Abstract

The adhesion strength between thin films has a significant effect on performance of micro-devices. It is introduced that the effects of three pre-treatment methods: acid, pulse reverse current and anodic current, on the adhesion performance of electrodeposited Ni films on Ni substrate. The adhesion strength, surface and fracture morphology of the Ni films were investigated. The dense oxide films on the Ni substrate were removed effectively by using the anodic dissolution current method in the acidic chloride solutions. Meanwhile, the Ni films treated with specific treatment conditions produced different roughness, which was responsible for the improved adhesion strength. The adhesion strength of the Ni films increased up to 629.8 MPa when substrates were treated with anodic current density of 30 mA/cm2 for 10 min, which is nearly two times higher than that of films treated by 5 vol % HCl for 10 min. The results indicate that the anodic current treatment method effectively improves the adhesion strength of Ni films.

1. Introduction

With the rapid development of micro-electro-mechanical systems (MEMS) technology, a large number of materials including silicon, metal and polymers are widely used in MEMS field. The MEMS micro-devices normally have laminated composite structure in which metals are recognized as the primary materials, such as electroplated nickels. Nickels have been widely used to fabricate micro-gear, micro-motor, micro acceleration switch and so on [1,2,3].

The adhesion strength between metal layers plays an important role in the manufacture of laminated micro-devices using Ultra-Violet Lithography, Galvanoformung, Abformung (UV-LIGA) technology. It is responsible for the failure of micro-devices and considered as a key property to realize the MEMS devices industrialization [4]. The Ni metals have been widely used in the field of aerospace and automotive industries as well as non-silicon MEMS technology [5]. The weak adhesion strength between Ni/Ni layers often leads to the delamination and failure in the harsh working environment, such as the removing of photoresist [6,7,8]. Therefore, it is a necessary and urgent task to improve the adhesion strength of the Ni/Ni films in MEMS to obtain high quality devices for reliability and long lifespans.

The adhesion strength between metal layers can be improved by some traditional surface treatment methods, such as a strong acid treatment method. However, these methods cannot effectively, or significantly, improve the adhesion strength. Other methods are also utilized to improve the adhesion strength between metal films, such as adding a transition layer between the laminated films [9,10]. These methods include: (a) zincate pretreatment for the Cu films and AZ91D alloys interfaces; (b) the Cu flash pre-plating for the Ni/Ni films interfaces on Ni substrate by using acid corrosion and the activation potential methods; (c) electrochemical reaction to improve the adhesion strength between carbon films and Ti substrate in molten salt system [11,12,13,14,15]. These methods, however, still cannot meet the requirement of the non-silicon MEMS devices, as they bring low adhesion strength and instability of the metal films. Electrochemistry as a general method is used to fabricate metal films, nanowires, honeycomb-like structures and microstructures with high aspect ratio [16,17,18,19]. This method could improve the adhesion strength of the film structure to some extent, but it is rarely studied in field of MEMS devices.

Although the metal Ni materials are frequently applied in the MEMS field, the systematic study of the adhesion strength between Ni/Ni films is lacking. It limits the process of microstructure devices based on metal Ni. In our previous work, it has been demonstrated that a hydrochloric acid and pulse reverse (PR) current treatments method could well improve the adhesion strength between Ni laminated films [20].

In the present paper, we study the adhesion strength between Ni laminated films, treated with three methods: acid, pulse reverse current and anodic current treatments. The influence of the anodic current and treatment time in the anodic treatment method as well as the surface roughness of the Ni films on the adhesion strength between Ni laminated films is investigated. The focus ion beam Electron Back-Scattered Diffraction (FIB-EBSD) method is used to observe the interfaces between Ni laminated films. The three methods produce different effects on the improvement of adhesion strength Ni laminated films. The acid treatment method increases the interfacial roughness. The pulse reverse treatment process removes the passive layer between layers meanwhile forms a transition layer, which caused the increasing of the interface roughness. The anodic current treatment method significantly improves adhesion strength, because it removes the oxygen between interfaces and increases the surface roughness.

2. Experimental

In this paper, the Ni films were electrodeposited onto the Ni substrate using electroplating solutions with direct current. The electrodeposited solutions component includes Ni (SO3NH2)2·4H2O 500 g/L, NiCl2·4H2O 5 g/L, H3BO3 25 g/L and saccharine 50 mg/L. pH value and temperature of the plating solution were set as 4.0 and 45 °C, respectively. Current density was 20 mA/cm2 during electrodeposition process. The Ni films were treated with three methods: acid, pulse reverse and anodic current treatments. Regarding the acid treatment method, the Ni films were treated by using 5 vol % HCl acid solution at room temperature of 5, 10 and 15 min, respectively. For the PR treatment method, the Ni films were treated in the electrodeposited solutions. The procedure is following: firstly, the Ni films were treated by solution with 5 min with the ratio of current density of cathode/anode (ic/ia) 1.0; Then, they were treated by the solution with the ration of ic/ia = 1.3 with 10 min and of ic/ia = 2.0 with 10 min, respectively; Finally, the Ni films were moved into the normal electrodeposition solution to be electrodeposited with direct current. Regarding the anodic current treatment method, the current density was set as 10, 20, 30 mA/cm2 and treatment time was set as 5, 10, 15 min respectively.

The adhesion strength of specimens was measured by the bonding tester (RHESCA, PTR-1100, RHESCA, Tokyo, Japan) using island-shear method [20]. The diameter of the island was 50 μm. Surface topography of the Ni films and fracture appearance was observed by scanning electron microscope (Ultra 55, Zeiss, Heidenheim, Germany). Surface roughness was obtained using three-dimensional optical profiling system (WYKO NT1100, Vecco, NY, USA). The cross-section morphology of the Ni films was measured by scanning electron microscope (SEM) with backscattering electron. The sliced samples used in the SEM examination were prepared by focused ion beam (FIB) technology. Energy dispersive X-ray spectroscopy (EDS) was used to analyze the O content on the surface of the Ni films.

3. Results and Discussion

3.1. Effect of Three Treatment Methods on Adhesion Strength

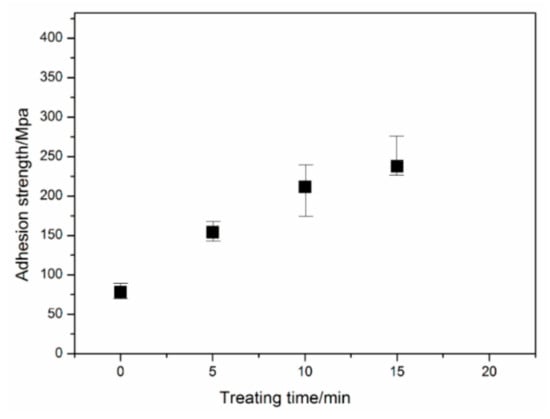

The effect of hydrochloric acid treatment time on the adhesion strength of the lower Ni films is shown in Figure 1. Three samples are tested for each of the tests. The meaning of the error bar is that the difference between the maximum and the average is the upper limit, the difference between the minimum and the average is the lower limit. The adhesion strength of the Ni laminated films increases linearly with increasing of treating time. In the first ten minutes, the adhesion strength increases significantly with a rising rate of 70 MPa/min, finally up to be 220 MPa. When the treating time is 15 min, the adhesion strength increases to approximately 250 MPa. It is indicated that the longer treating time is beneficial to the adhesion strength. The main reason is due to the increase of surface roughness with treating time.

Figure 1.

The adhesion strength of the Ni films treated by 5 vol % hydrochloric acid.

The effects of pulse reverse current on the adhesion strength of the Ni laminated films have been reported in our previous work [20]. Here we focus on the comparison of the adhesion strength of the Ni laminated films treated by optimized pulse reverse current (PR). The results indicate that an average shear adhesion strength of approximately 400 MPa is achieved for the Ni laminated films treated by PR method, which is higher than that of the Ni laminated films treated by hydrochloric acid. In this PR method, the increased micro roughness and transition layer are beneficial to improve the adhesion.

Table 1 lists the surface roughness (Ra) and the adhesion strength of the Ni laminated films treated by anodic current method with different current density and treating time. When the current density keeps a constant, the surface roughness and the adhesion strength increases with the increasing of treating time. Vice versa, when the treating time is fixed a value, the surface roughness and the adhesion strength increase with the increasing of the current density. Meanwhile, it can be seen that the value of the anodic current density is more than 20 mA/cm2 even with treating time of 5 min, the adhesion strength of the Ni laminated films is higher than the maximum of the Ni laminated films treated by hydrochloric acid (shown in Figure 1). It indicates that the adhesion strength of the Ni laminated films is improved significantly when the lower Ni films are treated by anodic current in the nickel chloride solution. One thing that cannot be denied is that the higher the surface roughness, then the higher the adhesion strength of the Ni films. So the surface roughness is responsible for the improvement of the adhesion strength. Moreover, these results may be related to removing the oxygen between the interfaces and increasing the surface roughness, thus significantly improving the adhesion strength.

Table 1.

The roughness and adhesion strength of the Ni laminated films treated by anodic current.

3.2. Surface Morphology

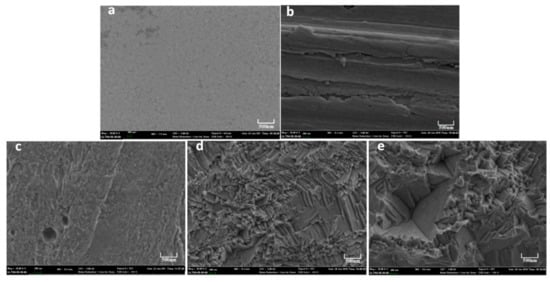

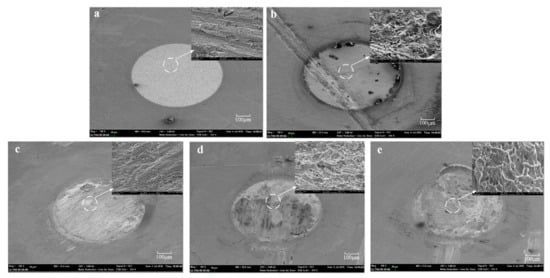

The surface morphologies of the Ni laminated films treated with different methods are shown in Figure 2. The untreated Ni film presents a smooth surface, shown in Figure 2a. When the Ni films are treated with a 5 vol % hydrochloric acid solution for 10 min, the surface of the Ni laminated films show significant roughness, accompanied by some groove strips, as shown in Figure 2b. Figure 2c corresponds to the surface morphology of the Ni films treated by anodic current with 10 mA for 10 min. It can be seen that there is a certain corrosion on the surface of Ni films. Compared with Figure 2c, surface corrosion is more obvious in Figure 2d with 20 mA for 10 min. Figure 2e shows the surface morphology of the Ni films treated by anodic current with 30 mA with 10 min. The surface of the Ni films is completely corroded. The surface shows some corrosion spits and steps resulting in a significant roughness. With the same treating time, the surface roughness changed significantly with the increase of anodic current.

Figure 2.

Surface morphology of Ni laminated films treated at different methods: (a) untreated; (b) treated with 5 vol % HCl with 10 min; (c) treated with anodic current of 10 mA with 10 min; (d) treated with anodic current of 20 mA with 10 min; (e) treated with anodic current of 20 mA with 10 min.

The morphology with uniform and big roughness is considered to be positive on the improvement of adhesion strength of the Ni laminated films. It not only improves the metal bonding between Ni laminated films but also enhances the mechanical occlusion property. Therefore, rough surface is responsible for the further improvement of the adhesion strength of the Ni laminated films.

In the previous paper, the Ni films were treated by the pulse reverse current. The uniform corrosion morphology on the Ni films is also achieved [20]. The Ni substrate has been coarsened owing to the presence of deposition current intermittent treatment. The adhesion strength of the Ni laminated films is improved, because the coarsened substrate increases the micro-surface area and the effect of physical interlocking between Ni films.

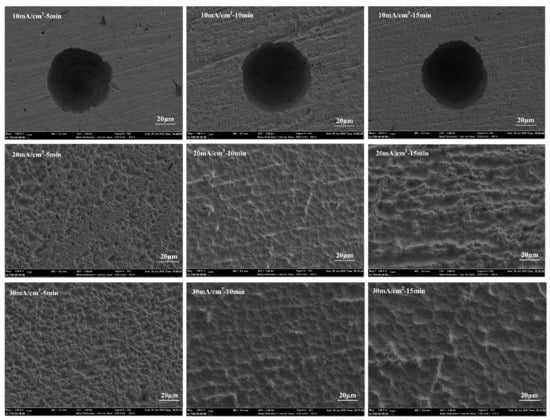

In order to obtain the influence of anodic current treatment on the surface morphology, the surface of the Ni films is treated with different current densities and treating time. The results are shown in Figure 3. As can be seen that the surface of the Ni films is strongly corroded with a dot when the anodic current density is 10 mA/cm2. However, the whole surface roughness of the Ni films treated with different treating time presents no significant change.

Figure 3.

Surface morphology of the metal Ni films treated with different anodic current density and time.

When the anodic current density is 20 mA/cm2, the whole surface is completely corroded and produces a significant roughness. In addition, with the increase of treating time, the surface roughness has been improving. Especially when the treating time reaches 15 min, the surface roughness is improved obviously. The adhesion strength of Ni sample also reached 500 MPa (Table 1). When the anodic current density goes up to be 30 mA/cm2, the further corrosion of the Ni films occurred. When the treating time reaches 10 min, the surface roughness is clearly changed. Moreover, when the treatment time reaches 15 min, the surface roughness has no obvious change, as compared with 10 min. The corresponding adhesion strength is also consistent with this result in Table 1. Therefore, the increase of surface roughness with increase of current densities and treating time is helpful for the enhancement of the physical occlusion between the Ni laminated films. It clearly explains the increase of adhesion strength of Ni films.

The surface morphology of electrodeposited Ni film is shown in Figure 4. It can be seen that the surface of electroplated nickel has a certain roughness. This phenomenon may be related to current density and deposition speed in electrodeposited process.

Figure 4.

Image of electrodeposited film surface.

The seed layer is treated with 1% diluted hydrochloric acid for 5 s to remove the oxide layer on the surface. Previous experiments show that this method is suitable for electroplating process. The seed layer has little influence on the morphology of electrodeposited films. Therefore, in this paper, all seed layers of sample are treated before electrodepositing.

3.3. Fracture Morphology

Figure 5 presents the fracture morphologies of the Ni films: untreated, treated by 5 vol % HCl with 10 min and different anodic current treatment with 10 min. The location and morphologies of the fracture shows significant difference after the measurement of the adhesion strength of the Ni laminated films. For both of the Ni films without treated and treated with 5 vol % HCl with 10 min, the fracture behavior takes place at interfaces between the first Ni layer and the second Ni layers, shown in Figure 5a,b. The adhesion strength of the Ni films treated with 5 vol % HCl with 10 min is two times that of the untreated Ni films. It is shown that the roughness caused by acid treatment may increase the adhesion strength of the Ni films to a limited extent.

Figure 5.

Fracture morphologies of the Ni films treated with different methods: (a) untreated; (b) 5 vol % HCl with 10 min; (c) anodic current of 10 mA with 10 min; (d) treated with anodic current of 20 mA with 10 min; (e) treated with anodic current of 30 mA with 10 min.

However, for the Ni films treated with HCl solution, no visible dimples in the part of fracture and the fracture takes place at interfaces between Ni film layers. Concerning the Ni films treated by the anodic treatment method, the interface can be seen clearly and the dimples are clearer than that of the Ni films treated by HCl solution, as shown in Figure 5c–e. Figure 5c corresponds to the fracture morphology of the Ni films treated by anodic current with 10 mA for 10 min. A part of the dimples appeared in Figure 5c. Compared with Figure 5c, there are more dimples in Figure 5d which is treated with 20 mA for 10 min. Figure 5e show that the fracture morphology has a large number of dimples in the part of fracture. The interfaces between the Ni film layers cannot be distinguished. In addition, the fracture morphology indicates that the interfaces between the Ni film layers mixed. Moreover, the fracture morphology shows a tear shape. This indicates that the interfaces inside the Ni films fused well together, which is helpful for the improvement of the adhesion strength of the Ni laminated films.

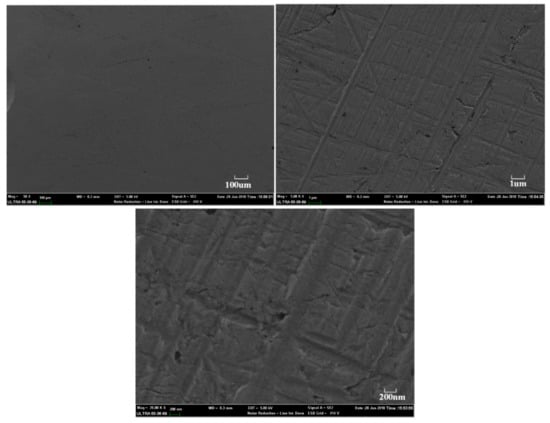

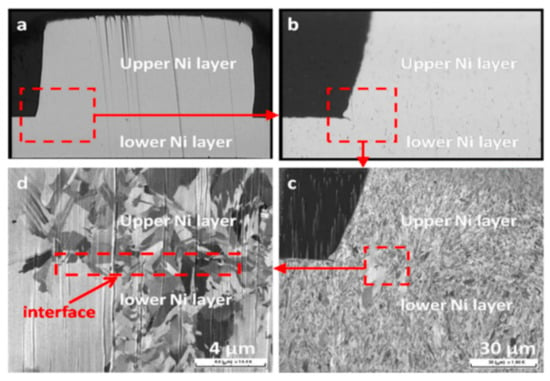

To further obtain the detailed interface information of the electrodeposited Ni films treated by anodic current of 30 mA/cm2 with 10 min, the Electron Backscattered Diffraction (EBSD) morphologies were measured and shown in Figure 6. The interfaces between the Ni films totally mixed, indicating that both Ni layers grew well together. This explains well the reason of good performance of the electrodeposited Ni films with the adhesion strength value of 629.8 MPa.

Figure 6.

Different magnification cross-section morphology and microstructure of the Ni films treated by anodic current.

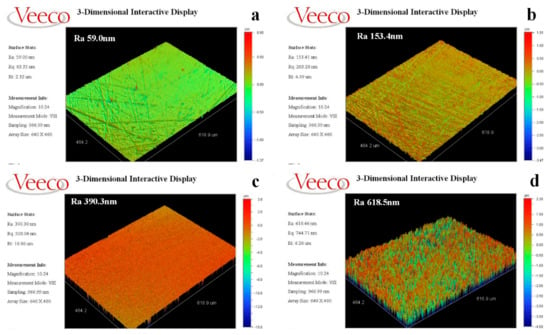

Figure 7 shows the results of the surface roughness of the metal Ni films treated with different methods: untreated, 5 vol % HCl with 10 min, pulse reverse current, anodic current for 30 mA with 10 min. It can be seen that the surface roughness of the metal Ni films presents significant difference.

Figure 7.

Surface roughness of the metal Ni films treated with different methods (a) untreated; (b) 5 vol % HCl for 10 min; (c) pulse reverse current; (d) anodic current density with 30 mA/cm2 for 10 min.

The roughness of the untreated metal Ni film is small, with a value of 59.0 nm, and the value raises up to be 153.4 nm when the metal Ni films are treated with 5 vol % HCl with 10 min. However, when the metal Ni films are treated with pulse reverse current and anodic current, the roughness significantly increased up to be 390.3 nm and 618.5 nm, respectively.

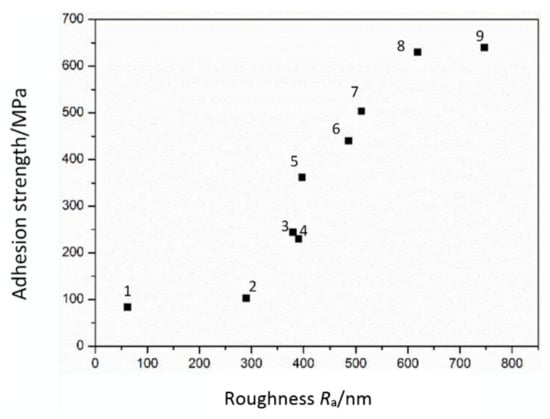

Figure 8 shows the relationship between adhesion strength and surface roughness of the metal Ni films. In these experiments, the seed layers of all sample are treated with 1% diluted hydrochloric acid for 5 s to remove the oxide layer on the surface firstly. Then, the lower Ni layer is electrodeposited with certain condition. After that, the lower Ni layer is treated by different conditions with anodic current treatment. Finally, the upper Ni films is electrodeposited on the lower Ni layer. We focus on adhesion strength between the lower Ni layer and upper layer in this paper. From the Figure 7, it indicates that the adhesion strength increases with the increasing of the surface roughness. The number 1, 2 and 3 are treated by anodic current density of 10 mA/cm2 with 5, 10 and 15 min, respectively. Three samples were tested for each value. The number 4, 5 and 6 are treated by anodic current density of 20 mA/cm2 with 5, 10 and 15 min. The number 7, 8 and 9 are treated by anodic current density of 30 mA/cm2 with 5, 10 and 15 min. Compared with the results of Figure 1, the adhesion strength of the Ni films is highly related to the surface roughness. This is due to the reason that the rough surface improves the physical occlusion effect between Ni/Ni layers. The same reason explains the improvement of adhesion strength of the metal Ni films treated by anodic current density of 30 mA/cm2 with 10 min.

Figure 8.

Relationship between the adhesion strength and surface roughness of the metal Ni films.

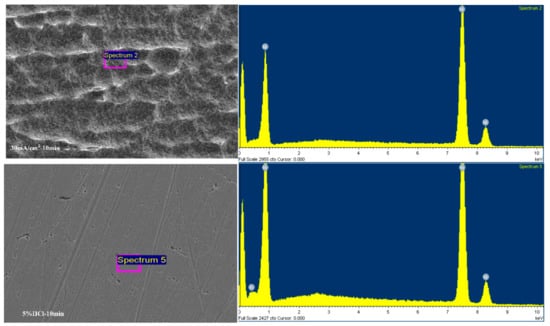

3.4. Surface Residual Oxides

To obtain the effect of surface residual oxides of the metal Ni films on the adhesion, element analysis are measured on the metal Ni films treated by anodic current density of 30 mA/cm2 with 10 min and 5 vol % HCl with 10 min. As can be seen from Figure 9, no oxygen was found on the surface of the metal Ni films treated by the anodic current density. The metal Ni films treated by 5 vol % HCl with 10 min shows the presence of oxygen with content of 2.67 wt %. It indicates that the presence of a large amount of chloride ions in the solution accelerates the removal of the nickel oxides, but the dense oxides cannot be removed completely only by using small current density or bath. The presence of the nickel oxides reduces the adhesion strength [21].

Figure 9.

Energy dispersive X-ray spectroscopy (EDS) results of the metal Ni films treated with both methods: anodic current density of 30 mA/cm2 with 10 min and 5 vol % HCl with 10 min.

It is mentioned, in Figure 3, that the surface morphology of the sample treated by anodic current density with 10 mA/cm2 differs from that of the sample treated by anodic current density of 20 mA/cm2. The sample shows inhomogeneous corrosion spots and does not change with treating time. Compared the results of Figure 1, it is found that when the current density is set as 10 mA/cm2, the increasing of the roughness is ascribed to the depth of corrosion spot. Excepting the big spots, the surface morphology of both samples treated by 5 vol % HCl with 10 min and anodic current density of 10 mA/cm2 are extremely similar but show no obvious improvement of interface adhesion strength. This phenomenon is mainly due to the presence of the nickel oxides on the top of the metal Ni films when it explores to the air atmosphere. Moreover, the inhomogeneous corrosion spot indicates that the oxides protect the parts without corrosion spots. The same phenomena occur on the metal Ni films treated by 5 vol % HCl with 10 min.

4. Conclusions

The effects of the acid, pulse reverse current and anodic current density treatment methods on the adhesion performance between metal Ni laminated films were studied. The results indicate that the dense oxides on the top of the metal Ni substrate can be removed effectively by anodic dissolution current in the nickel chloride solution. After the treatment of anodic current density of 30 mA/cm2 with 10 min, the adhesion strength of the both Ni films raises up to be 629.8 MPa and is higher than that of samples treated by 5 vol % HCl and pulse reverse current. In addition, the adhesion strength is related to the surface roughness and increases with the increase of roughness. The anodic dissolution is beneficial to the removal of Ni oxide films and to the improvement of adhesion strength. Moreover, the EBSD results present that the interfaces between both Ni layers totally mixed. The anodic current treatment method is an effective way for the enhancement of adhesion strength between Ni laminated films. It is a promising way to improve the reliability of MEMS devices, especially in electrodeposited metal structures.

Author Contributions

Design and Analysis, R.L.; Test, Y.Y.; Experimentation, H.W.; Formal Analysis, X.G.

Funding

This work is supported by the Advanced Research Project (625010105), the Program of Science and Technology Commission of Shanghai Municipality (11DZ2290203), the National Key Laboratory Foundation (9140C790103120C7906) and The National Natural Science Foundation of China (51205390) and (51702133).

Acknowledgments

We are thankful for support of the Key Laboratory for Thin Film and Microfabrication Technology of Ministry of Education, National Key Laboratory of Micro/Nano Fabrication Technology, Research Institute Micro/Nano Science and Technology.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lim, J.H.; Park, E.C.; Joo, J.; Jung, S.B. Effect of additives on microstructure and mechanical properties of nickel plate/mask fabricated by electroforming process. J. Electrochem. Soc. 2009, 156, 108–112. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Zhu, B.; Chen, W.G.; Ding, G.F.; Wang, H.; Zhao, X.L. Fabrication and characterization of a multidirectional-sensitive contact-enhanced inertial micro-switch with an electrophoretic flexible composite fixed electrode. J. Micromech. Microeng. 2012, 22, 045006. [Google Scholar] [CrossRef]

- Wang, P.H.; Tanaka, K.; Sugiyama, S.; Dai, X.H.; Zhao, X.L. A micro electromagnetic low level vibration energy harvester based on MEMS technology. Microsyst. Technol. 2009, 15, 941–951. [Google Scholar] [CrossRef]

- Tao, Y.; Ke, G.; Xie, Y.; Chen, Y.; Shi, S.; Guo, H. Adhesion strength and nucleation thermodynamics of four metals (Al, Cu, Ti, Zr) on AlN substrates. Appl. Surf. Sci. 2015, 357, 8–13. [Google Scholar] [CrossRef]

- Awahthi, S.; Maurya, R.; Pandey, C.P.; Balani, K. Interfacial mechanics of carbonaceous reinforcements in electrophoretically deposited nickel coatings. Surf. Coat. Technol. 2017, 310, 79–86. [Google Scholar]

- Tian, W.H.; Jia, J.Y.; Chen, G.Y. On adhesion force of MEMS micro-cantilever with rough surface. In Proceedings of the 2006 IEEE International Conference on Networking, Sensing and Control, Fort Lauderdale, FL, USA, 7–9 April 2006; pp. 1096–1101. [Google Scholar]

- Yu, W.; Desmulliez, P.; Drufke, A.; Leonard, M.; Dhariwal, R.S.; Flynn, D. High-aspect-ratio metal microchannel plates for microelectronic cooling applications. J. Micromech. Microeng. 2010, 20, 025004. [Google Scholar] [CrossRef]

- Shang, F.L.; Kitmura, T.; Hirakata, H. Experimental study on interface strength of micro/nano-materiasls and their structures. Adv. Mech. Eng. 2008, 38, 437–452. [Google Scholar]

- Yang, Y.F.; Gong, Z.Q.; Deng, L.Y.; Luo, B.P.; Ma, Y.T.; Yang, Z.H. Electrodeposition of Ni-Cr alloy on aluminum substrate. J. Cent. South Univ. 2006, 13, 219–224. [Google Scholar] [CrossRef]

- Tian, Z.J.; Wang, D.S.; Wang, G.F.; Shen, L.D.; Liu, Z.D.; Huang, Y.H. Microstructure and properties of nanocrystalline nickel coatings prepared by pulse jet electrodeposition. Trans. Nonferrous Met. Soc. China 2010, 20, 1037–1042. [Google Scholar] [CrossRef]

- Tang, J.W.; Azumi, K. Influence of zincate pretreatment on adhesion strength of a copper electroplating layer on AZ91 D magnesium alloy. Surf. Coat. Technol. 2011, 205, 3050–3057. [Google Scholar] [CrossRef]

- Feng, S.B.; Hu, F.H. Potential activation phenomenon and non-cyanide direct copper plating. Electroplat. Finish. 2008, 27, 4–6. (In Chinese) [Google Scholar]

- Song, Q.S.; Xu, Q.; Xing, C.Y. Preparation of a gradient Ti–TiOC-carbon film by electro-deposition. Electrochem. Commun. 2012, 17, 6–9. [Google Scholar] [CrossRef]

- Oh, Y.; Kim, E.J.; Kim, Y.; Choi, K.; Han, W.B.; Kim, H.S.; Yoon, C.S. Adhesion of sputter-deposited Cu/Ti film on plasma-treated polymer substrate. Thin Solid Films 2016, 600, 90–97. [Google Scholar] [CrossRef]

- Zhu, J.; Henry, P.; Weaver, M.L.; Reed, M.L.; Zangari, G. Enhanced Adhesion of Au Films by Electrodeposition onto Porous Si. J. Electrochem. Soc. 2013, 160, 507–512. [Google Scholar] [CrossRef]

- Morley, T.J.; Penner, L.; Schaffer, P.; Ruth, T.J.; Benard, F.; Asselin, E. The deposition of smooth metallic molybdenum from aqueous electrolytes containing molybdate ions. Electron. Commun. 2012, 15, 78–80. [Google Scholar] [CrossRef]

- Hu, C.C.; Chang, K.H.; Wu, Y.T.; Hung, C.Y.; Lin, C.C.; Tsai, Y.T. Pulse deposition of large area, patterned manganese oxide nanowires in variable aspect ratios without templates. Electrochem. Commun. 2008, 10, 1792–1796. [Google Scholar] [CrossRef]

- Zhao, Z.; Du, L.Q.; Xu, Z.; Shao, L.G. Effects of ultrasonic agitation on adhesion strength of micro electroforming Ni layer on Cu substrate. Ultrason. Sonochem. 2016, 29, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.C.; Lee, W.G.; Kim, W.J.; Kim, J.H.; Jung, J.P. Reduction of defects in TSV filled with Cu by high-speed 3-step PPR for 3D Si chip stacking. Microelectron. Reliab. 2011, 51, 2228–2235. [Google Scholar] [CrossRef]

- Wang, H.; Liu, R.; Jiang, W.Q.; Zhu, J.; Feng, J.Z.; Ding, G.F. A novel method for improving the adhesion strength of the electrodeposited Ni films in MEMS. Appl. Surf. Sci. 2011, 257, 2203–2207. [Google Scholar] [CrossRef]

- Feng, S.B.; Shang, S.B.; Feng, L.T. Initial process of pyrophosphate copper electroplating. Electrochemistry 2005, 11, 228–231. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).