properties of nanolaminated Ta–Zr coatings. Surf. Coat. Technol. 2013, 215, 209–217. [Google Scholar] [CrossRef]

- Steidel, C.A. Electrical and structural properties of co-sputtered tantalum–aluminum films. J. Vac. Sci. Technol. 1969, 6, 694–698. [Google Scholar] [CrossRef]

- Sina, H.; Iyengar, S.; Lidin, S. Reaction behavior and evolution of phases during the sintering of Ta–Al powder mixtures. J. Alloy. Compd. 2016, 654, 103–111. [Google Scholar] [CrossRef]

- Barin, I. Thermochemical Data of Pure Substances, 3rd ed.; VCH: New York, NY, USA, 1995. [Google Scholar]

- Seifert, M.; Rane, G.K.; Oswald, S.; Menzel, S.B.; Gemming, T. The influence of the composition of Ru100-xAlx (x = 50, 55, 60, 67) thin films on their thermal stability. Materials 2017, 10, 277. [Google Scholar] [CrossRef]

- Chen, Y.I.; Jhang, J.W. Thermal stability of laminated Ru–Al/Ru–Al–Zr coatings on Inconel 617. Surf. Coat. Technol. 2019, 361, 357–363. [Google Scholar] [CrossRef]

- Kattner, U.R. Ta-Al Phase Diagram. In Binary Alloy Phase Diagrams; Massalski, T.B., Ed.; ASM International: Materials Park, OH, USA, 1990. [Google Scholar]

- Witusiewicz, V.T.; Bondar, A.A.; Hecht, U.; Zollinger, J.; Petyukh, V.M.; Fomichov, O.S.; Voblikov, V.M.; Rex, S. Experimental study and thermodynamic re-assessment of the binary Al–Ta system. Intermetallics 2010, 18, 92–106. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).